Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Moment measure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In probability and statistics, a moment measure is a mathematical quantity, function or, more precisely, measure that is defined in relation to mathematical objects known as point processes, which are types of stochastic processes often used as mathematical models of physical phenomena representable as randomly positioned points in time, space or both. Moment measures generalize the idea of (raw) moments of random variables, hence arise often in the study of point processes and related fields.

Lane keeping assistant system

ActiveCN107150682ARealize the hold functionEase of hardware implementationSteering linkagesAutomatic steering controlDriver/operatorMoment measure

The invention relates to a lane keeping assistant system. The system comprises a sensing module, a control module and an execution module, wherein the sensing module is used for gathering lane information and vehicle information; the control module is connected with the sensing module and a vehicle controller, and is used for computing a lane keeping assistant moment according to received information and overlaying the lane keeping assistant moment to a driver true steering moment, so as to form a virtual driver steering moment; and the execution module is connected with the control module, and is used for responding the virtual driver steering moment. Compared with the prior art, the lane keeping assistant system has the advantages that the lane keeping assistant moment is overlapped to the driver true steering moment, so as to obtain a virtual driver steering moment, and the driver true steering moment measured through a steering moment sensor originally is replaced, so that a lane keeping function is realized, hardware is easy to realize, the lane keeping assistant system is convenient to refit, and the cost is low.

Owner:TONGJI UNIV

Measuring method and device for twisting property of flexible material

InactiveCN1587969AEffective torsional performance measurementAccurate torsional performance measurementMaterial analysis by optical meansStrength propertiesSelf excitedEngineering

The invention is a torsion property measuring method and apparatus for flexible material. The method is that upper end of simple holds to measure torsion moment and lower end hangs a weight to be revolved to a certain torsion moment or torsion angle then released to rotate back and reciprocate naturally, measuring autooscillation property and torsion modulus of the sample; or lower end is holded to have forced rotation or positive and negative, measuring once of the sample. The apparatus is consisted of moving beam, force, displacement sensor, torsion moment measuring mechanism, upper and lower holder, rotation mechanism, micro polarized light optical circuit and camera mechanism, moving and focusing mechanism, temperature cap, driving system and control circuit, program control and signal processing system, finishing measurement of self excited vibration, torsional fatigue and relaxation performance of flexible material with stationary load or stretch and observing degree of twist transfer of sample in and property change under different temperature, having simple but practical structure, convenient installation, many measurable parameters and accurate measurement.

Owner:DONGHUA UNIV

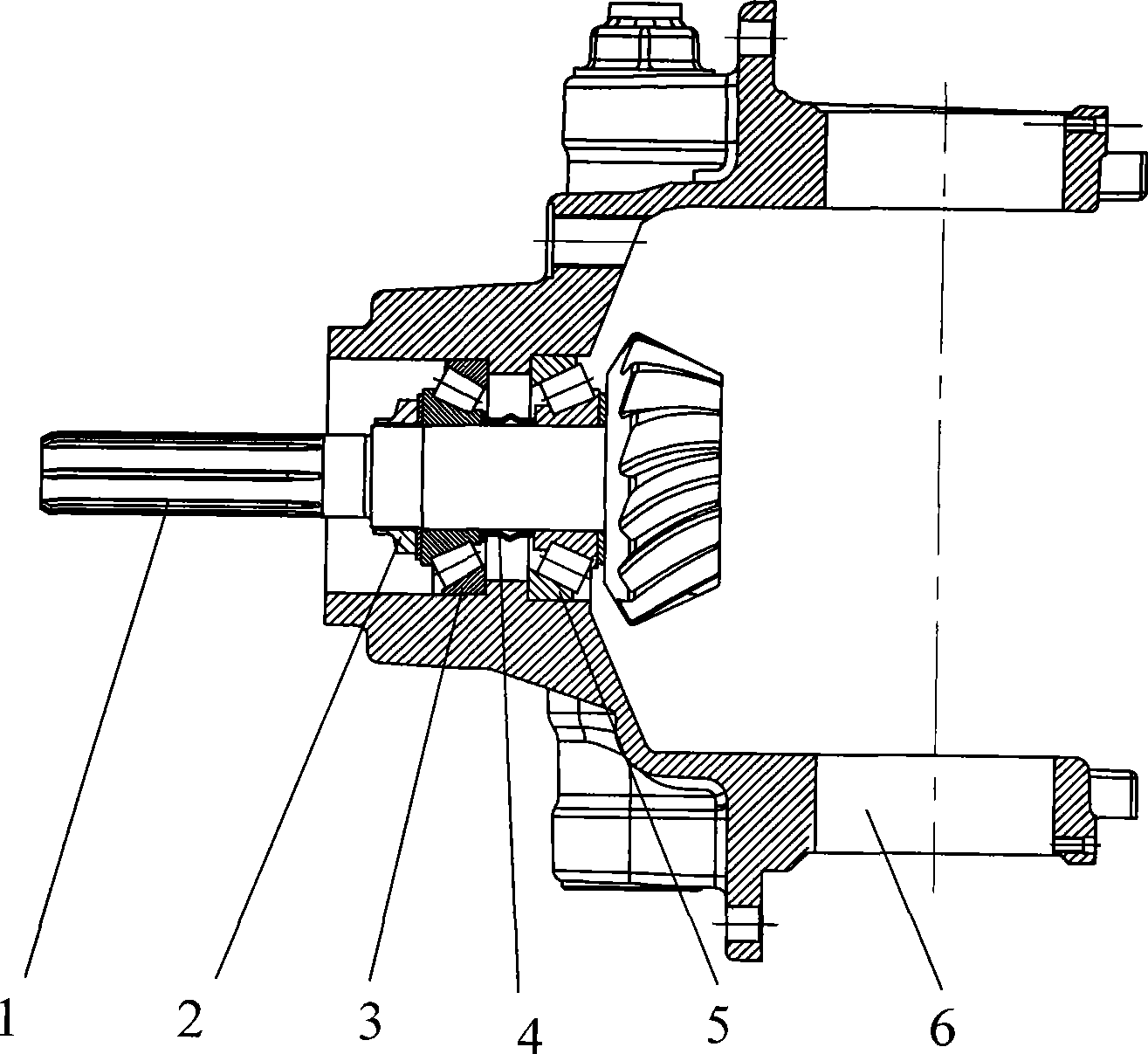

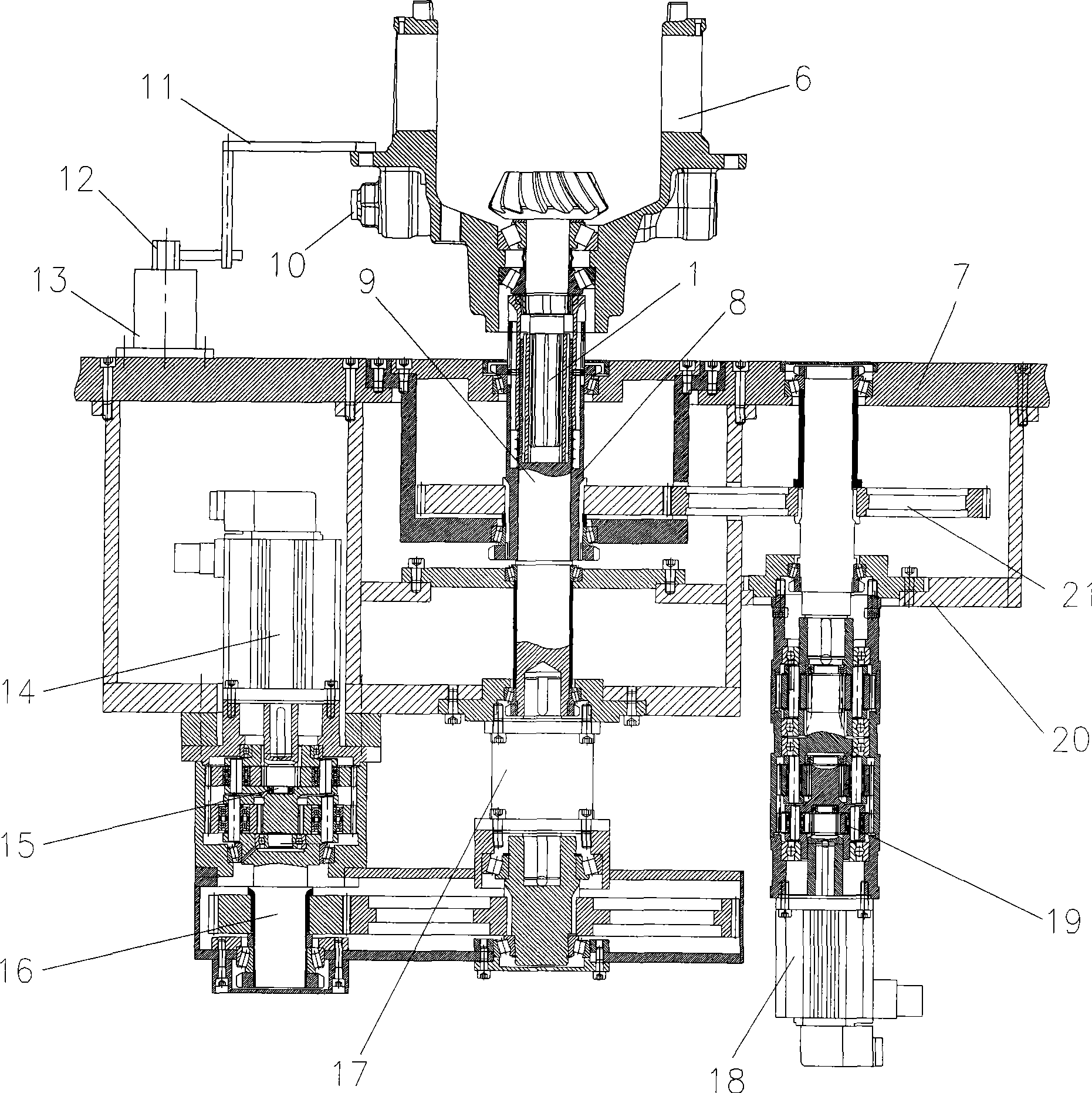

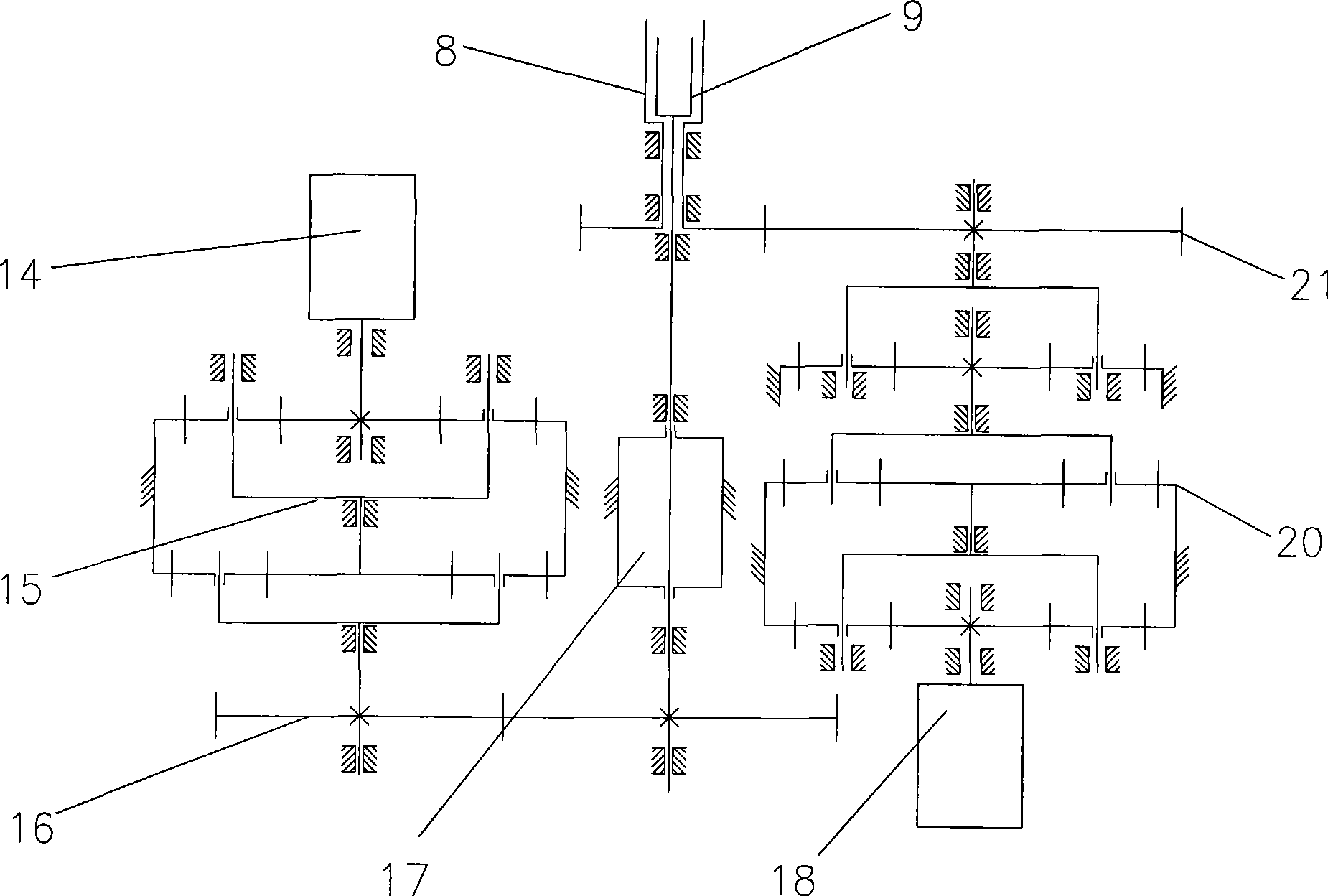

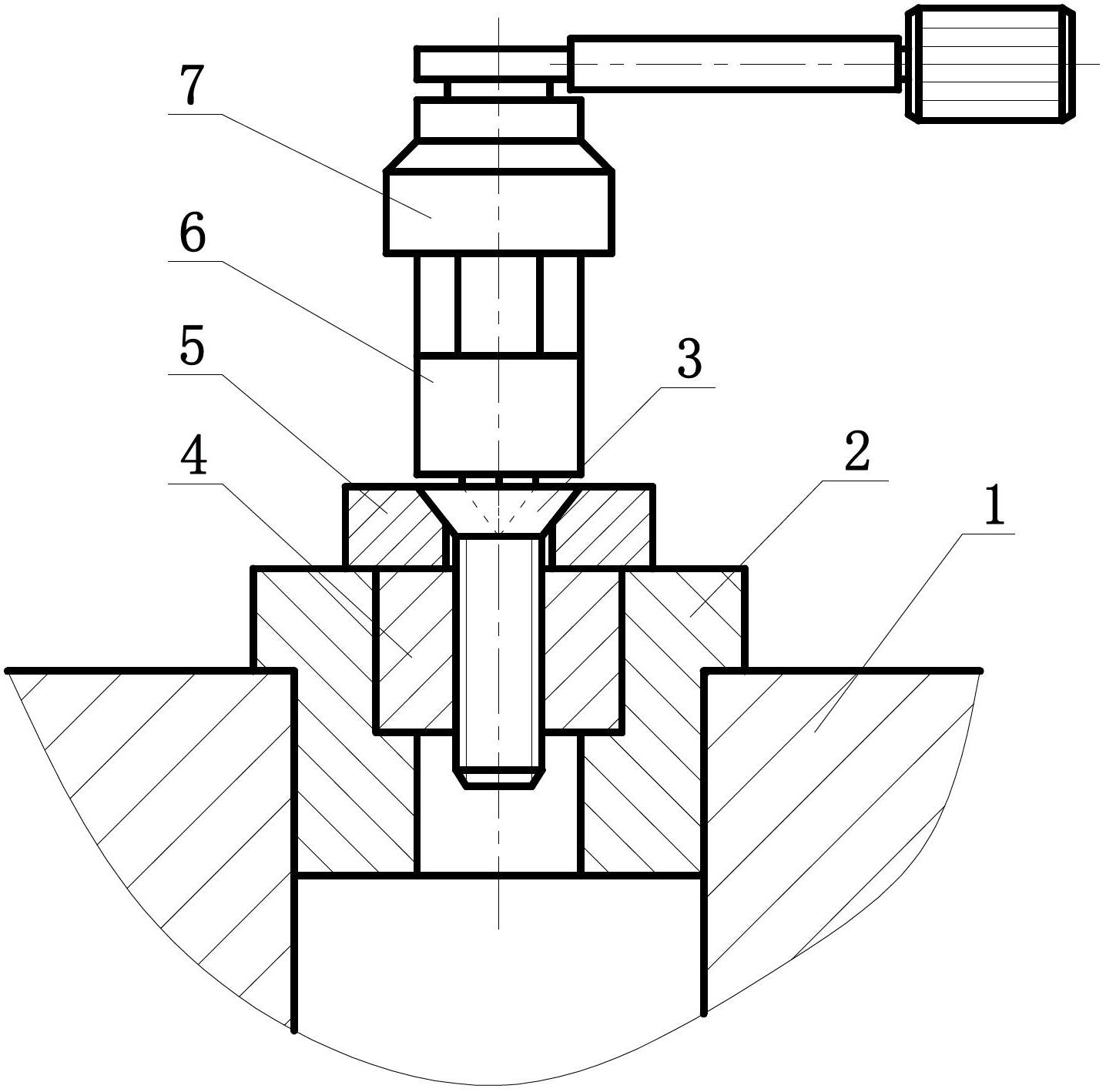

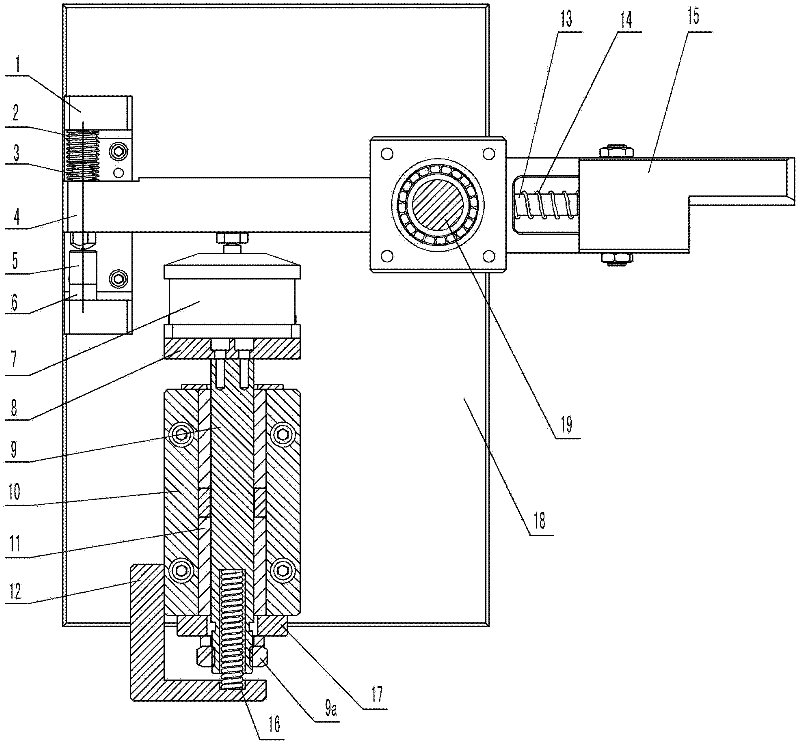

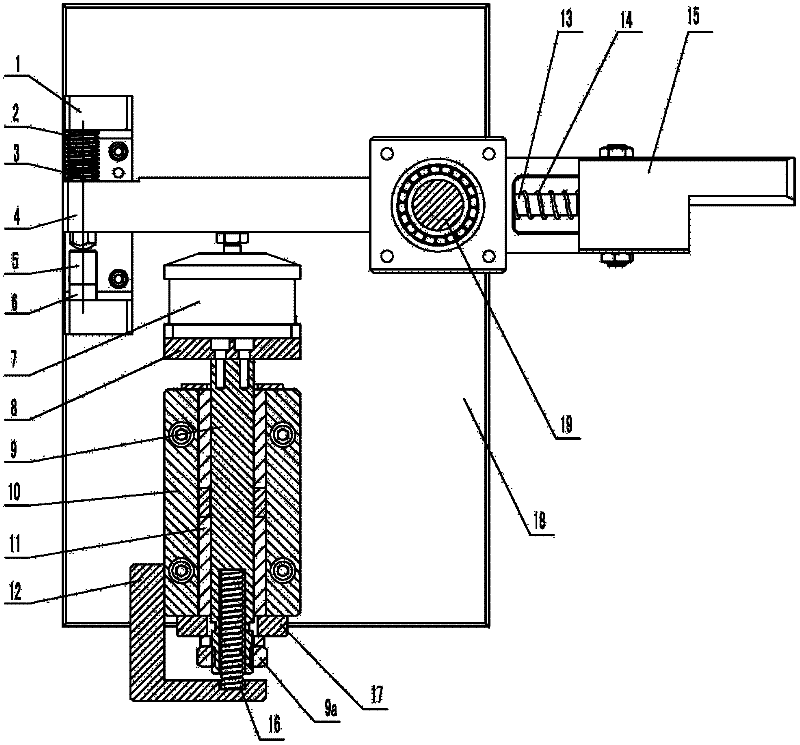

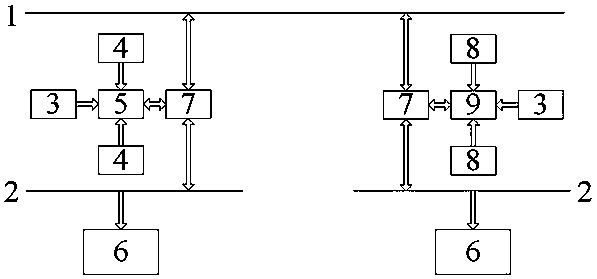

Differential screwed loader main cone pretightening force measuring set and method

InactiveCN101419106ARealize detectionAccurate measurementMeasurement of torque/twisting force while tighteningFriction torqueDifferential screw

The invention relates to a device and a method for measuring the pretightening force of a main cone of a loader based on differential speed tightening, which is characterized in that the measuring device is provided with a work top, a sleeve, an inner spline, a transmission line 1, a transmission line 2, and a pretightening moment measuring mechanism, wherein the work top is taken as a preassembling bench of the main cone and a bearing pedestal and a bearing pretightening moment measuring bench; the sleeve is matched with an opening of a locknut and used for screwing up the locknut; the inner spline is matched with an outer spline on the tail of the main cone and used for driving the main cone to rotate; the transmission line 1 takes a servomotor as a driving piece and the inner spline as a driven piece; and the transmission line 2 takes a servomotor as a driving piece and a sleeve as a driven piece. The method adopts the means of differential speed tightening to well realize detection of the starting friction torque.

Owner:HEFEI UNIV OF TECH

Brake force moment measuring device and method

InactiveCN1529142AReduce energy consumptionAvoid the hassle of frequent calibrationApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention refers to a kind of measuring device for measuring the brake moment of elevator arresting gear, especially measuring device and the method which uses torsion lever and strain piece as sensitive elements, and uses microprocessor to carry on signal calculation, analysis and process. The invention is made up of beam, torsion lever, main shaft, arresting gear and circuit. The arresting gear is connected with the beam through two pin shafts, the braking beam is connected to one end of the torsion lever, and the braking clamp is connected with the iron core, and then connected with the beam. The arresting gear coil is embedded in the iron core, there set strain pieces on the surface of torsion lever, the pieces are connects into a bridge circuit. The advantages of the invention are: it designs the zero calibration, deficiency analyzing of arresting gear and so on. It has a high accuracy, no float, and high reliability.

Owner:曾晓东

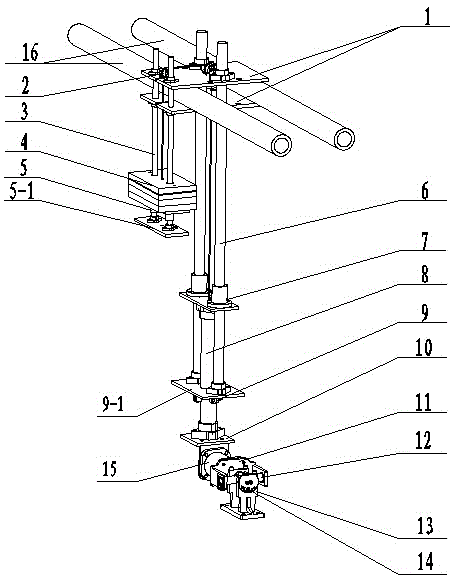

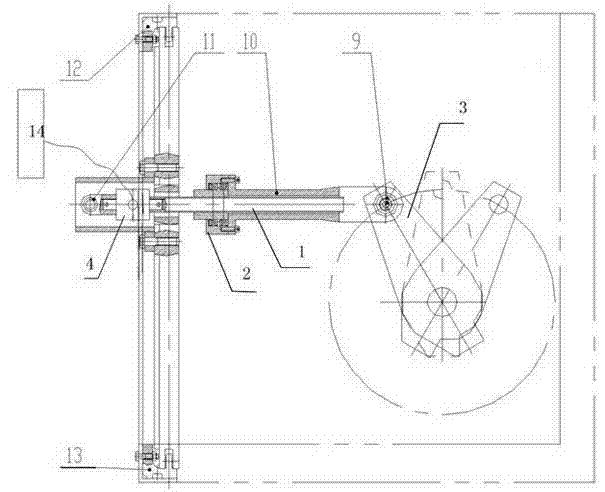

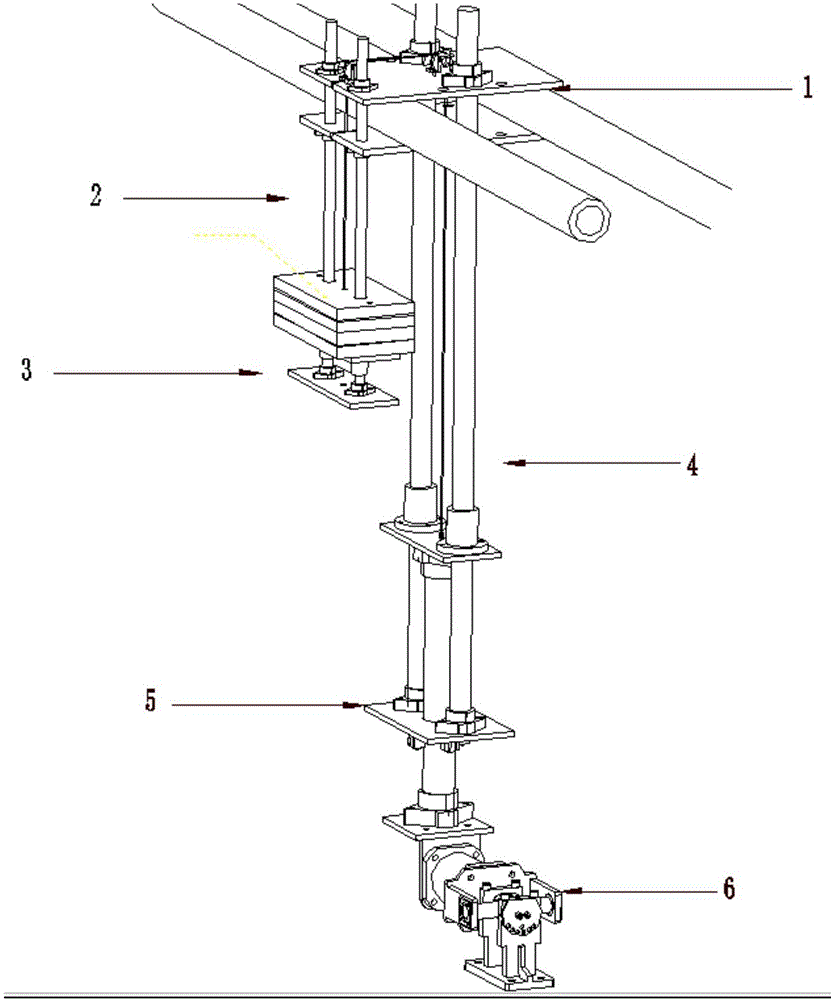

Hydrodynamic test model transverse moment measuring device

ActiveCN104596734AMaintain heel angleSolve the unmeasurableHydrodynamic testingWork measurementCross connectionMeasurement device

A hydrodynamic test model transverse moment measuring device comprises a pair of fixed connection plates (1), a connection steel rope guide pulley (2), an unloading unit fixing shaft (3), an unloading weight (4), an unloading unit sliding seat (5), a supporting unit fixing shaft (6), a supporting unit sliding seat (7), a supporting spindle (8), a supporting spindle guide (9), a right-angle adapter seat (10), a pitching direction rotating bracket (11), a cross connection shaft (12), a transverse direction rotating bracket (13), a transverse angle adjustment sheet (14) and a six-component measuring balance (15). The hydrodynamic test model transverse moment measuring device has the advantages that a model can freely move in the pitching direction in a hydrodynamic test, a needed transverse angle can be kept, the blank of a water test model transverse moment measuring measure in a towing tank is filled in, the transverse moment of a zero-speed model can be measured, and the transverse moment of a high-speed model can also be measured.

Owner:CHINA SPECIAL TYPE FLIER RES INST

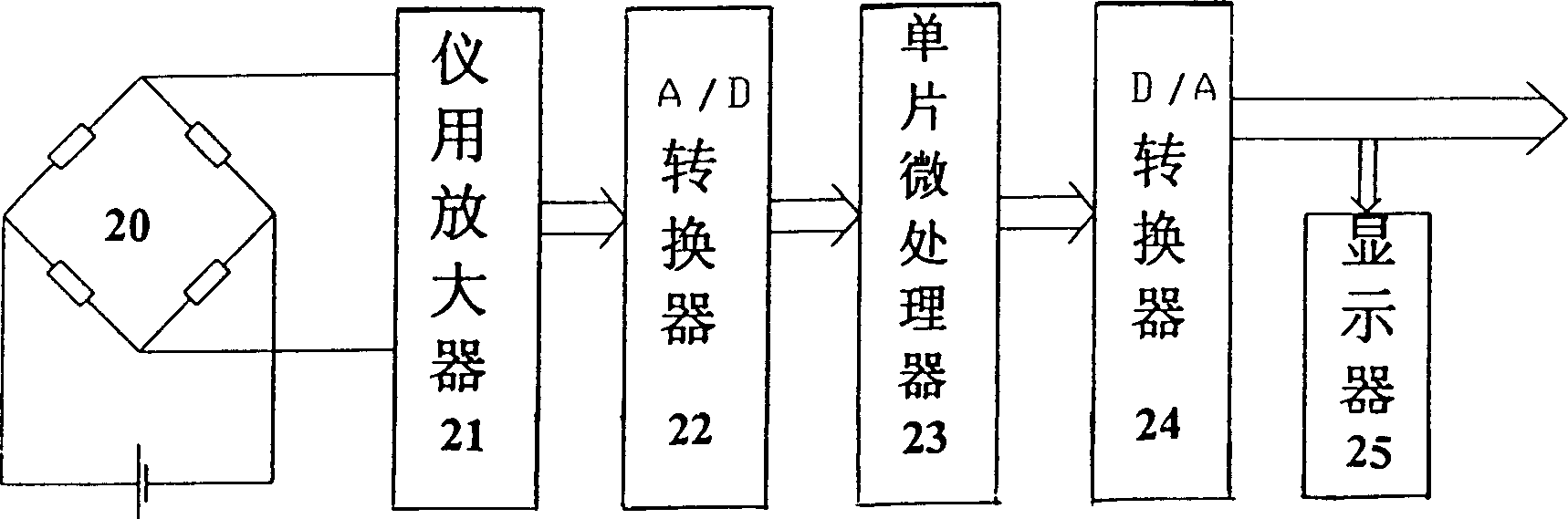

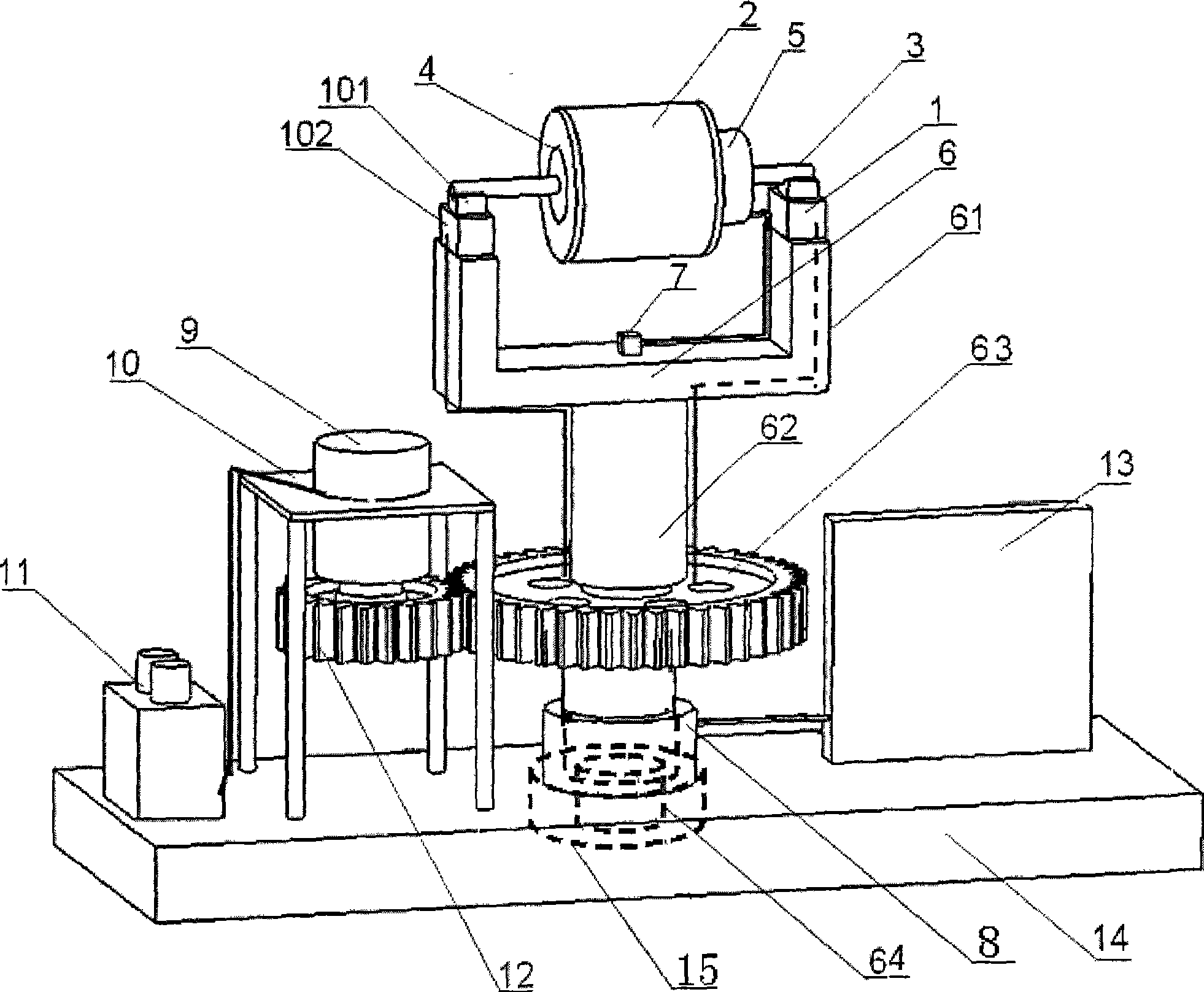

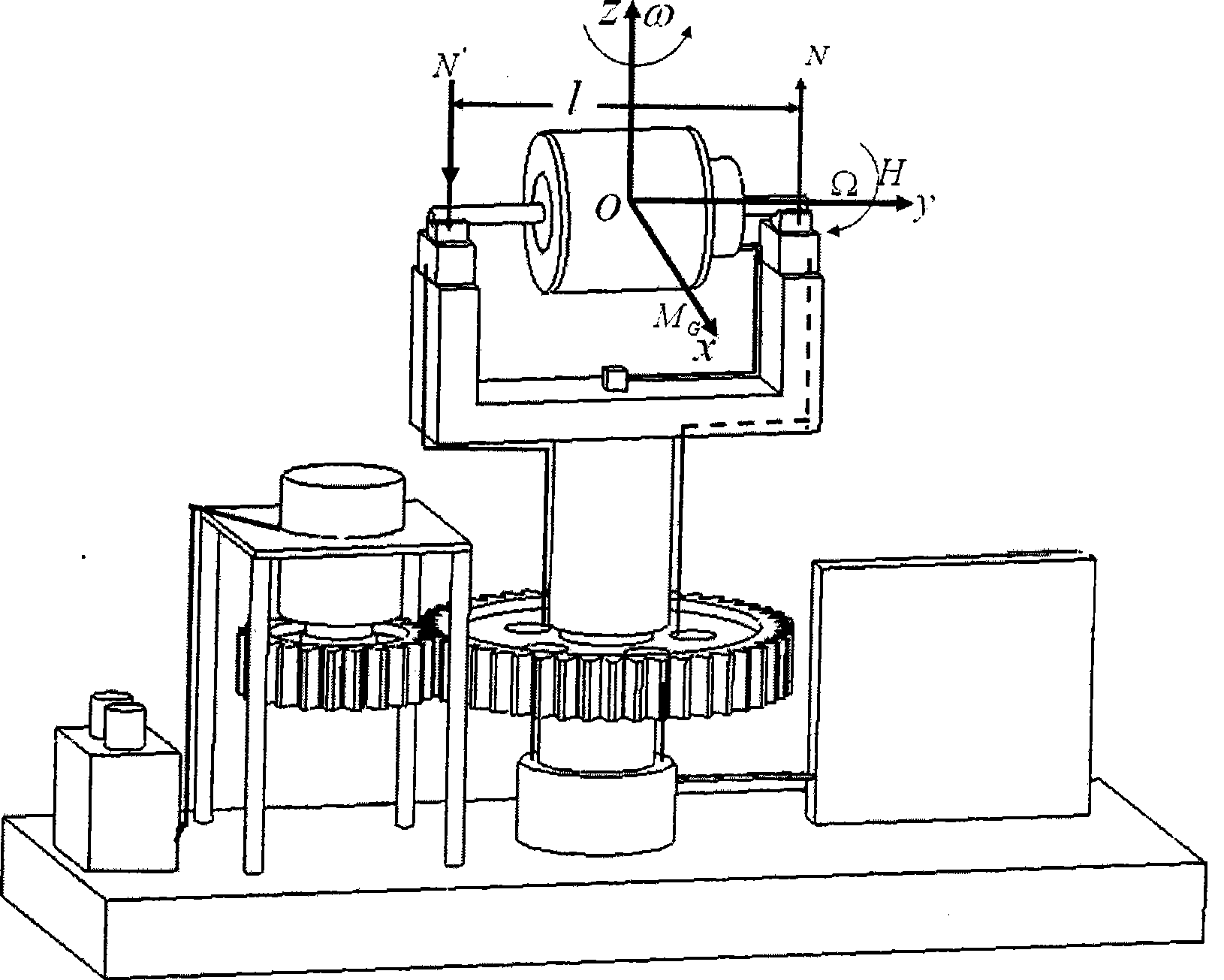

Apparatus and method for measuring gyro moment

InactiveCN101436356AAccurate pressurePrecise Gyro MomentCurrent/voltage measurementEducational modelsBall bearingDisplay device

The invention relates to a gyro moment measuring device, which mainly comprises a force transducer, a gyro rotor, a gyro stator shaft component, a ball bearing, a gyro power supply slip ring, a gyro bracket, a gyro power supply battery, a signal slip ring of the force transducer, a frame rotating motor, a bracket for the frame rotating motor, a revolution stepping switch for the frame rotating motor, a transmission device, a display device, a base and a deep groove ball bearing. The gyro stator shaft component is connected with the gyro rotor through the ball bearing and is fixedly connected with the force transducer, the force transducer is fixedly connected with the gyro bracket which is connected with the base through a rotating shaft, an output rotating shaft of the frame rotating motor is connected with the transmission device which is engaged with a gear on the gyro bracket, and the bracket for the frame rotating motor and the display device are fixedly connected with the base. The gyro moment measuring device uses the force transducer to measure pressure, calculate gyro moment and display the gyro moment in the display device, and can intuitively learn gyro moment effect.

Owner:BEIHANG UNIV

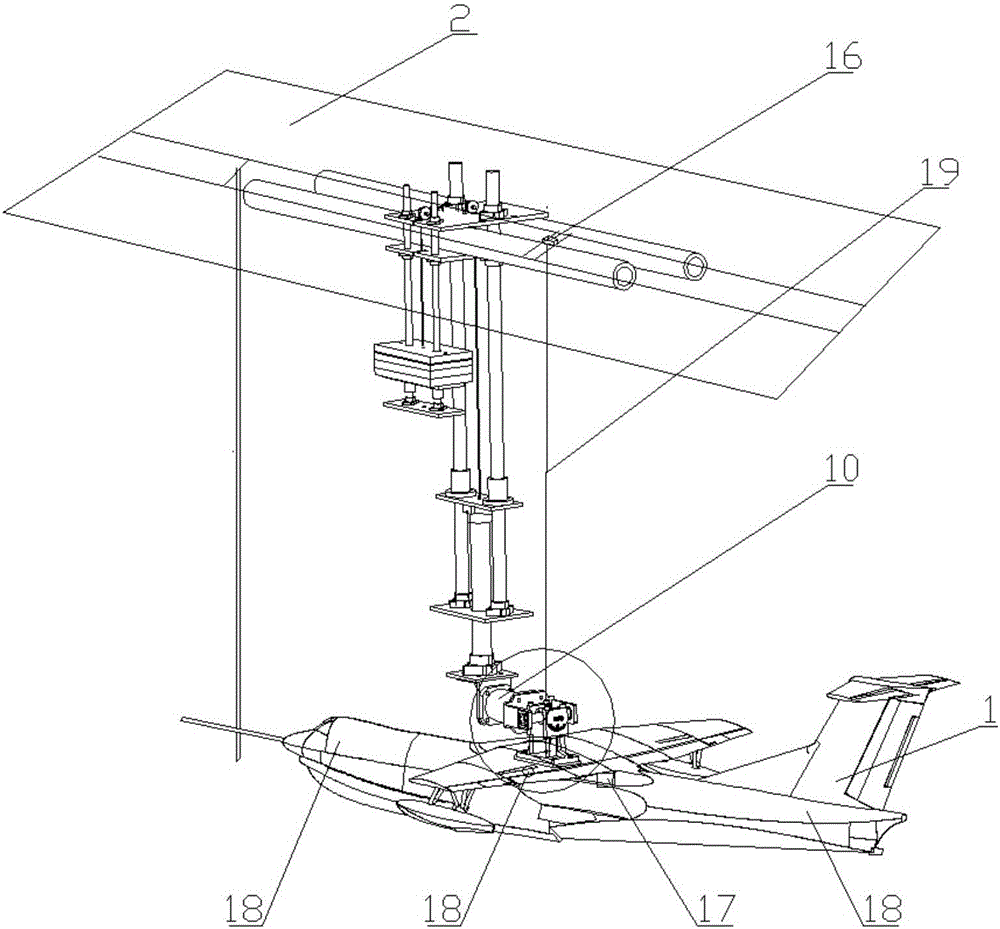

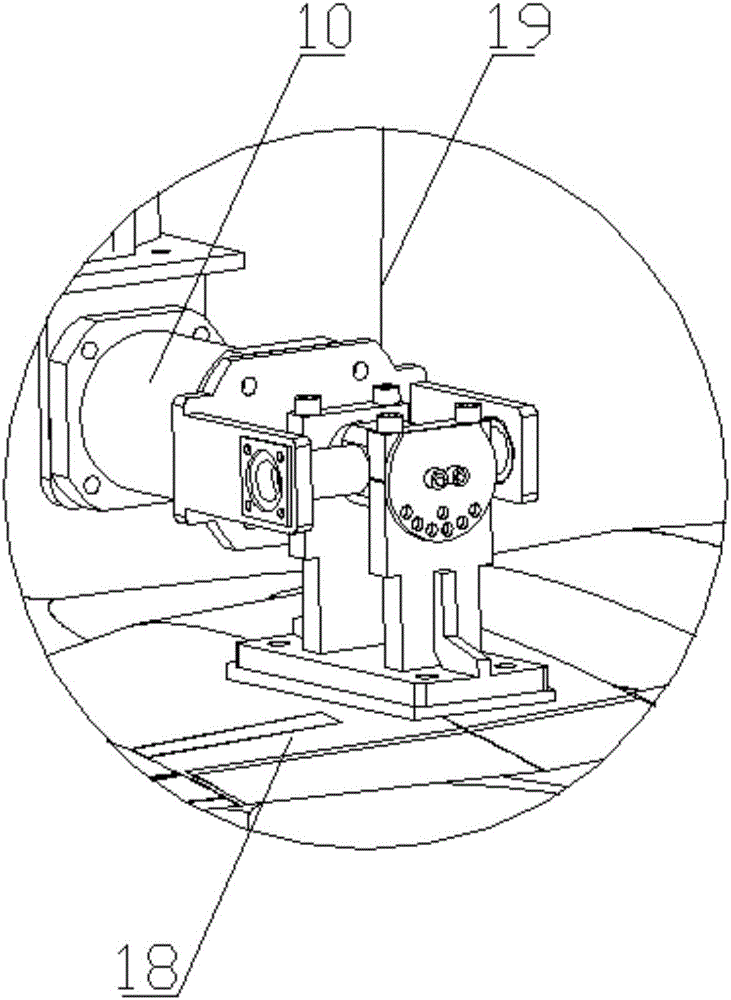

Method for testing hydrodynamic performance of water surface air vehicle in transverse inclination state

InactiveCN106289724ARealistic simulation of hydrodynamic performanceHydrodynamic testingMeasurement deviceAcceleration amplitude

The invention provides a method for testing hydrodynamic performance of a water surface air vehicle in a transverse inclination state. A testing device is installed first and electric signal connection and testing are achieved, and the testing device comprises a water surface air vehicle model, a water power high-speed test carriage, a transverse inclination moment measurement device and a sensor system. Secondly the water power high-speed test carriage moves on a track and drives the model to move on the water surface, after the carriage is accelerated to an operation speed meeting test requirements and is stabilized, a data acquirer is started to acquire sensor test data, acquisition is stopped after the carriage runs stably for a period of time, and the carriage is braked and decelerated till stop; after the testing process ends, the effectiveness of acquired test data is analyzed, effective test parameters including model gravity center, transverse inclination angle, weight, speed, gravity center position heaving value, dip angle value, bow, midship and stern acceleration amplitude, and force and moment measured by a six-component balance are recorded, and hydrodynamic performance is analyzed by comparing the test parameters with a design value or a normal value.

Owner:CHINA SPECIAL TYPE FLIER RES INST

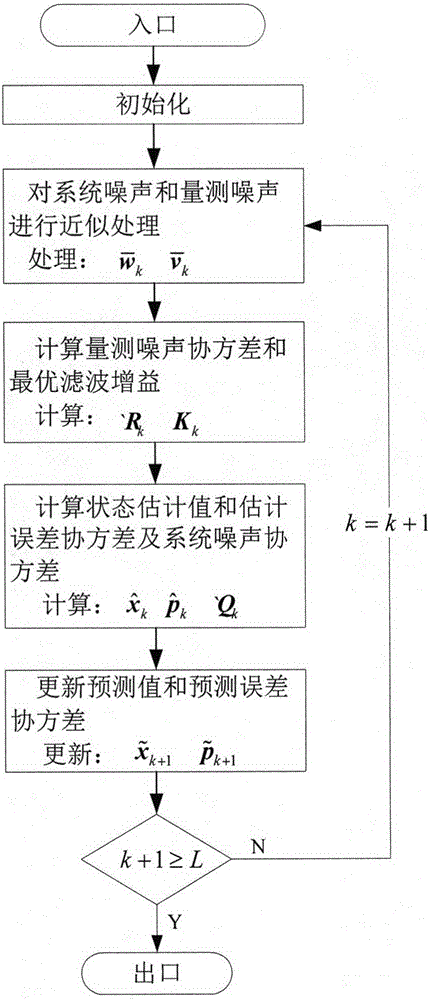

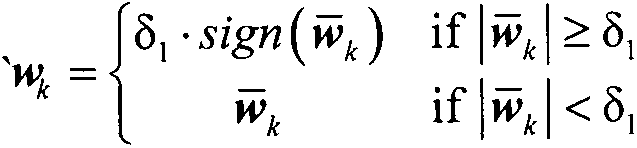

Fractional Kalman filter method for processing Levy noise

InactiveCN105930640AAddress limitationsSolving State Estimation ProblemsInformaticsSpecial data processing applicationsState predictionFilter gain

The invention discloses a fractional Kalman filter method for processing Levy noise. The method includes: firstly, giving a state prediction initial value and a predicted error covariance initial value; secondly, processing the Levy noise, and calculating a current moment measured noise covariance and a current moment optimal filtering gain; thirdly, calculating a current moment state estimated value through the current moment optimal filtering gain and a state prediction value, calculating a current moment estimated error covariance through the predicted error covariance, and calculating a current moment system noise covariance through the current moment state estimated value and the estimated error covariance; and finally, updating the next moment state prediction value through the current moment state estimated value, and updating the next moment predicted error covariance through the current moment estimated error covariance. The method can solve the problem of state estimation of a fractional linear discrete system in non-gaussian noise, and is easy to combine with existing state estimation software.

Owner:NANJING UNIV OF TECH

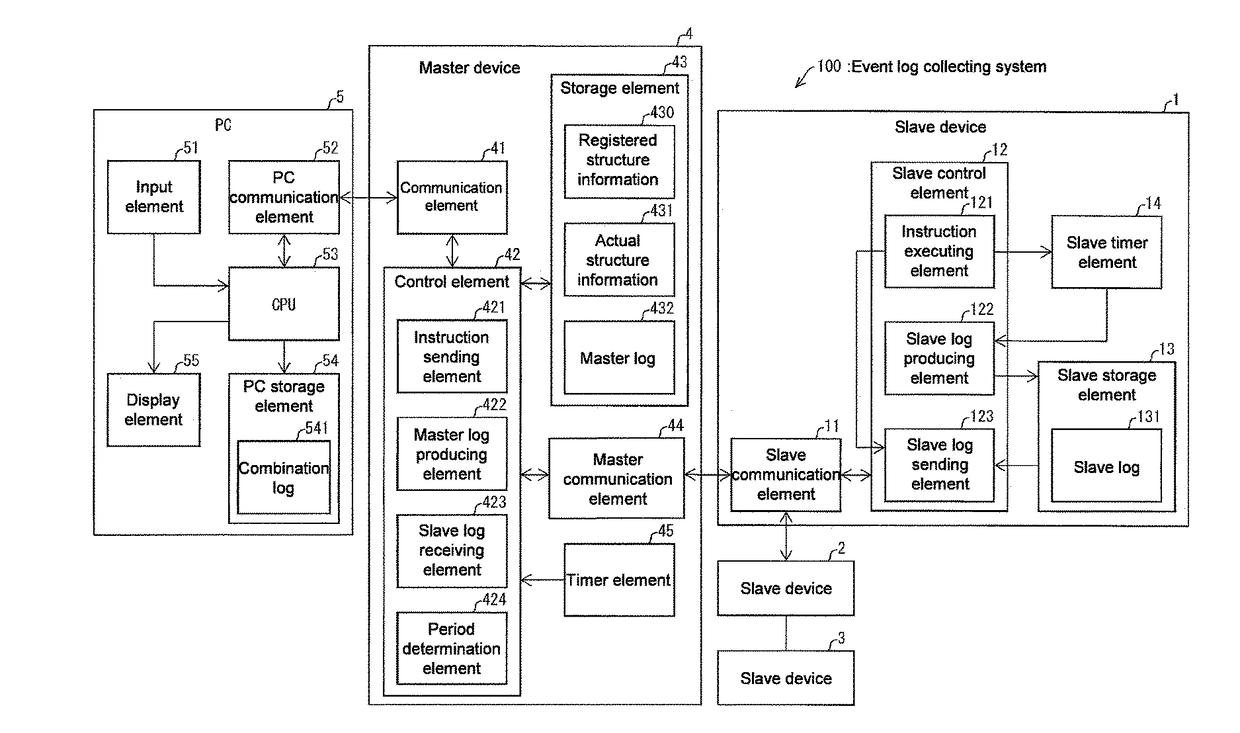

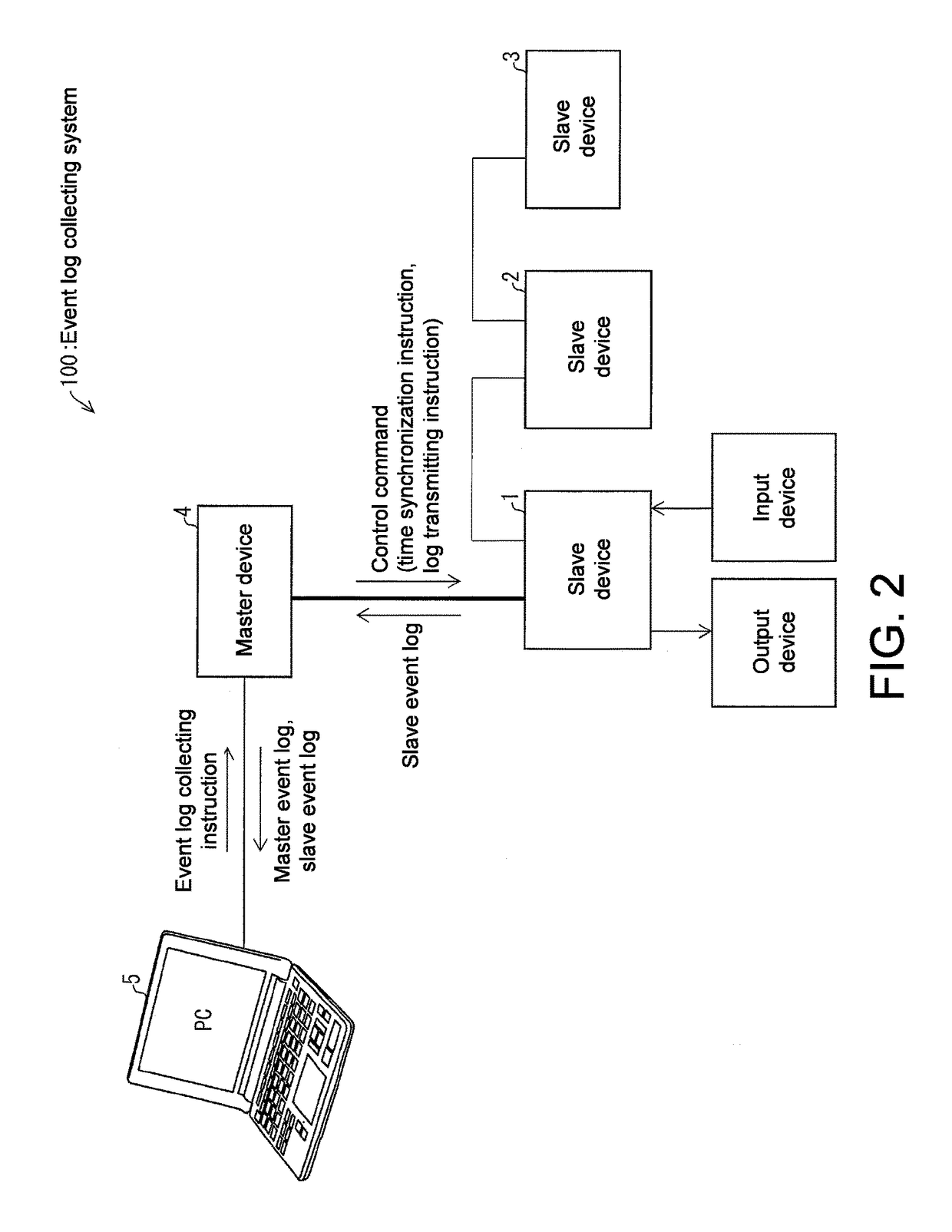

Master device, slave device, information processing device, event log collecting system, control method of master device, control method of slave device and control program

ActiveUS20170251059A1Data can be usedProgramme controlTime-division multiplexMoment measureTime synchronization

The invention is adapted to acquire more useful log data. A master device (4) includes a timer element (45), adapted to acquire a moment; an instruction sending element (421), adapted to synchronize a moment measured by a slave timer element (14) of slave devices (1-3) with a moment acquired by the timer element (45) according to a time synchronization instruction containing moment information corresponding to the moment acquired by the timer element (45); and a slave log receiving element (423), adapted to receive slave logs (131).

Owner:ORMON CORP

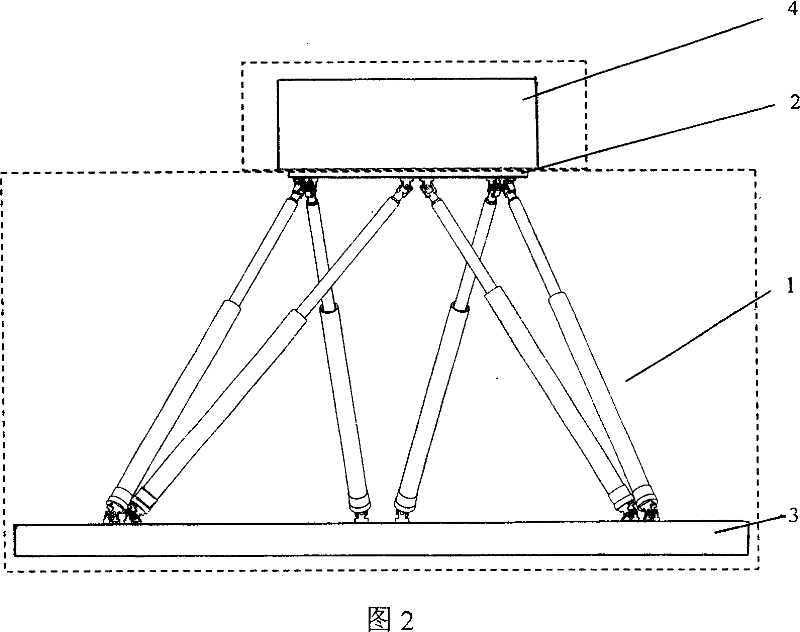

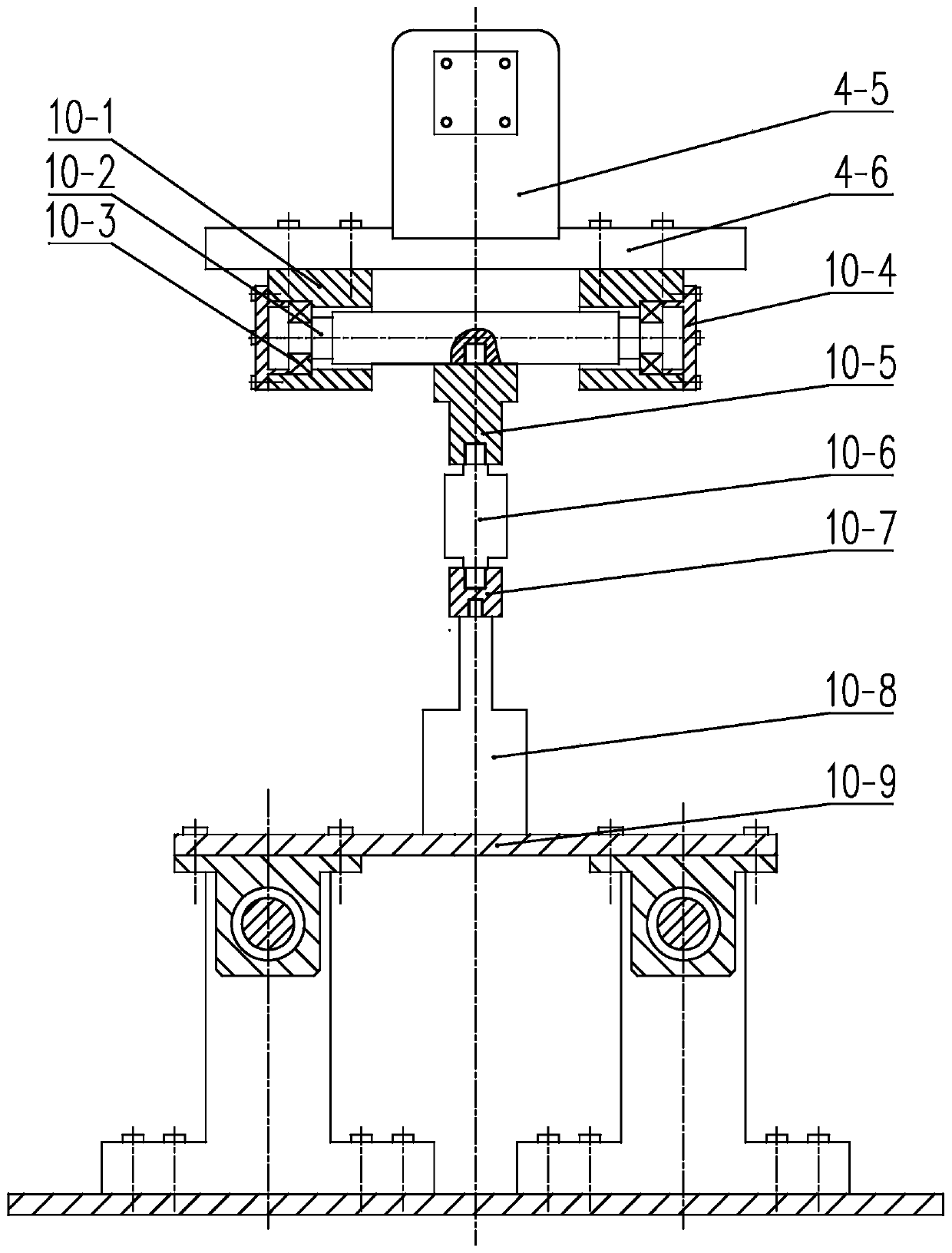

Spring structure type multiple free degree parallel mechanism generalized force and force moment testing device

InactiveCN101038219AIncrease stiffnessStable structureForce measurement by elastic gauge deformationMoment measureRelative motion

The present invention discloses a generalized force and force moment measuring device of the multiple-degree-of-freedom parallel mechanism in a spring structure format. The measuring device includes a multiple-degree-of-freedom parallel mechanism, a transverse spring, a diagonal drawn spring, a fixed external frame and a connection mechanism; the fixed external frame does not move relatively to the base of the parallel mechanism, and the connection mechanism is connected to the moveable platform of the multiple-degree-of-freedom parallel mechanism in a rigid and moveable mode and is connected to the fixed external frame through a plurality of springs. The present invention provides a compact, ideal and succinct measuring device of force and force moment, and the device can be used for measuring the generalized force and force moment of all kinds of multiple-degree-of-freedom platforms and for loading.

Owner:ZHEJIANG UNIV

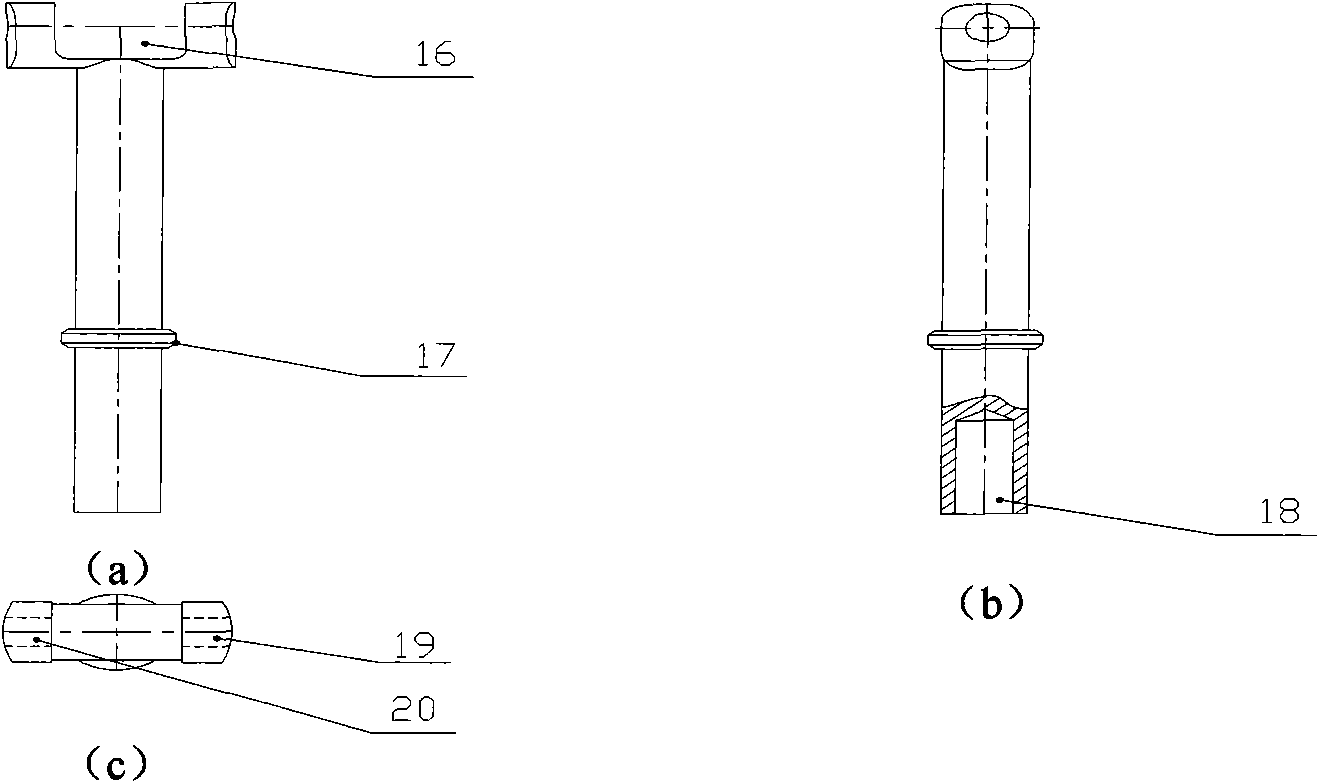

Force moment measuring device and usage thereof

InactiveCN102661826AMeet 100% passing requirementsEasy to operateMeasurement of torque/twisting force while tighteningMeasurement deviceMoment measure

The invention provides a force moment measuring device and the usage thereof. The device comprises a hexagon nut, a cross-recessed punch, a torque wrench and a positioning block. A cross-recessed screw is screwed onto the hexagon nut, a cross punch head of the cross-recessed punch is positioned in a cross recess of the cross-recessed screw, and the tail of the cross-recessed punch is positioned in a positioning hole of the torque wrench. The upper end face of the positioning bock is provided with a groove for holding the hexagon nut, the lower end face of the positioning block is provided with a through hole communicated with the groove, the positioning block is further provided with two parallel clamping faces which are symmetric relative to the central axis of the through hole on the positioning block, the two clamping faces are perpendicularly intersected with the upper end face of the positioning block, and the hexagon nut is clamped in the groove of the positioning block. The force moment measuring device has the advantages that by means of the technical scheme, unqualified products can be rejected, the requirement on 100% qualified cross-recessed screws can be met, and the force moment measuring device is easy to operate, low in cost and high in efficiency.

Owner:AEROSPACE PRECISION PROD INC LTD

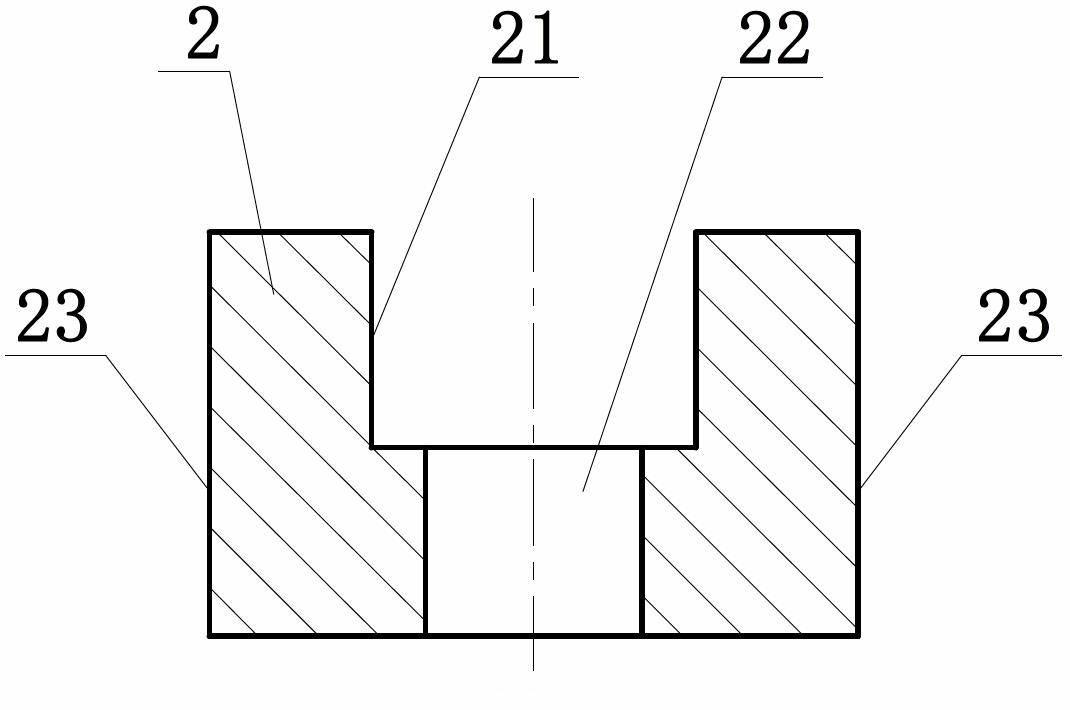

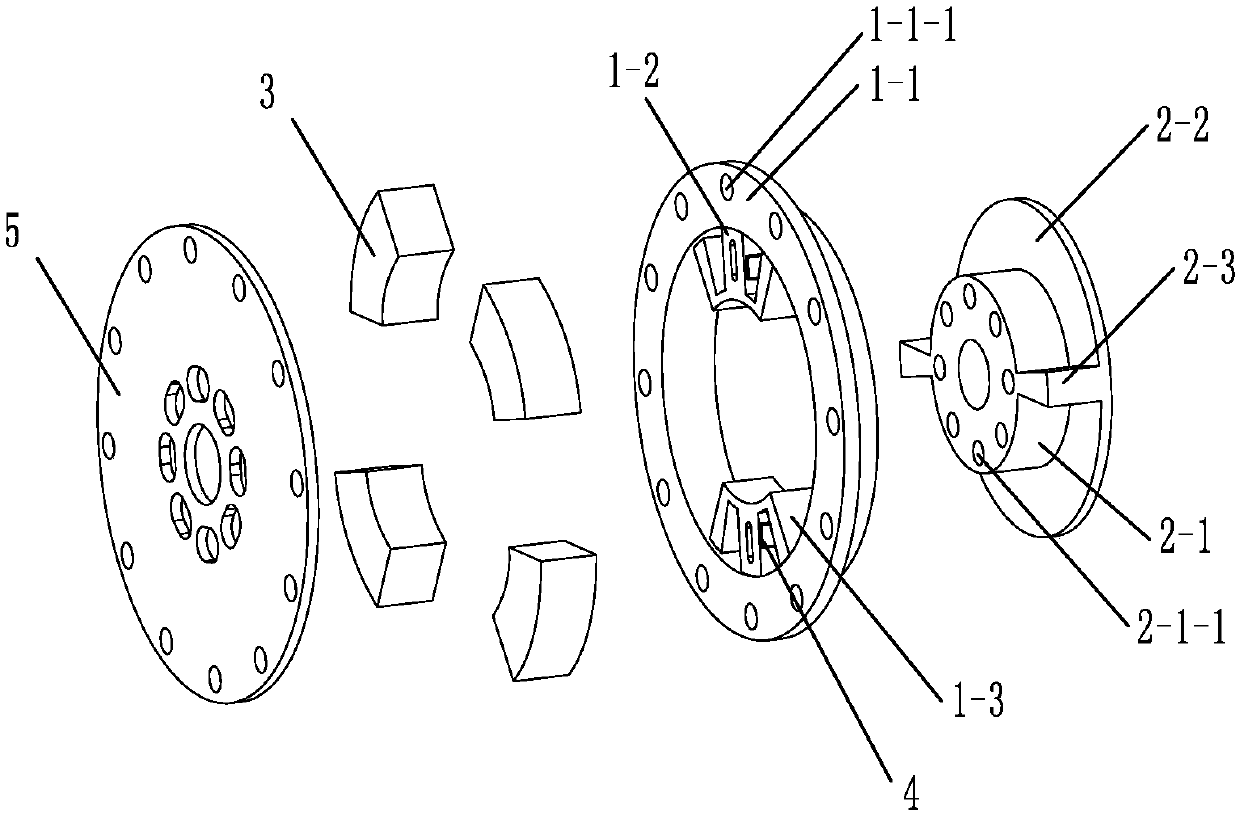

Moment-measuring compact metallic rubber elastic element of flexible robot joint

ActiveCN107671875AHigh damping characteristicsGood vibration reduction effectManipulatorSemi activeRubber material

The invention discloses a moment-measuring compact metallic rubber elastic element of a flexible robot joint, and relates to a passive damping elastic element. The moment-measuring compact metallic rubber elastic element is used for solving the problems that active vibration control adopted for suppressing flexible robot vibration at present is poor in reliability, when semi-active control is adopted, control elements such as motors need to be additionally arranged, thus, the size is large, the structure is complex, passive damping elastic elements made from common rubber materials are unstable in performance and limited in service life, and passive damping elastic elements of the design with metallic rubber only without strain gages cannot accurately estimate moment. A plurality of resistance strain gages are mounted on an outer ring basic body, an inner ring basic body is buckled to the outer ring basic body, a plurality of metallic rubber sheets are mounted in a regional space defined by the outer ring basic body and the inner ring basic body after buckling, and a baffle is mounted on the outer ring basic body in a covering mode. The joint driver for the flexible robot joint hasboth the moment sensing function and the passive damping function.

Owner:HARBIN INST OF TECH

Swinging movement hinge friction measurement device

InactiveCN101178333AAccurate measurementSimple structureWork measurementTorque measurementFriction torqueMeasurement device

The invention provides a friction measuring device for a swinging gemel and includes a supporter. The upward side of the supporter is provided with a bearing seat and two force sensors. A motor is arranged below the supporter. An output shaft of the motor is fixedly connected with a curved shaft and the other end of the curved shaft extends to a pin roll in a sliding slot on an oscillating arm. The other end of the oscillating arm is arranged on the bearing seat through an oscillating arm rotary shaft. The swinging side of the gemel is fixedly connected with the oscillating arm and is fixedly connected with a gemel rotary shaft. The measuring side of the gemel is arranged on the gemel rotary shaft. The measuring heads of the two force sensors are respectively extruded at two sides of the measuring side of the gemel. When the invention is used for measuring the friction, as the measuring side of the gemel does not move, the inertia force is not affected. The moment measured by the sensor is the friction moment of the gemel and the measuring result is accurate. The structure of the device is simple and the measuring is convenient.

Owner:HARBIN ENG UNIV

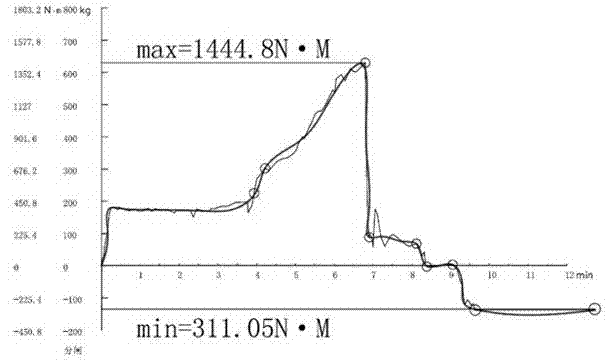

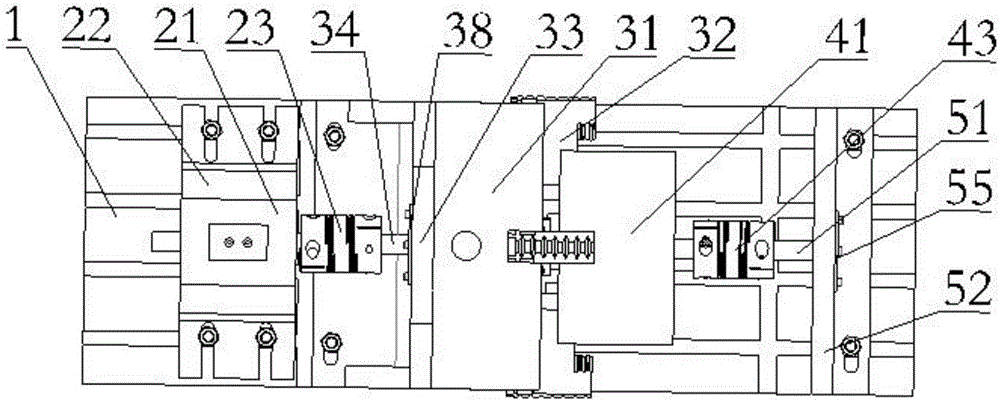

Moment measuring device for circuit breaker body

ActiveCN102650557AImprove purposeImprove accuracyApparatus for force/torque/work measurementResearch ObjectMoment measure

The invention relates to a moment measuring device for a circuit breaker body. The moment measuring device comprises a force transducer and a driving mechanism of which one end is used for being connected with an outer crank arm of a circuit breaker, wherein the other end of the driving mechanism is fixedly connected with the input end of the force transducer. The moment during the process of two limit positions of brake separating and closing of the qualified circuit breaker verified by tests is selected as a research object and relevant mechanical principles are combined to measure the moment of a main crank arm of the circuit breaker in the motion process and a standard characteristic curve is drawn for guiding subsequently-operated debugging work of a 800kV circuit breaker body and judging whether the assembly characteristics of the circuit breaker meet the work requirements or not, and thus the debugging time is shortened, the assembly and detection level of the circuit breaker are improved and the characteristics of the circuit breaker are improved.

Owner:PINGGAO GRP +1

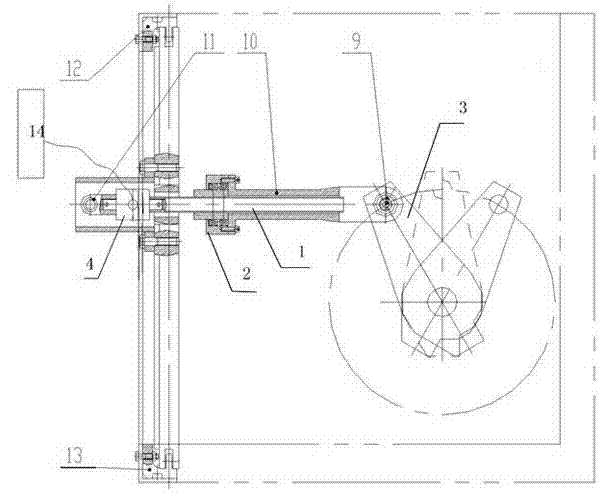

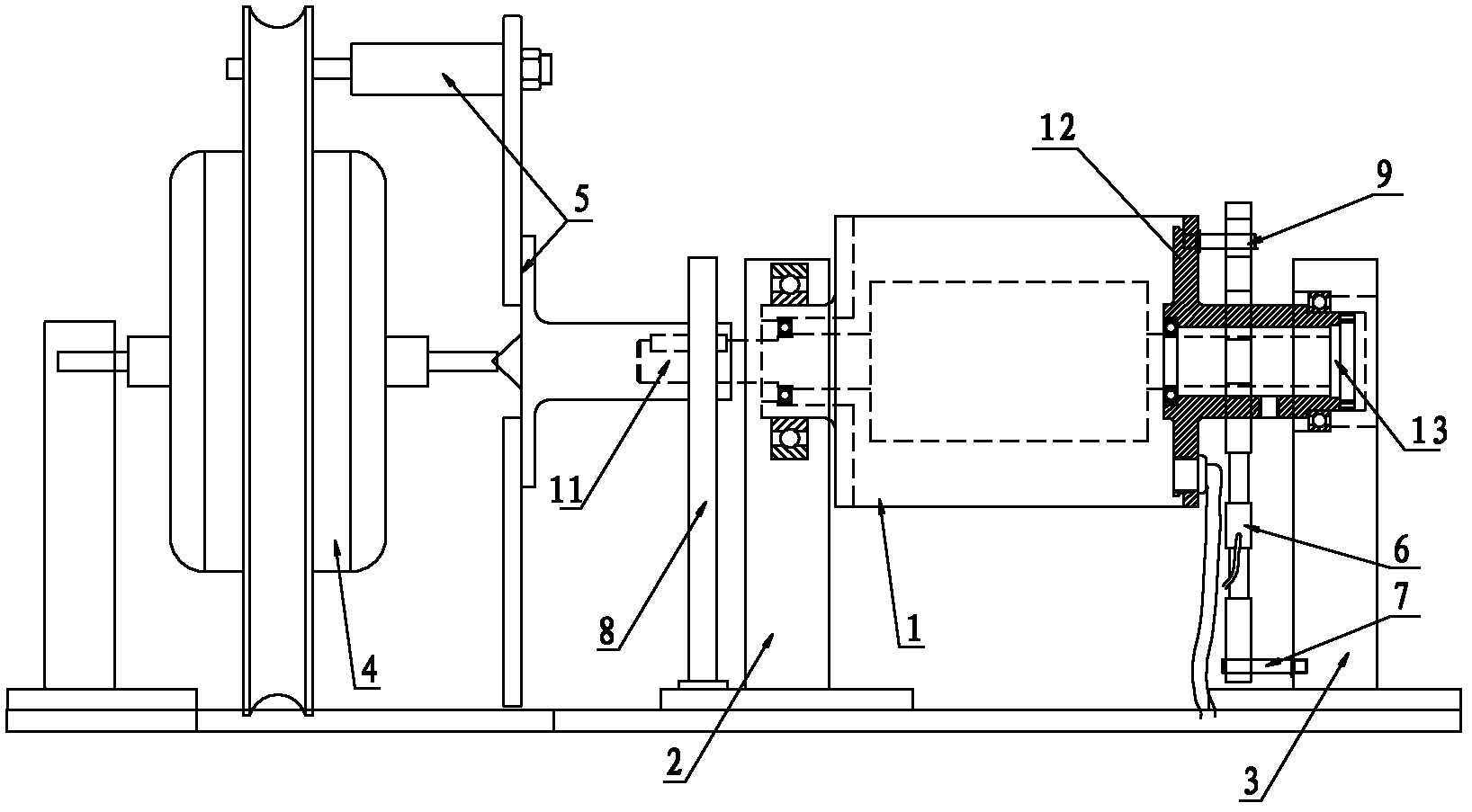

Measuring device suitable for micro moment of various motor

ActiveCN106248273AFirmly connectedRealize measurementWork measurementTorque measurementMeasurement deviceMeasuring instrument

The invention discloses a measuring device suitable for micro moments of various motors. The measuring device comprises a base, and a moment measuring part, a chuck supporting part, a to-be-measured motor part and a tail end supporting part which are arranged on the base, wherein one end of a moment measuring instrument is connected with a load, and the other end is connected with a first coupling; a three-jaw chuck supporting base is mounted on the base, a three-jaw chuck is mounted on the three-jaw chuck supporting base, a first connecting shaft is mounted on the three-jaw chuck supporting base, one end of the first connecting shaft is connected with the first coupling, the other end of the first connecting shaft and one end of a second connecting shaft are connected with limiting sliding blocks via limiting grooves, a motor to be measured is connected with one end of the second connecting shaft through a second coupling, the motor to be measured is connected with one end of a supporting connecting shaft through a third coupling, and a stator of the motor to be measured is mounted on the three-jaw chuck by means of a jaw; and the other end of the supporting connecting shaft is mounted on a supporting plate, and the supporting plate is mounted on the base. The device provided by the invention is suitable for measuring the micro moments of various motors, and avoids the design work of supporting platforms for motors with different outer diameters.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Residual moment measuring device and method of inertial device based on three-dimensional air flotation

ActiveCN110542439AReduce calculationHeavy calculationApparatus for force/torque/work measurementMeasurement deviceWireless transmission

The invention provides a residual moment measuring device and method of an inertial device based on three-dimensional air flotation, belonging to the technical field of detection. An on-stage system and an under-stage system in the device are connected through a wireless transmission system; the under-stage system comprises an under-stage data collecting and processing system, a server, a cabinetbox and an air supply system; the on-stage system comprises a power supply system, an inertial execution mechanism control system, an inertial execution mechanism to-be-tested product, an on-stage data collecting and processing system, a residual moment test system, a vibration isolating and supporting system, and a vacuum control system, the residual moment test system consists of an air flotation rotary table, a high-precision sensor device and an anti-overturning and protective device, and the high-precision sensor device is separately arranged in a vertical direction of the air flotation rotary table and in a horizontal direction outside the air flotation rotary table. The device can simulate orbit work of a satellite platform, provides a simulated spatial mechanical environment, outputs residual moment in real time, can be used for directly measuring multiple inertial devices, is low in calculation amount, and has high precision.

Owner:HARBIN INST OF TECH

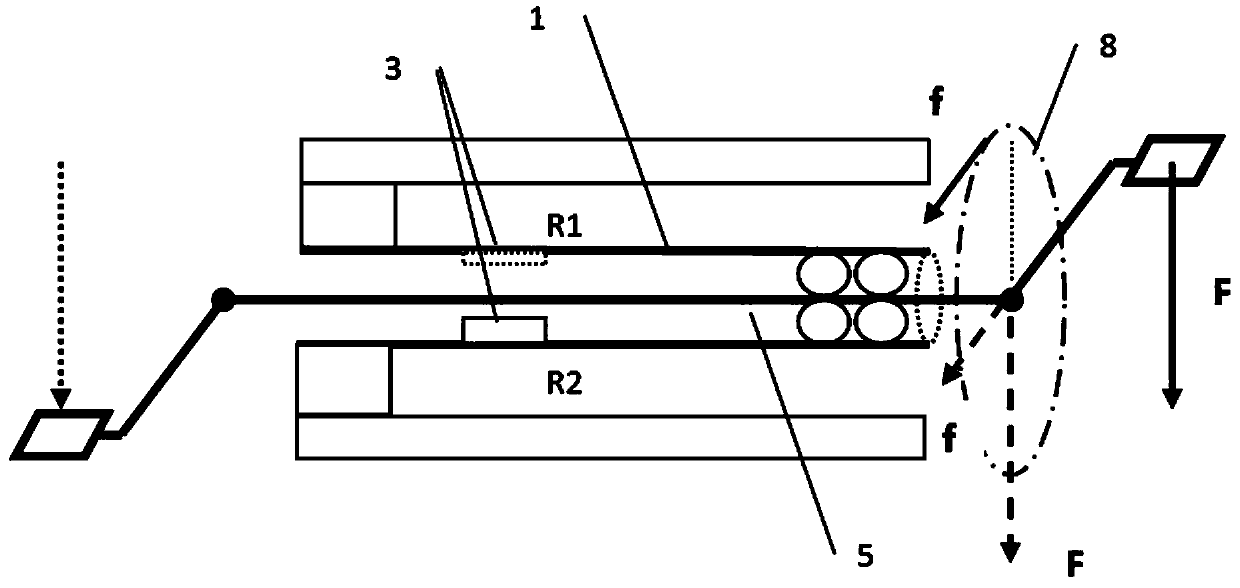

Undercarriage wheel brake kinetic moment measuring method

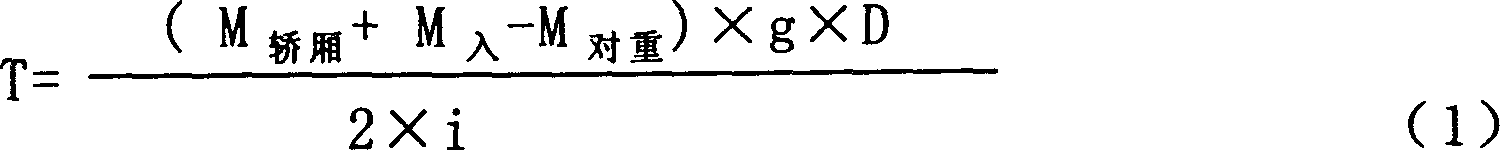

ActiveCN104596697AMeet the requirements of dynamic torque measurementMeeting the Difficulties of Braking Torque MeasurementApparatus for force/torque/work measurementMoment measureEngineering

An undercarriage wheel brake kinetic moment measuring method measures a brake kinetic moment in a loading state or an undercarriage wheel in a braking test of a large inertia dynamic test bed, solves the problems that a dynamic braking moment of a brake device cannot be directly measured as a torque / force sensor cannot be mounted on an undercarriage and the dynamic test brake moment of the undercarriage is measured, meets kinetic moment measuring requirements of a brake test of undercarriages with different structural sizes and is used for measuring the brake moment of a plane brake device in the loading state. The undercarriage can serve as an onboard device of a plane and has a huge use value. The measuring method has the advantages that the measuring method is simple in structure, convenient to mount, fine in universality and safety, can be widely used for undercarriage brake tests of various military aircrafts and civil aircrafts and other wheel power tests of an automobile and the like, and has important social significance and application prospects, and time and labor are saved.

Owner:XIAN AVIATION BRAKE TECH

Wide voltage energy-saving type permanent magnet motor power measuring system

ActiveCN102829910ASave electricityHigh precisionWork measurementTorque measurementEngineeringElectrical bonding

The invention provides a wide voltage energy-saving type permanent magnet motor power measuring system which comprises a power measuring motor, a power measuring machine controller, an adjustable direct current voltage stabilizing power supply, a force moment sensor, a force moment measuring device and a computer, wherein the power measuring motor adopts a permanent magnet alternative current motor; the power measuring motor is electrically connected with the power measuring machine controller; the power measuring machine controller is electrically connected with the adjustable direct current voltage stabilizing power supply; the force moment sensor is mechanically connected with the power measuring motor; a rotation speed signal is output through a rotation speed measuring device by using the combination of a code disc on a central shaft and an optical coupler; the computer is electrically connected with the power measuring machine controller, the force moment sensor and the rotation speed measuring device respectively; and the power measuring machine controller is used for supplying power to a tested motor and a tested controller after being connected with the adjustable direct current voltage stabilizing power supply in parallel. According to the wide voltage energy-saving type permanent magnet motor power measuring system provided by the invention, the permanent magnet alternative current motor instead of a magnetic powder brake or a magnetic hysteresis brake which is popular in the market is adopted, and a wide working voltage system is adopted so as to measure the power along with various tested controllers and tested motors at different voltage grades, and the consumed type power measurement is changed into generation type power measurement, so that a large quantity of electric energy is saved.

Owner:SHANGHAI EDRIVE +2

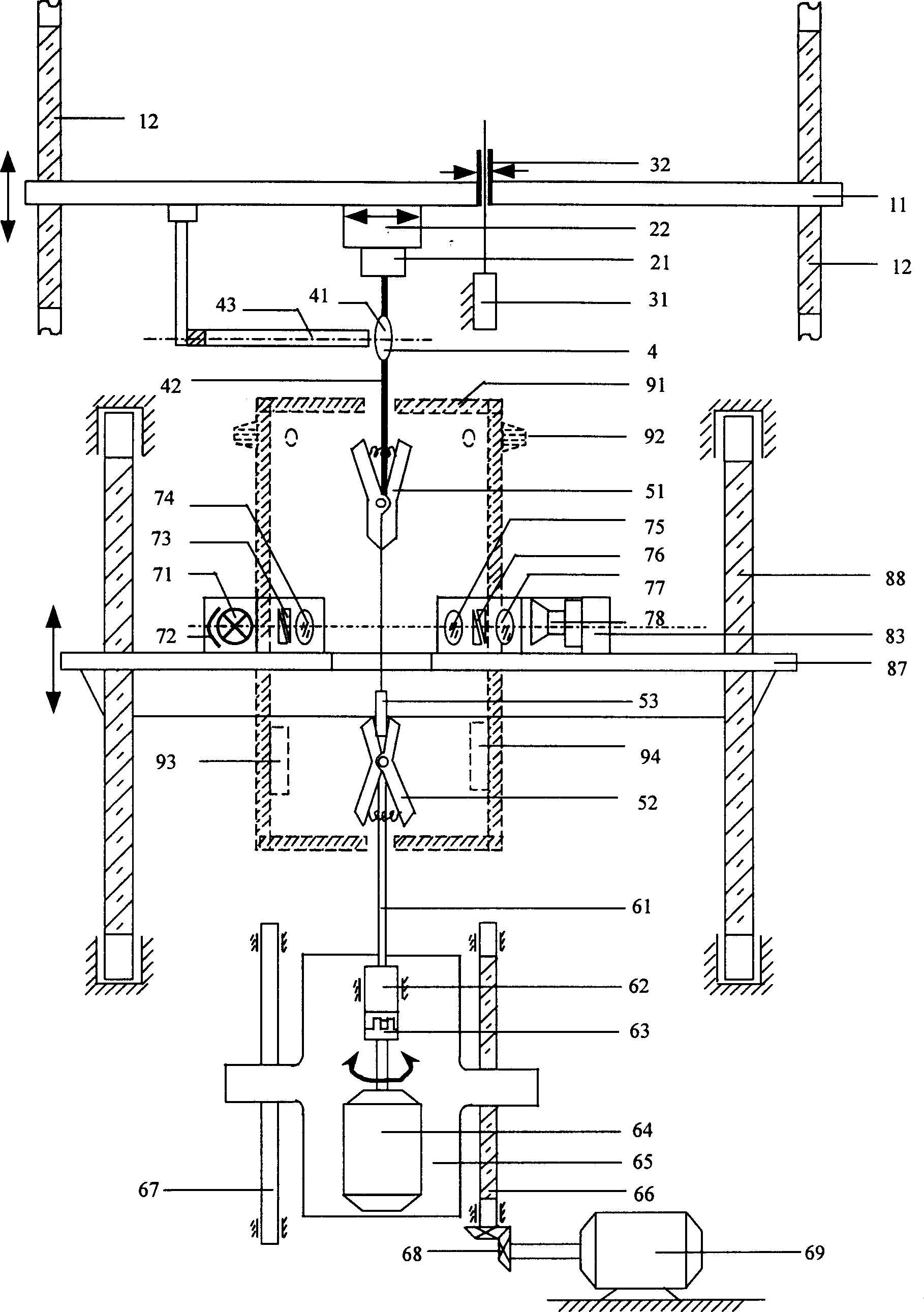

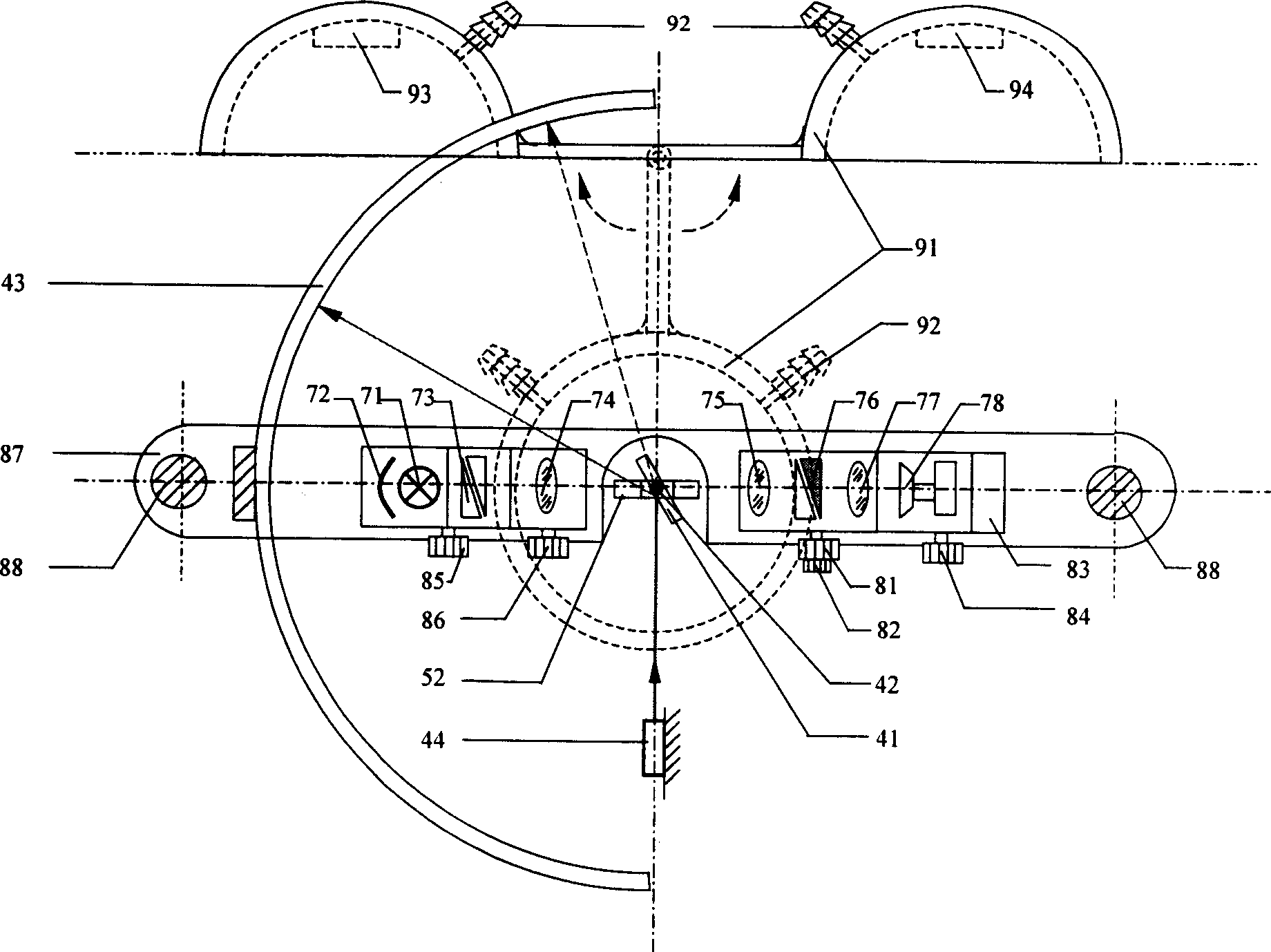

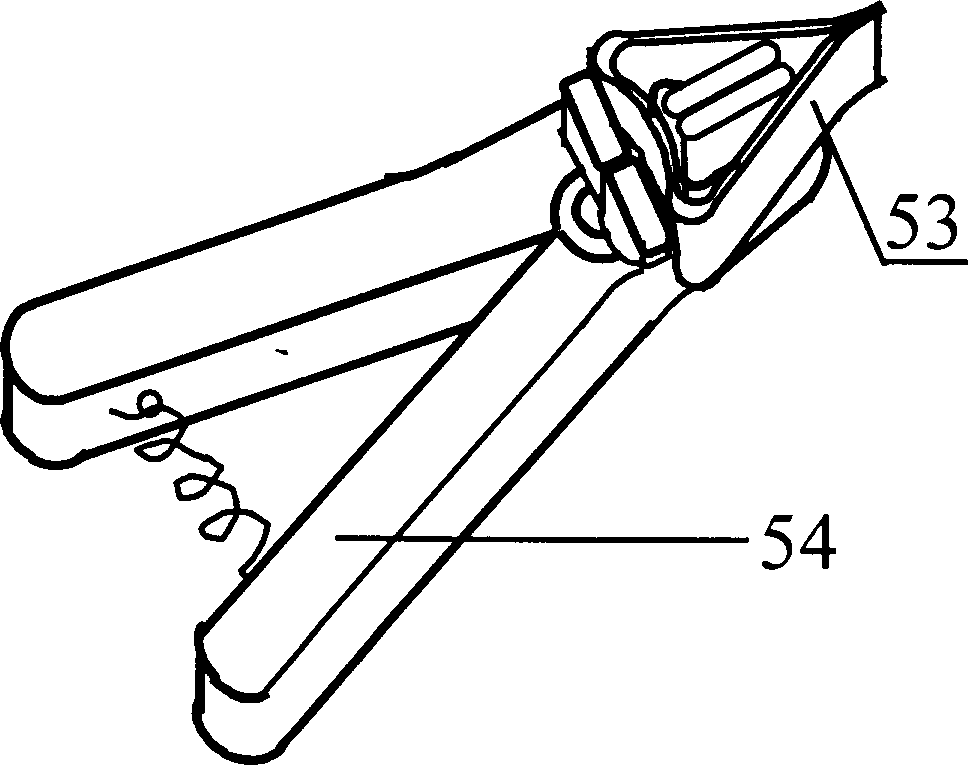

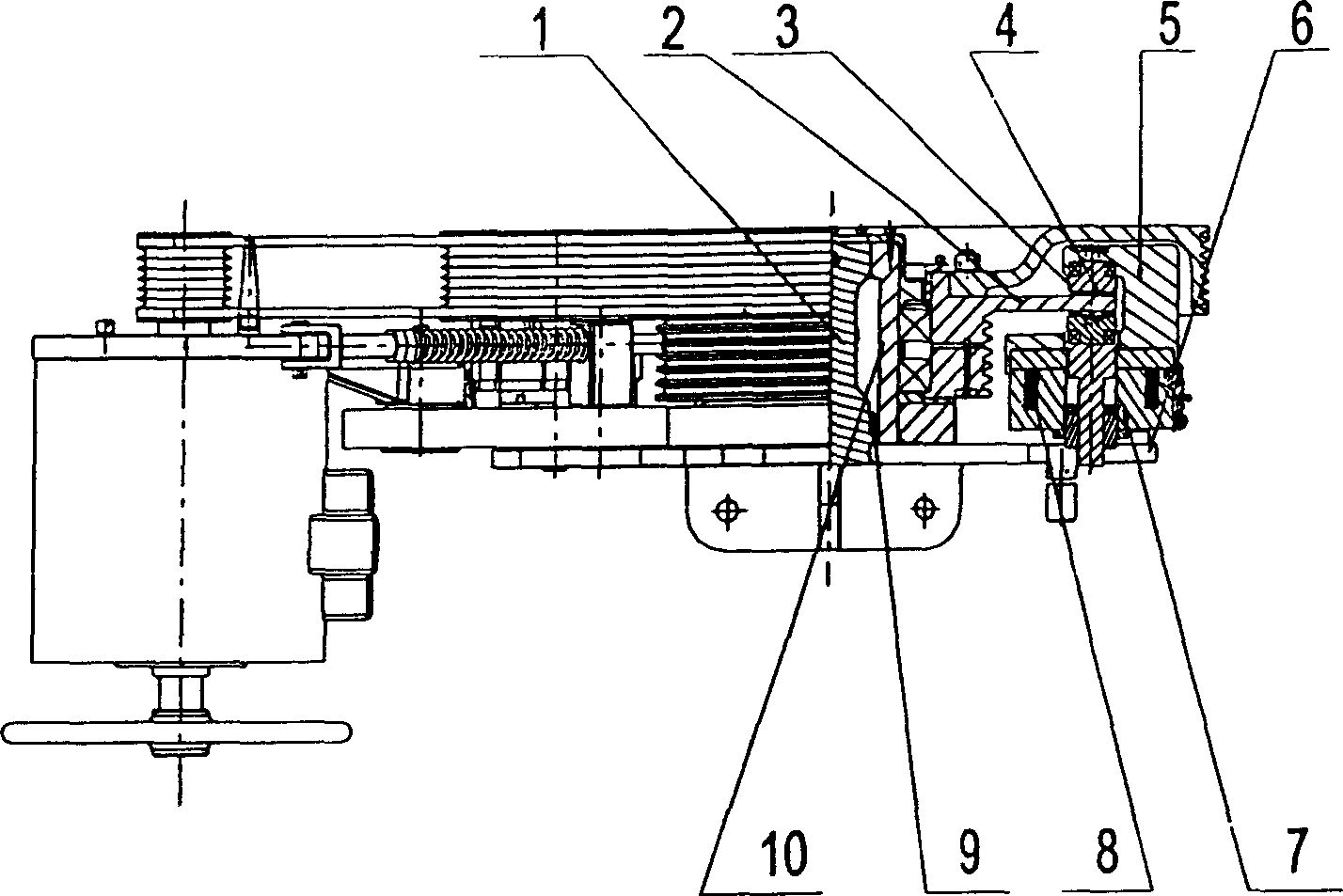

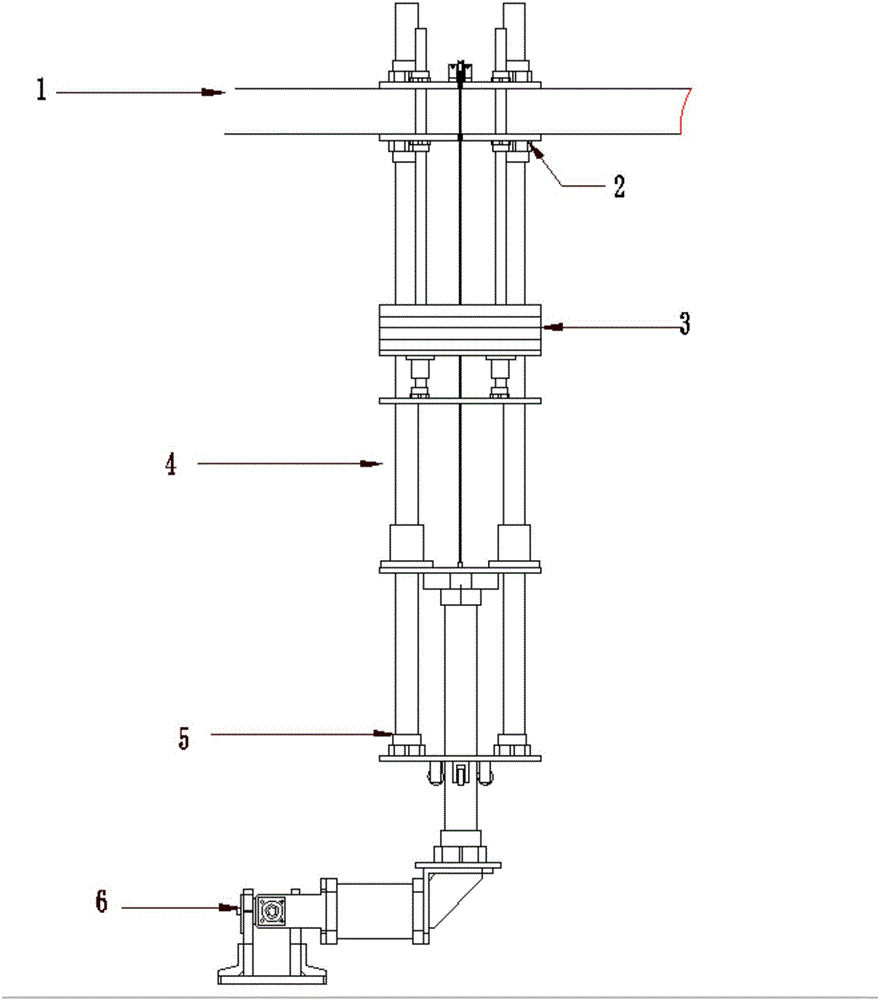

Lateral force and lateral restoring moment measuring instrument for ship model

InactiveCN106289722AEasy and intuitive to useGuaranteed accuracyHydrodynamic testingMeasurement of force componentsTransverse forceMeasuring instrument

The invention provides a lateral force and lateral restoring moment measuring instrument for a ship model. The lateral force and lateral restoring moment measuring instrument comprises a main sliding unit, a secondary sliding unit, an automatic unloading unit, a bearing unit and an angle adjusting unit, wherein the upper and lower sides of an airworthiness instrument are provided with an upper mounting plate and a lower mounting plate, and the upper end of the main sliding unit is connected with the airworthiness instrument through the upper mounting plate and the lower mounting plate; the upper end of the secondary sliding unit is connected with the airworthiness instrument through the upper mounting plate and the lower mounting plate, and the lower end of the main sliding unit is connected with the bearing unit; the lower end of the bearing unit is connected with the angle adjusting unit, and the lower end of the secondary sliding unit is connected with the automatic unloading unit. The lateral force and lateral restoring moment measuring instrument provided by the invention has the advantages that the required precision can be ensured in the complicated environment engineering and test environment, and the multi-cycle and long-time measurement requirement can be met.

Owner:HARBIN ENG UNIV

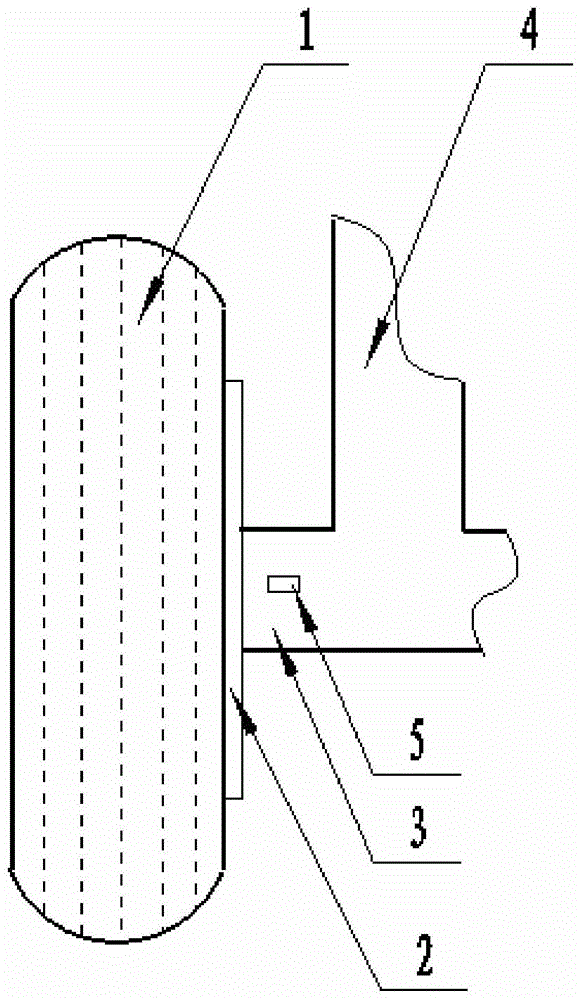

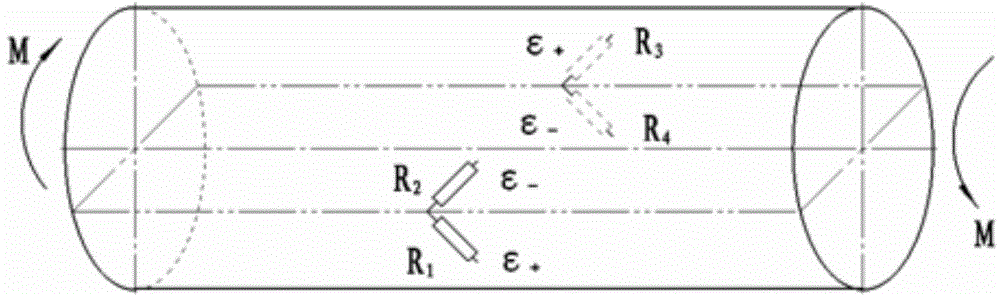

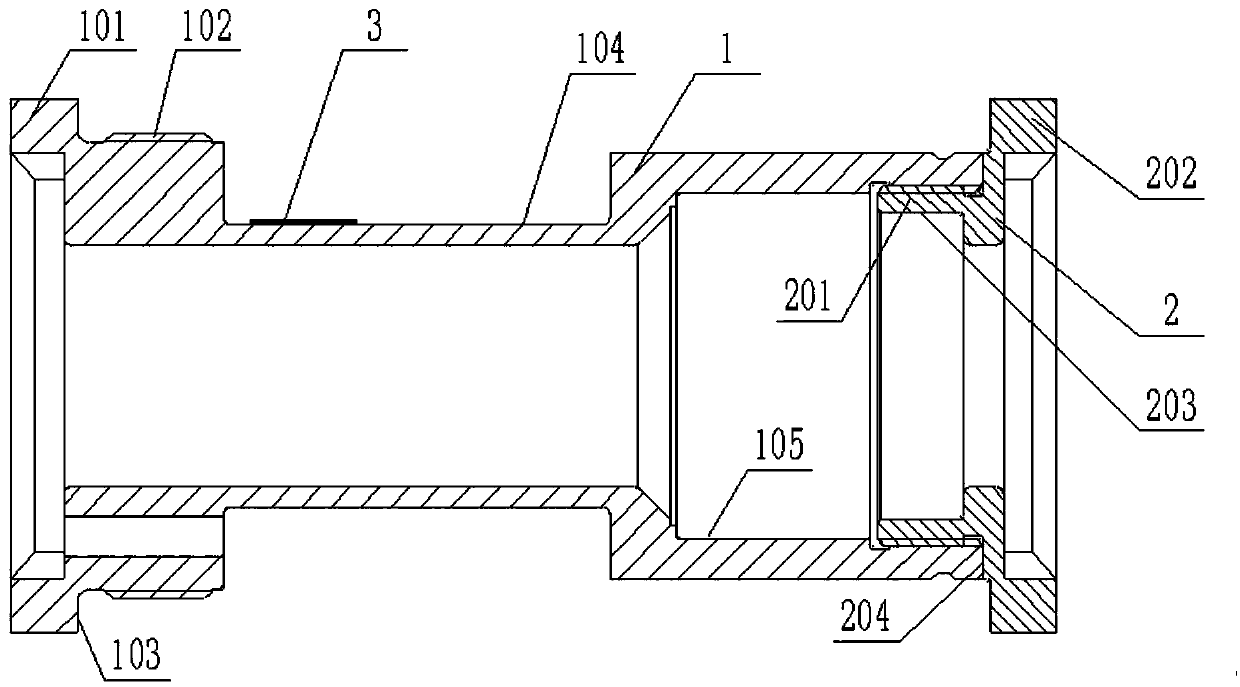

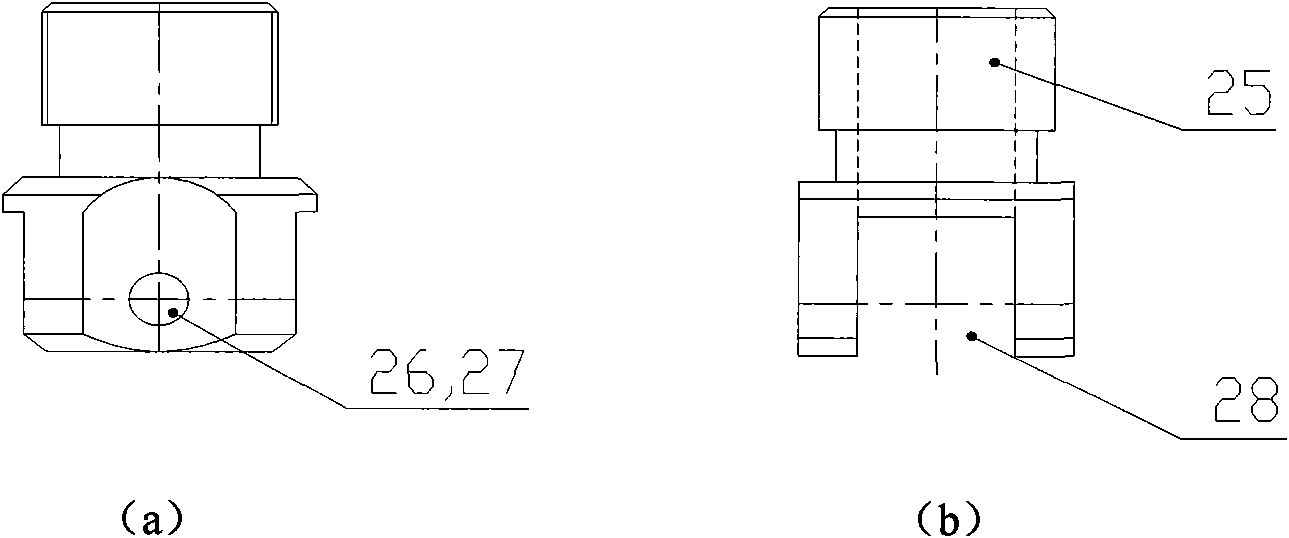

Cantilever central axle electric bicycle moment measuring device

The invention discloses a cantilever central axle electric bicycle moment measuring device, comprising a five-way tube arranged horizontally, a horizontal central axle is rotatably arranged in the five-way tube, the both ends of the central axle respectively penetrate out of the both ends of the five-way tube, a left crank assembly and a right crank assembly are connected to the both ends of the central axle, and the right crank assembly is also provided with a vertical sprocket. A cantilever beam sleeve which is arranged coaxially and spaced between the inner wall of the five-way tube and thecentral axle and is hollow cylindrical as a whole is also included, the left end of the cantilever beam sleeve is connected and fixed to the left end of the five-way tube, the central axis is rotatably arranged in the inner ring of a bearing arranged vertically in the cantilever beam sleeve, and the cantilever beam sleeve is fixed relative to the axial position of the central axis. An elastic strain sensing device arranged on the cantilever beam sleeve is also included. The device is installed in the five-way tube, one end is fixed and the other end is suspended, and the moment output by a cyclist is obtained by detecting the mechanical deformation of the cantilever beam sleeve. Linearity is good, measurement is accurate, and the device can be used for feeding back data for motor intelligent control.

Owner:CHONGQING UNIV OF TECH

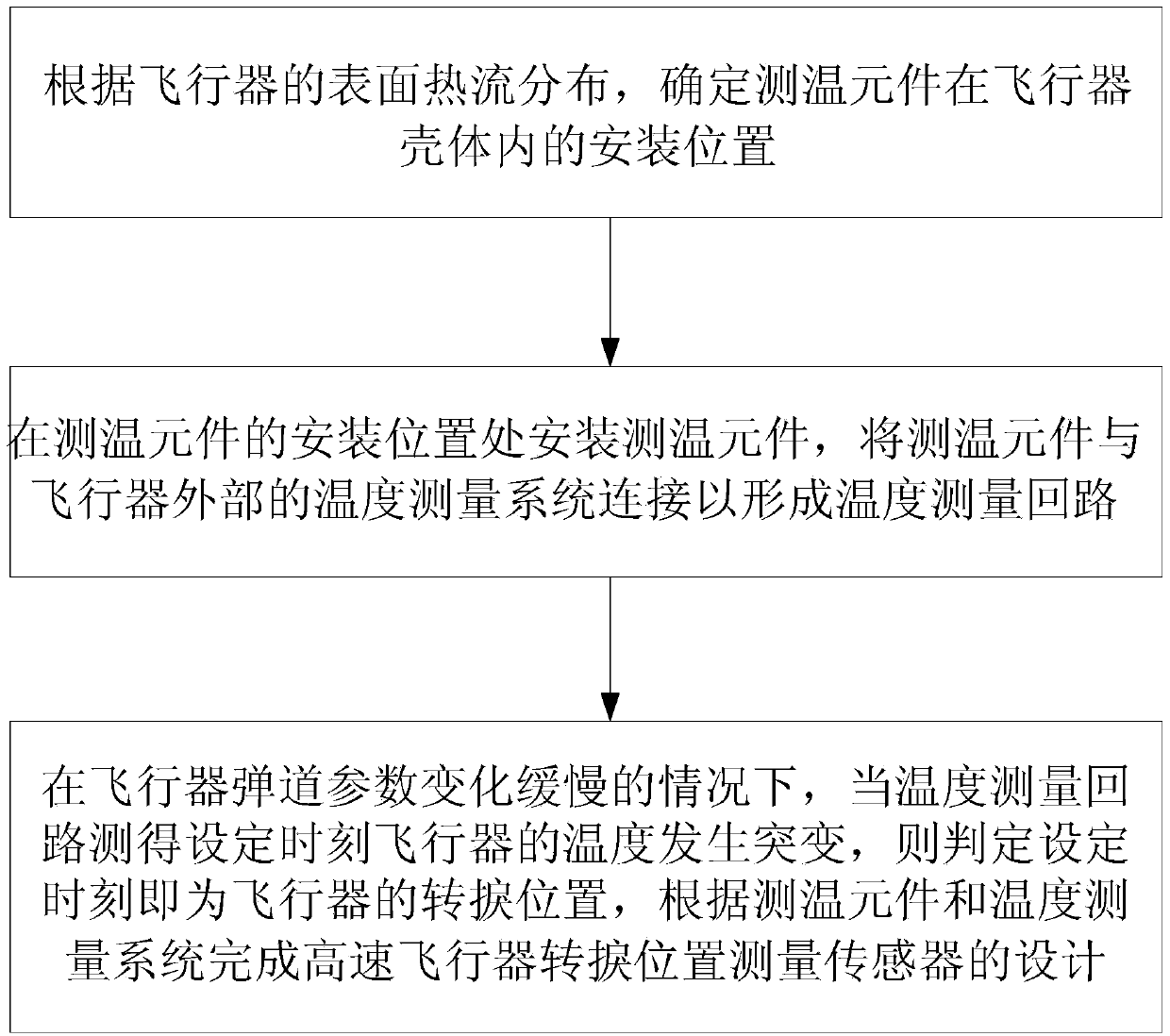

High-speed aircraft transition position measurement sensor design method based on temperature balance

ActiveCN109583067AEasy to useReduce measurement errorDesign optimisation/simulationSpecial data processing applicationsEngineeringMoment measure

The invention provides a high-speed aircraft transition position measurement sensor design method based on temperature balance, and the method comprises the steps: 1, determining the installation position of a temperature measurement element in an aircraft housing according to the surface heat flow distribution of an aircraft; 2, mounting a temperature measuring element at the mounting position ofthe temperature measuring element determined in the step 1, and connecting the temperature measuring element with a temperature measuring system outside the aircraft to form a temperature measuring loop; Step 3, measuring the temperature of the loop according to the temperature formed in the step 2; and in combination with the change of the trajectory parameters of the aircraft, when the temperature of the aircraft suddenly changes at the set moment measured by the temperature measurement loop, that the set moment is the transition position of the aircraft is judged and the design of the measurement sensor is finished according to the temperature measurement element and the temperature measurement system. By applying the technical scheme provided by the invention, the technical problems of complex measurement and poor accuracy of the transition position of the aircraft in the prior art are solved.

Owner:BEIJING AEROSPACE TECH INST

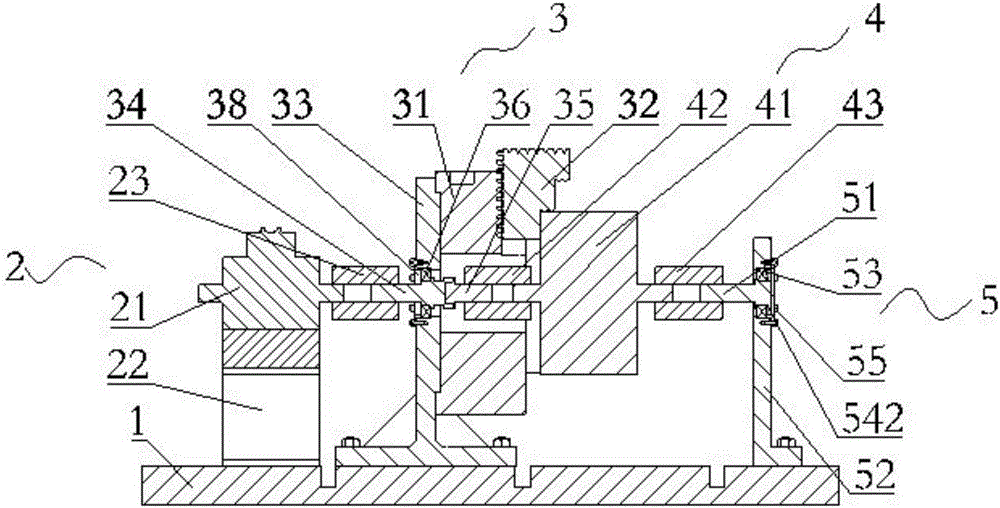

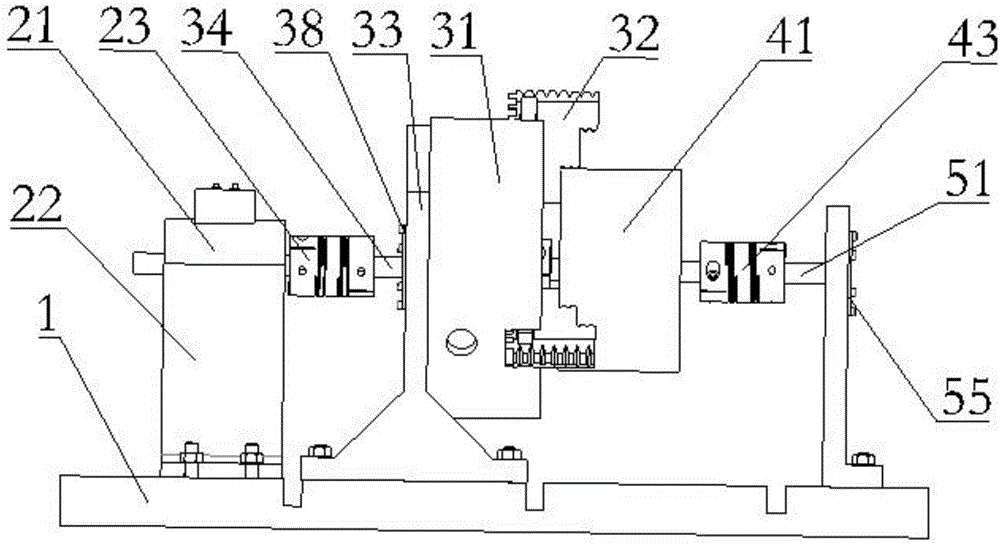

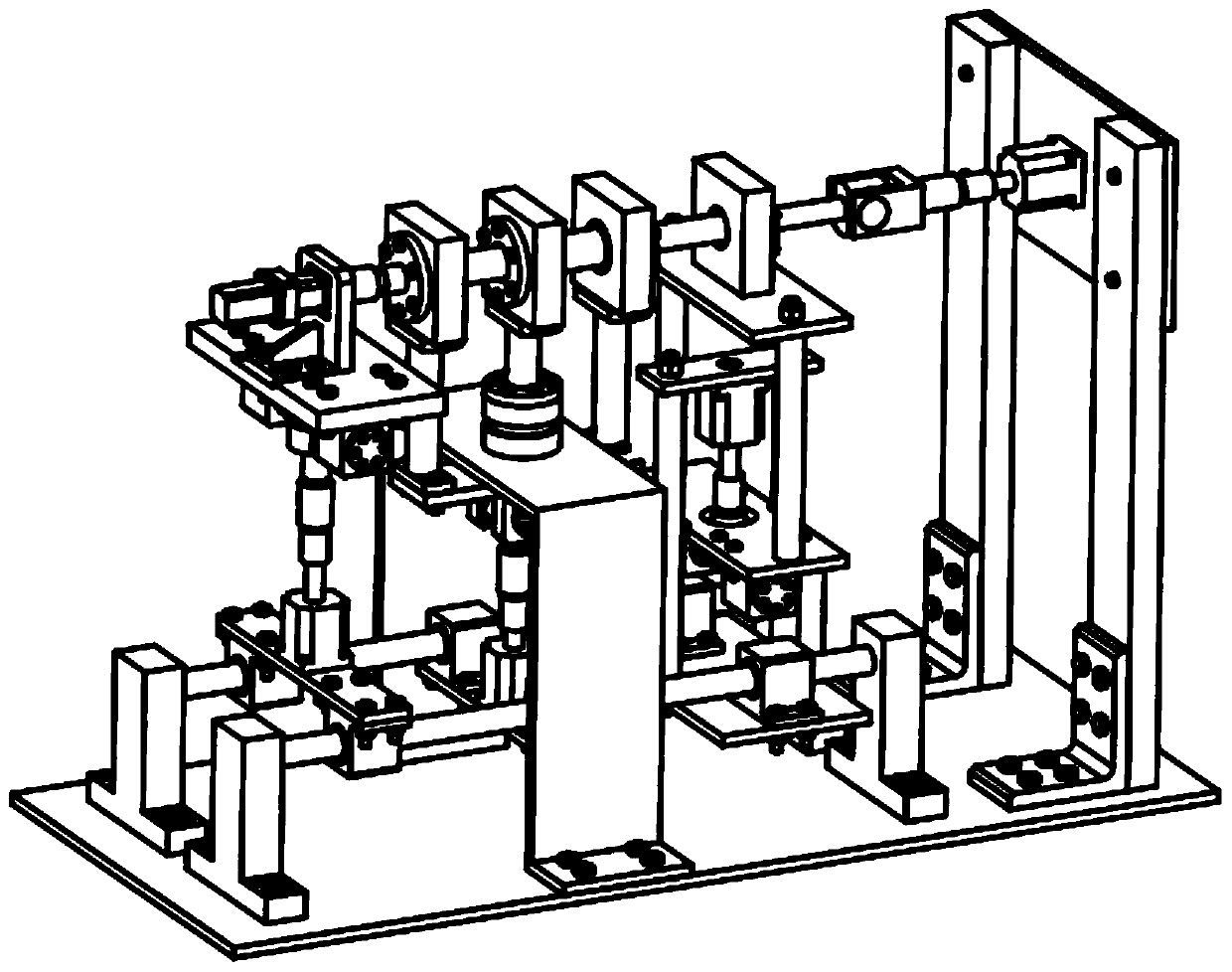

Low-speed angular contact ball bearing friction moment measuring device and loading measuring method

ActiveCN109708888AAchieve correctionImplement continuous loadingMachine bearings testingApparatus for force/torque/work measurementBall bearingLow speed

The invention discloses a low-speed angular contact ball bearing friction moment measuring device and a loading measuring method and relates to bearing radial load, axial load, moment load, joint loadloading and friction moment measurement. The device is formed by a pedestal, a driving system, a radial load loading system, an axial load loading system, a moment load loading system and a frictionmoment measuring system. For a problem that other components interfere a loading load during an existing angular contact ball bearing friction measuring device load loading process, a closed-loop feedback control system formed by a six-dimensional force sensor, the radial load loading system, the axial load loading system and the moment load loading system is used to eliminate an interference. Inthe invention, a friction moment measurement problem under the continuous high-precision loading of an angular contact ball bearing joint load is solved and friction moment measurement is accurate.

Owner:YANSHAN UNIV

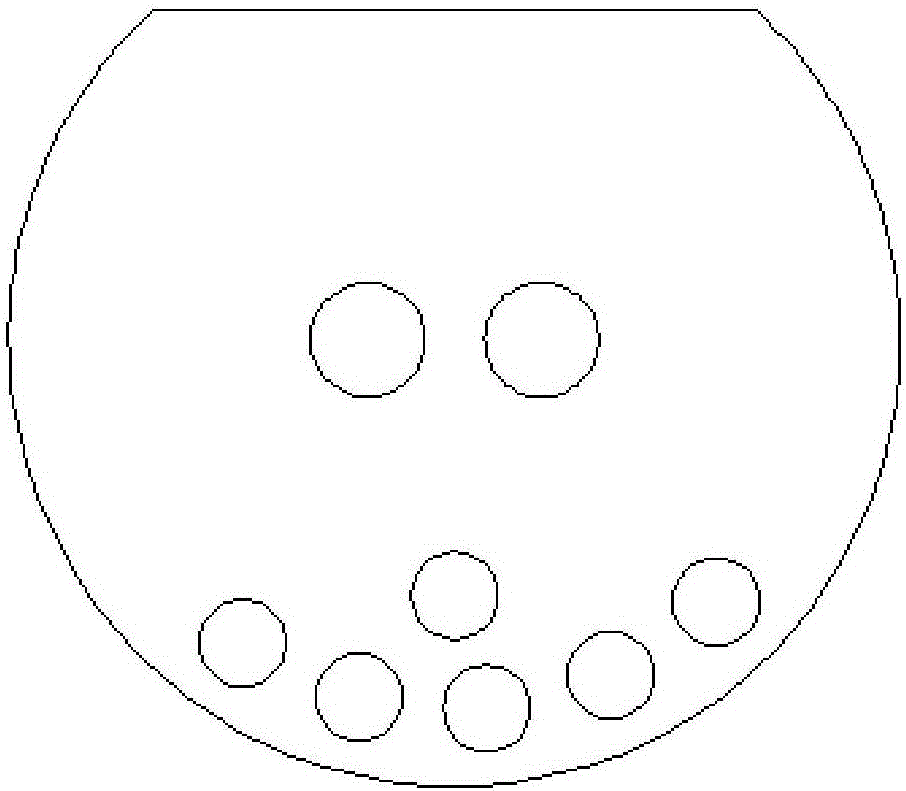

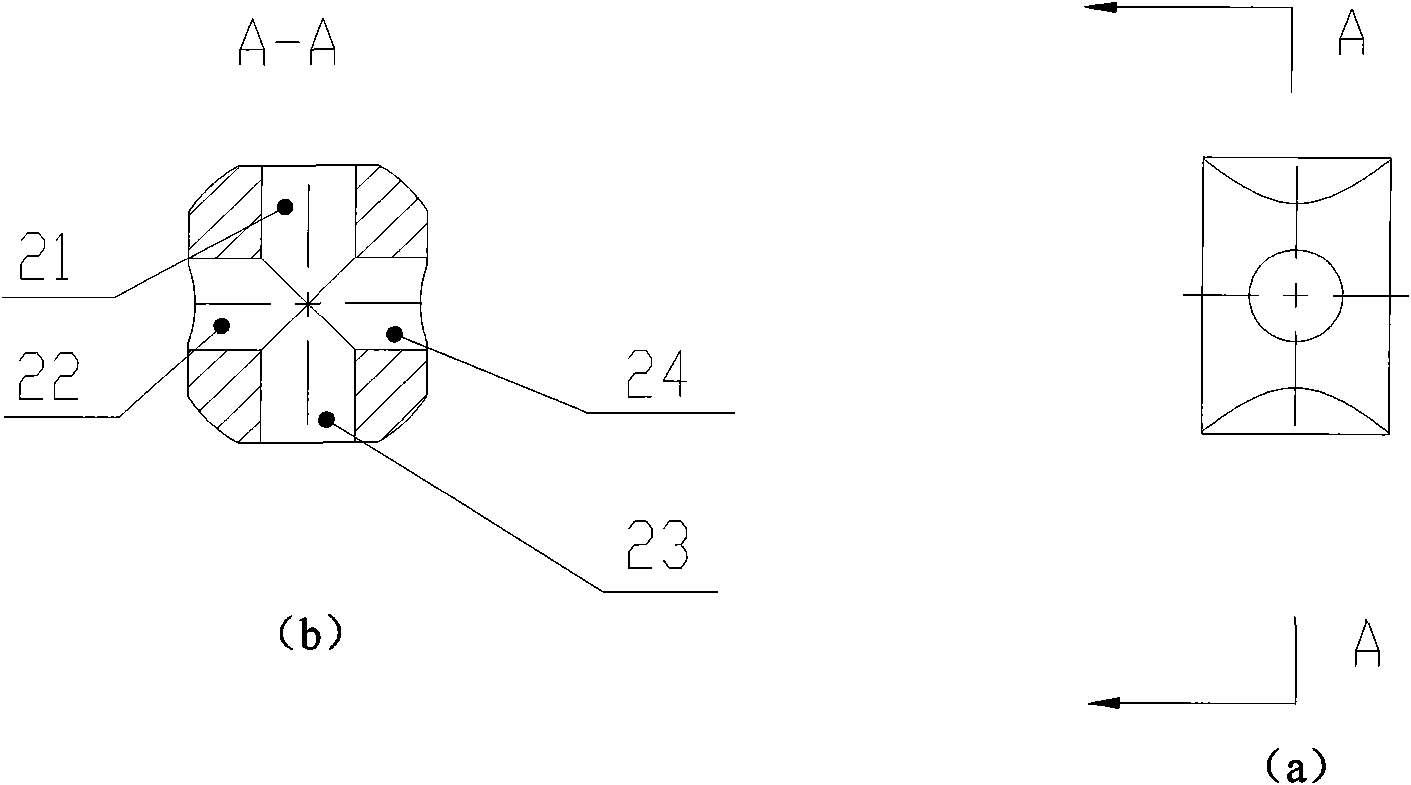

Multi-variant spherical travelling-wave ultrasonic motor moment measuring device

InactiveCN101586995AAccurate measurementSimple structurePiezoelectric/electrostriction/magnetostriction machinesWork measurementMeasurement deviceUniversal joint

The invention discloses a multi-variant spherical travelling-wave ultrasonic motor moment measuring device, comprising: a pressure sensor, a bracket, a bending plate, a force measuring rod, a short mandrel, a cross head, a hardwood concave indenter, a universal joint, an upper cover, a lower cover and a base, wherein four grooves are annularly arranged in the upper cover for placing the pressure sensor; the contact of the pressure senor faces to the direction of centre of circle; the lower cover has four rectangular column bodies which fix the pressure sensor in cooperation with the upper cover; the force measuring rod penetrates through the upper cover and the lower cover; an upper end of the force measuring rod is equipped with the cross head by using the short mandrel; the cross head is connected with the universal joint through the mandrel; the middle section of the force measuring rod has an annular bump; the hole in the bottom is equipped with the hardwood concave indenter; the bending plate is in the shape of circular arch of 180 degrees; the hole in the bottom end is also equipped with the hardwood concave indenter. The invention has small volume, simple structure and convenient installation and test.

Owner:ZHEJIANG UNIV

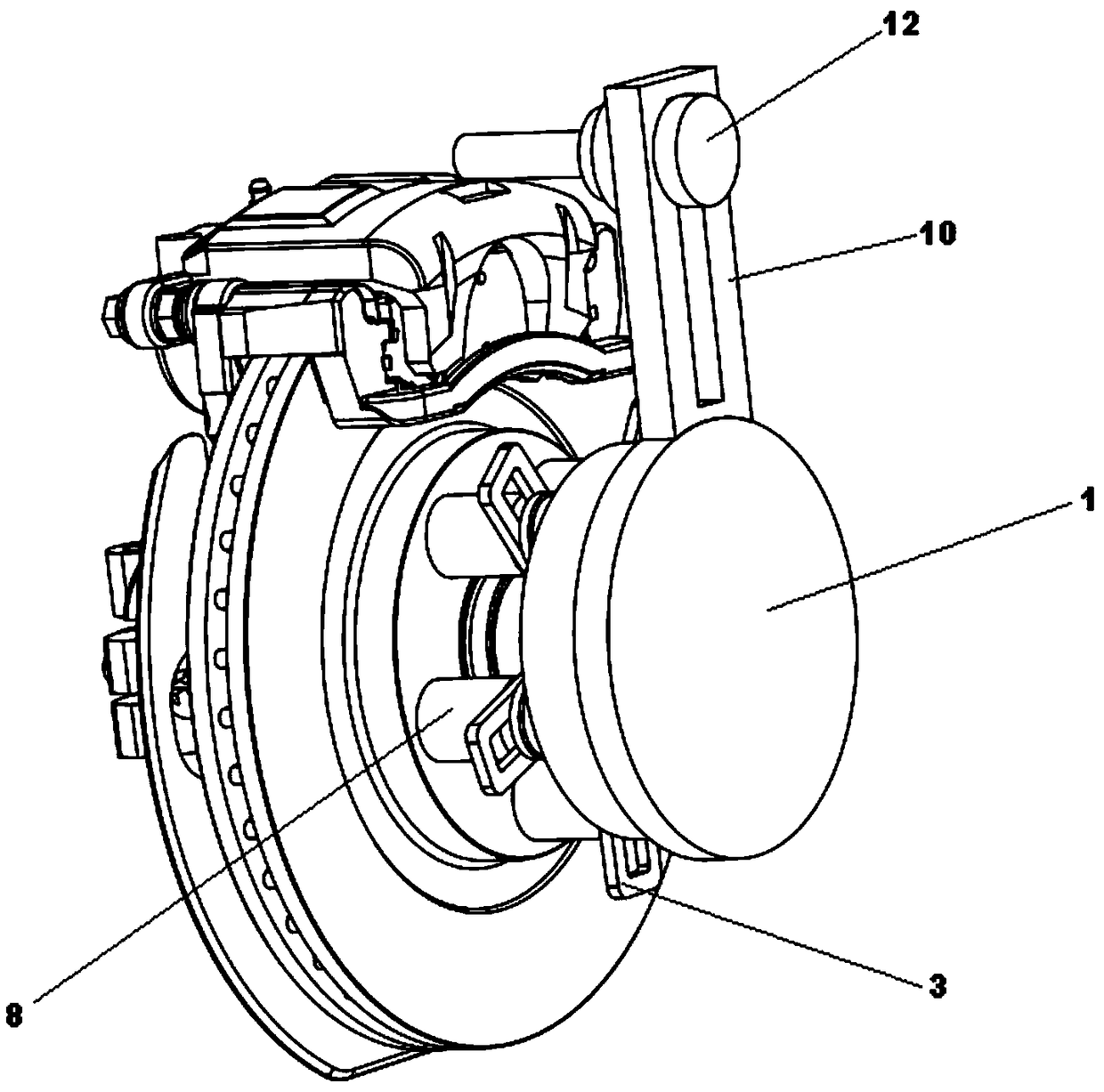

Friction moment measuring device used for sliding column

ActiveCN105698989AFriction torque measurement implementationVehicle testingWork measurementFriction torqueMoment measure

Owner:CHERY AUTOMOBILE CO LTD

Method for forecasting signal-to-noise ratio of mobile communication signals based on channel scene classification

InactiveCN103281716AAccurate trackingImprove performanceError preventionWireless communicationSignal-to-noise ratio (imaging)Current channel

The invention discloses a method for forecasting a signal-to-noise ratio of mobile communication signals based on channel scene classification. The method includes the following steps that first step, a signal-to-noise ratio of a moment is measured and compared with a moment forecast signal-to-noise ratio of moment forecast, and a deviation value between the moment measured signal-to noise ratio and the forecast signal-to-noise ratio is obtained; second step, at the moment, a current channel variation scene is judged as a channel slow variation scene, and a forecast scheme of the channel slow variation scene is adopted for forecasting a forecast signal-to-noise ratio of the moment; third step, at the moment, the current channel variation scene is judged as a channel moderate variation scene, a forecast scheme of the channel moderate variation scene is adopted for forecasting a forecast signal-to-noise ratio of the moment; fourth step, at the moment, the current channel variation scene is judged as a channel sudden variation scene, a forecast scheme of the channel sudden variation scene is adopted for forecasting a forecast signal-to-noise ratio of the moment; fifth step, a command of returning the first step is carried out. The method for forecasting the signal-to-noise ratio of mobile communication signals based on the channel scene classification can deal with the channel scenes very well in which a traditional forecasting technology is ineffective, can track variation of the signal-to-noise ratio rapidly and accurately and enables the performance of a whole system to be improved.

Owner:GUANGXI NORMAL UNIV

Bearing pedestal starting moment measuring apparatus

ActiveCN102419229AShort feedback timeImprove assembly efficiencyWork measurementTorque measurementBall bearingEngineering

The invention discloses a bearing pedestal starting moment measuring apparatus which is characterized by comprising a measuring rod with a lever structure. A middle part of the measuring rod is connected with a rotating shaft through a deep groove ball bearing. A rotation center of the rotating shaft is a lever fulcrum. A front end of the measuring rod is a lever acting force point and is set as a measuring head which can be driven by a transition rod. A tail of the measuring rod is a lever resistance point and is provided with a pressure sensor at a corresponding position. The pressure sensor measures a pressure value of a lever resistance point position. When turning the measuring head through the transition rod, the measuring head drives the measuring rod to rotate around the rotating shaft, the pressure sensor detects the pressure value at the tail of the measuring rod, and when a lever moment arm is fixed, starting moment is calculated according to the measured pressure value andthe moment arm. When press mounting of a main cone bearing is completed, measurement of bearing pedestal starting moment can be carried out, a feedback time is short, assembling efficiency can be greatly raised, and measurement accuracy is raised.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Air tightness detecting device and detecting method for movement process of high speed train

ActiveCN108844694ASimple structureShorten the timeMeasurement of fluid loss/gain rateMicrocontrollerHuman power

The invention provides an air tightness detecting device and detecting method for a movement process of a high speed train. The device includes two air pressure transmitters and one single chip microprocessor disposed on a head locomotive of the high speed train and two air pressure transmitters and one single chip microprocessor disposed on a tail locomotive of the high speed train. The device isadvantaged in that the structure is simple and air pressure leakage information can be displayed in real time. When air pressure leakage occurs, the position of an air pressure leakage point can be calculated; data can be stored in a CCU(Central Control Unit) and can be transmitted to a DMI (Driver-Machine Interface) through an MVB (Multifunction Vehicle Bus) connected with the CCU. The detectionmethod is that when air pressure leakage occurs, the single chip microprocessors on the head locomotive and the tail locomotive send air pressure abnormal values and abnormal moments measured by theair pressure transmitters to the CCU, calculate the air pressure leakage position according to time difference in combination with vehicle speed, vehicle length and air pressure propagation rate and gives real time alarm and display in the DMI. At the same time, the CCU can be started during in-factory maintenance of the high speed train and information of the air pressure leakage position can becalled, so that a large amount of time and labor can be saved in air tightness check.

Owner:LANZHOU JIAOTONG UNIV

Portable dragging moment measuring device and method based on PID control

InactiveCN109000842AAccurate measurementReduce adverse effectsWork measurementTorque measurementMeasurement deviceMoment measure

The invention relates to a portable dragging moment measuring device and method based on PID control. The problem that in the prior art, the vehicle dragging moment cannot be accurately measured underthe whole vehicle state is mainly solved. The portable dragging moment measuring device comprises a torque measuring device, a motor arranged on the torque measuring device, an adjustable mounting mechanism arranged on the motor, a first adjustable mounting frame connected with the torque measuring device, an adjustable length locking pin connected with the first adjustable mounting frame, and aPID controller for controlling the motor to rotate at a constant rotating speed. The PID controller is in circuit connection with the motor. The vehicle dragging moment can be accurately measured under the whole vehicle state, adverse influences of repeated dismounting and mounting on a vehicle are avoided, and thus the measuring process is easier, more convenient and more accurate.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Calibration method and measurement method of starting friction moment measuring instrument pressure value

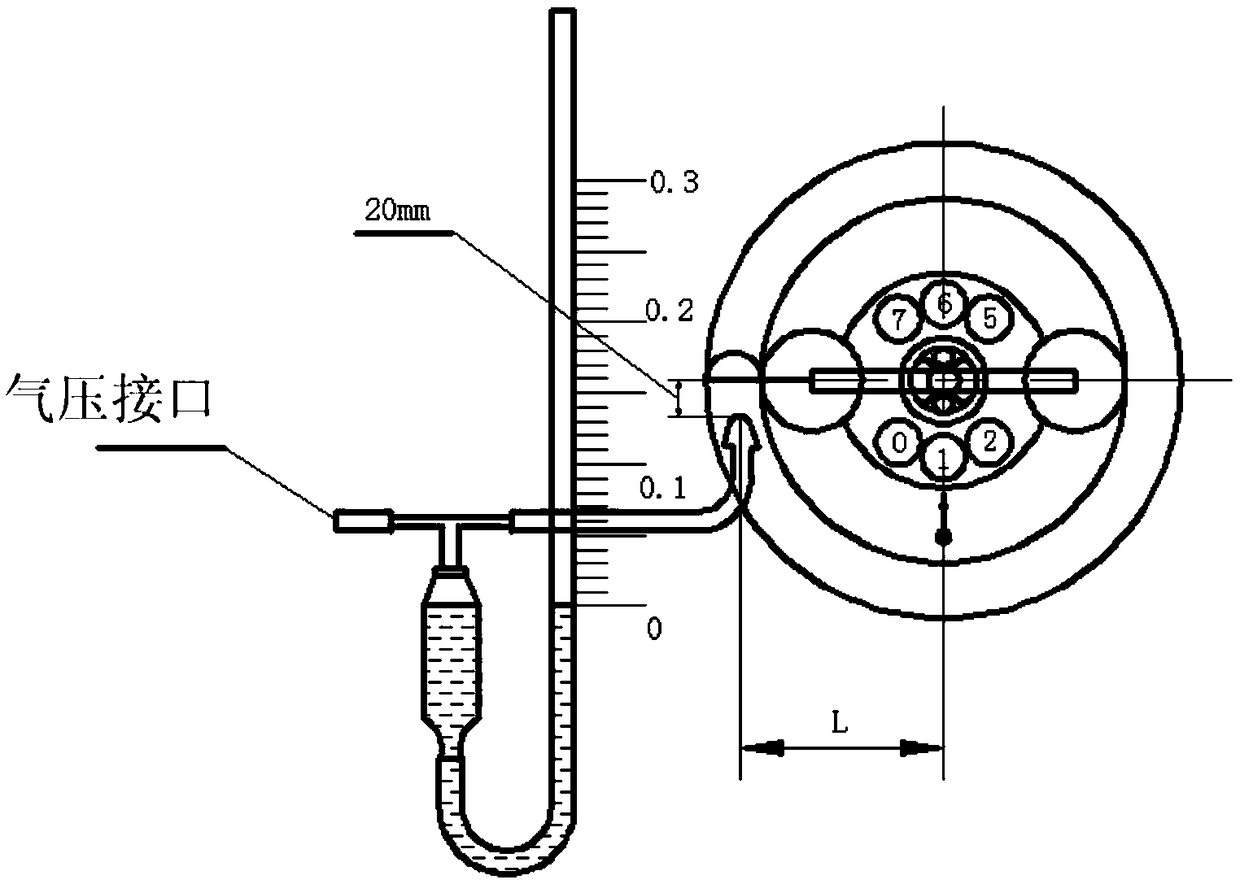

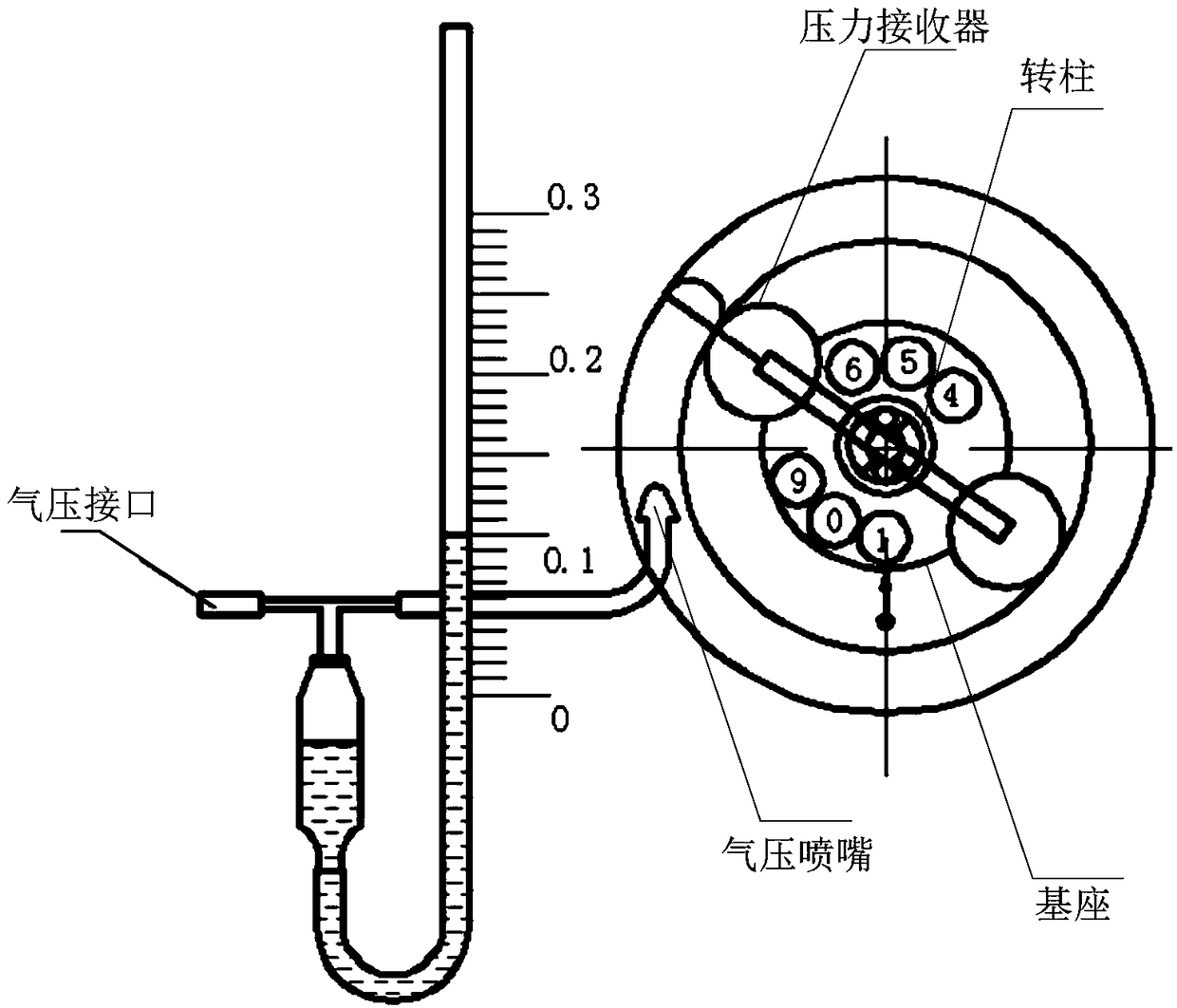

ActiveCN109186856AAccurate CalibrationEasy to operateForce/torque/work measurement apparatus calibration/testingMeasuring instrumentSpray nozzle

The invention discloses a calibration method and a measurement method of a starting friction moment measuring instrument pressure value, belonging to the technical field of bearing detection and usedfor solving problems of low efficiency, tedious calculation process, inaccurate pressure scale value after damage of a glass container of the existing starting friction moment measurement. In the measurement method of the starting friction moment measuring instrument pressure value, a measurement load device is placed on a tested bearing, a scale on a rotary column is aligned with a pedestal fixedpointer, and a pneumatic nozzle is placed to be opposite to a pressure receiver; if the pressure receiver rotates a range greater than or equal to the scale value on the pedestal relative to the pedestal, the friction moment is qualified, and otherwise, the friction moment is not qualified; and the friction moment of ten mark points is measured. The calibration method comprises the following steps: placing the air pressure nozzle vertically down 20mm from a precision electronic balance, opening a three-way valve, enabling air source pressure to increase from 0.1g, obtaining an actual pressurevalue through the precision electronic balance, and then, calibrating a position of the pressure scale value of the glass container. The calibration method and the measurement method are used for detection of aeronautical instrument bearings.

Owner:AVIC HARBIN BEARING

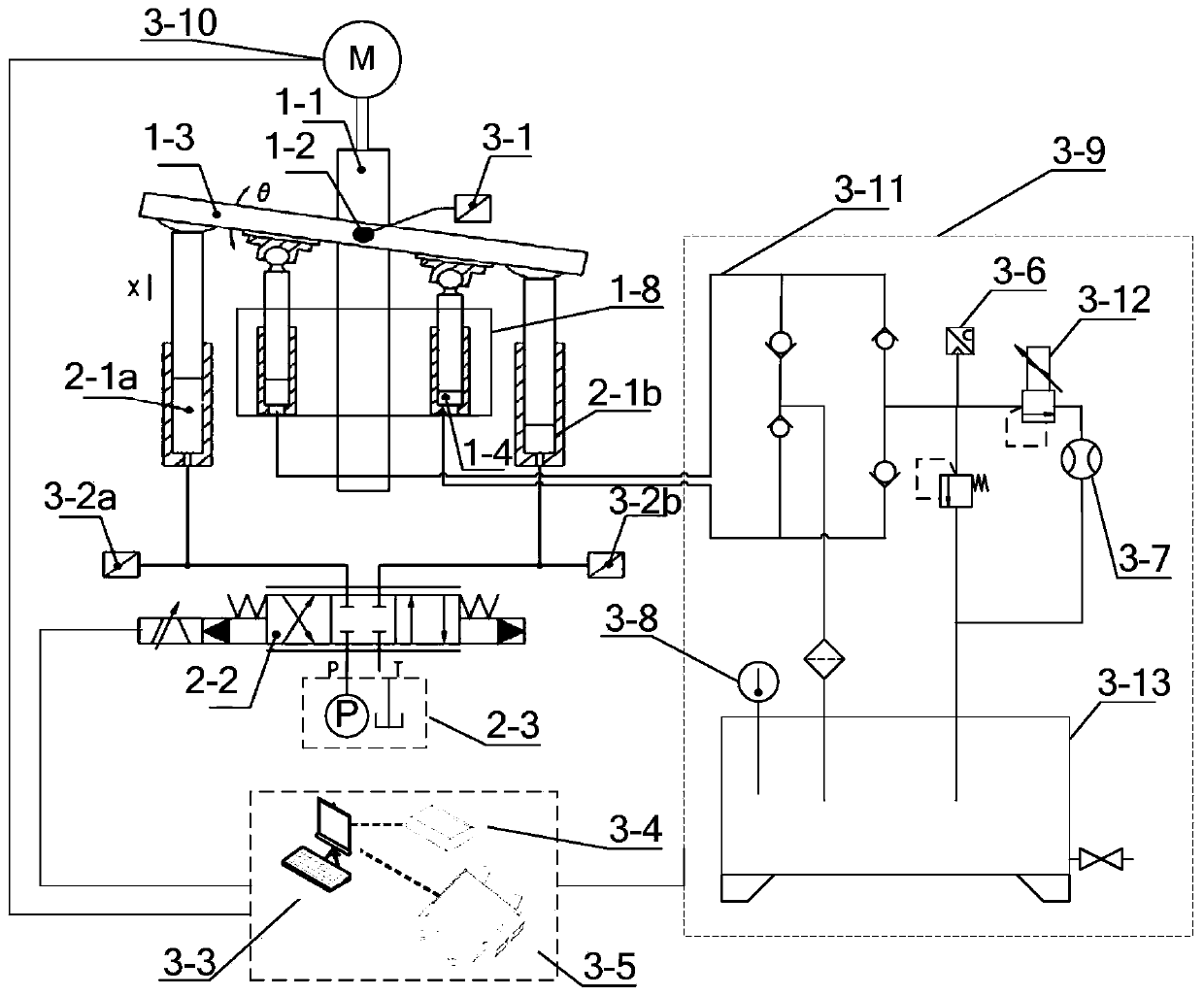

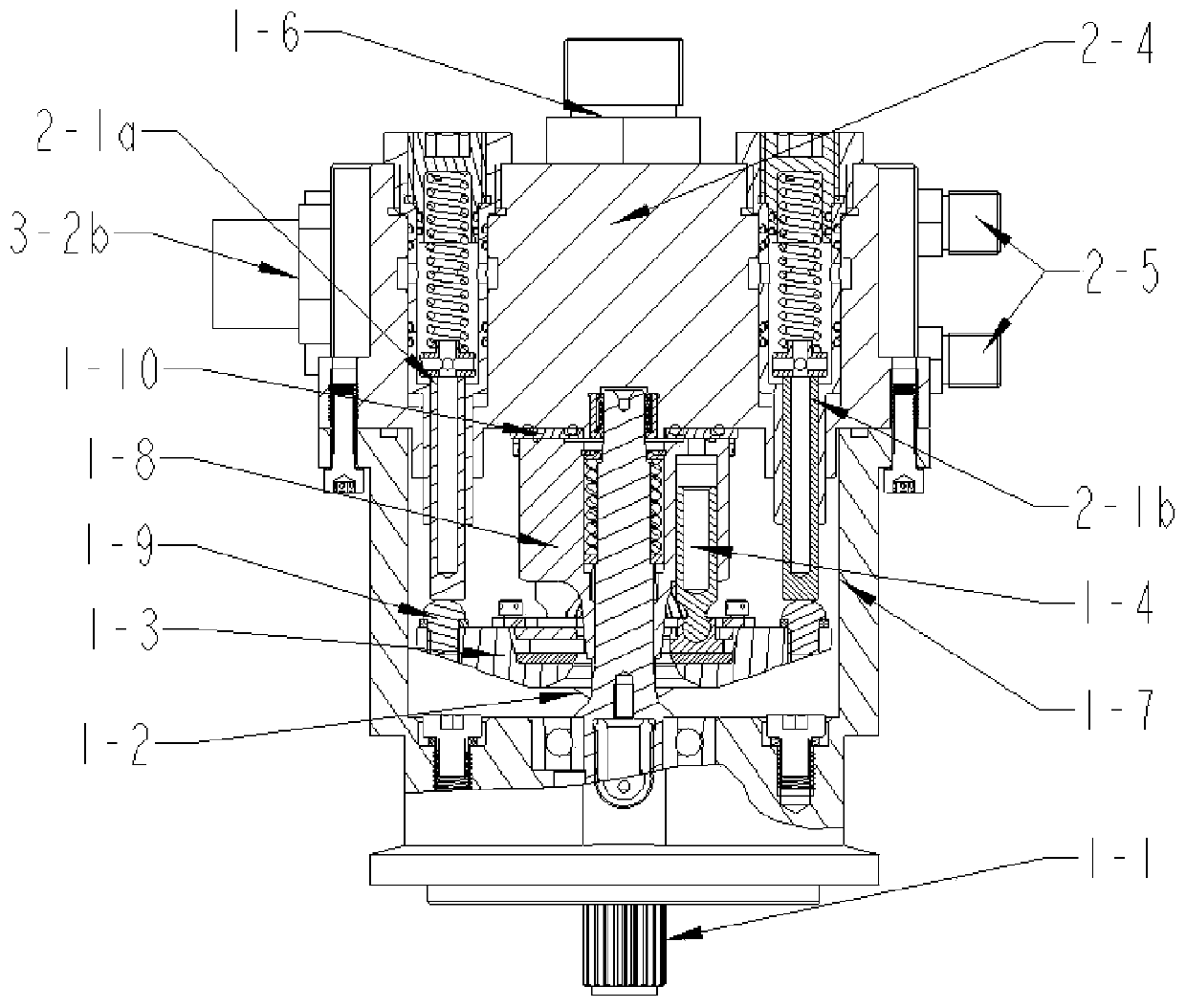

Variable pump swash plate control moment measuring device

ActiveCN110439800AEasy to turn toHighly integratedPump testingPositive-displacement liquid enginesControl systemEngineering

The invention discloses a variable pump swash plate control moment measuring device. The variable pump swash plate control torque measuring device comprises a pump body part, a swash plate variable system and a measurement and control system. By means of the device, the swing moment of a swash plate under different working conditions and under different swing angle conditions can be accurately measured, and data support is provided for subsequent mechanism design; the control moment of the swash plate of an existing model variable pump can be measured, and support can be provided for improvement design of the pump; and meanwhile, the device is a valve-controlled volume type servo pump and can be directly applied to a volumetric static pressure servo mechanism, and belongs to the technicalfield of plunger pumps.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com