Measuring device suitable for micro moment of various motor

A technology of torque measurement and measurement device, which is applied in the field of measurement devices for various motor micro-torques, can solve problems such as large experimental space and increase design cost, and achieve the effects of uniform overall distribution, avoiding design work, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

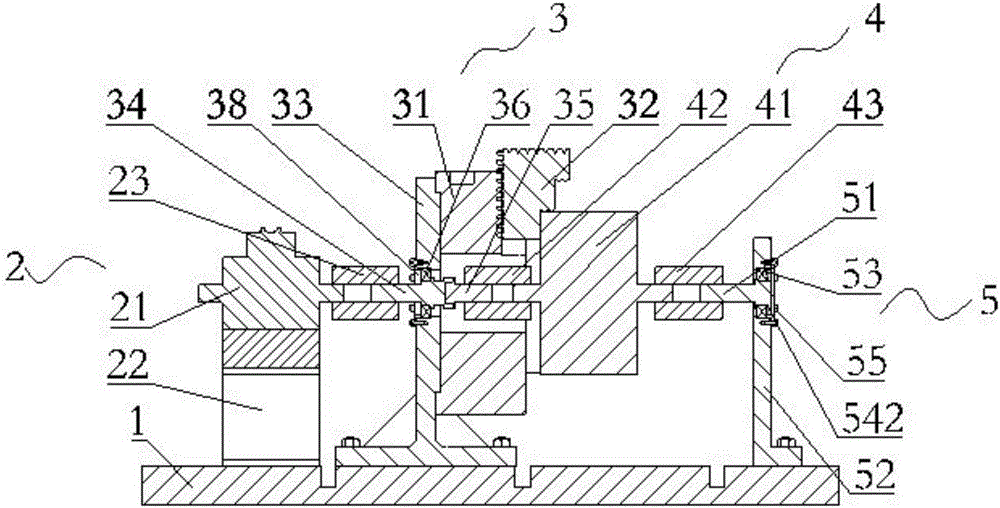

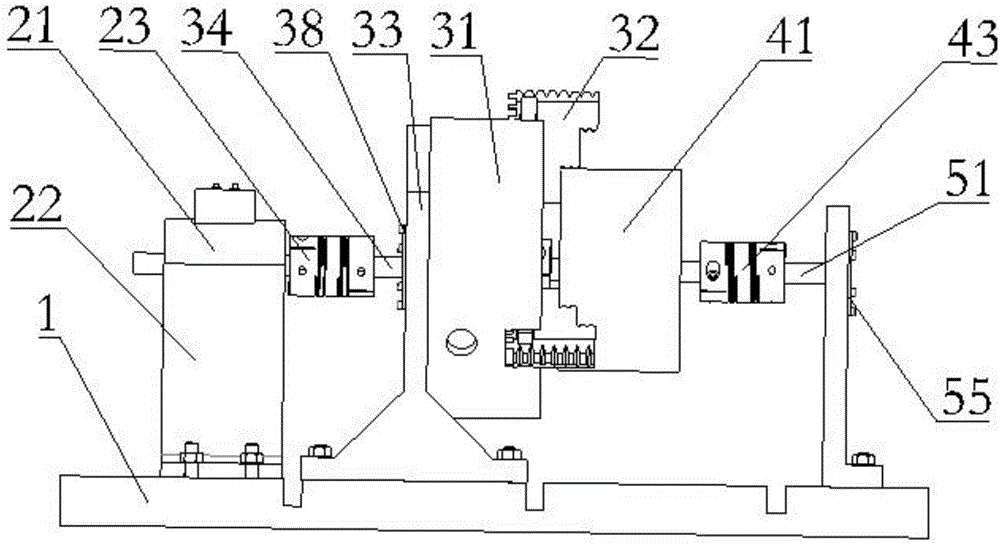

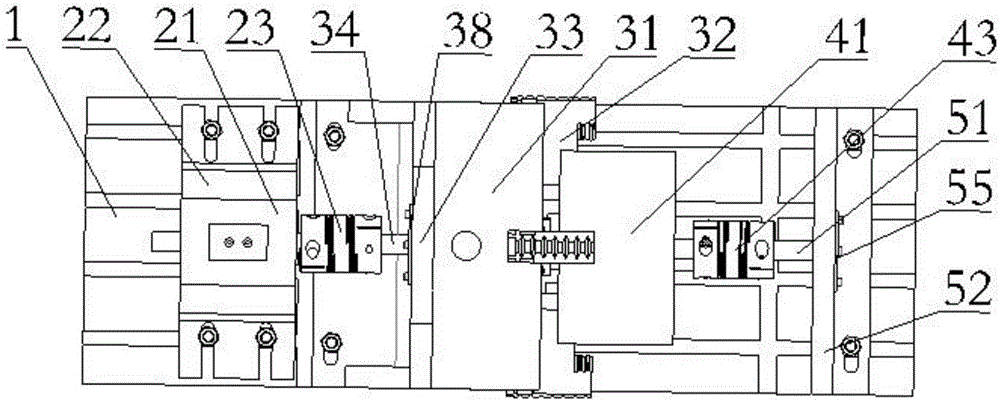

[0031] This embodiment provides a kind of measuring device applicable to the micro-torque of various motors, such as figure 1 , 2, 3 and 4, it includes a base 1 and a moment measuring part 2, a chuck supporting part 3, a motor part 4 to be tested and an end supporting part 5 arranged on the base 1, and the moment measuring part 2 includes a moment measuring instrument 21 and a moment The supporting seat 22 of the measuring instrument, the supporting seat 22 of the torque measuring instrument is installed on the base 1, the torque measuring instrument 21 is installed on the supporting seat 22 of the torque measuring instrument, one end of the torque measuring instrument 21 extends out of the shaft to connect with the load, and the other end extends out of the shaft to connect There is a first shaft coupling 23; the chuck support part 3 includes a three-jaw chuck 31, a claw 32, a three-jaw chuck support seat 33, a first connecting shaft 34 and a second connecting shaft 35, and t...

Embodiment 2

[0035] This embodiment provides a kind of measuring device applicable to the micro-torque of various motors, such as Figure 5 As shown, on the basis of Embodiment 1, the limiting groove 341 of this embodiment is a cross-shaped limiting groove, and the limiting slider 351 is a cross-shaped limiting slider, which can realize the first connecting shaft 34 and the second connecting shaft. The stable connection of the shaft 35 and the effective transmission of the torque can realize the automatic assembly of the two shafts and the reciprocating rotation without gaps, ensuring that the two shafts will not slip between the two shafts in any pose, and at the same time can better ensure the synchronization of the two shafts. axis.

[0036] Such as figure 1 , 2 , 3, and 4, the bottom plate 1 is provided with a trapezoidal groove 11, the trapezoidal groove 11 extends from one end of the bottom plate 1 to the other end, and the torque measuring instrument support seat 22, the three-jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com