Method for repairing oxidized graphene by organic matter containing amino group at low temperature

A repair method and amino group technology, which is applied in the field of repairing oxidized graphene, can solve problems such as explosion and fast reaction speed of sodium borohydride, and achieve the effects of low reaction temperature, non-toxic reaction system, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix 50mg of graphene that has been violently oxidized by strong acid with 1g of urea powder, grind it, let it mix evenly, put it into a crucible, and let it fully react for more than 24 hours in an oven at 150°C. After it cools, take it out and dissolve it in the water solution. The solution was filtered and washed with water continuously. Put the cleaned powder into an oven at 90°C for more than 1 hour to dry. Through the measurement of its powder resistance, it can be seen that it is an insulator before repairing, and the resistance is too large to be measured. The repaired resistance is less than 100 ohms.

Embodiment 2

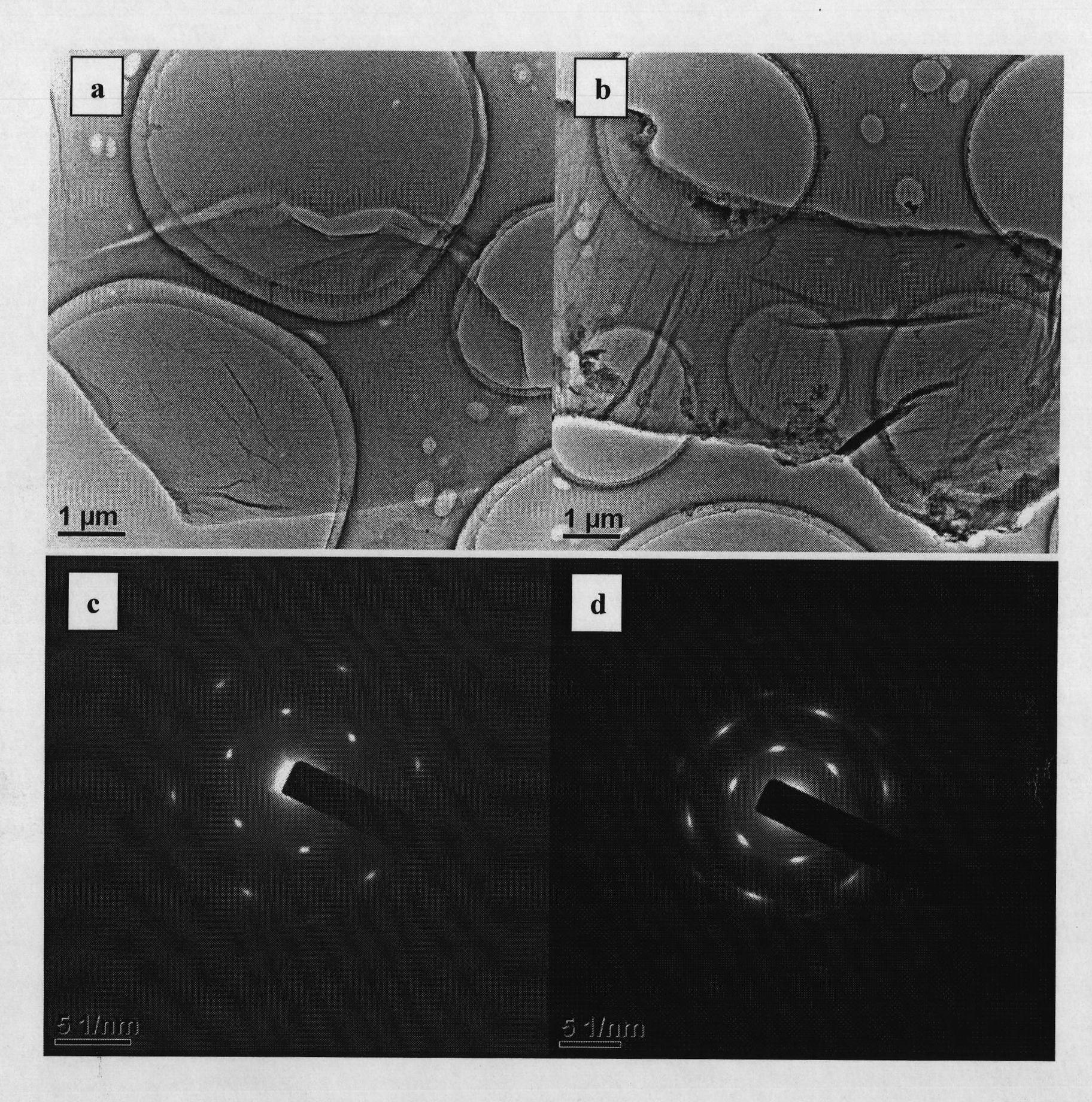

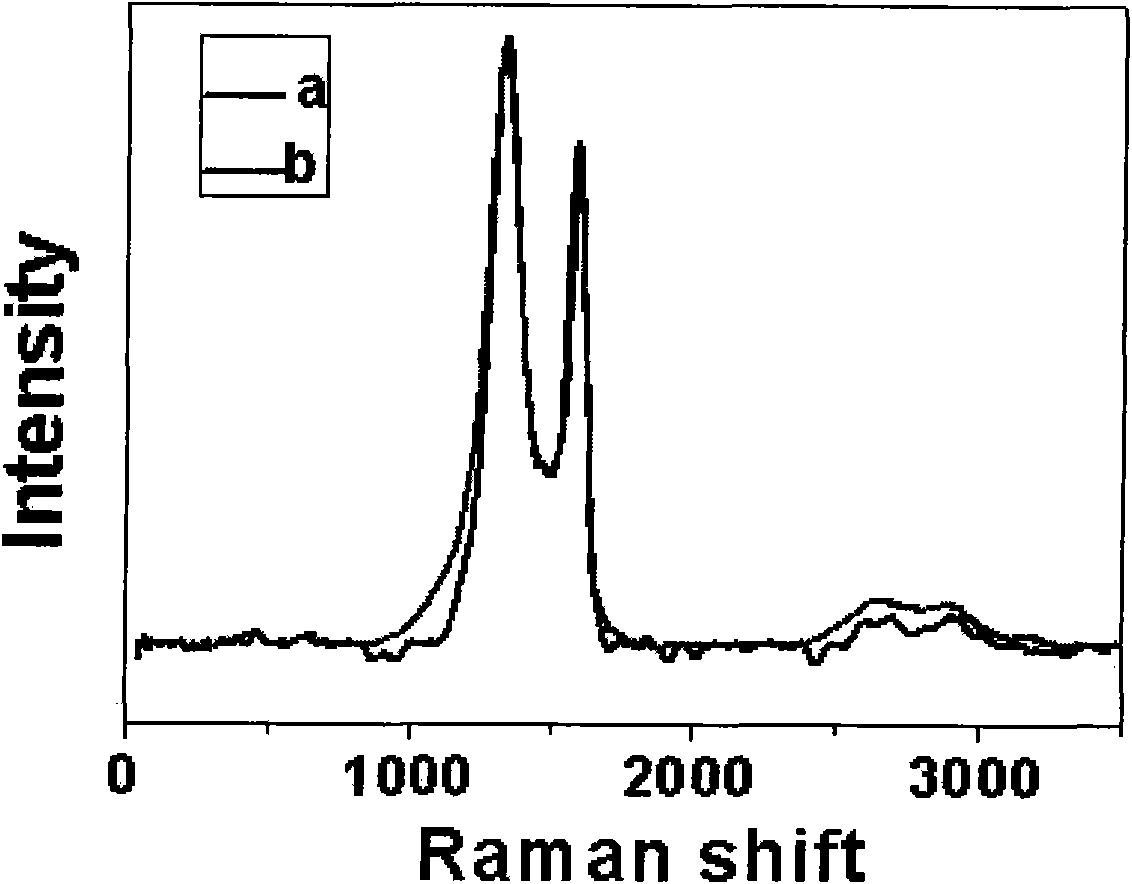

[0024] Pour 50mg of graphite that has been violently oxidized by a strong acid into a urea solution with a concentration of 1g / 2ml, ultrasonicate in a water bath for 15 minutes, and let it mix thoroughly. The solution was sealed and placed in an oven at 90° C. to allow the two to fully react for more than 1 day. Take it out, and after it cools down, filter its solution, and then wash it with water continuously. Put the cleaned powder into an oven at 90°C for more than 1 hour to dry. The resistance after the reaction is also reduced from insulation to below 100 ohms. From the topography of the transmission electron microscope ( figure 1 ) It can be seen that the oxidized graphene has a relatively complete structure, no cracks, a small thickness, and no shrinkage (a). The reduced graphene has more cracks, larger thickness, and shrinkage of the sheet structure (b). It can be seen from the electron diffraction pattern that the oxidized graphene sheet has fewer layers (c), only...

Embodiment 3

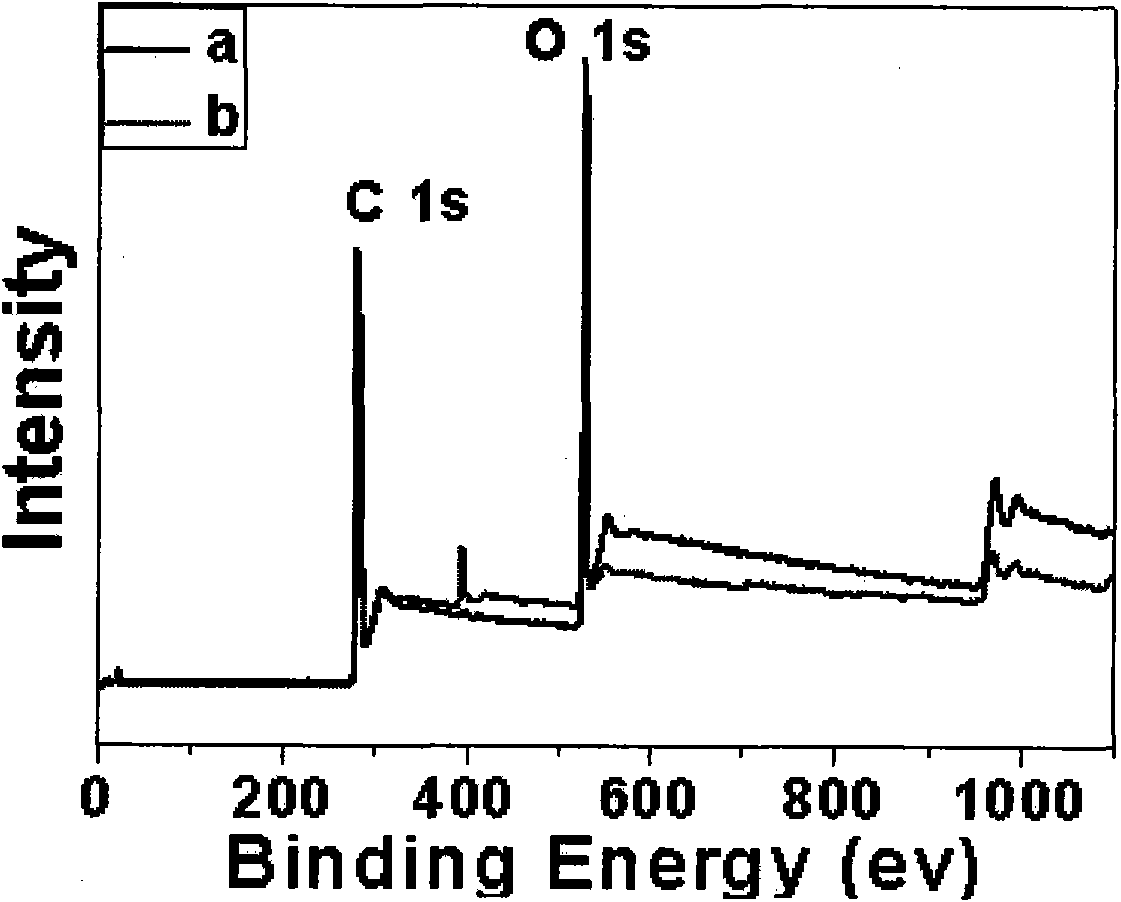

[0028] Put the oxidized graphene film into 100ml of an aqueous solution containing 10g of urea, seal the solution and put it in an oven at 90°C to allow the two to fully react for more than 1 day. After it cools down, take out the film, soak it in the aqueous solution for more than 1 minute, so as to clean off the excess urea and other reaction intermediate products sticking to the film, and then put it into an oven at 90°C to dry for more than 1 hour. From the XPS graph ( image 3 ), it can be seen that the oxygen content after restoration is significantly reduced. At the same time, the peak position did not change. That is, no doping occurs. From the resistance data (Table 2), it can be seen that the resistance of the repaired graphene is greatly reduced, and the conductivity is greatly improved. It can also be directly proved that the urea-based organic substances with amine groups can well repair the oxidized graphene.

[0029] Table 2: The electrical resistance data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com