A method for semi-continuous fermentation to produce bio-butanol

A bio-butanol, semi-continuous technology, applied in the field of bioengineering, to achieve the effects of shortening the production cycle, high solvent production intensity, and high solvent output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

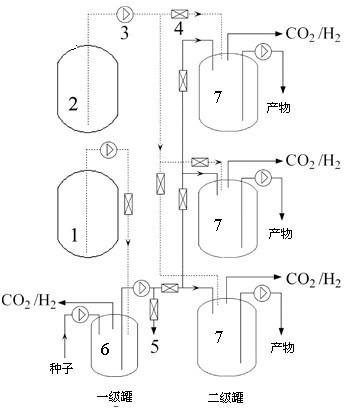

Image

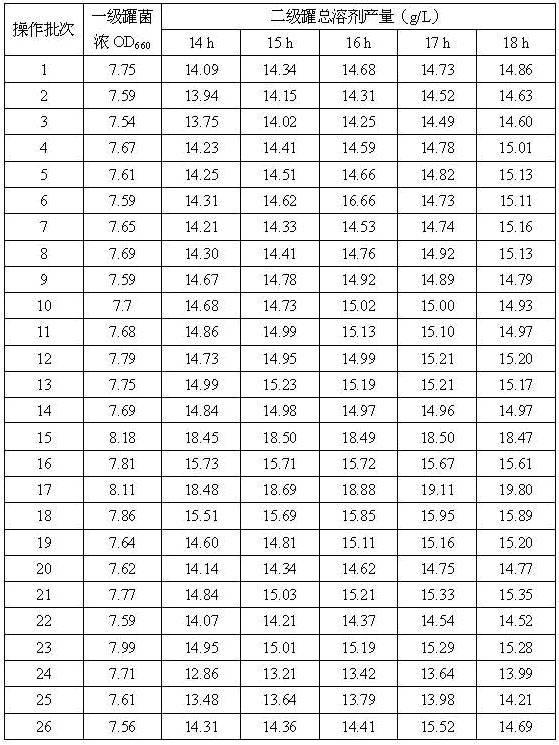

Examples

Embodiment 1

[0029] Clostridium saccharobutylicum Clostridium saccharobutylicumDSM 13864 is a strain for the production of bio-butanol by fermentation, using sugarcane molasses as the fermentation raw material.

[0030] The seed medium is RCM medium ( / L): yeast extract 3g, beef extract 10g, peptone 10g, soluble starch 1g, glucose 5g, cysteine hydrochloride 0.5g, NaCl 3g, NaAC 3g, resazurin 3mg , pH 6.5. Transfer 1 mL of strain spore liquid to 10 mL test tube seed medium, place in a vacuum desiccator to evacuate to a pressure of 0.065 MPa, and incubate at 37°C for 12-18 h.

[0031] Primary feed medium (SSM1) ( / L): total sugar 2%, CaCO 3 3.2 g, (NH 4 ) 2 SO 4 2 g, K 2 HPO 4 0.5 g, corn steep liquor dry powder 20g, MnSO 4 ·H 2 O 0.01 g, pH 6.7.

[0032] Secondary feed medium (SSM2) ( / L): total sugar 8%, CaCO 3 3.2 g, (NH 4 ) 2 SO 4 2 g, K 2 HPO 4 0.5 g, corn steep liquor dry powder 10g, MnSO 4 ·H 2 O 0.01g, pH 6.4, sterilized at 121°C for 20 min.

[0033] The prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com