Device and method for producing propionic acid and coproduced vitamin B12 by means of semi-continuous fermentation

A vitamin and B12 technology, applied in the field of bioengineering, can solve the problems of difficult production, difficulty in propionibacterium, low expansion bed filling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

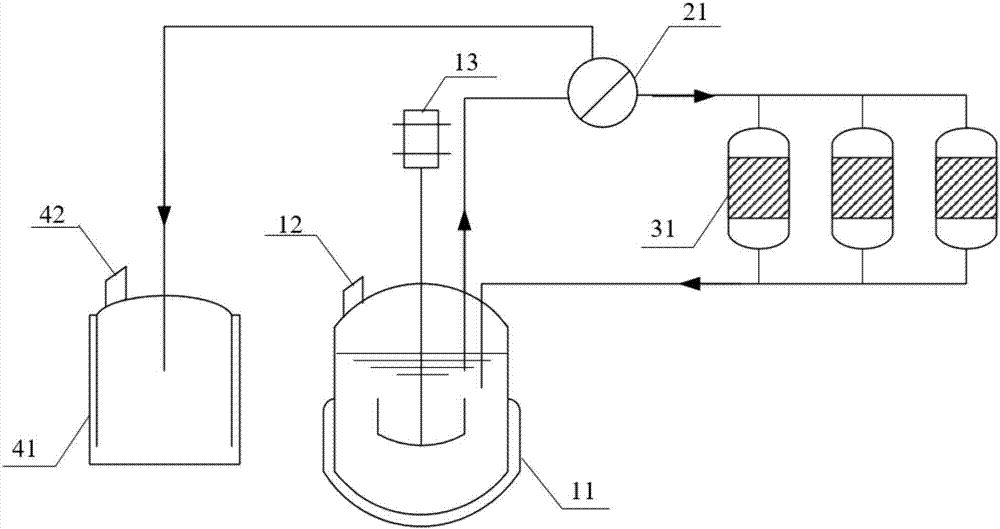

[0083] A semi-continuous fermentative production of propionic acid and co-production of vitamin B 12 devices such as figure 1 As shown, the device includes a fermentation unit, a membrane separation unit, a propionic acid separation unit and vitamin B 12 The conversion unit, the outlet of the fermentation unit passes through the membrane separation unit and the propionic acid separation unit and vitamin B 12 The feed port of the conversion unit is connected, and the discharge port of the propionic acid separation unit is connected with the reflux port of the fermentation unit;

[0084] Described fermenting unit comprises fermentor 11, and the upper half of the tank body of described fermentor 11 is provided with fermentor feed inlet 12, and the tank top of described fermentor 11 is provided with stirring device 13, and described feed inlet 12 Used for the supplement of feed liquid and the addition of nutrients;

[0085] The propionic acid separation unit includes a chromato...

Embodiment 2

[0092] Example 2: Production of propionic acid and co-production of vitamin B by semi-continuous fermentation 12 Methods

[0093] (1) Fermentation culture of Propionibacterium freunderi

[0094] Activation culture of strains: activate the strains stored in glycerol tubes or slopes by streaking on a plate, and place them in constant temperature anaerobic culture at 30°C for 72 hours;

[0095]Seed liquid culture: Take the activated slant seeds and insert them into the liquid medium, and culture them at 30°C for 48 hours;

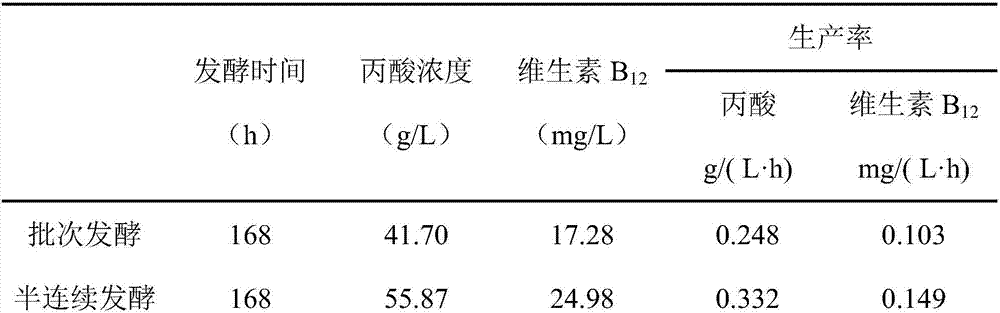

[0096] Fermentation tank culture: Inoculate 10% of the inoculum into a 10L fermenter, culture at 30°C, 50r / min, add high-concentration glucose when the glucose concentration is lower than 10g / L, and adjust the pH to 6.8 with ammonia water -7.2, regularly take samples to measure the OD600 value of the bacteria. When the fermentation lasted for 84 hours, the intracellular vitamin B12 metabolic intermediate Ado-cbi accumulated to the maximum value, at this tim...

Embodiment 3

[0107] Example 3: Production of propionic acid and co-production of vitamin B by semi-continuous fermentation 12 Methods

[0108] (1) Fermentation culture of Propionibacterium freunderi

[0109] Activation culture of strains: activate the strains stored in glycerol tubes or slopes by streaking on a plate, and place them in a constant temperature anaerobic culture at 35°C for 40 hours;

[0110] Seed liquid culture: Take the activated slant seeds and insert them into the liquid medium, and culture them at 35°C for 42 hours;

[0111] Fermentation tank culture: Inoculate 10% of the inoculum into a 10L fermenter, culture at 35°C and 30r / min, add high-concentration glucose when the glucose concentration is lower than 10g / L, and adjust the pH to 6 with ammonia water -8, take samples regularly to determine the OD600 value of the bacteria. When the fermentation proceeded to 80 hours, the intracellular vitamin B12 metabolic intermediate Ado-cbi accumulated to the maximum value, at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com