Calibration method and measurement method of starting friction moment measuring instrument pressure value

A friction torque and measurement method technology, applied in the direction of force/torque/work measuring instrument calibration/test, measurement device, instrument, etc., can solve the problem of inaccurate pressure scale value, low start-up friction torque measurement efficiency, complicated calculation process, etc. problems, to achieve the effect of accurate assessment, saving operation links and measurement time, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

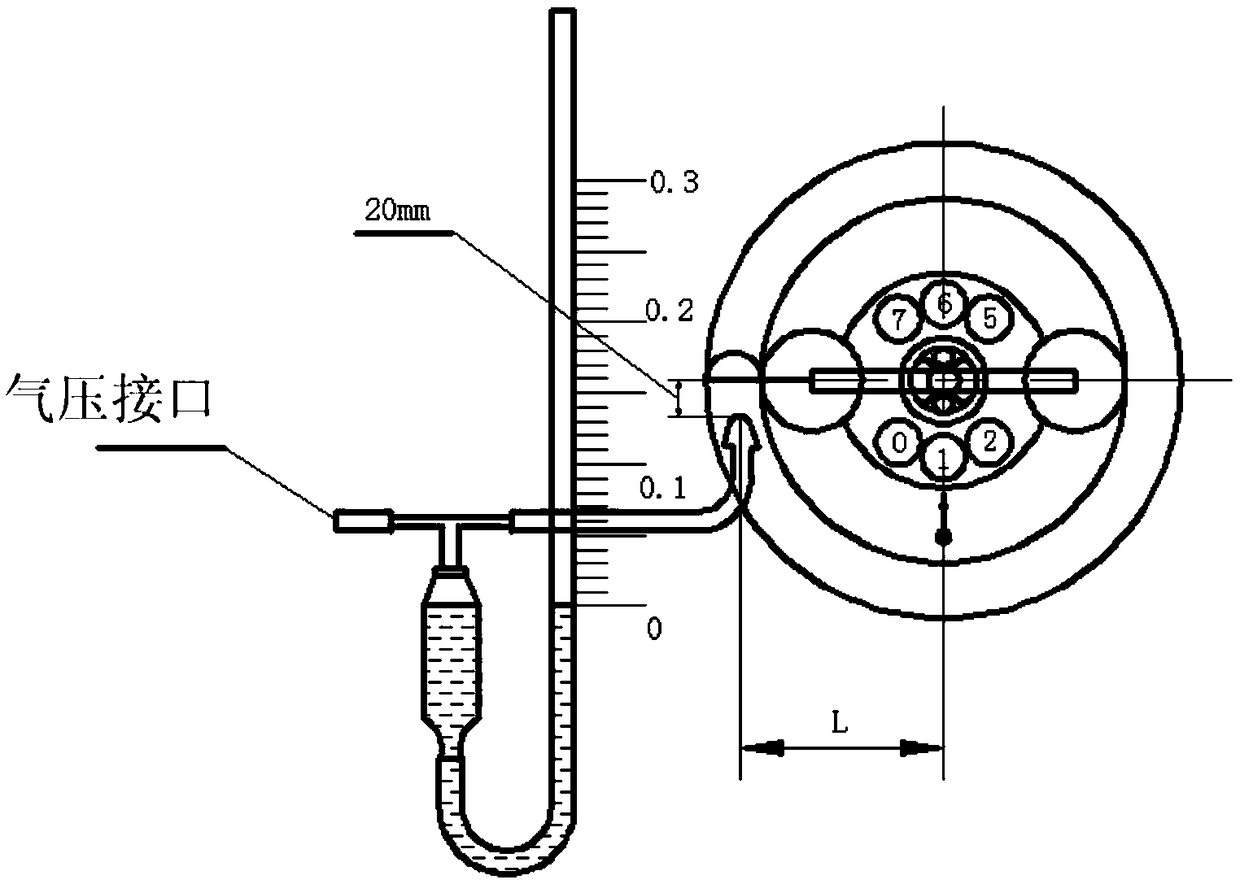

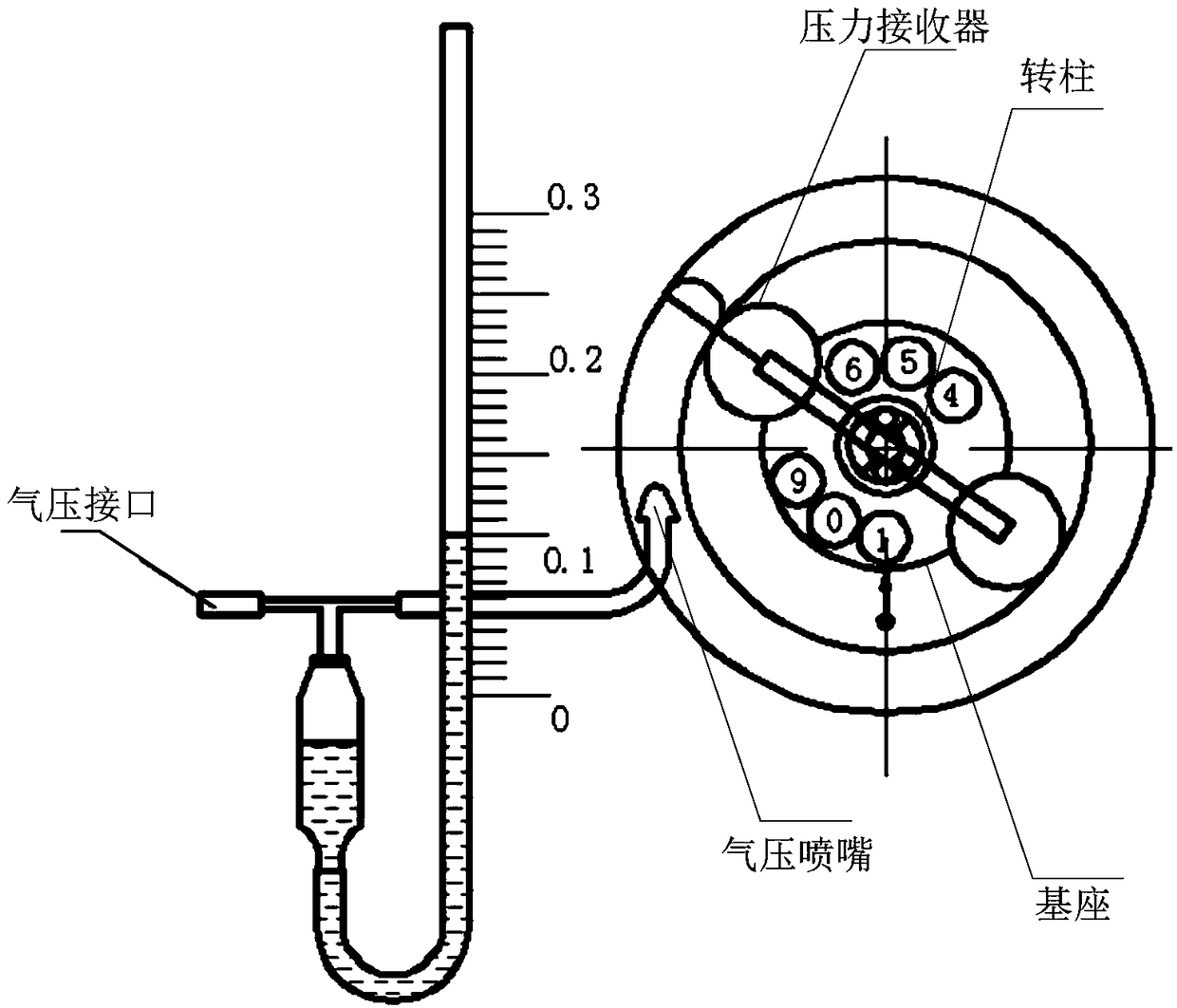

[0030] Specific implementation mode one: the following combination figure 1 , figure 2 and image 3 Describe the present embodiment, the measuring method of starting friction torque measuring instrument pressure value described in the present embodiment, the specific process of this measuring method is:

[0031] Step 1. Obtain the air pressure value F according to the standard value of the friction torque and the length of the arm;

[0032] Step 2. Mark the position corresponding to the air pressure value F and the liquid level on the glass container through the electronic balance;

[0033] Step 3. Calibrate the rotating column of the measuring instrument through the level to keep the measuring instrument in a horizontal state;

[0034] Step 4. Place the bearing under test at the measurement position, place the measuring load device on the bearing stably, keep a distance of 20mm between the air pressure nozzle and the pressure receiver, make the centers of the nozzle and t...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment further explains Embodiment 1. The specific process of obtaining the air pressure value F described in step 1 is: Substituting the friction torque standard value Mtp and the arm length L=8cm into the friction torque calculation formula Mtp=F× L, get air pressure value

[0042] In this embodiment, the friction torque standard value Mtp is obtained by consulting the technical standards, the unit is g.cm, the unit of the air pressure value F is g, and the length of the force arm is the distance between the center of the pressure receiver and the center of the load rotation axis, which is a fixed value 8cm.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment further explains Embodiment 1. The specific process of keeping the measuring instrument in a horizontal state as described in step 2 is: place the level on the upper end surface of the rotating column of the measuring instrument, and rotate the adjustment level below the base. Props so that the balance point of the level is within the center range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com