Brake force moment measuring device and method

A braking torque, measuring device technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., to achieve the effects of compact structure, high precision, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

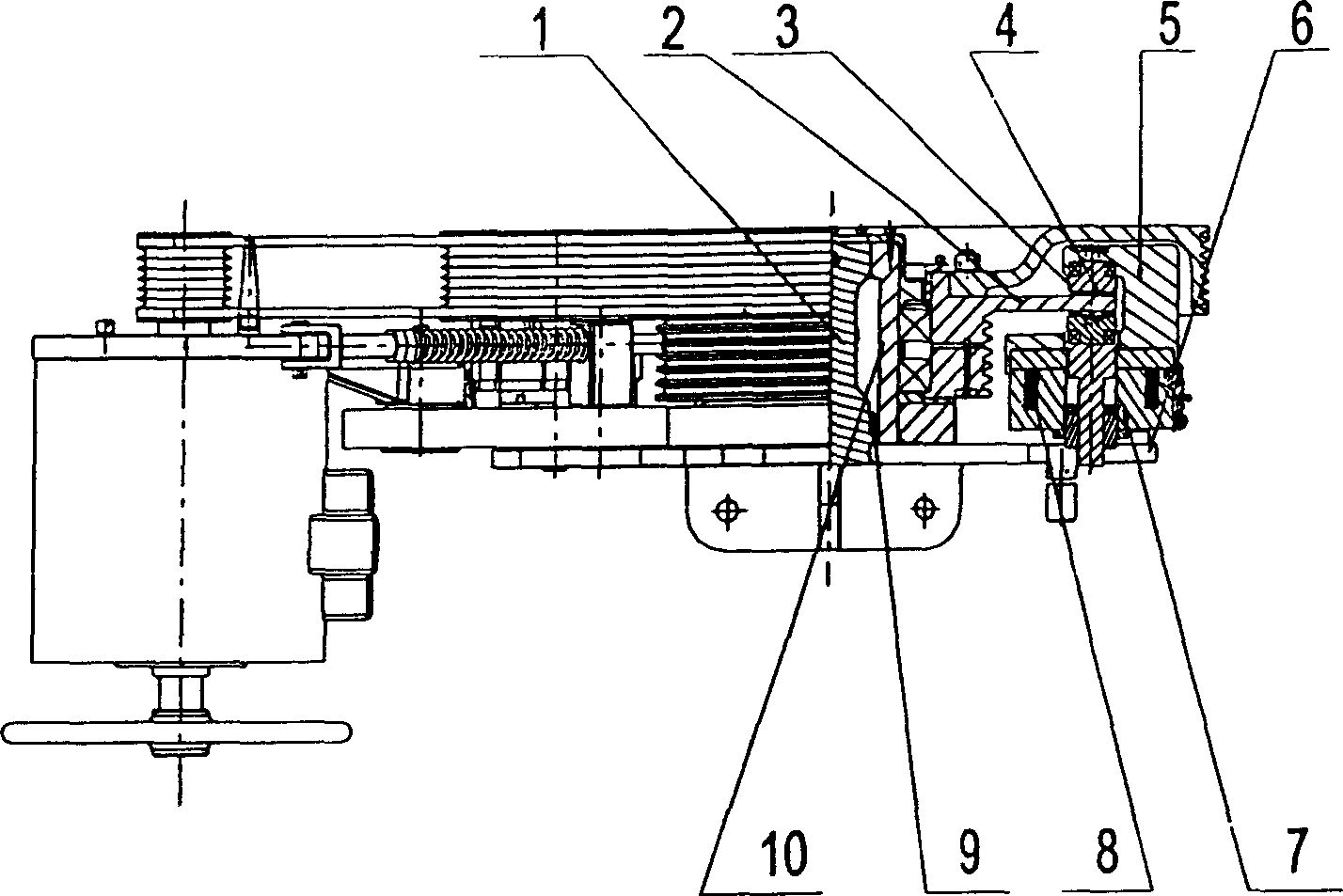

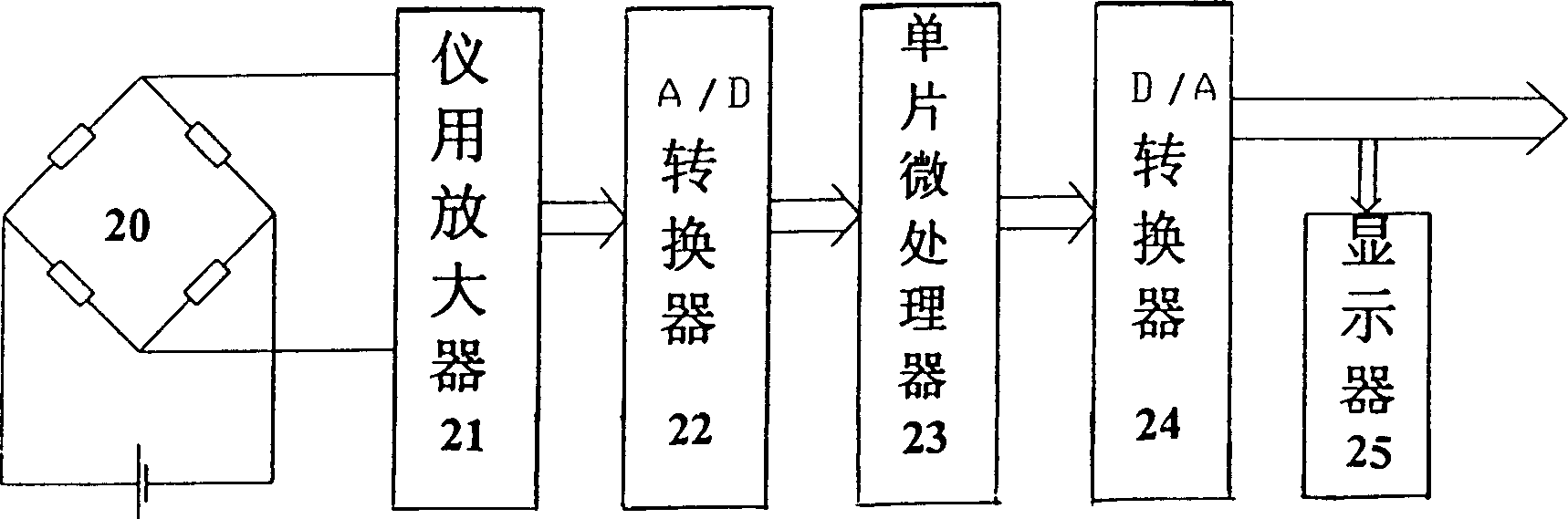

[0036] Please refer to the attached figure 1 As shown, the present invention is made up of components such as beam 6, torsion bar 1, main shaft 10, brake and circuit part. The other end of the rod 1 is connected to the main shaft 10 through a fixed pin, and there is a bearing 9 between the torsion bar 1 and the main shaft 10. The braking torque on the brake disc 2 is transmitted to the brake disc body 3 through the friction disc 4, and is controlled by the brake disc 4. The moving caliper body 5 bears, the brake caliper body 5 is connected with the iron core 7, and then connected with the beam 6, the torque 1 is transmitted to the beam 6, the torsion bar 1 and the main shaft 10, the brake coil 8 is embedded in the iron core 7, and There is a pressure regulating device, and a strain gauge is pasted on the surface of the torsion bar 1, and the strain gauge is connected as a bridge circuit, and its output signal is connected with the input end of the circuit part.

[0037] Pleas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com