Measuring method and device for twisting property of flexible material

A technology of torsional properties and flexible materials, which is applied in measurement devices, analysis materials, and material analysis by optical means. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

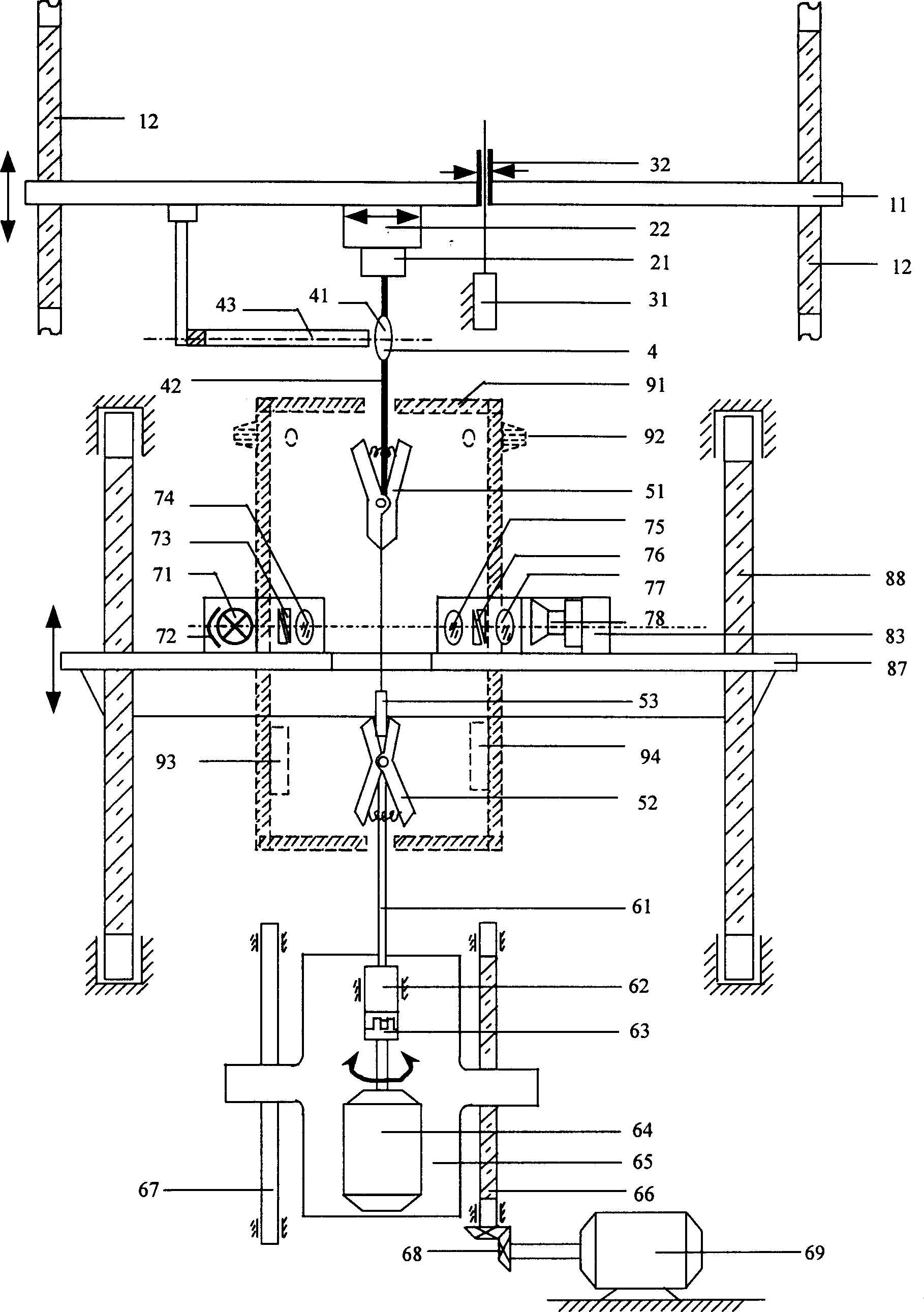

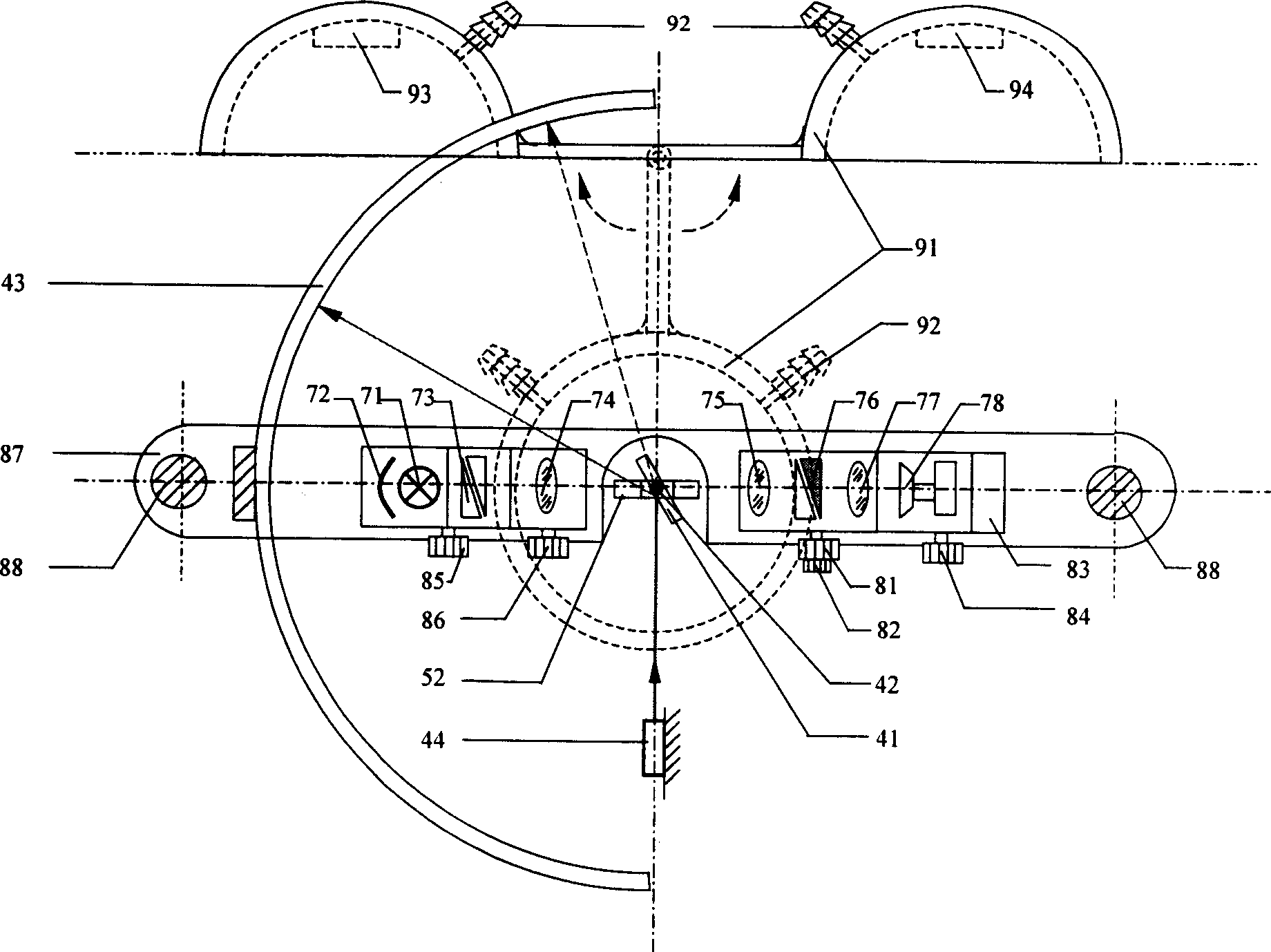

[0050] Embodiment 1 Torsional natural vibration test

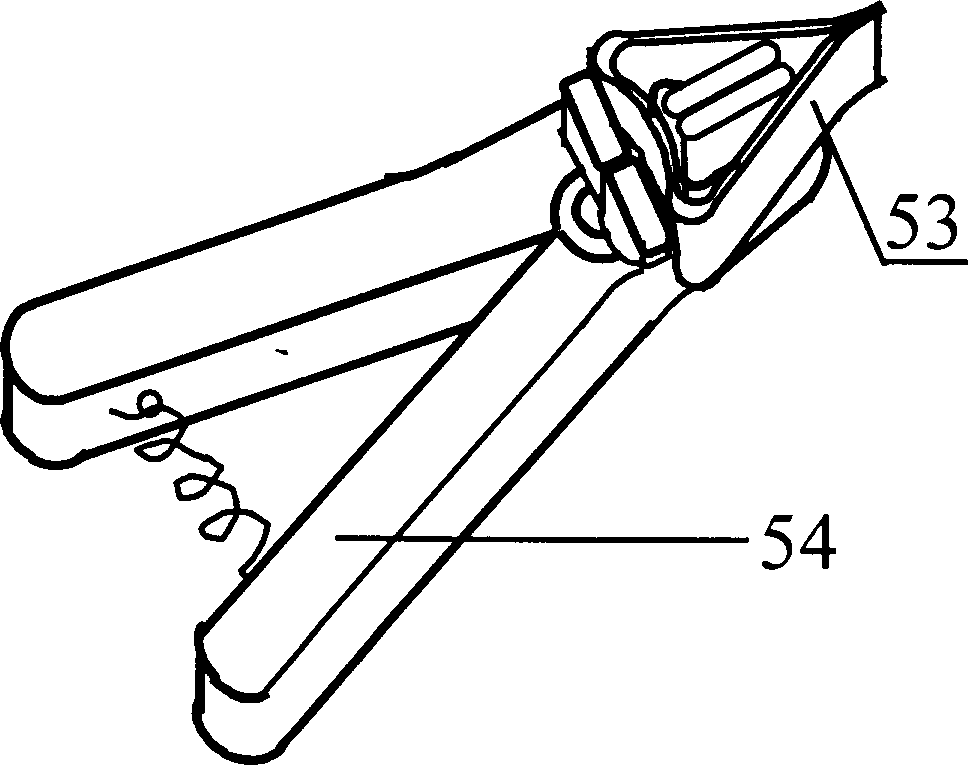

[0051] First, use the clip opener 54 to open the micro spring clip 53, clamp one end of the aramid fiber in the micro spring clip 53, then lift the other end of the aramid fiber, clip it in the upper chuck 51, and adjust the centering adjustment Device 22, align the fiber axis with the clamping center of the lower chuck, and clamp the micro spring piece 53 in the lower chuck 52, as attached figure 1 shown. At this time, a certain torque or rotation angle is applied by the rotating mechanism 6 connected with the lower chuck 52, and then the spring clip 52 is opened, and the moving plate 65 is moved down rapidly at the same time to ensure the self-vibrating torsional movement of the spring clip. And self-oscillating torsion can make the reflection mirror 41 of torque measurement mechanism 4 produce deflection, and the reflection point on the reflection mirror 41 is irradiated by laser source 44 changes, se...

Embodiment 2

[0052] Example 2 constant load single fiber torsional fatigue test result

[0053] Using the device of the present invention, the fiber sample is directly clamped between the upper chuck 51 and the lower chuck spring clamp 52, the pretension is applied through the displacement of the upper chuck 51 or the lower chuck 52, and the pretension is controlled by the tension sensor 21 The size is determined according to the fineness of the sample. The twist angle of the sample is determined by the number of positive and negative rotations of the rotating mechanism 6 connected to the lower chuck 52 . See attached figure 1 shown. In order to ensure that the size of the prestress is consistent and comparable, the size of the pretension is selected as 1.2, 1.5, 2cN / dtex, and the twist angle β=10°, 20° and 25°. The specific test results are shown in Table 1.

[0054] condition

Embodiment 3

[0055] The fracture twist angle α test result of embodiment 3 fiber

[0056] Using the operation method and device used in Example 2, the sample is clamped between the upper chuck 51 and the lower chuck spring clamp 52, and the reciprocating motor 64 is controlled to rotate in a single direction until the sample breaks, and the sample can be obtained by calculation fracture twist angle.

[0057] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com