Environment-friendly nano modified halogen-free flame retardant polypropylene and preparation method thereof

A flame-retardant polypropylene and nano-modification technology, which is applied in the field of polypropylene, can solve the problems of low mechanical properties of flame-retardant polypropylene, and achieve the effects of improving flame-retardant performance, less surface cracks, and good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

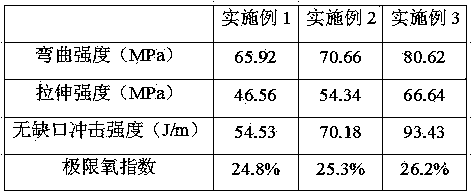

Embodiment 1

[0027]A nano-modified environmentally friendly halogen-free flame-retardant polypropylene, which consists of a polypropylene matrix, a halogen-free expansion flame retardant, a synergistic flame-retardant conductive filler, additives, nano-modified particles, a compatibilizer, an antioxidant, and a lubricant. In parts by weight: the polypropylene matrix is composed of 66 parts of high-impact polypropylene; the halogen-free intumescent flame retardant is 20 parts of phosphorus-nitrogen series flame retardants; the synergistic flame-retardant conductive filler is 2 parts of carbon black with a particle size of 15nm; the additive is 3 parts of hollow glass microspheres with a particle size of 1 to 50 microns; the nano-modified particle is 1 part of nano-SiO modified by KH550 2 , KH550 and nano-SiO 2 The weight ratio is 1:100; the described compatibilizer is 5 parts of maleic anhydride grafted polypropylene; the described antioxidant is 1 part of phosphite antioxidant; the descr...

Embodiment 2

[0035] A nano-modified environmentally friendly halogen-free flame-retardant polypropylene, which consists of 66 parts of high-impact polypropylene, 2 parts of nano-carbon black, 20 parts of halogen-free expansion flame retardant, and 2 parts of hollow glass with a particle size of 1-50 microns Microbeads, 2 parts of nano-SiO modified by KH550 2 , 5 parts of maleic anhydride grafted polypropylene, 1 part of phosphite antioxidant and 2 parts of simethicone oil; wherein, the particle size of carbon black is 15nm, and the particle size of nano-modified particles is 10~40nm ; Halogen-free intumescent flame retardants are phosphorus nitrogen series flame retardants, the phosphorus content is 0~24%, the nitrogen content is 0~22%, and the particle size is 2~10um.

[0036] The specific preparation steps of a nano-modified environmentally friendly halogen-free flame-retardant polypropylene are: step 1, KH550 and nano-SiO 2 Mix by the weight ratio of 1:100, make nano-modified particle ...

Embodiment 3

[0043] A nano-modified environmentally friendly halogen-free flame-retardant polypropylene, which consists of 66 parts of high-impact polypropylene, 2 parts of nano-carbon black, 20 parts of halogen-free expansion flame retardant, and 1 part of hollow glass with a particle size of 1-50 microns Microbeads, 3 parts of nano-SiO modified by KH550 2 , 5 parts of maleic anhydride grafted polypropylene, 1 part of phosphite antioxidant and 2 parts of simethicone oil; wherein, the particle size of carbon black is 15nm, and the particle size of nano-modified particles is 10~40nm ; Halogen-free intumescent flame retardants are phosphorus nitrogen series flame retardants, the phosphorus content is 0~24%, the nitrogen content is 0~22%, and the particle size is 2~10um.

[0044] The specific preparation steps of a nano-modified environmentally friendly halogen-free flame-retardant polypropylene are: step 1, KH550 and nano-SiO 2 Mix by the weight ratio of 1:100, make nano-modified particle A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com