Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Shear forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shear forming, also referred as shear spinning, is similar to metal spinning. In shear spinning the area of the final piece is approximately equal to that of the flat sheet metal blank. The wall thickness is maintained by controlling the gap between the roller and the mandrel. In shear forming a reduction of the wall thickness occurs.

Alginate-based hydrogel dressing and preparation method thereof

ActiveCN106492260AGood moisturizing effectHigh transparencyAbsorbent padsBandagesShear formingUlcer care

The invention relates to an alginate-based hydrogel dressing and a preparation method thereof, and belongs to the technical field of medical supplies. Raw materials of the invention are a compound of sodium alginate or other alginates and a thickener, a moisturizer and other functional matters, are subjected to swelling dosing, pre-crosslinking, film coating, spray crosslinking, constant-temperature crosslinking plasticizing and film-covering shear forming, and are then prepared into a three-dimensional water-containing grid structure through covalent cross-linking and ion cross-linking. The medical hydrogel dressing is a topical gel dressing, has good moisturizing performance, toughness and adhesion, is mainly suitable for superficial skin damage, such as cut wound, lacerated wound, scratch, burns, suture wounds and the like, protects skin wound healing of a patient, has effects of easing pain, inhibiting bacteria, resisting inflammation, keeping the wound moist, promoting wound healing, and improving the wound repairing quality, is more suitable for treating bedsore wounds, ulcer wounds and other sites hard to be bound after a surgery, can also be used for non-wound sites, and plays a role of moisturizing.

Owner:QINGDAO CHENLAND MARINE BIOTECH CO LTD

High-strength resin-based composite material track insulating components

ActiveCN101229815ASuitable mechanical propertiesIncrease production costPlastic/resin/waxes insulatorsRail jointsShear formingResin-Based Composite

The invention relates to a fastener used by a railway track, which comprises a track pitch baffle, a baffle base and an insulation track pitch block. The technical proposal is that: prepreg of thermoplastic resin composite is taken as the base material and is cut to be shaped; after being preheated, pulled, pressed, solidified and shaped, the material is made into insulation components of the track. The prepreg of thermoplastic resin composite refers to prepreg composite obtained by combining the thermoplastic resin and nemaline reinforced material; the thickness of the prepreg of thermoplastic resin composite is ranging between 0.1 mm-0.6mm, and the proportion of the reinforced material inside the prepreg of thermoplastic resin composite is 20-40 percent of that of the thermoplastic resin. The invention is characterized by great strength and modulus, good size stability, lasting static resistance, small friction coefficient, wear resistance, long service life, etc.

Owner:NINGBO SHUXIANG NEW MATERIAL

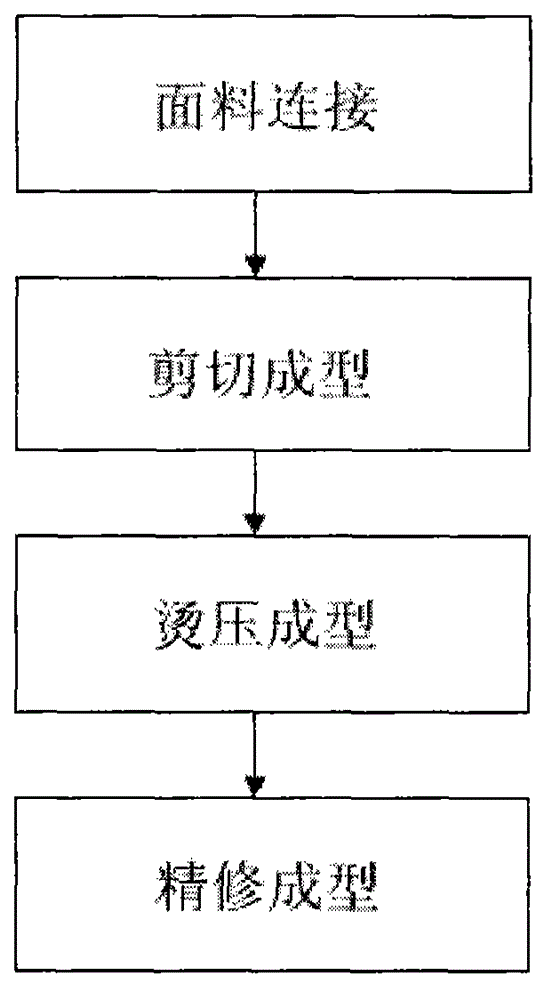

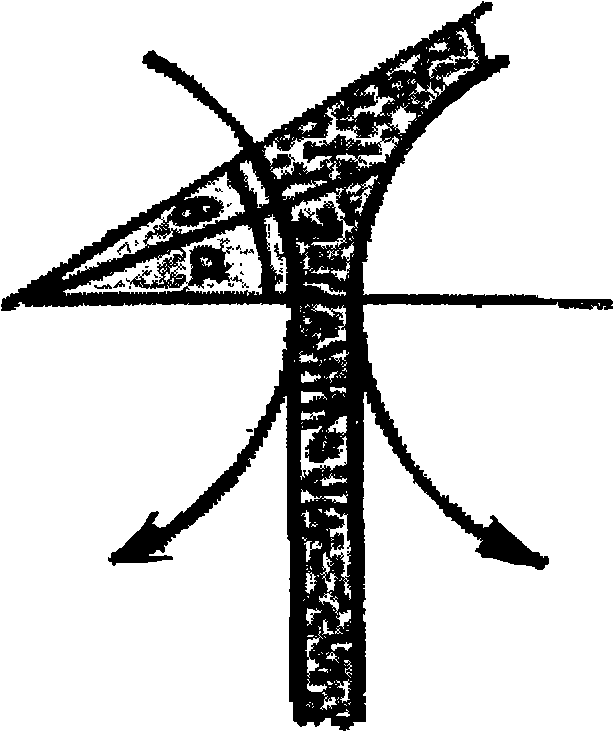

Method for manufacturing slipper vamps in ultrasonic integrated hot-pressing forming mode

InactiveCN104605570AImprove processing efficiencyImprove processing qualityShoe gluingProcess efficiencyShear forming

The invention relates to a method for manufacturing slipper vamps in an ultrasonic integrated hot-pressing forming mode. The method comprises the steps of fabric connection, shear forming, hot-pressing forming and finishing forming. Compared with a method that slipper vamps are processed through traditional knitting connection, the method has the advantages that processing efficiency is high, fabric connection structure strength is high, processing precision is high, and fabric surface quality is good; on one hand, processing efficiency and quality of the slipper vamps are improved, on the other hand, the service life of the slipper vamps is prolonged, the appearance attractiveness degree of the slipper vamps is improved, and the method can be widely applied to processing of fabric of various slipper vamps.

Owner:张军

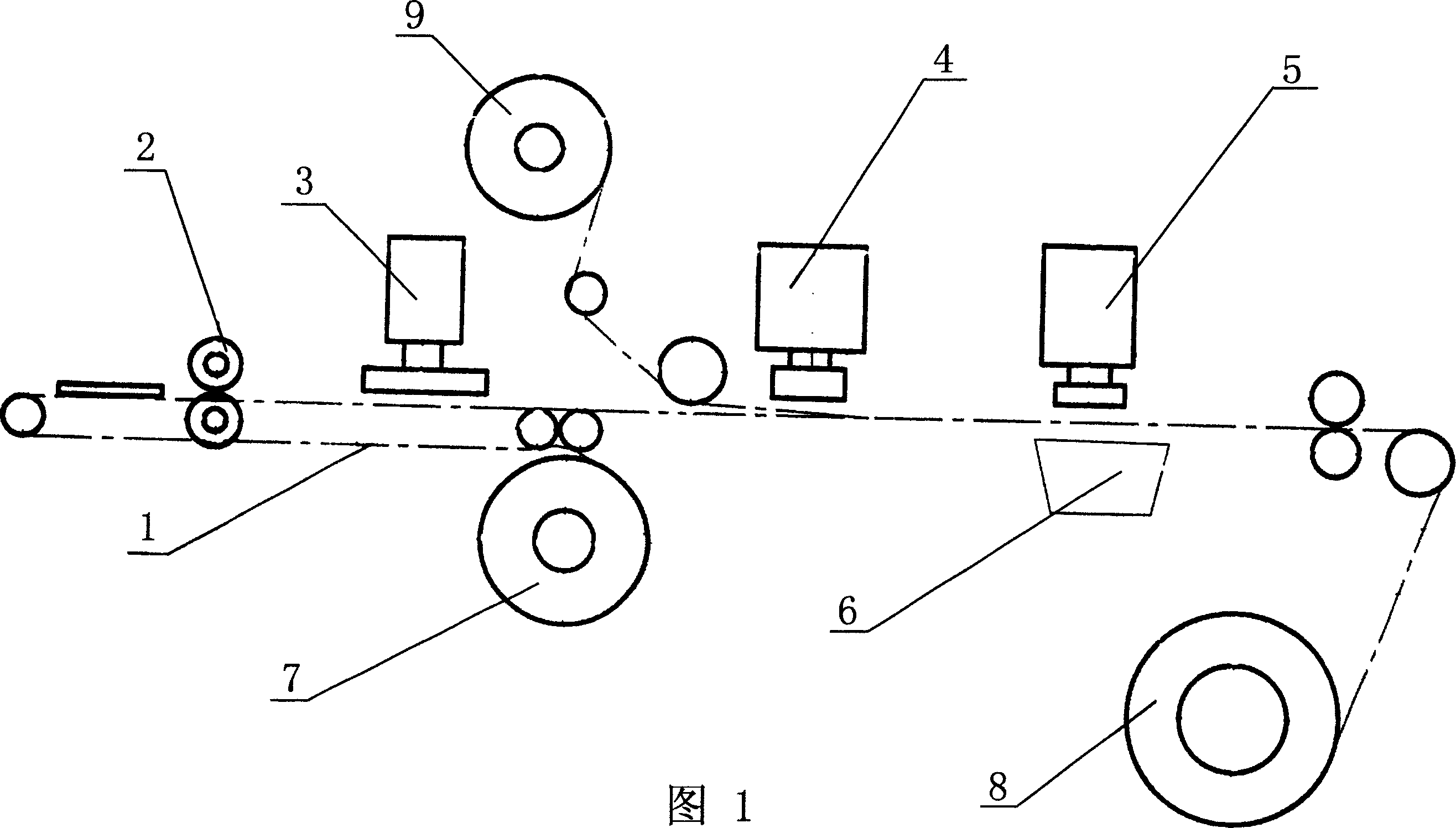

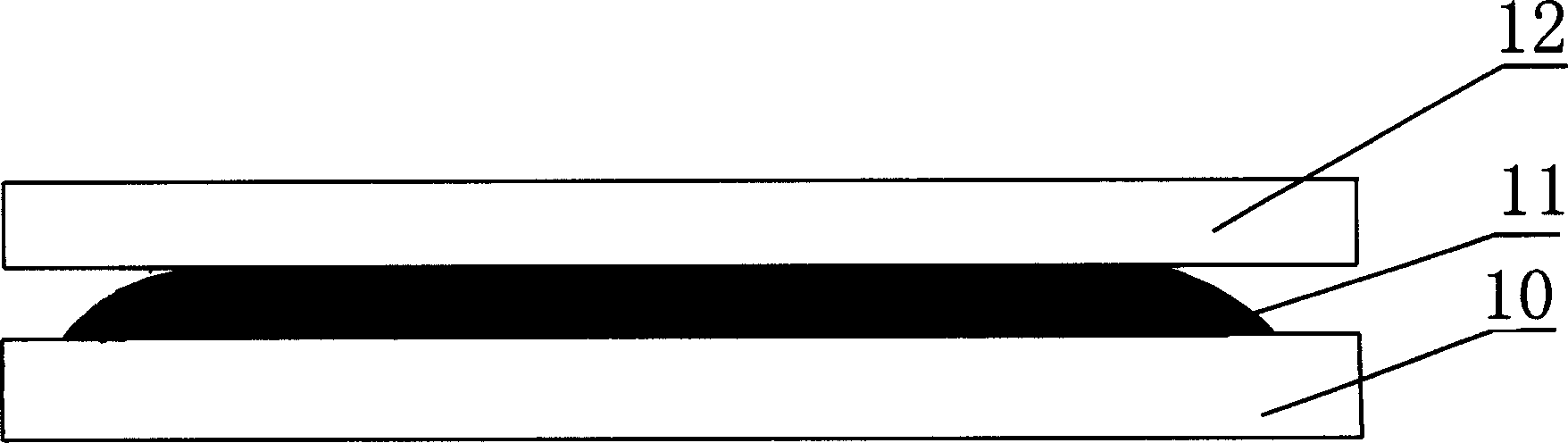

Thin plaster, plaster thinning making method and apparatus

InactiveCN1839798AUnified specificationsThin and lightAerosol deliveryOintment deliveryTemperature controlWood veneer

This invention relates to thin black plaster comprising back-up material layer and plaster layer adhered on the back-up material layer. The black plaster thickness is 0.1-0.9mm, and its processing steps contains: 1) Process boiled plaster into plaster blank; 2) heating compress the plaster blank to thin piece whose thickness maintains between 0.1-0.9mm; 3) Cut the molded thin piece to some shape and package to obtain finished product. The thin black plaster equipment comprises delivery mechanism, at the front end of the delivery mechanism a temperature controlling and piece compressing device is arranged for heating and compress the plaster stuff; behind the temperature controlling and piece compressing device, a blank shaping device is arranged for strike the lamellar plaster stuff into wafer shape; a heating and compressing device is arranged behind the blank shaping device for compressing the plaster blank into flakes. The black plaster can be directly pasted on affected part without heating and can be pasted for many times. The shaping machine has simple structure and is convenient to handle; it achieves mechanization continuous production of black plaster molding.

Owner:莫有双 +1

Preparation technique of micropore titanium plate

The invention belongs to a technology for preparing a millipore titanium plate in the technical field of metal material processing, and is implemented according to the following steps: (1) preparing powder: selecting sponge titanium and adopting the hydrogenation dehydrogenization method to extract low-oxygen, low-hydrogen and high-purity titanium powder; (2) selecting powder: using a magnetic extractor to remove ferruginous impurities from the titanium powder, and using a screen grader to grade the titanium powder according to the granule size; (3) cleaning processing: using acid to clean metal and nonmetal impurities from the graded titanium powder and then using pure water to clean the titanium powder; (4) drying: performing vacuum dustless drying to the cleaned titanium powder; (5) preparing and grading: culling and grading the dried titanium powder according to granule size; (6) rolling: using a rolling mill to roll the titanium powder of the same grade into sectional material; (7) sintering: keeping the degree of vacuum at least below 10Pa, and sintering at the temperature of 1,000 to 1,300 DEG C; and (8) forming by shearing: the plate formed after sintering is leveled off and sheared into specified dimensions according to required specifications. The aperture ratio of the rolled titanium plate is easy to control, the plate is shaped at a time, the thickness of the plate can be freely adjusted, and the rolling cost is low.

Owner:BAOJI JIKAI TECH & TRADING

Method for making arts and crafts picture by cutting and pasting birch bark

InactiveCN1730297AThree-dimensionalThe picture is clear and vividDecorative surface effectsSpecial ornamental structuresEngineeringShear forming

A method for binding art picture engraved by birch bark, includes such technique steps as layouting rough sketch for a painting, preserving and mothproof, shear forming, stickup combination, anti-deforming treatment, provided with clear level, different color and shape, which can express real birch texture effect and aesthetics. The image is of clear and active, nature, cubic effective. The invention changes waste into treasure, so to full utilize of birch bark.

Owner:ARSHAN CITY BAILANG TIANYUAN FORESTRY

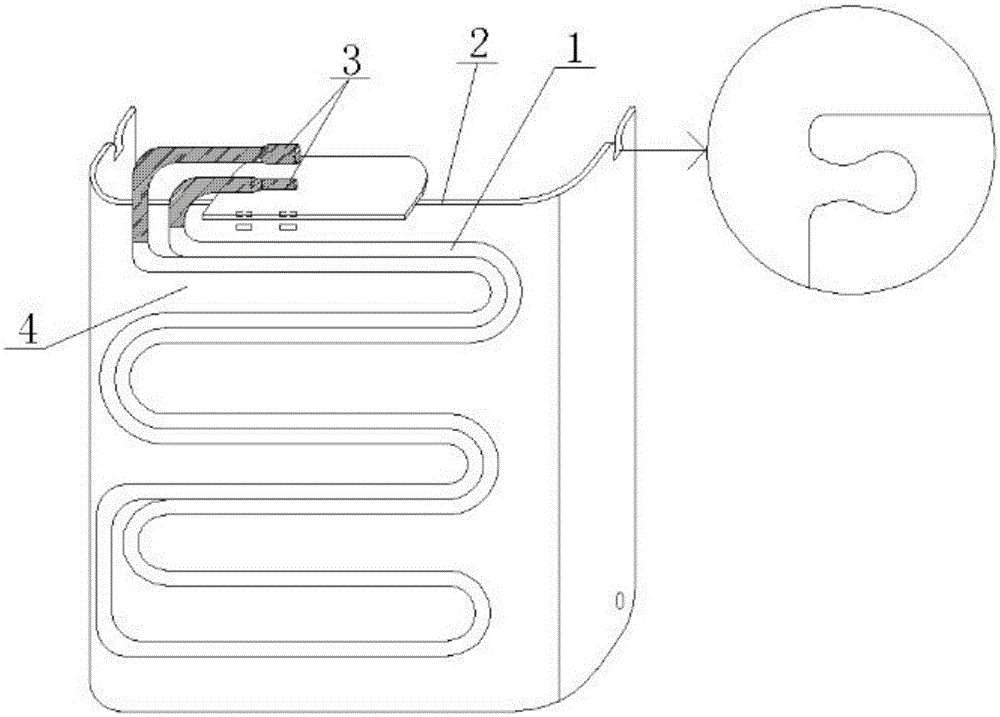

Manufacturing process of novel tube-sheet evaporator

InactiveCN105004104AExtended service lifeEasy to disassembleEvaporators/condensersEngineeringShear forming

The invention discloses a manufacturing process of a novel tube-sheet evaporator. The manufacturing process comprises the steps that an aluminum tube coil material is straightened and cut into a straight material of a specific length; the straight material is bent to be an S-shaped aluminum tube with fourteen bent corners; flattening forming is conducted; at the same time, it is ensured that the specific size of the tube end of the S-shaped aluminum tube is not flattened, and the height of the flattened area of the aluminum tube is controlled to be 0.6-0.68 time of the original diameter; then a copper transition tube is welded to the pipe end of the S-shaped aluminum tube; the surface of an aluminum board which is subjected to shear forming is coated with a sulfuration film; the flattened S-shaped aluminum tube and the aluminum board with the surface coated with the sulfuration film are subjected to sulfidizing; the product after sulfidizing forming is bent to be in a U shape; paint spraying, curing and drying are conducted on the U-shaped product, and the novel tube-sheet evaporator is manufactured. The tube-sheet evaporator is good in refrigerating effect, low in energy consumption, high in corrosion resistance and suitable for being used on novel energy-saving and environment-friendly refrigerators.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

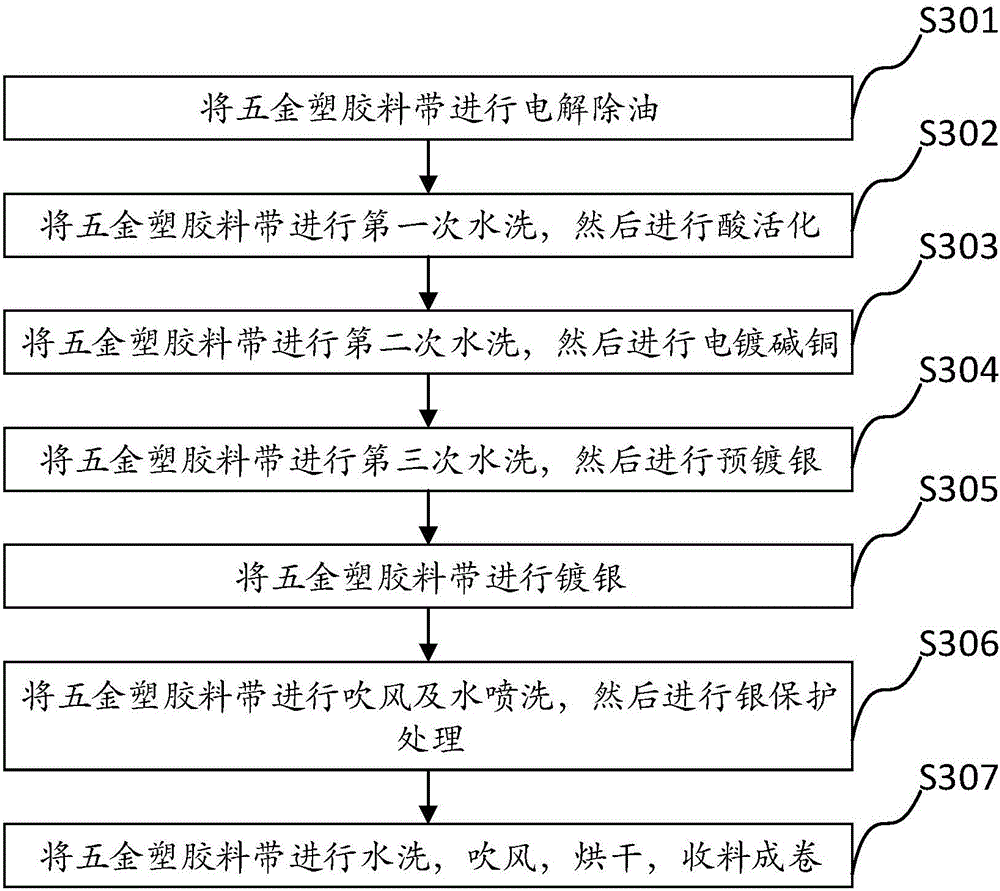

Hardware injection molded switch preparation method

InactiveCN105751427AAvoid quality problemsContinuous electroplating productionElectric switchesOptoelectronicsShear forming

The invention belongs to the technical field of switch accessory preparation and discloses a hardware injection molded switch preparation method. The hardware injection molded switch preparation method includes steps: S1, subjecting a hardware strip to continuous impact molding to obtain a hardware terminal strip; S2, subjecting the hardware terminal strip to continuous injection molding to obtain a hardware plastic strip with a plurality of hardware injection molded switch elements; S3, subjecting the hardware plastic strip to continuous electroplating to obtain a finished strip with a plurality of hardware injection molded switches; S4, subjecting the finished strip to shear forming to obtain a plurality of hardware injection molded switches. By means of continuous hardware impact molding, continuous injection molding and continuous electroplating, continuous automatic operations are realized, manpower and cost are saved, and the quality problem caused by plastic scraps generated in friction and terminal deformation resulted from intertwining and collision of parts in an electroplating process is solved.

Owner:COMAX ELECTRONICS HUL ZHOU

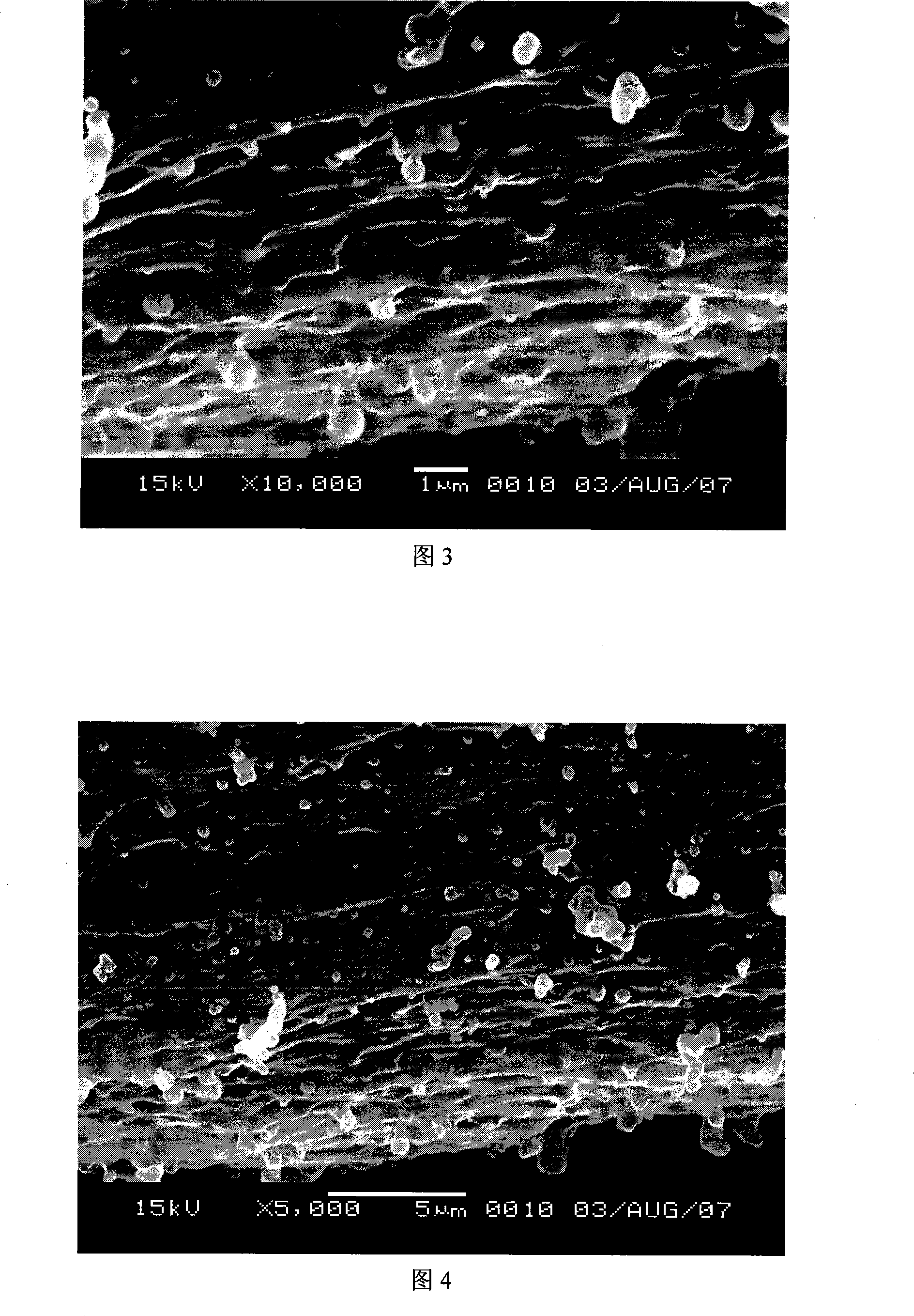

High-melting-point three-element aromatic polyamide polymer and method for preparing precipitation fiber therefrom

InactiveCN106832263AEasy to makeDensity improvedSynthetic cellulose/non-cellulose material pulp/paperPolymer sciencePolyamide

The invention discloses a high-melting-point three-element aromatic polyamide polymer and a method for preparing a precipitation fiber therefrom. The method comprises the following steps: preparing a three-element aromatic polyamide polymer from a phenylenediamine monomer and two phthaloyl chloride monomers, diluting with polar solvent, neutralizing, directly injecting the neutralized three-element aromatic polyamide resin into high-speed rotating mechanical shearing equipment without filtering, and simultaneously injecting compound precipitation agent to obtain a precipitation fiber suspension; and washing off solvent, salt, aids and other impurities contained in the suspension to obtain the three-element aromatic polyamide precipitation fiber which can be used for aramid fiber paper preparation. The aromatic polyamide precipitation fiber prepared by the method has a certain melting point, and the melting point is higher than 340 DEG C; the preparation process is simple, no filtering procedure needs to be implemented after neutralizing, and shear forming is directly performed; the shape of the finished product can be accurately controlled, thereby avoiding the production of thick and big fibers; and the prepared precipitation fiber can favorably improve and enhance the compaction degree of aramid fiber paper.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

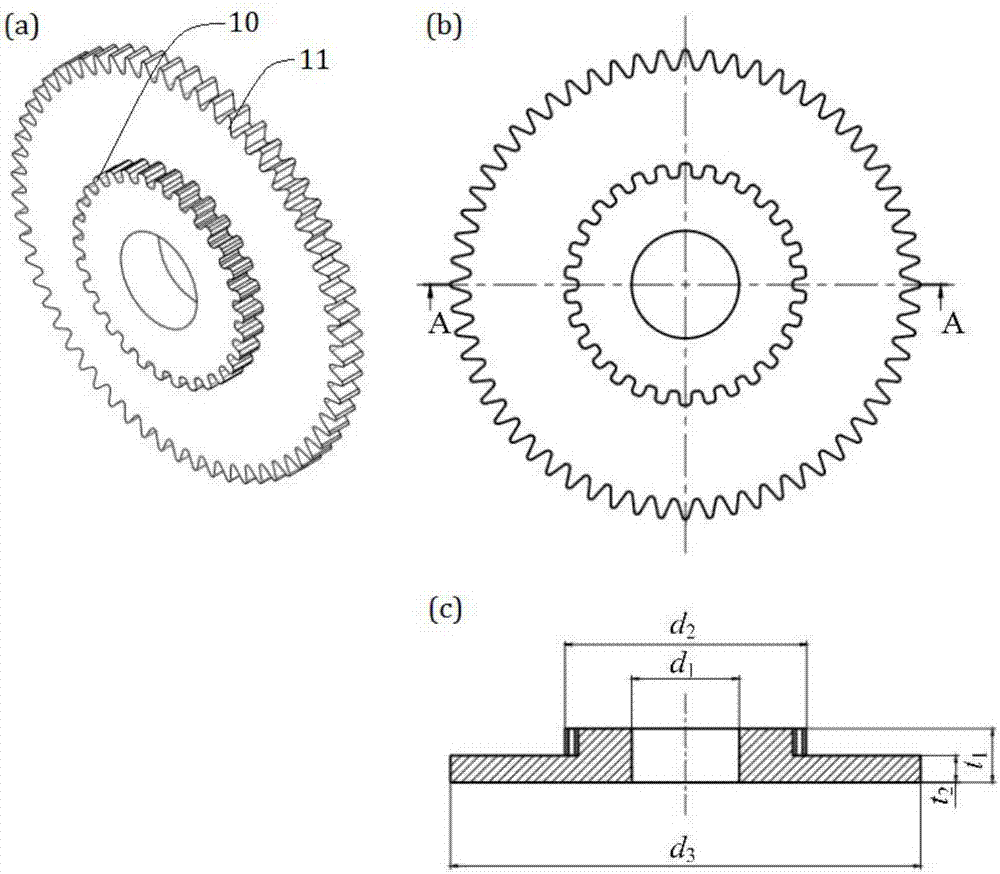

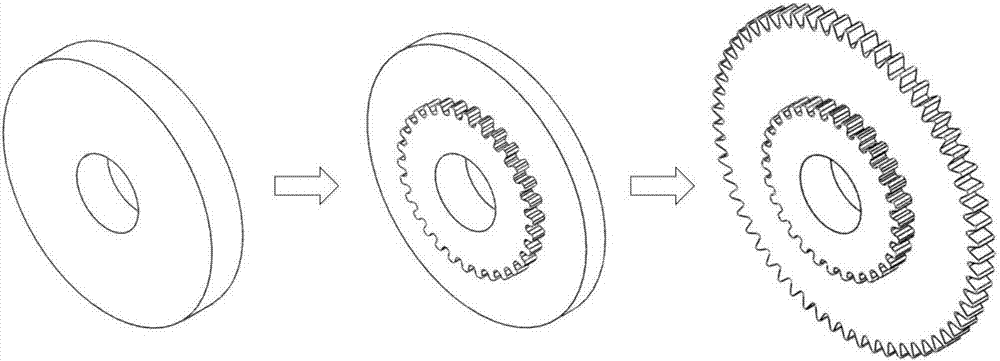

Duplicate gear forging process and mold based on plate bulk forming

ActiveCN107186158AGood thermoforming qualityIncrease productivityForging/hammering/pressing machinesWheelsGear wheelShear forming

The invention discloses a duplicate gear forging process and mold based on plate bulk forming. Firstly, an annular plate blank is obtained according to a designed finished product through laser cutting or blanking, and the size of a shaft hole of the annular plate blank is the same as that of a shaft hole of the finished product; then shearing is performed to form flange inner teeth, and upsetting and thinning are performed on the part, on the outer sides of the inner teeth, of a flange; and finally extruding is performed to form flange outer teeth. According to the duplicate gear forging process and mold, shearing forming of the flange inner teeth, upsetting and thinning of the area, on the outer sides of the inner teeth, of the flange and extrusion forming of the flange outer teeth are completed in one working procedure in sequence, the formed duplicate gear is good in surface quality and high in size precision, and the material utilization rate is high. The forming belongs to near-net forming. The duplicate gear forging process and mold also have the advantage that the mold cost is low.

Owner:SHANGHAI JIAO TONG UNIV +1

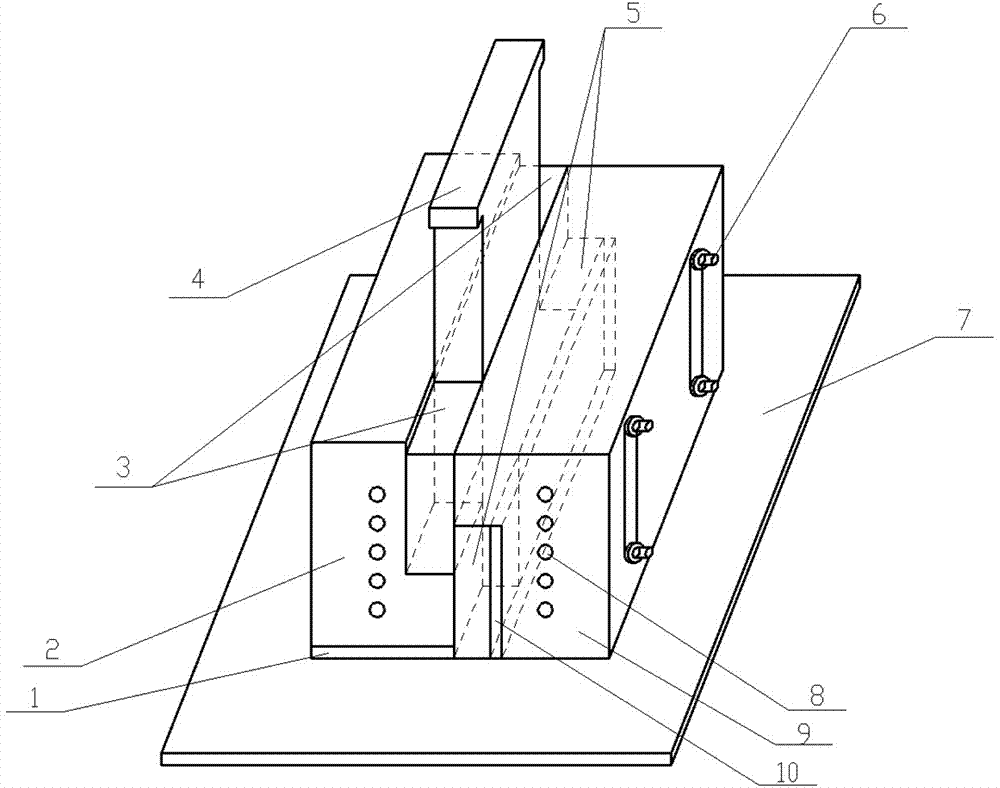

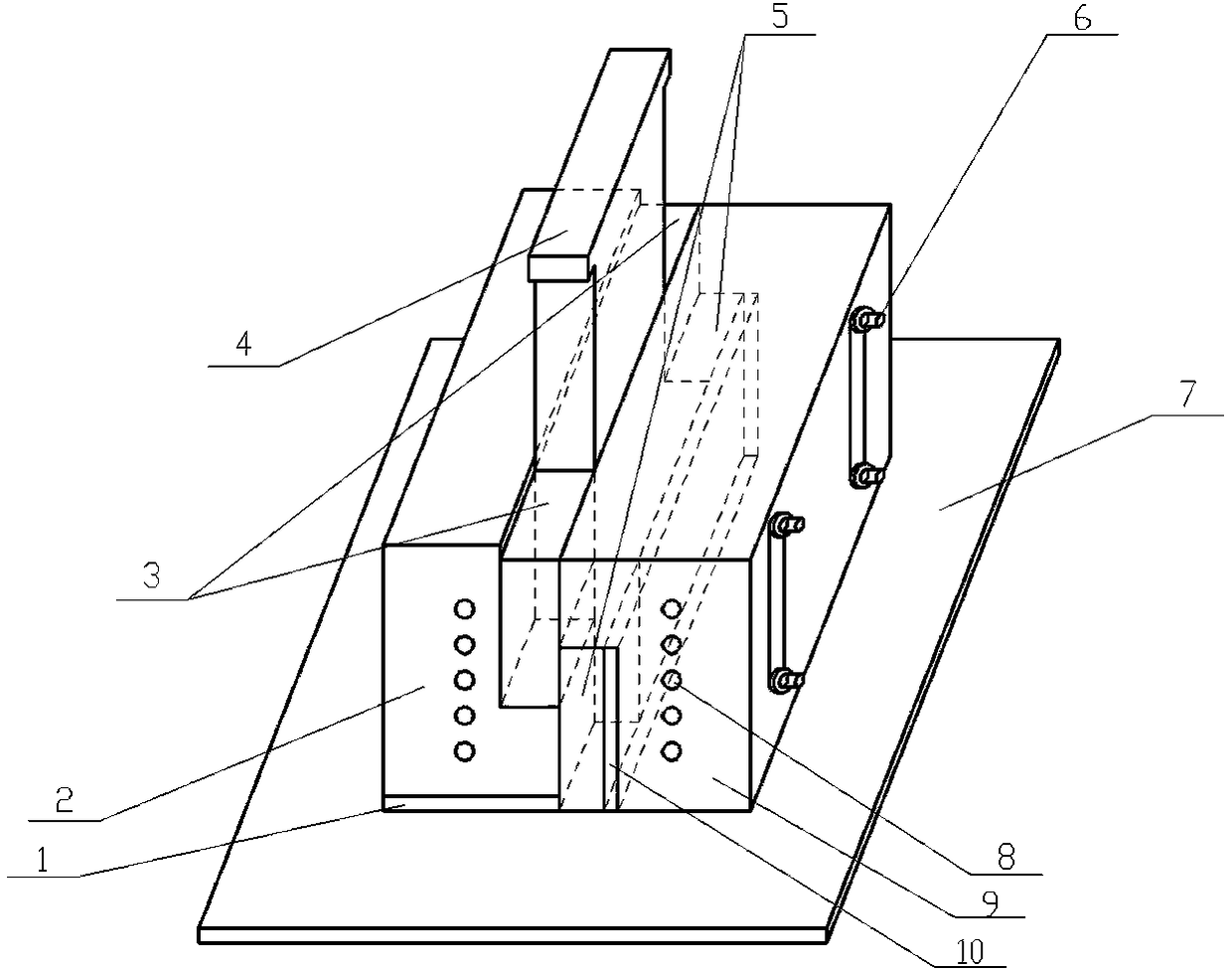

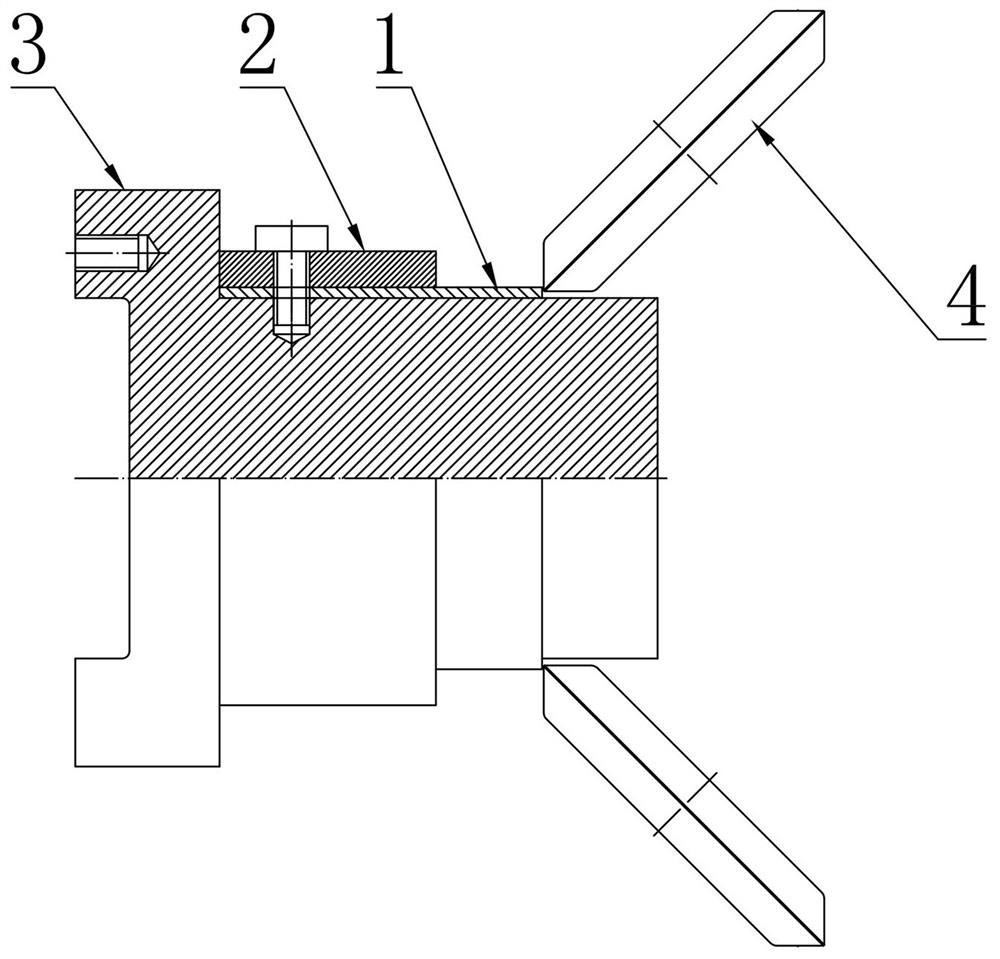

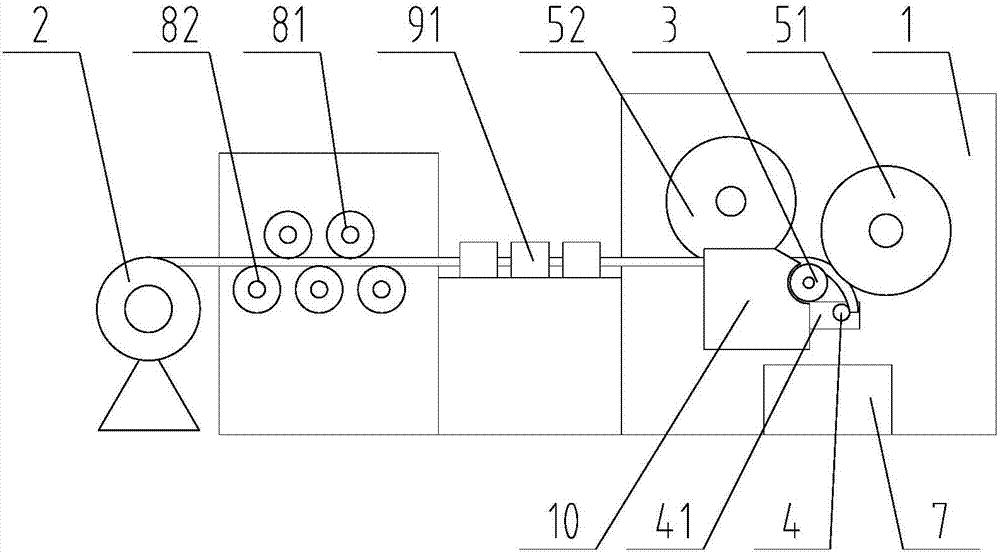

Shearing extrusion-rolling composite forming method and device for preparing high-performance panel

ActiveCN106984667AImprove surface qualityGood formabilityMetal working apparatusMetal rolling arrangementsShear formingMetal

The invention discloses a shearing extrusion-rolling composite forming method for preparing a high-performance panel. The method comprises the following steps that a shearing extrusion forming device is firstly utilized for repeated shearing forming, and blank grains are refined; then thinning shearing forming is conducted, and a metal panel with a strong shearing texture is prepared; and finally, the surface quality of the panel is improved through rolling deformation, meanwhile, the texture is balanced, and the metal panel forming performance is improved. A die is simple in structure, convenient to operate and low in cost, panel equal-thickness repeated shearing forming and thinning shearing extrusion forming functions can be achieved, a heating device on the device can be adopted for preheat treatment to improve the plastic deformation capability of the panel, a fine grain panel with a strong shearing texture is prepared through the shearing extrusion forming device, finally, panel surface quality improving and texture balancing are achieved through rolling, and the high-performance metal panel with the excellent mechanical performance is prepared. The invention further discloses a shearing extrusion-rolling composite forming device for preparing the high-performance panel.

Owner:HUNAN UNIV OF SCI & TECH

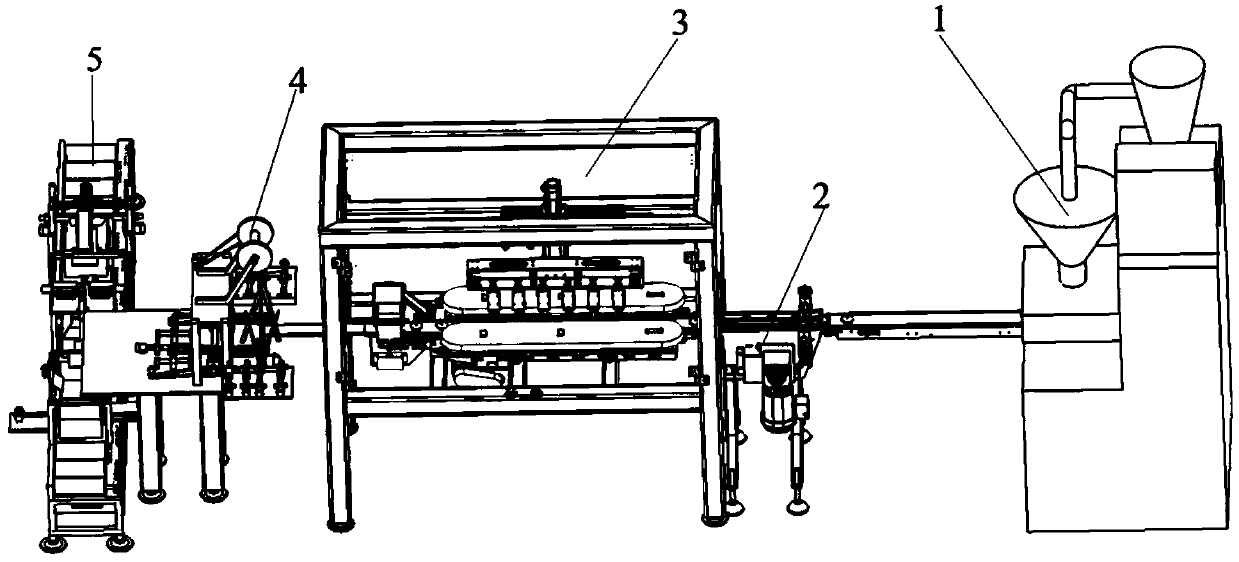

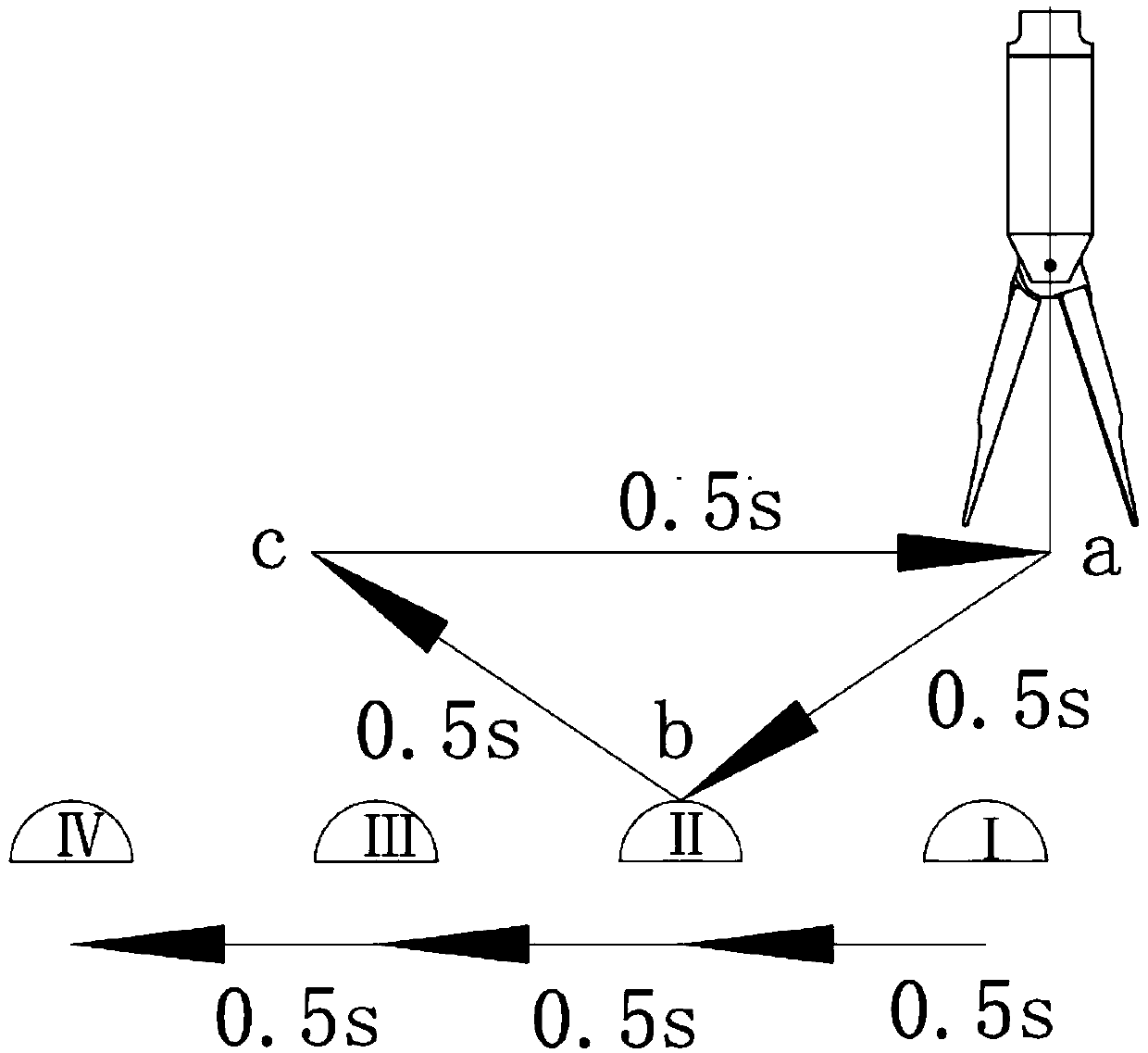

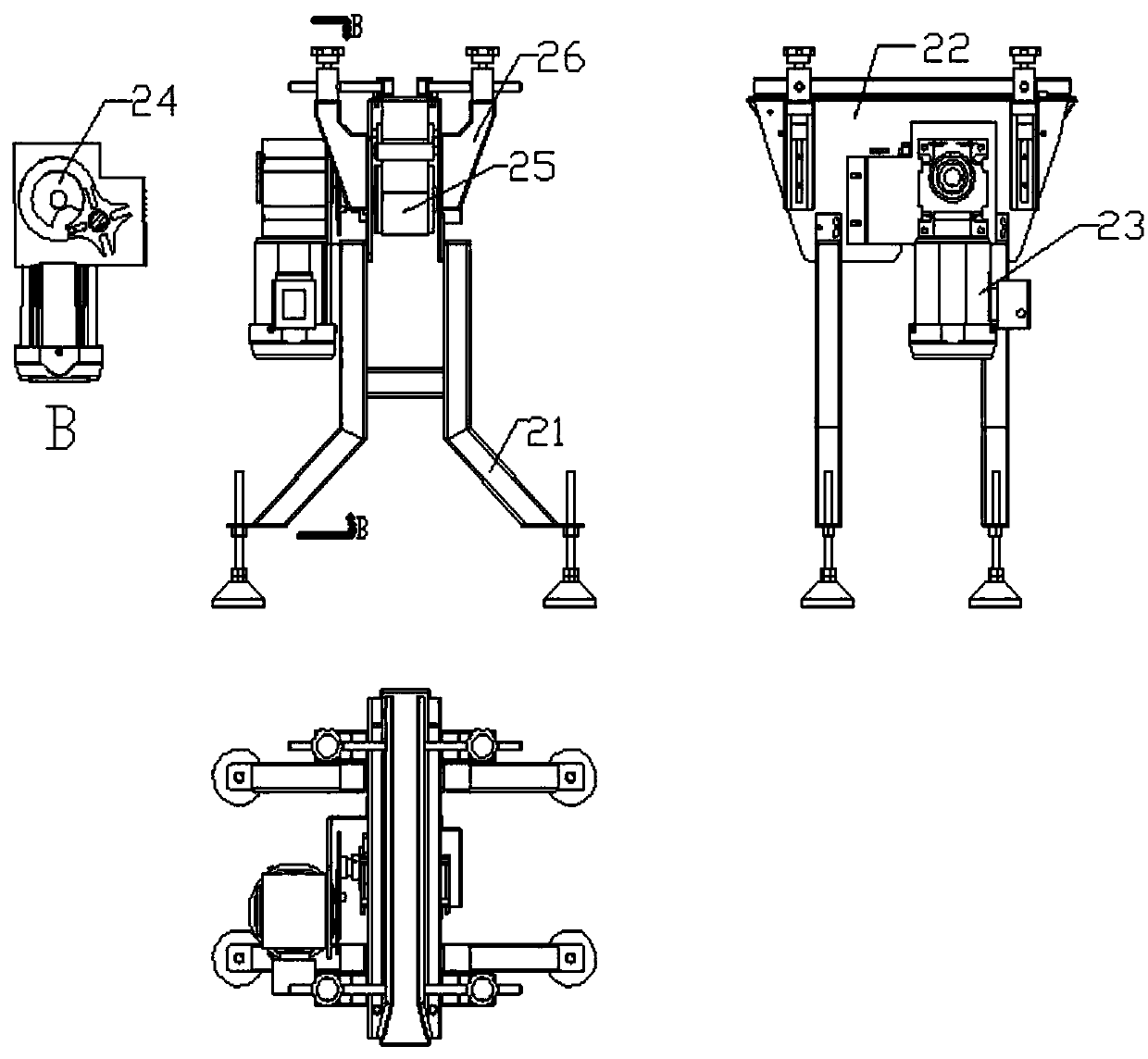

Mechanical control type processing, bagging and packaging integrated device

The invention discloses a mechanical control type processing, bagging and packaging integrated device. The device is characterized by comprising a food production machine, an interval adjusting machine, a shearing and conveying machine, a bagging machine and a packing machine, the food production machine is fixedly installed on the ground of a workshop, the interval adjusting machine is connectedwith the food production machine through a conveying belt, the shearing and conveying machine is connected with the interval adjusting machine through the conveying belt, the bagging machine is connected with the tail end of the shearing and conveying machine, a shear frame in the shearing and conveying machine is used for rapidly processing sheared food into a cross shape, then the sheared food is conveyed to the bagging machine, the sheared food is arranged and then bagged by the bagging machine, the bagged food is boxed and packaged by the packaging machine. According to the processing, bagging and packaging integrated device, one-time shearing forming of the sheared food is realized, so that the effects of being efficient and rapid are achieved, meanwhile, the processing, bagging and packaging integrated device further comprises the bagging machine and the packing machine, so that the full-mechanical control of a production line is realized, the work is stable and reliable, the service life of equipment is long, processing, bagging and packaging are integrated, so that manpower is saved, and the working efficiency is improved.

Owner:QINGDAO UNIV OF SCI & TECH

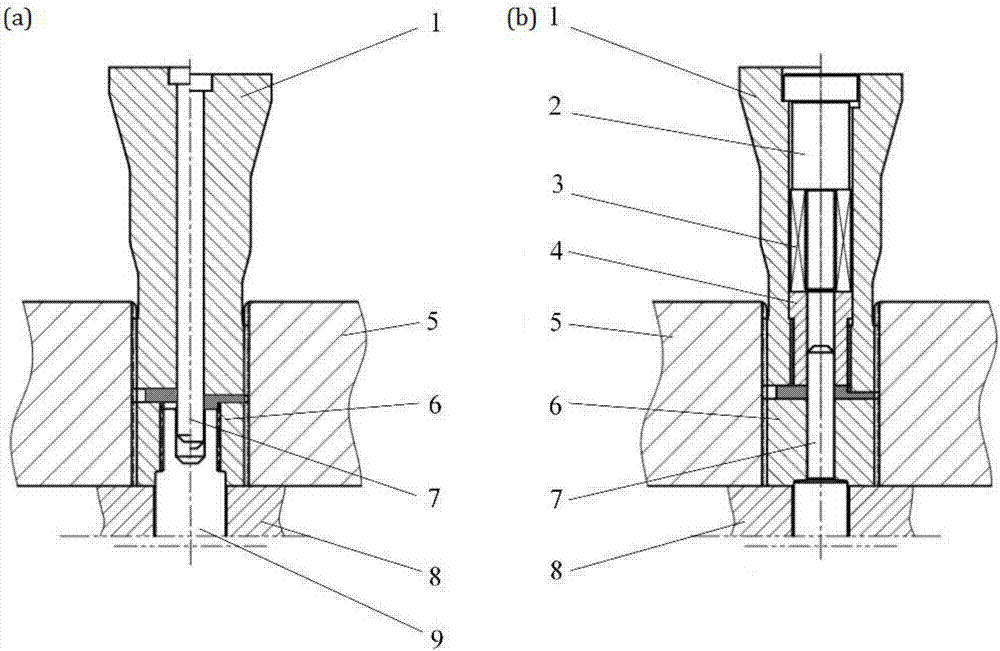

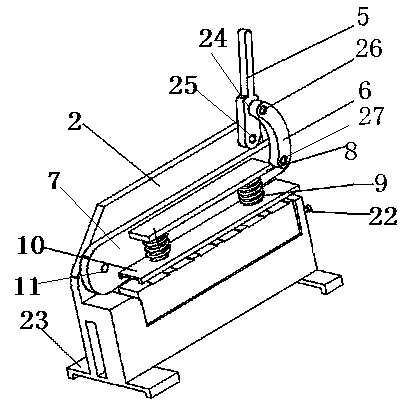

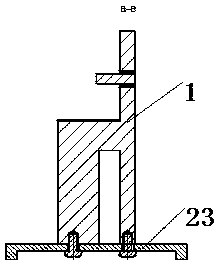

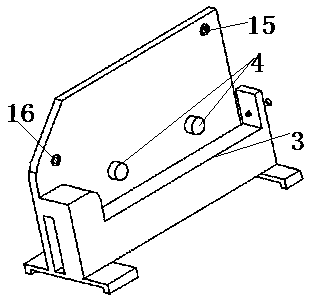

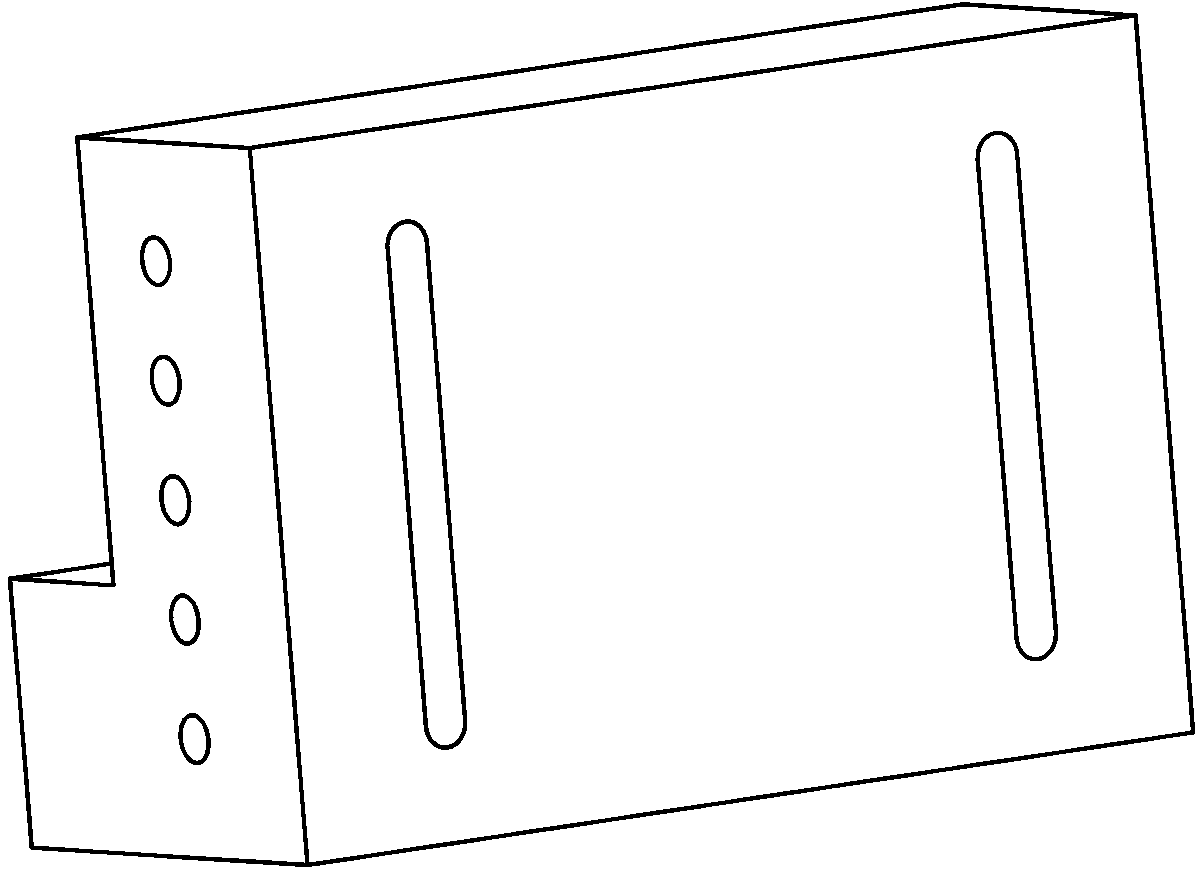

Resistance element lead pin shear-formation device and method

The invention belongs to the technical field of assembly of electronic elements and particularly relates to a resistance element lead pin shear-formation device and a resistance element lead pin shear-formation method. By organic combination of a mounting bracket, a driving part, a shearing mechanism, a clamping mechanism and a locking mechanism, the invention provides a resistance element lead pin shear-formation device which is simple in structure, low in cost, flexible and convenient to operate. The resistance element lead pin shear-formation device realizes high shear-formation precision,high formation efficiency and high universality of a resistor. The resistor shorn by the resistance element lead pin shear-formation device provided by the invention is good in consistency and meets the technological requirements.

Owner:中船重工西安东仪科工集团有限公司

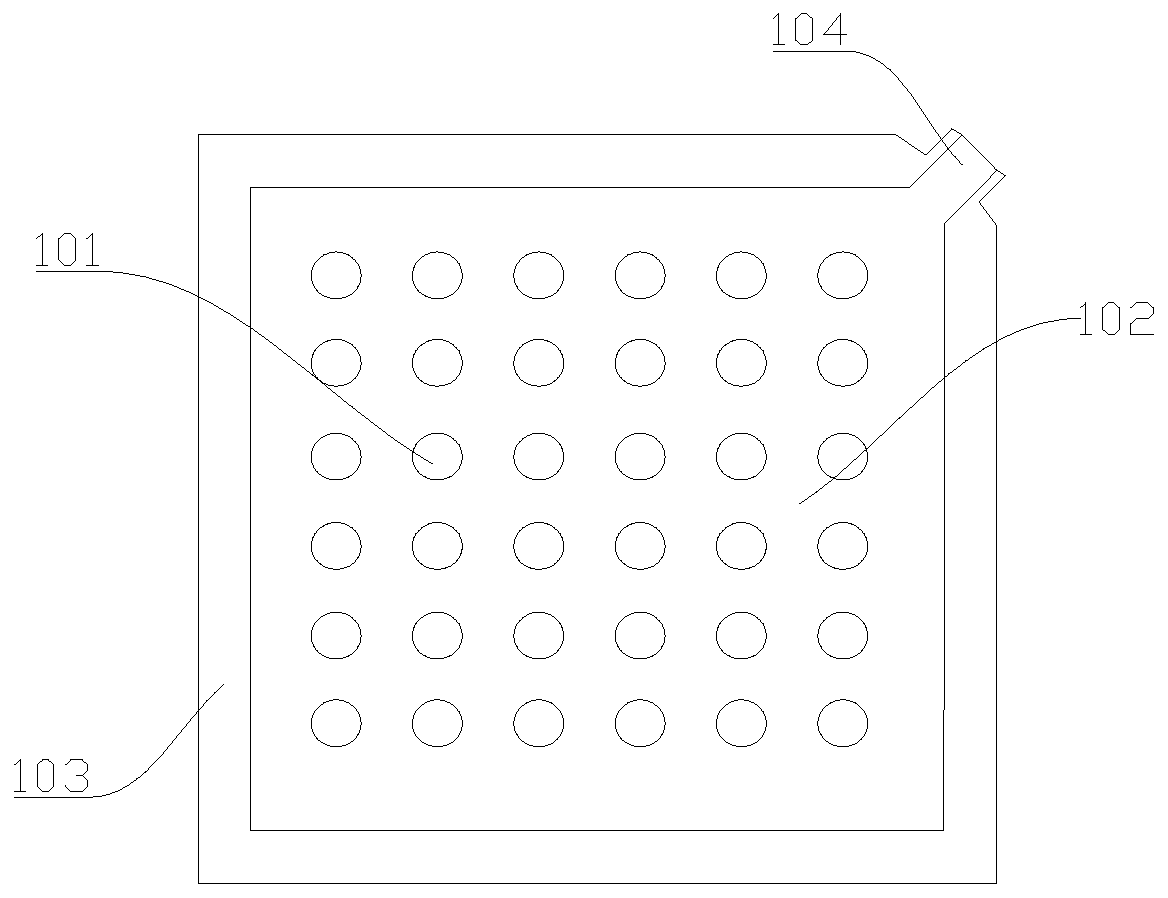

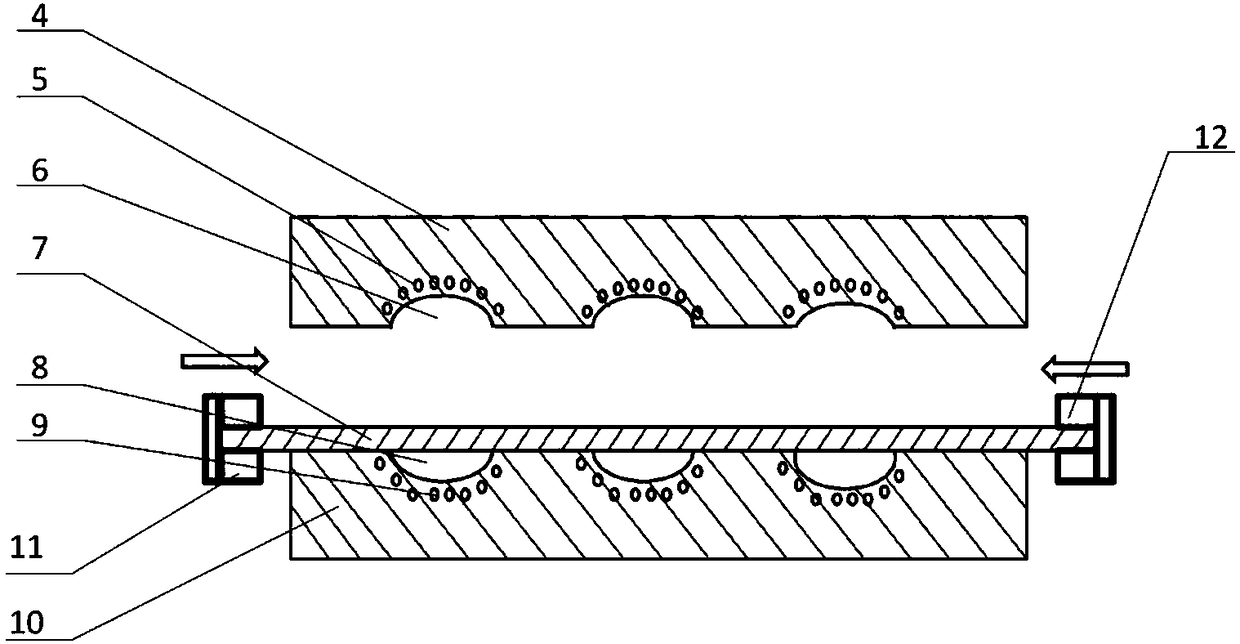

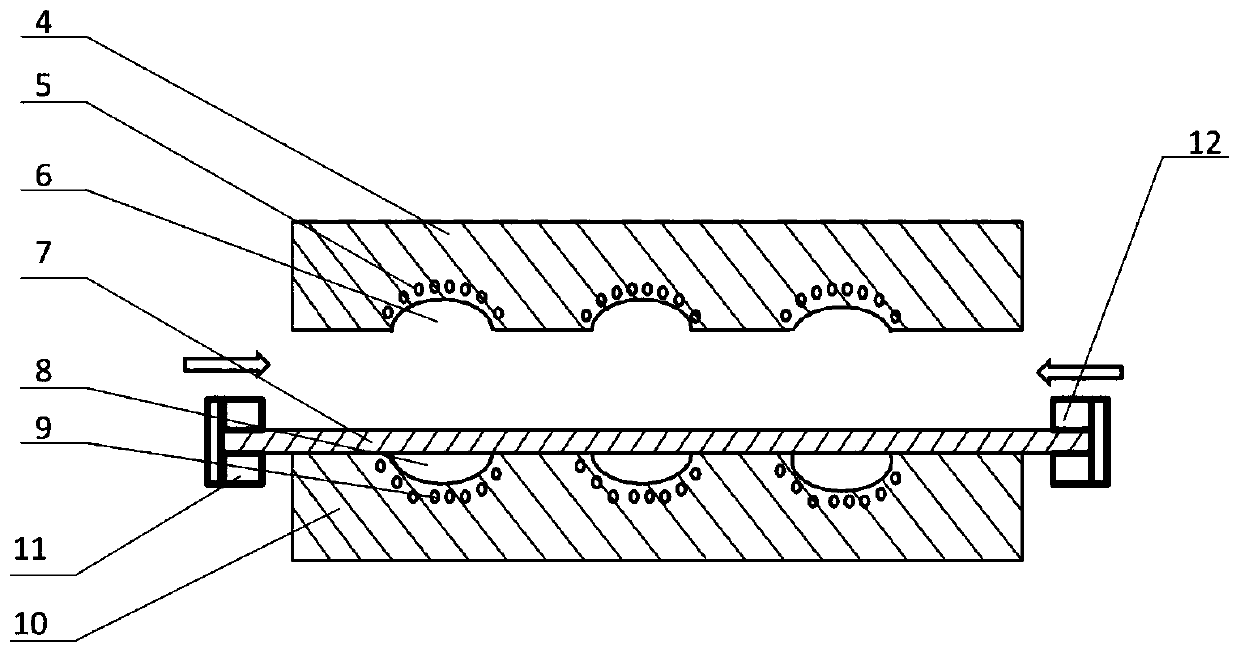

Vapor chamber semi-shearing forming method

ActiveCN110779362AAvoid pollutionLittle change in thicknessSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

The invention discloses a vapor chamber semi-shearing forming method. The vapor chamber semi-shearing forming method includes the following steps of providing a first cover plate and a second cover plate, forming a plurality of supporting columns in the middle of the first cover plate in a semi-shearing stamping mode, performing semi-shearing on the edge to form a welding flange edge, reserving anair outlet, buckling the second cover plate on the first cover plate and performing sealing along the welding flange edge after a heat adsorption core body is adsorbed into the first cover plate or the second cover plate to form a cavity, vacuumizing the cavity after injecting working fluid into the cavity through the air outlet to form negative pressure, and finally sealing the air outlet to prepare a vapor chamber. The vapor chamber cover plates are manufactured in the semi-shearing stamping mode, production cost is reduced, and the environmental protection is facilitated; by arranging positioning blocks, the positioning precision is ensured, and the percent of pass of the product is improved; and through a welding mode, the production cycle of the whole technological process is greatlyshortened, and efficient production is realized.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

Oblique edge sheet shearer with thick wave shape edge

InactiveCN102825326ASimple structureEasy to operateShearing machinesShearing toolsHydraulic cylinderWave shape

The invention discloses an oblique edge sheet shearer with a thick wave shape edge. The oblique edge sheet shearer is composed of a serial hydraulic cylinder, a tool rest, a frame, a work bench, an oblique edge wave shape upper blade and a flat edge wave shape lower blade. The oblique edge sheet shearer with the thick wave shape edge is characterized in that the oblique edge wave shape upper blade is fixedly connected with the tool rest; the flat edge wave shape lower blade is fixedly connected with the work bench; the serial hydraulic cylinder pushes the tool rest to move up and down under the action of hydraulic power; the tool rest moves downwards; the oblique edge wave shape upper blade is gradually combined with the oblique edge wave shape lower blade; ripples are orderly sheared and formed; and the tool rest returns after the shearing is finished. Compared with the traditional linear cutting technology, the oblique edge sheet shearer with the thick wave shape edge has the characteristics of being high in efficiency and suitable for mass production, and is a preferred product for processing the thick wave shape edge of a metal sheet.

Owner:陈道宝 +2

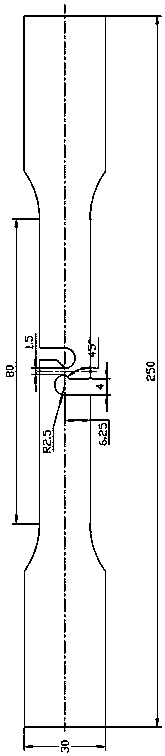

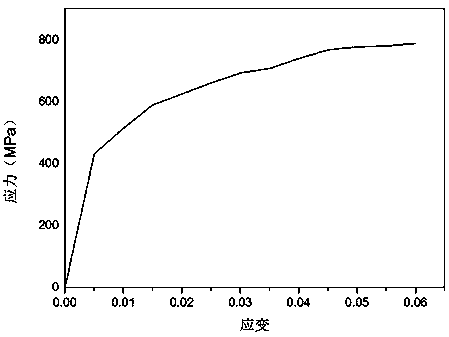

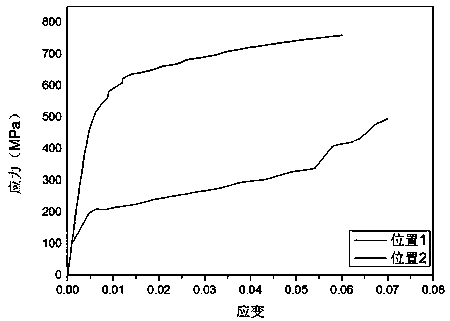

Method for judgingshear forming resistance of material during stamping

PendingCN111595697AUniform shear forceGuaranteed accuracyMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesStampingMetallic materials

The invention relates to a method for judging the shear forming resistance of a material during stamping, and belongs to the technical field of methods for testing and judging shear fracture of metalmaterials. The technical scheme of the invention is as follows: the method comprises the following steps: processing and manufacturing a sample, carrying out a shearing test on a plate, processing test data, calculating shearing energy, carrying out forming simulation on a part, deriving a stress-strain curve of a sheared force position, calculating the shearing energy, comparing the shearing energy of the part with the shearing potential energy of the shearing test,and judging whether the part can resist shear deformation and does not crack or not. The invention provides the method for judging the shear forming resistance of the material during stamping, so that the forming simulation accuracy is continuously improved, and the method has the advantages of simplicity in operation, low cost, high efficiency and the like.

Owner:TANGSHAN IRON & STEEL GROUP +1

Forming method

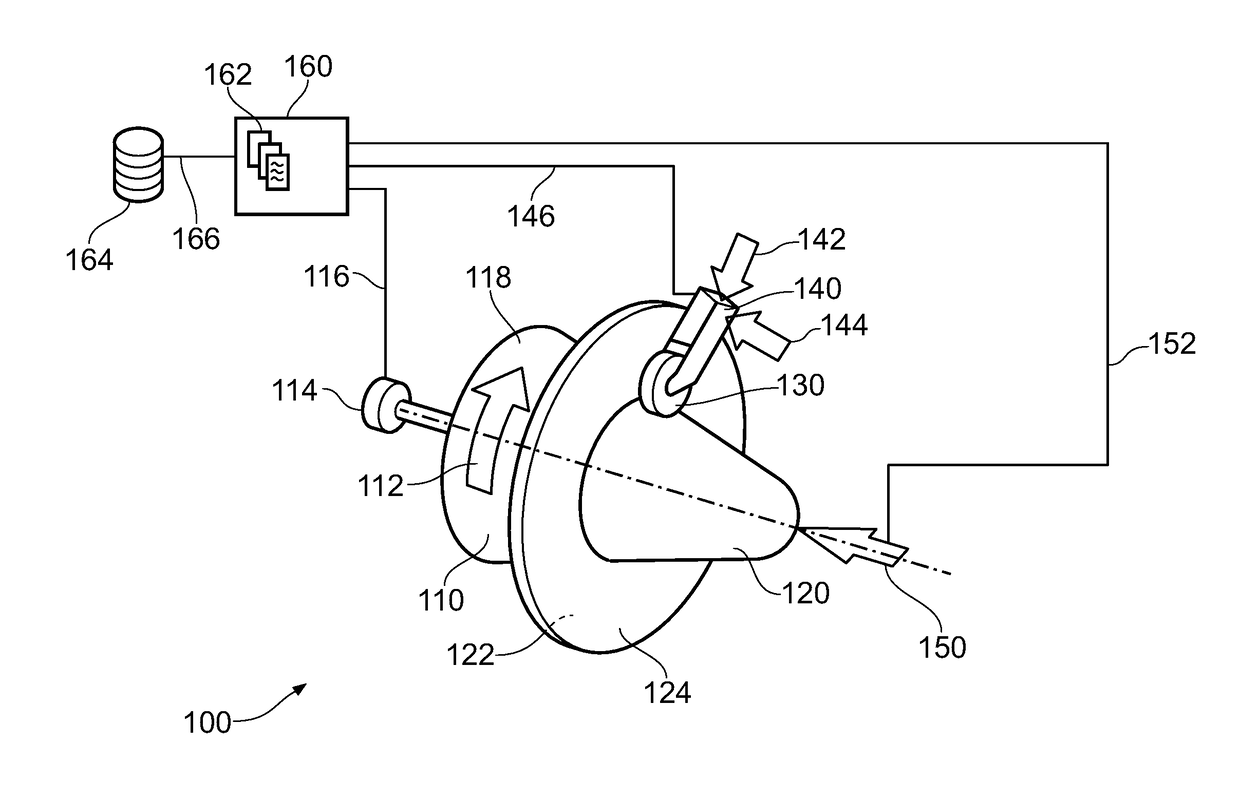

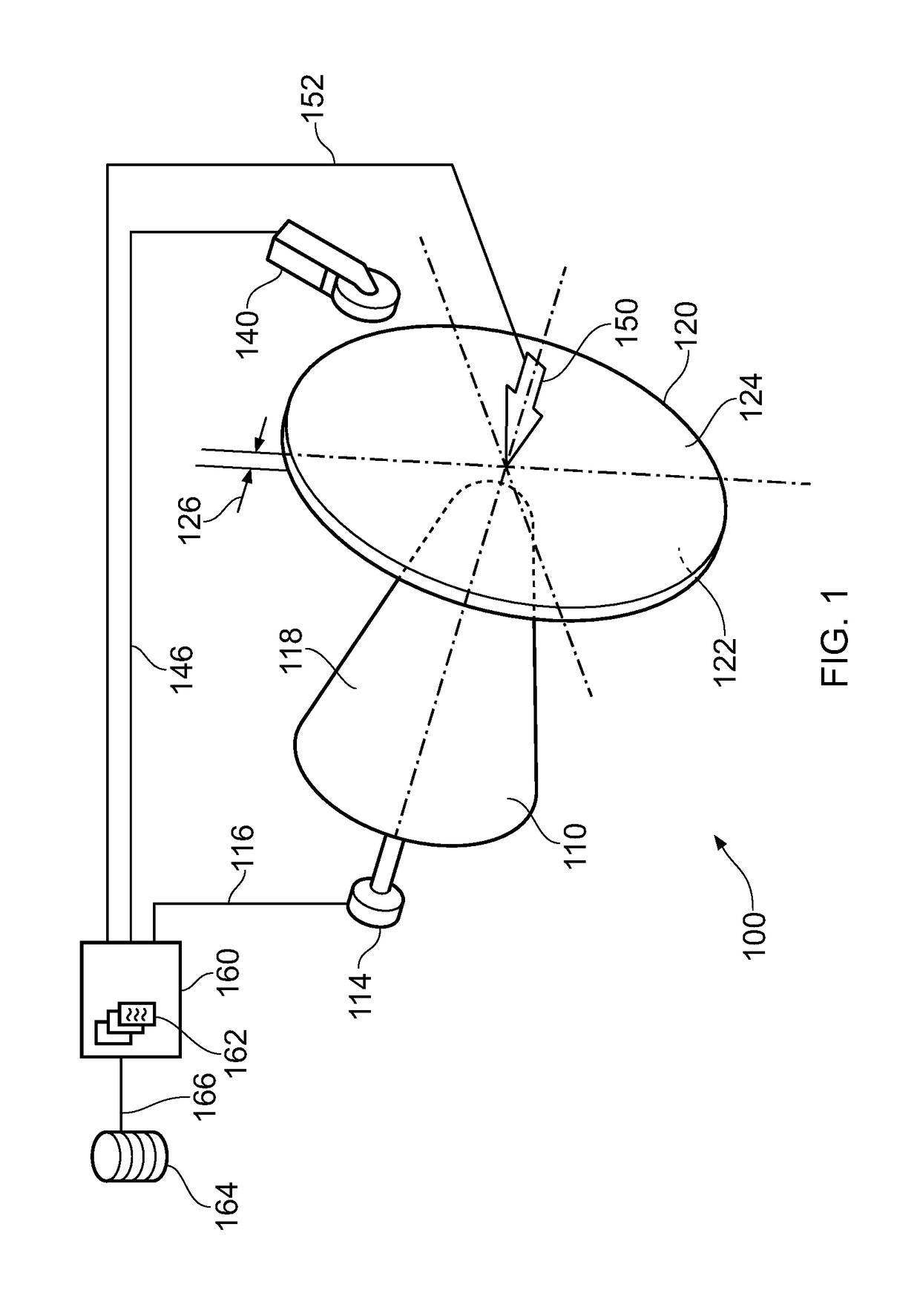

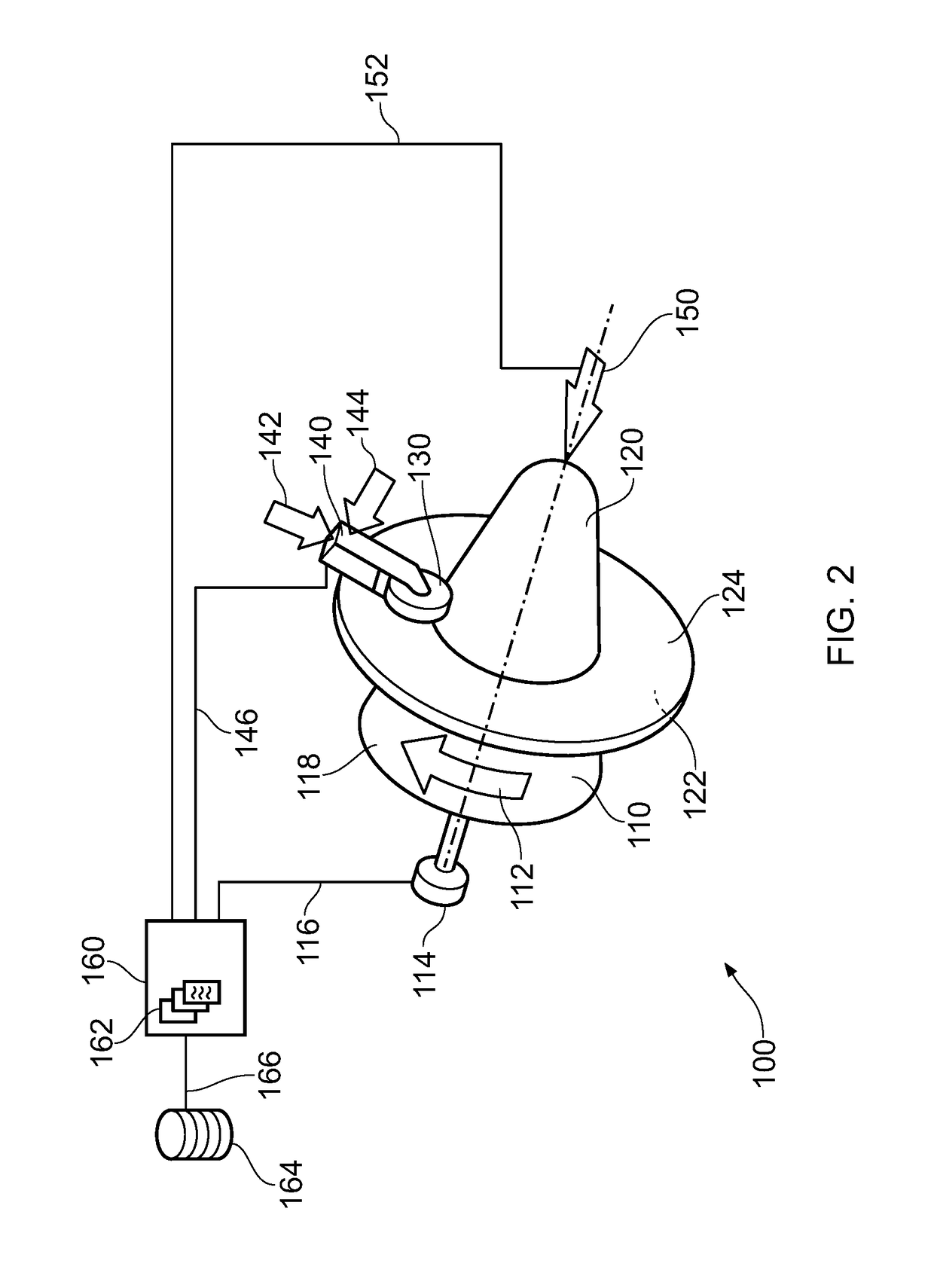

InactiveUS20180229284A1Improve fatigue performanceMetal rolling stand detailsWork treatment devicesSurface roughnessShear forming

A method of shear forming a component comprises the steps of:(i) providing a pre-formed metallic sheet blank, the sheet blank having a first surface and an opposite second surface, the perpendicular separation between the first surface and the second surface defining a thickness of the sheet blank;(ii) applying a surface modification process to the first surface of the sheet blank to reduce a surface roughness of the first surface to a first predetermined roughness value;(iii) positioning the second surface of the sheet blank against a mandrel; and(iv) applying a roller to the first surface of the sheet blank in a shear forming operation to form the sheet blank into the component.

Owner:ROLLS ROYCE PLC

Shear extrusion-rolling compound forming method and device for preparing high-performance plate

ActiveCN106984667BImprove surface qualityGood formabilityMetal working apparatusMetal rolling arrangementsShear formingMetal

The invention discloses a shearing extrusion-rolling composite forming method for preparing a high-performance panel. The method comprises the following steps that a shearing extrusion forming device is firstly utilized for repeated shearing forming, and blank grains are refined; then thinning shearing forming is conducted, and a metal panel with a strong shearing texture is prepared; and finally, the surface quality of the panel is improved through rolling deformation, meanwhile, the texture is balanced, and the metal panel forming performance is improved. A die is simple in structure, convenient to operate and low in cost, panel equal-thickness repeated shearing forming and thinning shearing extrusion forming functions can be achieved, a heating device on the device can be adopted for preheat treatment to improve the plastic deformation capability of the panel, a fine grain panel with a strong shearing texture is prepared through the shearing extrusion forming device, finally, panel surface quality improving and texture balancing are achieved through rolling, and the high-performance metal panel with the excellent mechanical performance is prepared. The invention further discloses a shearing extrusion-rolling composite forming device for preparing the high-performance panel.

Owner:HUNAN UNIV OF SCI & TECH

High-strength resin-based composite material track insulating components

ActiveCN101229815BSuitable mechanical propertiesIncrease production costPlastic/resin/waxes insulatorsRail jointsShear formingResin-Based Composite

The invention relates to a fastener used by a railway track, which comprises a track pitch baffle, a baffle base and an insulation track pitch block. The technical proposal is that: prepreg of thermoplastic resin composite is taken as the base material and is cut to be shaped; after being preheated, pulled, pressed, solidified and shaped, the material is made into insulation components of the track. The prepreg of thermoplastic resin composite refers to prepreg composite obtained by combining the thermoplastic resin and nemaline reinforced material; the thickness of the prepreg of thermoplastic resin composite is ranging between 0.1 mm-0.6mm, and the proportion of the reinforced material inside the prepreg of thermoplastic resin composite is 20-40 percent of that of the thermoplastic resin. The invention is characterized by great strength and modulus, good size stability, lasting static resistance, small friction coefficient, wear resistance, long service life, etc.

Owner:NINGBO SHUXIANG NEW MATERIAL

Drawing method for large-scale production of cartoon and produced cartoon

InactiveCN101712258AReduce difficultyIncrease contentOutline designsAnimationShear formingMaterial resources

The invention discloses a drawing method for the large-scale production of cartoon and the produced cartoon. The drawing method comprises the following steps: 1. printing a drawing; 2. cutting drawings; 3. coloring; 4. nipping and drying; 5. binding; 6. performing additional processing; and 7. scanning or photographing the above mother set to obtain an electronic mother set drawing. The drawing method for the large-scale production of cartoon of the invention ensures that the traditional kirigami can be effectively combined with the digital mode to produce folk and antique kirigami type cartoon series; and the manufacturing cost of the cartoon is low, the yield is high, the manpower and material resources are saved, and the creation procedure and the cutting forming procedure can be separated to perform, thus the method of the invention is applicable to the large-scale production of the cartoon and has fast speed and high efficiency.

Owner:陈教芳

Full-automatic film sheet forming device

ActiveCN111761635AGuaranteed stabilityImprove yieldCleaning using toolsMetal working apparatusPunchingDust control

Owner:盐城东福电子科技有限公司

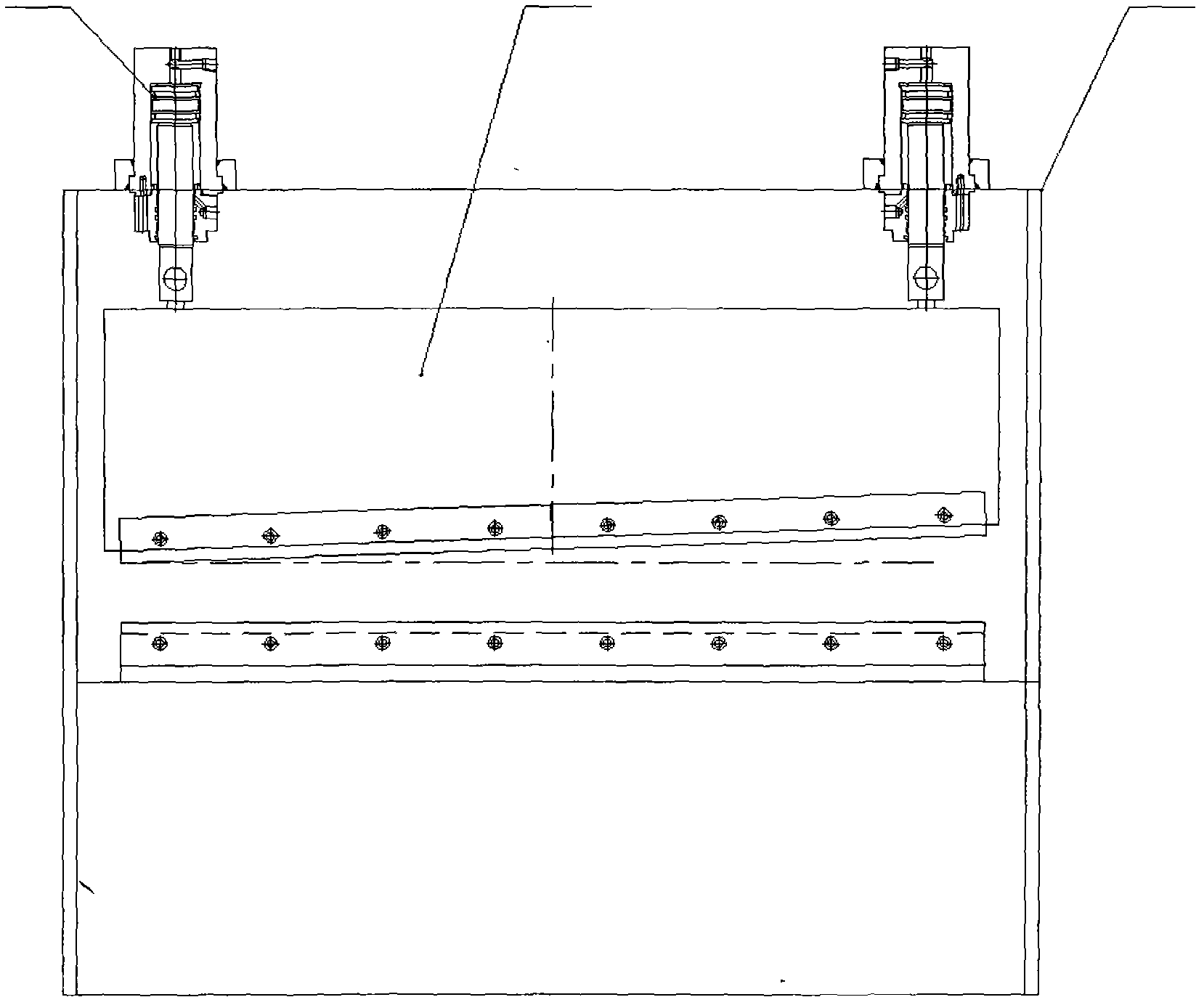

Shearing forming method for annular outer rib cylindrical part

PendingCN114192647ARealize high-dimensional precise formingSolve the problem of difficult forming of external reinforcement structureShearing deformationShear forming

The invention belongs to the technical field of metal plastic processing, and discloses an annular outer rib cylindrical part shearing forming method which comprises the following steps: based on a cylindrical part spinning forming process, applying radial constraint to a cylindrical part blank by adopting an annular back pressure mold, selecting a shearing spinning roller and changing the working angle of the shearing spinning roller at the same time; and the shearing working face of the shearing spinning roller makes contact with the cylindrical part blank in an assembling face mode, and the cylindrical part blank is sheared and spun till the annular outer rib is formed. According to the principle of material shearing separation and shearing deformation, and in combination with the characteristics of a local forming process, the problem that in a traditional process, an outer rib structure is difficult to form is solved, and high-dimensional accurate forming of the thin-wall annular outer rib cylindrical part can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

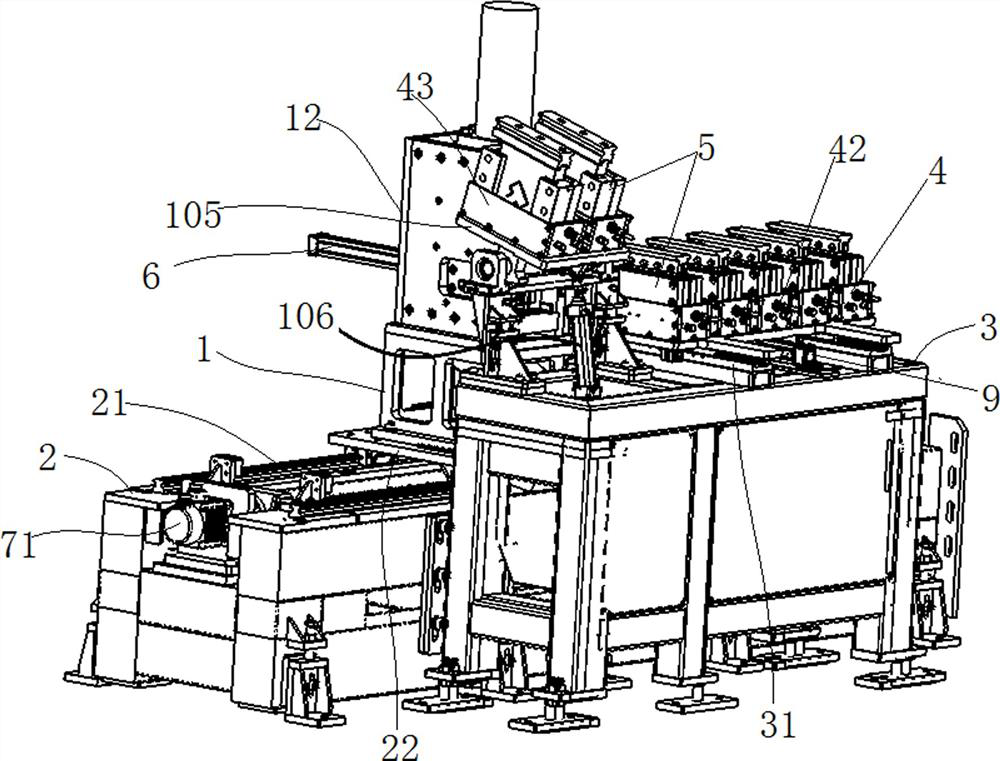

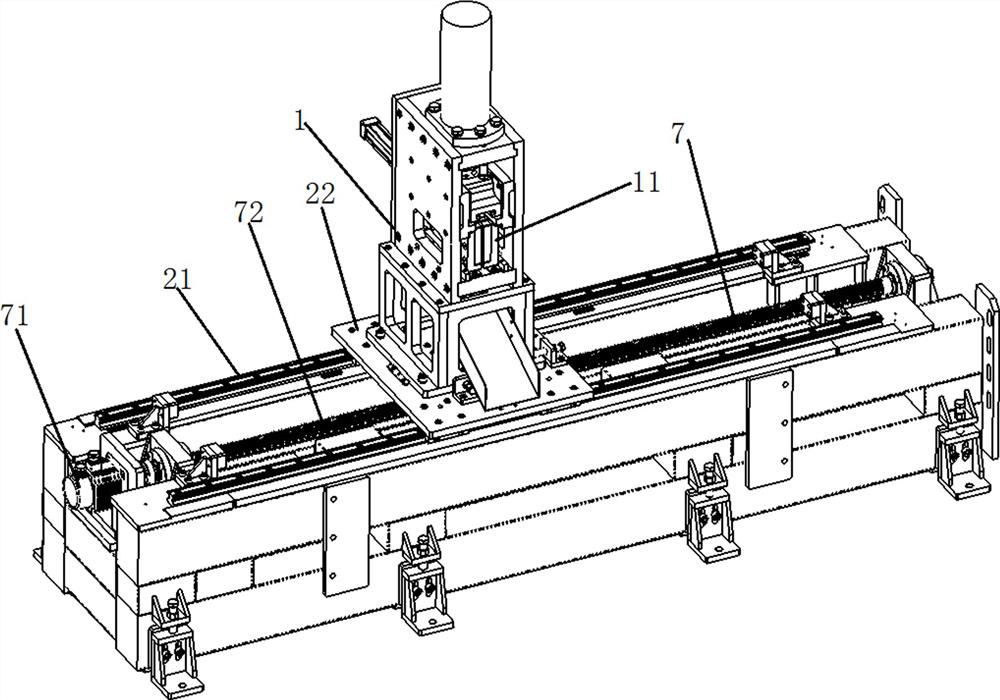

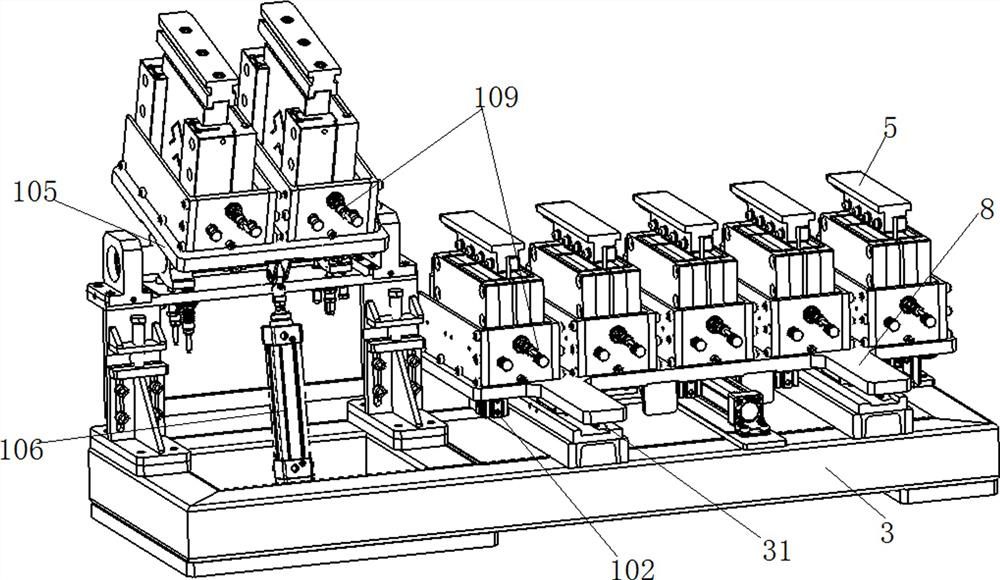

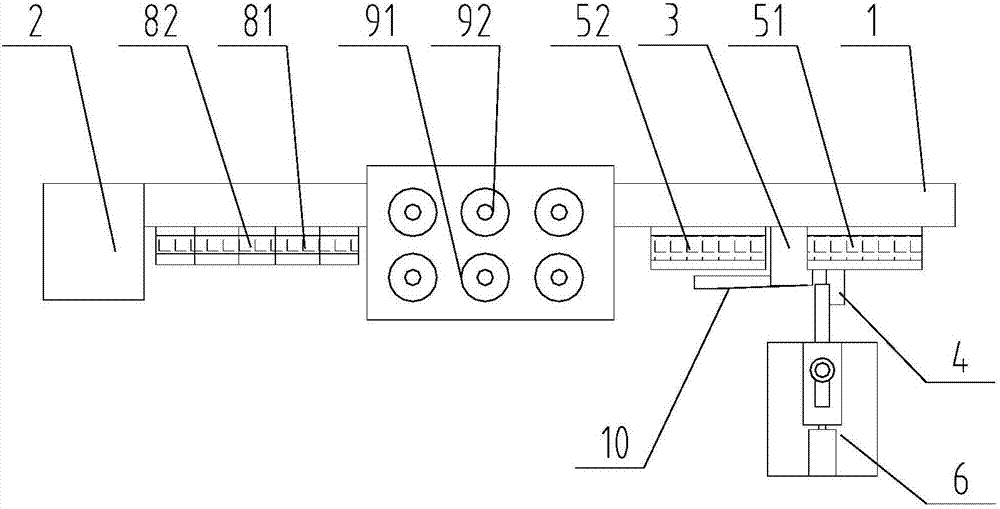

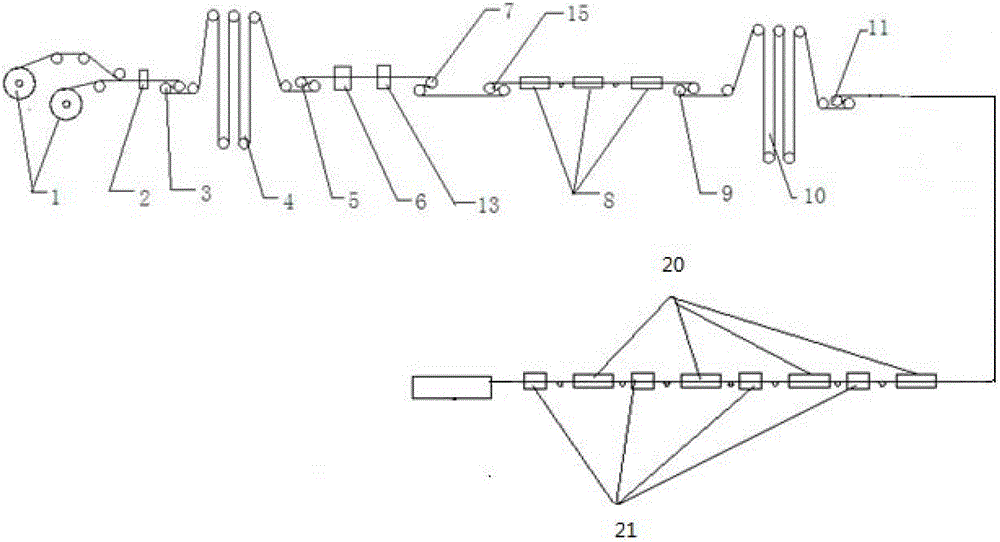

Profile forming production line

ActiveCN113021047AImprove replacement efficiencyImprove stabilityShearing machinesPositioning apparatusEngineeringShear forming

The invention relates to a profile forming production line. The profile forming production line comprises a profile cold bending forming device, a shaping device and a forming shear tool changing device. In the profile forming process, the devices move from back to front, the forming shear tool changing device comprises a forming tool shear frame and a forming tool module driving mechanism, and the forming tool shear frame reciprocates forwards and backwards and is arranged on a tool shear frame moving platform. Tool magazines on a tool magazine platform are arranged in the moving direction of the forming tool shear frame. A tool magazine driving mechanism is used for driving the tool magazines to move so that tool magazine openings can be close to and opposite to forming tool module openings. According to the profile forming production line, the tool magazines are movably arranged on the tool magazine platform of the forming shear tool changing device, all the tool magazines are arranged in the moving direction of the forming tool shear frame, after the forming tool shear frame moves to the target tool magazine, the tool magazine driving mechanism can drive the corresponding tool magazine to move so that the corresponding tool magazine opening can be close to and opposite to the corresponding forming tool module opening, and then replacement of forming tool modules can be accomplished, and the replacement efficiency of the forming shear forming tool modules is improved.

Owner:XINXIANG TIANFENG MACHINERY MFG

Production process of brass strip low in earing ratio

InactiveCN109852825AIncrease the number of processing passesEliminate side ear trappingIngot castingShear forming

The invention discloses a production process of a brass strip low in earing ratio, and relates to the technical field of brass material processing. The production process comprises the following processing steps of ingot casting heating, hot rolling, cold rolling, annealing, cleaning, finish rolling and shear forming. According to the production process, the sintering temperature of a stepping furnace is reduced, the hot rolling and cold rolling processing pass is increased, and the edge earing phenomenon during cogging of a blooming mill can be completely eradicated; and the method is simple,and the product quality is high.

Owner:JIANGXI KAIAN INTELLIGENT LTD BY SHARE CO LTD

PA6/PP blends low temperature pressure inducement flowing shaping method

The invention relates to a low temperature pressure inducing flow forming method of a PA6 / PP mixed material, comprising the steps of (1) the PA6 / PP mixed material sample bars are injected and formed by a double screw under the injection condition of 170 to 260 DEG C; (2) the prepared PA6 / PP mixed material sample bars are cut into shape; (3) the cut mixed material are arranged in the middle of the chamber of a die, and the low temperature pressure inducing flow appears under the condition of temperature of 20 to 150 DEG C, time of 5 to 150 minutes and pressure of 3 to 10.5 MPa. The method has the advantages of simple forming process, low energy loss, and having wide application prospect in the process of PA6 / PP mixed material.

Owner:DONGHUA UNIV

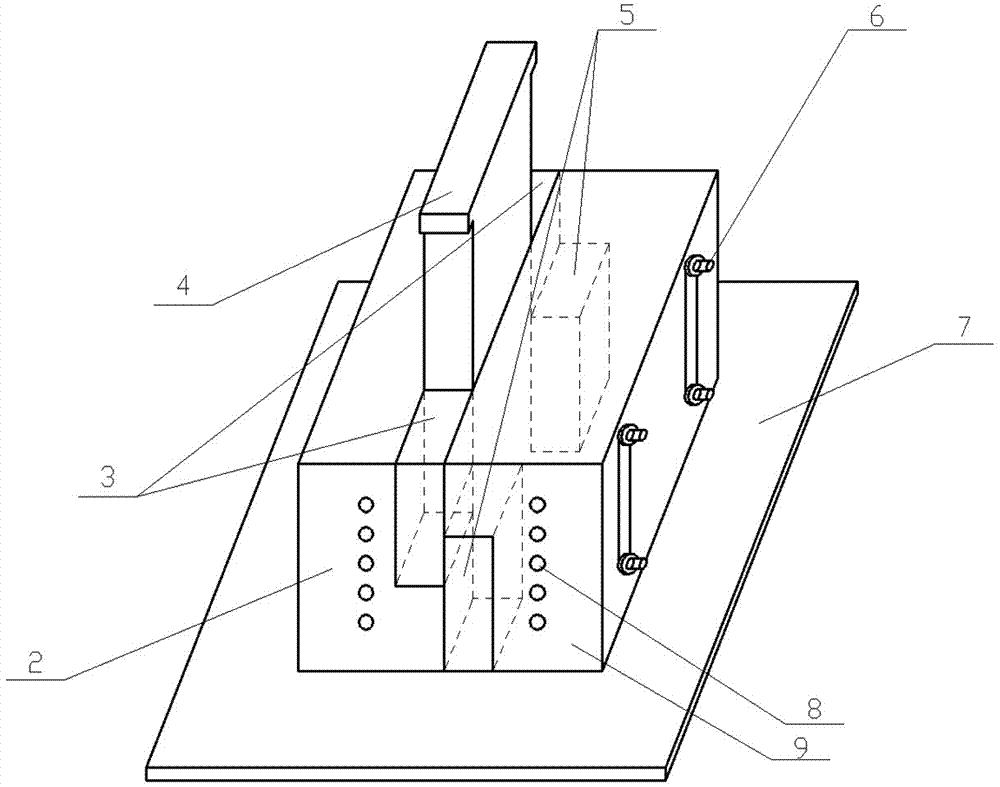

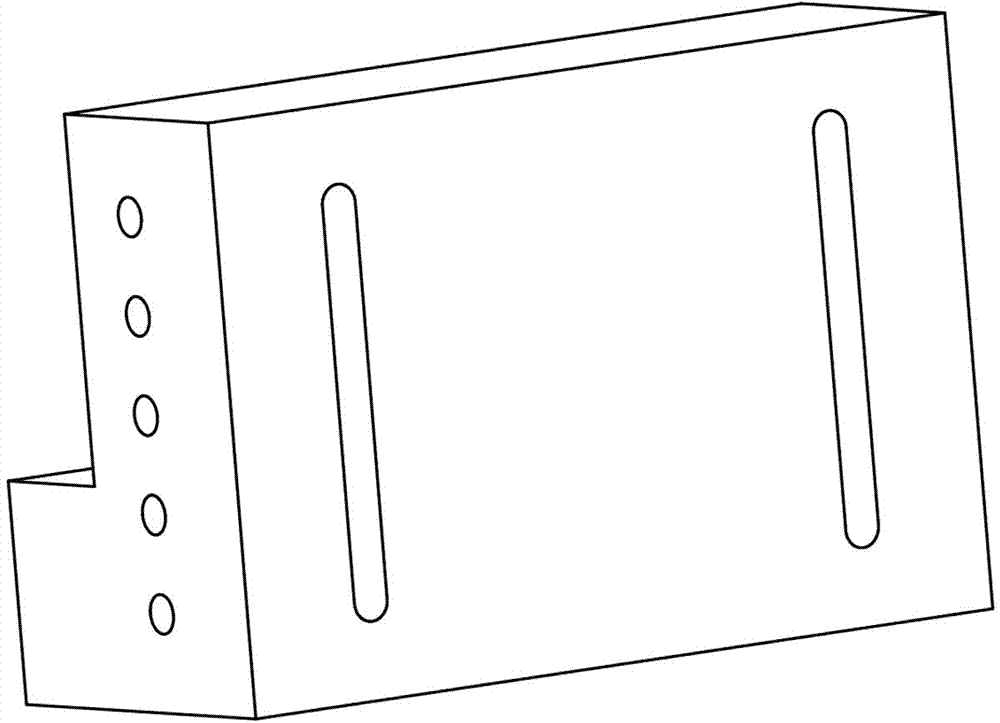

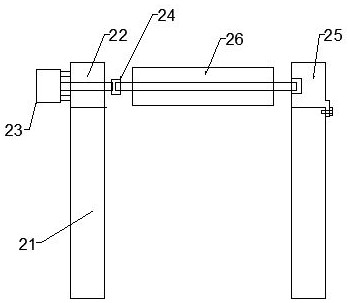

Isometric, continuous and repeated shearing type metal forming method and device

ActiveCN107030236AUniform shear deformationImprove mechanical propertiesForging/hammering/pressing machinesEngineeringSlide plate

The invention discloses an isometric, continuous and repeated shearing type metal forming method and device. The device comprises a slide plate, an upper rotating plate, a lower rotating plate, a top plate, a connecting block, an opening-closing plate, a fixed plate, a bottom plate, a base, a heating device, a distance bolt, a connecting rod and a fork rod, wherein the upper rotating plate and the lower rotating plate are correspondingly hinged with the bottom plate and the top plate; the slide plate slides in guide chutes of the opening-closing plate and the fixed plate; the opening-closing plate is connected with the fixed plate; the connecting block is welded on the slide plate; the connecting rod passes through the connecting block and the fork rod; the fork rod is connected with a press, and the press is able to drive the slide plate to move up and down through the fork rod and the connecting rod so as to realize the rotating of the upper rotating plate and the lower rotating plate; parallelepiped-shaped mold cavities composed of the slide plate, the upper rotating plate, the lower rotating plate, the opening-closing plate, the fixed plate and the bottom plate remain unchanged in size, and the shape continuously changes, thus realizing the isometric, continuous, repeated and uniform shearing deforming of a metal blank. The method and the device are convenient to operate, low in cost and high in efficiency.

Owner:HUNAN UNIV OF SCI & TECH

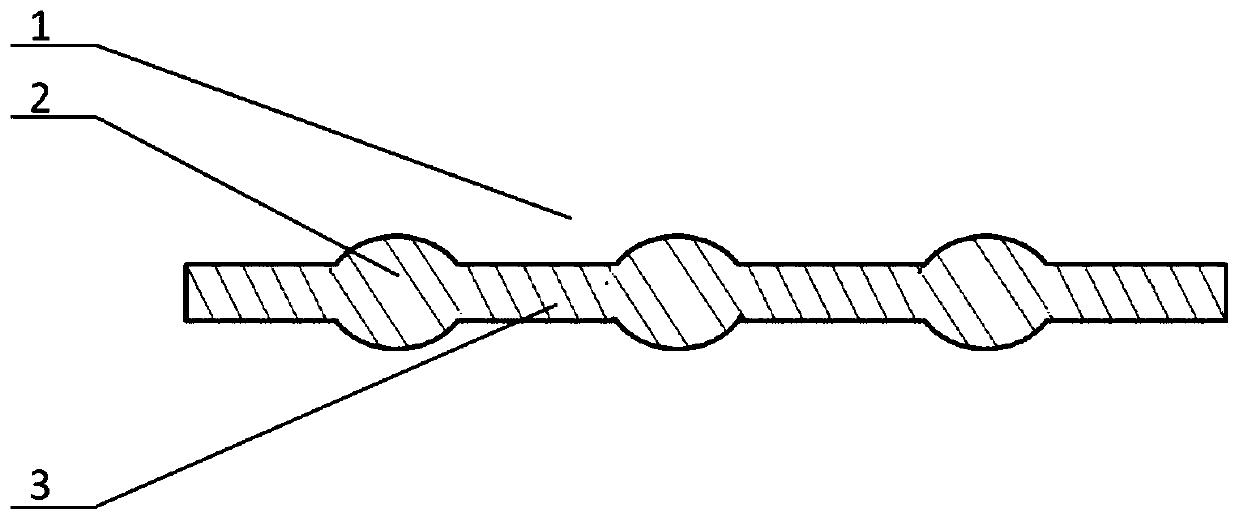

Manufacturing method of partial circular convex steel plate strip

The invention discloses a manufacturing method of a partial circular convex steel plate strip. The partial circular convex steel plate strip can be obtained after being mainly subjected to the steps of slab reinforcement, partial circle projection, performing texturing treatment and shearing forming. According to the manufacturing method of the partial circular convex steel plate strip, the manufacturing process is simple, production efficiency is high, and the partial circular convex steel strip has better concrete binding force compared with an existing steel bar structure; and safety and stability of a building or the prefabricated plate structure are improved, and a good market prospect is achieved.

Owner:施仙增

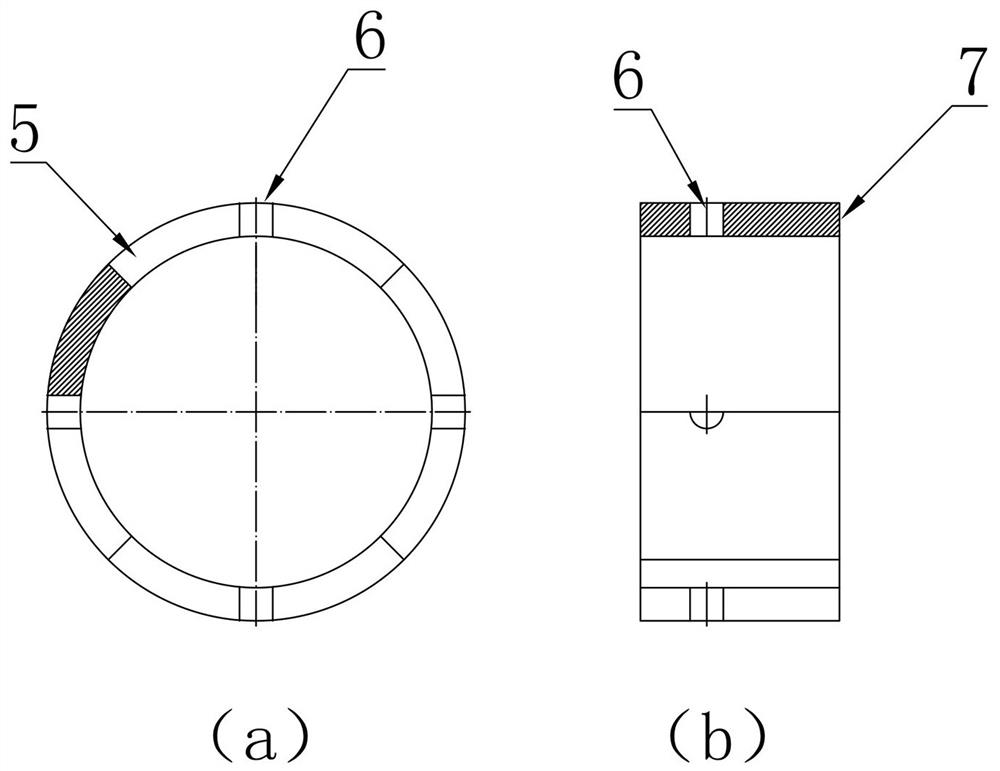

A retaining ring processing and forming equipment

ActiveCN106239157BAchieve continuous bendingHigh forming precisionOther manufacturing equipments/toolsShear formingPulp and paper industry

The invention discloses a check ring processing forming device. A first extrusion roller is horizontally arranged, a sizing roller and the first extrusion roller are parallelly arranged, the sizing roller is located on one side of the first extrusion roller, the sizing roller and the first extrusion roller are arranged at intervals, and an extrusion channel is formed between the sizing roller and the first extrusion roller. A second extrusion roller is parallel to the first extrusion roller and is located on one side of the extrusion channel close to the first extrusion roller and located on one side of the first extrusion roller close to the feeding end of the extrusion channel, a limiting column is located below the first extrusion roller and located on one side of the extrusion channel close to the sizing roller, and the limiting column is located on one side of the sizing roller far away from the feeding end of the extrusion channel. Through the check ring processing forming device undergoing optimized design, a check ring can be subjected to continuous bending and shearing forming, the forming precision is high, and the processing automation is greatly improved.

Owner:ANHUI NINGGUO DONGBO FASTENER

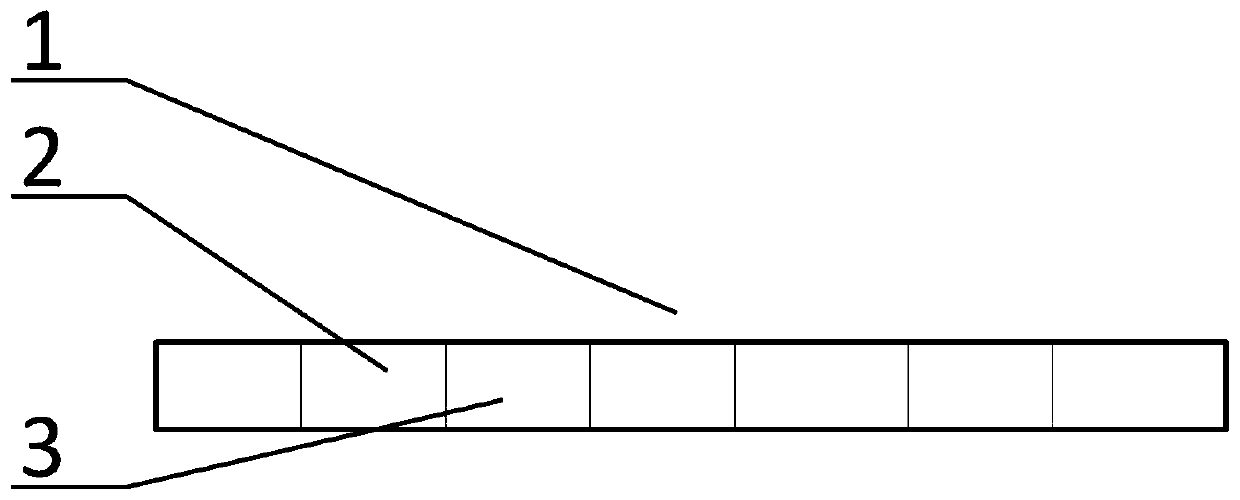

Production line of graph code steel plate integrating spray coating and screen printing

InactiveCN103158337BAchieve levelingReduce printing difficultyScreen printersScreen printingProduction line

The invention provides a production line of a graph code steel plate integrating spray coating and screen printing. The production line comprises a screen printing section which is provided with a screen printing component. The screen printing component comprises a printing table which is used for containing a steel belt, wherein the steel belt is processed by cold rolling and / or hot rolling and shear forming. A leveling device is arranged on the bottom portion of the printing table and used for leveling the surface of the steel belt before the surface of the steel belt is printed by the screen printing section. Due to the facts that the leveling device is arranged on the bottom portion of the printing table, the leveling device can level the steel belt which is processed by cold rolling and / or hot rolling and shear forming, a scrapper can conduct printing ink transfer print under the action of uniform force in the screen printing section, printing difficulty is reduced, and therefore the possibility that the screen printing can be applied to production of the graph code steel plate is achieved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

A method of manufacturing partially rounded convex steel strips

The invention discloses a manufacturing method of a partial circular convex steel plate strip. The partial circular convex steel plate strip can be obtained after being mainly subjected to the steps of slab reinforcement, partial circle projection, performing texturing treatment and shearing forming. According to the manufacturing method of the partial circular convex steel plate strip, the manufacturing process is simple, production efficiency is high, and the partial circular convex steel strip has better concrete binding force compared with an existing steel bar structure; and safety and stability of a building or the prefabricated plate structure are improved, and a good market prospect is achieved.

Owner:施仙增

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com