On-line monitoring device and method for flow state of chemical cleaning pipeline of superheater in power station

A technology for chemical cleaning and monitoring devices, which is applied to measuring devices, electrical devices, instruments, etc., can solve the problems of inability to detect timely, inconvenient for personnel to operate, and continuous monitoring, etc., and achieves simple structure, short feedback time, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

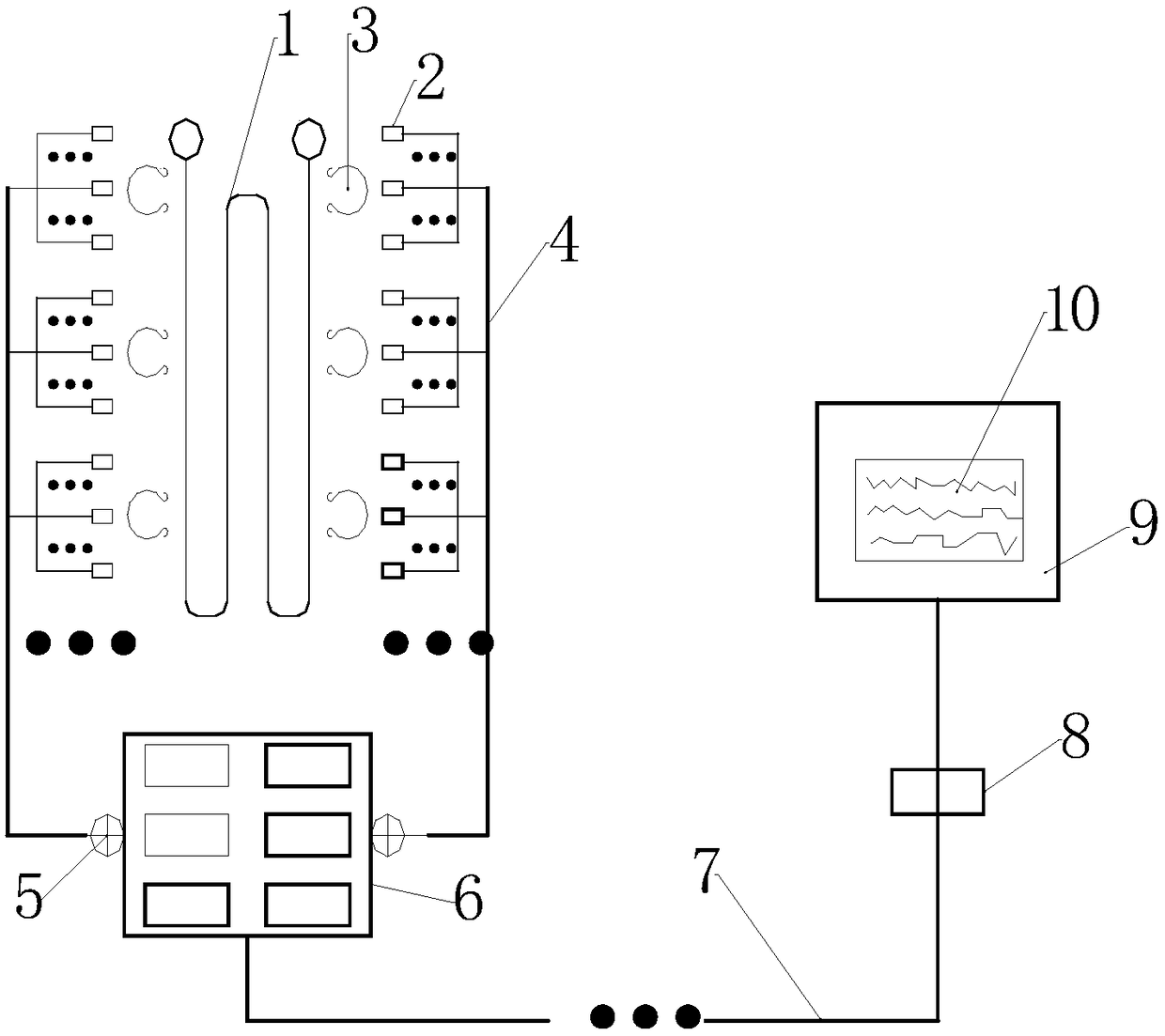

[0028] Such as figure 1 As shown, the present invention is an on-line monitoring device for the flow state of the chemical cleaning pipeline of a power station superheater, including a sensor 2 and a fixed thermal insulation device 3, installed on the outer wall of the monitored equipment 1 away from the header and subjected to thermal insulation treatment, and sensors for all measuring points 2 The outgoing signal line 4 is connected to the inspection equipment 6 through the quick connector 5, and the inspection equipment 6 is placed outside the boiler furnace at room temperature to ensure its normal operation. After the inspection equipment 6 packages all the data measured by the sensors 2, it is transmitted to the communication converter 8 through the data line 7, converted into a signal that can be recognized by the computer, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com