Continuous casting method for low-alloy steel wide and thick slabs

A low-alloy steel, continuous casting technology, applied in the field of continuous casting, can solve problems such as unsuitable secondary cooling system, and achieve the effects of optimizing product quality, optimizing heat flow, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

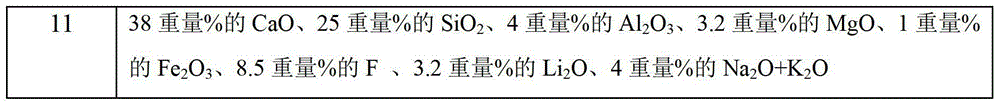

[0032] Carry out 11 groups of continuous casting operations to produce low-alloy steel wide and thick slabs. The steel type of the low-alloy steel wide-thick slabs produced by the 1st to 8th groups is P510L, and the steel types of the low-alloy steel wide-thick slabs produced by the 9th to 11th groups are respectively They are X80, X60 and P590L, wherein Groups 1 to 6 and Groups 9 to 11 are cast by the method of the present invention, and Groups 7 and 8 are comparative examples. Each group casts 1,000 furnaces of molten steel. The continuous casting equipment used in these 11 groups of continuous casting operations is a straight arc continuous casting machine. In each continuous casting operation, molten steel is poured from the tundish to the crystallizer; Covering agent is added; in the crystallizer, mold slag is added on the liquid surface of the molten steel, and the molten steel is solidified into a billet with a liquid core by cooling in the crystallizer; then the billet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com