Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Semi continuous fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-continuous fermentation process. The invention relates to a method for the biosynthesis of biomolecules by microorganisms and to a fermentation vessel which can be used advantageously in the inventive method. Numerous pharmaceutical (intermediate) products are currently produced by the biochemical route.

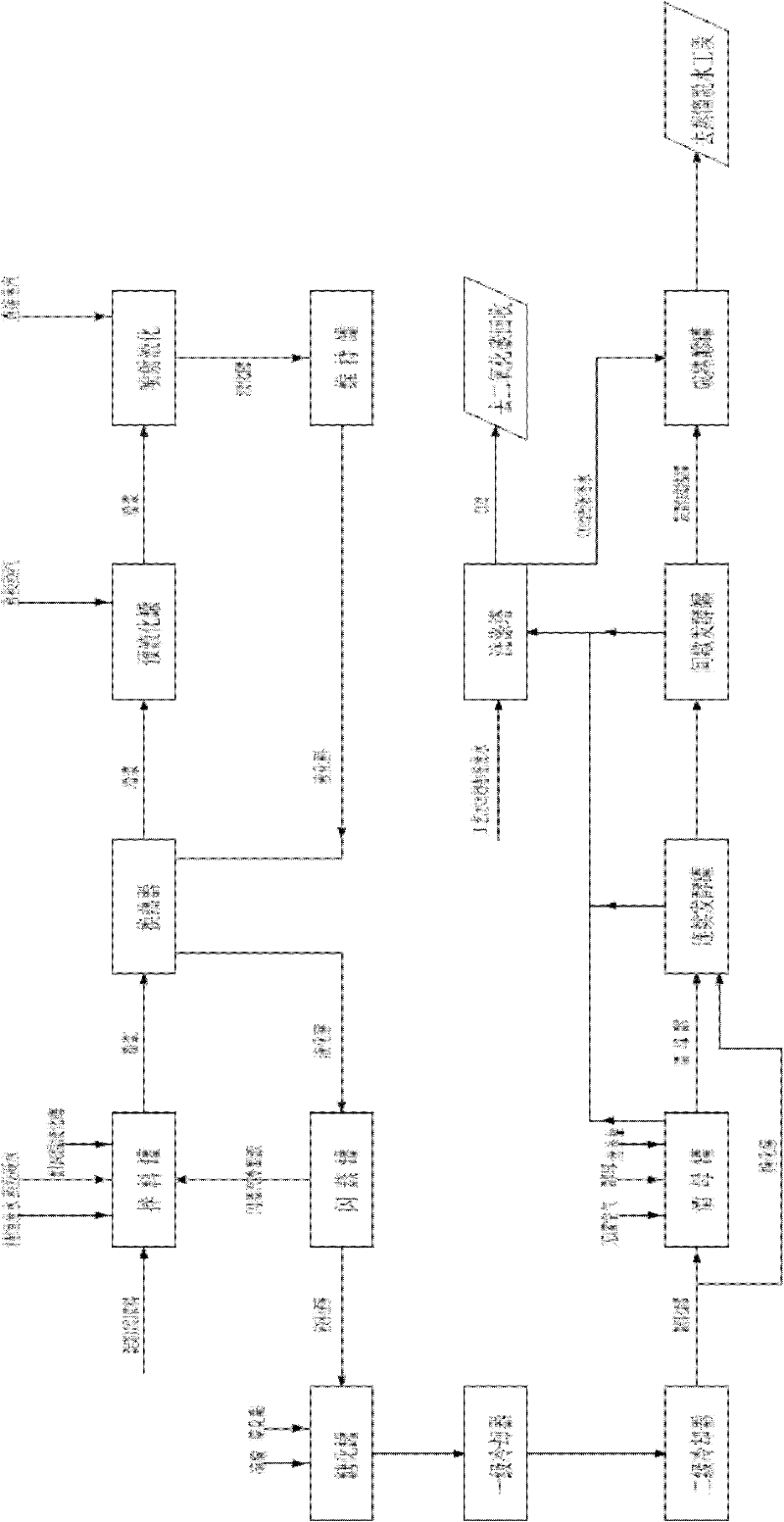

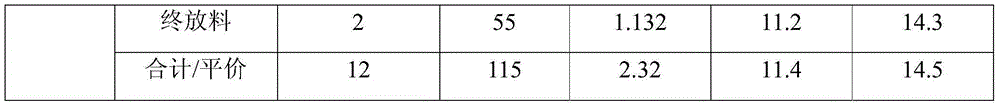

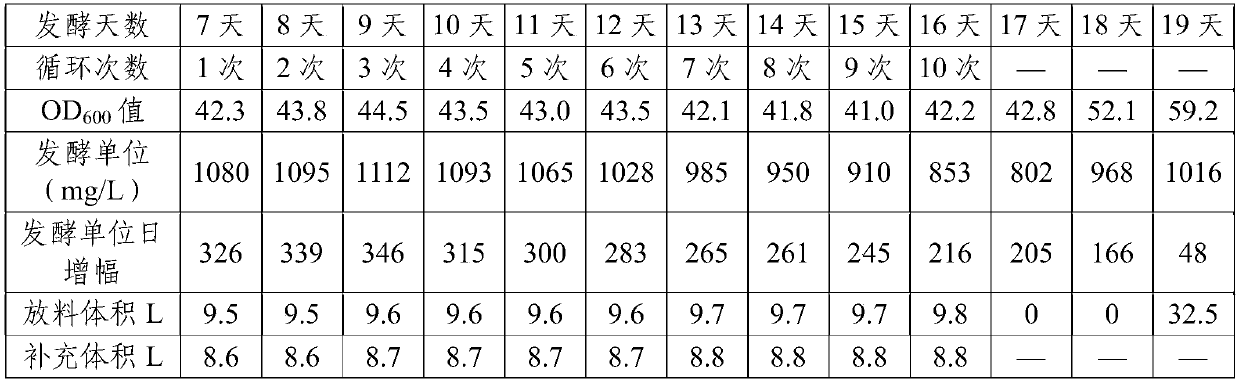

Method for producing amber acid by continuous fermentation or semi-continuous fermentation

InactiveCN101302546AIncrease production intensityLess investmentBacteriaMicroorganism based processesBatch fermentationSweet sorghum

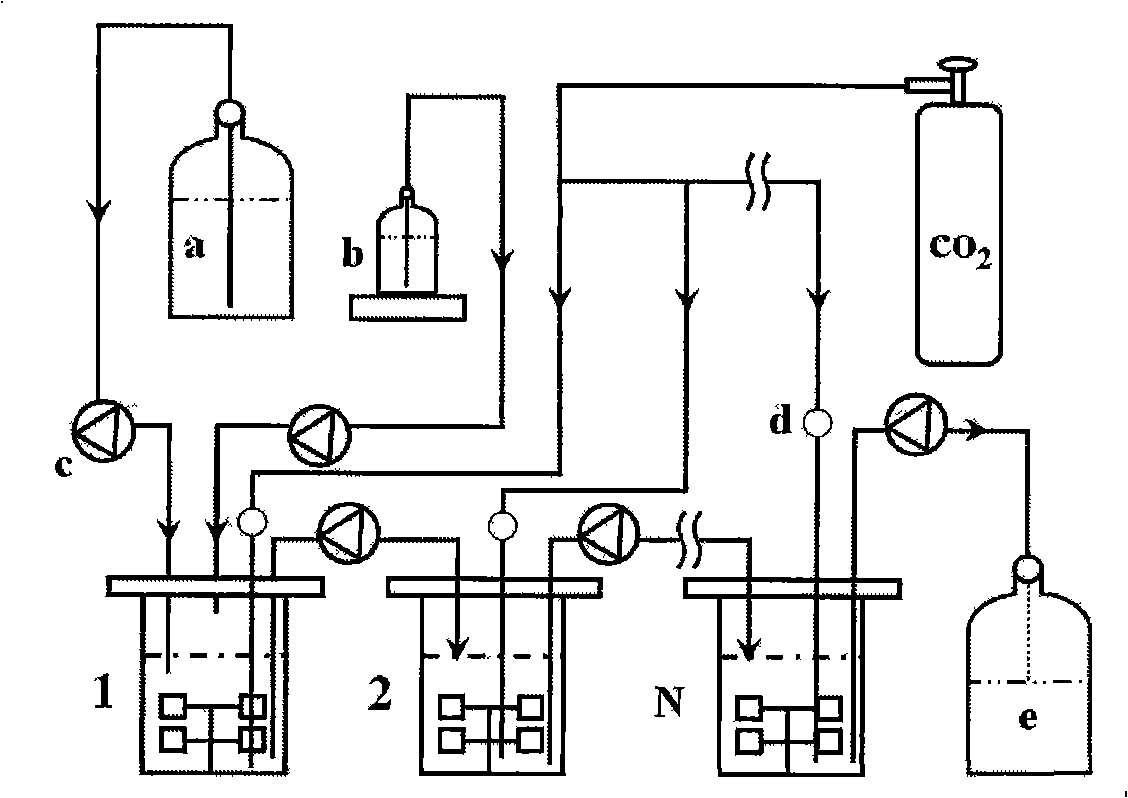

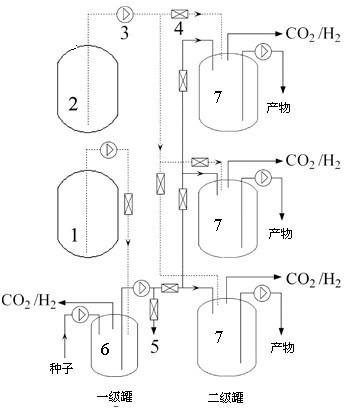

The invention discloses a method for producing butane diacid through continuous fermentation or semi-continuous fermentation, which belongs to the bioengineering technical field. The invention provides application of Actinobacillus succinogenes in the method for continuously or semi-continuously preparing the butane diacid by utilizing carbohydrate raw materials such as cane molasses, corn starch syrup, Jerusalem artichoke hydrolysis syrup, sweet sorghum straw syrup, and lignocellulose hydrolysis syrup and so on. The method utilizes multi-step continuous fermentation or two-step semi-continuous fermentation, which can improve germ concentration and cell activity and can obtain high butane diacid output and high butane diacid production intensity; the method is easy to realize automatic and continuous operation; compared with batch fermentation, the method can save non-fermentation time such as repeated tank cleaning, sterilization and so on, so the production efficiency can be greatly improved; the semi-continuous fermentation for producing the butane diacid is easier to control fermentation parameters than the continuous fermentation, has high sugar utilization rate, target product yield and target product output, has simple and easy equipment and operation, and is suitable for industrialized production.

Owner:JIANGNAN UNIV

A kind of clean production method of starch-based fuel ethanol

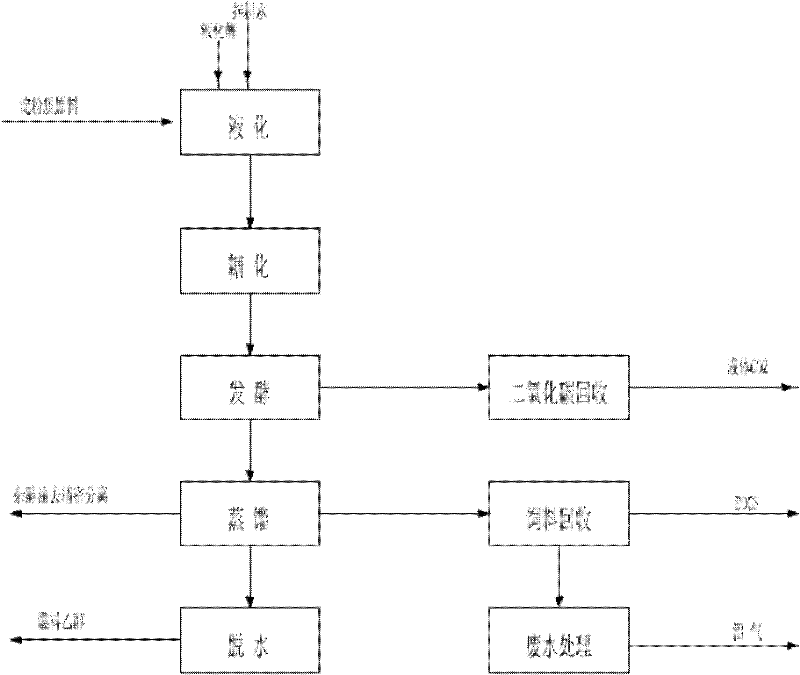

ActiveCN102286544AIncrease added valueFood processingClimate change adaptationDistillationEthanol fuel

The invention relates to a clean production method of starch-based fuel ethanol, which includes the following steps: (1) liquefaction, (2) saccharification, (3) fermentation, (4) distillation and dehydration, and also includes comprehensive treatment of waste residues and recycling of by-products section. Among them, the liquefaction section adopts a low-pressure ejector continuous cooking process; the fermentation section adopts a semi-continuous fermentation system to keep the fermented mash in a flowing state and promote the uniform contact between yeast and mash; The combination tower with wine vapor heating on the top of the tower, the thermal coupling scheme of the crude distillation tower with wine vapor heating on the top of the combined tower, the obtained anhydrous ethanol is mixed to obtain denatured fuel ethanol, the quality meets the national standard GB18350-2001, and passed The waste residue comprehensive treatment and by-product recycling section recycles waste residue and useful substances in waste gas. In this method, the heat exchange network and water network of each production section are reasonably matched, and the goal of clean production with low material consumption and energy consumption and full resource utilization is realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +2

Microbial synthesis method of gamma-linolenic acid oil

InactiveCN101445815AIncrease productivityLow costMicroorganism based processesFermentationContinuous fermentationTO-18

A method for producing gamma-linolenic acid oil by microbial fermentation comprises the following process steps: culturing high-level expression strains of malic enzyme and gamma-linolenic acid synthetase; performing activation and amplification culture on original strains; then performing primary fermentation, secondary fermentation, third-stage fermentation and a fourth-stage fermentation; dehydrating, drying and extracting the oil. The method has the advantages of good strains, high yield, high dry bacteria yield up to 10-30%, good oil yield up to 35-55%, satisfactory gamma-linolenic acid yield up to 18-29% and low production cost. The method can help reduce the cost of raw materials for the production process by 50-70%. The semi-continuous fermentation or continuous fermentation process is advanced, scientific and mature, can be used for large scale industrialized production, and achieve 50-500t fourth-stage fermentation level.

Owner:北京有容建业科技发展有限责任公司

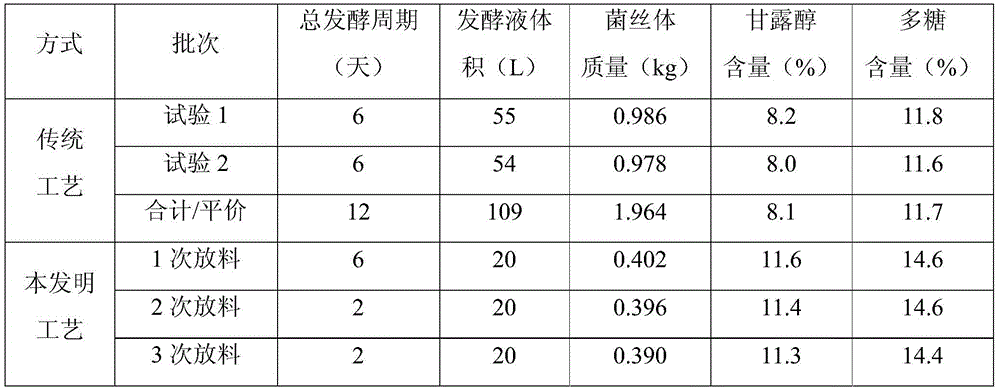

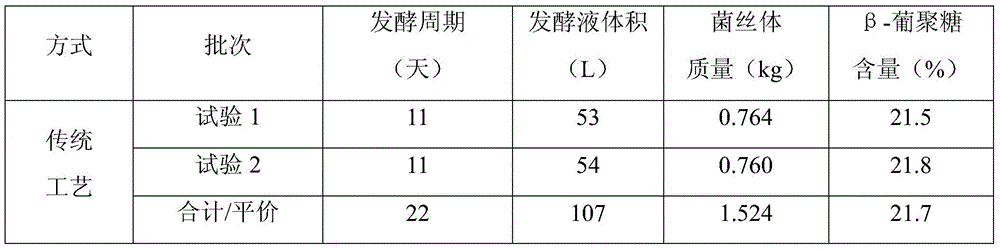

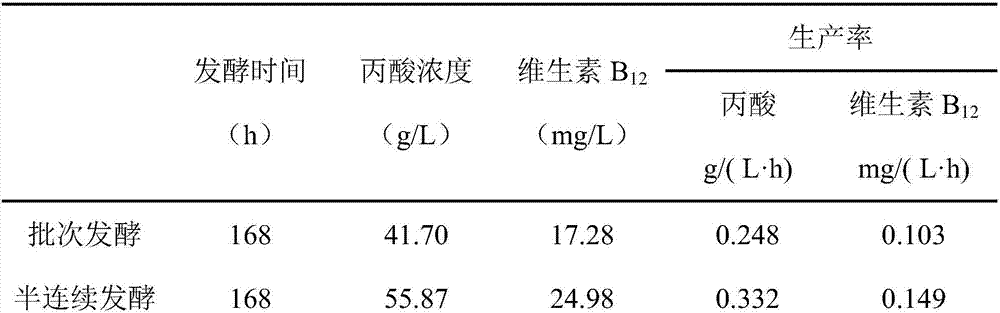

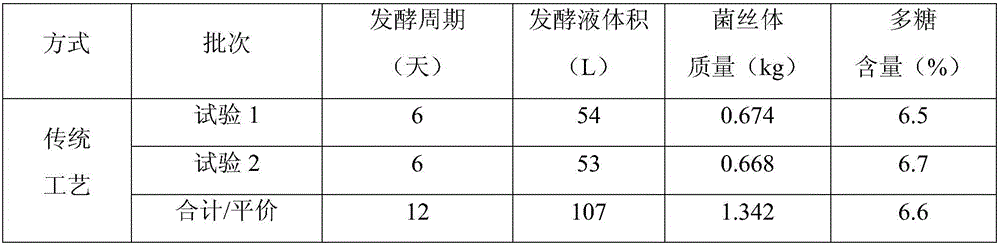

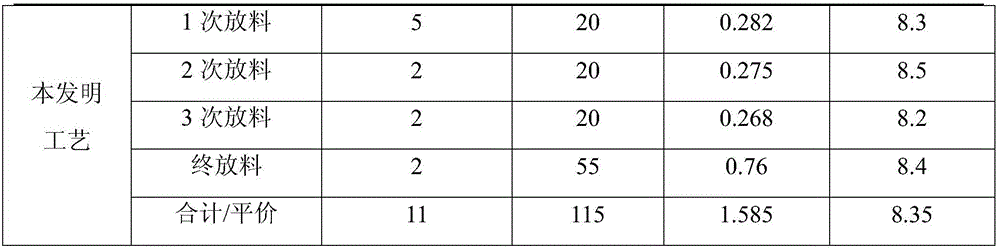

Method for producing cordycepin through semi-continuous liquid fermentation of cordyceps militaris

InactiveCN102965416AEasy to separateIncrease fermentation intensityChemical recyclingFermentationBiotechnologyBatch fermentation

The invention discloses a method for producing cordycepin through semi-continuous liquid fermentation of cordyceps militaris, and the method comprises the following concrete operating steps of: (1) putting hyphae of the Cordyceps militaris on a PDA (Potato Dextrose Agar) solid culture medium and activating to generate a bacterial lawn with a plenty of dense mycelia; (2) putting the bacterial lawn on a seed culture medium, carrying out shake cultivation, and forming a plenty of mycelium pellets after 5 days, thereby obtaining seed liquid; (3) transferring the seed liquid into a seed liquid fermentation tank to carry out expanding culture; (4) transferring the seed liquid after being subjected into the expanding culture in a 500L tank to carry out first-batch fermentation; and (5) carrying out semi-continuous fermentation in 10 batches in the 500L tank under the same conditions. In the fermentation process, a method of adjusting the culture medium composition and the fermentation conditions is adopted to control the cordyceps militaris to form the mycelium pellets with regular shape and uniform size and the average diameter of the mycelium pellets is 3-5mm, so that the separation of fermentation broth and thalli is easy; the carbon and nitrogen source and other inorganic salts needed in the growth of mycelium pellets are saved by utilizing the repeated fermentation of the mycelium pellets of the cordyceps militaris, so that the cost is saved; and the fermentation cycle is shortened and the fermentation intensity is increased, so that the method is suitable for industrial production.

Owner:HEFEI UNIV OF TECH

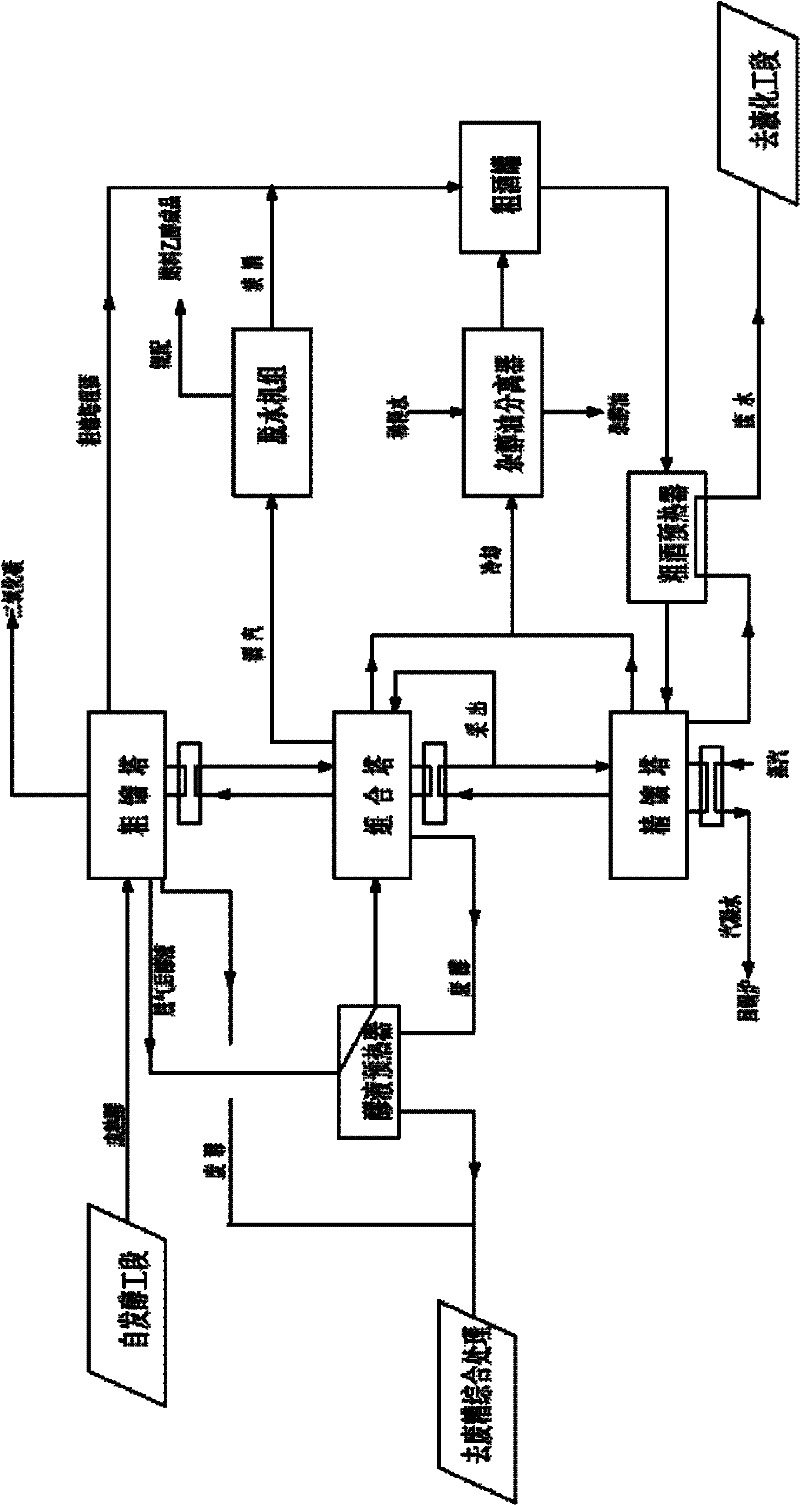

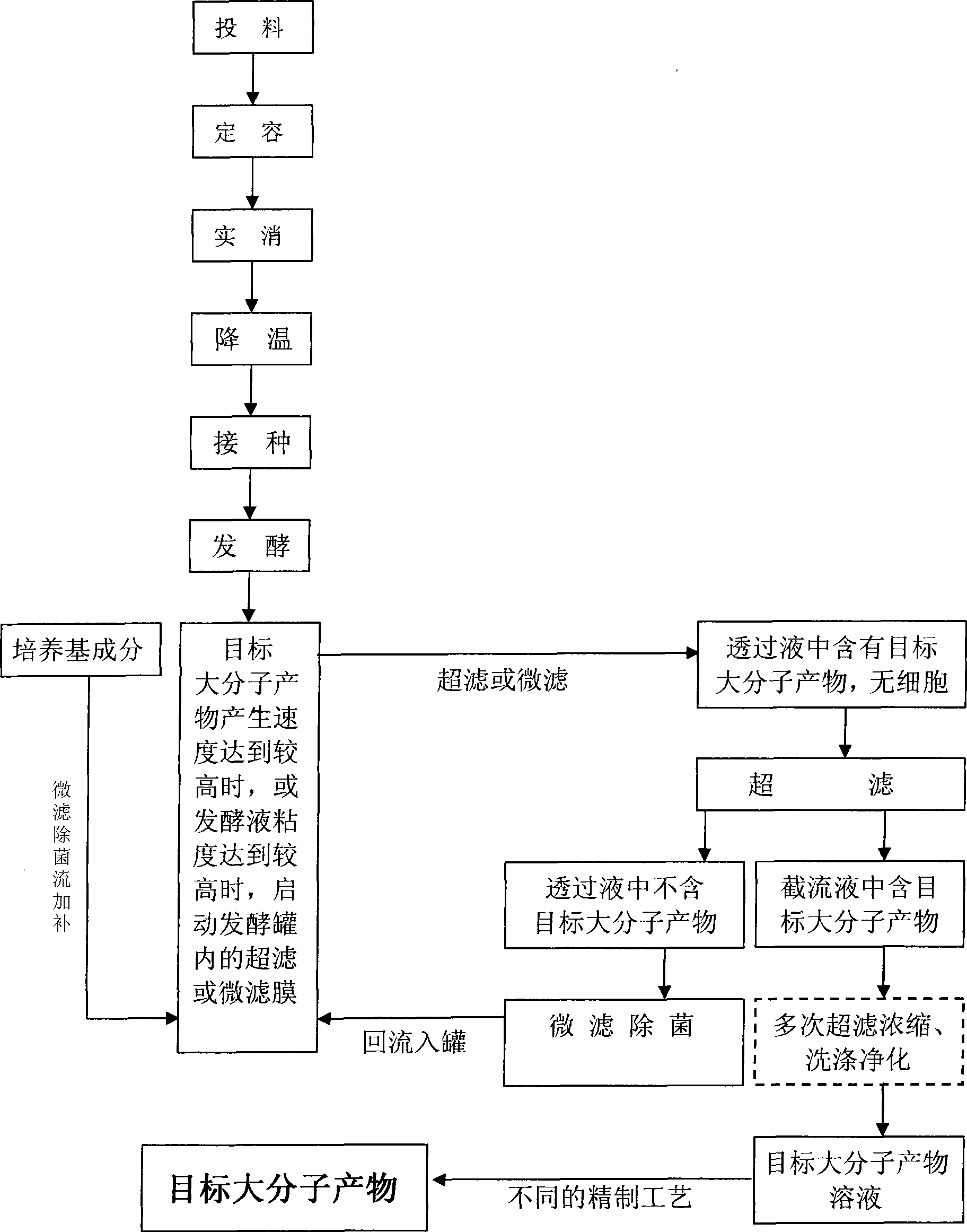

Method and device for continuous fermentation and separation coupling of biomacromolecule product

InactiveCN101503707AGuaranteed permeabilityReduce viscosityApparatus sterilizationFermentationBiological macromoleculePollution

The invention discloses a method and a device for the continuous fermentation and separate coupling of biomacromolecule products. By utilizing membrane in a fermentor and a membrane separation device outside the fermentor, while target biomacromolecules are fermented and produced, target products are continuously separated out from the fermentor through a membrane system so as to remove the product inhibition of fermentation and reduce the viscosity of fermentation broth. Continuous or semi-continuous fermentation and separate coupling are realized through one set or a plurality of sets of fed-batch devices so as to improve equipment utilization rate and raw-material conversion rate, reduce production cost and raise the continuous and automation level of a process. As fermentation and product extraction are hermetically carried out in a container and a pipeline, external pollution and interference are reduced. In addition, for certain extrazellular synthetic biomacromolecules, due to the separation control of the membrane on molecular weight, the molecular weight of macromolecules can be simultaneously controlled during fermentation so as to obtain products uniform in molecular weight.

Owner:姜泓芳

Method for preparing nuclease P1 through penicillium citrinum semi-continuous fermentation

ActiveCN104560913AShorten fermentation timeShorten the fermentation timeHydrolasesMicroorganism based processesContinuous fermentationBatch fermentation

The invention discloses a method for preparing nuclease P1 through penicillium citrinum semi-continuous fermentation. A fermentation culture medium containing vitamin B substances is used for preparing the nuclease P1 through the penicillium citrinum semi-continuous fermentation. According to the method disclosed by the invention, the single batch fermentation time is shortened from 60 hours to 20 hours, the enzyme activity is improved from 3000 U / mL to 6500 U / mL, and more than 12 batches can be continuously fermented. With the adoption of the method, the fermentation time can be obviously shortened, and the production cost can be reduced.

Owner:NANJING UNIV OF TECH +1

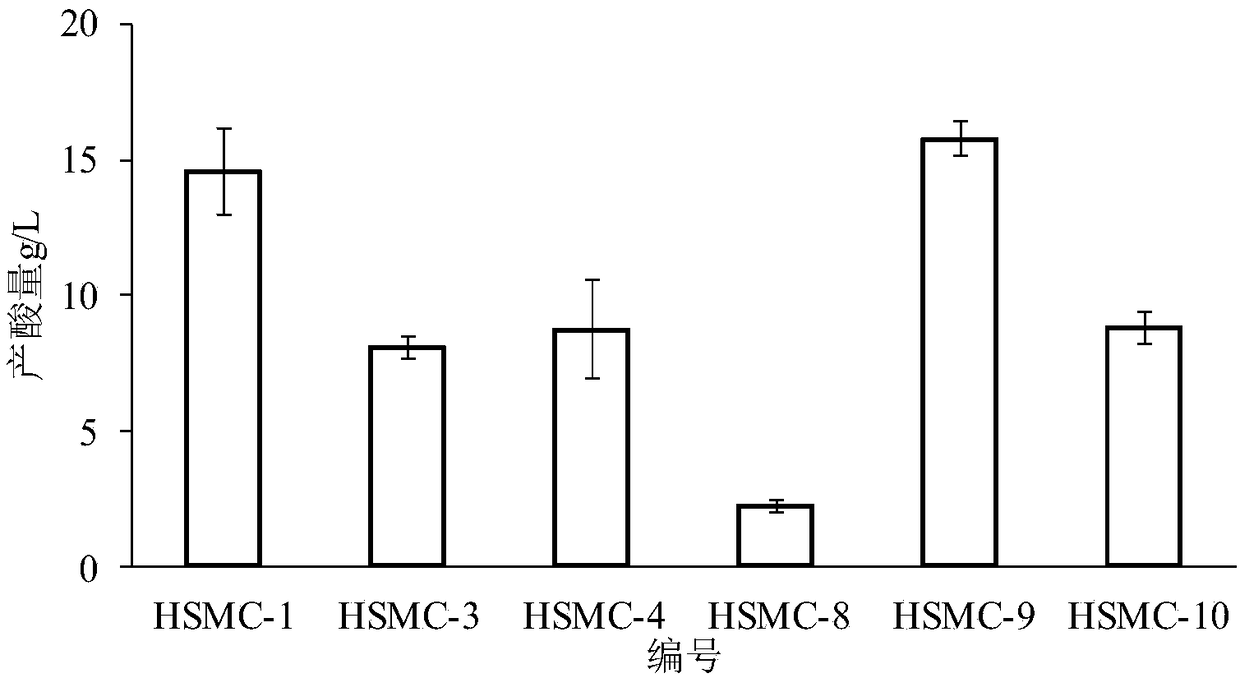

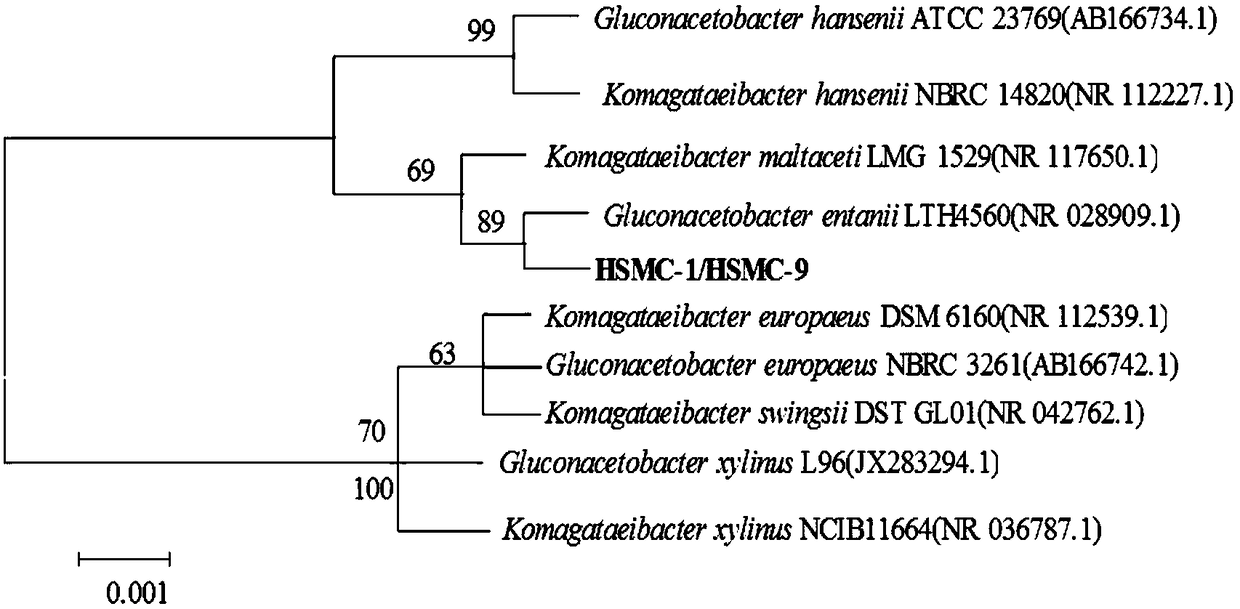

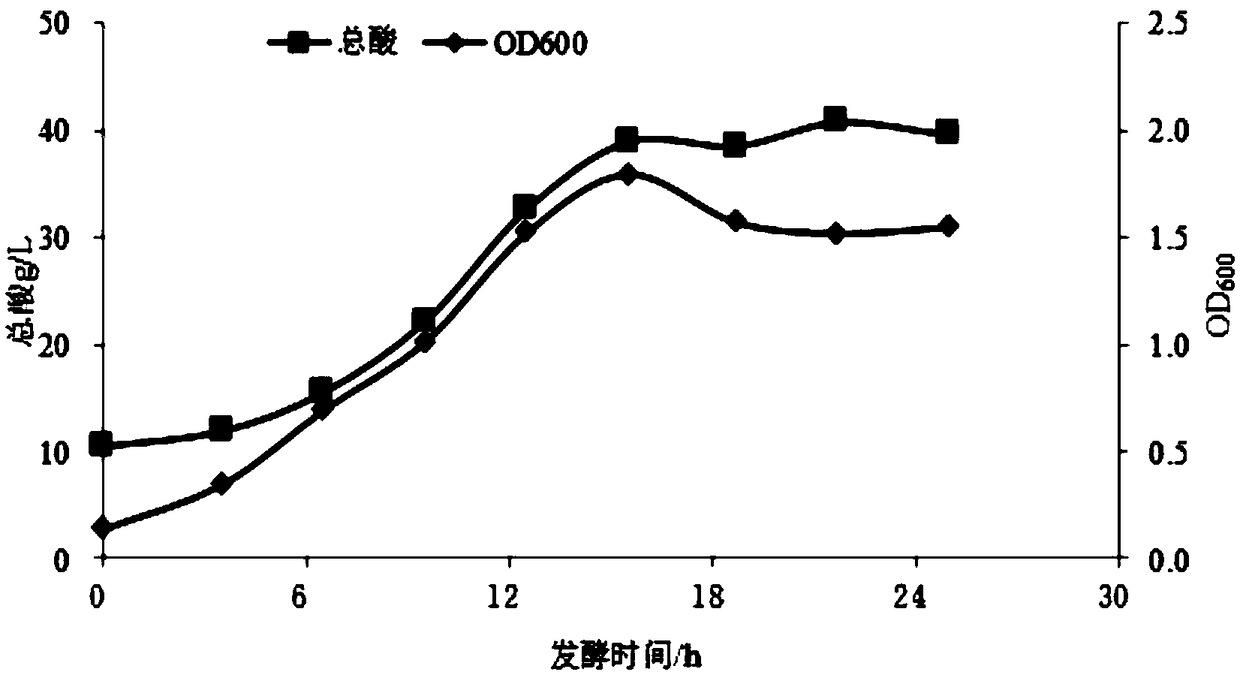

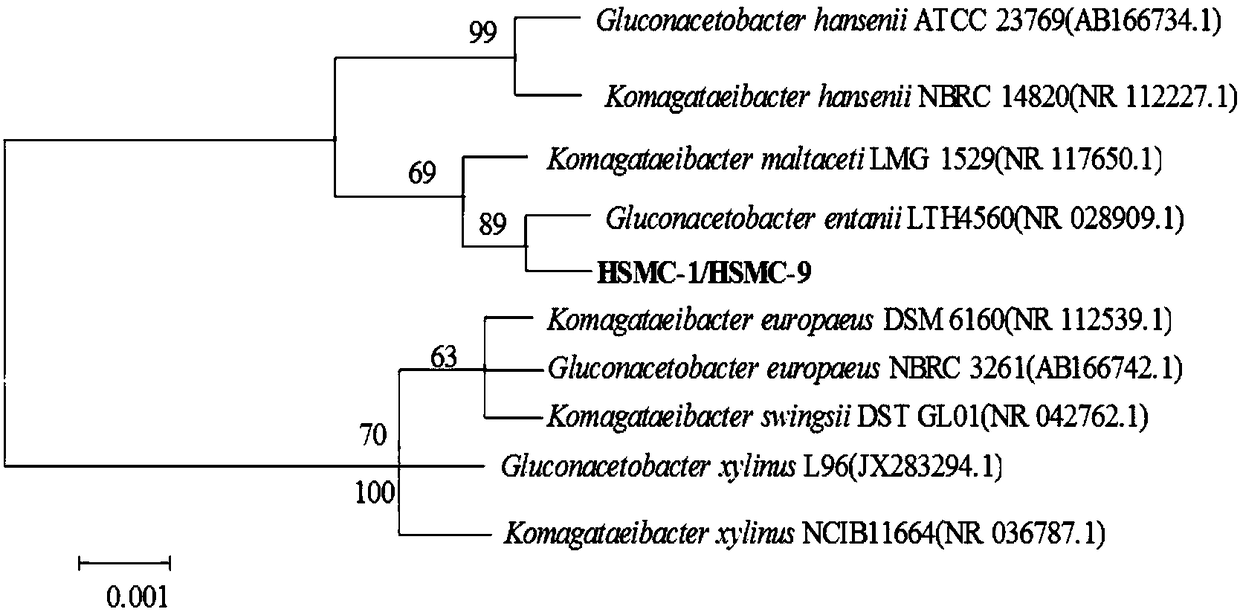

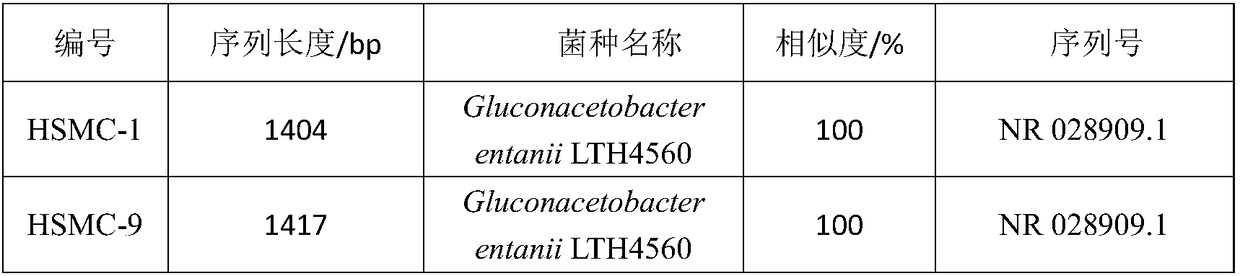

Acetic bacterium for highly yielding acid and application of acetic bacterium to brewing of high-acidity vinegar

ActiveCN108384737AIncrease acidityImprove efficiencyBacteriaMicroorganism based processesBiotechnologyAcetic acid

The invention discloses acetic bacterium for highly yielding acid and application of the acetic bacterium to brewing of high-acidity vinegar, and belongs to the technical field of biology. The aceticbacterium belongs to glucose acetobacter, and is preserved in China Center for Type Culture Collection, with the preservation number being CCTCC NO: M2017563. The bacterium strain serving as fermentedculture takes edible alcohol or fruit wine and food wine as a main material, a sectional feeding method is adopted to start a fermentation mode of fermentation in combination with semicontinuous fermentation and perform brewing to obtain the high-acidity vinegar, the total acid can reach 90-120g / L (calculated based on acetic acid), the maximum acid production rate reaches 8.19g / (L. h) which is greater than reported the acetic bacterium production rate (0.1-3.5g / *(L. h)). The bacterium strain can obviously improve the production efficiency when being used for performing acetic fermentation, and improve the enterprise benefit. The acetic bacterium and the fermentation technology are suitable for the production of high-acidity vinegar.

Owner:JIANGSU UNIV

Method of increasing gas production rate of sewage gas fermentation using xylanase

InactiveCN1757742AIncrease gas productionIncrease the amount of gasWaste based fuelFermentationMicroorganismContinuous fermentation

A fermenting method using microbes and enzyme for generating marsh gas with high gas output rate features that the xylanase-type hemi-cellulase is externally added to new marsh gas pool in the ratio of 0.55-0.5 IU / ml (material liquid) and for the normal marsh gas pool, the ratio of xylanase is increased to 5.0 IU / ml. Its advantages are high gas output rate and high content of methane in gas.

Owner:YUNNAN NORMAL UNIV

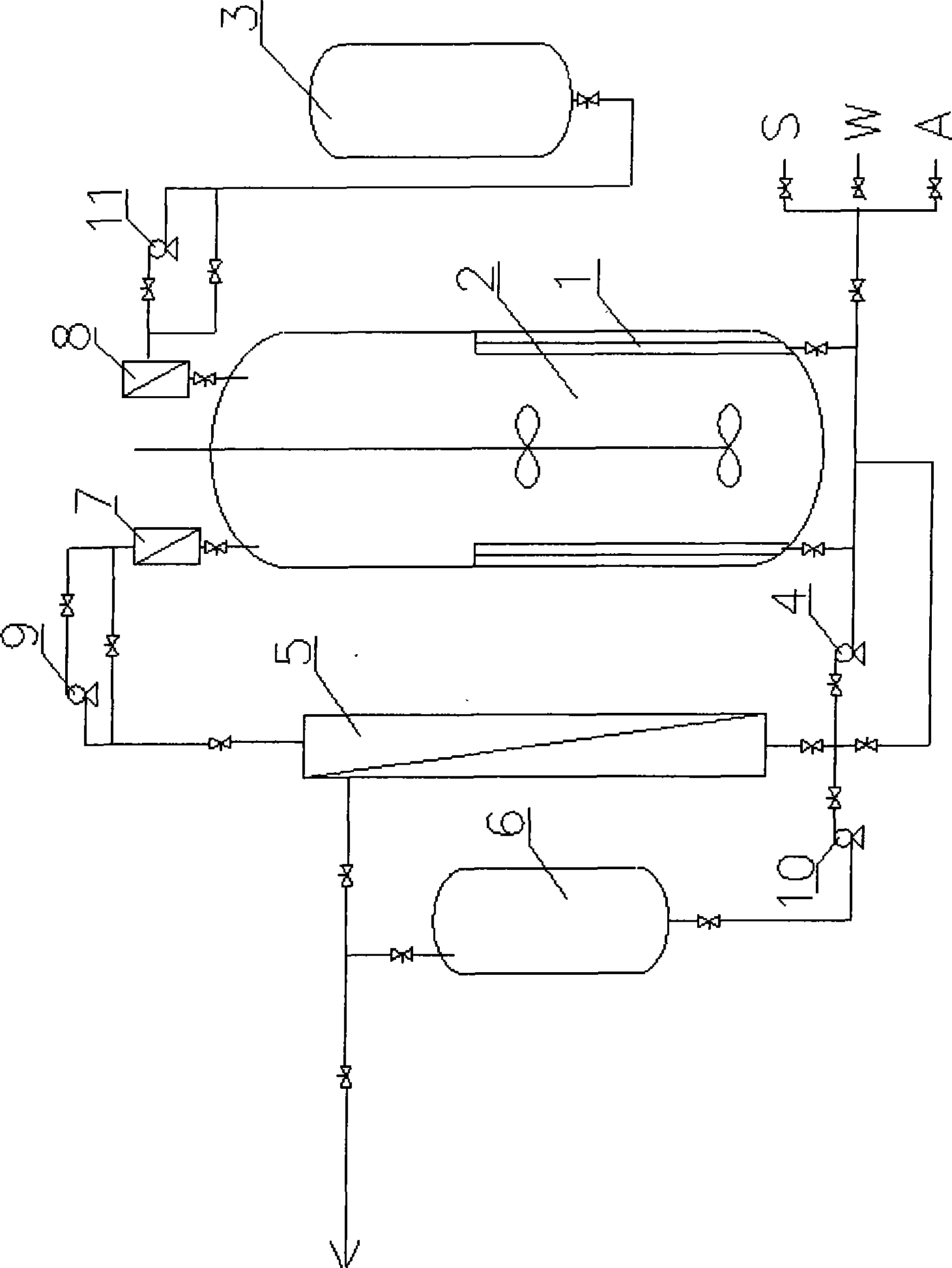

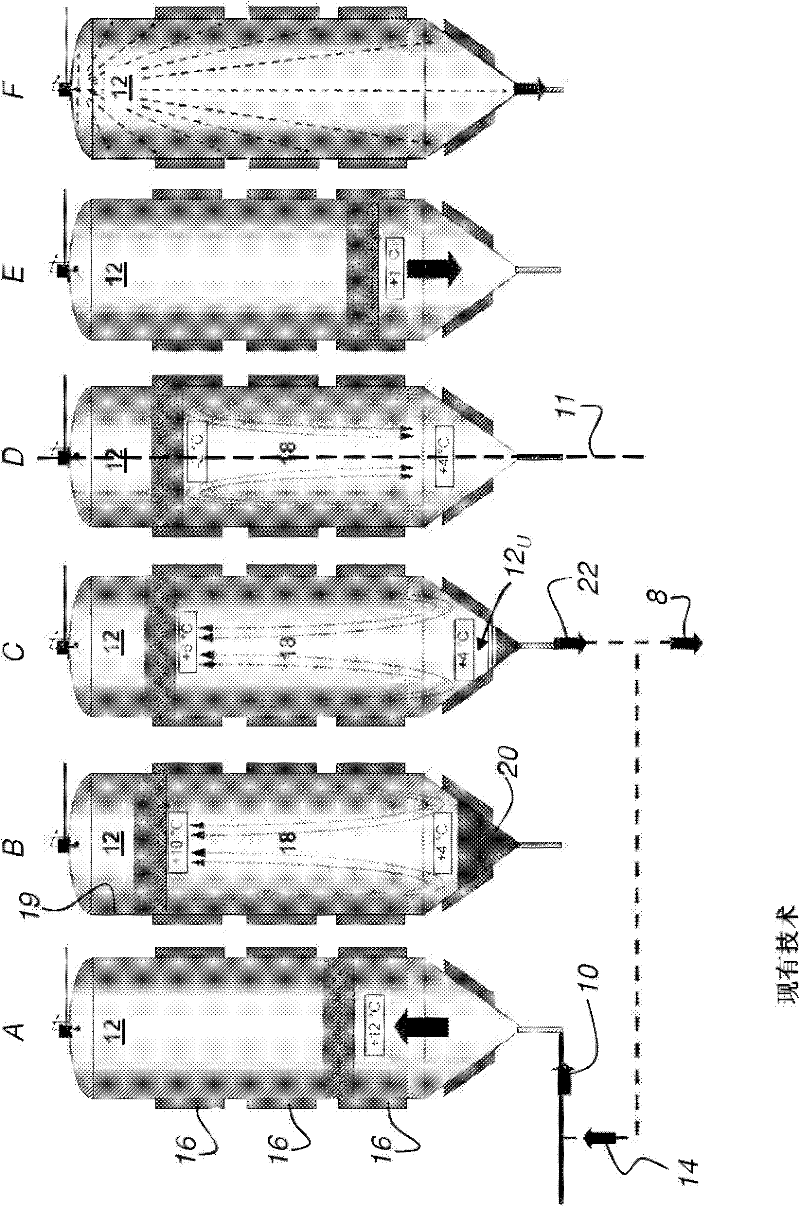

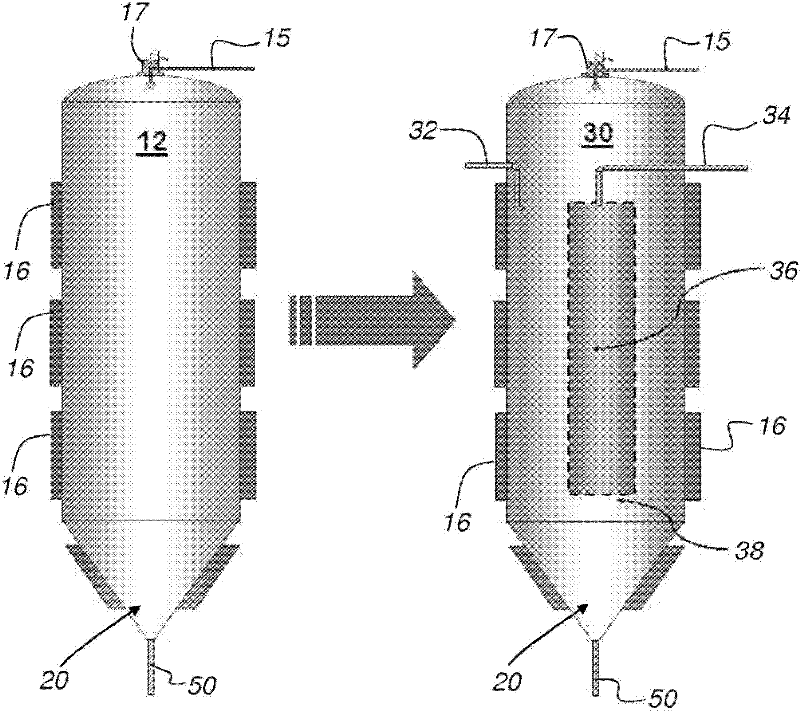

Tank for fermentation and method, device, and use for fermentation

InactiveCN102597209ABioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSemi continuous fermentation

The present invention relates to a tank (30) for fermentation, having at least one filling line (32) for feeding a fresh fluid and at least one discharge line (34) for discharging an at least partially fermented fluid. The tank (30) comprises a pipeline (36) associated with the filling line (32) or the discharge line (34) and guiding or calming the fluid present in the tank (30). The pipeline (36) comprises an open bottom side (38). The invention further relates to a device for fermentation from a multistage arrangement (54) of two or more tanks (301, 302, 303, 304, 305) coupled to each other in a cascade for fermentation. The invention further relates to a method for continuous or semi-continuous fermentation of a substrate and / or of fluids within at least one tank (301, 302, 303, 304, 305) for fermentation.

Owner:KRONES AG

Edible vinegar liquid-state fermentation nutrition salt formula and edible vinegar liquid-state semi-continuous fermentation method

ActiveCN104877886AIncrease productionShorten the fermentation cycleVinegar preparationContinuous fermentationPhosphate

The present invention relates to an edible vinegar liquid-state fermentation nutrition salt formula and an edible vinegar liquid-state semi-continuous fermentation method. According to the present invention, the components in the formula comprise 41.6% of glucose, 22.3% of yeast powder, 13.9% of ammonium sulfate, 11.1% of potassium dihydrogen phosphate, 8.3% of magnesium sulfate, and 2.8% of ferrous sulfate; the edible vinegar liquid fermentation adopts the semi-continuous fermentation method; and the nutrition salt formula of the present invention can meet the nutrition required during the edible vinegar liquid-state fermentation process, and the edible vinegar liquid-state semi-continuous fermentation method is combined so as to improve the actual wine vinegar conversion rate, shorten the fermentation cycle, reduce the production cost, and achieve the high economic benefit.

Owner:NANJING UNIV OF TECH

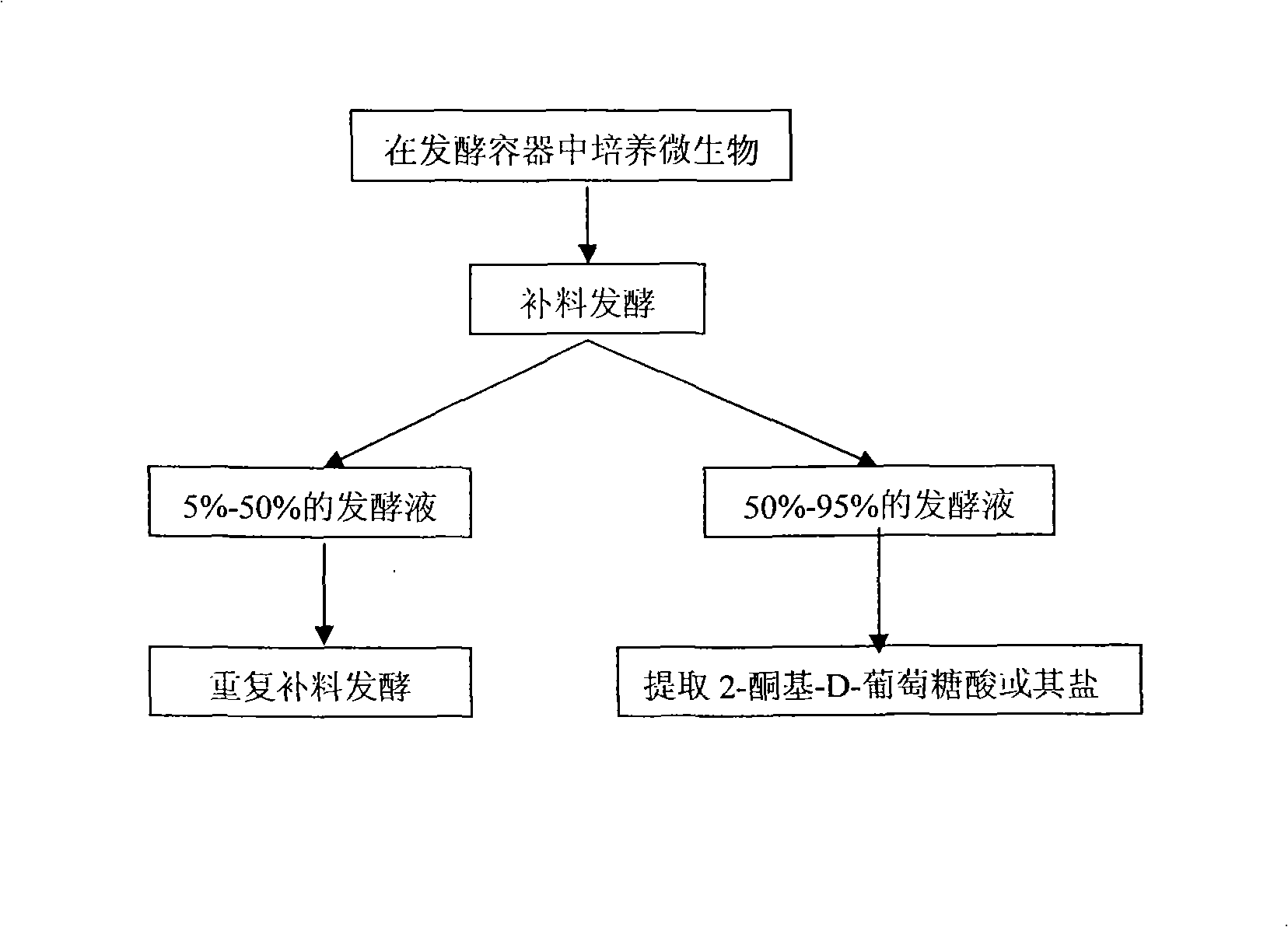

2-keto-d-gluconic acid semicontinuous fermentation process

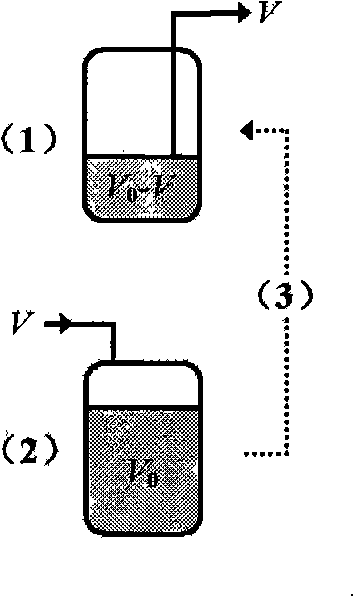

The invention relates to a method for fermentation production of 2-ketone-D-gluconic acid and salt thereof in high yield from glucose or amylum hydrolysis sugar. The method is realized through semicontinuous fermentation, namely the repeated feeding and batch fermentation technology. The method comprises the following steps: a microorganism with the capacity of converting the glucose into the 2-ketone-D-gluconic acid is cultured in a fermentation vessel; a culture medium containing the glucose is fed into the fermentation vessel until the culture medium is 60 to 85 percent of the volume of the fermentation vessel; after feeding is completed, 50 to 95 percent of fermentation broth is released from the fermentation vessel so as to recover the 2-ketone-D-gluconic acid and the salt thereof (the concentration of the glucose in the fermentation broth is lower than 2 grams per liter at the time); and residual fermentation broth in the fermentation vessel is taken as a seed to perform repeated feeding and batch fermentation.

Owner:江西省德兴市百勤异VC钠有限公司 +2

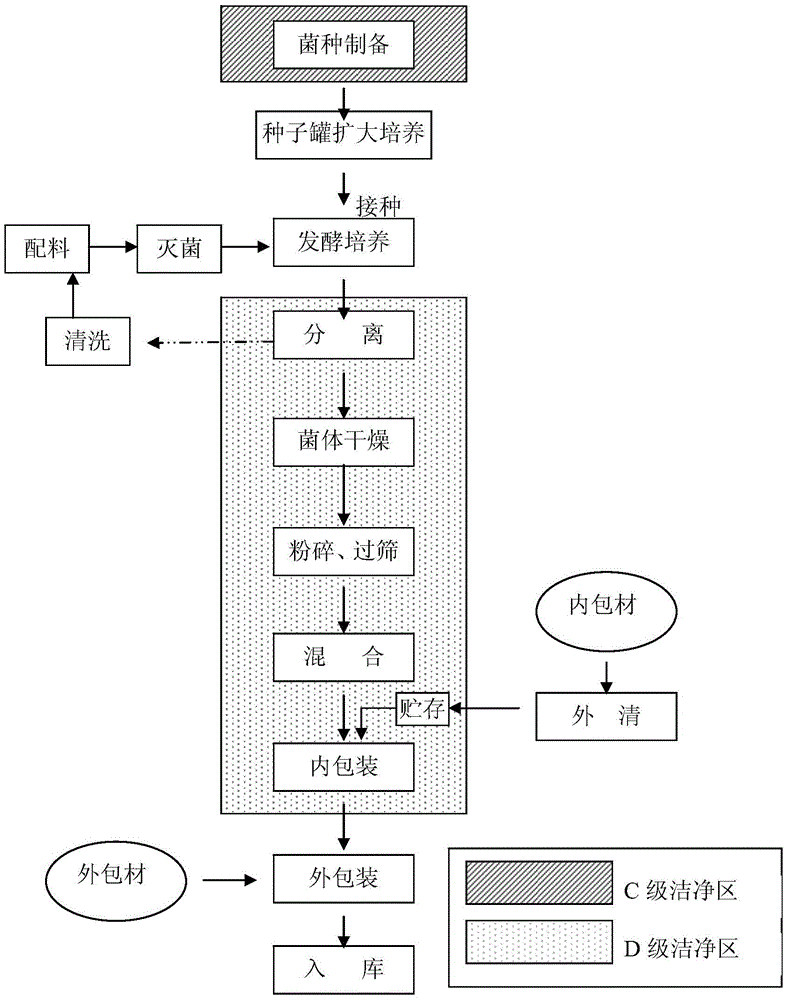

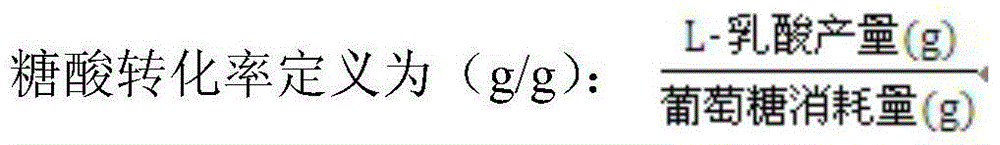

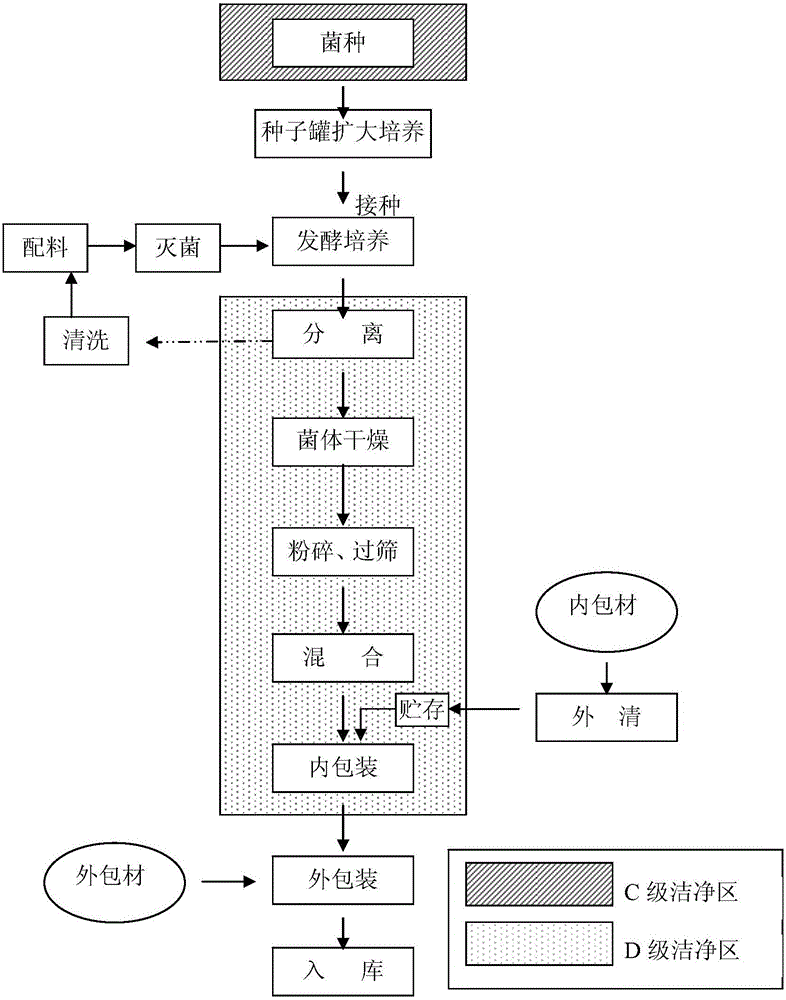

Rapid liquid submerged fermentation method for producing paecilomyces cicadae powder

InactiveCN105647814AShort fermentation cycleReduce process linksFungiMicroorganism based processesBiotechnologyFiltration membrane

The invention discloses a rapid liquid submerged fermentation method for producing paecilomyces cicadae powder. According to the method, paecilomyces cicadae strains are adopted, then a semi-continuous fermentation technology is used to rapidly produce fermentation broth containing a large amount of mycelia, and finally the fermentation broth is separated by a micro filtration membrane to obtain mycelia of paecilomyces cicadae. The conventional paecilomyces cicadae intermittent batch fermentation technology is changed, and at the same time, the mycelia are separated by a high efficient ceramic micro-filtration membrane to replace the conventional centrifugal separation. The shortages of conventional batch fermentation technology such as a lot of steps, long time period between steps, low equipment efficiency, and the like are overcome by semi-continuous fermentation technology. Moreover, a high efficient ceramic membrane is used to filter fermentation broth to reduce the mycelia that enter the filtrate, the yield of mycelia is improved, the COD of filtrate is reduced, thus the processing amount of sewage is reduced, the cells are not obstructed, and effective components in cells can be completely recovered therefore. Compared with the conventional method, the provided method can generate prominent economic benefit, social benefit, and environmental benefit.

Owner:JIANGSU SHENHUA PHARMA

Semi-continuous black-tea fungus fermentation broth preparation method and apparatus

PendingCN110892928APrevents the phenomenon of bacterial cellulose film formationReduce generationPre-extraction tea treatmentBiotechnologyContinuous fermentation

The invention belongs to the technical field of food, and discloses a semi-continuous black-tea fungus fermentation broth preparation method and apparatus. The preparation method comprises a culture liquid preparation step, an expanding culture step, and a fermentation tank fermentation step, and further comprises a semi-continuous fermentation step, wherein the semi-continuous fermentation step is that a part of a black-tea fungus fermentation raw liquid after the fermentation tank fermentation step is discharged from the fermentation tank, and is subjected to subsequent inactivation, filtration, concentration and filling steps, and a sterilized sugar tea soup is supplemented into the tank after a part of the black-tea fungus fermentation raw liquid is discharged from the original fermentation tank, so that the remaining black-tea fungus fermentation raw liquid in the original fermentation tank is used as a seed liquid to perform continue fermentation. The method utilizes a stepwise amplification dynamic fermentation mode, and the disadvantages of long process time and relatively large flavor difference between batches of static fermentation of black-tea fungus are avoided.

Owner:ZHEJIANG MINGHUANG NATURAL PRODS DEV

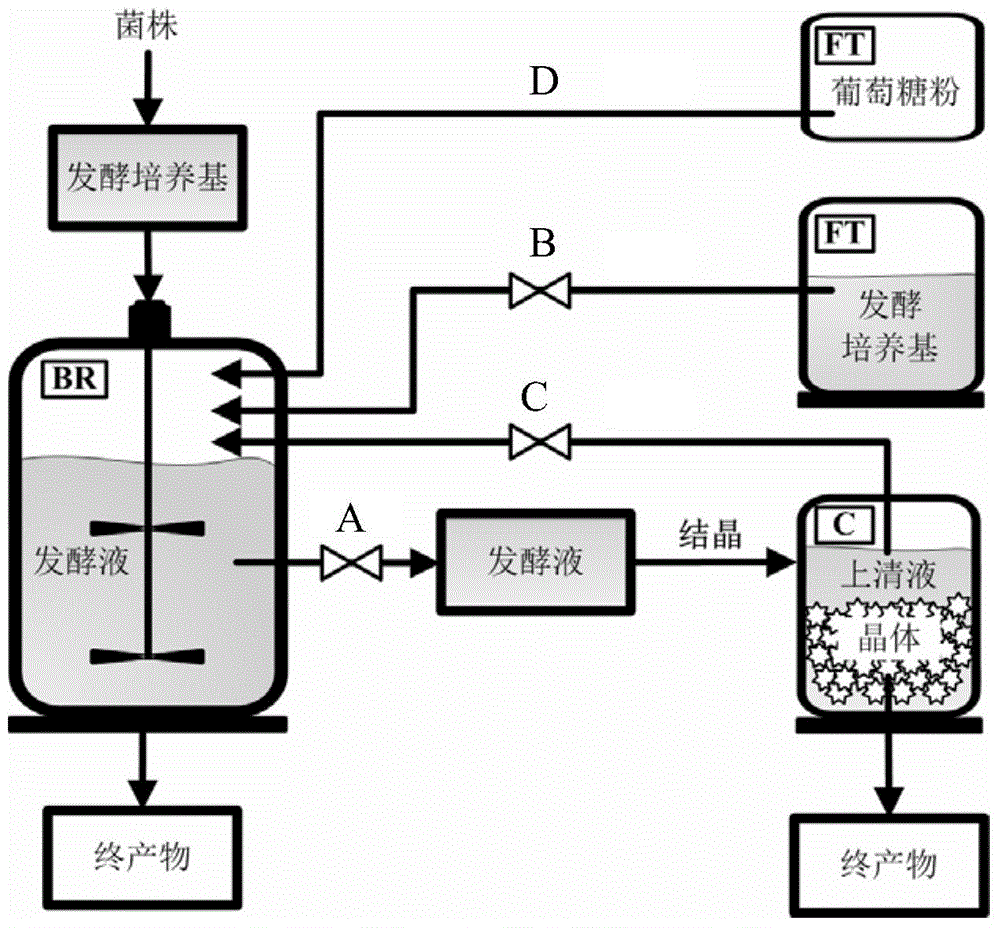

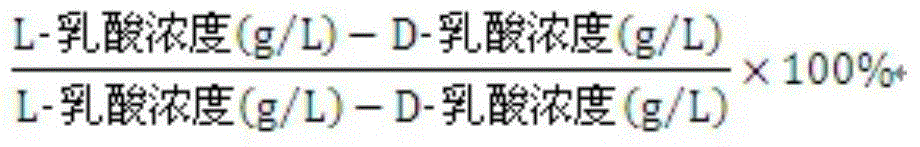

Bacillus coagulans and application thereof in calcium lactate production by in-situ product separating and fermentation

ActiveCN103952331AImprove continuous production capacityIncrease concentrationBacteriaMicroorganism based processesProduction rateContinuous fermentation

The invention discloses bacillus coagulans H-1 and a method using the bacillus coagulans H-1 for calcium lactate production by in-situ product separating and fermentation. The strain is Bacillus coagulans H-1, and the accession number is CCTCC (China Center For Type Culture Collection) NO:M2013105. Calcium lactate with a high optical purity is obtained by seed solution culture and then 50 to 250 hours of fermentation at 50-60 DEG C. Crystallized calcium lactate crystals can be obtained by continuous fermentation with an in-situ product separating and fermentation technology until the final production concentration in a fermentation tank is 167-171g / L, the production rate can be up to 5g / L / h, the optical purity can be up to 99.7%, and the conversion rate can be up to 0.95g / g. Semi continuous fermentation process can be repeatedly combined with the in-situ product separating and fermentation technology according to needs, the separation process is simple, economic, efficient, environmental-friendly, and sustainable. According to the method for calcium lactate production by in-situ product separating and fermentation, the cost is saved, meanwhile the production efficiency is improved, and the method has important industrial application value.

Owner:SHANGHAI JIAO TONG UNIV

Semi-continuous fermentation method for bacillus used for microbial fertilizer

ActiveCN102242075AReduce the number of expansionEasy production controlBacteriaMicroorganism based processesBiotechnologyContinuous fermentation

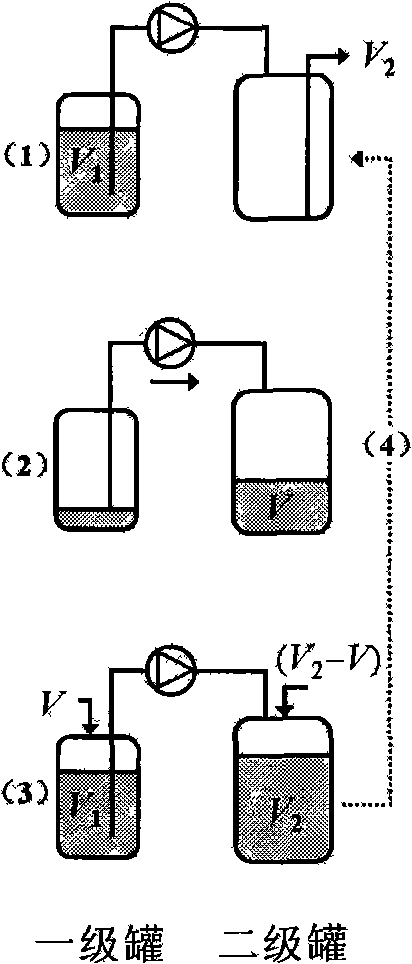

The invention relates to a semi-continuous fermentation method for bacillus used for a microbial fertilizer. The method comprises the following steps of: preparing a bacillus fermentation liquor by suing a two-step culture method; culturing the fermentation liquor until a late stage of a log phase or an initial stage of a stable phase, flowing partial fermentation liquor into another fermentationtank, and culturing into mature fermentation liquor; and performing fed batch culture on the original fermentation tank. The fed batch times can be 16 to 20 times, the times of expanding culture of seeds is greatly reduced, the production period is shortened, the production efficiency is improved, and the semi-continuous industrial production can be realized.

Owner:江苏科邦生态肥有限公司

Semicontinuous fermentation method for producing gamma-aminobutyric acid by lactic acid bacteria

InactiveCN102108370AGuaranteed productionReduce dosageMicroorganism based processesFermentationSolventOxygen

The invention discloses a semicontinuous fermentation method for producing gamma-aminobutyric acid by lactic acid bacteria, which comprises the following steps: inoculating lactic acid bacteria onto an Man, Rogosa and Sharpe gelatin (MRSG) culture medium; and fermenting in a mode of segmental substrate addition, segmental temperature control and segmental oxygen control to obtain gamma-aminobutyric acid, wherein the solvent of the MRSG culture medium is water, and the solute comprises the following materials at concentration: 7 to 12g / L glucose, 20 to 30g / L peptone, 30 to 40g / L beef extract, 0.05 to 1g / L manganese sulfate, 0.01 to 0.05g / L vitamin B, and 2 to 5g / L sodium glutamate. When the method provided by the invention is adopted, the yield of the gamma-aminobutyric acid can reach 13.1to 38.7g / L.

Owner:山东水晶生物科技股份有限公司

Quick deep-layer liquid state fermentation method for producing sparassis crispa bacterial powder

InactiveCN105586278AShort fermentation cycleReduce process linksFungiMicroorganism based processesFiltration membraneAdditive ingredient

The invention discloses a quick deep-layer liquid state fermentation method for producing sparassis crispa bacterial powder. According to the method, the semi-continuous fermentation process is adopted to treat sparassis crispa strains to obtain fermentation liquor rich in abundant mycelia fast, and then the fermentation liquor is treated and separated through a micro-filtration membrane to obtain mycelia of sparassis crispa. The traditional intermittent sparassis crispa batch fermentation process is changed, and the mycelia are separated in the mode of efficient ceramic membrane micro-filtration instead of the separation mode of a centrifugal machine. The semi-continuous fermentation process overcomes the defects that the number of process links of traditional batch fermentation is large, middle clearance time is long, and equipment efficiency is low. The efficient fermentation liquor filtered through the ceramic membrane is adopted, the mycelia entering filter liquor can be reduced, the yield of the mycelia can be increased, COD of the filter liquor is reduced, the sewage handling capacity is reduced, damage to cells is avoided, and it is ensured that effective ingredients in the cells are recovered completely. Compared with the traditional technology, the method has remarkable economic benefits, social benefits and environment-friendly benefits.

Owner:JIANGSU SHENHUA PHARMA

Method for preparing sodium gluconate through adopting semicontinuous fermentation technology

ActiveCN102517347AIncrease sodium acid contentReduce the number of sterilizationMicroorganism based processesFermentationCulture fluidAspergillus niger

Owner:黑龙江中瑯生物科技有限公司

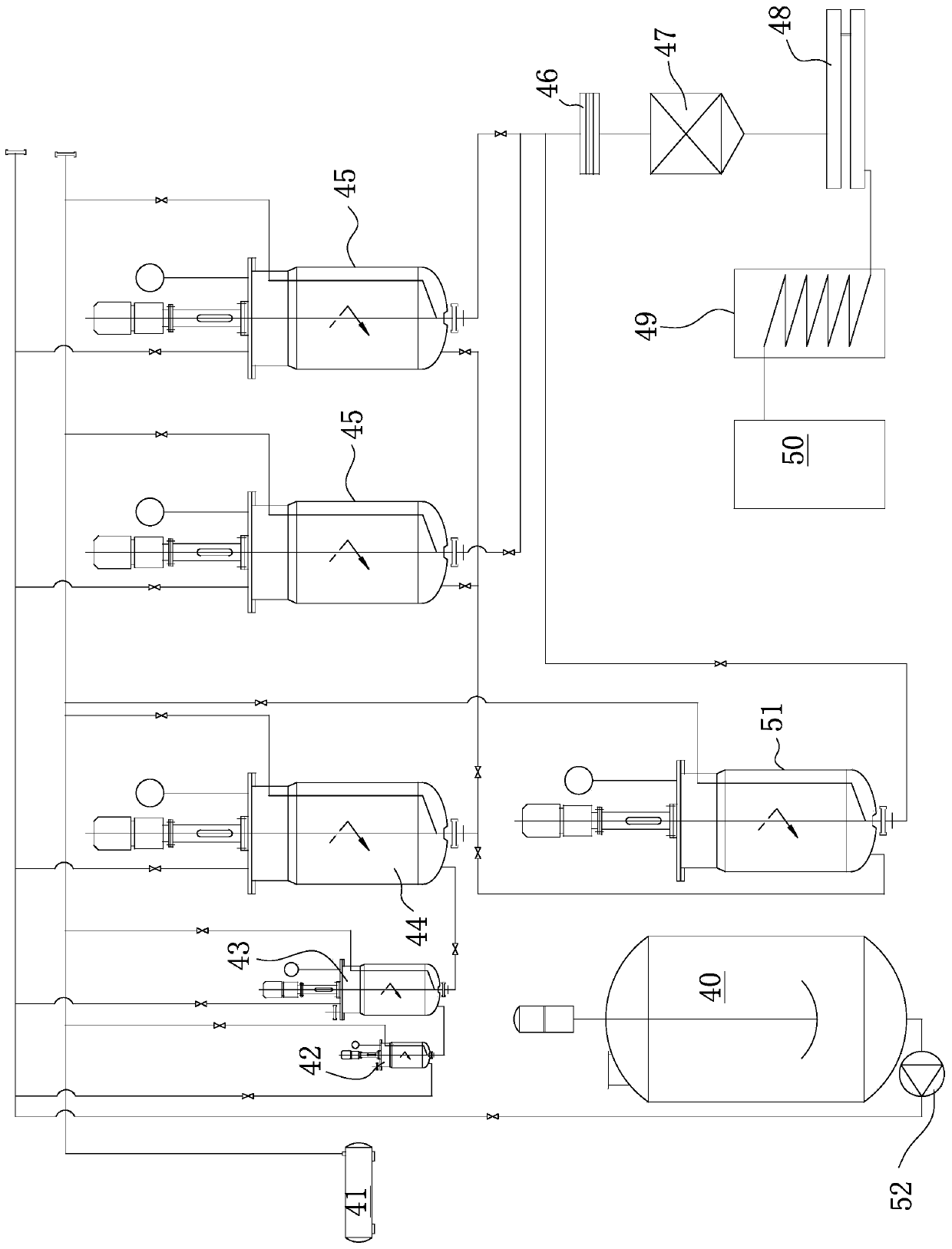

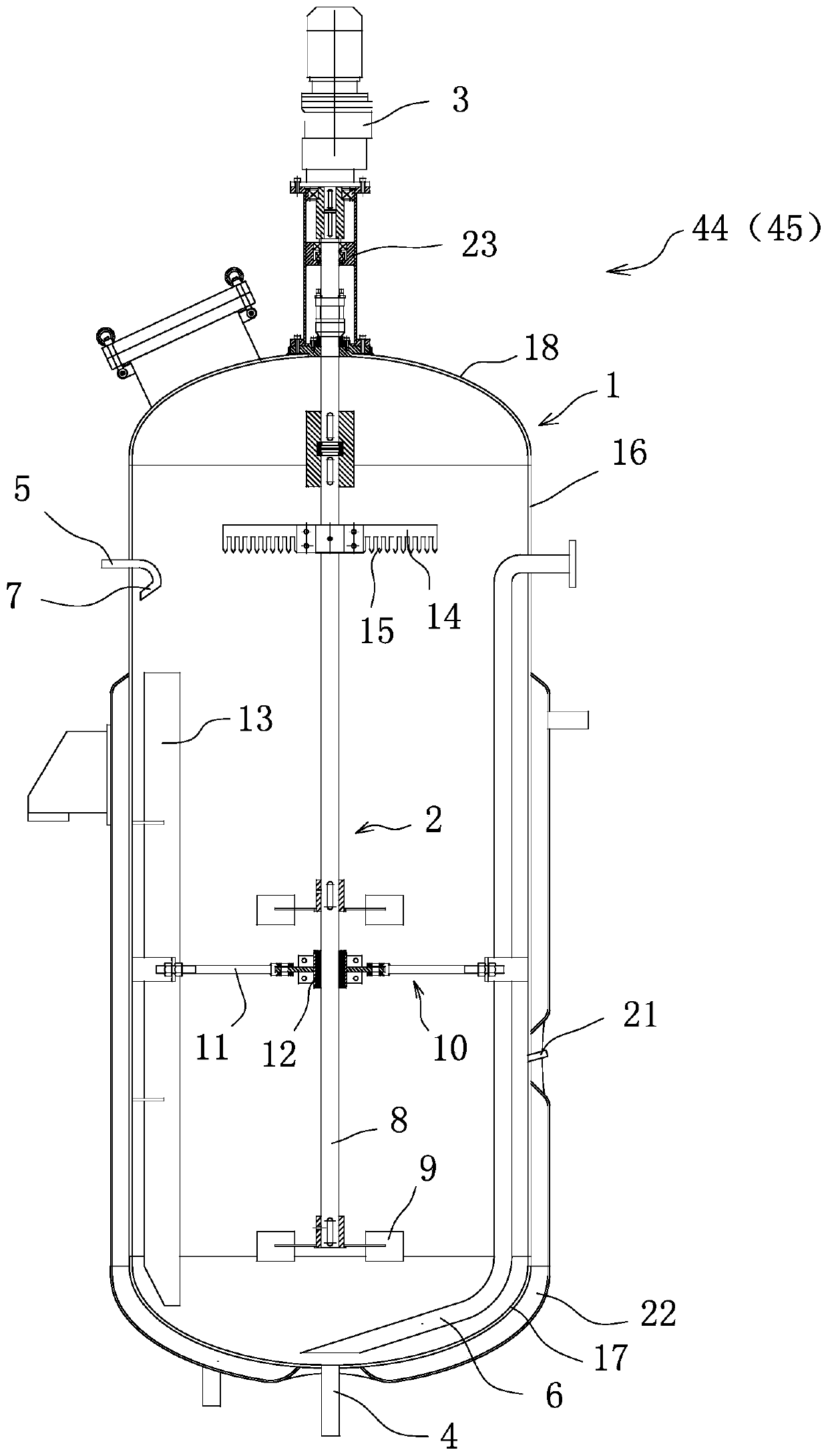

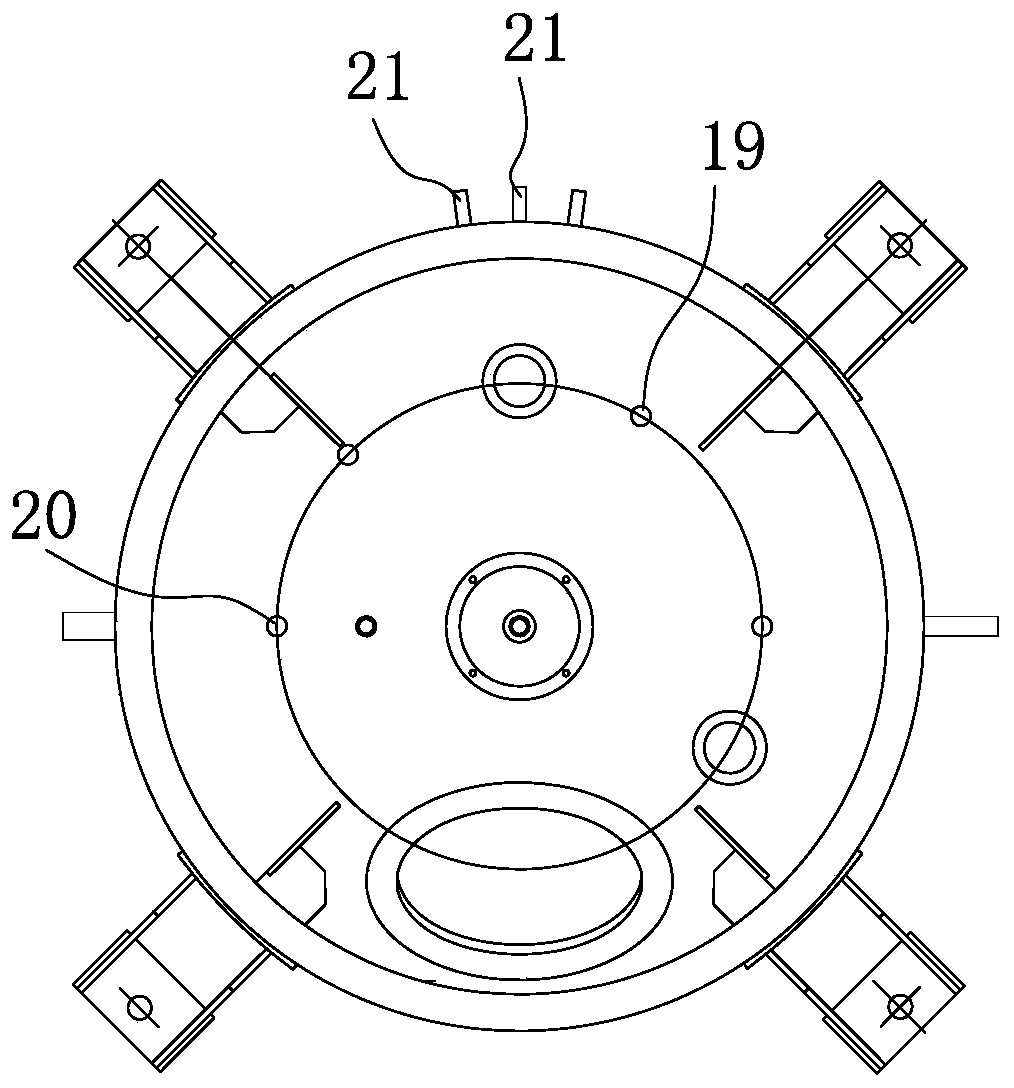

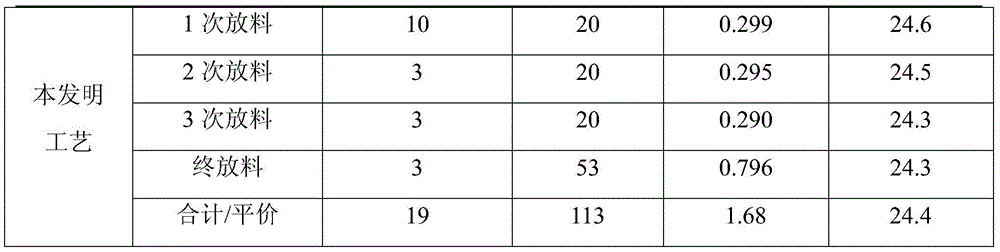

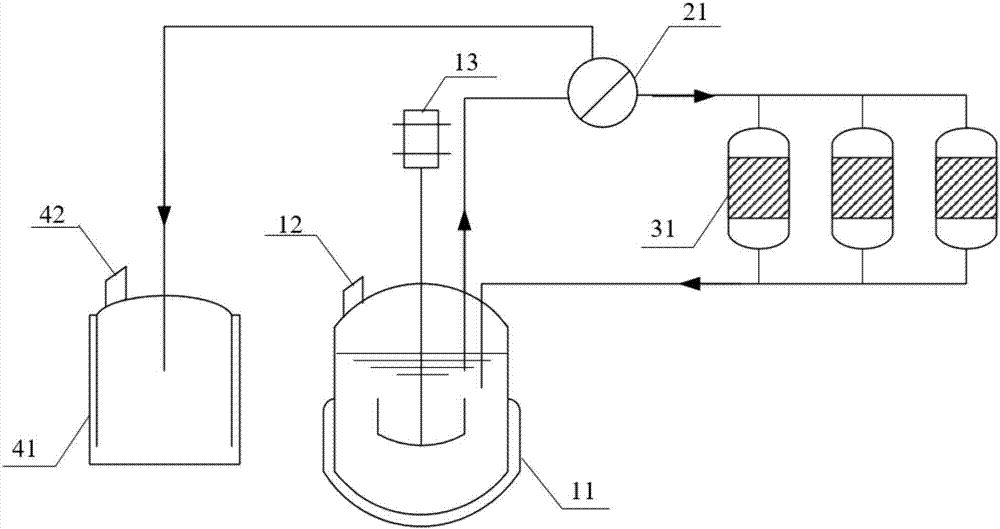

Device and method for producing propionic acid and coproduced vitamin B12 by means of semi-continuous fermentation

ActiveCN106916729AImprove conversion rateRealize joint productionBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxPropanoic acid

The invention provides a device and a method for producing propionic acid and coproduced vitamin B12 by means of semi-continuous fermentation. The device comprises a fermentation unit, a membrane separation unit, a propionic acid separation unit and a vitamin B12 conversion unit, wherein a discharge hole of the fermentation unit is connected with a feeding hole of the propionic acid separation unit and a feeding hole of the vitamin B12 conversion unit by the membrane separation unit; a discharge hole of the propionic acid separation unit is connected with a reflux inlet of the fermentation unit; the membrane separation unit comprises a membrane separation device; the membrane separation device comprises a membrane core; the aperture of the membrane core is 0.1-0.22mu m. The method and the device not only effectively overcomes the feedback inhibition action of the propionic acid for fermentation, but also overcomes the disadvantages that an expanded bed is low in filling efficiency and difficult to enlarge, solves the problem that the addition of DMB has adverse effects on resource utilization of fermentation wastewater, and realizes the cyclic utilization of the fermentation wastewater.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing ophiocordyceps sinensis powder through rapid and deep liquid state fermentation

InactiveCN105670942AShort fermentation cycleReduce process linksFungiMicroorganism based processesFiltration membraneBatch fermentation

The invention discloses a method for producing ophiocordyceps sinensis powder through rapid and deep liquid state fermentation. The method comprises the steps that fermentation liquor rich in mycelia is rapidly obtained from ophiocordyceps sinensis strains through a semi-continuous fermentation technology, and then the fermentation liquor is subjected to micro-filtration-membrane treatment and separation, so that ophiocordyceps sinensis mycelia are obtained. By means of the method, the traditional intermittent batch fermentation process for ophiocordyceps sinensis is changed, and in addition, the centrifugal separation mode is replaced with efficient ceramic membrane microfiltration for separation of the mycelia. By means of the semi-continuous fermentation process, the defects that the traditional batch fermentation process is large in number of process links, long in intermediate gap time, low in equipment efficiency and the like are overcome; the fermentation liquor is filtered through an efficient ceramic membrane, the situation that filtrate enters the mycelia can be reduced, the yield of the mycelia can be raised, COD of the filtrate is lowered, sewage treatment amount is decreased, cells are not destroyed, and it is guaranteed that all effective constituents in the cells are recycled. Compared with the traditional process, the method has remarkable economic benefits, social benefits and environment protection benefits.

Owner:JIANGSU SHENHUA PHARMA

A method for semi-continuous fermentation to produce bio-butanol

ActiveCN102286547AIncrease productionHigh strengthMicroorganism based processesFermentationAutomatic controlBio engineering

The invention relates to a method for producing biological butyl alcohol by semicontinuous fermentation, belonging to the technical field of biological engineering. The invention relates to a semicontinuous fermentation method, particularly application of Clostridium saccharobutyricum DSM13864 in a biological butyl alcohol preparation process by fermenting cane molasses, beet molasses, lignocellulose hydrolyzed syrup and other saccharide raw materials. By using the method provided by the invention, higher solvent yield and solvent production intensity can be obtained; the invention only needssterilization and inoculation once, thereby saving the non-fermentation time, including repeated tank washing, sterilization and the like, shortening the production cycle and greatly increasing the equipment utilization ratio; and the fermentation plant is simple, easy to implement automatic control, and applicable to industrialization.

Owner:江苏惠利生物科技有限公司

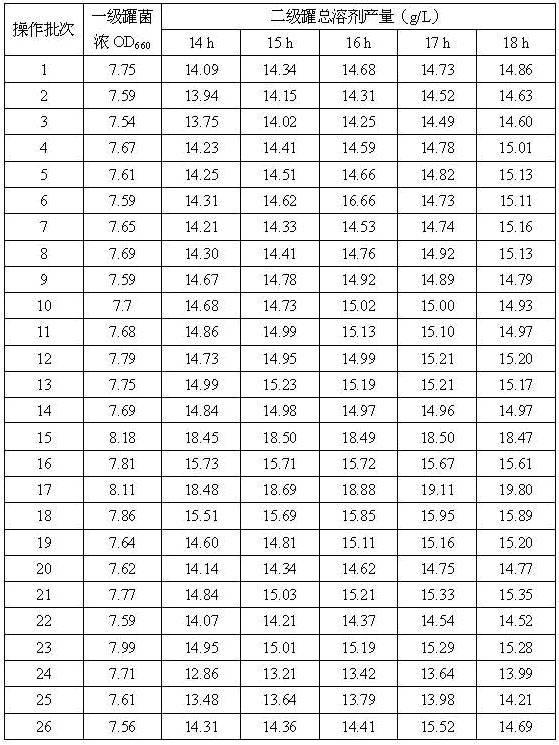

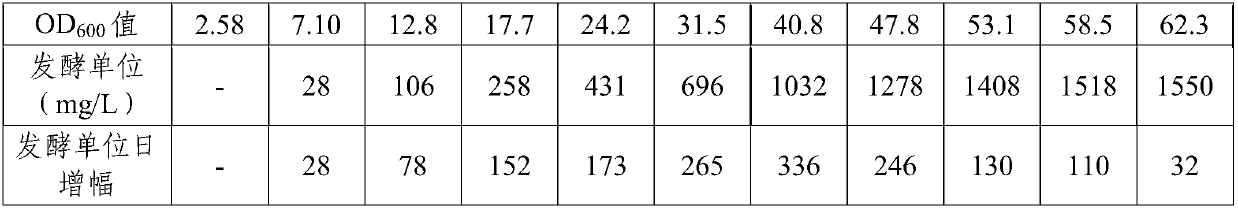

Method of adopting semi-continuous fermentation technology to produce pyrroloquinoline quinone

ActiveCN109628509AThe volume is basically constantHigh-speed synthesis period extendedMicroorganism based processesFermentationBatch fermentationPyrroloquinoline quinone

The invention provides a method of adopting a semi-continuous fermentation technology to produce pyrroloquinoline quinone. The method comprises the steps that on the basis of a conventional feeding fermentation technology, steps are conducted for multiple circulations that discharging is conducted partly and fresh fermentation mediums are replenished, and then fermentation continues; the OD600 value of fermentation liquid is controlled within a certain range, so that during a semi-continuous fermentation circulation period, the fermentation liquid is always in a high-speed synthesis stage of the pyrroloquinoline quinone, and thus the production efficiency is improved. Compared with the conventional feeding batch fermentation technology, by the adoption of the method, the production efficiency is improved by 25-50%, the unit consumption of main fermentation raw materials is lowered by 12-20%, the production continuity is improved, and the method has broad application prospects.

Owner:NEW FOUNDER HLDG DEV LLC +2

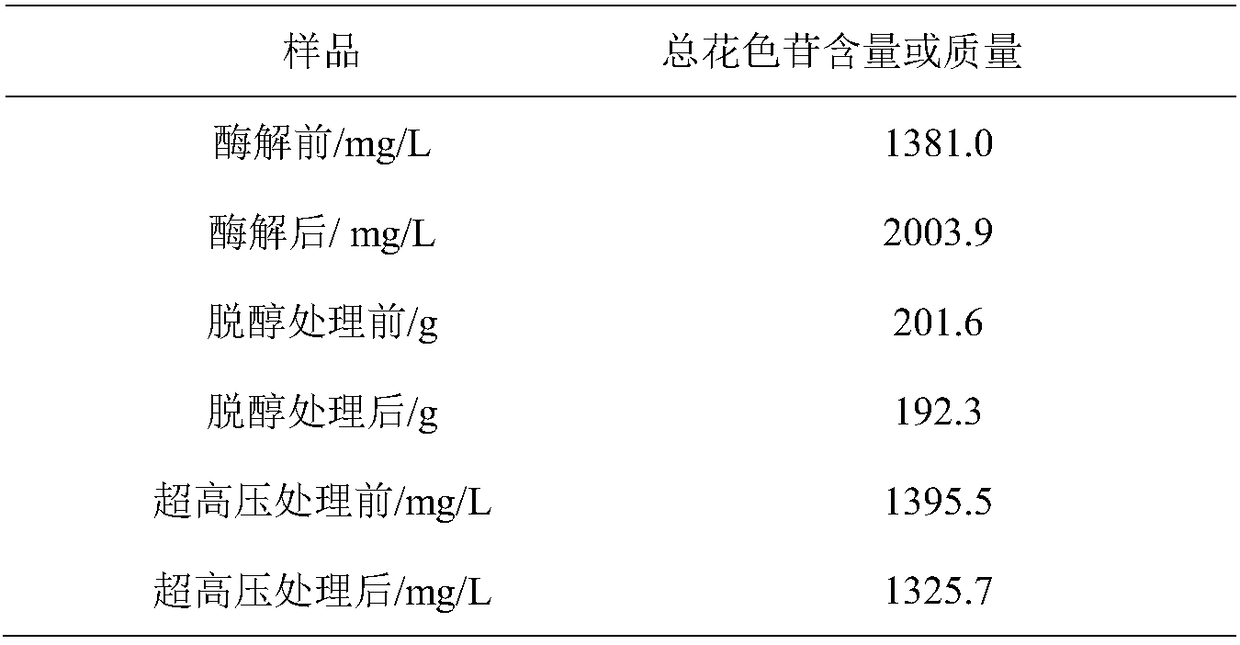

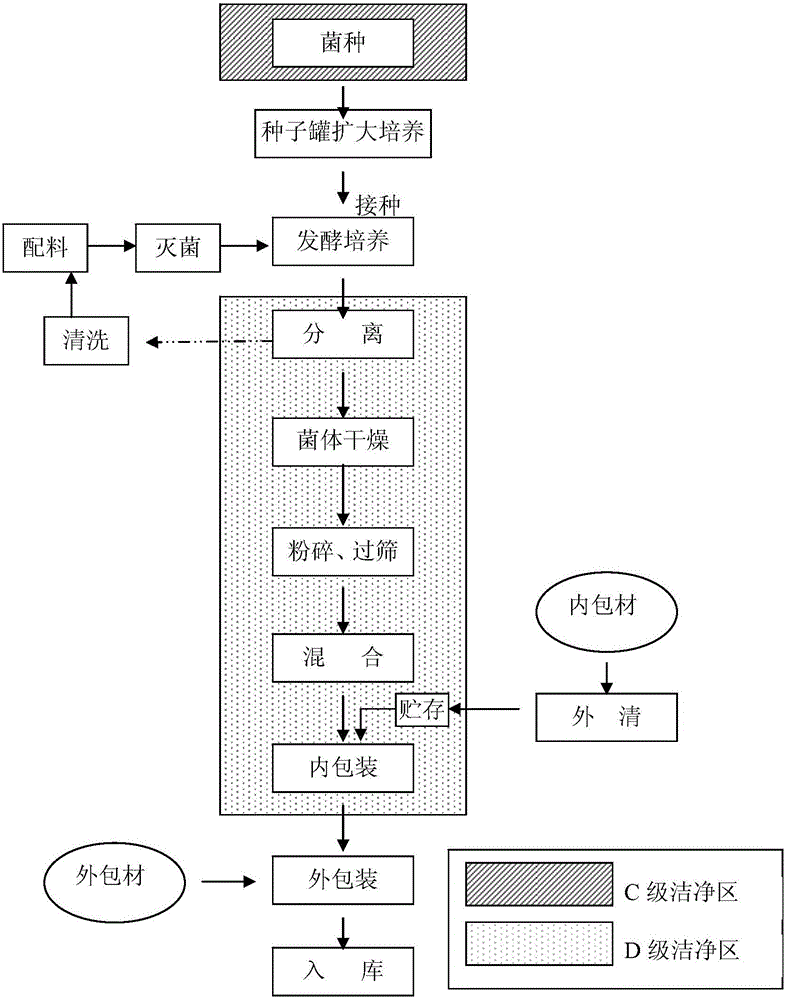

Method for preparing fermented fruit vinegar rich in anthocyanin

ActiveCN108384701AHigh dissolution rateIncrease the enzymatic hydrolysis processMicroorganism based processesVinegar preparationAcetic acidAlcohol

The invention discloses a method for preparing fermented fruit vinegar rich in anthocyanin and belongs to the technical field of biological fermentation of foods. The method comprises the following steps: taking fruits rich in anthocyanin as raw materials, performing raw material treatment, enzymolysis, alcohol fermentation and centrifugation so as to obtain a fruit wine fermentation liquor; treating the fruit wine fermentation liquor by using a vacuum dealcoholization technique so as to obtain a concentrated fermentation liquor and an alcohol liquor; performing acetic fermentation on the evaporated alcohol liquor in a fermentation mode that flowing liquor is replenished for multiple times and semi-continuous fermentation is carried out, so as to obtain an acetic acid liquor; finally mixing the concentrated fermentation liquor obtained through dealcoholization treatment with the acetic acid liquor according to a certain ratio, and performing sterilization and aging acceleration on themixture by using a super-high pressure technique, so as to obtain the fermented fruit vinegar rich in anthocyanin. By adopting the method, an enzymolysis procedure is added in the fruit vinegar fermentation process, so that the dissolution amount of anthocyanin in fruit pulp is increased; moreover, due to the adoption of the dealcoholization technique and the super-high pressure technique, oxydative degradation and thermal degradation of the anthocyanin can be effectively avoided, the content of total anthocyanin in the fermented fruit vinegar made by using the method is up to 200-1200mg / L, and the fermented fruit vinegar is bright in color and gentle in sourness.

Owner:JIANGSU UNIV

Method for semi continuous fermentation of L-alanine

InactiveCN107164420AEliminate the steps of disinfectionSimple processFermentationBiotechnologyContinuous fermentation

The invention relates to the technical field of fermentation engineering, and in particular relates to a method for semi continuous fermentation of L-alanine. The method comprises the following steps: preparation of a seed fluid; preparation of a culture medium; semi continuous fermentation culture of the L-alanine; collection of fermentation broth; and purification to obtain the L-alanine. The method is simple in process, green and environmentally-friendly, eliminates the step of disinfection of each batch of the seed liquid, a fermentation tank and the culture medium, and has the advantages of saving time, low energy consumption and high yield.

Owner:JING JING PHARMA

Method for producing microbial rennet by semicontinuous fermentation

ActiveCN101870967AReduce incubation timeAvoid damageHydrolasesMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a method for producing microbial rennet by semicontinuous fermentation, relating to a method for producing rennet by fermentation. The invention solves the problems of long fermentation cycle, low fermentation productivity and low yield of microbial fermentation production. The method comprises the following steps of: 1. seed culture; 2. fermentation culture; 3. fed-batch culture and 4. collecting to obtain the rennet. The method effectively controls the discharge and the feeding of fermentation liquor and ensures that fewer nutritional ingredients in the whole fermentation process are broken, and the whole fermentation process is easy to control. The invention has short fermentation cycle, high fermentation productivity and high yield of fermentation production.

Owner:AMTECH BIOTECH

Method for producing pullulan with different molecular weights by semi-continuous method

InactiveCN106282263AShort fermentation timeHigh repetition rateMicroorganism based processesFermentationPullulanBatch fermentation

The invention discloses a method for producing pullulan with different molecular weights by a semi-continuous method. The method is characterized by comprising the following steps of inoculating a fermented seed solution into a fermentation medium; draining a certain amount of fermentation broth in the fermenting process by adopting semi-continuous fermentation; supplementing a fresh fermentation medium with the same volume, adjusting a pH value, and continuously fermenting; after fermentation for a certain time, continuously draining the fermentation broth, and supplementing the fresh fermentation medium with the same volume; then adjusting a pH value, repeatedly operating, and adjusting pH values of fermentation to be different, thus obtaining the fermentation broth containing the pullulan with the different molecular weights. According to the method disclosed by the invention, an effect of obtaining the pullulan with the different molecular weights is realized by combining the semi-continuous fermentation with adjustment of different pH values of the fermentation. Compared with a method of obtaining the pullulan with the different molecular weights by batch fermentation in batches, the method disclosed by the invention has the advantages that fermentation time required by the semi-continuous fermentation is shorter, and the repetitive rate of obtaining the pullulan with the same molecular weight is higher; in addition, by adopting the mode, the fermentation is more stable.

Owner:天津北洋百川生物技术有限公司

Method for producing inonotus obliquus powder through rapid and deep liquid state fermentation

InactiveCN105670944AShort fermentation cycleReduce process linksFungiMicroorganism based processesFiltration membraneBatch fermentation

The invention discloses a method for producing Inonotus obliquus bacterial powder by rapid deep liquid fermentation. The method is to quickly obtain a fermented liquid rich in a large amount of mycelium by adopting a semi-continuous fermentation process for the Inonotus obliquus strain, and then The fermented liquid is treated and separated by a microfiltration membrane to obtain the mycelia of Inonotus obliquus. The invention changes the traditional intermittent batch fermentation process of Inonotus obliquus, and the separation of mycelium adopts efficient ceramic membrane microfiltration to replace the centrifuge separation mode. The semi-continuous fermentation process overcomes the shortcomings of the traditional batch fermentation process, such as many process links, long intermediate intervals, and low equipment efficiency; and the use of high-efficiency ceramic membranes to filter the fermentation liquid can reduce the mycelium entering the filtrate, which can not only improve the bacterial The yield of silk can reduce the COD of the filtrate, reduce the amount of sewage treatment, without destroying the cells themselves, and ensure the recovery of all active ingredients in the cells. Compared with the traditional technology, the invention has remarkable economic benefit, social benefit and environmental protection benefit.

Owner:JIANGSU SHENHUA PHARMA

Immobilized semi-continuous lactic acid fermentation method of juice

The invention provides an immobilized semi-continuous lactic acid fermentation method of juice. The method comprises the following steps of: pretreatment of a carrier, preparation of fermentation substrate, bacteria enrichment of the carrier, and semi-continuous fermentation. The juice fermented by the method has typical lactic acid fermentation fragrance, namely, is better is flavor; the method is short in production period and high in production rate, and can be used for inoculating a plurality of batches of semi-continuous fermentation for once, thus being convenient for production operation and reducing the production cost.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Semicontinuous fermentation technology of gluconate

InactiveCN102321689AReduce the number of culturesSave sugar consumptionFermentationContinuous fermentationOxygen

The invention discloses a semicontinuous fermentation technology of gluconate, comprising the following steps: using biological fermentation process, carrying out seed cultivation, fermentation, sterilization, discoloration, condensation, crystallization, drying and other steps to let glucose be subject to fermentation to generate gluconate. In the step of fermentation, when dissolved oxygen (DO) rises to 100, 50 % of the fermentation broth in a fermentation cylinder is discharged, and the rest 50 % of the fermentation broth is used as seed and kept in the fermentation cylinder, then 650 g / L glucose liquid and nutrient are added by one time, then fermentation is carried out unceasingly; and the step of semicontinuous fermentation is started, the semicontinuous fermentation is repeated 6-10 times, and the total fermentation period is 110-130 h. The technology disclosed in the invention reduces the times of seed culture, and saves the sugar consumption in seed culture, and the yield can be increased to 115+ / -3 %.

Owner:山东福洋生物科技股份有限公司

Semi-continuous culture method for spores recovered from cordyceps sinensis fermentation liquor

InactiveCN104263651AGuaranteed survival rateReduce the cost of trainingFungiMicroorganism based processesFiltrationTotal recovery

The invention belongs to the technical field of cordyceps sinensis fermental cultivation, and particularly relates to a semi-continuous culture method for spores recovered from a cordyceps sinensis fermentation liquor. The semi-continuous culture method comprises the steps of preparing a semi-continuous fermentation tank and a culture medium, detecting fermentation, concentrating mycelia, separating the fermentation liquor from spores and continuing fermental cultivation. Mycelia entering a filtrate are reduced by selecting a membrane filter during filtration and even selecting a selective membrane for filtration, so that the yield of mycelia is improved, the COD of the filtrate is reduced, the sewage treatment capacity is lowered, cells are not destroyed, and the total recovery of effective components in the cells is guaranteed; a selective membrane filter system has a good effect in separating mycelia from spores, the quantity of separated cordyceps sinensis spores is relatively large, and environmental transformation is mild, so that the adaptation time of a seed solution is shortened, the seed solution directly enters the multiplicative fermentation process, and accordingly, the fermentation period is also shortened by about 16 hours; and the production efficiency is improved, the production power consumption is reduced and better benefits are acquired.

Owner:GUIZHOU QIAN KUN BIOPHARM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com