Variable pump swash plate control moment measuring device

A technology for controlling torque and measuring devices, which is applied in the field of plunger pumps, can solve problems such as hard to obtain and oil pressure pulsation, and achieve the effects of easy replacement, reduced mass, and easy assembly, commissioning, and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

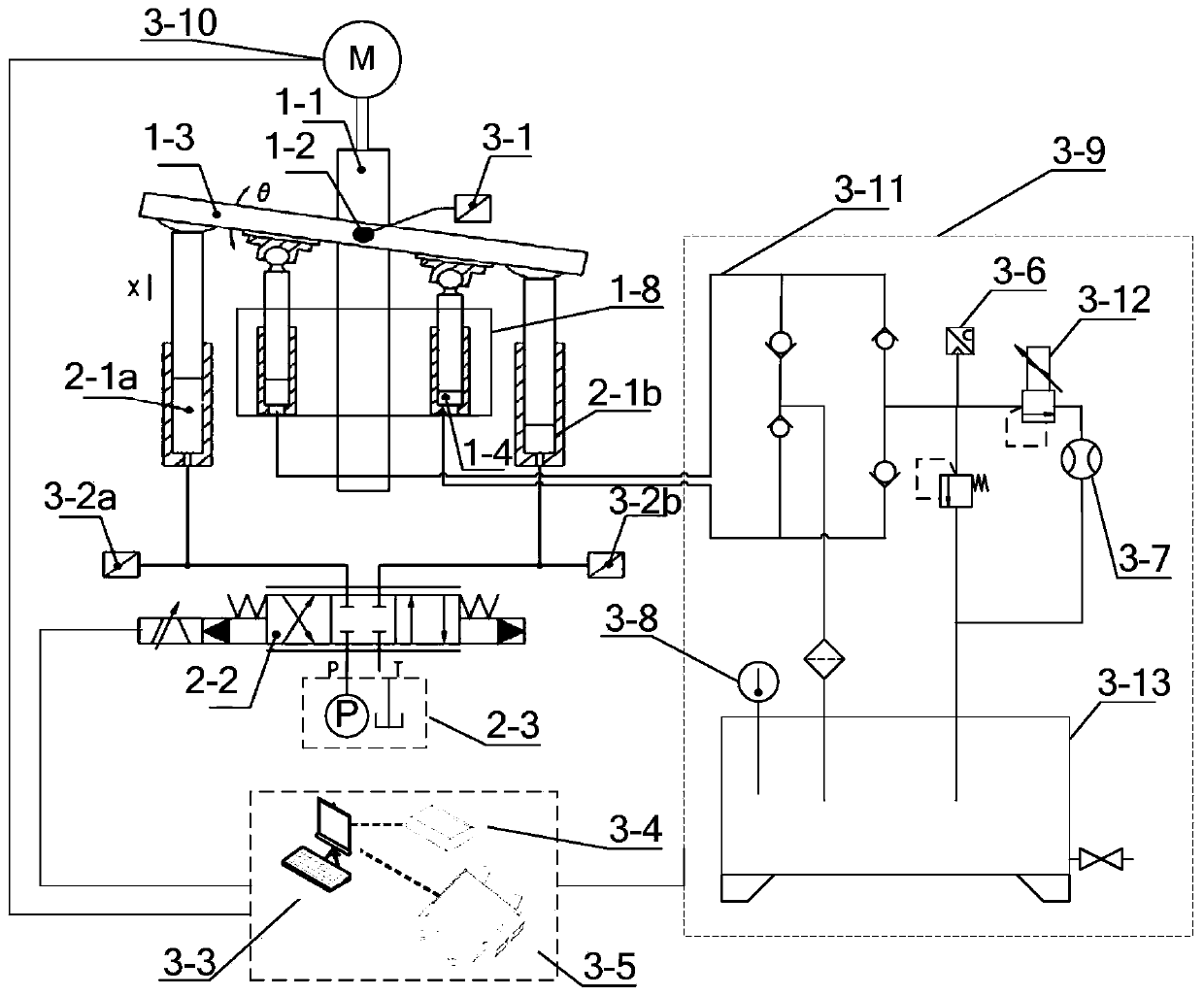

[0038] A variable displacement pump swash plate control moment measuring device, such as figure 1 shown, including

[0039] Host computer 3-3, controller 3-4, data acquisition card 3-5, pressure oil source 2-3, high frequency pressure sensor 3-2, swash plate drive cylinder 2-1, plunger assembly 1-4, Disc 1-3, shaft assembly 1-1, resolver 3-1, variable frequency motor 3-10, servo valve 2-2, loading system 3-9, rotor 1-8, ball screw 1-9, integrated valve block Body 2-4, valve plate 1-10, indicator needle 1-13;

[0040] The upper computer 3-3 controls the speed of the variable frequency motor 3-10, the loading pressure of the proportional overflow valve 3-12 in the loading system 3-9, and the action of the servo valve 2-2 through the controller 3-4;

[0041] The variable frequency motor 3-10 drives the rotor 1-8 through the shaft assembly 1-1, and the rotor 1-8 drives the plunger assembly 1-4 to move. When the plunger assembly 1-4 moves, the slider end of the plunger assembly 1...

Embodiment 2

[0055] In this embodiment, a device for measuring the control moment of the swash plate of a variable variable pump is designed. Through this device, the swing torque of the swash plate under different working conditions and different swing angles can be accurately measured, and provide data support for subsequent mechanism design. This embodiment It can also measure the control torque of the swash plate of the existing model variable pump, which can provide support for the improved design of the pump. At the same time, the device itself is also a valve-controlled volumetric servo pump, which can be directly applied to a volumetric static pressure servomechanism.

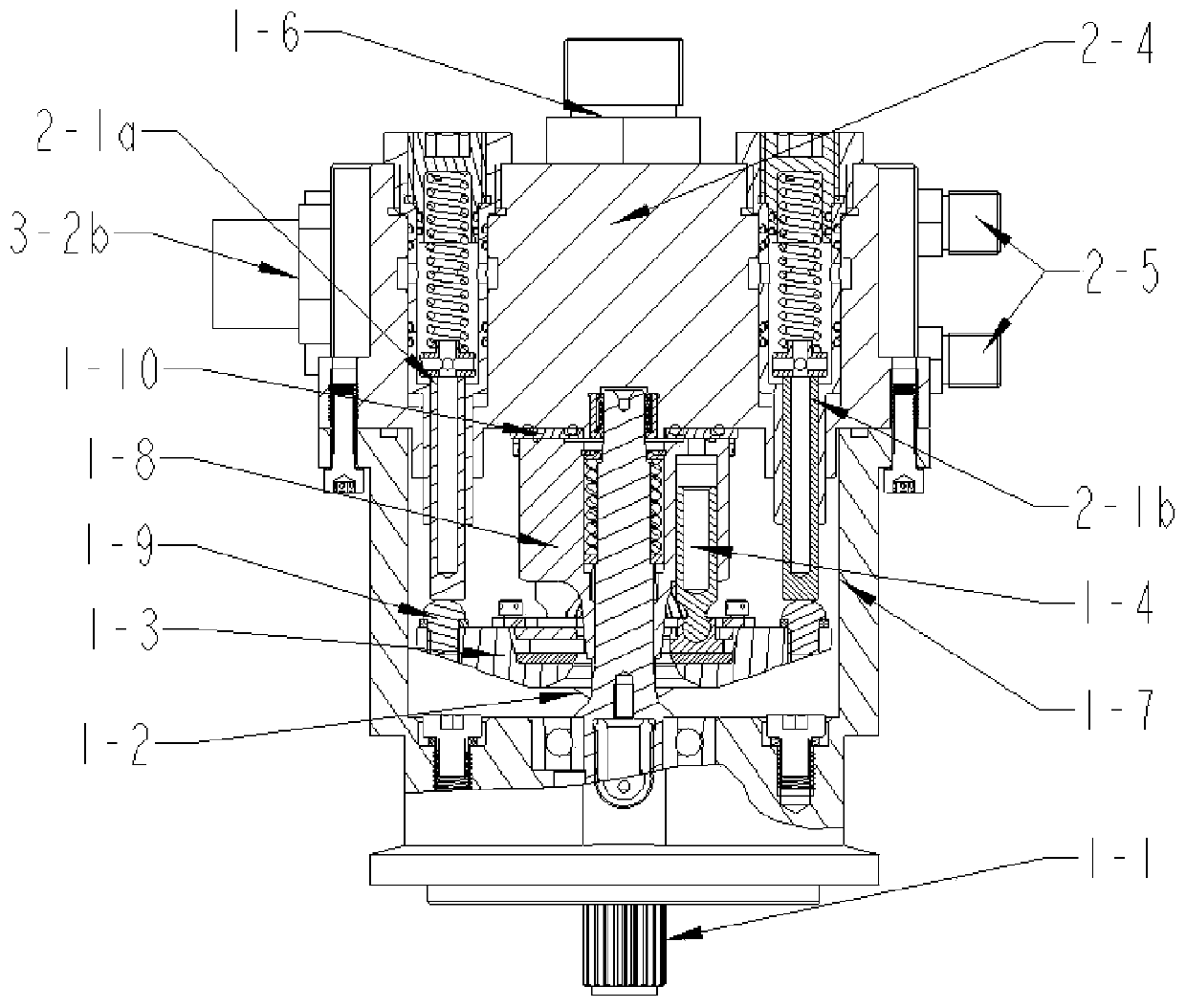

[0056] This embodiment is mainly composed of three parts: the pump body part 1, the swash plate variable system 2, and the measurement and control system 3.

[0057] pump parts such as Figure 2-4 As shown, the pump core of the pump to be tested includes the rotor 1-8, the plunger assembly 1-4, the shaft assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com