Bearing pedestal starting moment measuring apparatus

A technology for starting torque and measuring device, which is applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problems of long feedback time, influence test results, influence on assembly efficiency, etc., achieve short feedback time, improve assembly efficiency, improve The effect of measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

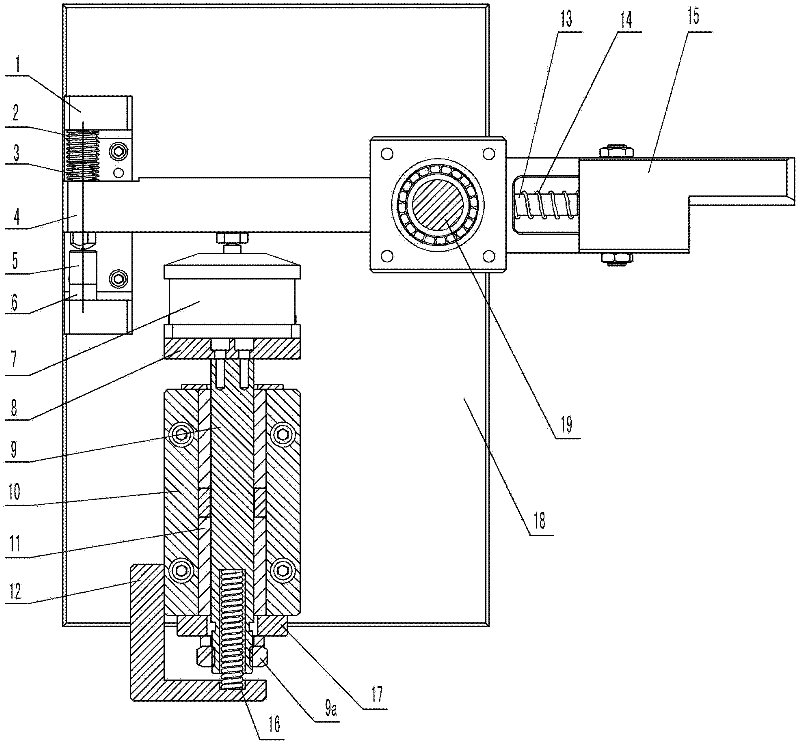

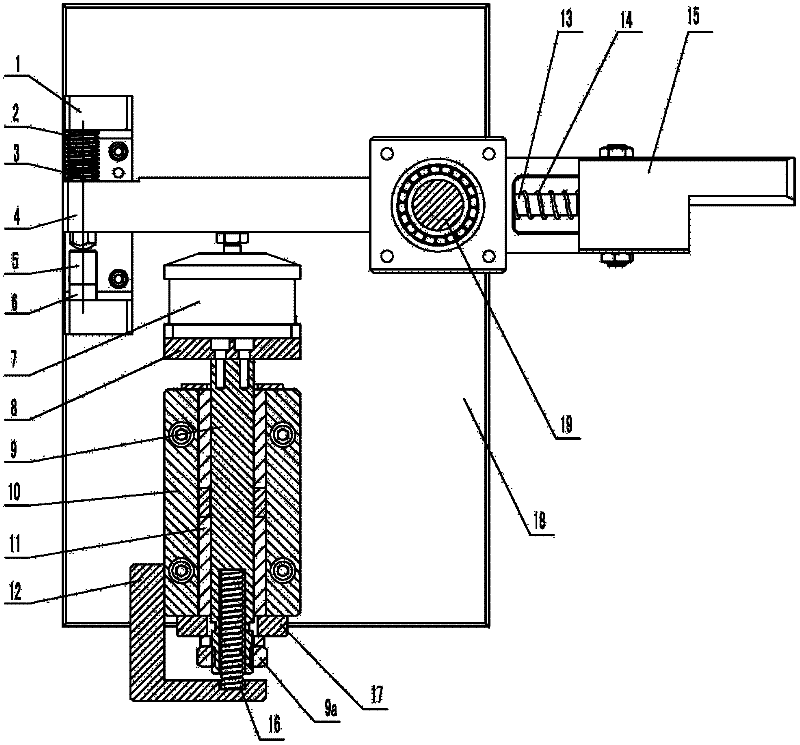

[0013] see figure 1 , in the present embodiment, the starting moment measuring device for the bearing seat is to set a measuring rod 4 with a lever structure, and the measuring rod 4 is connected with the rotating shaft 19 through a deep groove ball bearing in the middle; as the lever fulcrum is the rotation center of the rotating shaft 19, as a lever The front end of the measuring rod 4 at the force point is set as a measuring head 15 that can be driven by the transition rod; a pressure sensor 7 is arranged at the corresponding position of the tail of the measuring rod 4 as the lever resistance point, and the position of the lever resistance point is measured by the pressure sensor 7. pressure value.

[0014] In specific implementation, the corresponding structural settings also include:

[0015] A base 18 is provided, and the rotating shaft 19 is fixedly arranged on the base 18 .

[0016] The measuring head 15 is arranged in an axial floating structure at the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com