Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106 results about "Reference type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer programming, data types can be divided into two categories: value types and reference types. A value of value type is the actual value. A value of reference type is a reference to another value.

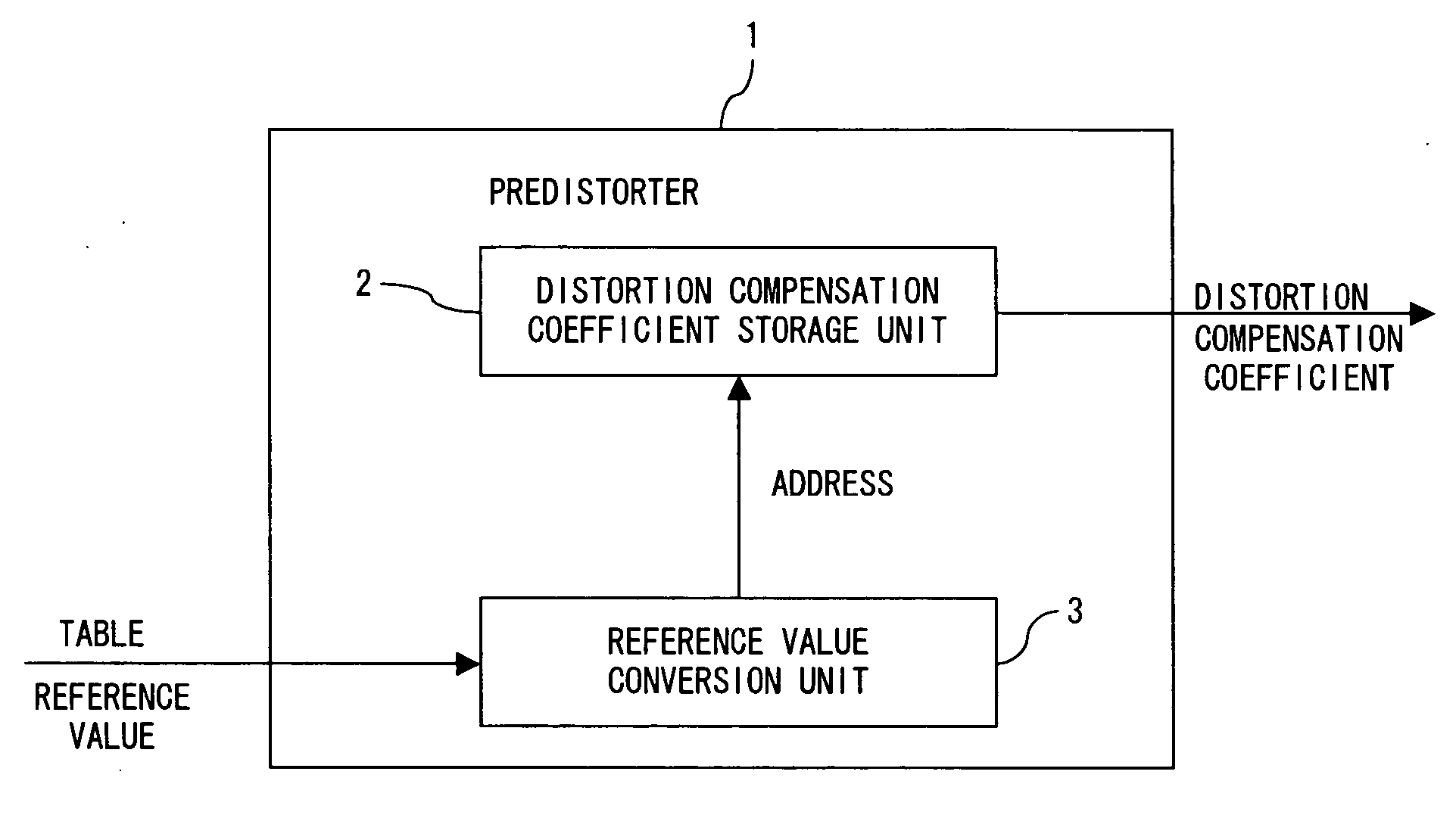

Table reference type predistorter

InactiveUS20050079834A1Amplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceAudio power amplifierReference type

The purpose of the present invention is to compensate the distortion of an amplifier by a predistorter which compensates the distortion of a power amplifier even when a frequency amplitude deviation exists. The predistorter comprises a distortion compensation coefficient storage unit for storing a distortion compensation coefficient corresponding to the reference value using the characteristic quantity of the envelope of a transmission signal before being inputted to the power amplifier as a reference value; and a reference value conversion unit for converting the characteristic quantity into a predetermined value according to the size of the characteristic quantity, and when the characteristic quantity is, for example, the amplitude value of an envelope and the amplitude value is small, that value is rounded up, for example, to an upper-limit value within a linear range of the amplifier.

Owner:FUJITSU LTD

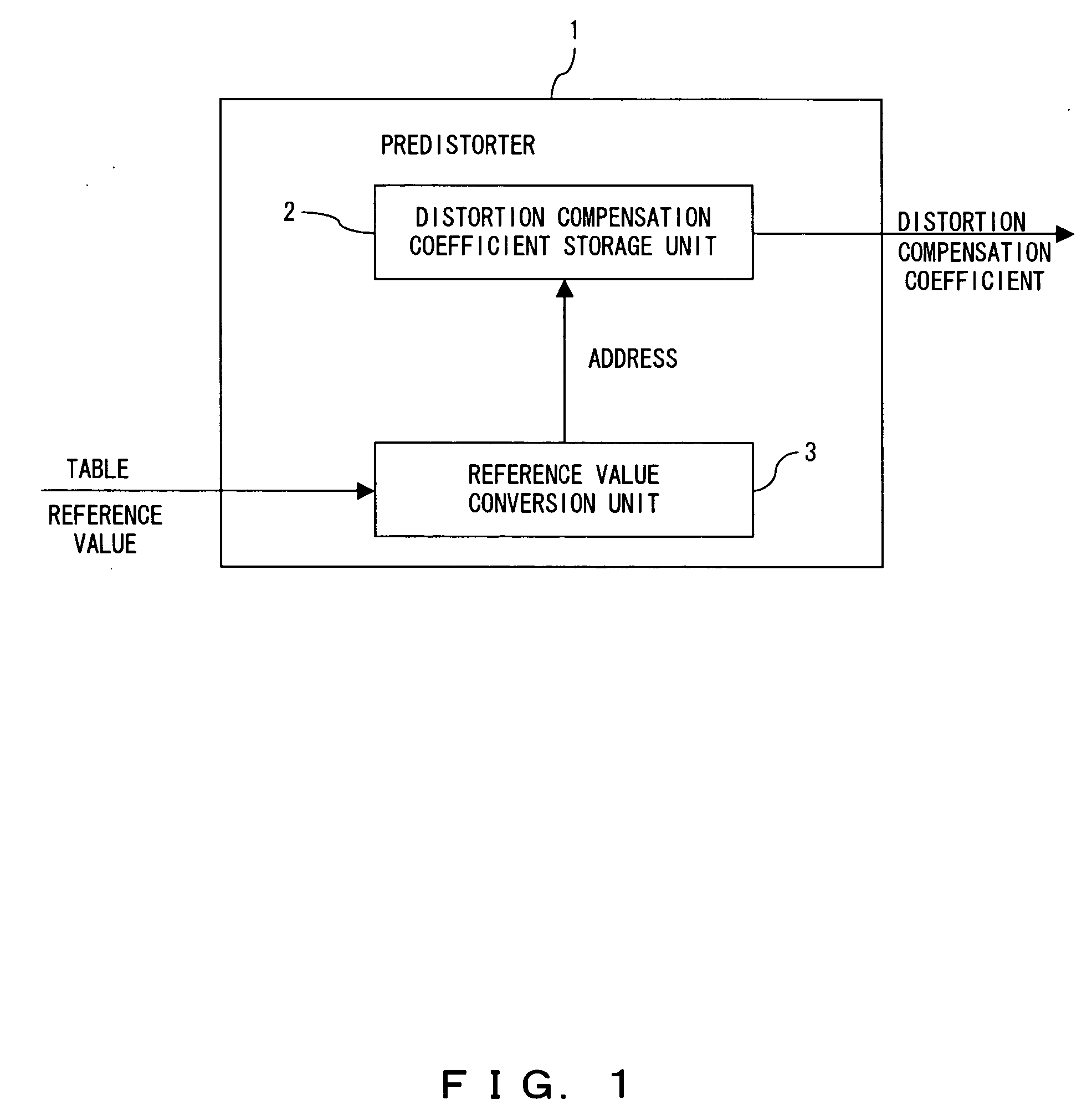

Visual administrator for specifying service references to support a service

ActiveUS20050216860A1Multiple digital computer combinationsProgram controlGraphicsApplication server

A method, apparatus, and system are provided for a visual administrator for specifying service references to support a service. According to one embodiment, a hierarchical tree structure having one or more tree nodes is displayed in a graphical user interface. Each of the one or more tree nodes may represent a resource of an application server. In an embodiment, at least one of the tree nodes represents a service of the application server. The tree node representing the service may be selected via a cursor control device. In one embodiment, upon selecting the tree node, a list of one or more service references associated with the service is displayed in the graphical user interface. Each listed service reference may include, for example, a server reference name, a service reference type, and / or a relationship value. In one embodiment, the relationship value specifies whether the listed service reference is to be automatically started when the service represented by the selected tree node is started.

Owner:SAP AG

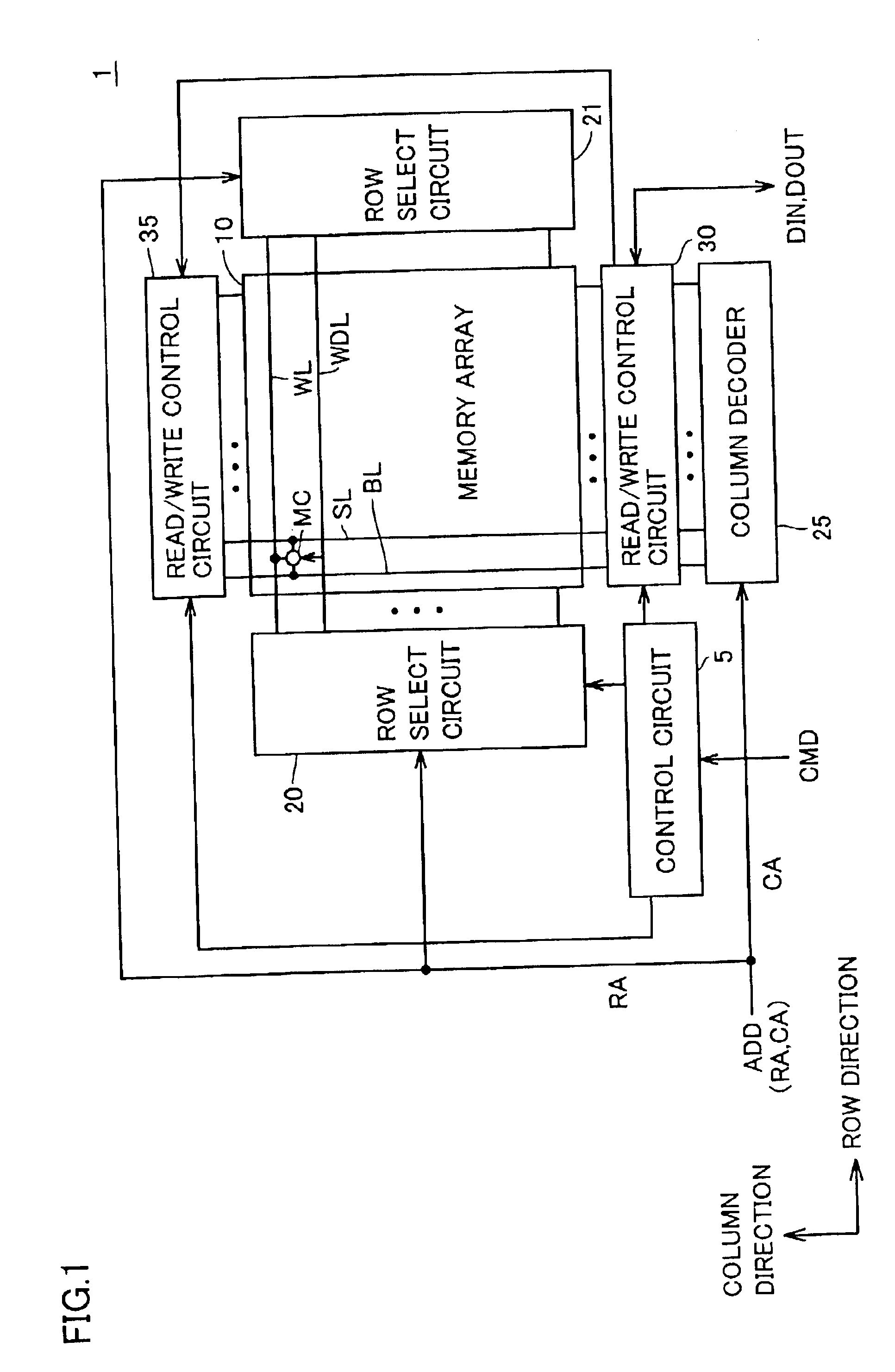

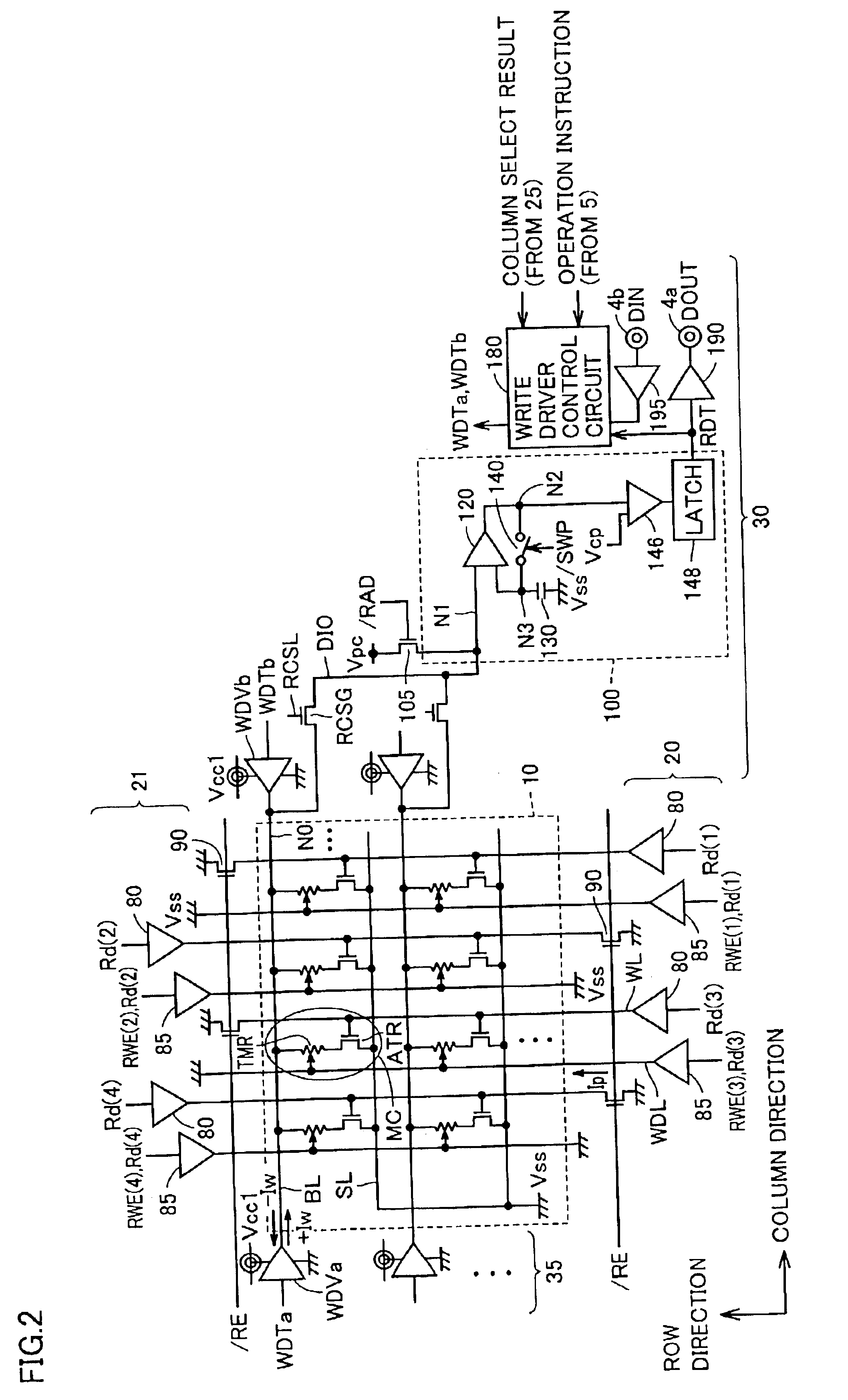

Thin film magnetic memory device executing self-reference type data read

InactiveUS6842366B2High operating requirementsSimple structureMagnetic-field-controlled resistorsSolid-state devicesHigh rateReference type

In one data read operation, data read for reading stored data before and after a predetermined data write magnetic field is applied to a selected memory cell, respectively, is executed, and the data read is executed in accordance with comparison of voltage levels corresponding to the data read operations before and after application of the predetermined data write magnetic field. In addition, data read operations before and after the application of a data write magnetic field are executed using read modify write. It is thereby possible to avoid an influence of an offset or the like resulting from manufacturing irregularities in respective circuits forming a data read path, to improve efficiency of the data read operation with accuracy and to execute a high rate data read operation.

Owner:RENESAS ELECTRONICS CORP

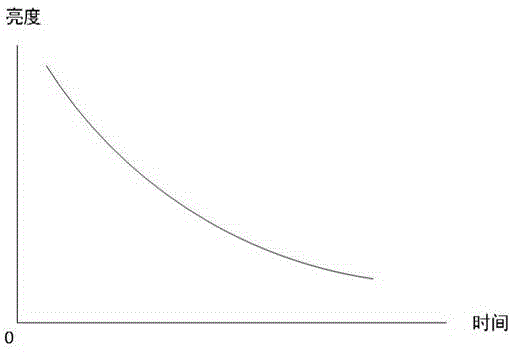

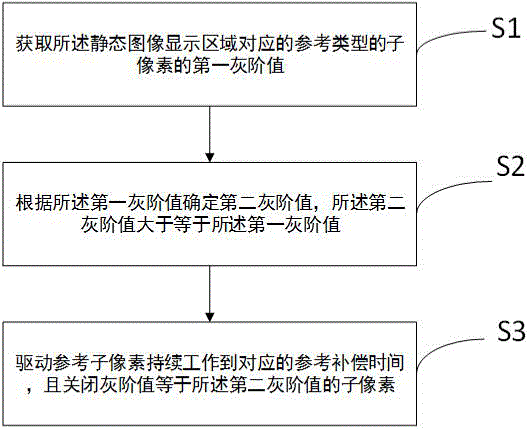

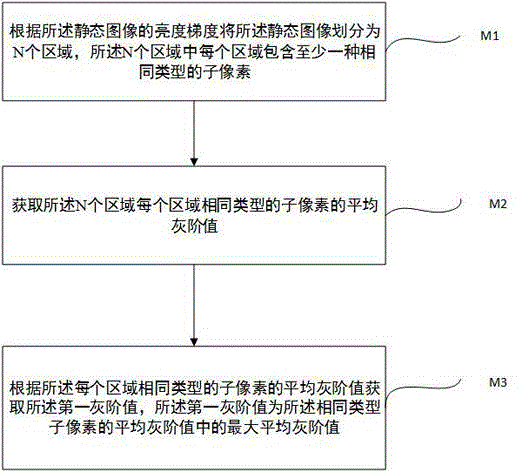

Method and system for eliminating afterimage defect of static-state image display area

ActiveCN104318893AReduced grayscale attenuation varianceEliminate afterimageStatic indicating devicesReference typeGray level

The invention discloses a method and system for eliminating an afterimage defect of a static-state image display area, and is applied to a self-luminous display apparatus. The static-state image display area comprises at least two sub pixels of the same type yet with different grayscale values. The method comprises: obtaining the first grayscale value of a sub pixel of a reference type corresponding to the static-state image display area, wherein the reference type is any one from RGB types, and the first grayscale value is the maximum grayscale value in the grayscale values of all the sub pixels of the reference type; according to the first grayscale value, determining a second grayscale value, the second grayscale value being greater than or equal to the first grayscale value; and driving a reference sub pixel to work continuously for corresponding reference compensation time, and closing a sub pixel whose grayscale value is equal to the second grayscale value, wherein the reference sub pixel is any one sub pixel of the reference type, whose grayscale value is smaller than the second grayscale value, and the reference compensation time is the continuous work time of the reference sub pixel. By using the technical scheme provided by the embodiments of the invention, once an image of the self-luminous display apparatus generates the afterimage defect problem, the problem can be rapidly eliminated.

Owner:HISENSE VISUAL TECH CO LTD

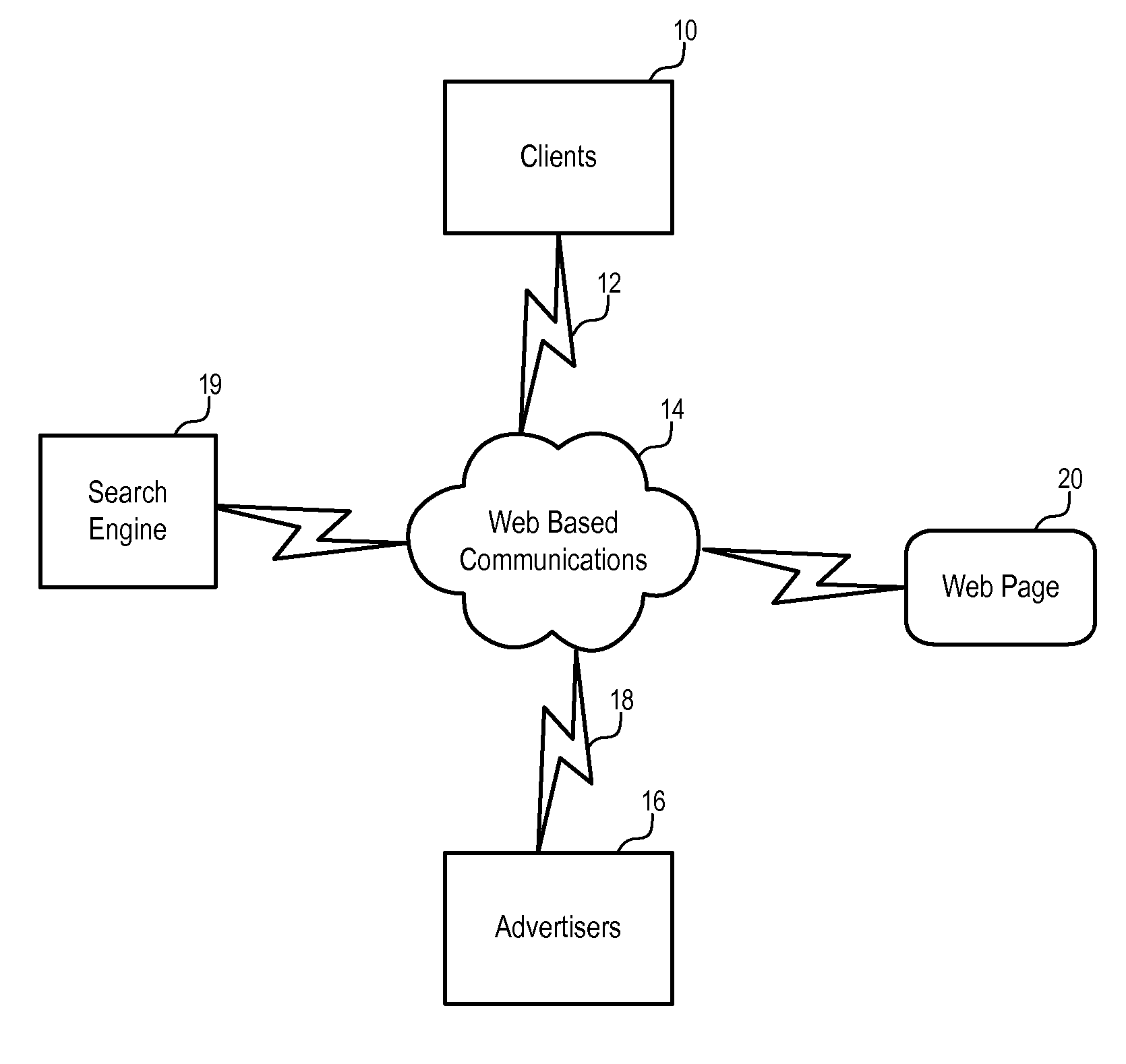

Methods and Apparatuses to Select Communication Tracking Mechanisms

Methods and apparatuses to select tracking mechanisms for the performance determination of advertisements. One embodiment includes: selecting one reference type from a plurality of reference types; and determining a reference of the selected type, the reference to be embedded in an advertisement to count communication leads generated from the advertisement. In one embodiment, the advertisement is to be charged according to a performance measure based on communication leads generated from the advertisement. For example, a price for the advertisement can be specified by a party for which the advertisement is to be presented. For example, the advertisement can be charged in response to a voice communication responding to the advertisement. In one embodiment, the plurality of reference types correspond to different mechanisms to track communication leads generated from the advertisement.

Owner:THRYV INC

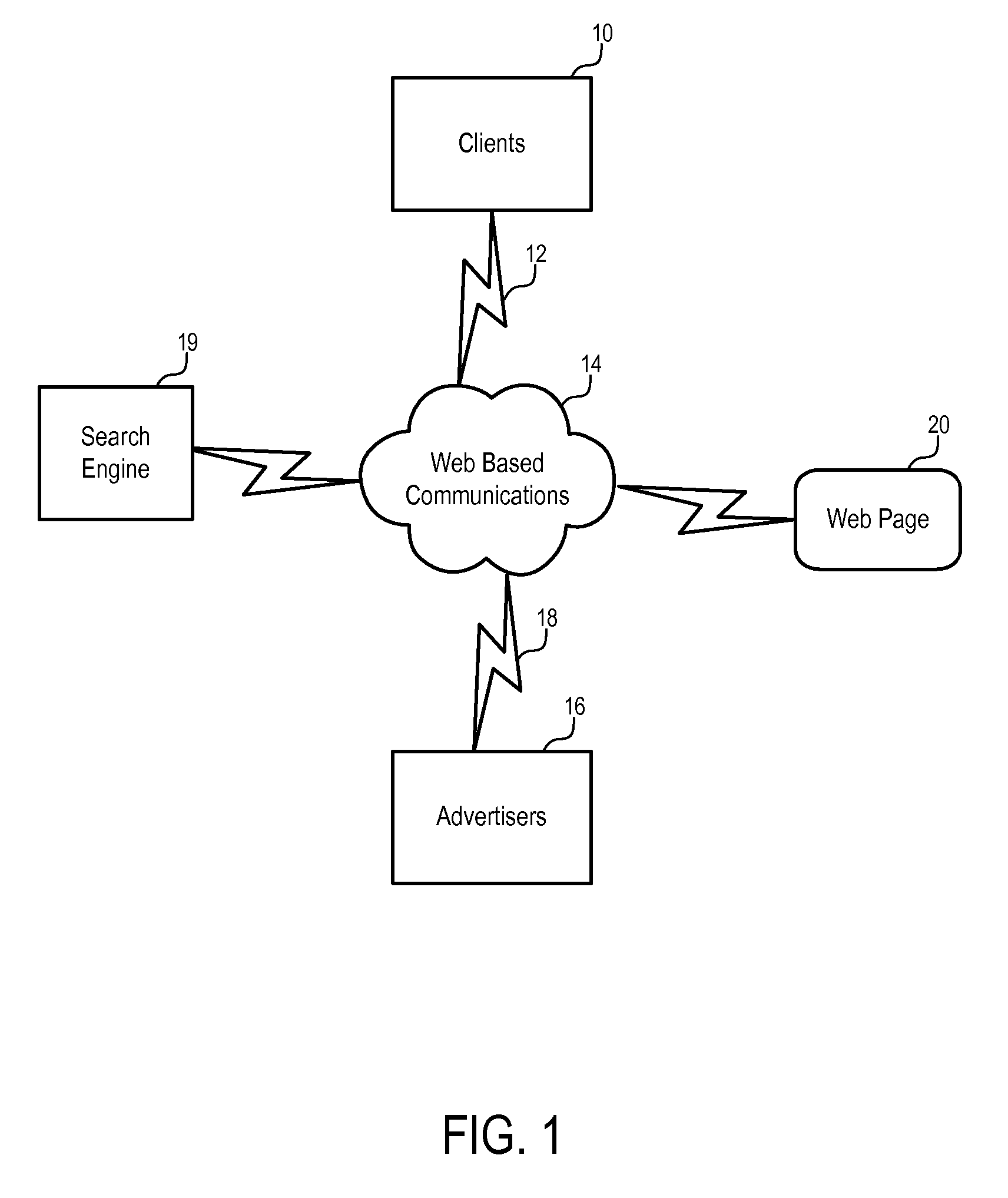

Hierarchical database apparatus, components selection method in hierarchical database, and components selection program

InactiveUS20050203869A1Efficiently formedAvoid difficult choicesDigital data processing detailsObject oriented databasesReference typeDatabase

A database apparatus stores a first contents table which includes first components including first contents data rows, and a second contents table which includes second components including second contents data rows. The first and second contents data rows each have a selection reference relationship between the first and second contents tables, and a selection reference condition is described using a selection reference type property. A selection reference processor is configured to query the second contents table under the selection reference condition to find candidates of second contents data rows. The candidates are referenced from a selected first contents data row according to the selection reference relationship. At least one second contents data row designated in the candidates displayed on the screen is selected. A combination device is configured to generate a combined contents table corresponding to a combined-type product, by combining the first and second contents data rows.

Owner:KK TOSHIBA

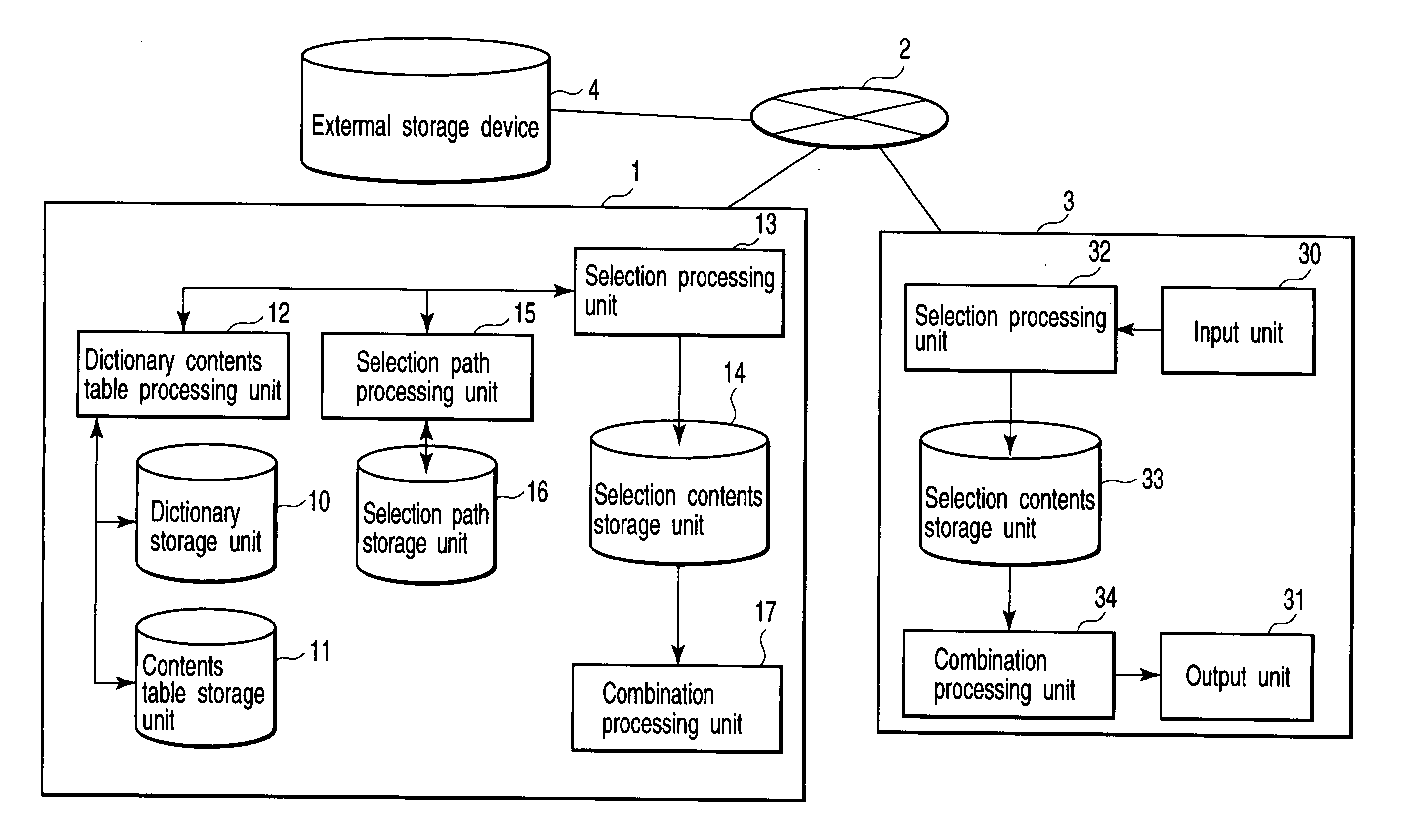

Hierarchical hybrid shot change detection method for MPEG-compressed video

InactiveUS7027509B2Rapidly detecting shot changeQuick changeTelevision system detailsPicture reproducers using cathode ray tubesCoding blockReference type

The present invention relates to a hierarchical hybrid shot change detection method in MPEG-compressed video circumstances, wherein the method according to the present invention comprises: detecting a shot change candidate region, by hierarchically applying a global color distribution difference among the frames by the color histogram; detecting an abridged shot change candidate region by using the difference of the global color histogram difference among adjacent I, P frames after additionally decoding P frames existed in the detected candidate region; decoding B frames within a abridged shot change detection candidate region at a macro block level in a sequence of the B frames sharing adjacent two anchor frames; determining a distribution characteristic of an intra coded block and a reference pattern type of each B frame in the region; and detecting a hard cut by using the distribution characteristic and reference type.

Owner:LG ELECTRONICS INC

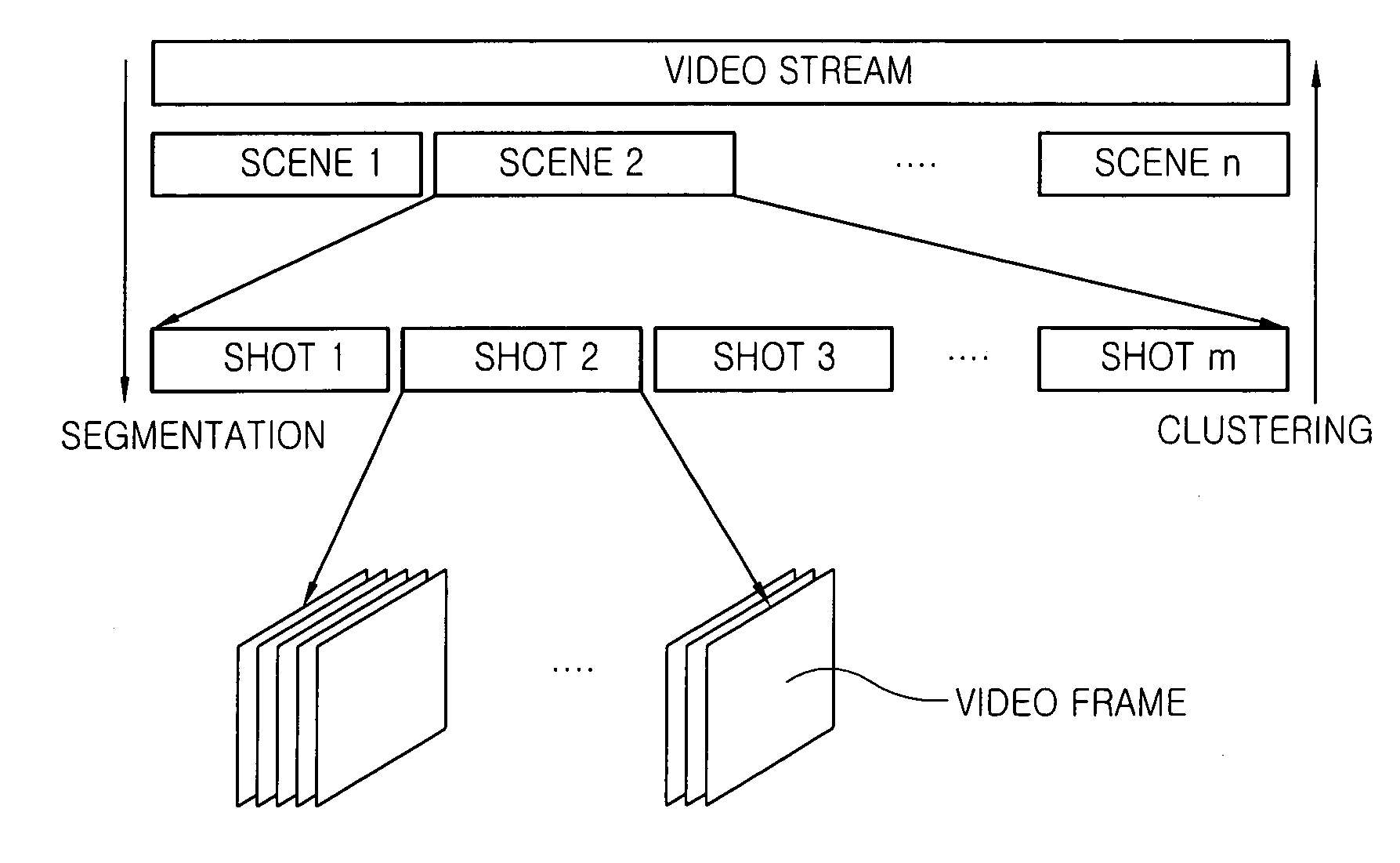

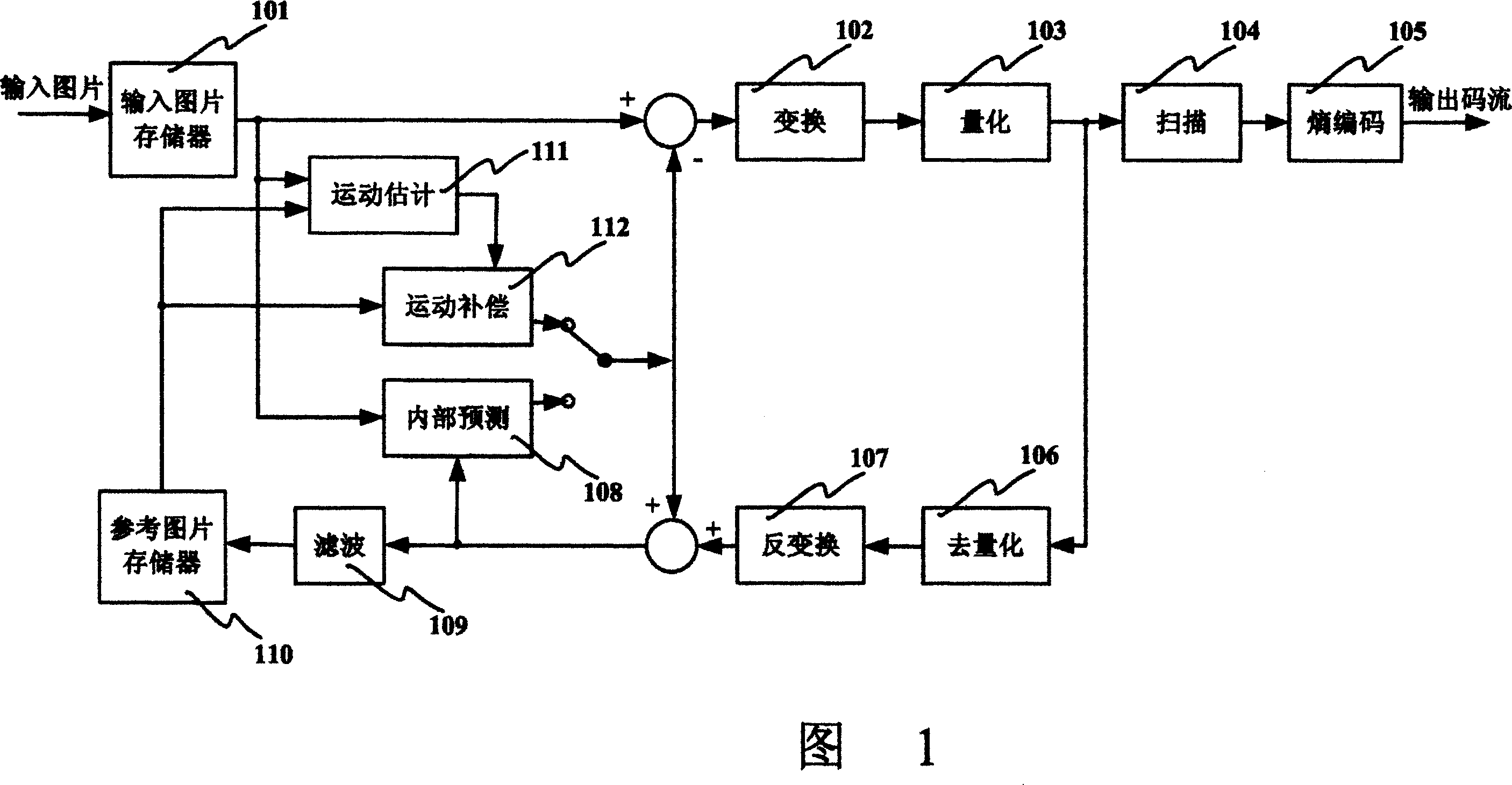

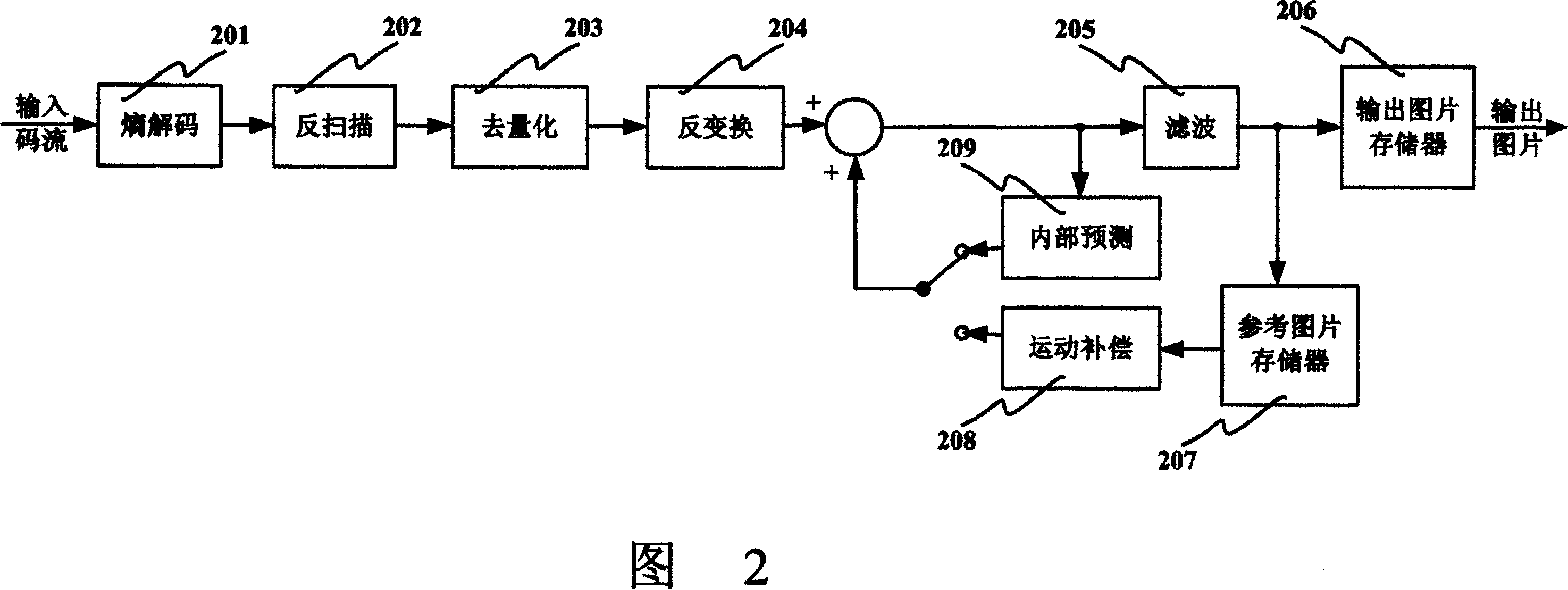

Coding and decoding method and device for dynamic image, and computer readable record medium

InactiveCN101005614ATelevision systemsDigital video signal modificationDecoding methodsReference type

The invention reveals a method for organizing, saving and establishing new reference image, expanses the application range of the reference image, and provides the apparatus and record medium for executing said method. Based-on each pixel, the reference image can be made with some operations such as deletion, modification and addition; the reference image is saved in the memory in a compressed format. The invention also reveals a new image type-reference type image, which can be used in two-way estimation, code rate control and anti-error capability.

Owner:鲁海宁

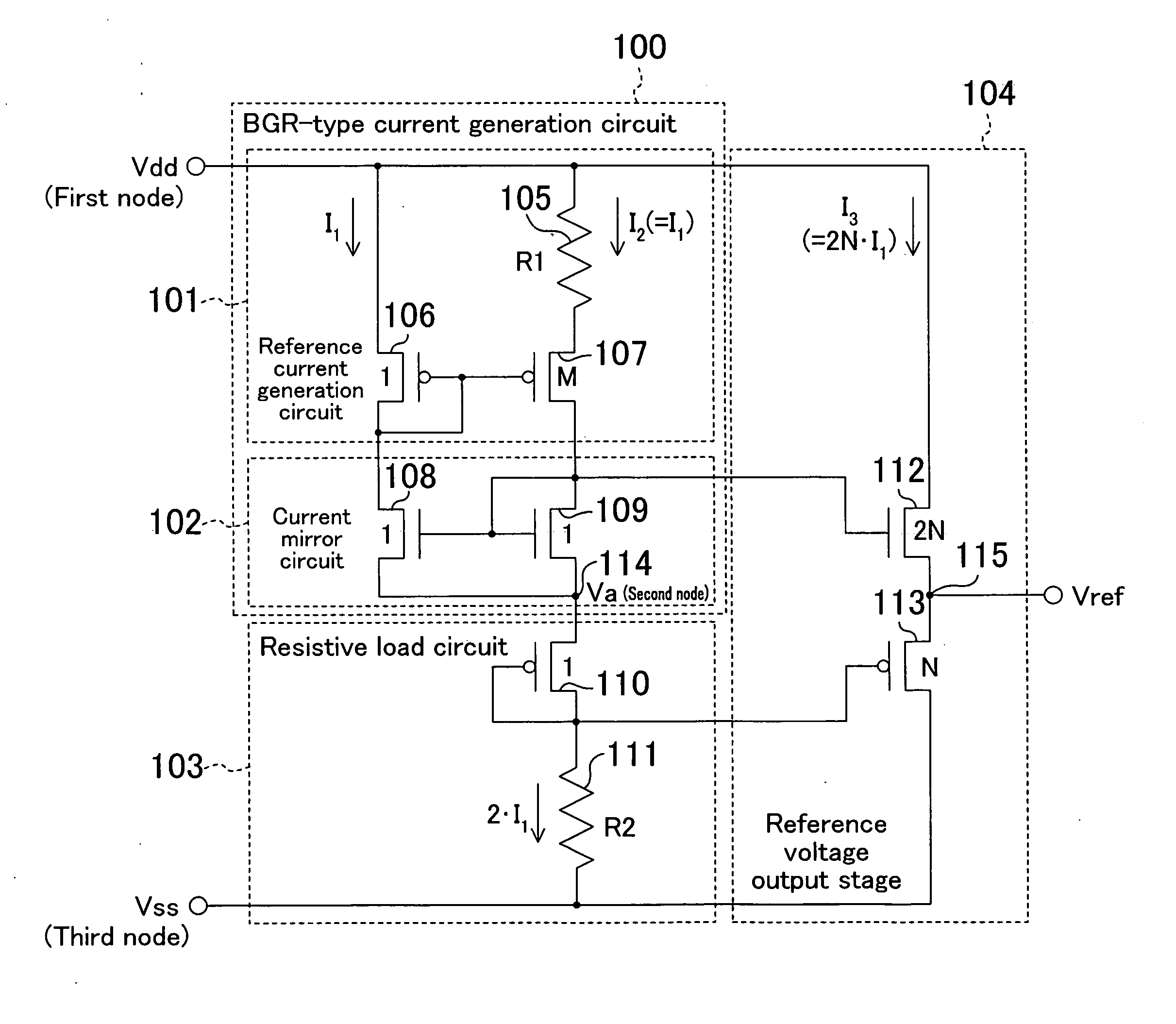

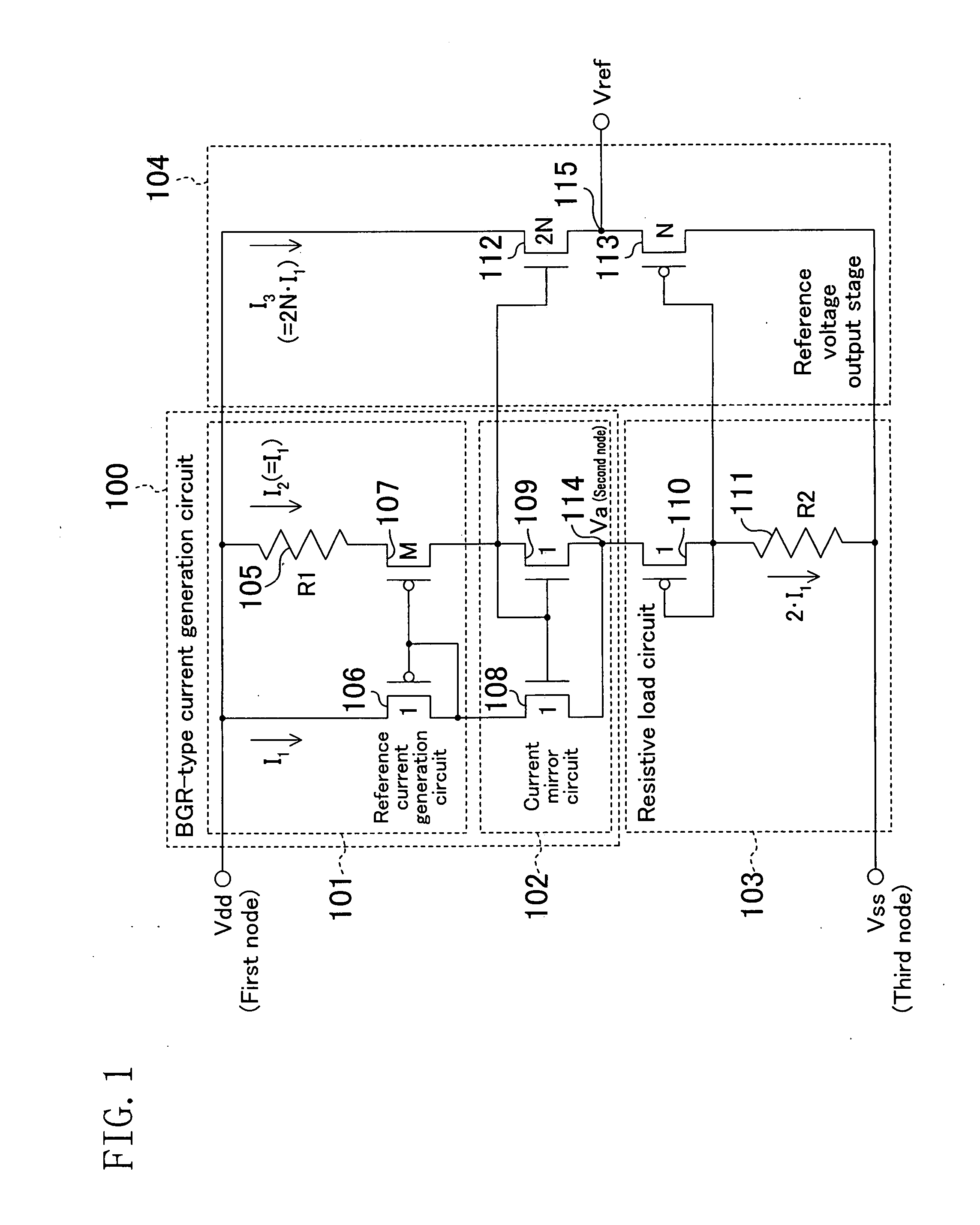

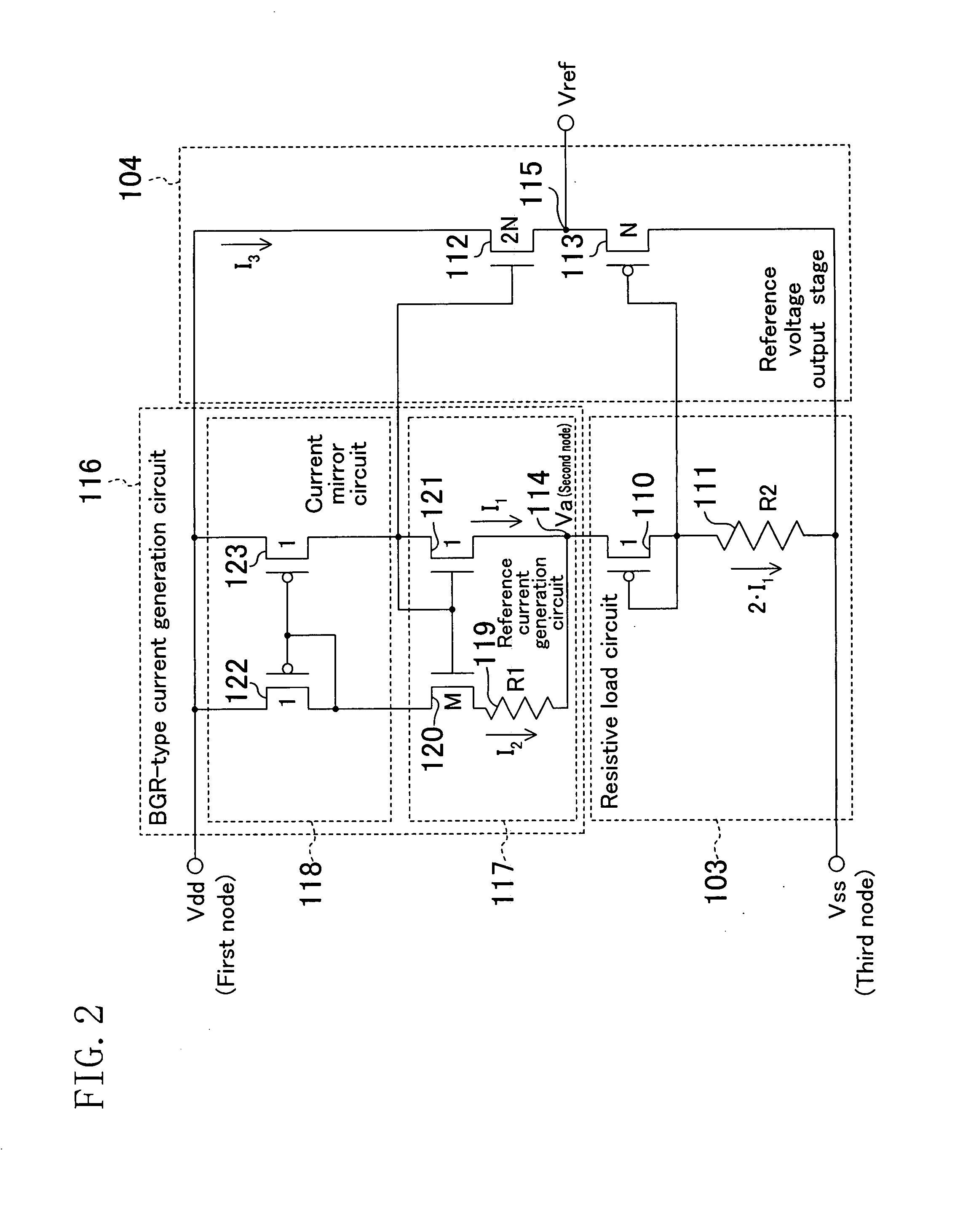

Reference voltage generation circuit

ActiveUS20080007243A1High power consumptionElectric variable regulationReference typeReference current

A reference voltage generation circuit of the present invention includes: a band gap reference-type current generation circuit for controlling each of currents flowing through a first current path and a second current path, which are extending from a first node to a second node, to be a predetermined reference current, by utilizing a voltage difference occurring between a pair of transistors or diodes; and a resistive load circuit provided between the second node and a third node.

Owner:SOCIONEXT INC

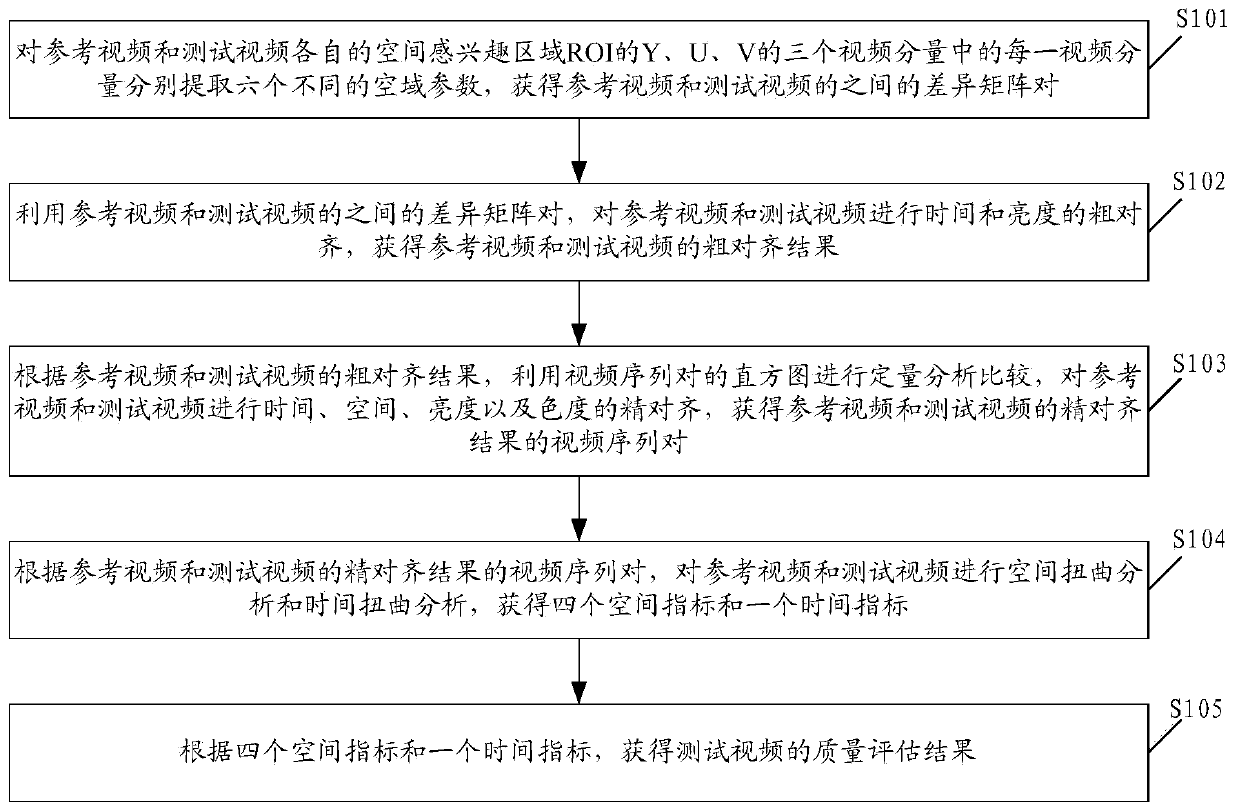

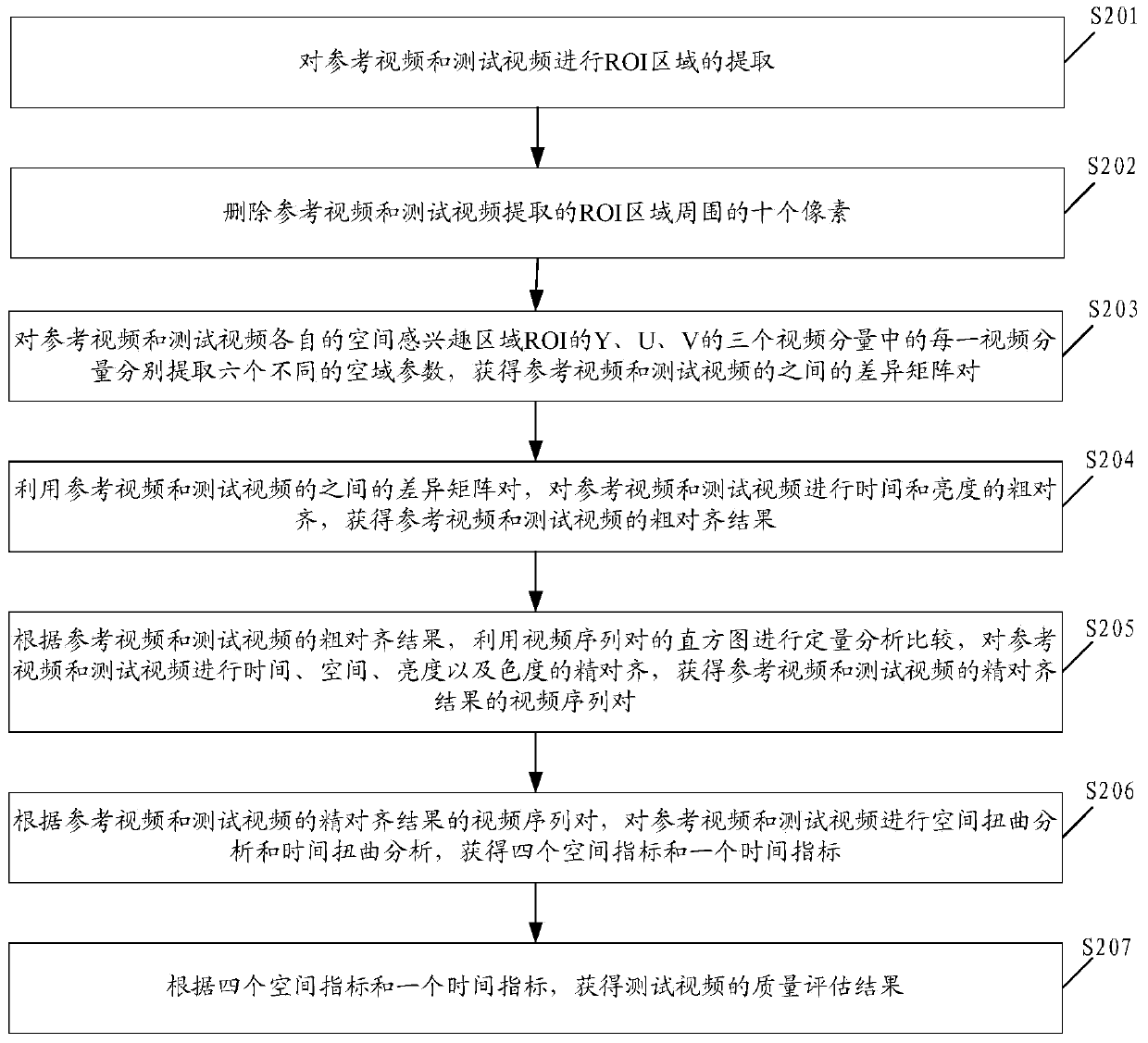

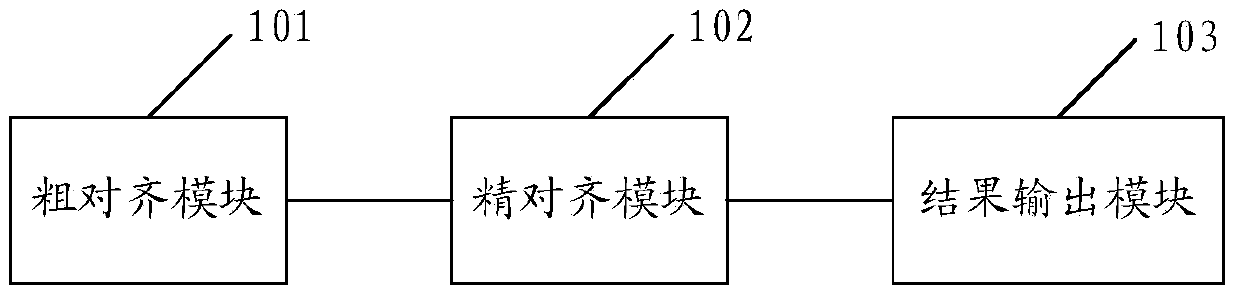

Method for full reference type video quality assessment, apparatus for full reference type video quality assessment and video quality testing device for full reference type video quality assessment

ActiveCN103731664AImprove accuracyCoarse alignment works wellTelevision systemsTime distortionVideo sequence

The invention discloses a method for full reference type video quality assessments, an apparatus for full reference type video quality assessments and a video quality testing device for full reference type video quality assessments. The method includes that six different spatial parameters are extracted from each of video components of YUV of each ROI of referencing videos and testing videos, so that a pair of difference matrixes can be achieved, utilizing the pair of difference matrixes, time and brightness rough alignment is performed on the referencing videos and the testing videos, and the result of rough alignment can be achieved. According to the result of rough alignment, time, space, brightness and chromaticity precise alignment is performed on the referencing videos and the testing videos, and the result of precise alignment of the pair of video sequences can be achieved. According to the result of precise alignment of the pair of video sequences, the space distortion analysis and the time distortion analysis are conducted to the referencing videos and the testing videos, four space indexes and one time index can be achieved, and a quality assessment result can be achieved according to the four space indexes and the one time index. According to the method, the method for full reference type video quality assessments, the apparatus for full reference type video quality assessments and the video quality testing device for full reference type video quality assessments is capable of getting better result of rough alignment, and the accuracy of the video quality assessment results can be improved.

Owner:MIGU CO LTD

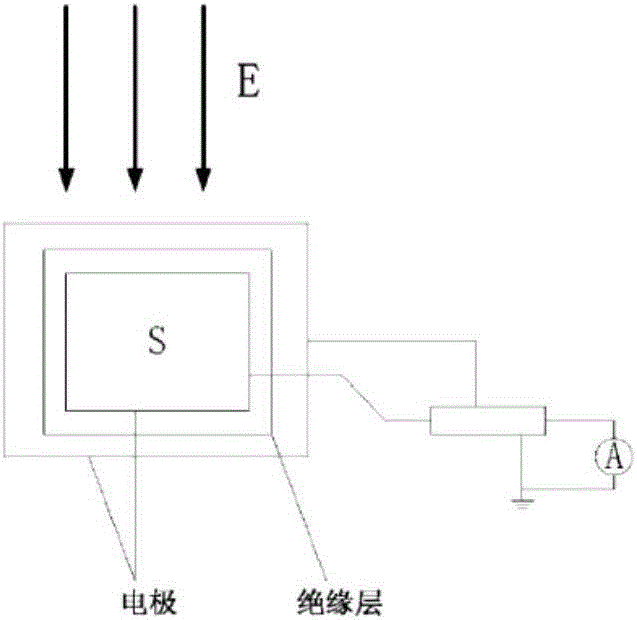

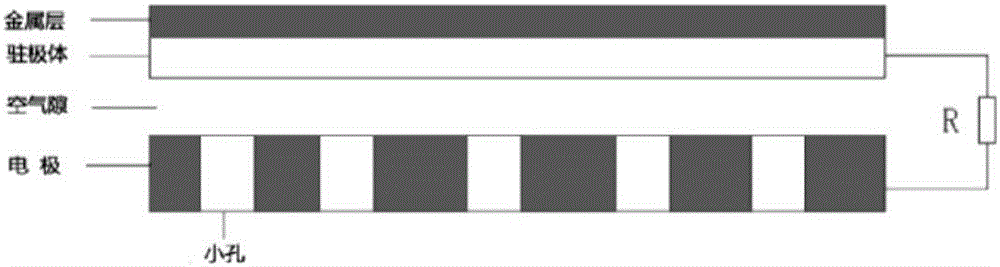

Wide domain all-state electromagnetic environmental monitoring system and method based on multi-parameter collaborative monitoring

InactiveCN106840258APower frequency magnetic field real-time monitoringReal-time monitoring of power frequency magnetic fieldMeasurement devicesElectric field sensorCorrelation analysis

The invention discloses a wide domain all-state electromagnetic environment monitoring system and method based on the multi-parameter collaborative monitoring. The system comprises a multi-parameter detection unit and a monitoring center, the detected electromagnetic environment data are sent to the monitoring center by the multi-parameter detection unit, the multi-parameter detection unit comprises a three dimensional ground reference type electric field sensor probe, a three dimensional magnetic field sensor, a digital type temperature humidity integrated sensor, a digital type pressure sensor and an electret capacitor microphone. The electromagnetic environment monitoring system achieves the integrated monitoring of the power frequency electric field, the power frequency magnetic field, the audible noise, the environmental temperature, the environmental humidity, the air pressure and other parameters, and provides data references for the correlation analysis and design verification of the electromagnetic environment information influence factors; and a full-day 24-hour continuous monitoring is conducted through the research monitoring device continuous power supply assurance unit.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

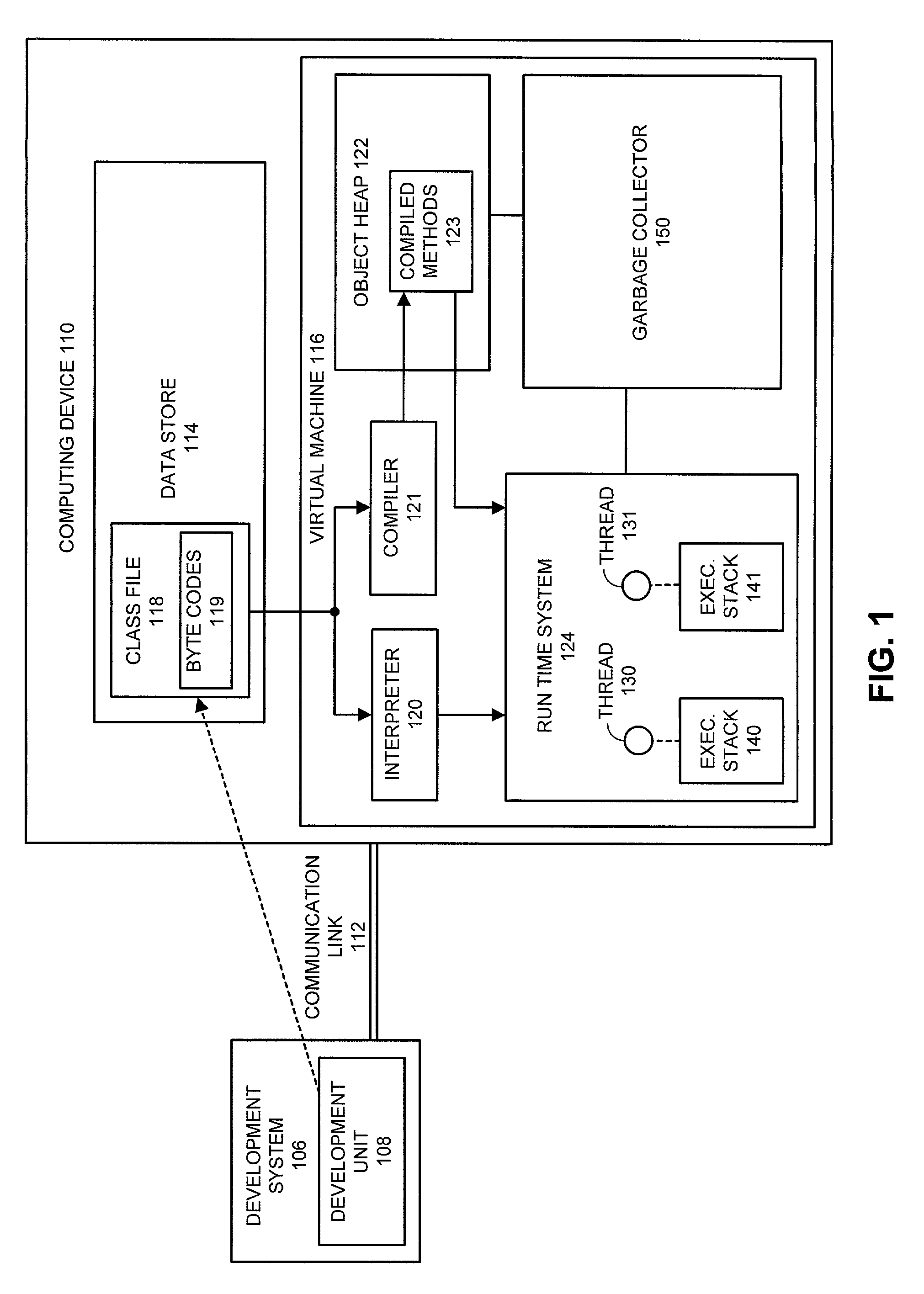

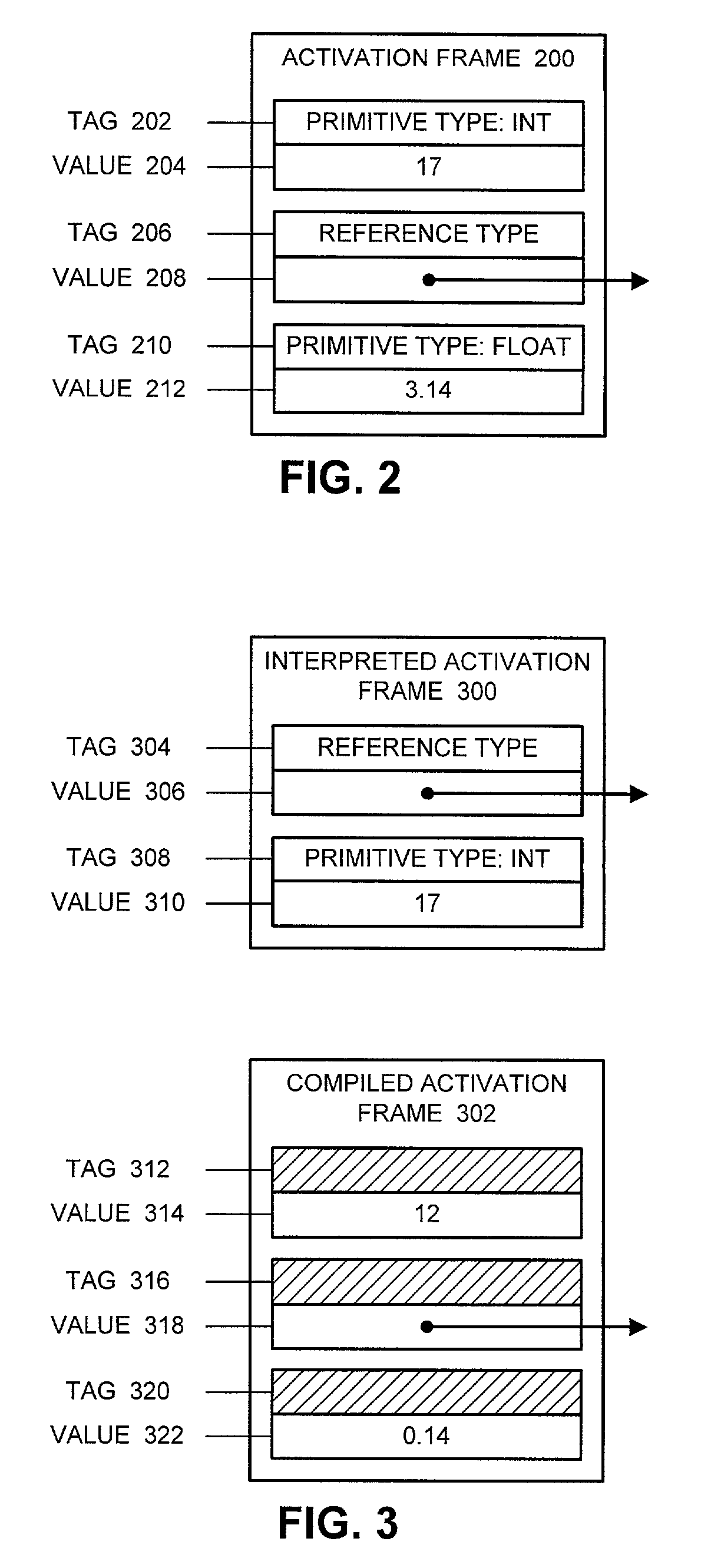

Method and apparatus for facilitating lazy type tagging for compiled activations

InactiveUS7181732B2Data processing applicationsMemory adressing/allocation/relocationReference typeWaste collection

One embodiment of the present invention provides a system for type tagging values in a compiled activation frame in a lazy manner to facilitate garbage collection. This system operates in a mixed-mode environment that supports both interpretation of byte codes and execution of compiled native code. Upon receiving an invocation of a method, the system creates an activation frame for the method on the execution stack. If the method is executing in interpreted mode, the interpreter maintains a tag for each value in the activation frame during execution. The tag indicates whether the value is a reference type or a primitive type. However, if the method is executing in compiled mode, the system allocates space for tags for each value in the activation frame, but does not fill in the tags during execution. This allows the tags to be filled in at a future time when needed.

Owner:ORACLE INT CORP

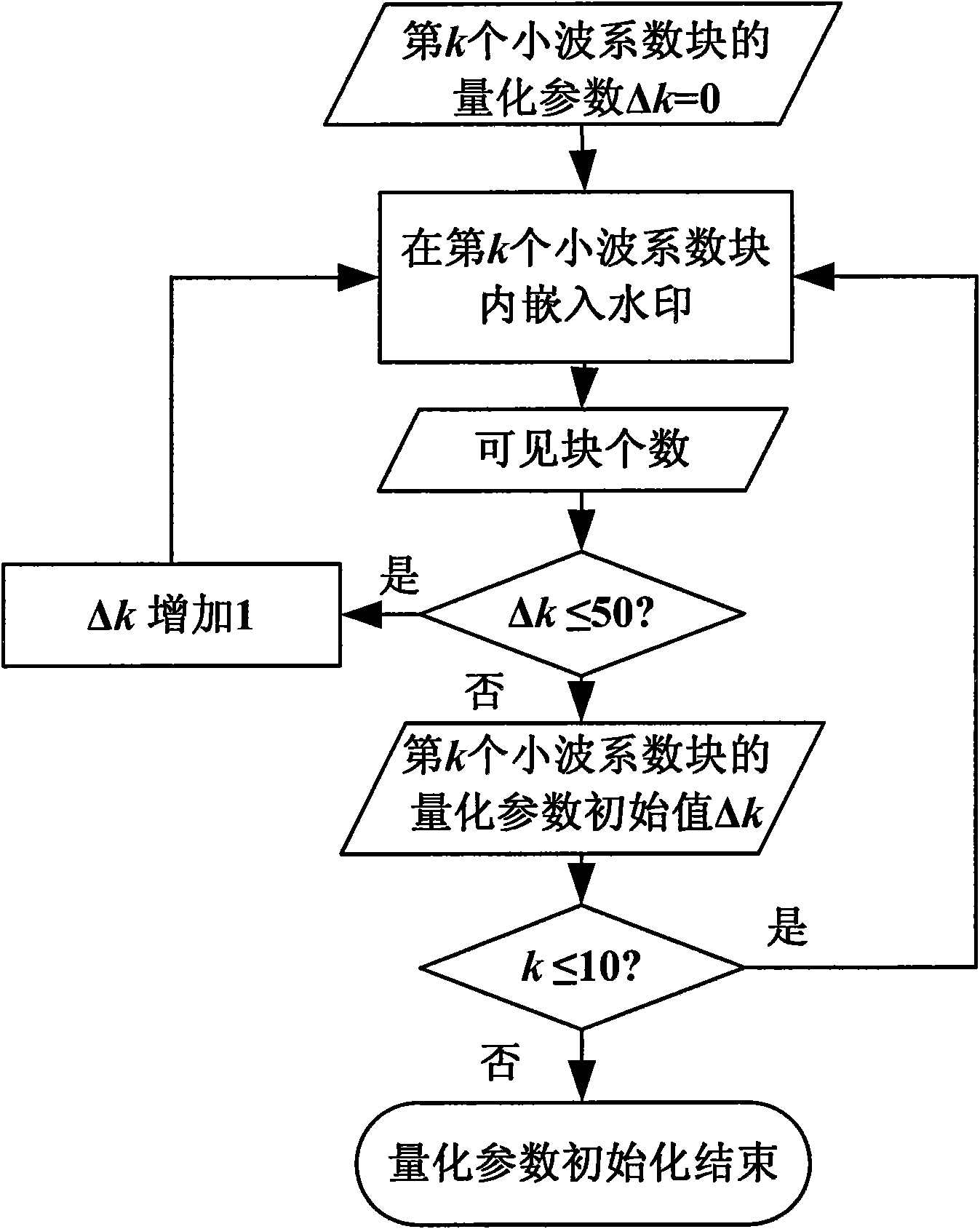

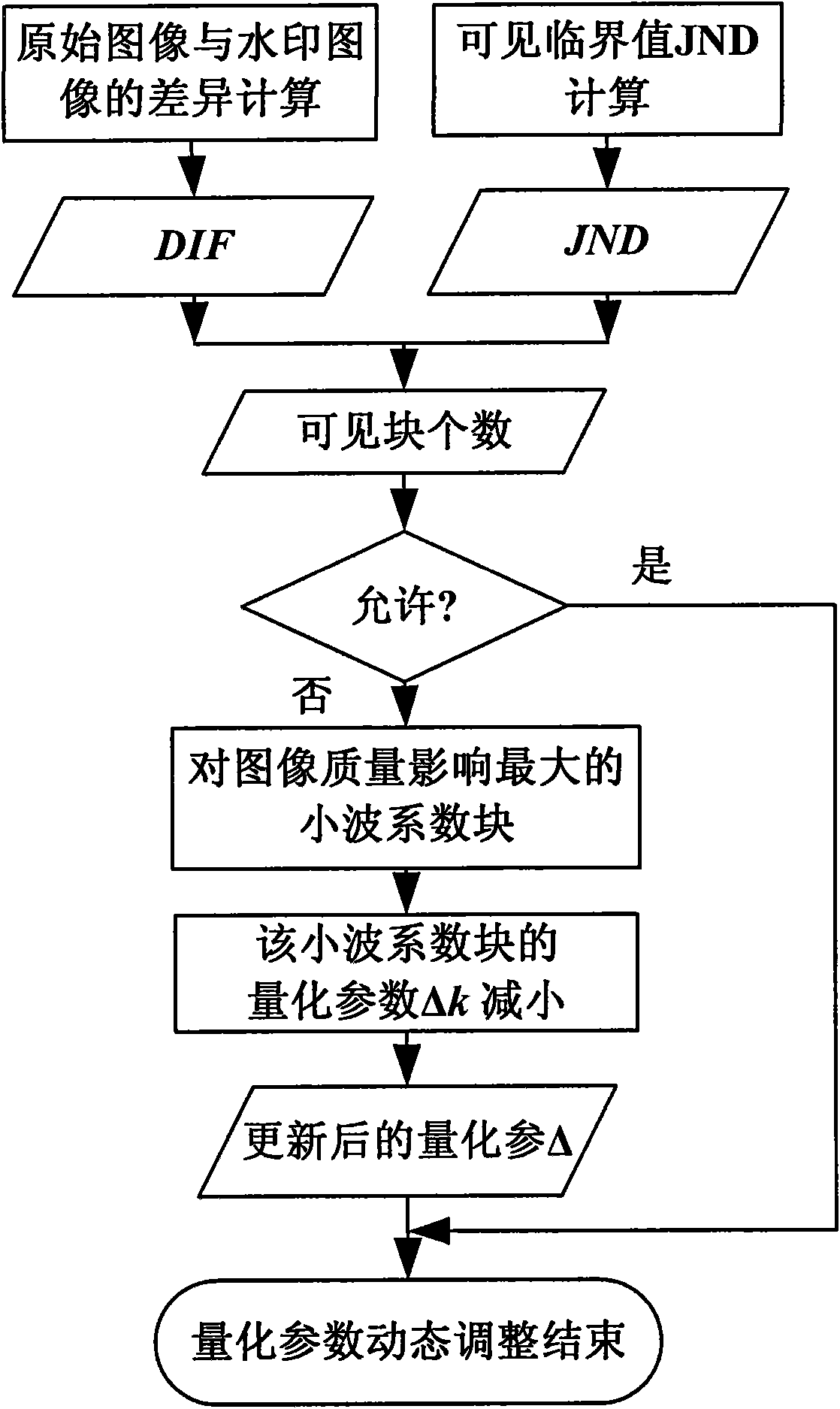

Method for evaluating objective quality of partial reference type image

ActiveCN101605272AMonitor transmission qualityTelevision systemsImage data processing detailsObjective qualityReference type

The invention discloses a method for evaluating objective quality of a partial reference type image. The method comprises the following steps of: 1) at the image sending end, analyzing the texture complexity of the original image to obtain a watermark embedding indicator diagram; 2) at the image sending end, using a quantization parameter initialization adjusting system and a quantization parameter dynamic reverse adjusting system to determine a quantization parameter; 3) at the image sending end and the image receiving end, performing the wavelet transform of the original image to obtain wavelet self sub-band images, and according to the watermark embedding indicator diagram and the quantization parameter, embedding and extracting digital watermarks in all wavelet sub-band images; and 4) at the image receiving end, weighting the recovery rates of the watermarks extracted in the wavelet sub-band images, and obtaining the evaluation of the objective quality of the image. Under the condition of insufficient original images at the image receiving end, by the method, the objective quality of the images can be correctly reflected by using the digital watermarks hidden in the images, so that the method has a wide application prospect.

Owner:ZHEJIANG UNIV

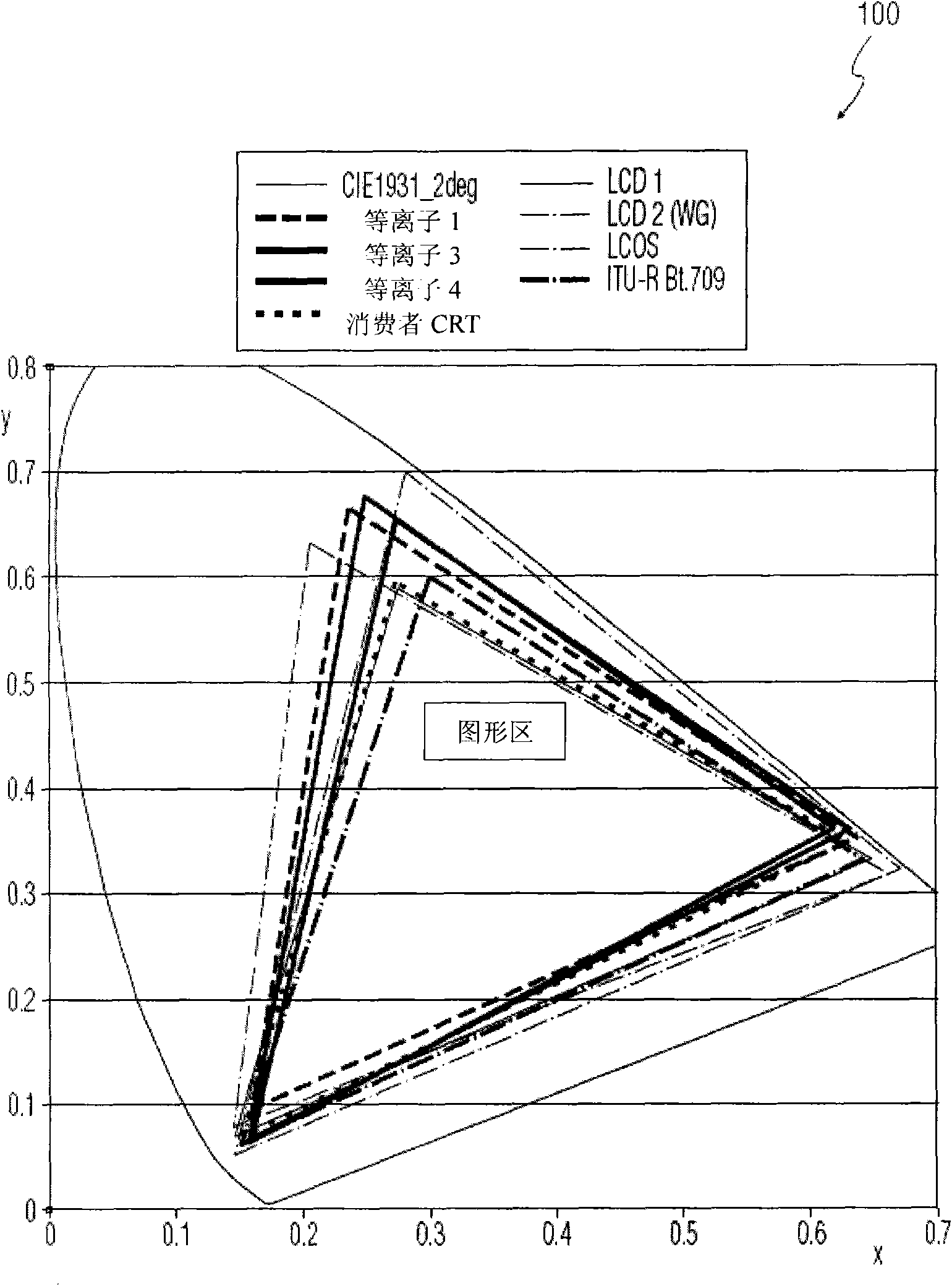

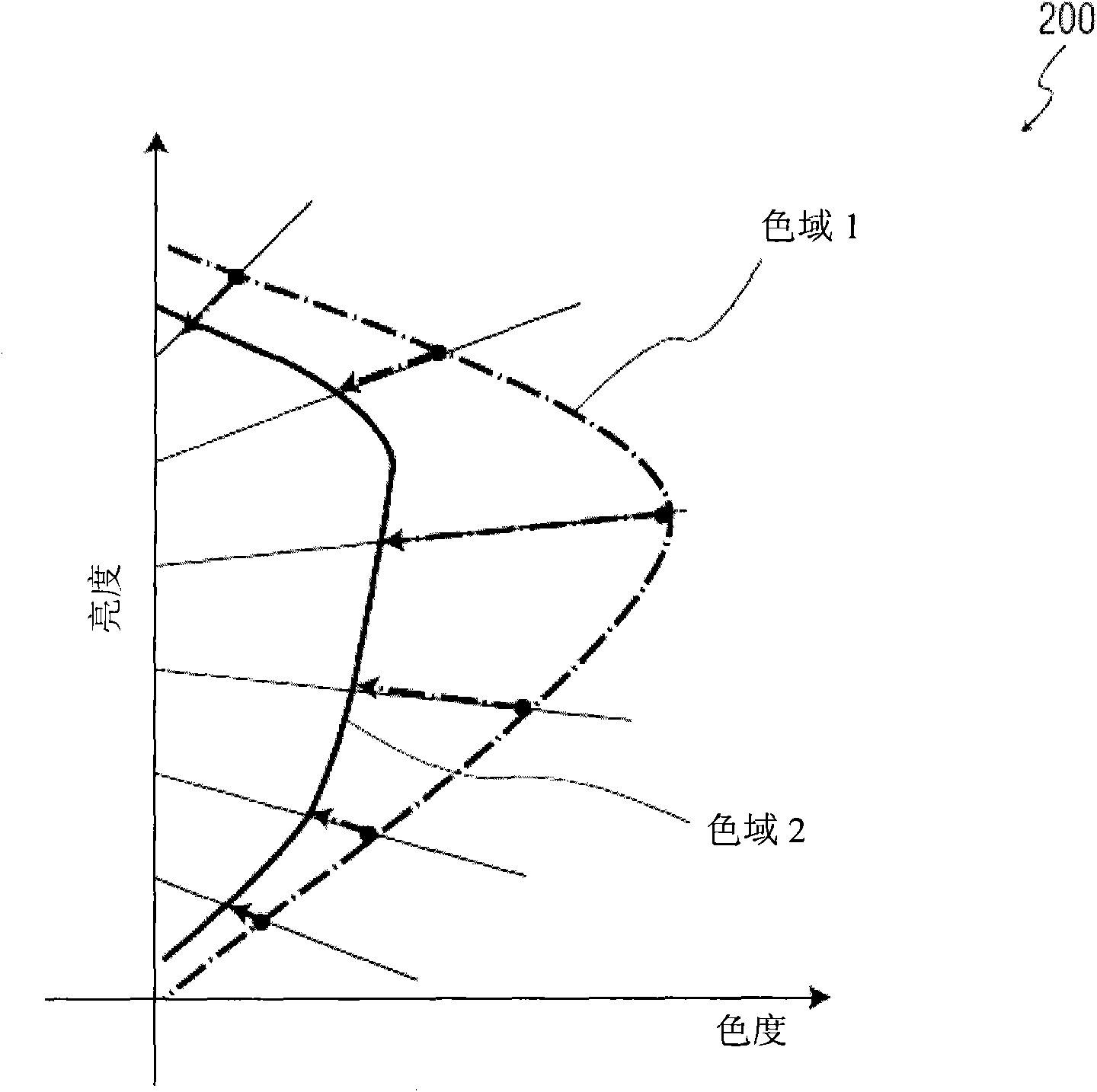

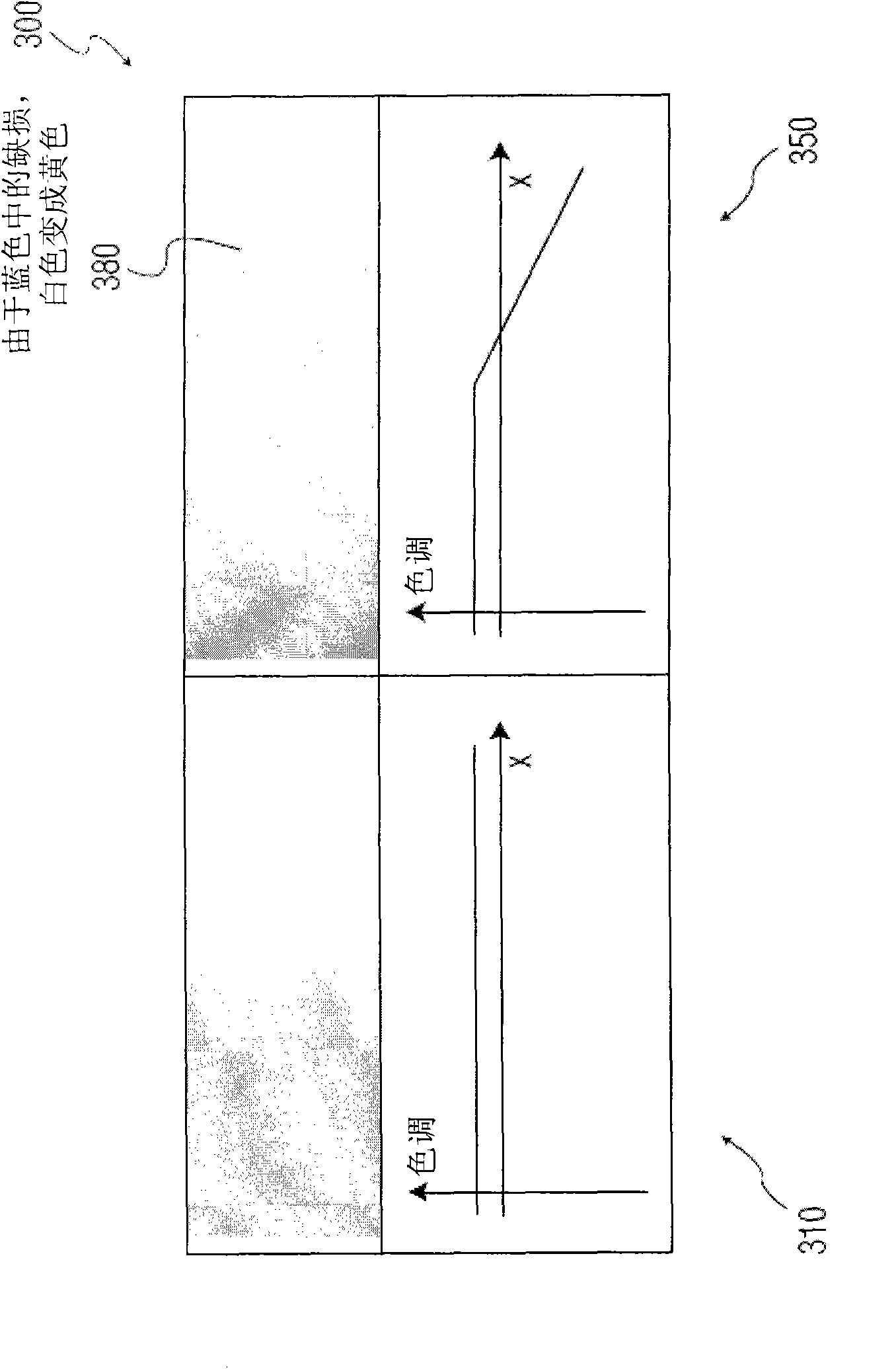

Methods and systems for displays with chromatic correction with differing chromatic ranges

The invention relates to methods and systems for displays with chromatic correction with differing chromatic ranges. A method comprises carrying out a chromatic correction on the content of an image source, by means of at least one of a display of non-reference type with a non-reference chromatic range and a display of the reference type with a reference chromatic range. The above step includes reformatting (530) the content of the image source to give a reformatted image source content which has undergone a chromatic correction for display on displays of the non-reference type with a non-reference chromatic range. The above step also comprises generation (586) of metadata for mapping chromatic range which chromatically transforms the reformatted image content which has undergone a chromatic correction for display on displays of the reference type with a reference chromatic range. The source image content is only reformatted for display of the non-reference type with the non-referencechromatic range.

Owner:INTERDIGITAL CE PATENT HLDG

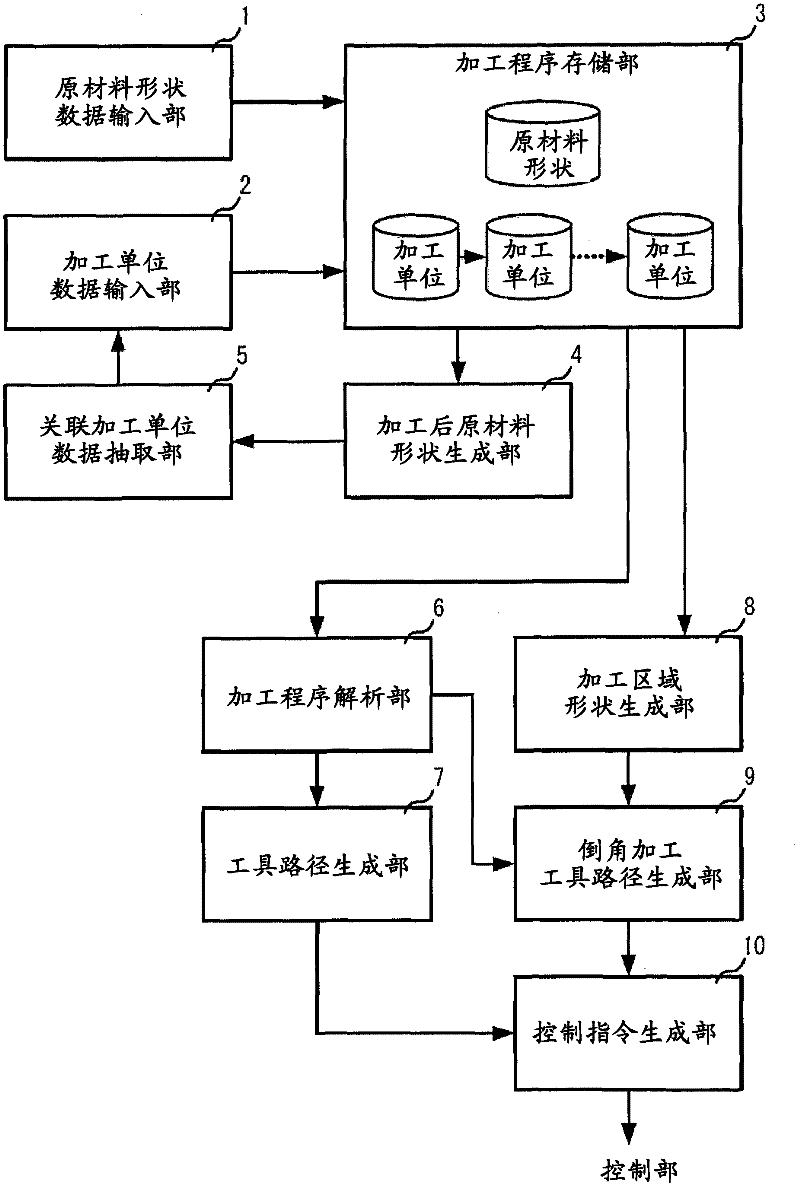

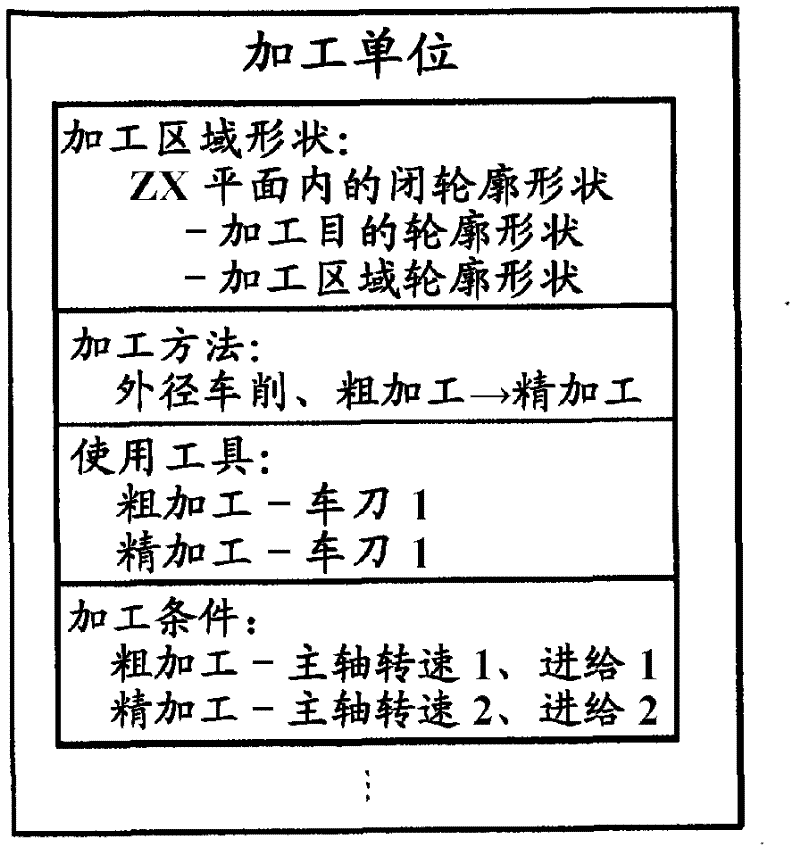

Automatic programming device and method

ActiveCN102473008ASimple definitionProgramme controlAutomatic control devicesReference typeDatum reference

In order to obtain an automatic programming device which makes it easy to define machining-unit data and makes it possible to form an appropriate machining area shape in accordance with the shape of a curve section even if the shape of a part to be machined such as a hole or the edge of a groove, which is formed on a cylindrical surface is a complicated curve, disclosed is an automatic programming device which is provided with a raw-material shape data input unit (1) for inputting raw-material shape data, a machining program storage unit (3) for storing the raw-material shape data and the machining-unit data, a machining-unit data input unit (2) for inputting other machining-unit reference type of machining-unit data, which references the machining area shape data included in the machining-unit data, a machining area shape generating unit (8); for generating machining area shape data associated with the machining-unit data of partial machining on the basis of the raw-material shape data and the machining area shape data referenced by other machining-unit reference type of machining-unit data, and a control command generating unit (10) for generating control command data on the basis of the machining-unit data of the partial machining including the machining area shape data.

Owner:MITSUBISHI ELECTRIC CORP

Software test method applying interval operation

InactiveCN101286133AReduce false alarm rateImprove accuracySoftware testing/debuggingReference typeSoftware engineering

The invention relates to the field of software testing technique. The invention can solve the technical problems of ineffective calculation of the unreachable path and insufficiently used variable value information in a program state test to some extent. The invention provides the concept of interval set, defines a set operation and a four arithmetic operation in the numerical variable interval set and defines an interval calculation method for Boolean typed variables, reference typed variables and expression. The method of the invention collects the value and expression range information of the variable in the prophase of software testing processing, and applies the information to the sentence nodes of a control flow graph; experiments show that the software testing method with interval operation added has lower false alarm rate of the testing results and higher testing accuracy than the original software testing method without interval information added.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Method and system for optimizing array sizes in a JAVA virtual machine

InactiveUS20060242635A1Minimize impactProgram controlMemory systemsData processing systemArray data structure

A method, computer program product, and data processing system for allocating memory for arrays in a fragmented heap is disclosed. In a preferred embodiment, a JAVA virtual machine (JVM) is enhanced to organize each array as an array of arrays (or, internally, an array of pointers to arrays, since JAVA arrays are reference types). The individual “inner arrays” within the “outer array” are segments that collectively simulate a larger “virtual array.” Because all accesses and allocations of these arrays are performed by the JAVA virtual machine, the array segmentation is entirely transparent to the programmer, at least at the JAVA-language level. Support for native methods is provided by making relatively minor modifications to some of the array manipulation functions of the JAVA Native Interface (JNI), so as to minimize the impact of the segmentation scheme on native code.

Owner:IBM CORP

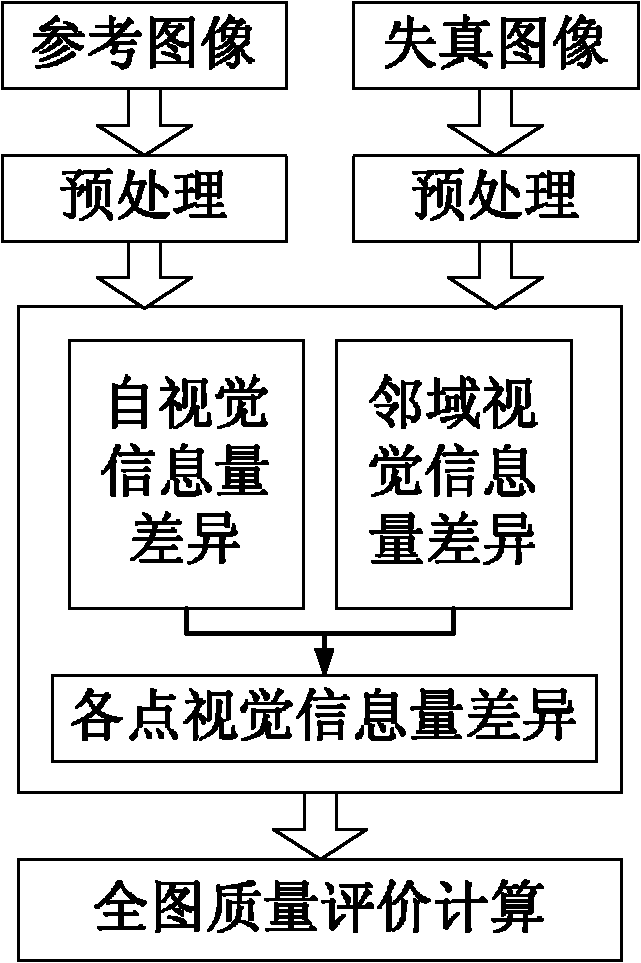

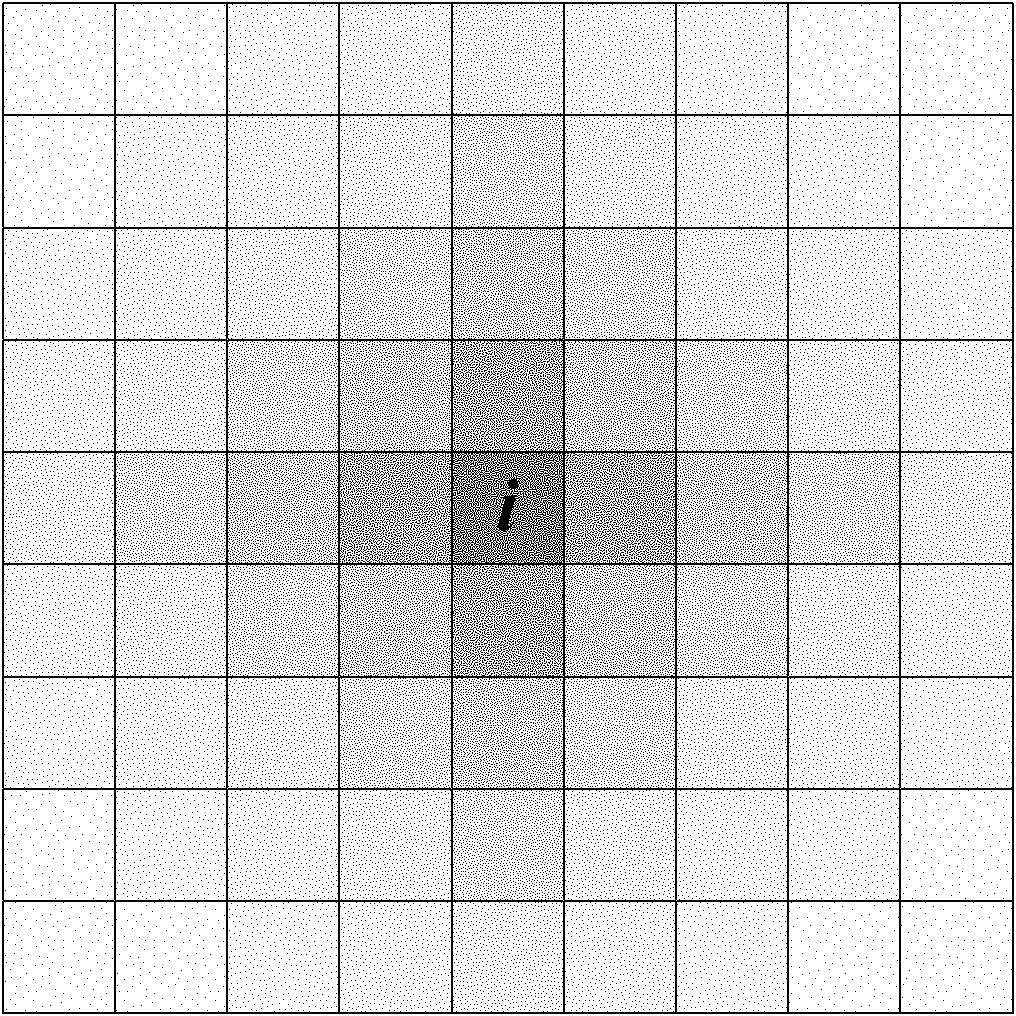

Full-reference type image quality evaluation method based on visual information amount difference

ActiveCN102036098AEase of evaluationImprove relevanceTelevision systemsPattern recognitionEvaluation result

The invention relates to a full-reference type image quality evaluation method for evaluating distorted image quality quantitatively based on visual information amount difference, comprising the following steps: carrying out the selective preprocessing operation on an image firstly; then calculating the self-visual information amount difference value and neighborhood visual information amount difference value of each corresponding point of the reference image and the distorted image respectively, and calculating the visual information amount difference value of each point based on the two values; and finally using the weighted sum of the visual information amount difference value of each point as the evaluation value of the distorted image quality. The image quality evaluation method provided by the invention is stable in performance, easy for implementation and lower in time complexity compared with the similar algorithm, and ensures that the evaluation result is consistent with the visual feeling, thereby being more suitable for the application fields of image quality evaluation and image processing with higher real-time requirement.

Owner:BEIHANG UNIV

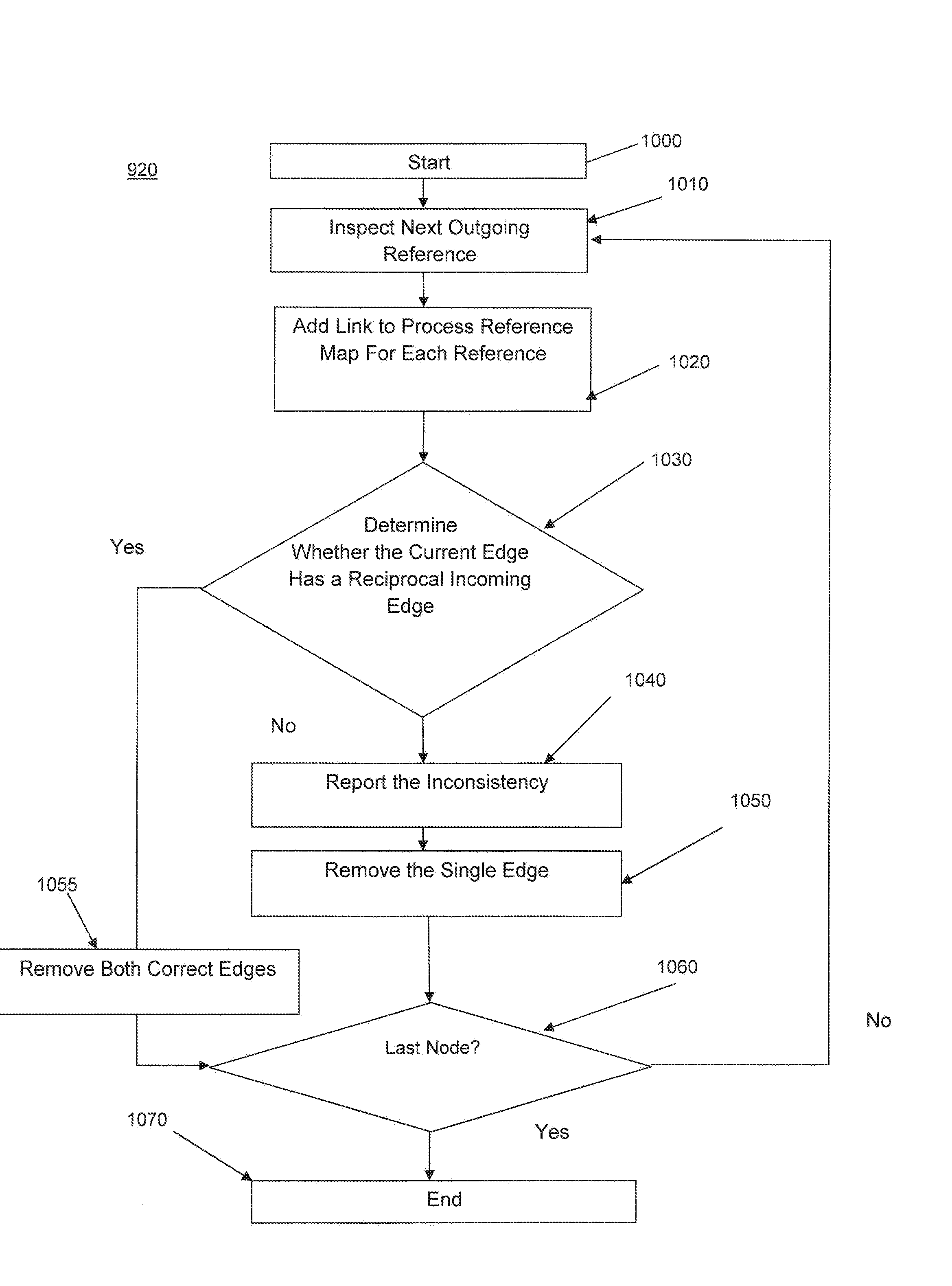

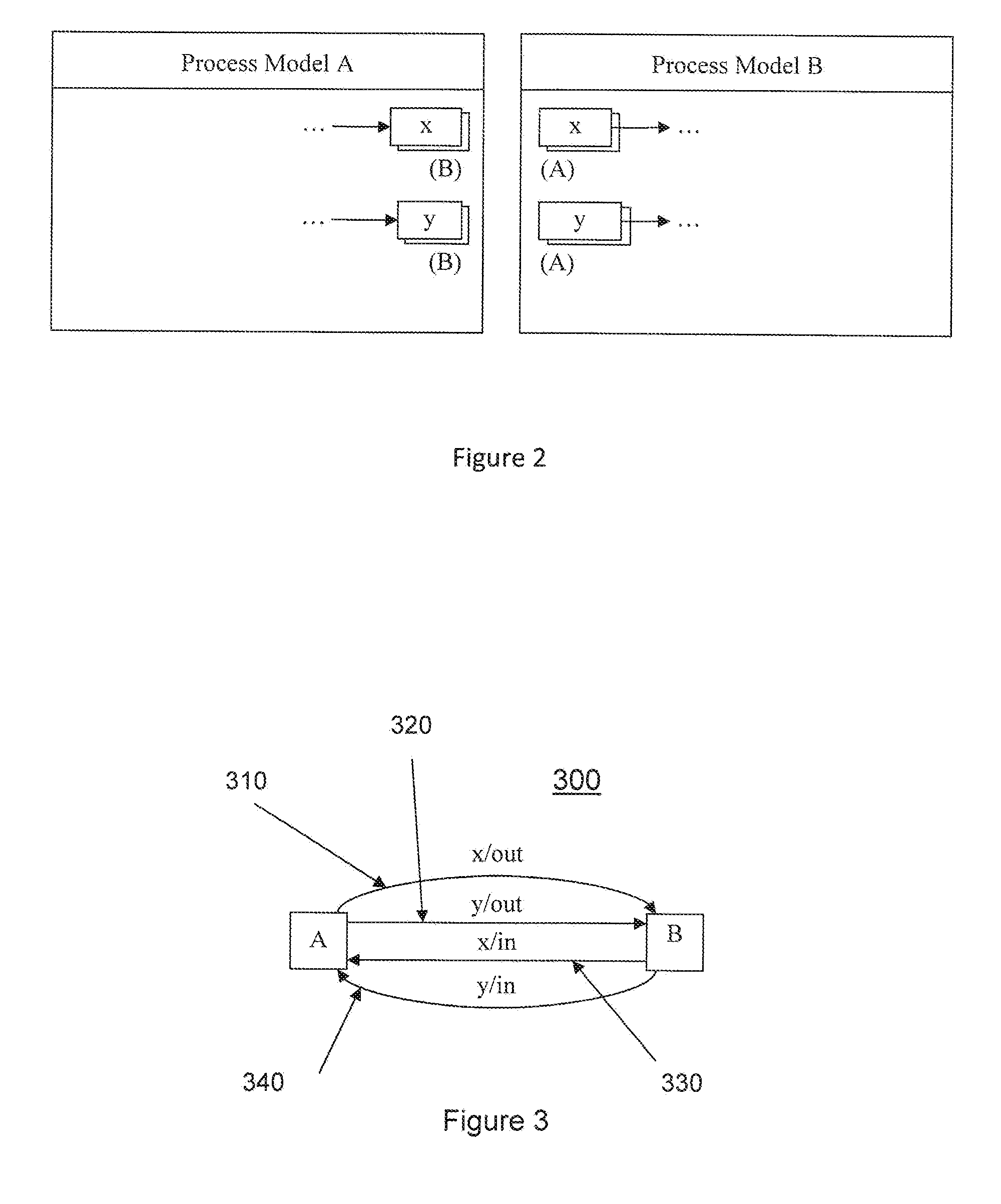

System and method to create process reference maps from links described in a business process model

A method of constructing a process reference map. The method includes iterating over each of a plurality of process models. An intermediary reference graph is created. A directed link for each reference in the process models is added to the intermediary reference graph, the link pointing from a node in the reference graph representing a process model within which a reference occurred to a node representing a process model that the reference is pointing towards. The method determines, between two process models of the plurality of process models, whether an inconsistency including one of an outbound process reference missing inconsistency, an inbound process reference missing inconsistency, and an unavailable information inconsistency exists. A new process model map is created from the intermediary reference graph with one element each representing a process models and the elements being linked representing the references therebetween. Each link comprises an attribute indicating one of a context, type of reference, and a modeling element.

Owner:IBM CORP

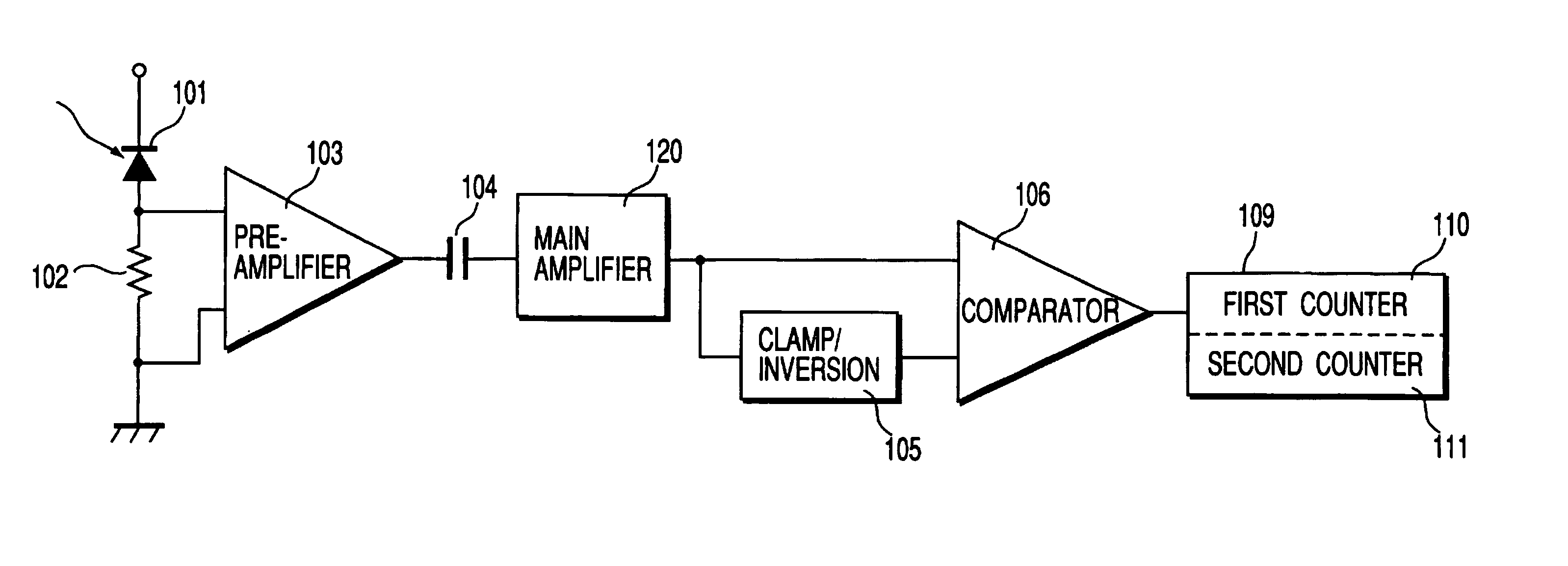

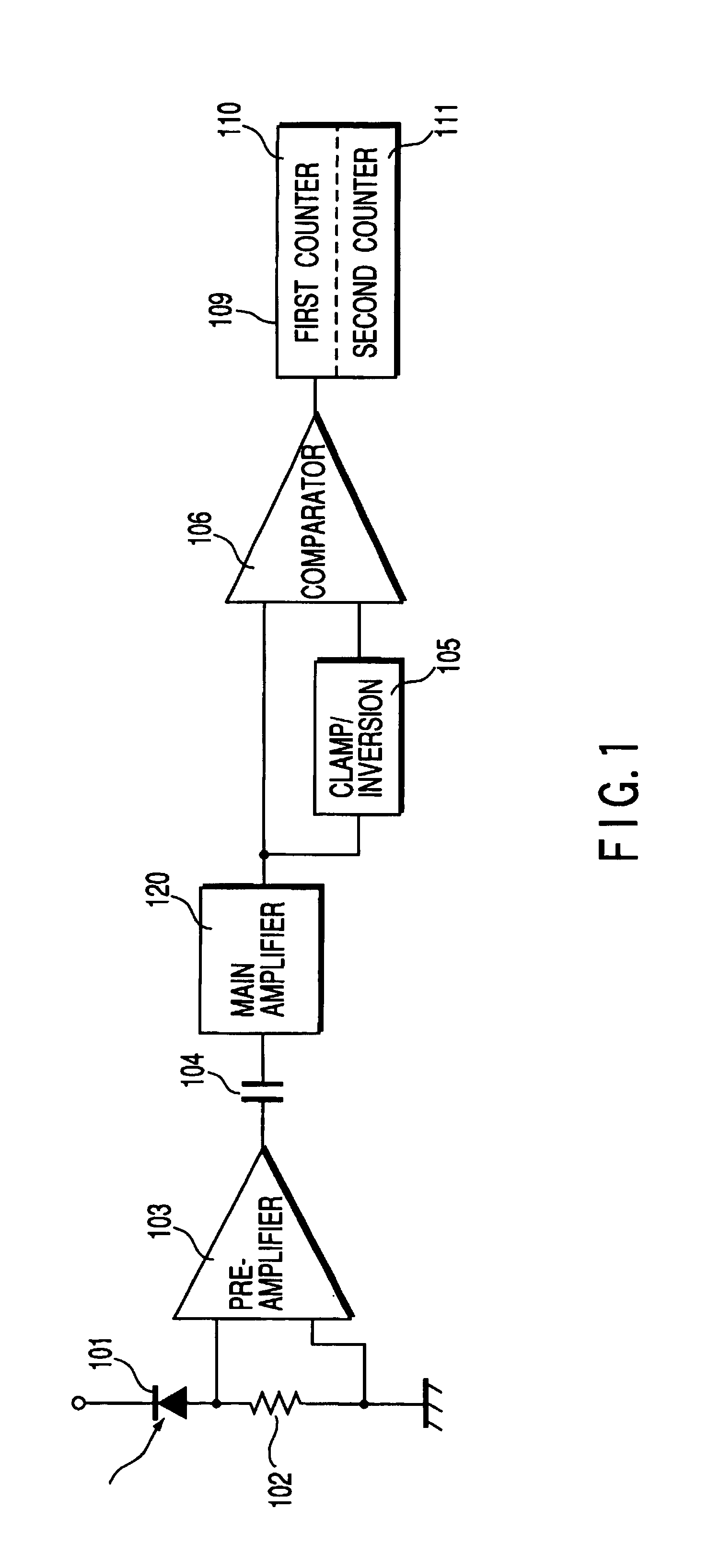

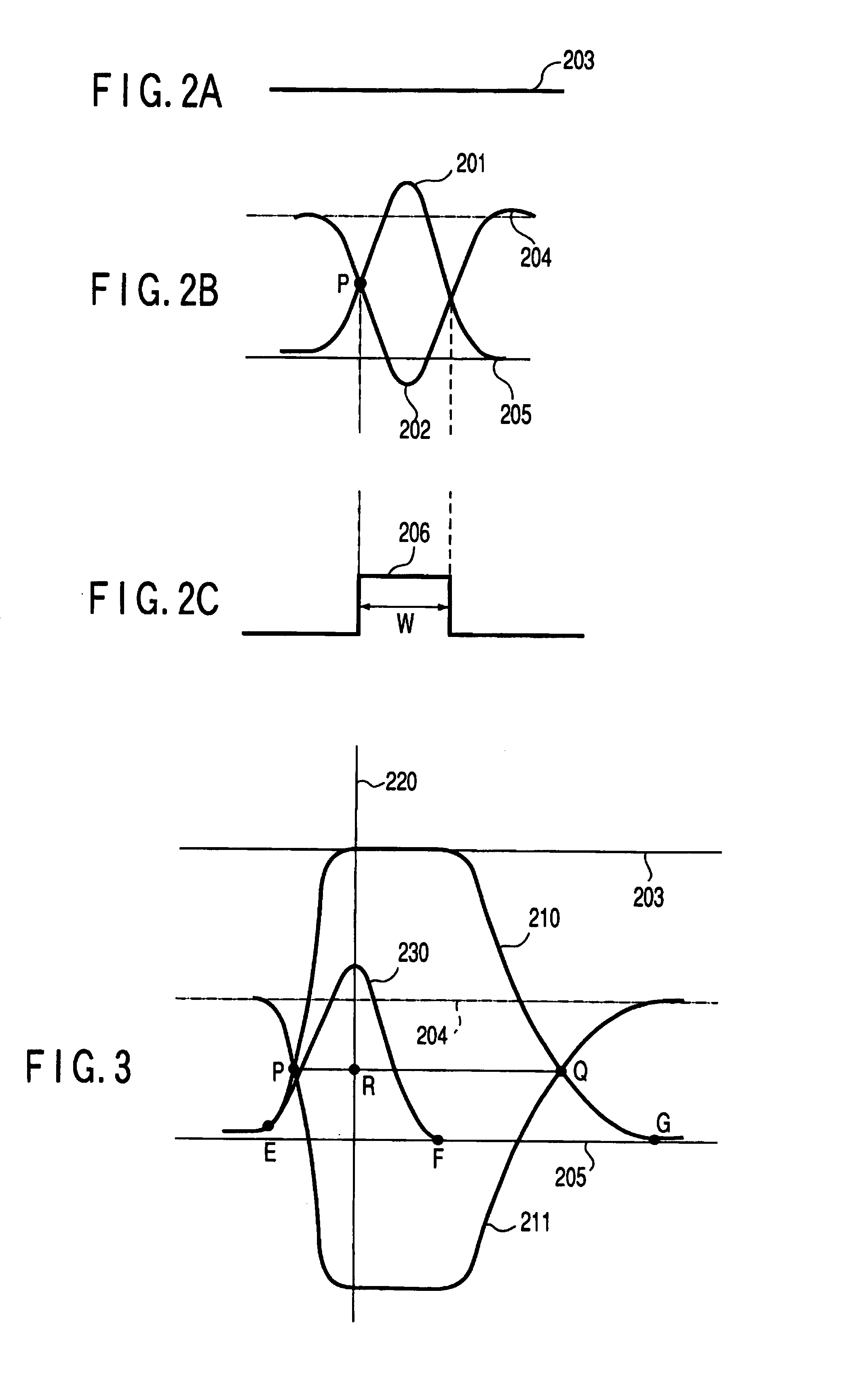

Self reference type distance measuring method and distance measuring apparatus using an optical pulse

InactiveUS7088433B1Accurately determineAccurately determinedMultiple input and output pulse circuitsOptical rangefindersElectricityReference type

A distance measuring apparatus measure the distance to a target by measuring the time required for an emitted beam of light to go to and return from the target. The light receiving section of the apparatus converts the received light into an electric signal. The clamp / inversion section of the apparatus clamps and inverts the output of the light receiving section. The comparing section of the apparatus compares the output of the light receiving section and the output of the clamp / inversion section. The determining section of the apparatus identifies the time of receiving the light on the basis of the outcome of the operation of the comparing section.

Owner:OLYMPUS CORP

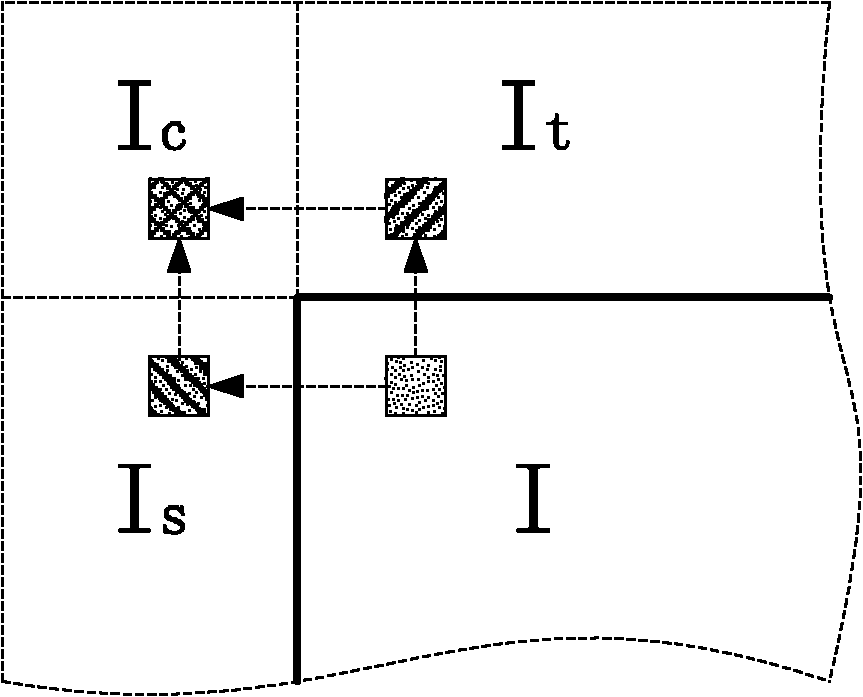

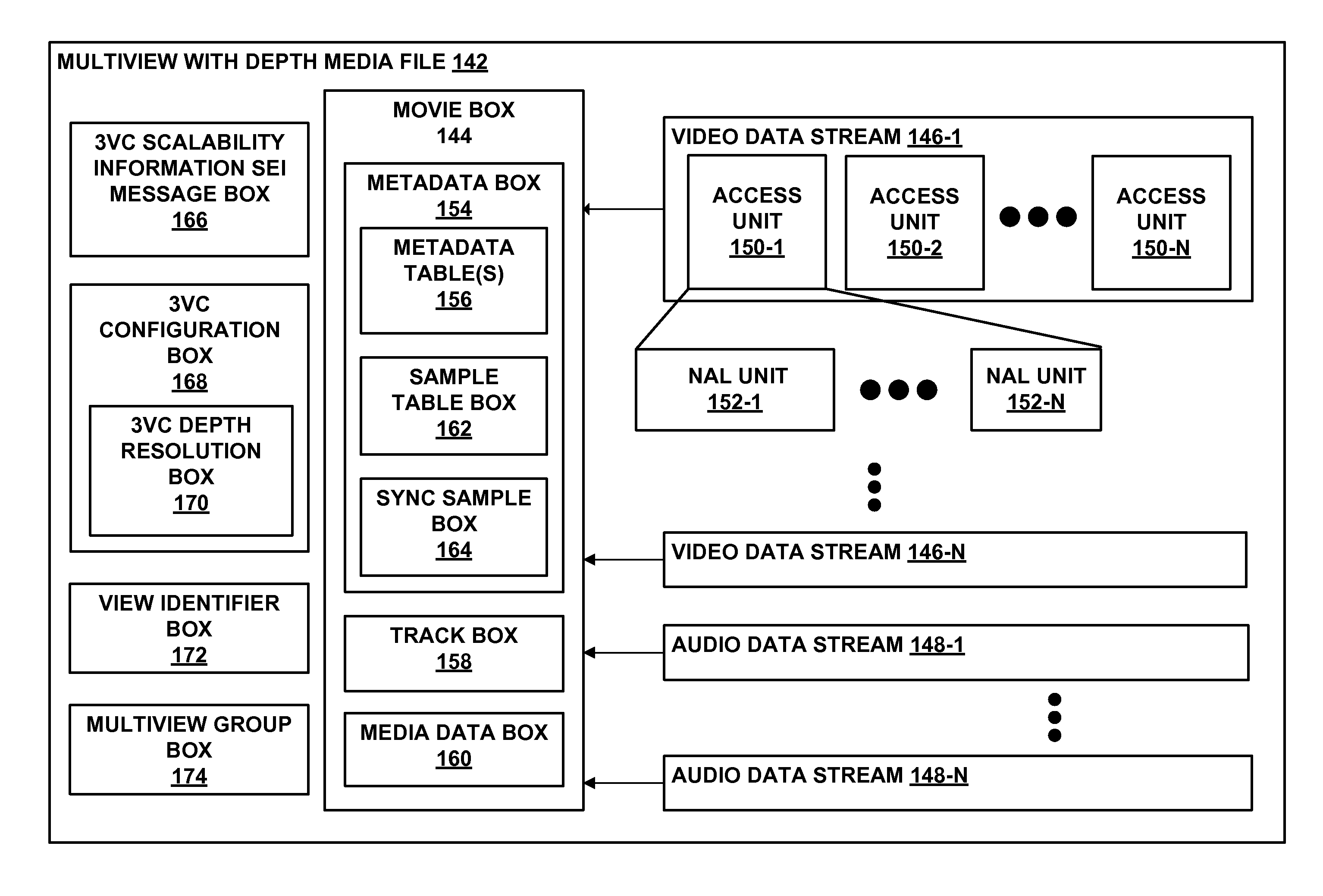

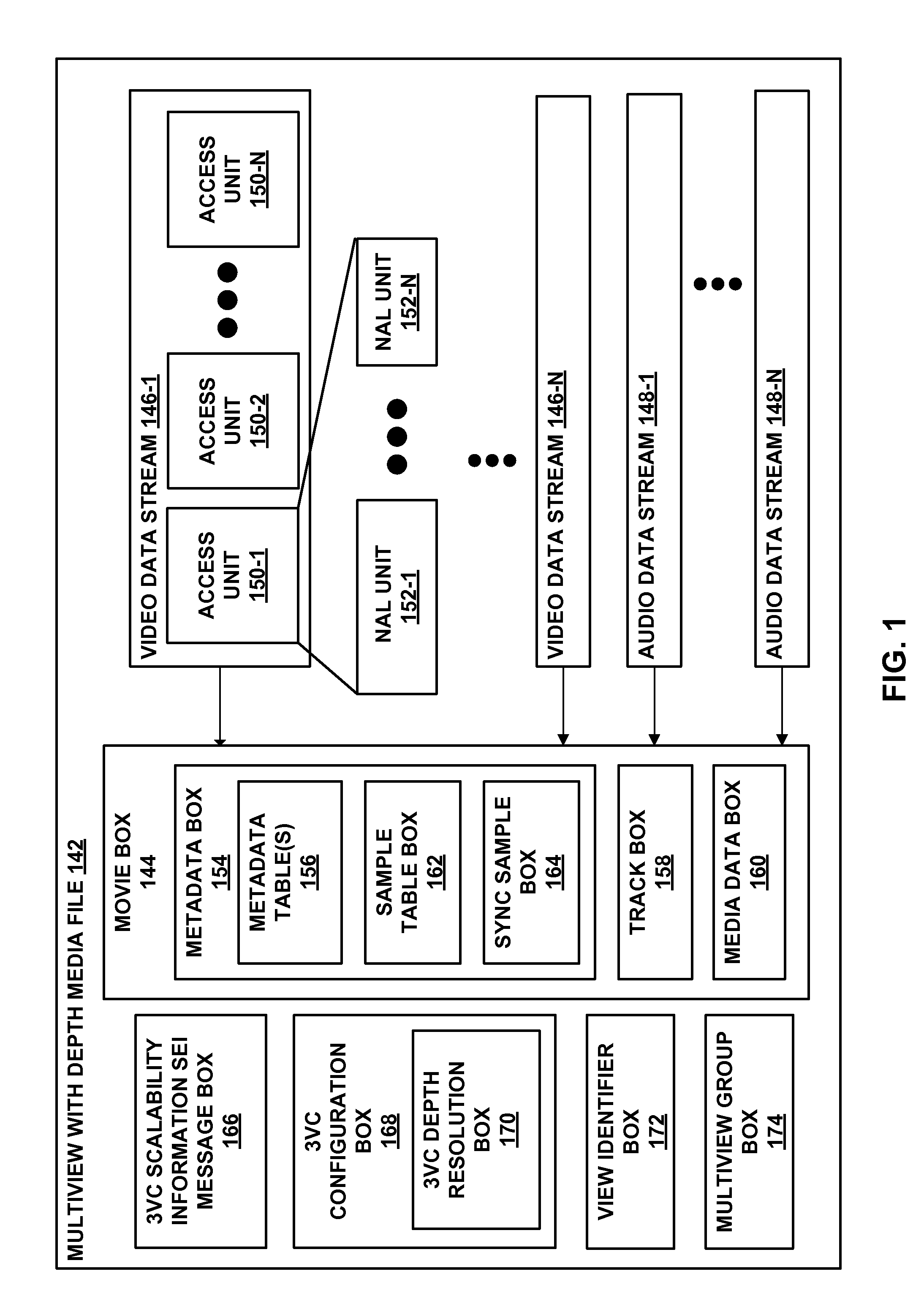

Separate track storage of texture and depth views for multiview coding plus depth

ActiveUS20140193139A1Television system detailsColor television detailsReference typeComputer graphics (images)

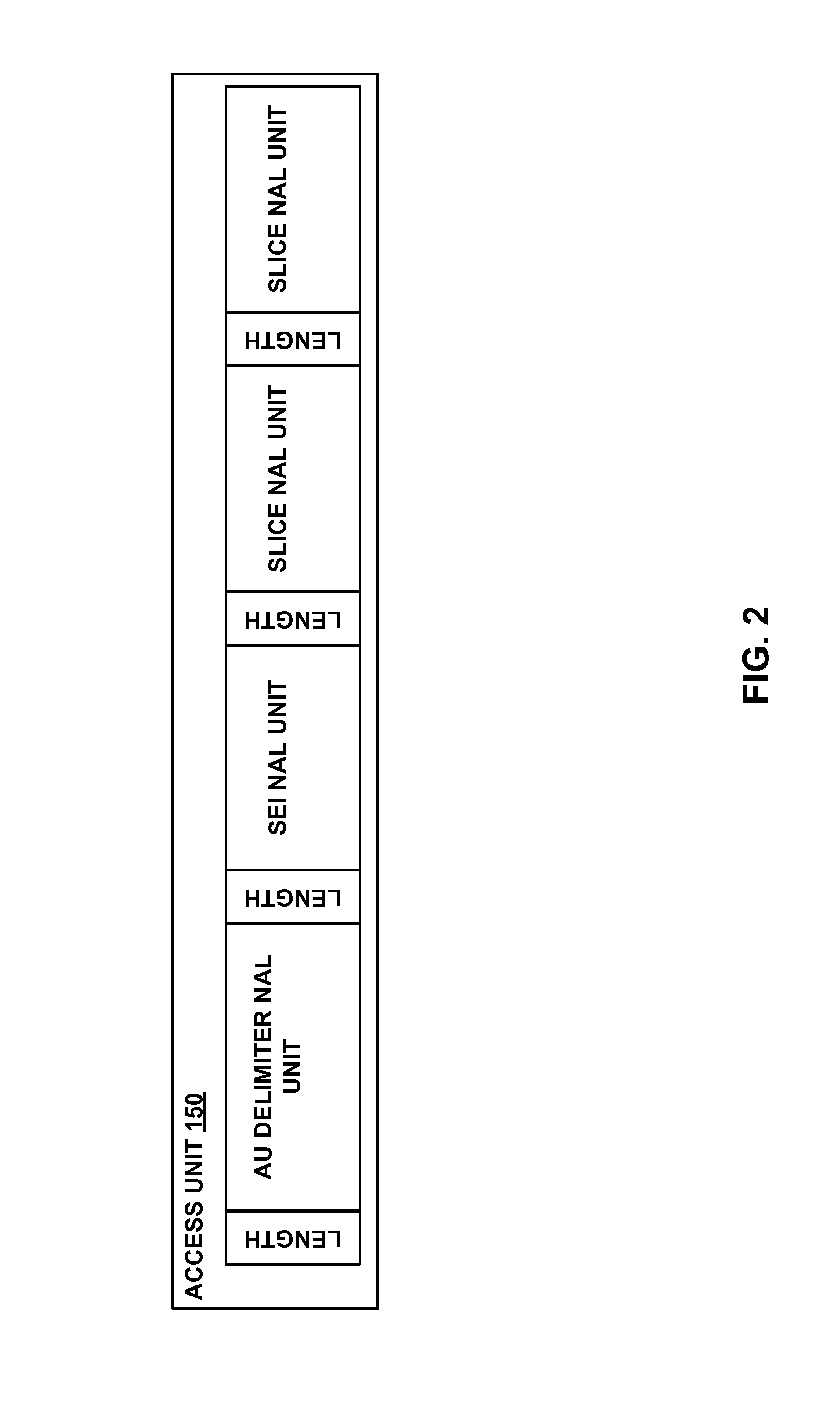

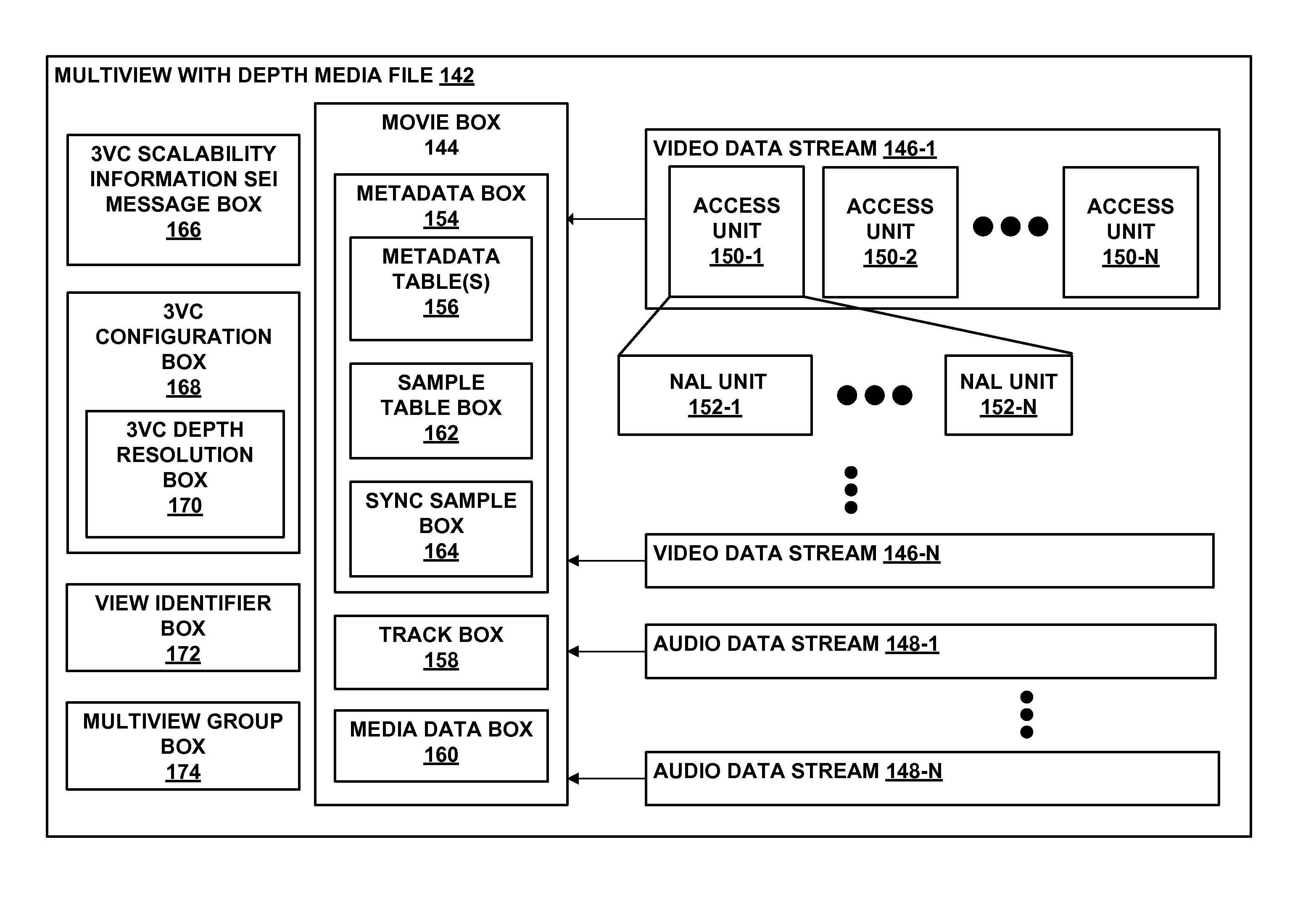

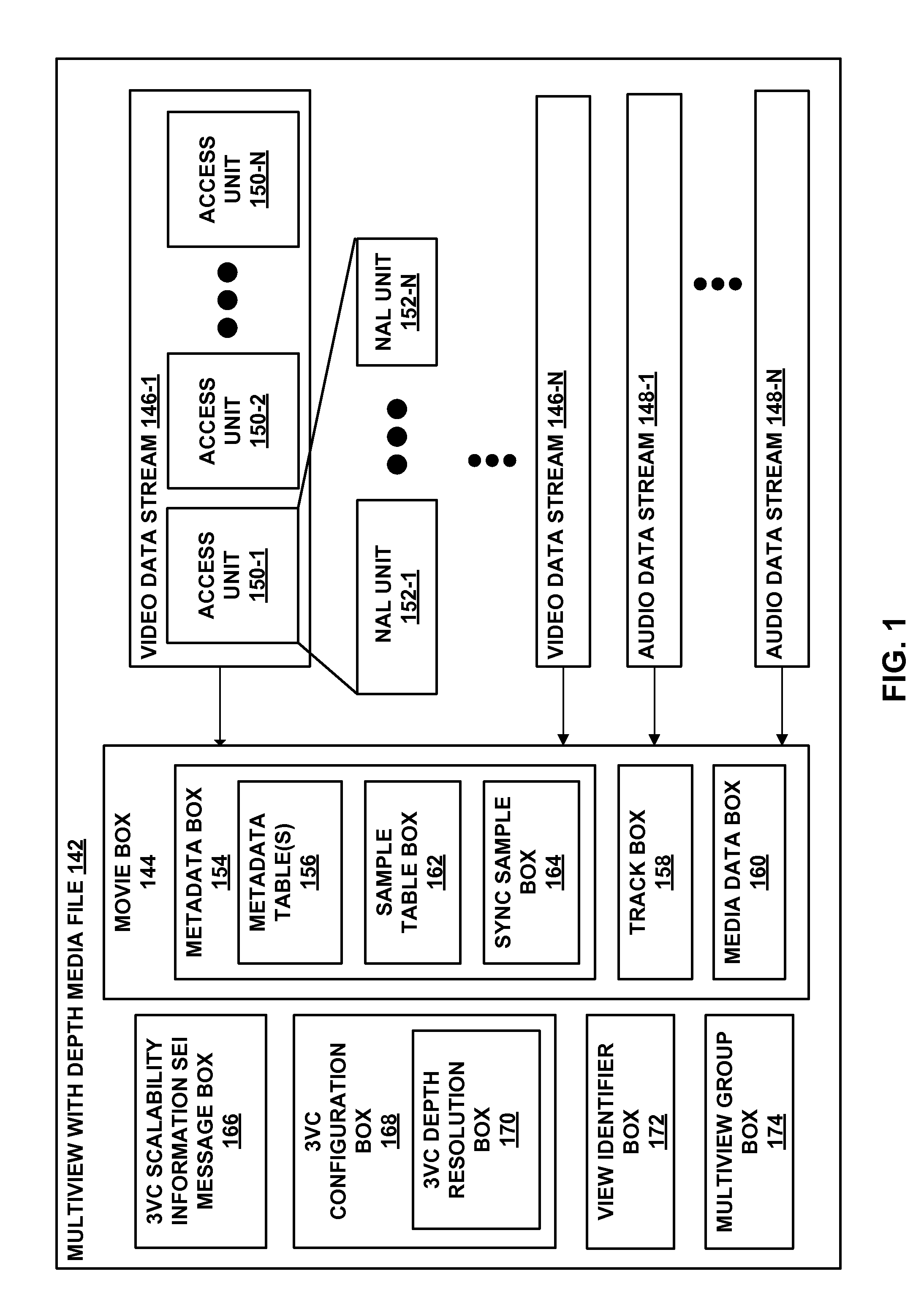

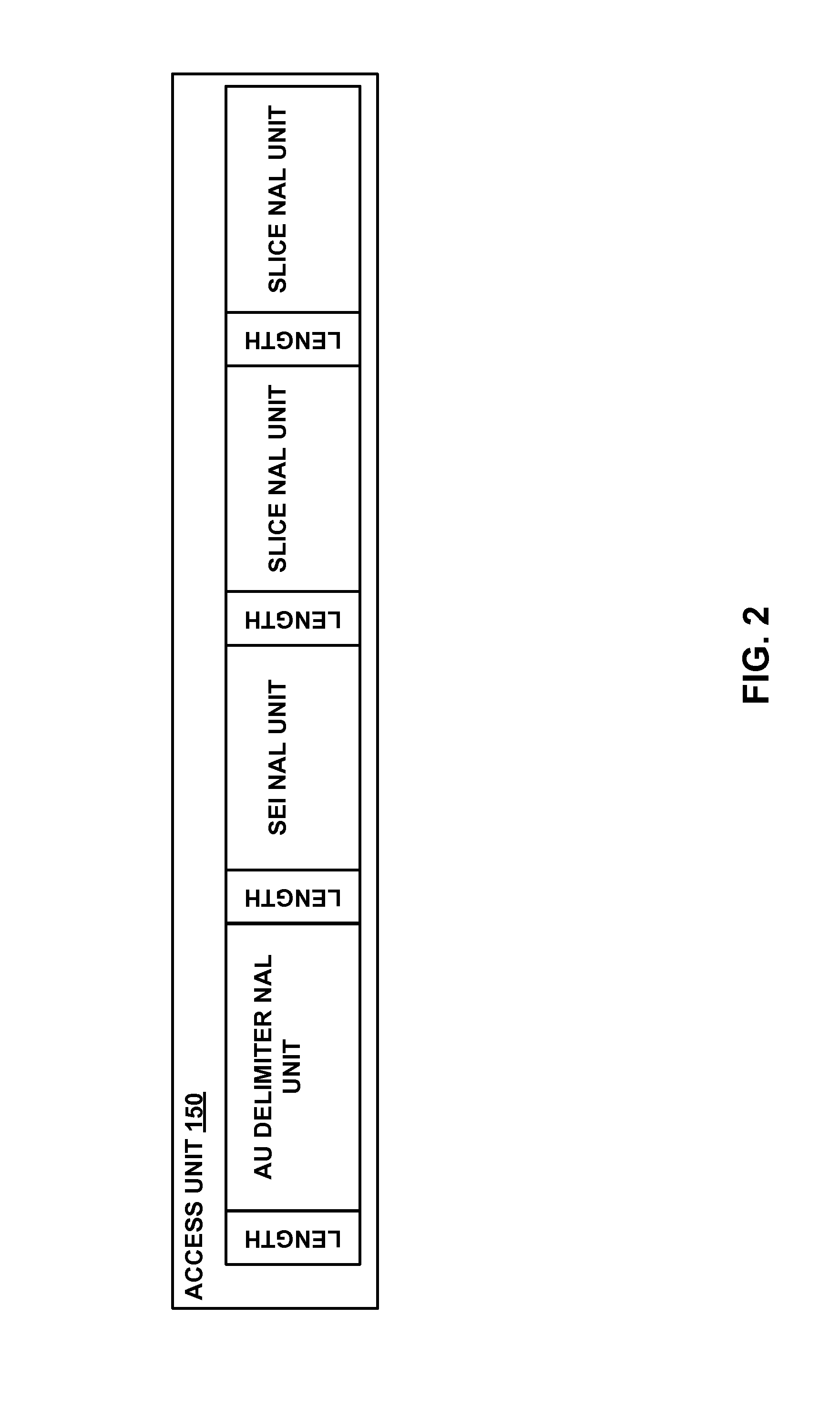

Techniques for encapsulating video streams containing multiple coded views in a media file are described herein. In one example, a method includes parsing a track of multiview video data, wherein the track includes one or more views, including only one of a texture view of a particular view and a depth view of the particular view. The method further includes parsing a track reference to determine a dependency of the track to a referenced track indicated in the track reference. Track reference types include ‘deps’ that indicates that the track includes the depth view of the particular view and the reference track includes the texture, ‘tref’ that indicates that the track depends on the texture view which is stored in the referenced track, and ‘dref’ that indicates that the track depends on the depth view which is stored in the referenced track.

Owner:QUALCOMM INC

Separate track storage of texture and depth views for multiview coding plus depth

ActiveUS9357199B2Television system detailsColor television detailsReference typeComputer graphics (images)

Techniques for encapsulating video streams containing multiple coded views in a media file are described herein. In one example, a method includes parsing a track of multiview video data, wherein the track includes one or more views, including only one of a texture view of a particular view and a depth view of the particular view. The method further includes parsing a track reference to determine a dependency of the track to a referenced track indicated in the track reference. Track reference types include ‘deps’ that indicates that the track includes the depth view and the reference track includes the texture view, ‘tref’ that indicates that the track depends on the texture view which is stored in the referenced track, and ‘dref’ that indicates that the track depends on the depth view which is stored in the referenced track.

Owner:QUALCOMM INC

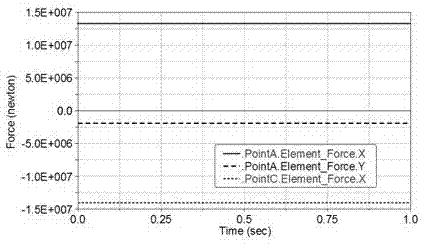

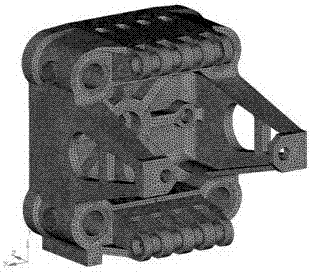

Lightweight design method for large-sized die-casting machine tail boards

ActiveCN107423512AImprove work efficiencyReduce weightGeometric CADDesign optimisation/simulationTopology optimizationComputer aid

The invention discloses a lightweight design method for large-size die-casting machine tail boards. The lightweight design method includes building three-dimensional models through computer-aided cartography (CAC), building a virtual prototype (VPT) through multibody dynamic simulation software to perform simulation and to draw curves of acting force, subjecting existing tail boards, in reference types, of die clamping mechanisms to numerical simulation of static performance and dynamic performance through computer aided engineering (CAE), calculating to obtain the stress, the rigidity and the modal frequency threshold, defining the design space and the non-design space of the tail boards, searching the optimum load transmission path meeting requirements of critical threshold and large-sized tail board lightweight structure meeting requirements of processing technique, and finally building lightweight models by digitizing means, and performing analysis verification so as to realize the lightweight design on the large-sized die-casting machine tail boards. By comprehensive application of multiple digitizing design techniques and variable-density method based topological optimization design techniques, work efficiency of design staff can be improved, weight of the large-sized die-casting machine tail boards can be reduced, and processing feasibility is guaranteed.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

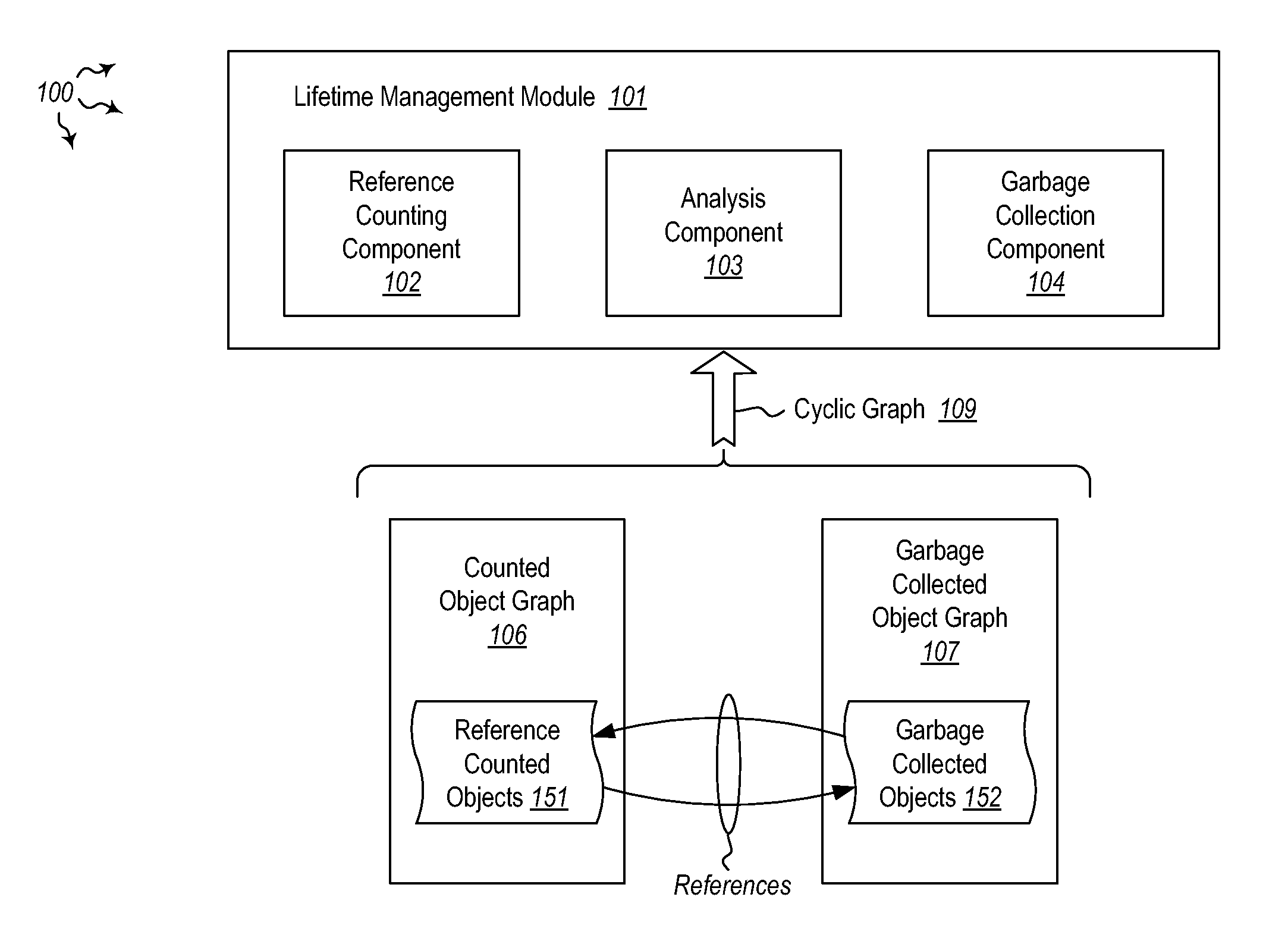

Managing object lifetime in a cyclic graph

ActiveUS20130066927A1Well formedMemory architecture accessing/allocationSpecial data processing applicationsReference typeObject lifetime

The present invention extends to methods, systems, and computer program products for managing object lifetime in a cyclic graph. Embodiments of the invention include reclaiming allocated system resources, for example, from a graph of objects that mixes different resource reclamation techniques (such as reference counting and garbage collection). In response to determining that garbage collection is to be performed, references between GC objects and Ref. Counted objects are detected. A reference type (e.g., direct, indirect, standard, tracked, weakened, etc.) for any detected references is also determined. Garbage collection is performed to determine if any allocated system resources can be reclaimed. Garbage collection considers references and references types between GC objects and Ref. Counted objects when determining if objects are to be reclaimed.

Owner:MICROSOFT TECH LICENSING LLC

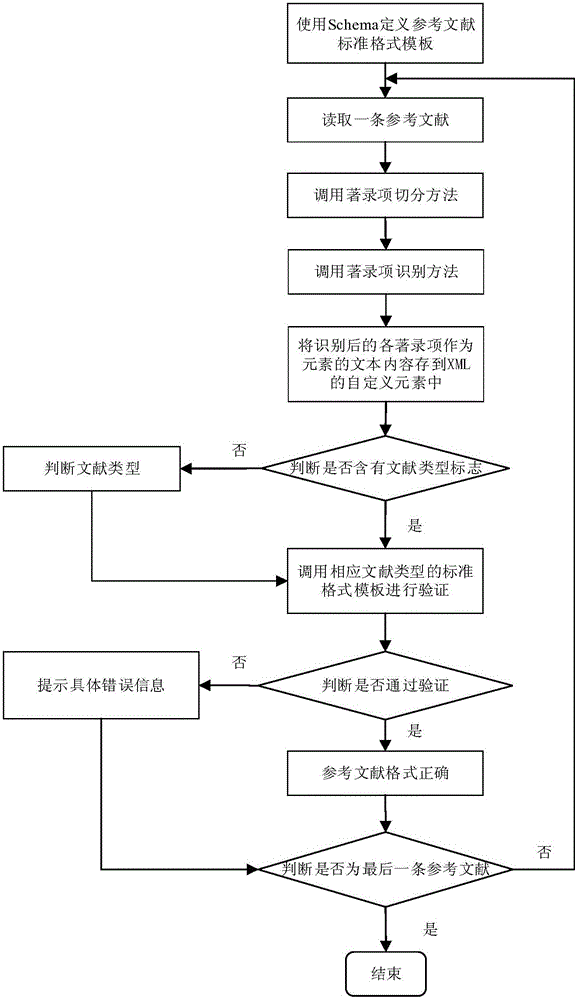

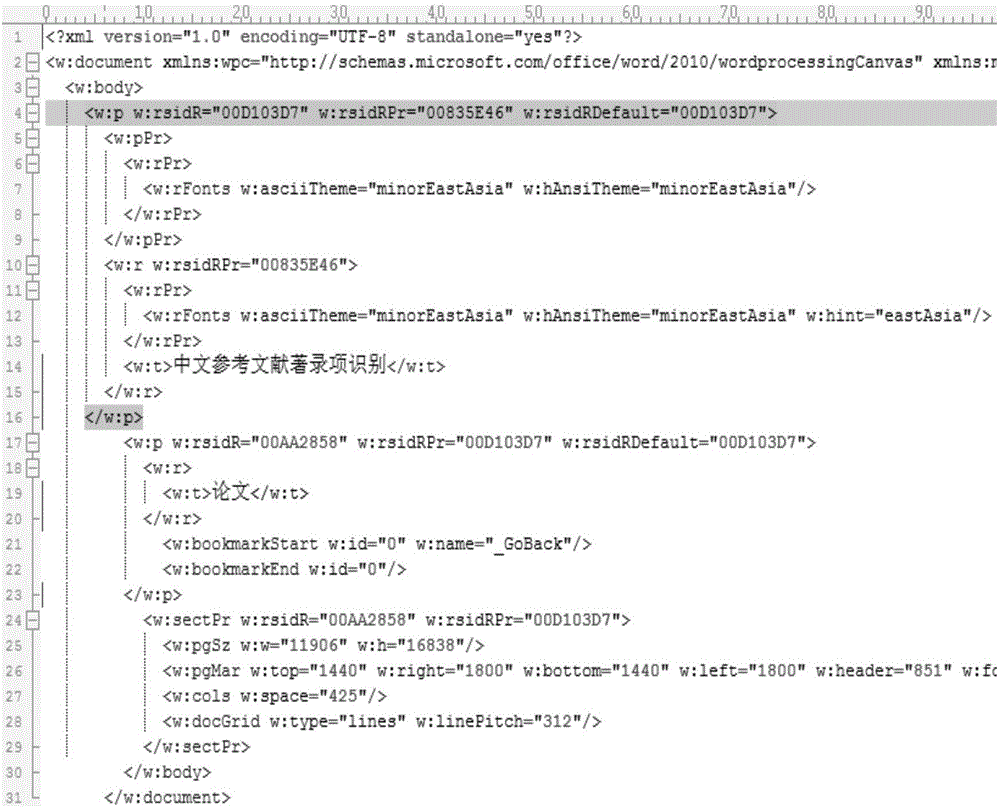

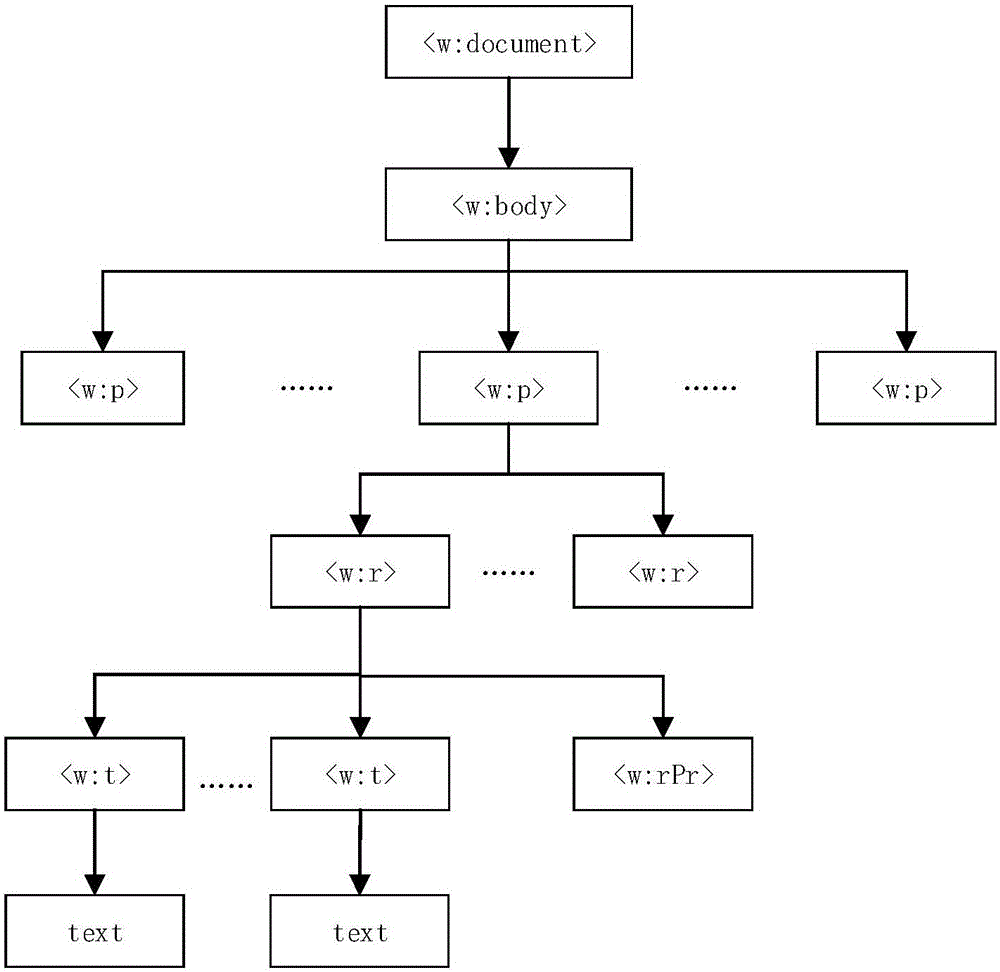

Reference format checking method

ActiveCN105824791AReduce descriptive errorsImprove efficiencyText processingSpecial data processing applicationsReference typeExtensible markup

The invention provides a reference format checking method. The method comprises the following steps: 1, expressing a reference bibliographical particular format rule through Schema, wherein a reference bibliographical particular format comprises at least one of the following bibliographical particulars: an author, a title, a reference type, a publisher, a publication date and a page number; 2, reading references, and partitioning the bibliographical particulars; 3, recognizing the reference bibliographical particulars, extracting the recognized bibliographical particulars into XML (Extensible Markup Language) nodes, judging whether the reference bibliographical particulars include a literature type tag or not at the same time, and if not, adding the literature type tag of the reference according to the bibliographical particulars, wherein the bibliographical particulars include at least one of the author, the title, a publication place, the publisher, the publication date and the like; 4, verifying the description particulars by using the reference bibliographical particular format rule.

Owner:BEIJING INFORMATION SCI & TECH UNIV

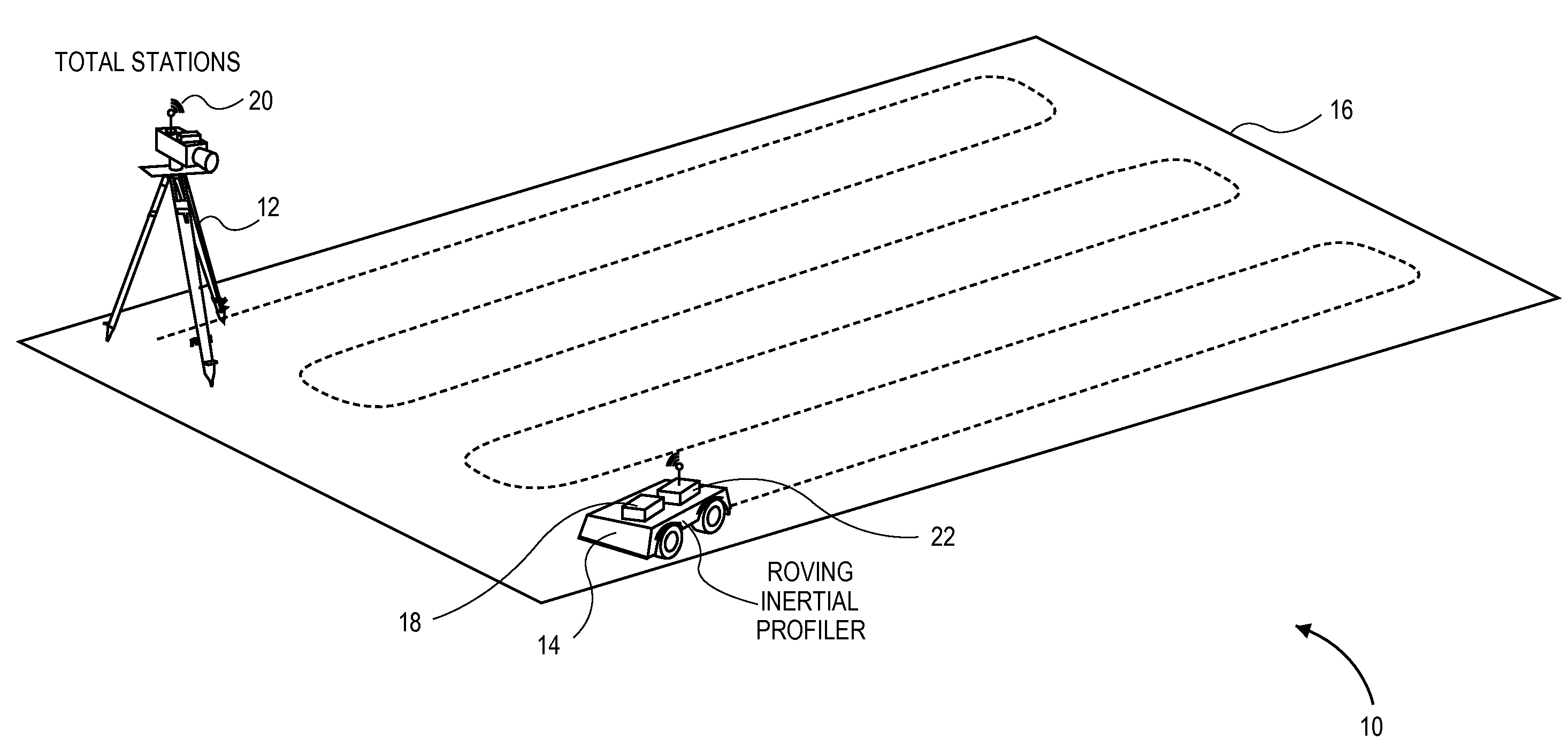

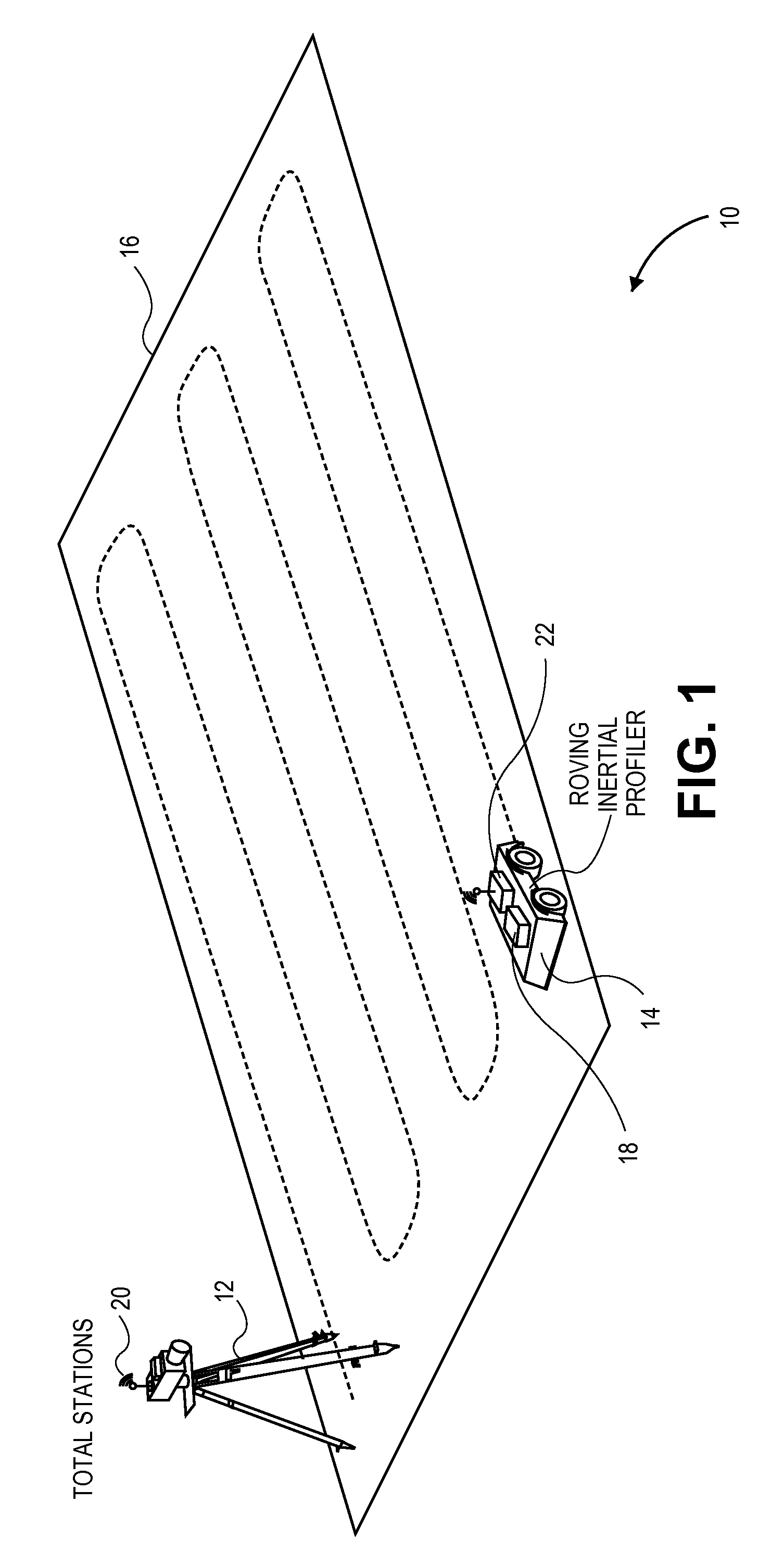

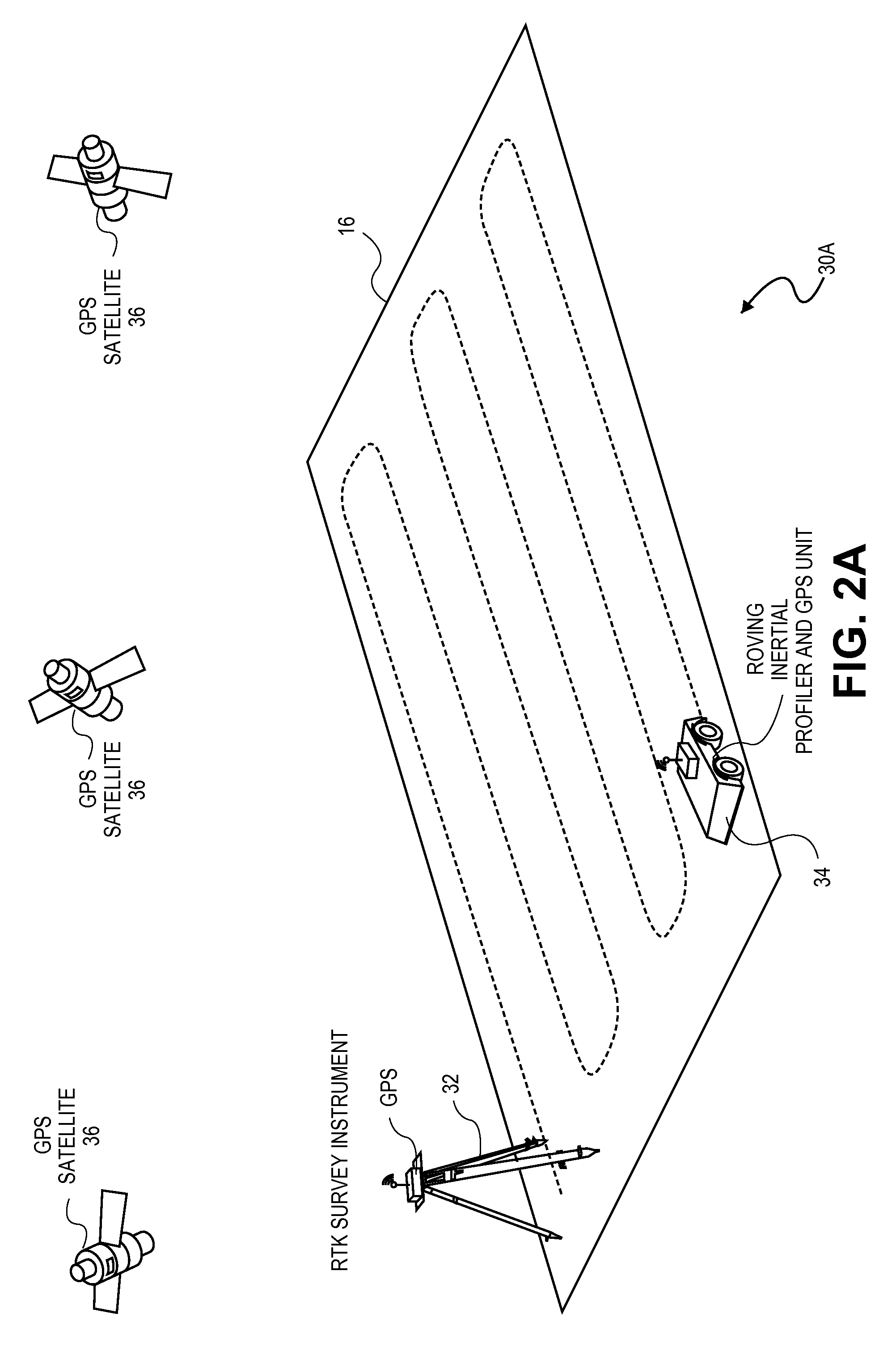

Apparatus for generating high resolution surface topology map using surface profiling and surveying instrumentation

ActiveUS20100198516A1High resolutionSurveying instrumentsNavigation instrumentsReference typeMeasuring instrument

A profiling apparatus configured to generate a high-resolution surface topology map of a surface using surface profiling data combined with surveying data. The apparatus is configured to collect both a plurality of survey sample points and a plurality of profile sample points of the surface. The profile sample points are then correlated with the survey sample points in the Z direction. Once the correlation is performed, the correlated profile sample points are merged or “filled-in” between the survey sample points. The high-resolution surface topology map is generated from the merging of the survey and profile sample points. In various embodiments, the survey data may be generated using an inertial profiler, an inclinometer based walking device, or a rolling-reference type profile device.

Owner:SURFACE SYST & INSTR

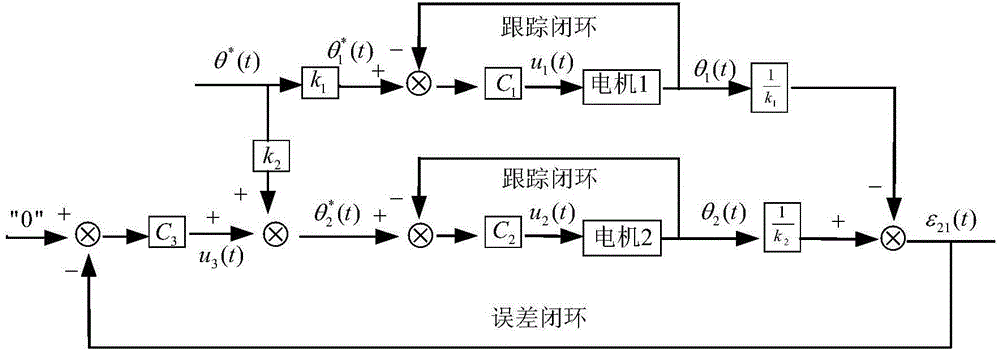

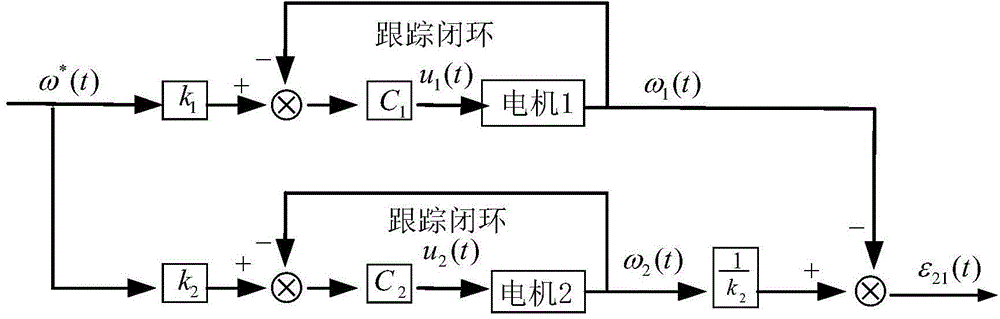

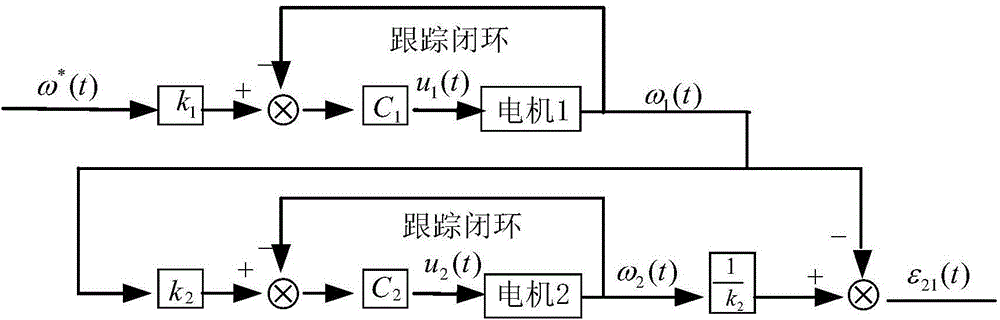

Synchronization control method used for space optical remote sensor servo system

ActiveCN104932251AImprove synchronous motion errorSatisfy the requirement that the trajectory remains unchangedAdaptive controlReference typeClosed loop

The invention provides a synchronization control method used for a space optical remote sensor servo system. Position servo commands of a main shaft scanning system and a slave shaft scanning system are designed by utilizing a preset index requirement; a main shaft tracking error controller is designed so that rotating scanning movement control performance of the main shaft system is enabled to meet a preset scanning linearity requirement; a slave shaft tracking error controller is designed so that the closed-loop characteristics of the slave shaft tracking error controller are enabled to be identical to those of the main shaft tracking error controller; and a synchronization error controller is designed so that the stable 0 tracking command of the two-shaft servo system is enabled to be stable, theta<z><cmd>xk<2> is added at the output end of the synchronization error controller and output of the main shaft tracking error controller is subtracted so that a synchronization control closed loop is formed, and synchronization control of the space optical remote sensor two-shaft servo system is completed. Compared with master command reference type synchronization and master-slave reference type synchronization, two-shaft synchronization movement precision is greatly enhanced by the method without influencing movement tracks of a main rotating system.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

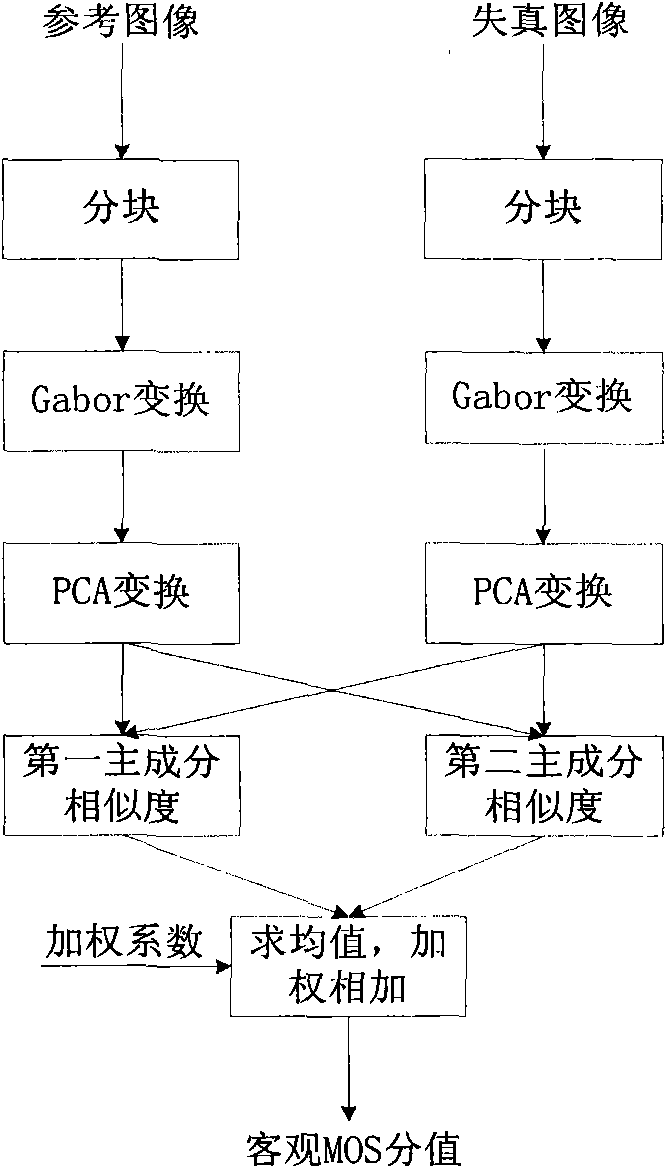

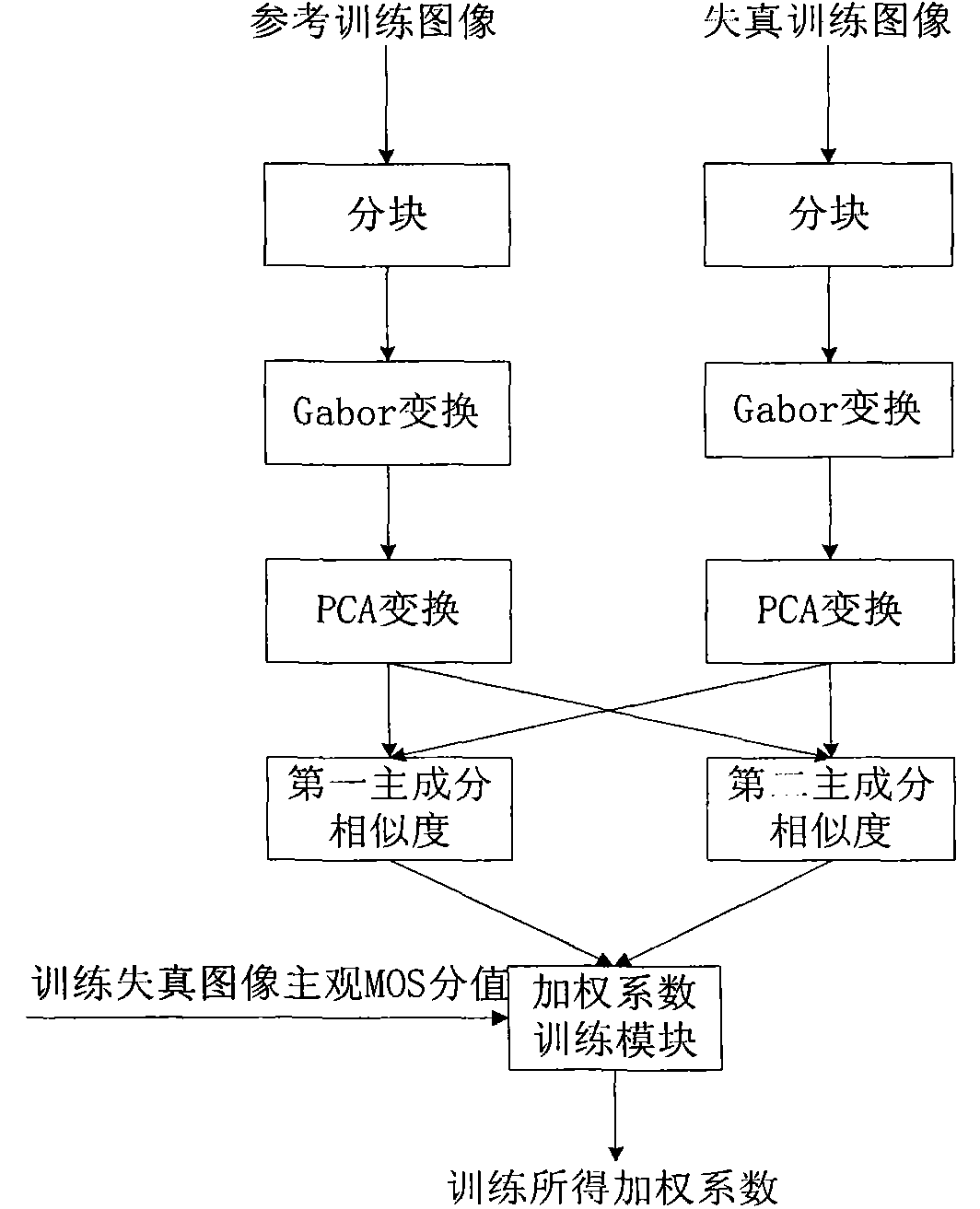

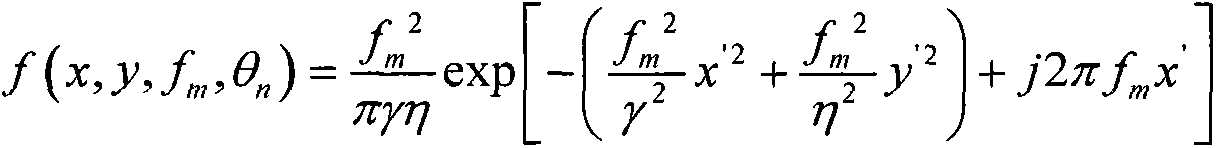

Full-reference-type image quality evaluation method based on Gabor weighted characteristics

The invention relates to a full-reference-type image quality evaluation method based on Gabor weighted characteristics. Specific steps of the method are as follows: 1. inputting an distorted image and a reference image; 2.carrying out two-dimension Gabor conversion on the input distorted image and reference image so as to obtain Gabor factors; 3. forming a matrix through the Gabor factors of the distorted image and the reference image and carrying out principal component analysis on the matrix so as to obtain first and second principal component components; 4. forming principle component matrixes through the first and second principle component components of the distorted image and the reference image and calculating the similarities and similarity mean values of the principle component matrixes of the distorted image and the reference image; 5. carrying out weighed sum on the similarity mean values so as to obtain an objective evaluation score. The full-reference-type image quality evaluation method based on the Gabor weighted characteristics converts the images through adoption of Gabor conversion and PCA conversion and carries out weighted sum on the similarity mean values so as to obtain the objective evaluation score and thus the precision of the image quality evaluation is improved.

Owner:JIAXING UNIV

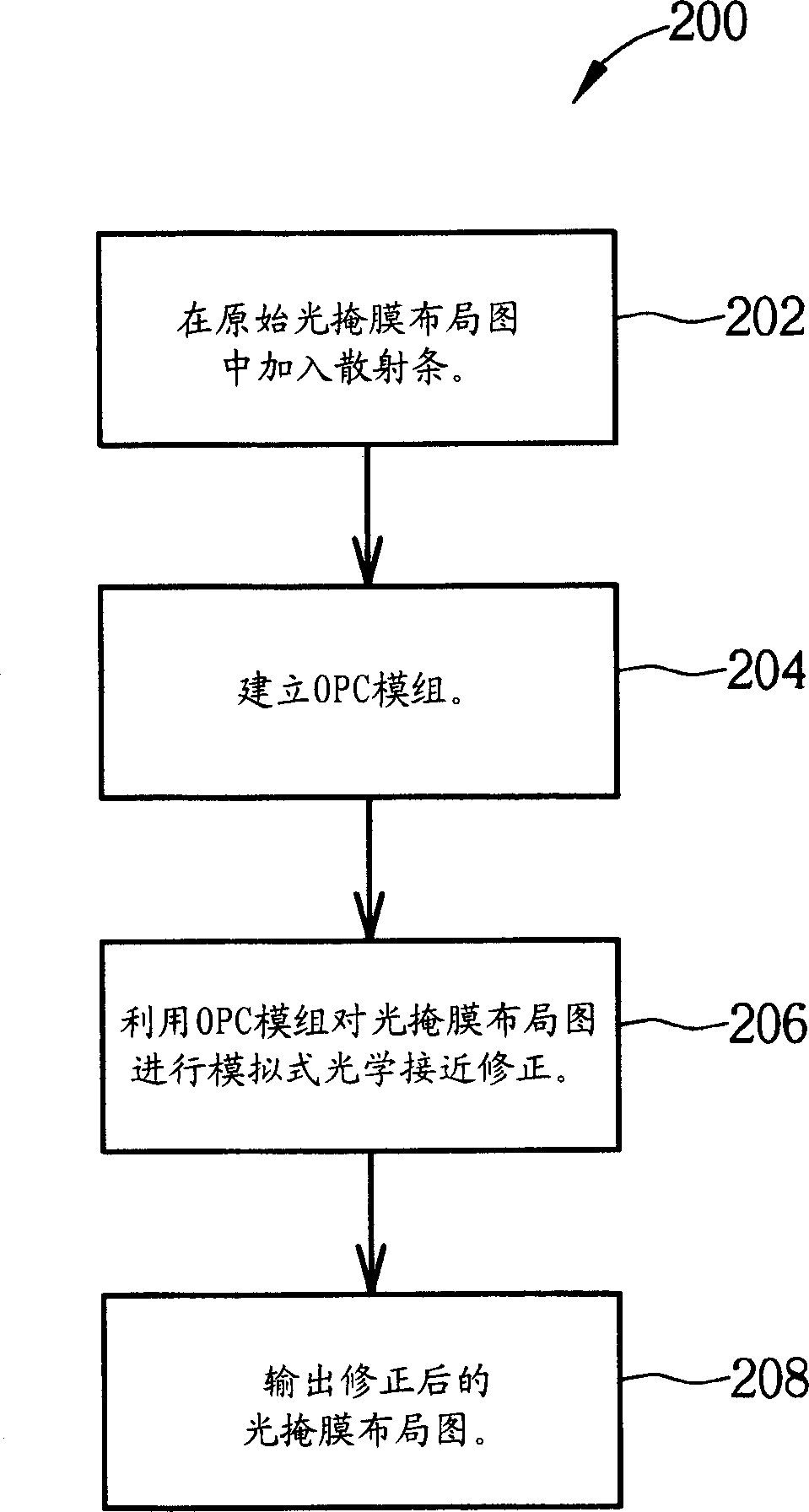

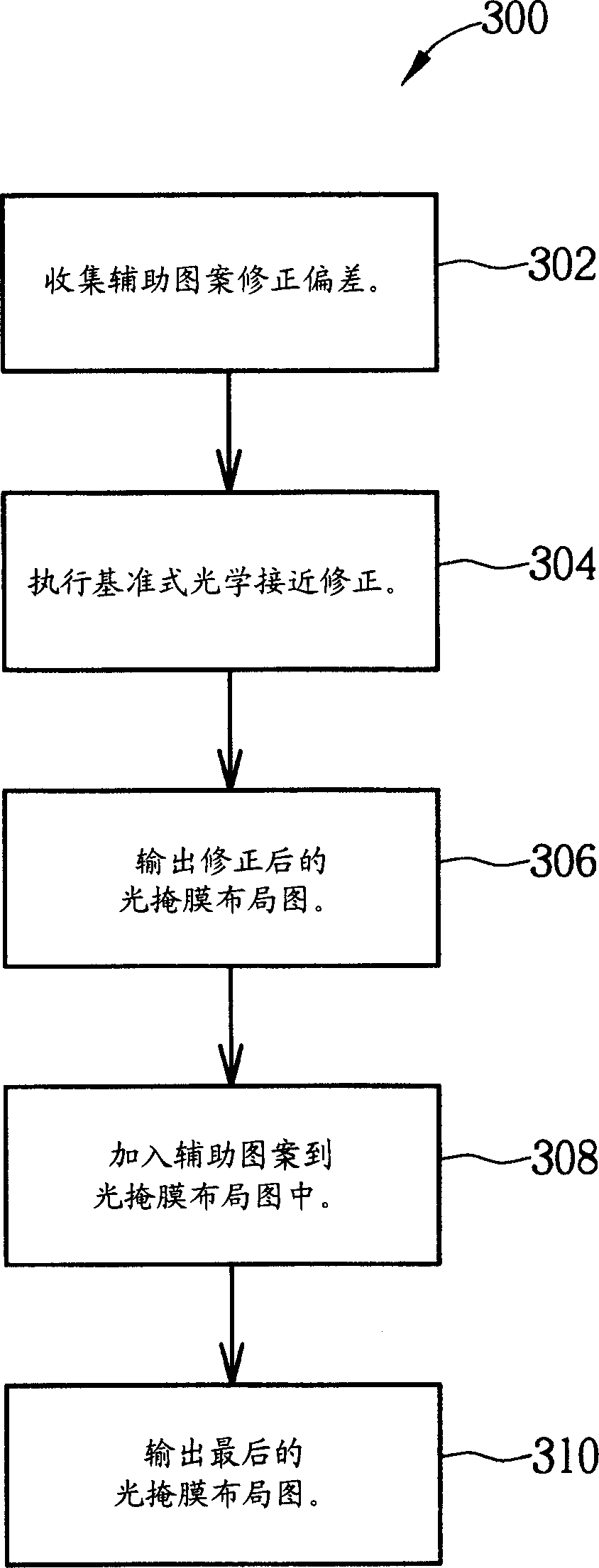

Optical proximity correcting method

ActiveCN1591200AImprove Exposure AccuracyImprove process marginOriginals for photomechanical treatmentSpecial data processing applicationsReference typeComputer science

The present invention provides an optical proximity correction method for photomask placement diagram, in which said photomask diagram at least includes one photomask pattern. Said method includes the following steps: collecting auxiliary pattern correction deviation value of auxiliary pattern which is one of predefined auxiliary patterns to be added into said photomask placement diagram; then combining said auxiliary pattern correction deviation value to make reference type optical proximity correction, calculating target correction deviation value required for correction of said photomask pattern and according to the calculated result make correction of said photomask pattern, outputting corrected photomask placement diagram, finally adding said auxiliary pattern into said corrected photomask placement diagram.

Owner:NAN YA TECH

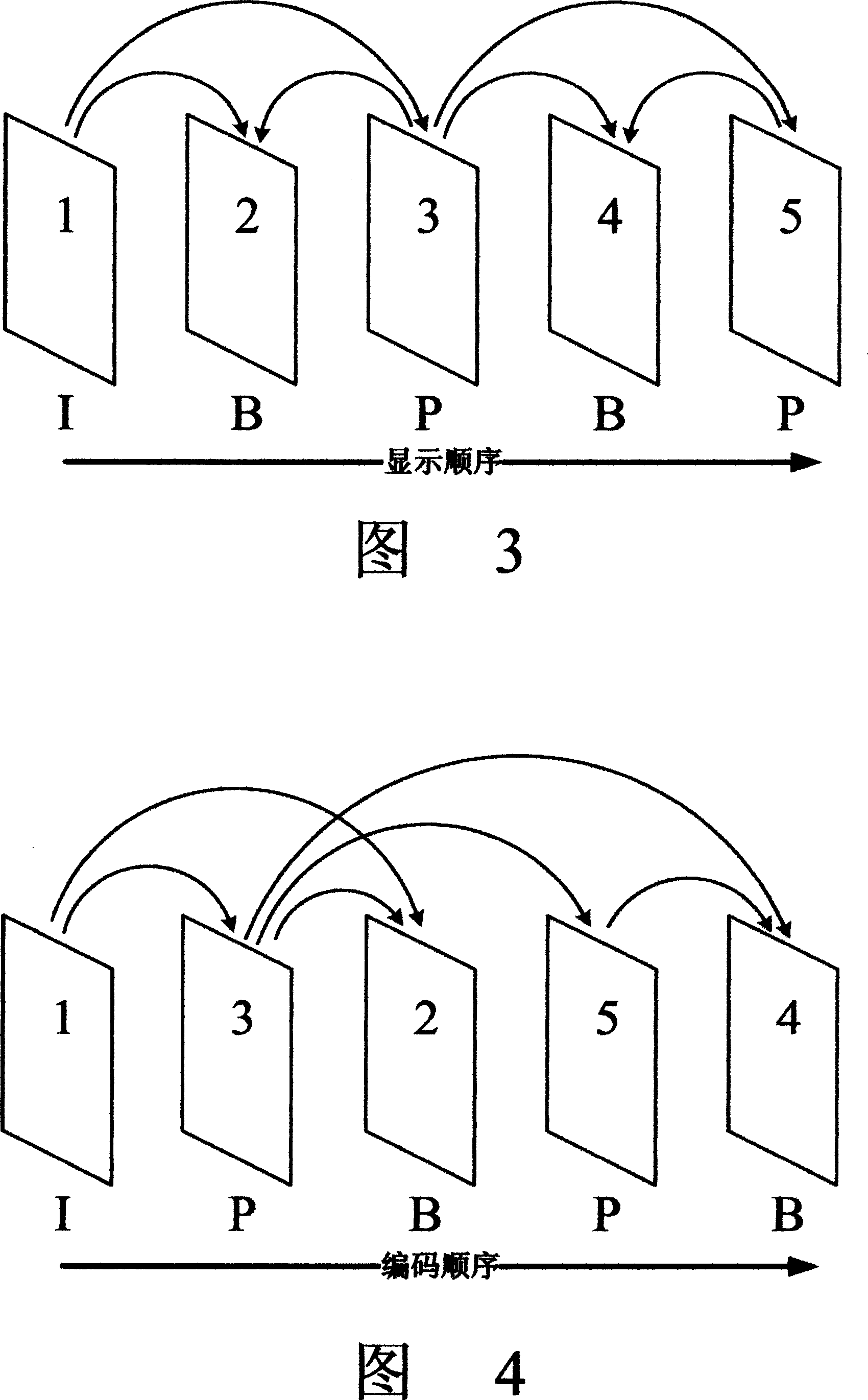

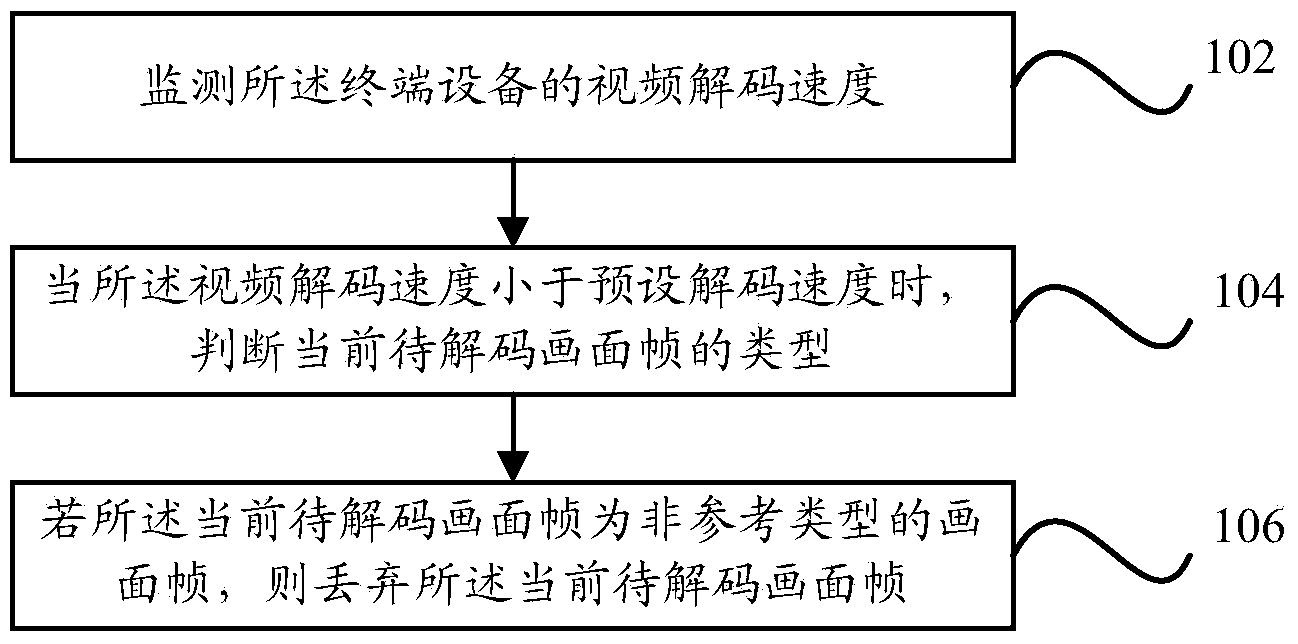

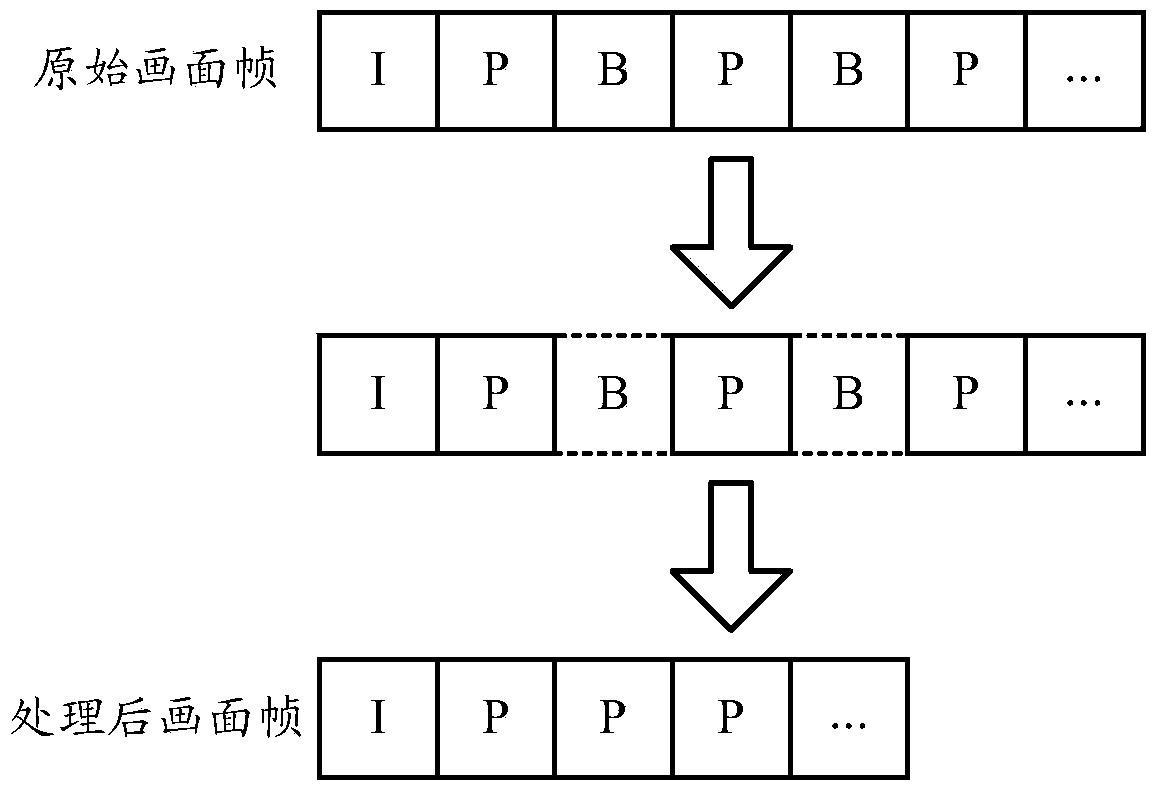

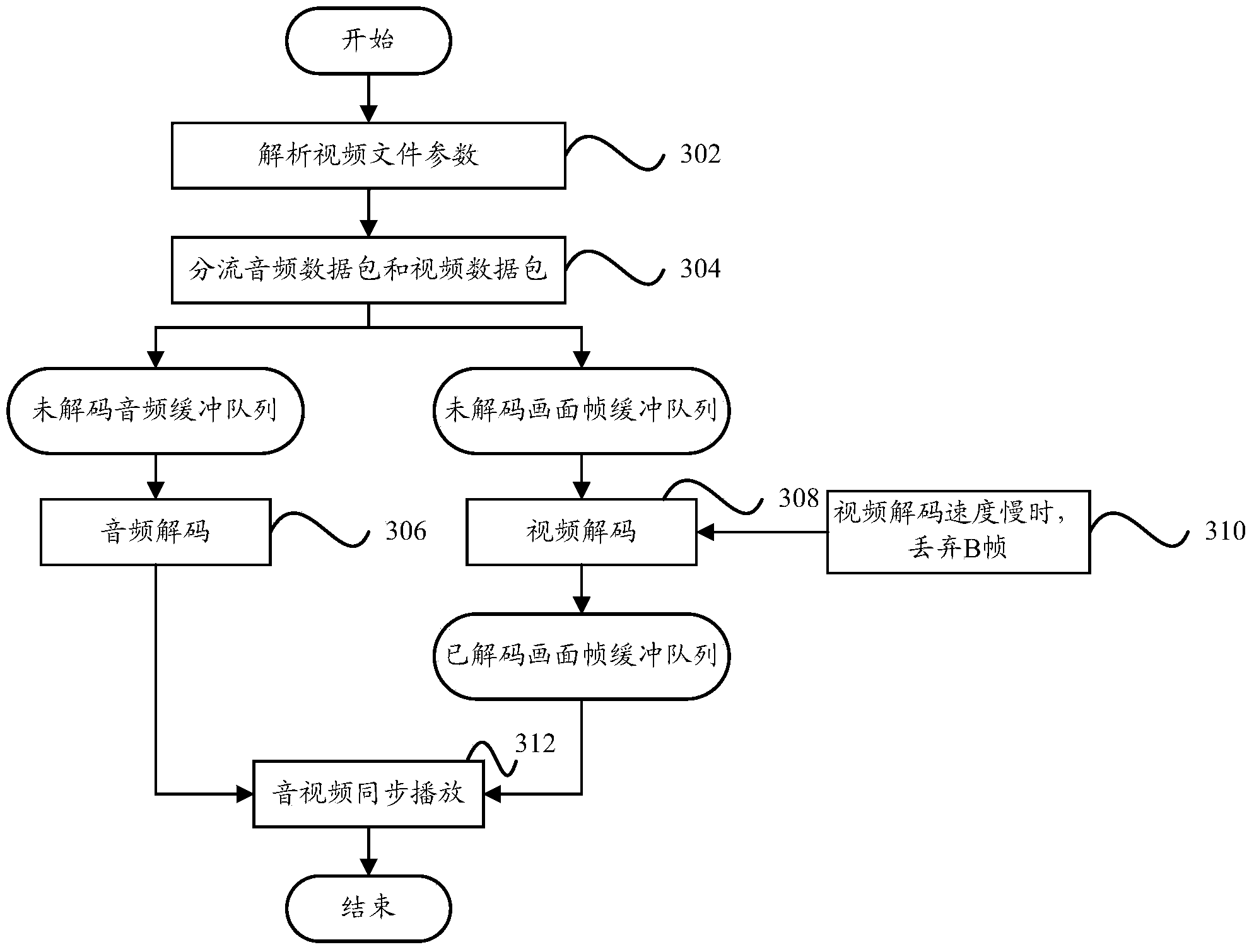

Video decoding method and device

InactiveCN104053002AReduce in quantityReduce decoding burdenDigital video signal modificationReference typeTerminal equipment

The invention provides a video decoding method and device which are applied to terminal equipment. The video decoding method includes the steps that the video decoding speed of the terminal equipment is monitored; when the video decoding speed is smaller than a preset decoding speed, the type of a picture frame to be decoded at present is judged; if the picture frame to be decoded at present is a non-reference type picture frame, the picture frame to be decoded at present can be discarded. According to the technical scheme, the non-reference type picture frame is discarded, on the basis that other picture frames cannot be affected to be decoded, the total number of picture frames needing to be decoded is decreased, the video decoding method and device are conducive to lowering the video decoding burden, the decoding speed is increased, and therefore the video blocking phenomenon can be avoided.

Owner:LETV INFORMATION TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com