A kind of clean production method of starch-based fuel ethanol

A fuel ethanol and clean production technology, applied in the biological field, can solve the problems of high material consumption and energy consumption, poor system integration optimization of the whole plant, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

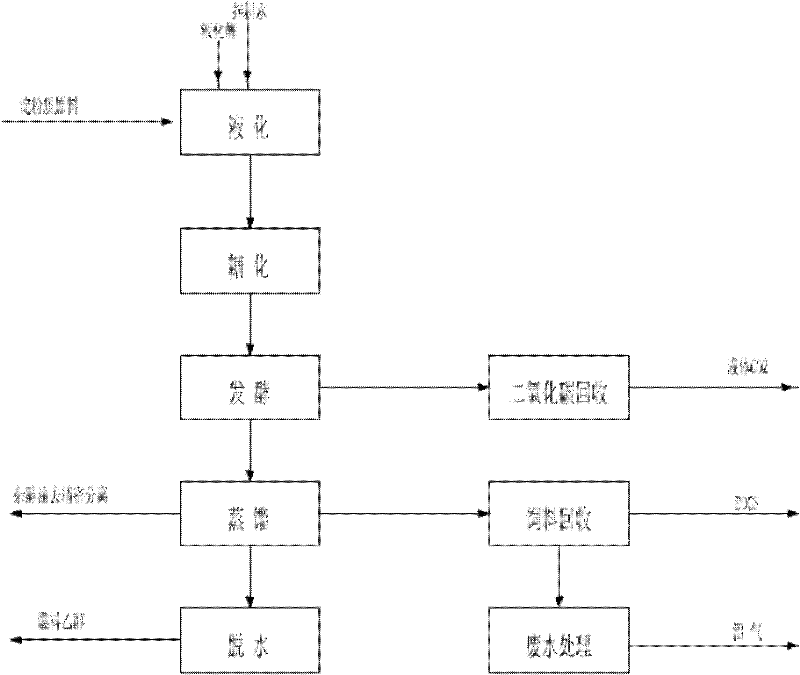

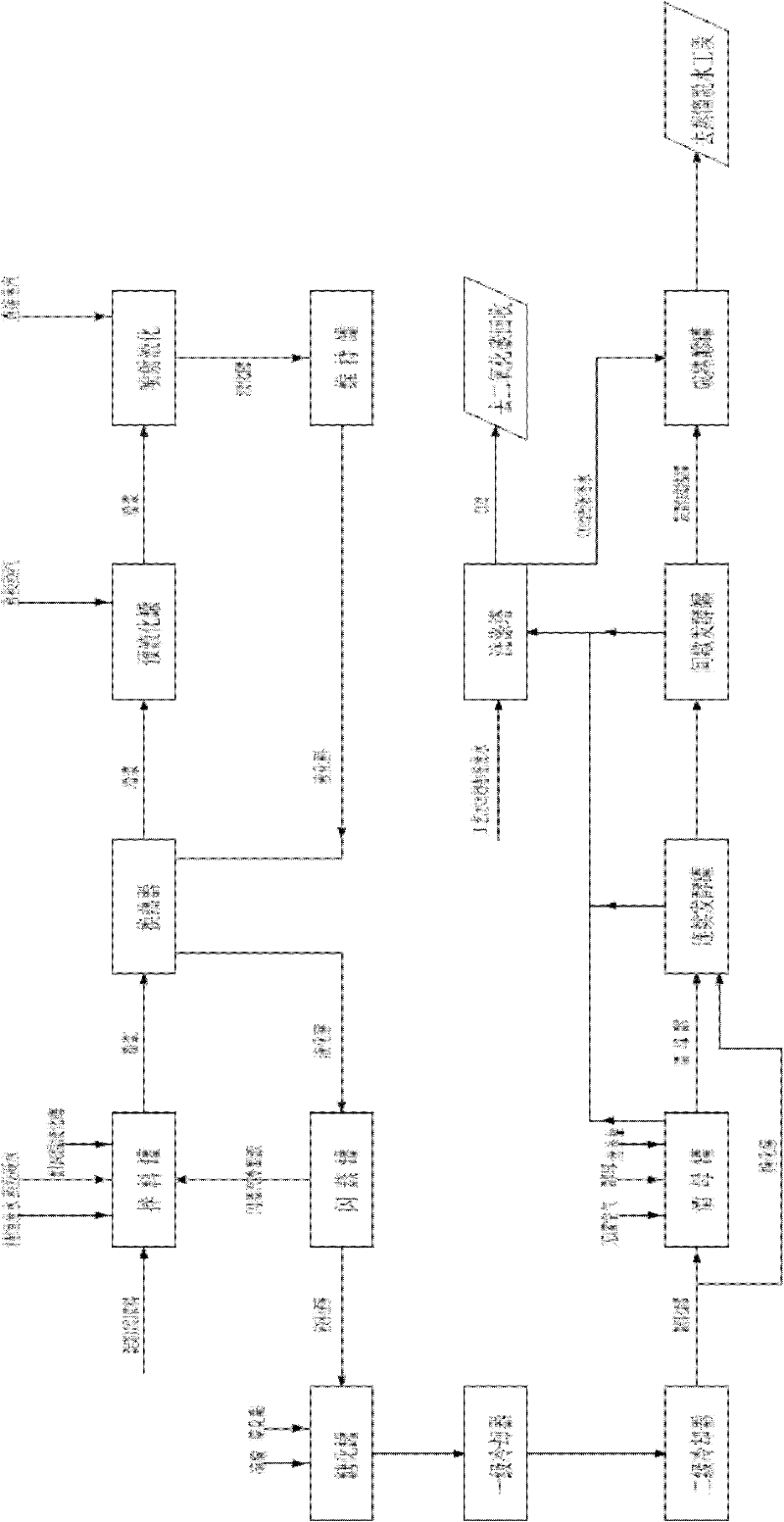

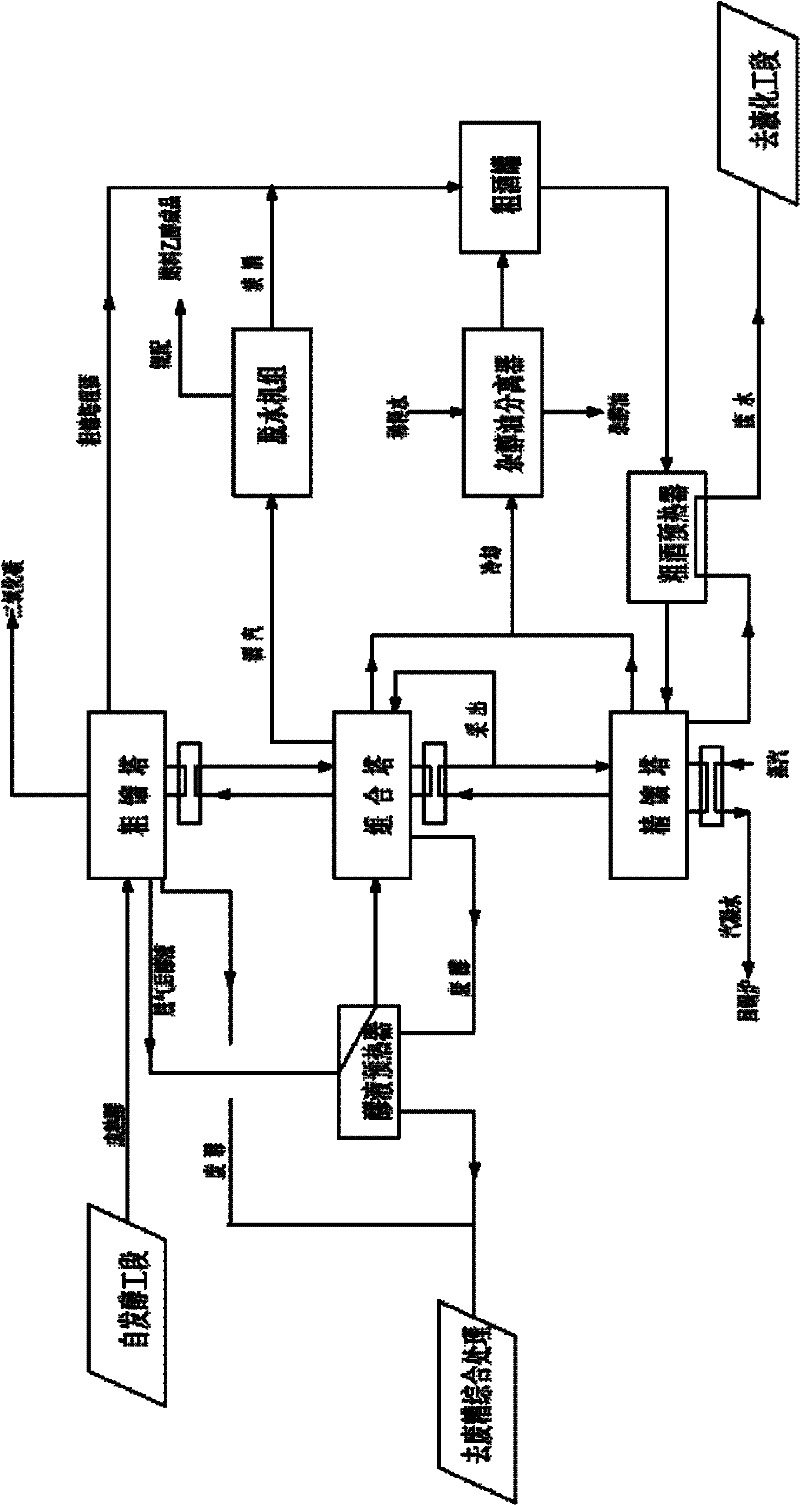

[0037] The process of producing fuel ethanol from corn starch is as follows:

[0038] 37.7t / h corn (starch content is 65%, moisture content is 14%) is crushed to an average particle size of 2mm and sent to the pre-liquefaction tank, adding 84.6t / h mixing water, α-amylase 22kg / h, Obtain a slurry with a dry matter mass content of 26.5%. In order to mix the slurry evenly, the tank is equipped with an agitator, and the slurry is preheated to 78°C and then sent to a pre-liquefaction tank. In the pre-liquefaction tank, the above-mentioned slurry Heated by direct steam to 86°C, the stirrer drives the insoluble material into a stable suspension. When operating at full load, the residence time of slurry in the tank is 40min.

[0039] Then the slurry is pumped to the jet liquefier, and the outlet temperature of the steam jet is controlled to be 105° C. to obtain heated mash. The heated mash is sent to the cooking column and kept at 105°C for 1.5h for cooking and slaking. The matured ...

Embodiment 2

[0046] The process of producing fuel ethanol with dried cassava as raw material is as follows:

[0047] 20t / h dried cassava chips (68% starch content, 12% water mass content) were crushed to an average particle size of 3mm and sent to the pre-liquefaction tank, 40t / h mixing water was added, and α-amylase 12.5 kg / h to obtain a slurry with a dry matter content of 29.3%. In order to mix the slurry evenly, the tank is equipped with an agitator, and the slurry is heated to 75°C and then sent to the pre-liquefaction tank. In the pre-liquefaction tank, The above slurry is heated to 84°C by direct steam, and the stirrer promotes the insoluble matter to reach a stable suspension state. When operating at full load, the residence time of slurry in the tank is 30 minutes.

[0048] Then the slurry is pumped to the jet liquefier, and the outlet temperature of the steam jet is controlled to be 106° C. to obtain heated mash. The heated mash is sent to the cooking column and kept at 106°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com