Bacillus coagulans and application thereof in calcium lactate production by in-situ product separating and fermentation

A technology for the separation of Bacillus coagulans and in-situ products, applied in fermentation, microbial-based methods, bacteria, etc., can solve the problems of substrate loss, microbial cytotoxicity, and high equipment requirements, and achieve cost savings, low nutritional requirements, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

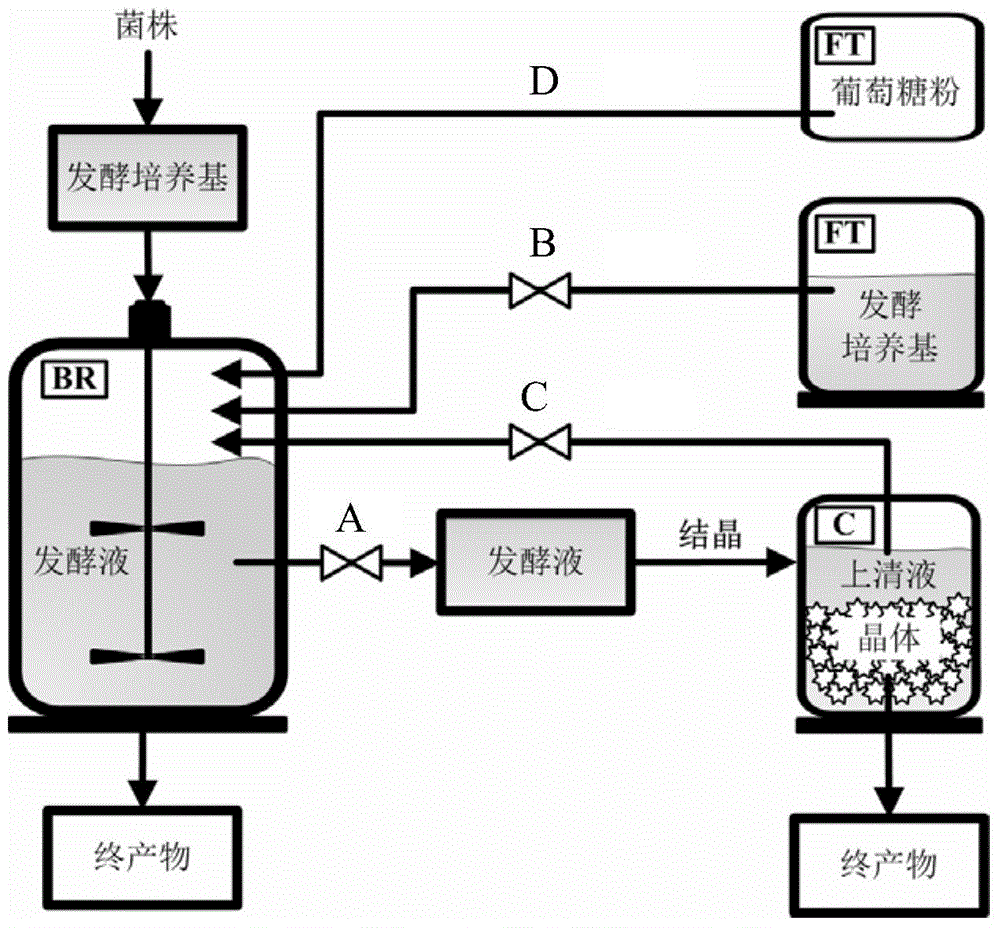

Method used

Image

Examples

Embodiment 1

[0041] The composition of medium used in the present embodiment is as follows:

[0042] Slant medium: glucose 10g / L, yeast powder 10g / L, soybean peptone 5g / L, calcium carbonate 5g / L, agar powder 15g / L, pH 6.0.

[0043] Seed medium: glucose 80g / L, yeast powder 10g / L, soybean peptone 5g / L, pH 6.0.

[0044] Fermentation medium: glucose 200g / L, yeast powder 12.6g / L, soybean peptone 1.2g / L, cottonseed protein 3g / L, sodium nitrate 1g / L, ammonium chloride 1g / L, pH 6.2.

[0045] The steps of producing optically pure L-calcium lactate by the open in-situ product separation and fermentation method of the present invention are as follows:

[0046] (1) Slant culture: inoculate Bacillus coagulans H-1 on the slant medium, and culture at 50-60°C for 24-48 hours.

[0047] (2) Seed culture: inoculate the slant culture of step (1) into 30 mL seed medium under sterile conditions, add 40 g / L calcium carbonate to control the pH of the fermentation broth, and culture at 50-60 °C for 10 ~ 24 hour...

Embodiment 2

[0054] The composition of medium used in the present embodiment is as follows:

[0055] Slant medium: glucose 10g / L, yeast powder 10g / L, soybean peptone 5g / L, calcium carbonate 5g / L, agar powder 15g / L, pH 6.0.

[0056] Seed medium: glucose 80g / L, yeast powder 10g / L, soybean peptone 5g / L, pH 6.0.

[0057] Fermentation medium: glucose 200g / L, yeast powder 12.6g / L, soybean peptone 1.2g / L, cottonseed protein 3g / L, sodium nitrate 1g / L, ammonium chloride 1g / L, pH 6.2.

[0058] The steps of producing optically pure L-calcium lactate by the open in-situ product separation and fermentation method of the present invention are as follows:

[0059] (1) Slant culture: inoculate Bacillus coagulans H-1 on the slant medium, and culture at 50-60°C for 24-48 hours.

[0060] (2) Seed culture: inoculate the slant culture of step (1) into 30 mL seed medium under sterile conditions, add 40 g / L calcium carbonate to control the pH of the fermentation broth, and culture at 50-60 °C for 10 ~ 24 hour...

Embodiment 3

[0067] The composition of medium used in the present embodiment is as follows:

[0068]Slant medium: glucose 10g / L, yeast powder 10g / L, soybean peptone 5g / L, calcium carbonate 5g / L, agar powder 15g / L, pH 6.0.

[0069] Seed medium: glucose 80g / L, yeast powder 10g / L, soybean peptone 5g / L, pH 6.0.

[0070] Fermentation medium: glucose 200g / L, yeast powder 12.6g / L, soybean peptone 1.2g / L, cottonseed protein 3g / L, sodium nitrate 1g / L, ammonium chloride 1g / L, pH 6.2.

[0071] The steps of producing optically pure L-calcium lactate by the open in-situ product separation and fermentation method of the present invention are as follows:

[0072] (1) Slant culture: inoculate Bacillus coagulans H-1 on the slant medium, and culture at 50-60°C for 24-48 hours.

[0073] (2) Seed culture: inoculate the slant culture of step (1) into 30 mL seed medium under sterile conditions, add 40 g / L calcium carbonate to control the pH of the fermentation broth, and culture at 50-60 °C for 10 ~ 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com