Temperature effect-based fluorescent oil film thickness calibration method

A calibration method and temperature effect technology, which is applied in the direction of optical devices, machine/structural component testing, measuring devices, etc., can solve the problems of calibration oil film thickness, temperature, error, etc., and achieve high accuracy, good stability, and ease of use. Measured and Calculated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described step by step in conjunction with the accompanying drawings.

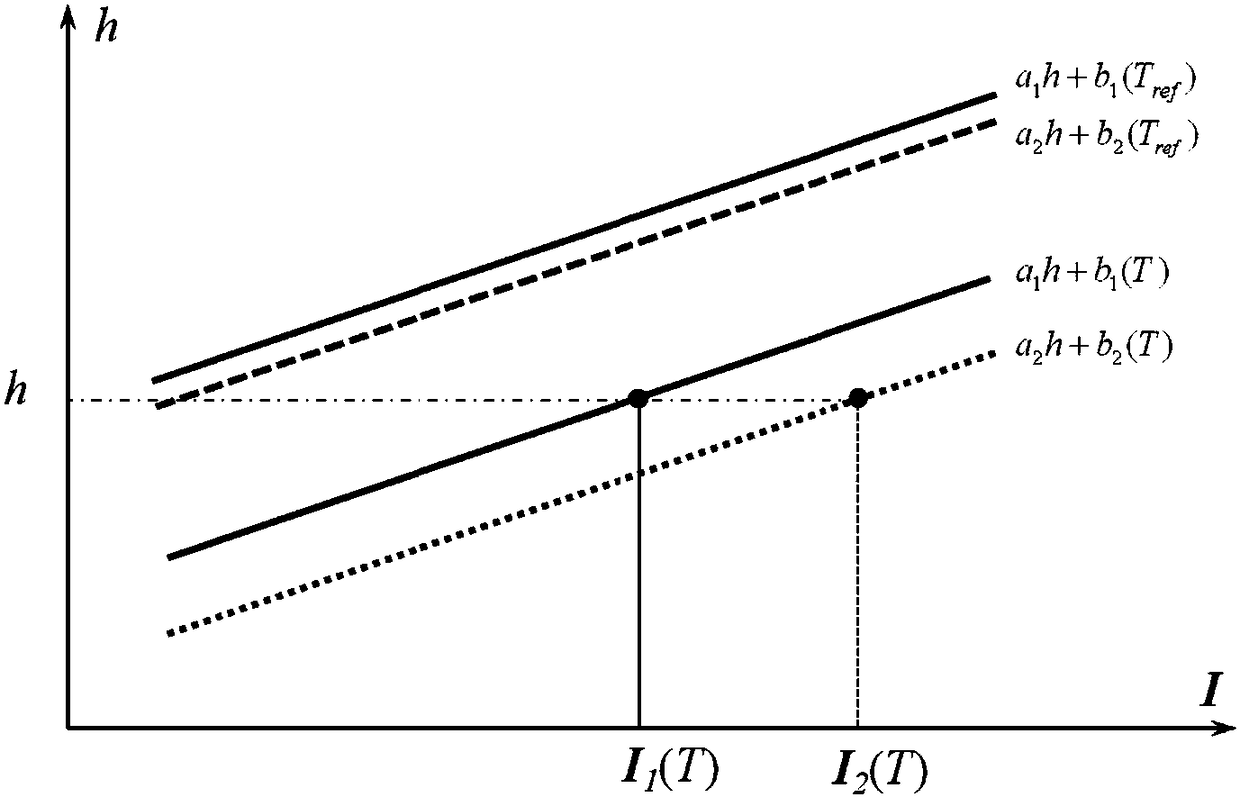

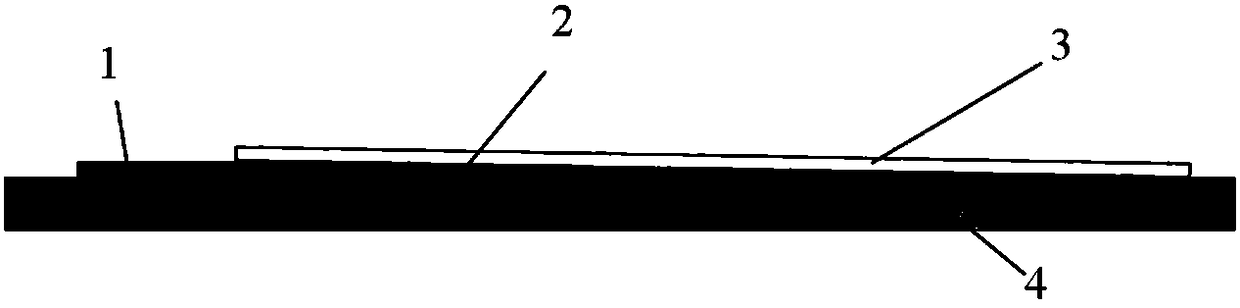

[0038] A method for calibrating the thickness of fluorescent oil film considering the temperature effect proposed by the present invention requires the following preconditions: first, the oil film to be calibrated must contain two fluorescent substances of different components, and the two fluorescent substances of different components must have the same The excitation light band is generally the ultraviolet light band, with a center wavelength of 365nm-400nm; two fluorescent substances with different components have different stimulated emission light bands. In order to distinguish clearly and facilitate color camera detection, the green light band (495nm- 570nm) and red light band (620nm-750nm), the base oil used is dimethyl silicone oil; secondly, when carrying out ground calibration and wind tunnel tests, the ultraviolet light source (365nm) is generally used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com