Turbotype electrical respirator

A ventilator and turbine-type technology, applied in the field of ventilators, can solve problems such as difficulty in achieving oxygen concentration, air flow, difficulty in precise control of oxygen flow, large flow rate and flow of mixed gas, and achieve the effect of ensuring accurate oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

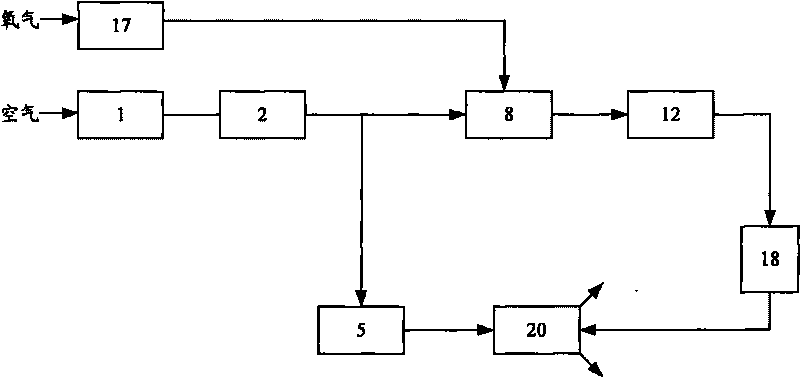

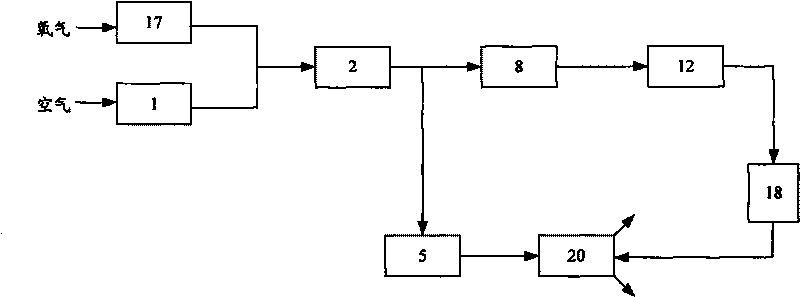

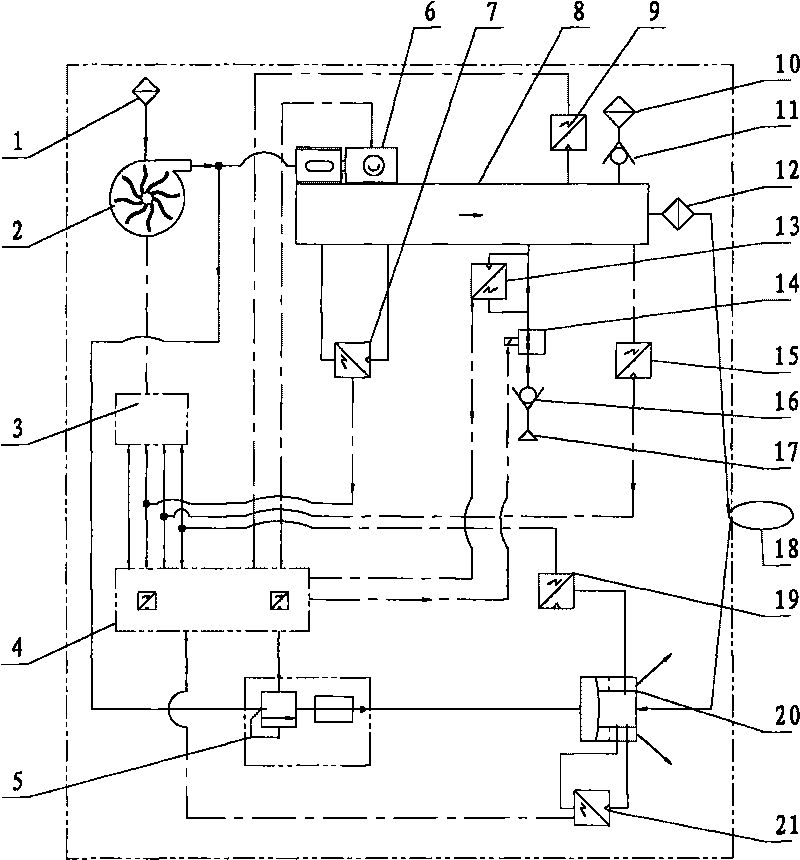

[0017] figure 2 A structural module diagram of the turbo electric ventilator 100 according to an embodiment of the present invention is shown, wherein only main structural modules are shown for the sake of clarity. see figure 2 It can be seen that the turbine electric ventilator 100 of this embodiment mainly includes: an air inlet 1; a microturbine 2, which sucks the air entering through the air inlet 1 into the ventilator 100; an oxygen inlet 17, which provides high-pressure oxygen to the ventilator 100 ; the air-oxygen mixing chamber 8, the air sucked by the turbine 2 and the high-pressure oxygen provided via the oxygen inlet are thoroughly mixed in this chamber 8; Port 18 communicates to provide the patient with an inhalable gas mixture. In order to form a complete air circuit, this figure also shows the structural modules that constitute the exhalation circuit. A part of the low-pressure air sucked into the air-oxygen mixing chamber 8 by the microturbine 2 reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com