Method for preparing fermented fruit vinegar rich in anthocyanin

An anthocyanin and fermented technology, which is applied in the field of fermented fruit vinegar preparation, can solve the problems of easy deterioration of flavor, dull color, low anthocyanin content, etc., and achieve the goal of increasing dissolution rate, bright color, and increasing enzymatic hydrolysis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

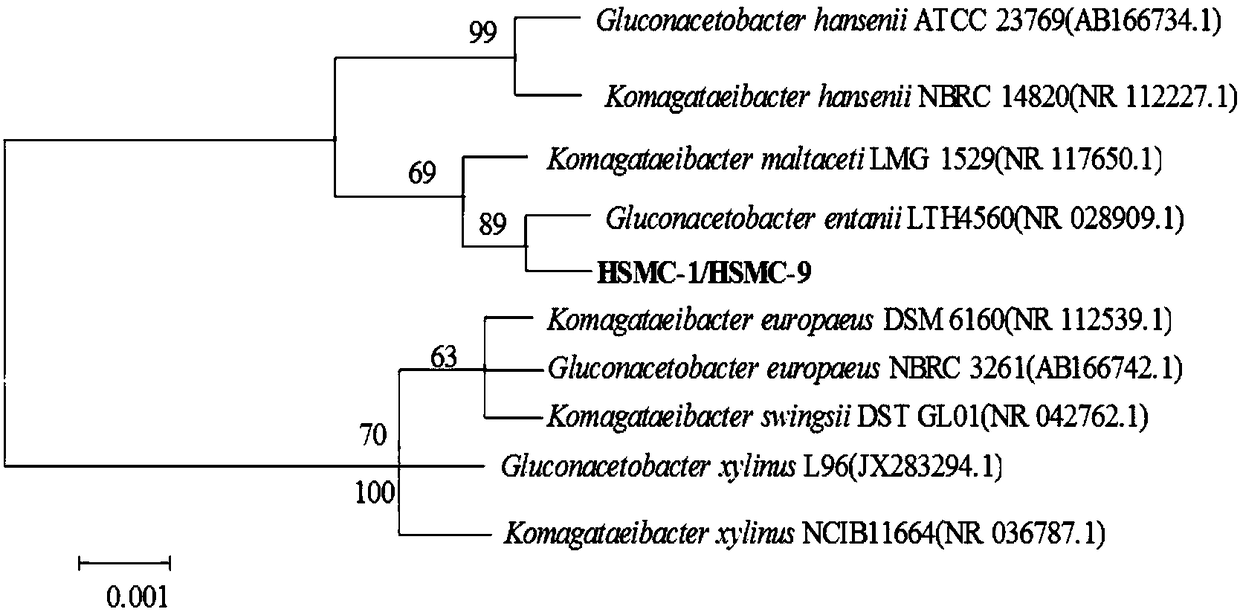

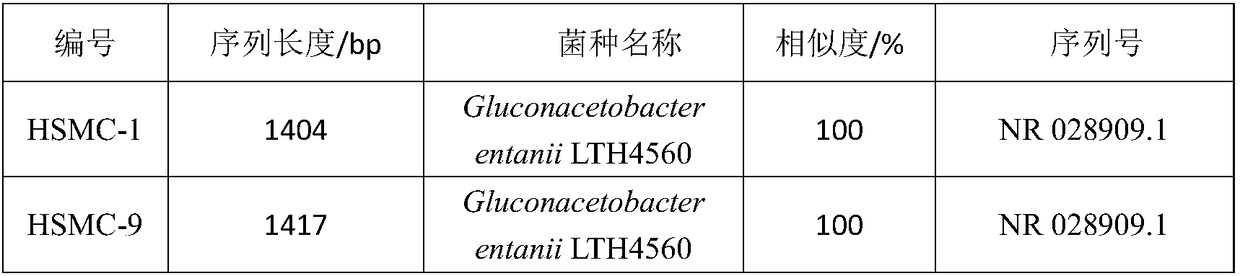

[0035] The separation and screening of embodiment 1 acetic acid bacteria

[0036] 1. Strain proliferation and purification

[0037] Take 5mL of high-acidity acetic acid fermentation broth in the fermentation state, put it into a 500mL Erlenmeyer flask filled with 100mL of proliferation medium, shake it at 30°C and 200r / min for 36h, and then carry out dilution coating. Dilute the proliferation medium to 10 with sterile saline -4 , 200 μL of each dilution was drawn and spread on the separation medium, and placed at 30°C for 2-3 days. Pick a single colony with a large color change circle and dominant growth and purify it on the isolation medium. When the colonies on the isolation medium had the same shape and the individual shapes observed under the microscope were roughly the same, the purification was stopped, and a total of 10 strains were obtained, which were numbered HSMC-1 to HSMC-10 in sequence. Pick a single strain with a large color change circle and inoculate it on t...

Embodiment 2

[0049] Embodiment 2 A kind of preparation method of fermented mulberry fruit vinegar rich in anthocyanins

[0050] Raw material pretreatment: pick 200kg of disease-free, mildew-free, eight-mature mulberries, wash the surface sediment and attached microorganisms with running water, drain, and crush the mulberries with a crusher.

[0051] Enzymolysis: Add EX-V pectinase produced by French Laman Company to mulberry pulp at 0.05g / kg, and enzymolysis at 45°C for 1.5h.

[0052] Alcoholic fermentation: adjust the sugar content of mulberry pulp to 15°Bx by adding sucrose, and inoculate Lalvin 71B active dry yeast produced by French Laman Company at 0.25g / kg for alcoholic fermentation, and set the fermentation temperature to 22°C. When the alcohol content of the fermented liquid reached 6.0% vol, the fermented liquid was centrifuged to obtain 136.2L clarified mulberry fermented liquid.

[0053] Dealcoholization treatment: Use a vacuum evaporation concentrator with a heat pump to deal ...

Embodiment 3

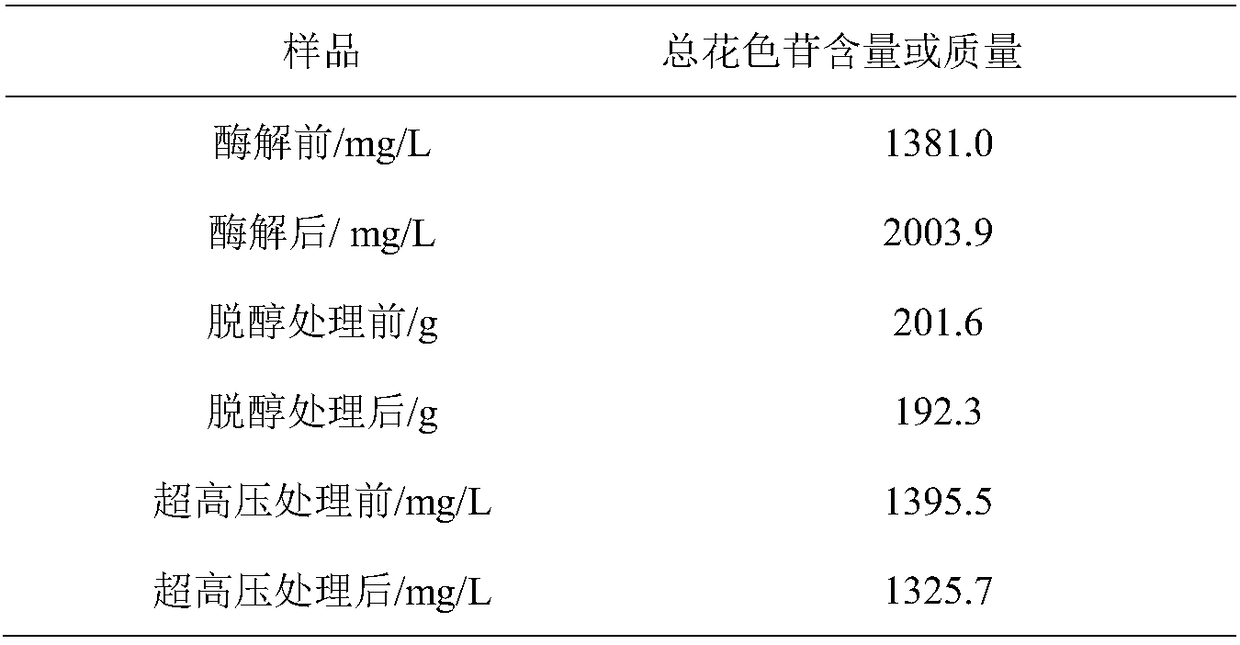

[0059] The change of total anthocyanin content in the preparation process of embodiment 3 mulberry fruit vinegar

[0060] With 200kg mulberry fruit as raw material, prepare 136.3L mulberry fruit vinegar according to the concrete steps of embodiment 1. Samples were taken before and after enzymatic hydrolysis, before and after dealcoholization treatment, and before and after ultra-high pressure treatment, and the total anthocyanin content in the sample was measured by the pH differential method, and the total anthocyanin content and depleted The quality of the total anthocyanins in the mulberry fermentation broth before and after alcohol, the specific data are shown in Table 2. According to the data in Table 2, the total anthocyanin content in the pulp has been increased by 45% through enzymolysis treatment, which significantly improves the anthocyanin dissolution rate of mulberry pulp; However, the original anthocyanins in the fermentation broth were basically retained; the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com