Differential screwed loader main cone pretightening force measuring set and method

A technology of measuring device and measuring method, which is applied to measure torque/torsional force and other directions during tightening, can solve the problems of inability to guarantee, the main cone cannot rotate at a uniform speed, and the inability to accurately measure the bearing pre-tightening torque, and achieve accurate and accurate measured data. The effect of accurate measurement and stable test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

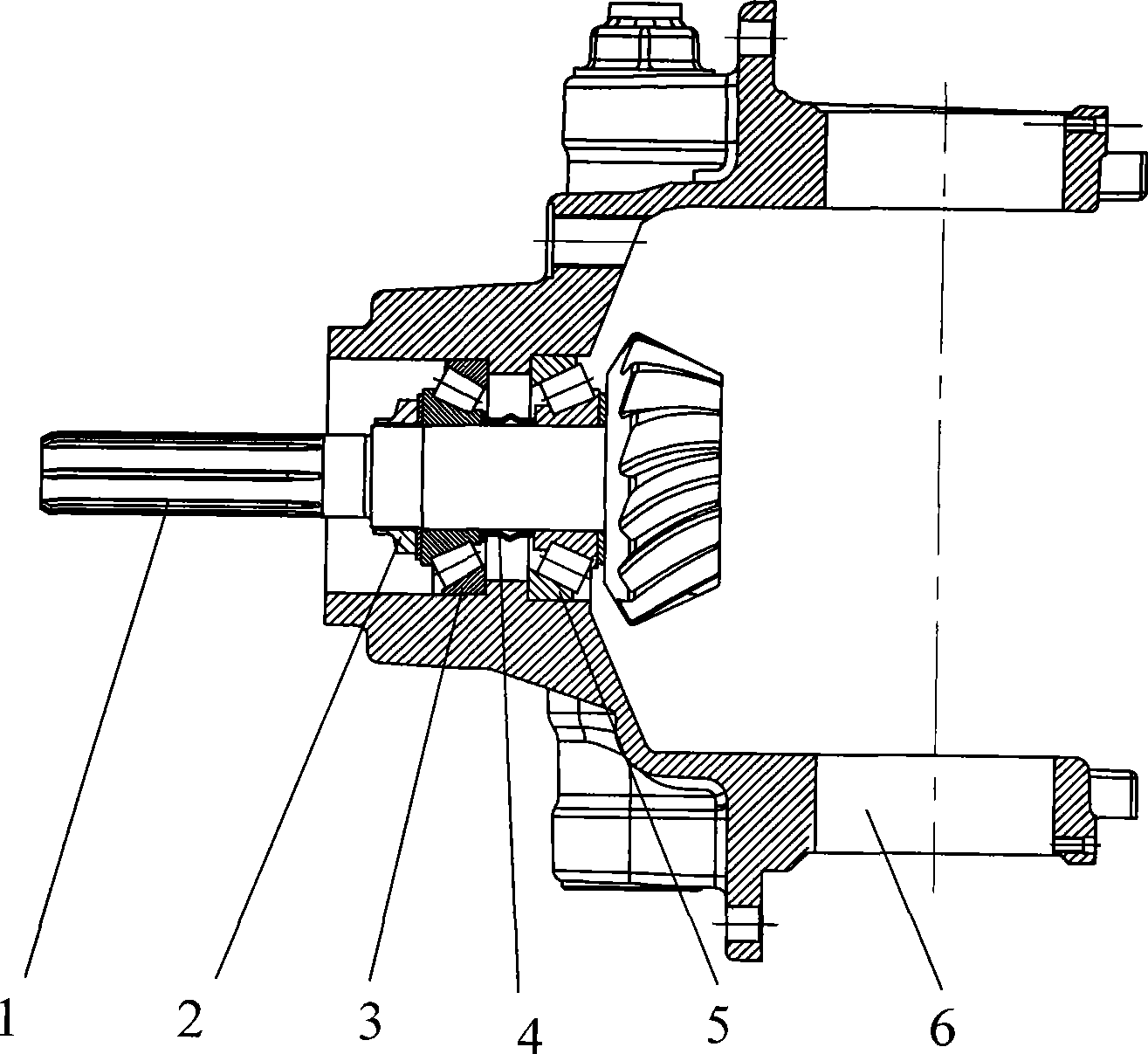

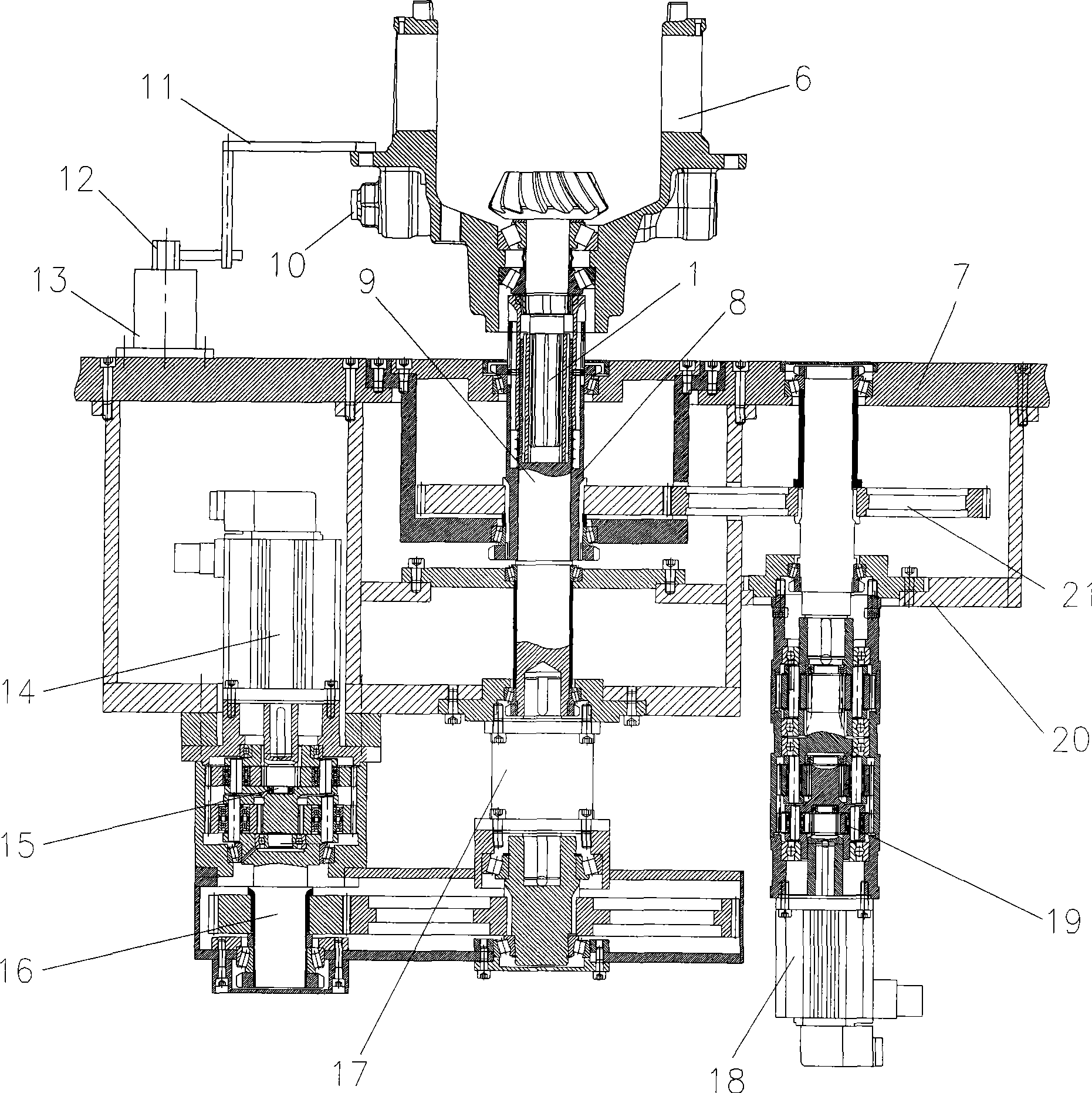

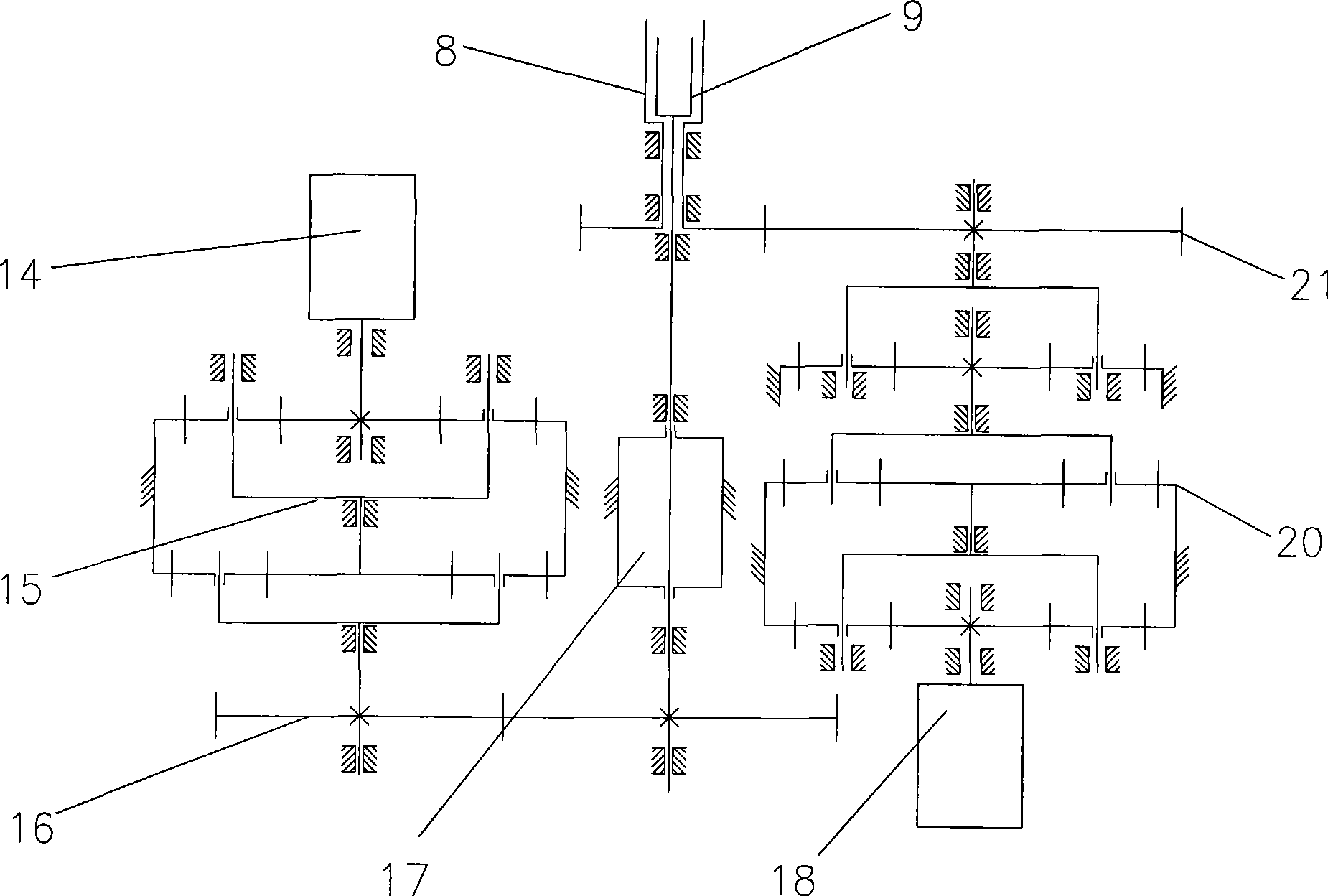

[0035] see figure 1 , figure 2 and image 3 , the loader main cone preload measuring device in this embodiment has the following components:

[0036] A working platform 7, used as a pre-installation platform for the main cone 1 and the bearing seat 6 and a measurement platform for the pre-tightening torque of the bearing;

[0037] A sleeve 8 is threadedly matched with the lock nut 2 for tightening the lock nut 2; the sleeve 8 is configured as a quick replaceable structure to adapt to switching of lock nuts 8 of different specifications. The specific implementation is that on the end face where the lock nut 2 cooperates with the sleeve 8, the lock nut 2 fits with the end face rib of the sleeve 8 with its end face groove;

[0038] An internal spline 9, matched with the external spline at the tail of the main cone 1, used to drive the main cone 1 to rotate;

[0039] The transmission line I, with the servo motor I as the driving member, passes through the two-stage planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com