Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Polybutadiene acrylonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polybutadiene acrylonitrile (PBAN) copolymer, also noted as polybutadiene—acrylic acid—acrylonitrile terpolymer is a copolymer compound used most frequently as a rocket propellant. It was the binder formulation widely used on the 1960s-1970s big boosters (e.g., Titan III and Space Shuttle SRBs).

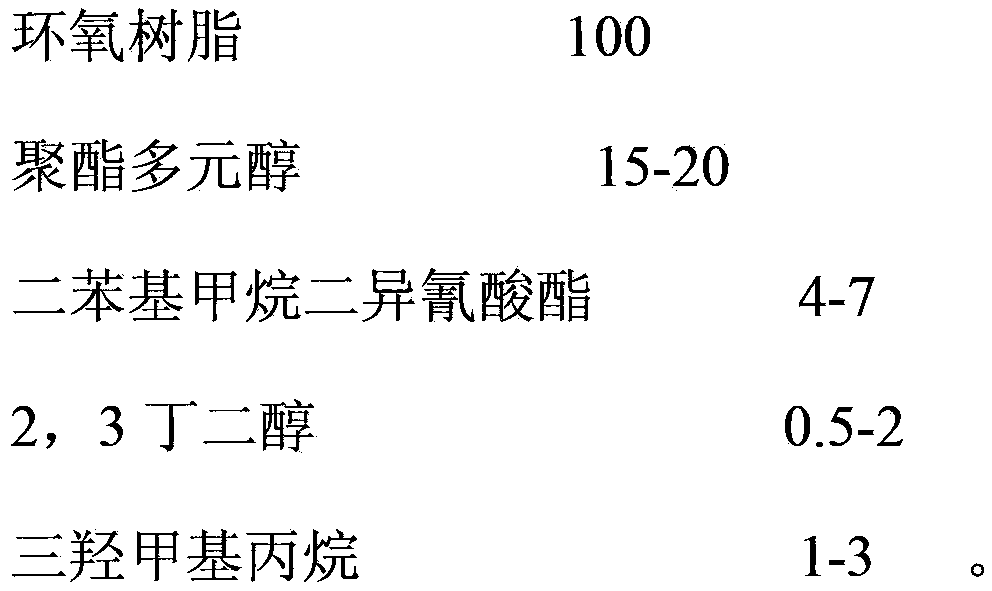

Polyurethane modified epoxy resin adhesive and preparation method thereof

InactiveCN103173183AGood adhesionSimple processPolyureas/polyurethane adhesivesEpoxy resin adhesivesEpoxyPolybutadiene acrylonitrile

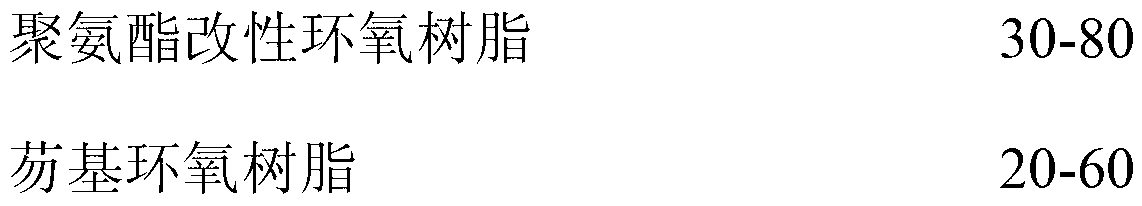

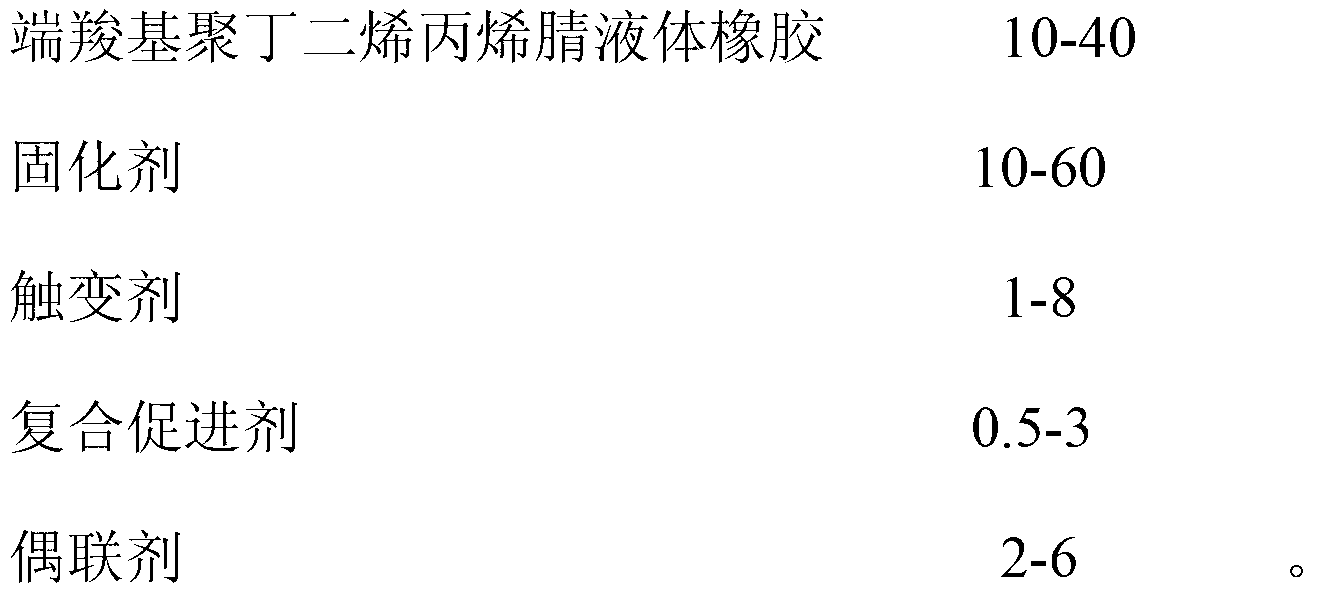

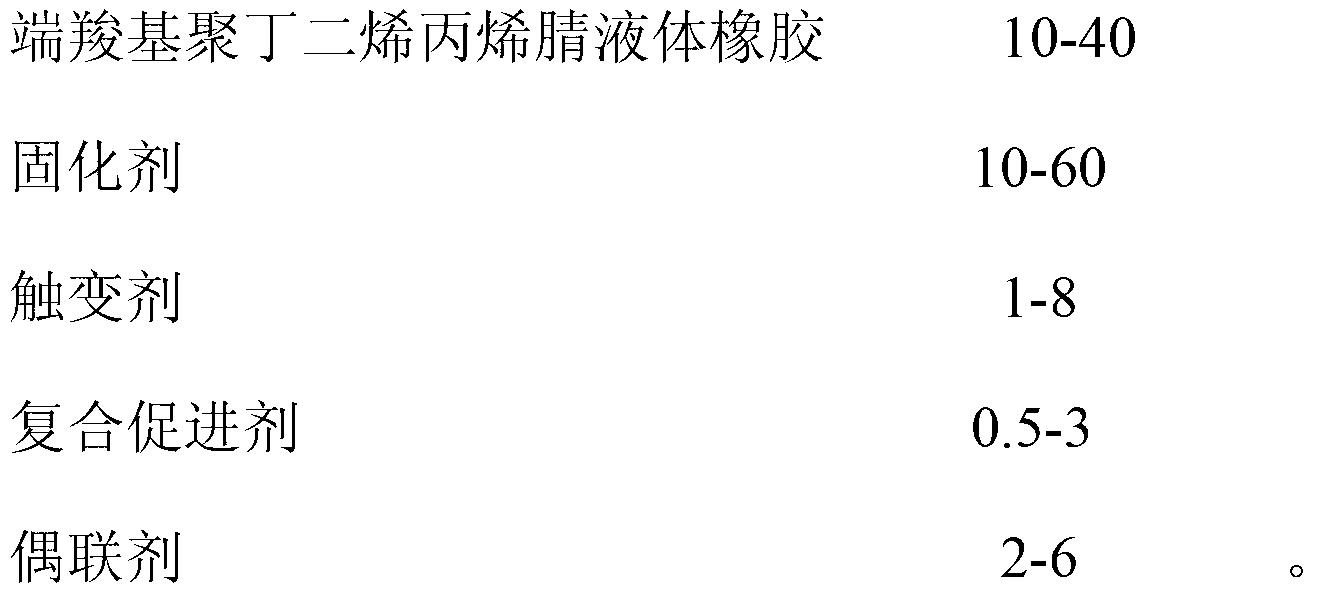

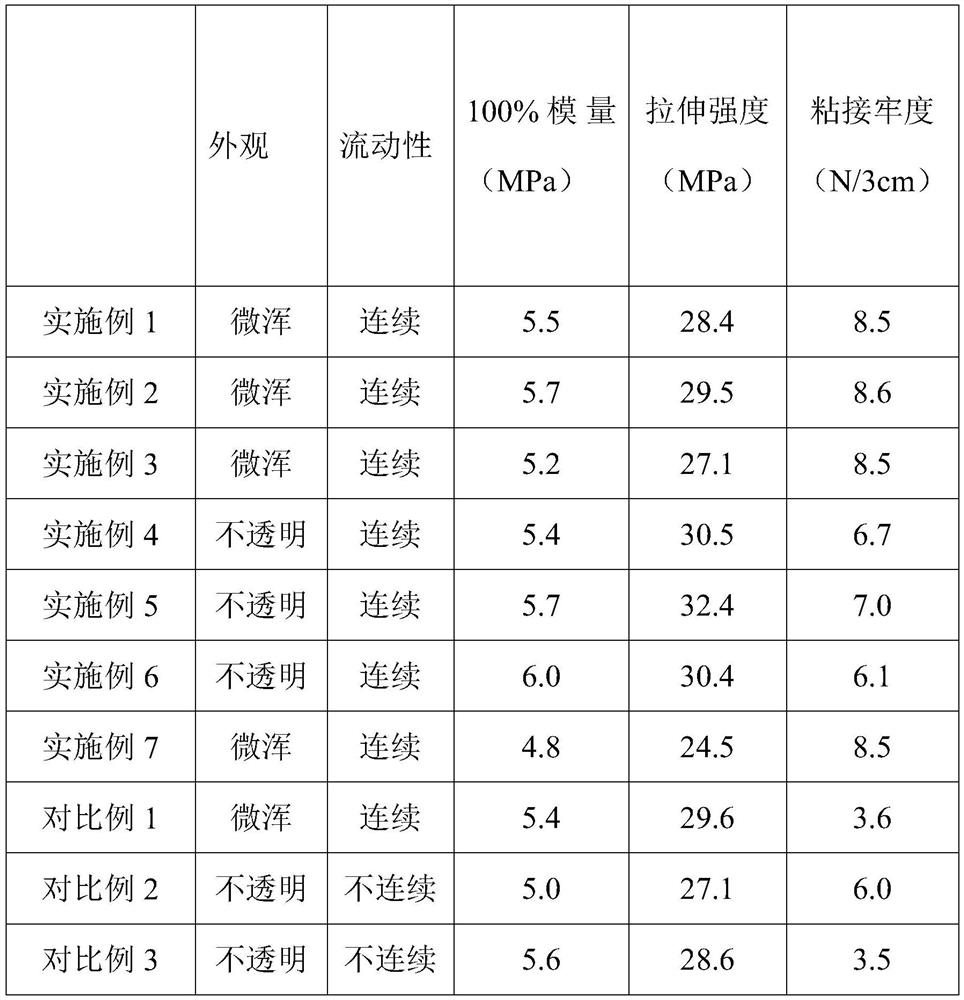

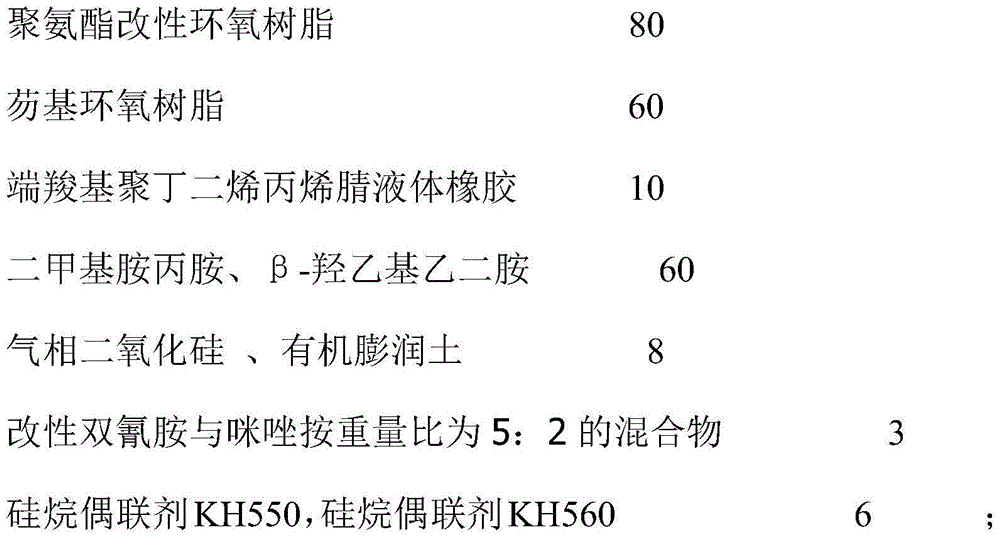

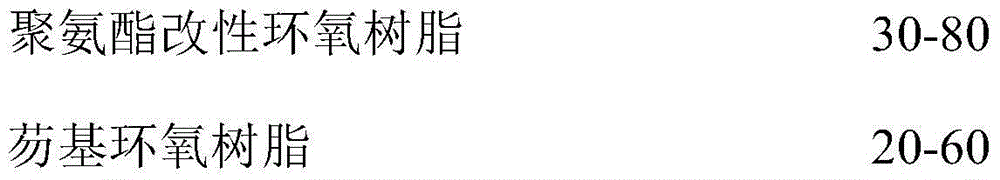

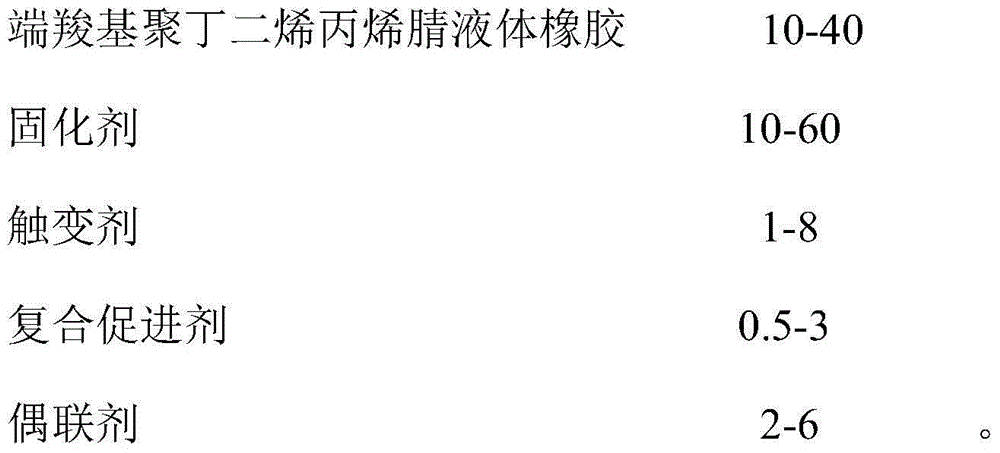

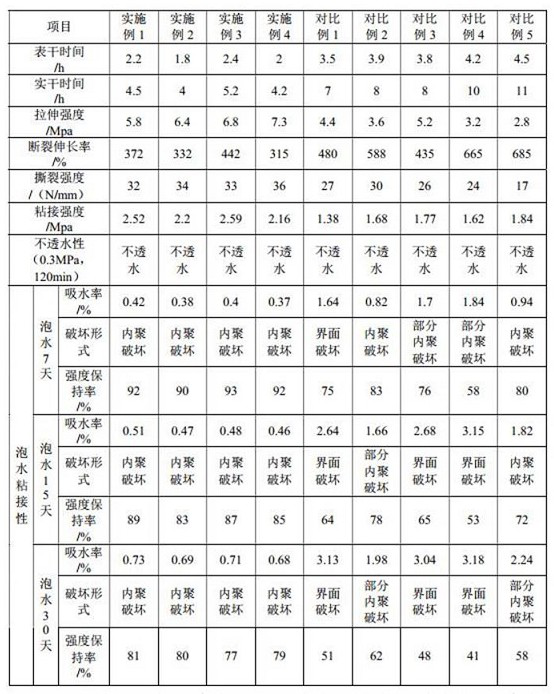

The invention discloses a polyurethane modified epoxy resin adhesive and a preparation method thereof. The adhesive is prepared from the following components of 30-80 parts polyurethane modified epoxy resin, 20-60 parts of fluorene-based epoxy resin, 10-40 parts of carboxyl-polybutadiene acrylonitrile liquid rubber, 10-60 parts of curing agent, 1-8 parts of thixotropic agent, 0.5-3 parts of compound accelerator and 2-6 parts of coupling agent. The preparation method comprises the steps of weighing each component according to the ratio, evenly mixing the polyurethane modified epoxy resin, the fluorene-based epoxy resin and the carboxyl-polybutadiene acrylonitrile liquid rubber under agitation at 50-70 DEG C; adding the curing agent, the thixotropic agent and the coupling agent and heating to 70-90 DEG C; evenly agitating, and cooling to room temperature after vacuum defoaming; and adding the compound accelerator under agitation at 40-50 DEG C until evenly mixing. The polyurethane modified epoxy resin adhesive disclosed by the invention is good in adhesion and simple in process, and can be used for materials such as buildings, metal, glass, plastic ceramic, and the like.

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

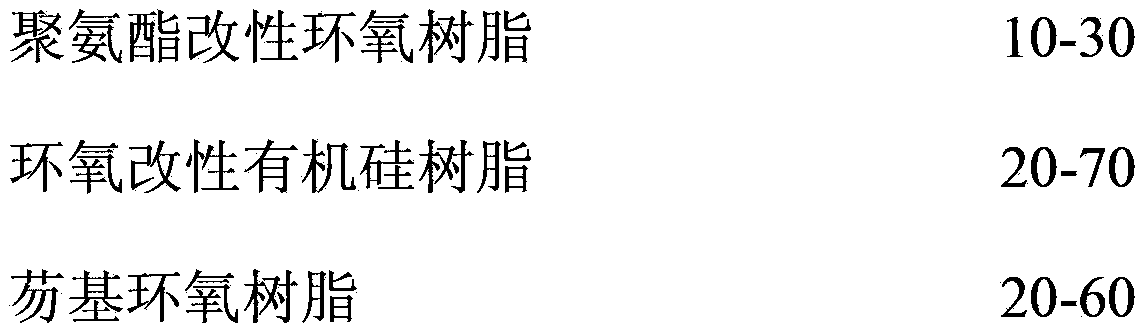

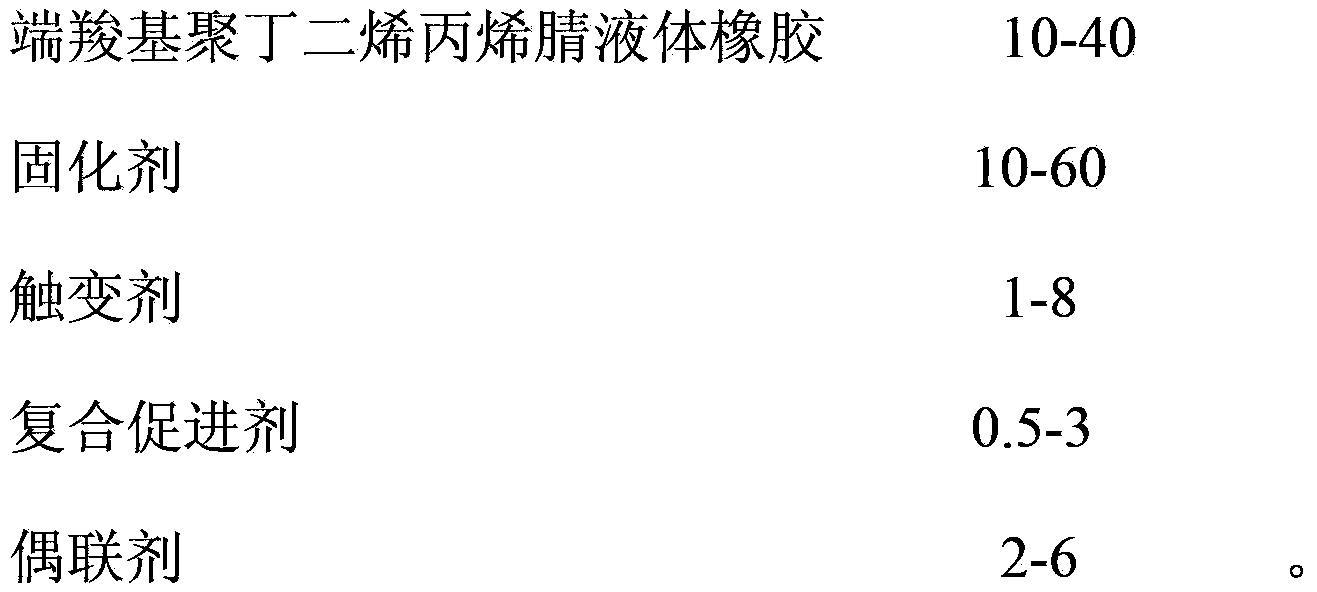

Epoxy modified organic silicon resin adhesive and preparation method thereof

InactiveCN103173114AGood adhesionSimple processPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolybutadiene acrylonitrile

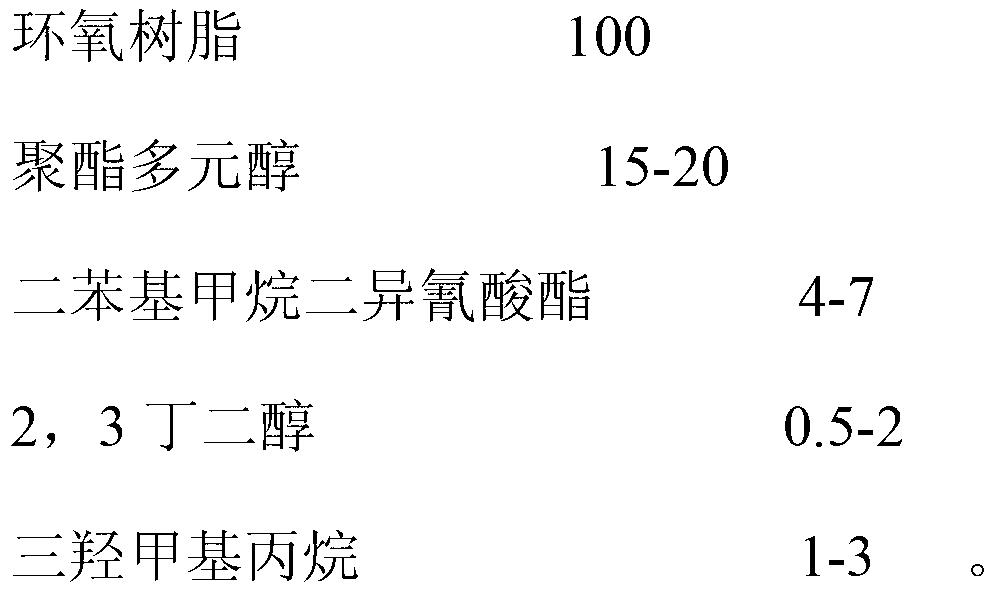

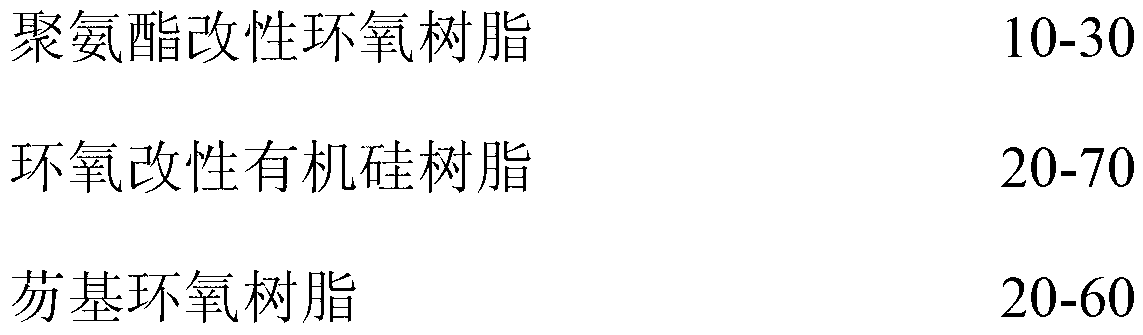

The invention discloses an epoxy modified organic silicon resin adhesive and a preparation method thereof. The adhesive is prepared from the following components of 10-30 parts of polyurethane modified epoxy resin, 20-70 parts of epoxy modified organic silicon resin, 20-60 parts of fluorene-based epoxy resin, 10-40 parts of carboxyl-polybutadiene acrylonitrile liquid rubber, 10-60 parts of curing agent, 1-8 parts of thixotropic agent, 0.5-3 parts of compound accelerator and 2-6 parts of coupling agent. The preparation method comprises the steps of weighing each component according to the ratio, evenly mixing the polyurethane modified epoxy resin, the epoxy modified organic silicon resin, the fluorene-based epoxy resin and the carboxyl-polybutadiene acrylonitrile liquid rubber under agitation at 50-70 DEG C; adding the curing agent, the thixotropic agent and the coupling agent and heating to 70-90 DEG C; evenly agitating, and cooling to room temperature after vacuum defoaming; and adding the compound accelerator under agitation at 40-50 DEG C until evenly mixing. The modified epoxy resin adhesive is good in adhesion and simple in process, and has good adhesion on materials such as metal, glass, and plastic ceramic.

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

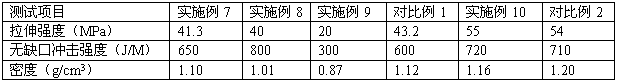

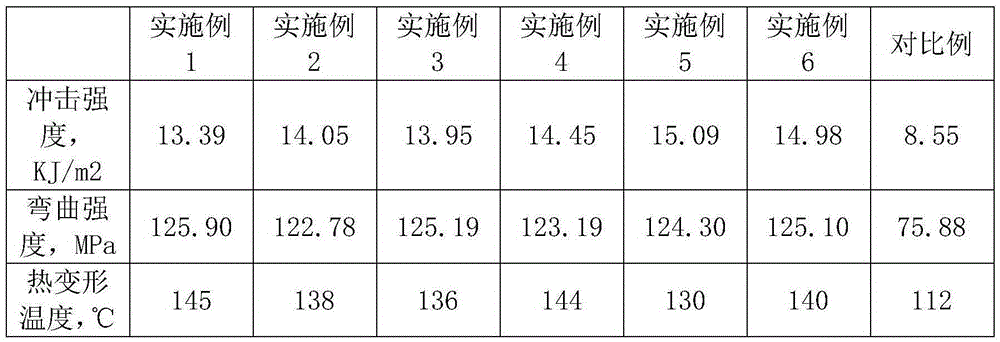

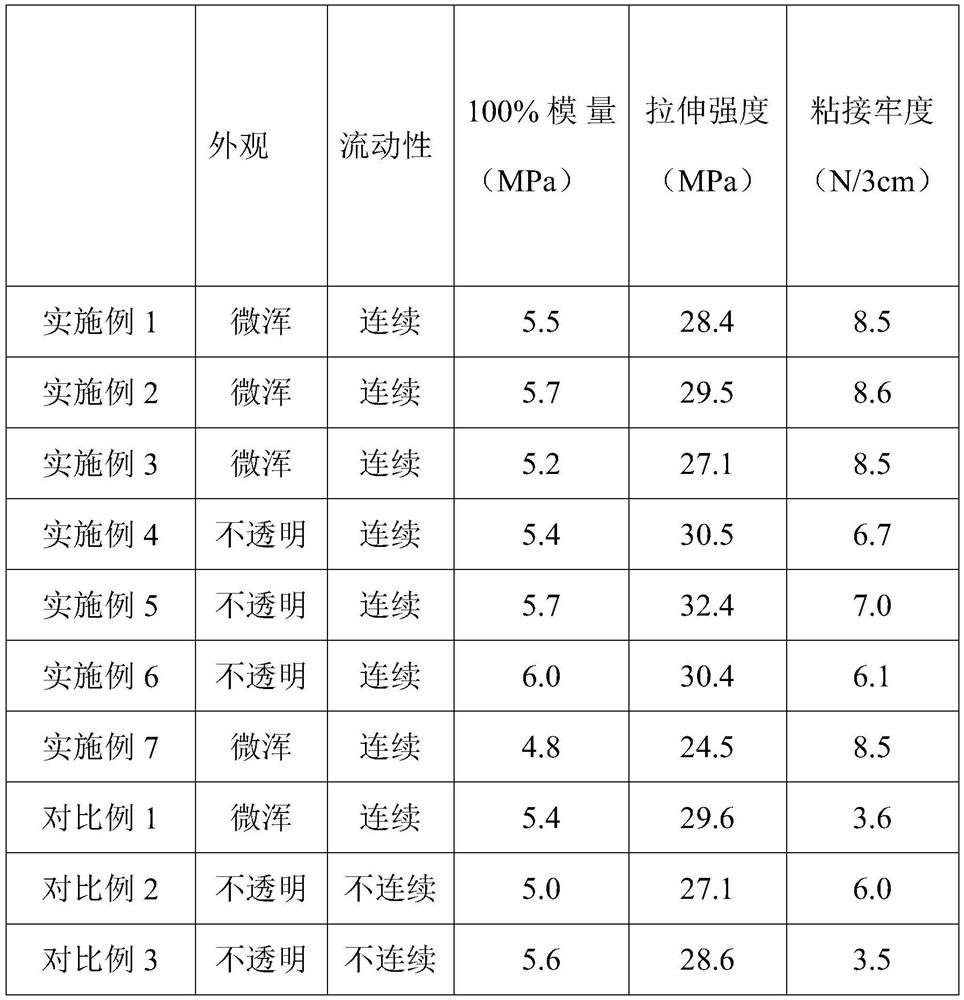

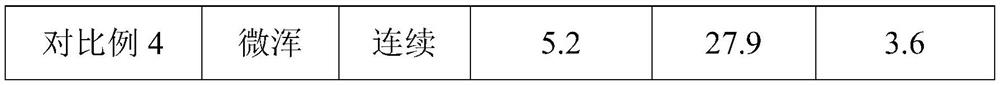

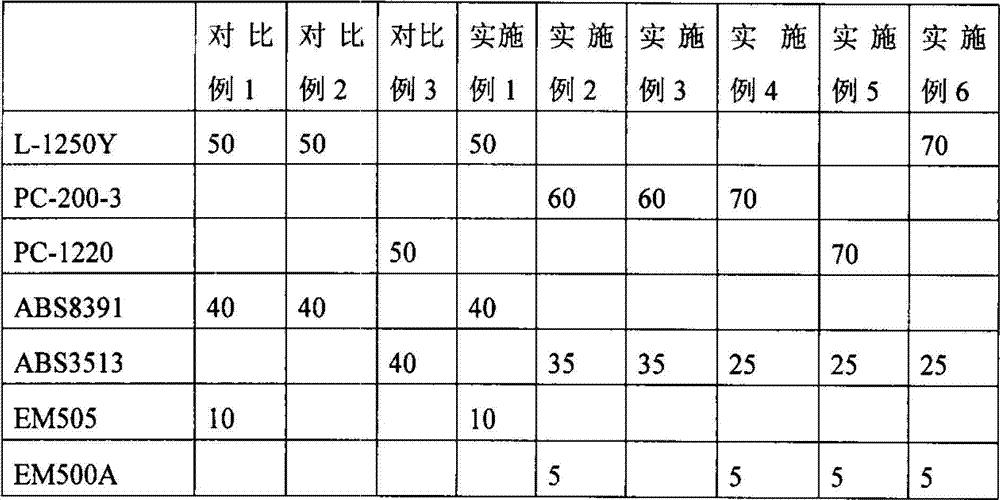

High multi-axis impact polycarbonate composition and preparation method thereof

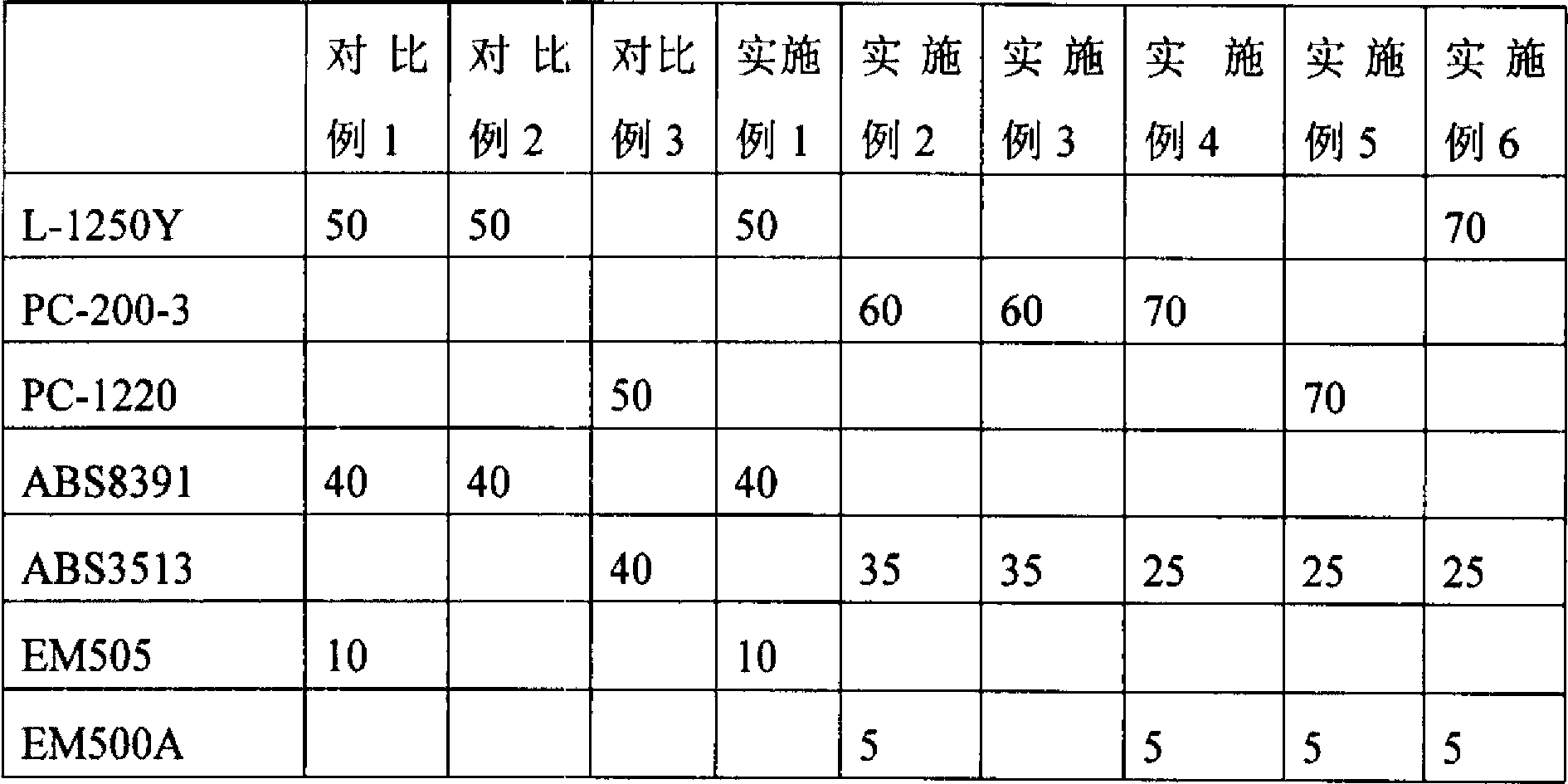

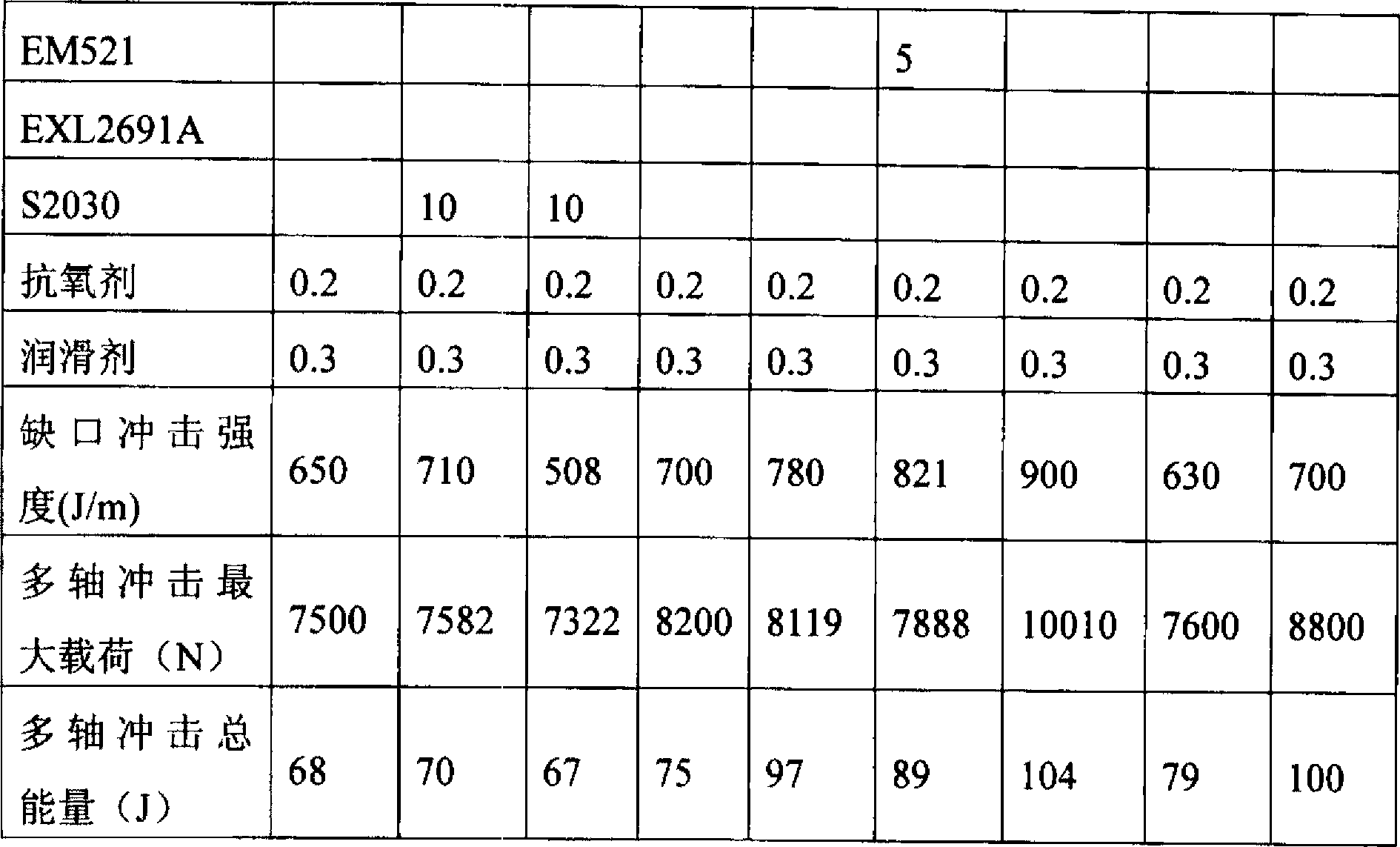

The invention relates to a high multi-axis impact polycarbonate composition and a preparation method of the high multi-axis impact polycarbonate composition. The composition comprises the following components in parts by weight: 50-70 parts of polycarbonate resin PC, 25-50 parts of polybutadiene-acrylonitrile-styrene copolymer resin ABS, 2-10 parts of toughening agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method of the high multi-axis impact polycarbonate composition comprises the following steps of: dividing raw material into parts A and B, wherein the part A comprises the PC, the antioxidant and the lubricant while the part B comprises the ABS and the toughening agent; and respectively premixing the parts A and B in a high-speed mixer, subsequently adding the premixed materials into a double-screw extruder, feeding the part A from a primary feeding opening and feeding the part B from a secondary feeding opening, fusing and extruding at 200-280 DEG C with the rotation speed of the screw extruder at 200-600rpm and the pressure at 2-3MPa, then fusing, extruding and pelleting to obtain the product. Compared with the prior art, through the special toughening agent, PC and processing technologies, the multi-axis impact performance of the polycarbonate composition provided by the invention is improved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Epoxy resins adducted with reactive liquid rubber having improved low temperature performance properties

ActiveUS7847026B2High bound acrylonitrile contentUnexpected low temperature propertyEpoxyPolybutadiene acrylonitrile

A blend of epoxy resins includes a) an epoxy resin composition derived from the reaction of a liquid epoxy resin, a carboxyl terminated butadiene (CTB), and a carboxyl terminated polybutadiene-acrylonitrile (CTBN) and / or a random and terminal carboxyl functional polybutadiene-acrylonitrile (CTBNX), and b) unreacted epoxy resin. The carboxyl terminated butadiene is miscible with the unreacted epoxy resin and does not separate therefrom even upon aging. Upon cure as with a latent cure agent, a toughened epoxy resin is produced having unexpected good low temperature properties such as peel strength.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

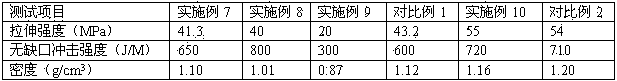

Lightweight polycarbonate composition and preparation method thereof

The invention discloses a lightweight polycarbonate composition which comprises following raw materials, by weight, 50-90 parts of polycarbonate, 10-50 parts of polybutadiene-acrylonitrile-styrene copolymer resin, 0.2-2 parts of chemical foamer with the decomposition temperature from 200 DEG C to 260 DEG C and 0.1-1.0 part of antioxidant. The invention further provides a preparation method for the lightweight polycarbonate composition. The method includes: weighing the raw materials according to the parts by weight, feeding the raw materials into a twin-screw extruder by a metering device after the raw materials are fully mixed in a medium-speed mixer, fusing for extruding, and cooling in a die for forming. The lightweight polycarbonate composition and the preparation method thereof are fewer in kinds of the raw materials and simple in production process, the polycarbonate and the polybutadiene-acrylonitrile-styrene copolymer resin are added into the chemical foamer, so that the obtained lightweight polycarbonate composition has the advantage of low density while excellent mechanical performances are maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

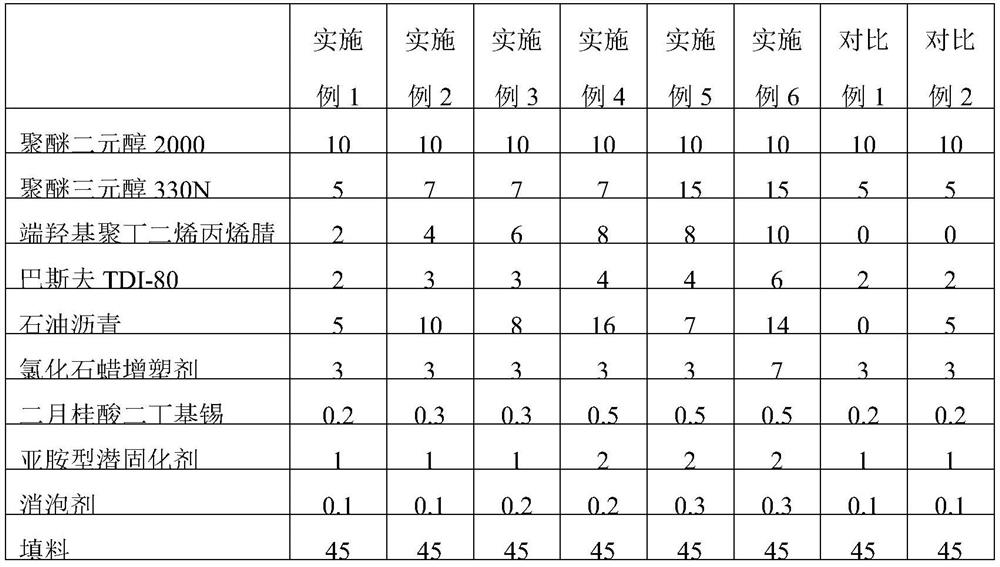

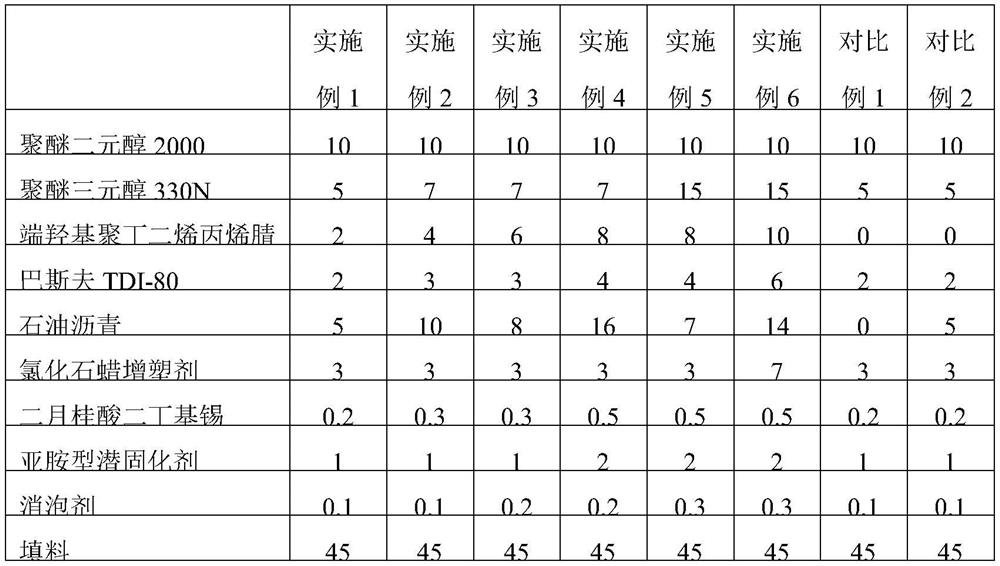

Asphalt polyurethane waterproof coating and preparation method thereof

ActiveCN113528001AReduce polarityGood compatibilityPolyurea/polyurethane coatingsBituminous coatingsPolymer sciencePolyolefin

The invention discloses an asphalt polyurethane waterproof coating and a preparation method thereof. The asphalt polyurethane waterproof coating comprises the following main raw materials by weight: 15-25 parts of polyether polyol; 2-10 parts of polyolefin polyol; 2- 6 parts of diisocyanate; and 5 -20 parts of asphalt. According to the invention, hydroxyl-terminated polybutadiene acrylonitrile is used for partially replacing traditional polyether polyol and is reacted with isocyanate, and two chain segments of non-polar butadiene and strong-polar acrylonitrile are introduced into the synthesized polyurethane prepolymer, so that the compatibility of the polyurethane prepolymer and asphalt is greatly enhanced, and the prepared asphalt polyurethane coating has relatively good compatibility and adhesion with an asphalt coiled material.

Owner:KESHUN WATERPROOF TECH CO LTD

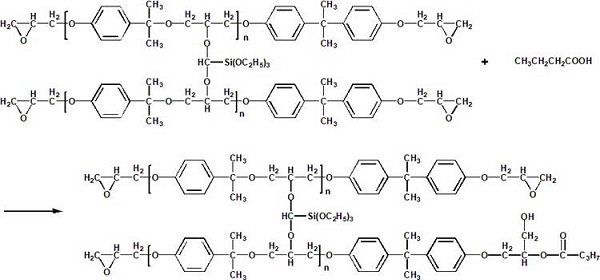

Preparation method of hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer/carbon nanotube conducting composite film

The invention discloses a preparation method of a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method comprises the following steps: carrying out in-situ coupling reaction on a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and uniform hydroxy multiwall carbon nanotubes subjected to ultrasonic dispersion to form a polyurethane compound by using hexamethylene diisocyanate, coating a film, and drying at room temperature to obtain the hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method is simple to operate and easy for film formation, and has the advantages of low energy consumption, short operation time and favorable dispersibility of the carbon nanotubes; the obtained conducting composite film can implement detection on benzene and methylbenzene solvent vapor, has the advantages of short response time, high sensitivity and high selectivity, can not cause permanent damage to the conducting film, can implement the ppm-level detection on the benzene vapor, and can implement repeated use.

Owner:SHAANXI NORMAL UNIV

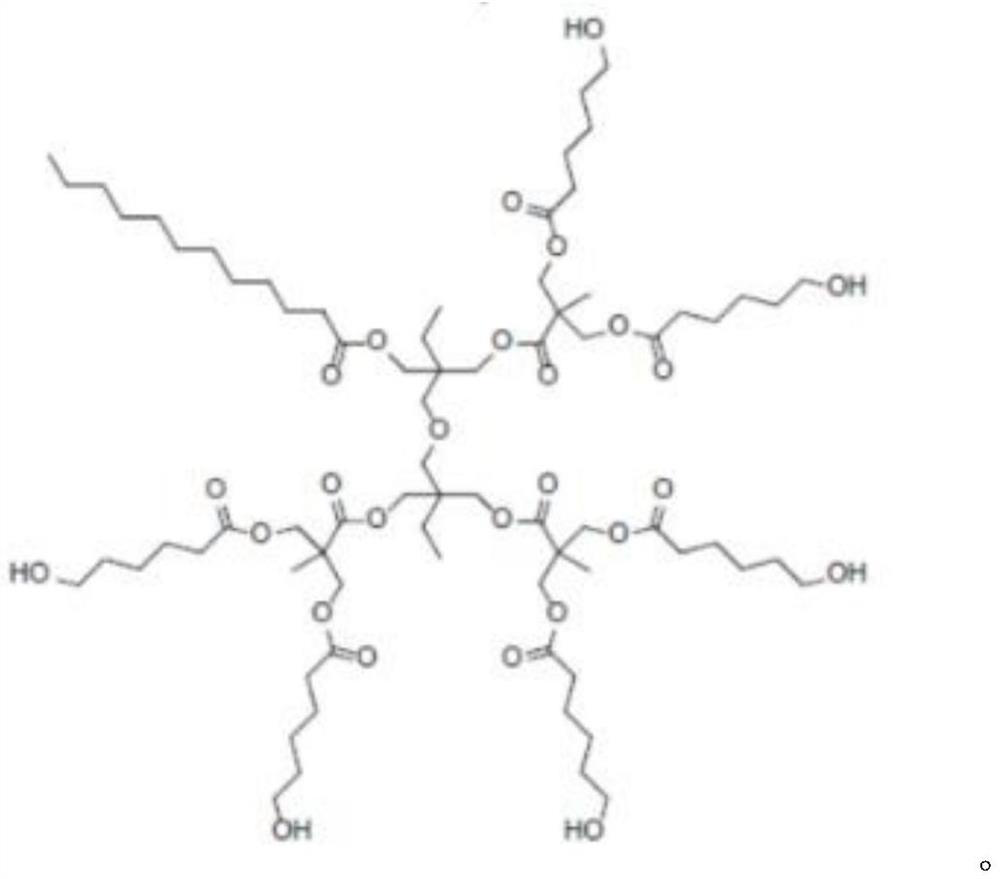

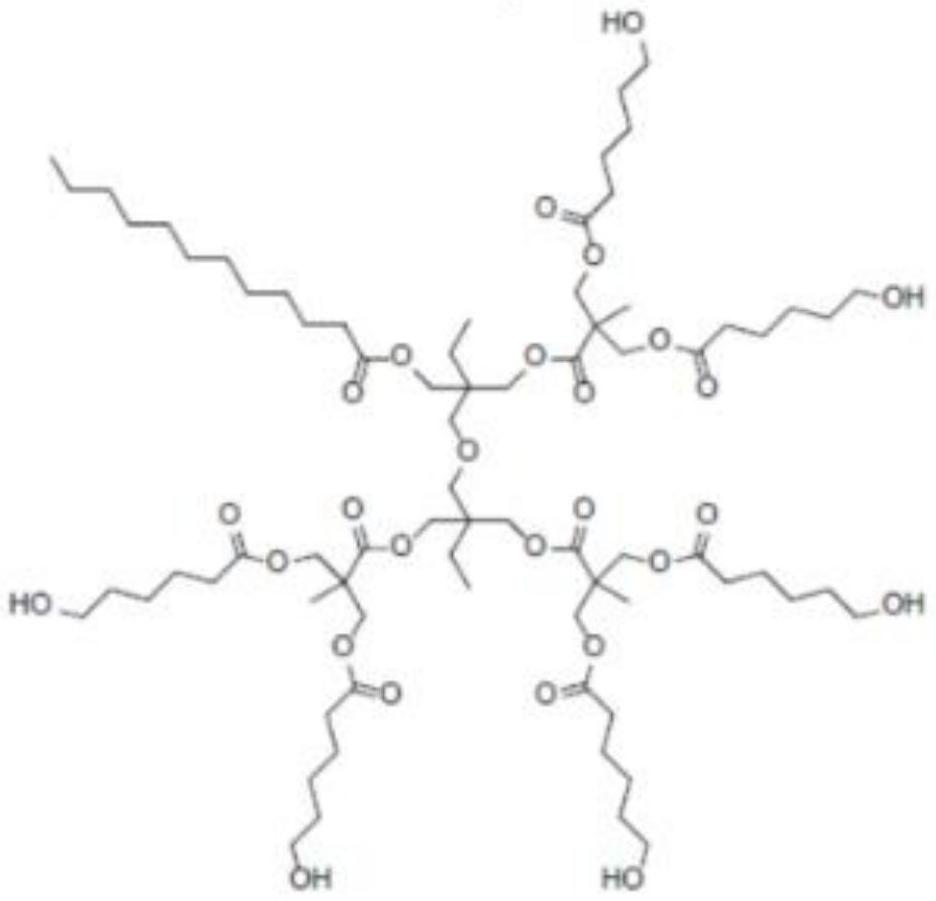

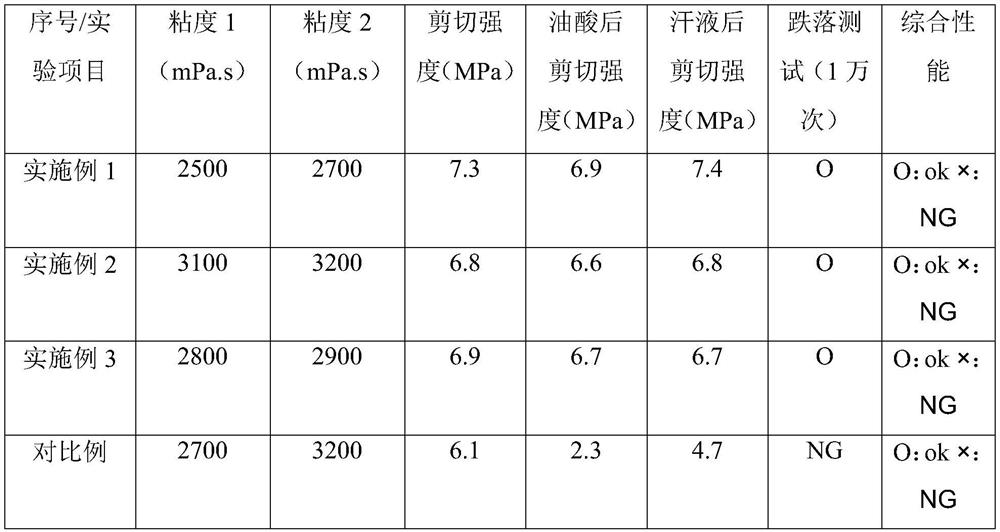

High-performance polyurethane hot melt adhesive and preparation method thereof

ActiveCN112662368AGood oil resistanceGood adhesionPolyureas/polyurethane adhesivesPolyesterPolymer science

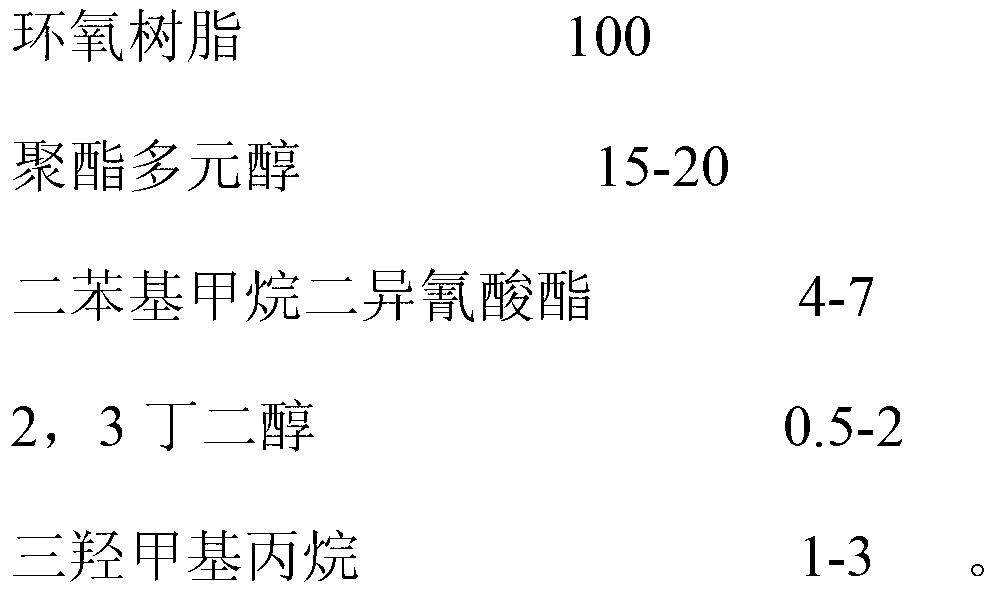

The invention relates to a high-performance polyurethane hot melt adhesive, which is prepared from the following raw materials in parts by mass: 50 to 80 parts of polyester polyol, 10 to 30 parts of hydroxyl-terminated polybutadiene acrylonitrile, 1 to 5 parts of multi-arm star-terminated hydroxyl polyester polyol, 0.05 to 0.1 part of catalyst and 10 to 20 parts of diphenylmethane diisocyanate. According to the invention, hydroxyl-terminated polybutadiene acrylonitrile is introduced into a molecular chain together with polyester polyol to be synergistically blocked into the molecular chain, so that the adhesive has good oil resistance, adhesion and aging resistance on the basis of endowing the adhesive with excellent elasticity. In addition, the multi-arm structure of the multi-arm star hydroxyl-terminated polyester polyol and the telechelic structure of the hydroxyl-terminated polybutadiene acrylonitrile are interspersed to form strong intermolecular Van der Waals' force, and the erosion of substances such as moisture, sweat, grease, oleic acid and the like to colloid can be effectively avoided, so that the excellent performance of the glue is achieved.

Owner:YANTAI DARBOND TECH

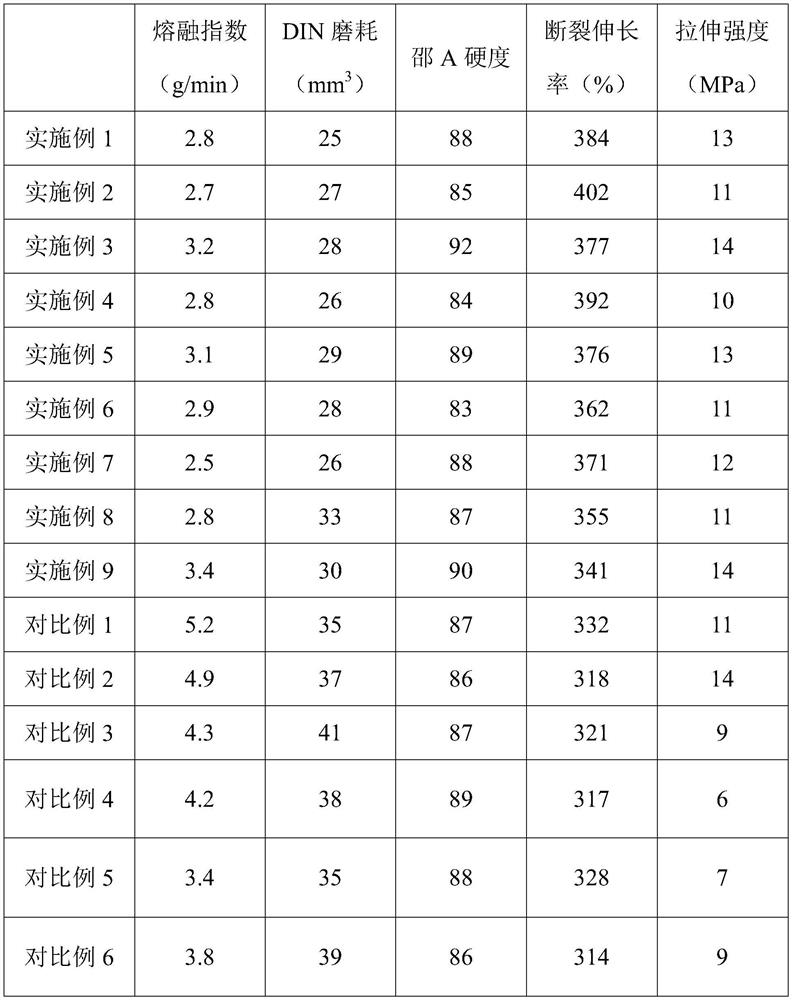

High-fluidity and high-wear-resistance thermoplastic polyurethane and preparation method thereof

The invention relates to high-fluidity and high-wear-resistance thermoplastic polyurethane and a preparation method thereof. The thermoplastic polyurethane comprises a component A and a component B, the component A is prepared from the following raw materials in parts by weight: 20 to 40 parts of diisocyanate, 50 to 60 parts of polycaprolactone polyol, 10 to 15 parts of hydroxyl-terminated polybutadiene acrylonitrile, 5 to 10 parts of amine chain extender and 0.01 to 0.05 part of catalyst; the component B is prepared from the following raw materials in parts by weight: 3 to 5 parts of nano silicon dioxide, 4 to 8 parts of carboxymethyl cellulose, 3 to 5 parts of hydroxyl-terminated polysiloxane and 5 to 10 parts of auxiliaries. The thermoplastic polyurethane disclosed by the invention not only has good flowability and wear resistance, but also has relatively high hardness, relatively high elongation at break and excellent comprehensive performance, and the tensile strength is in a relatively high range.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH +1

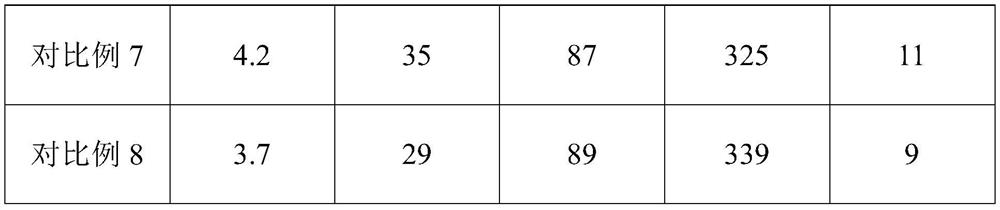

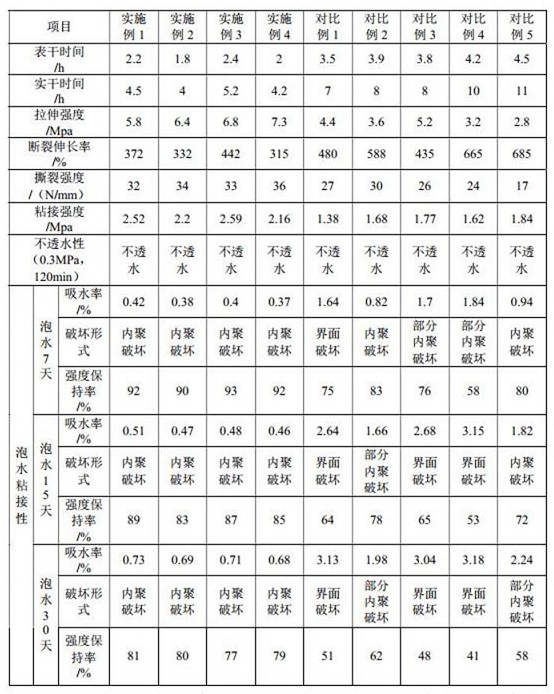

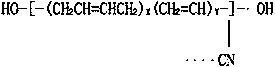

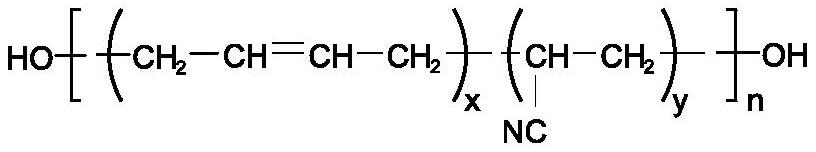

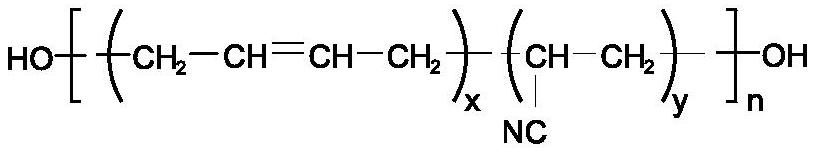

Single-component polyurethane waterproof coating composition and preparation method thereof

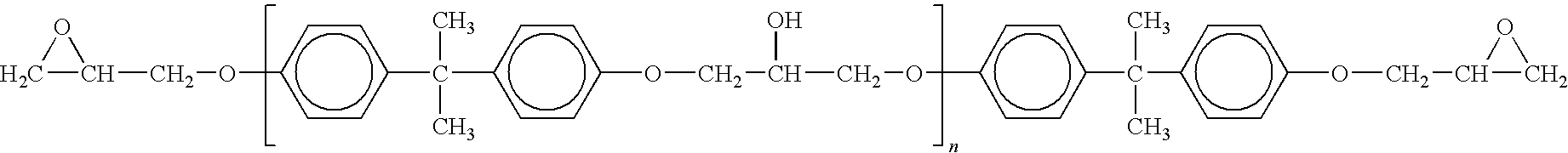

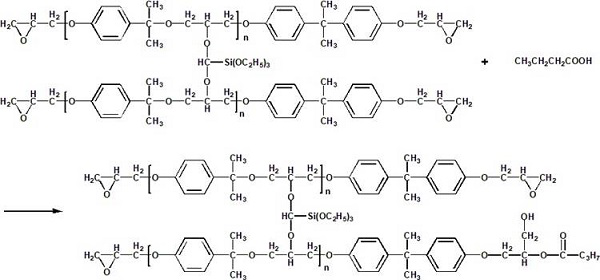

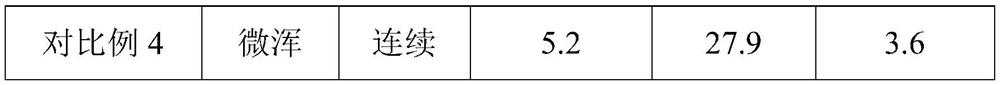

The invention belongs to the technical field of waterproof coatings, and provides a single-component polyurethane waterproof coating composition and a preparation method thereof. The single-component polyurethane waterproof coating composition comprises polyurethane film-forming resin, a dispersing agent and an optional additive; the polyurethane film-forming resin comprises a molecular chain skeleton of an isocyanate-terminated polyurethane prepolymer, the isocyanate-terminated polyurethane prepolymer is obtained through reaction of hydroxyl-terminated polybutadiene acrylonitrile, polyether polyol and isocyanate, the polyurethane film-forming resin comprises a chain segment structure which is connected with the molecular chain skeleton and is shown in the formula 1, and the formula 1 is shown in the description, wherein R1, R2, R3, R4, n and n' are defined in the description. A coating film formed by the single-component polyurethane waterproof coating composition has excellent water resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

Polyurethane resin as well as preparation method and application thereof

The invention provides polyurethane resin as well as a preparation method and application thereof. The polyurethane resin is prepared from the following raw materials: a combination of polyester polyol, polybutadiene diol (HTPB), polybutadiene acrylonitrile diol (HTBN), a chain extender and aliphatic diisocyanate. Low-polarity HTPB and HTBN are introduced into the preparation raw materials, polyester polyol and aliphatic isocyanate are matched, the overall polarity of the finally obtained polyurethane resin is greatly reduced, the compatibility of the polyurethane resin and a TPR material is promoted, the polyurethane resin and the TPR material can have high binding strength in the injection molding process without adding a binding agent, and the polyurethane resin has important research significance.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

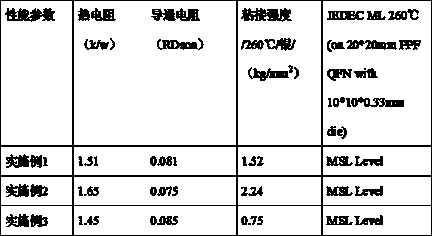

Electrically conductive die bond adhesive applied to packaging large-size chips, method for preparing electrically conductive die bond adhesive and application thereof

ActiveCN109135657AImprove toughnessImprove flexibilityPolyureas/polyurethane adhesivesSemiconductor/solid-state device detailsPolybutadiene acrylonitrileAcrylonitrile

The invention discloses electrically conductive die bond adhesive applied to packaging large-size chips, a method for preparing the electrically conductive die bond adhesive and application thereof. The electrically conductive die bond adhesive is made from hydroxyl terminated polybutadiene acrylonitrile, thermoplastic resin, liquid phenolic resin, blocked isocyanate latent curing agents, couplingagents, electric conductivity accelerators and electrically conductive materials. The electrically conductive die bond adhesive, the method and the application have the advantages that electrically conductive adhesive films prepared from the electrically conductive die bond adhesive are excellent in toughness and flexibility, and the electrically conductive die bond adhesive can be applied to packaging the large chips (with the chip sizes larger than or equal to 10*10 mm) and packaging chips with high electric conductivity (the volume resistivity lower than or equal to 0.002 ohm-cm).

Owner:深圳广恒威科技有限公司

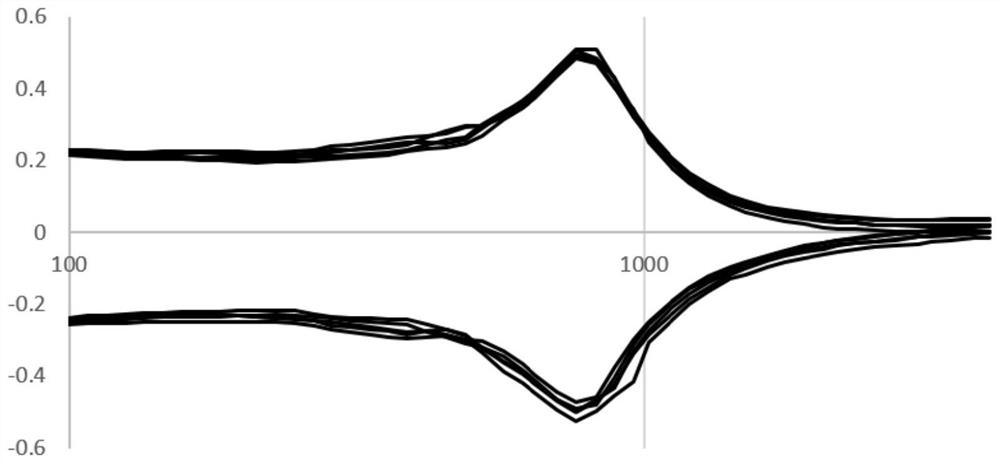

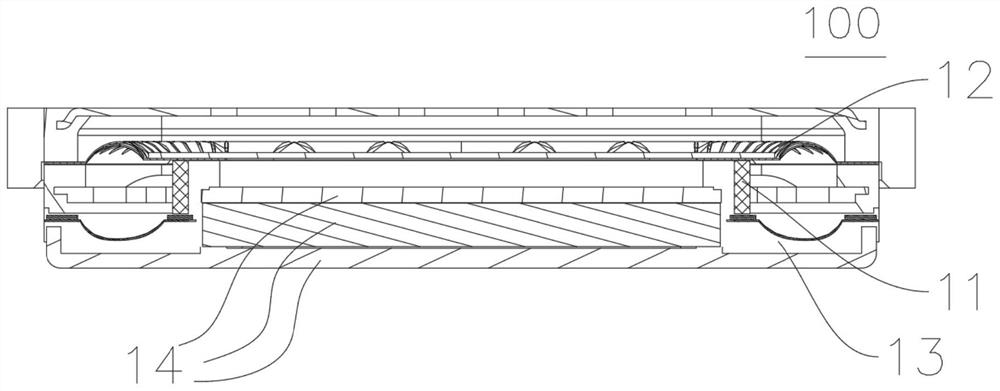

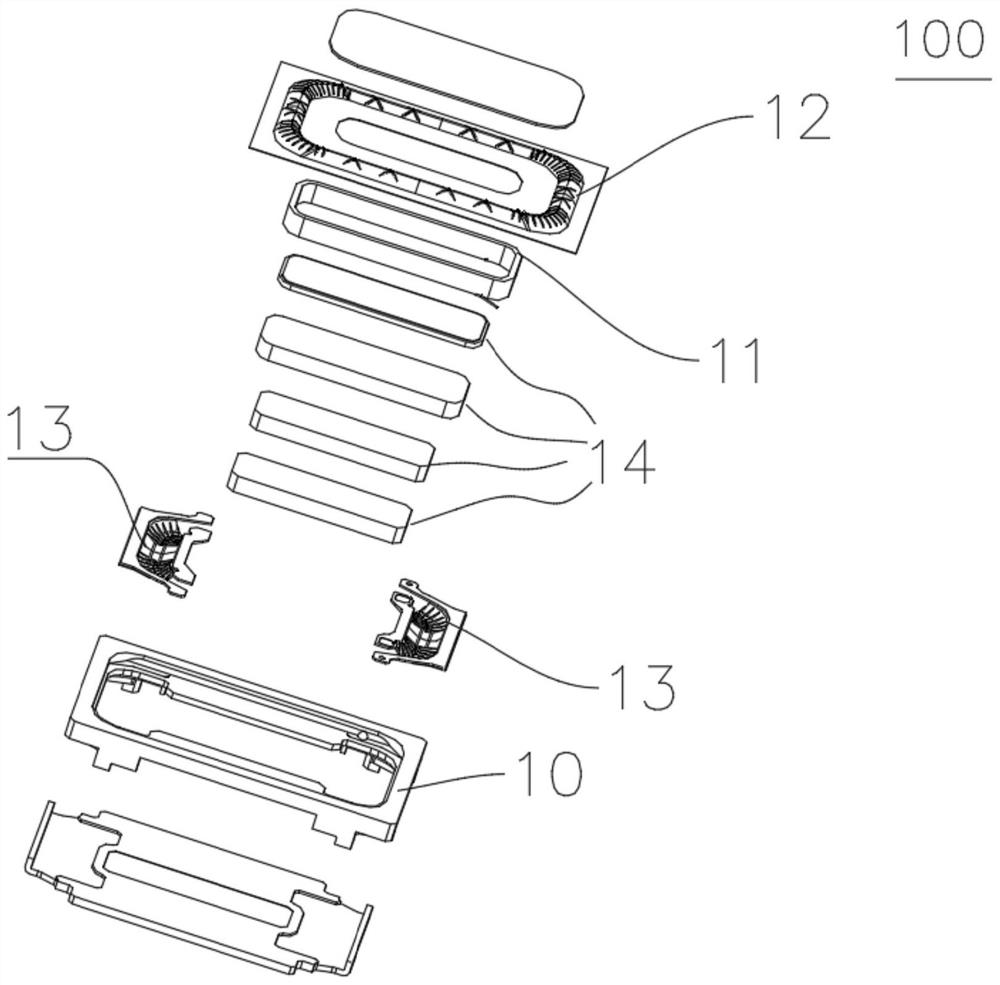

Vibrating diaphragm of sound production device, and sound production device thereof

PendingCN113773533ASmall distortionImprove mechanical propertiesElectrical transducersPolymer sciencePolybutadiene acrylonitrile

The invention discloses a vibrating diaphragm of a sound production device, and the sound production device. The vibrating diaphragm of the sound production device comprises at least one modified ethylene propylene rubber membrane layer, the modified ethylene propylene rubber membrane layer is made of modified ethylene propylene rubber, and the modified ethylene propylene rubber is formed by a cross-linking reaction of base rubber and a reactant, wherein the base rubber is ethylene propylene diene monomer and / or ethylene propylene diene monomer, and the reactant is one or more of polyacrylate, polyethylene-acrylate, polyethylene-vinyl acetate and hydrogenated polybutadiene-acrylonitrile. According to the vibrating diaphragm, the modified ethylene propylene rubber formed by adding the reactant into the ethylene propylene diene monomer and / or the ethylene propylene diene monomer to carry out the crosslinking reaction is adopted as the raw material to prepare the vibrating diaphragm, so that the good rebound resilience and adhesion of the vibrating diaphragm can be ensured, the damping performance of the vibrating diaphragm can be improved, and the acoustic performance of the sound production device is effectively ensured.

Owner:GOERTEK INC

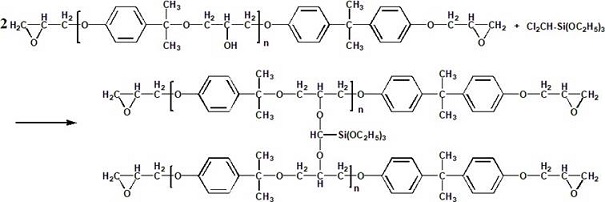

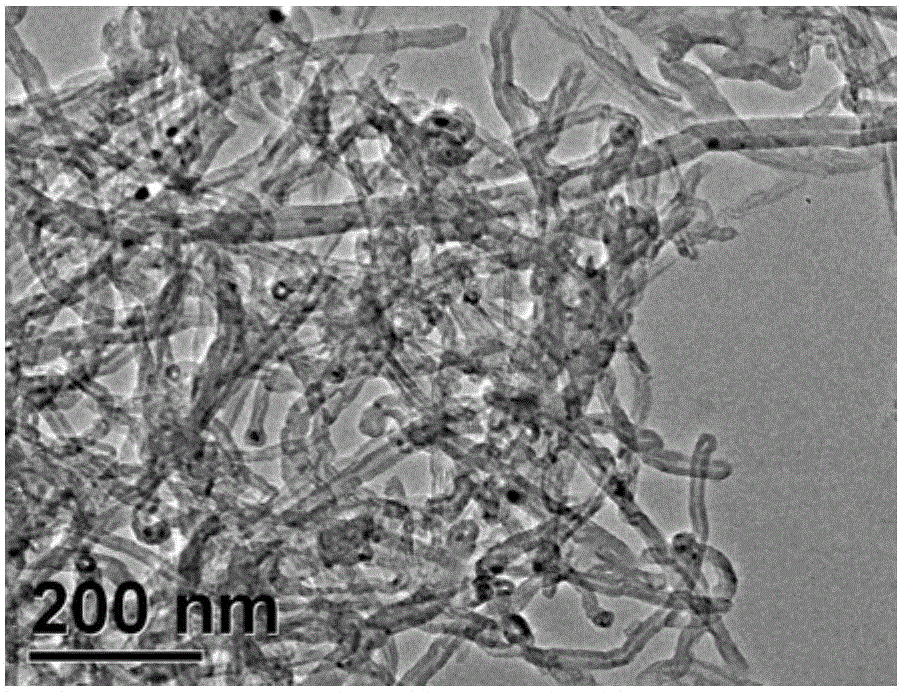

Urea terminated butadiene polymers and butadiene acrylonitrile copolymers

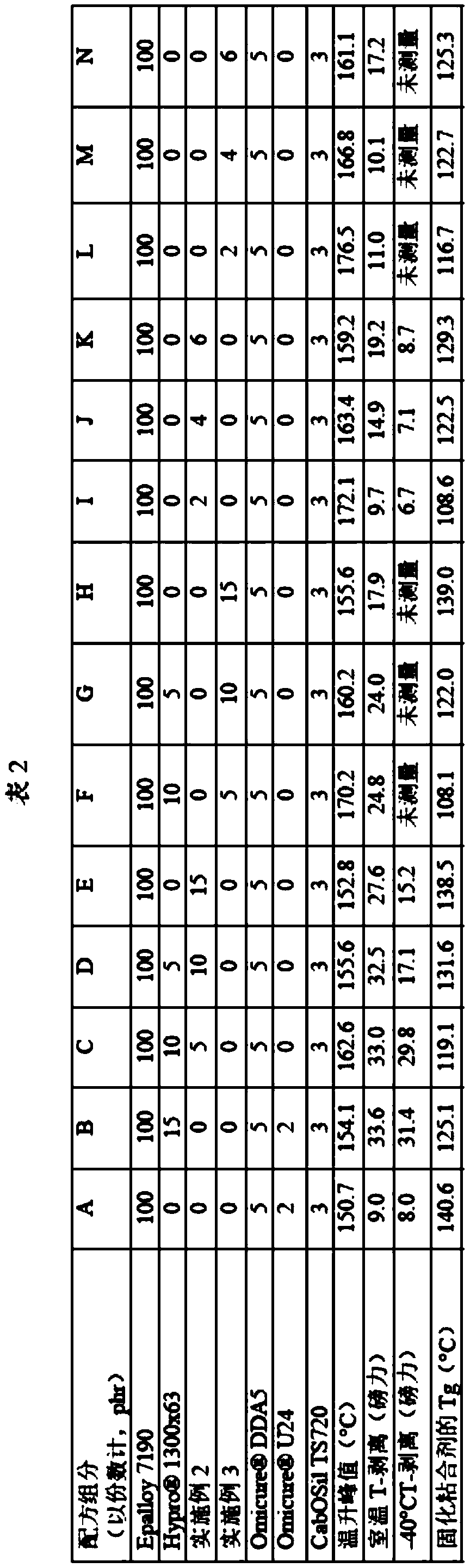

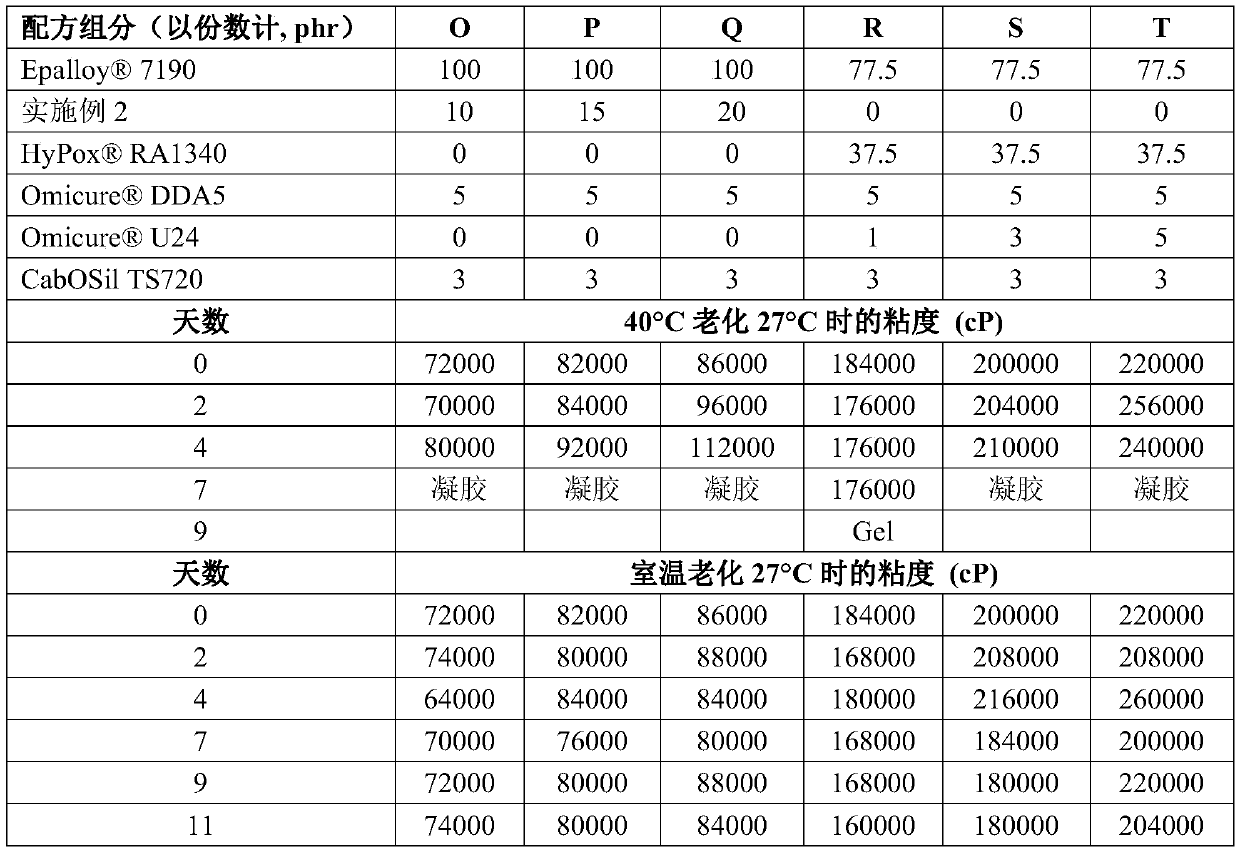

Urea-terminated polybutadiene polymers and polybutadiene acrylonitrile copolymers useful as both accelerators and tougheners are disclosed for use in epoxy formulations cured with dicyandiamide. The inventive urea-terminated polymers achieve comparable toughness in cured epoxy formulations when compared to that achieved with traditional polymeric or rubber tougheners with little to no change in glass transition temperature. Viscosity improvement and stability over time are also an advantage. A method of preparation emphasizing aspects of reaction stoichiometry is also disclosed.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Brightness enhancement film suitable for television backlight

InactiveCN107656328ABrightening effect is highMaterials are cheap and readily availableWax coatingsOptical elementsPolyethylene oxidePolyphthalamide

A brightness enhancement film suitable for television backlight comprises a brightness enhancement film body, a front coating coated on a front side of the brightness enhancement film body, and a backcoating coated on a back side of the brightness enhancement film body. The brightness enhancement film body comprises, by weight, 2-6 parts of polyamide, 4-5 parts of polybutadiene-acrylonitrile, 2-4parts of polybutyl acrylate, 5-8 parts of ethylene-ethyl acrylate copolymers, 20-25 parts of polyphthalamide, 10-20 parts of polyethylene oxide, 30-40 parts of polyethylene, and 12-18 parts of polyarylester. The brightness enhancement film is specially designed for the television backlight. Appropriate materials are selected for the brightness enhancement film, and the front coating and the backcoating are coated on the front side and the back side respectively so that a brightness enhancement effect of the brightness enhancement film is 5%-10% higher than the effect of a common brightness enhancement film. Simultaneously, the materials are cheap and are easy to get, and cost is saved.

Owner:张永宏

Epoxy modified organic silicon resin adhesive and preparation method thereof

InactiveCN103173114BGood adhesionSimple processPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolybutadiene acrylonitrile

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

Polyurethane modified epoxy resin adhesive and preparation method thereof

InactiveCN103173183BGood adhesionSimple processPolyureas/polyurethane adhesivesEpoxy resin adhesivesEpoxyPolybutadiene acrylonitrile

The invention discloses a polyurethane modified epoxy resin adhesive and a preparation method thereof. The adhesive is prepared from the following components of 30-80 parts polyurethane modified epoxy resin, 20-60 parts of fluorene-based epoxy resin, 10-40 parts of carboxyl-polybutadiene acrylonitrile liquid rubber, 10-60 parts of curing agent, 1-8 parts of thixotropic agent, 0.5-3 parts of compound accelerator and 2-6 parts of coupling agent. The preparation method comprises the steps of weighing each component according to the ratio, evenly mixing the polyurethane modified epoxy resin, the fluorene-based epoxy resin and the carboxyl-polybutadiene acrylonitrile liquid rubber under agitation at 50-70 DEG C; adding the curing agent, the thixotropic agent and the coupling agent and heating to 70-90 DEG C; evenly agitating, and cooling to room temperature after vacuum defoaming; and adding the compound accelerator under agitation at 40-50 DEG C until evenly mixing. The polyurethane modified epoxy resin adhesive disclosed by the invention is good in adhesion and simple in process, and can be used for materials such as buildings, metal, glass, plastic ceramic, and the like.

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

One-component polyurethane waterproof coating composition and preparation method thereof

The application belongs to the technical field of waterproof coatings, and provides a one-component polyurethane waterproof coating composition and a preparation method thereof. The one-component polyurethane waterproof coating composition includes polyurethane film-forming resin, dispersant and optional additives; polyurethane film-forming resin Including the molecular chain skeleton of isocyanate-terminated polyurethane prepolymer, which is obtained by the reaction of hydroxyl-terminated polybutadiene acrylonitrile, polyether polyol and isocyanate, and polyurethane film-forming resin. The chain segment structure shown in formula 1, formula 1, wherein R 1 ~R 4 and n, n ’ respectively as defined herein. The coating film formed by the one-component polyurethane waterproof coating composition of the present application has excellent water resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

Preparation method of hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer/carbon nanotube conductive composite film

The invention discloses a preparation method of a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method comprises the following steps: carrying out in-situ coupling reaction on a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and uniform hydroxy multiwall carbon nanotubes subjected to ultrasonic dispersion to form a polyurethane compound by using hexamethylene diisocyanate, coating a film, and drying at room temperature to obtain the hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method is simple to operate and easy for film formation, and has the advantages of low energy consumption, short operation time and favorable dispersibility of the carbon nanotubes; the obtained conducting composite film can implement detection on benzene and methylbenzene solvent vapor, has the advantages of short response time, high sensitivity and high selectivity, can not cause permanent damage to the conducting film, can implement the ppm-level detection on the benzene vapor, and can implement repeated use.

Owner:SHAANXI NORMAL UNIV

Urea terminated butadiene polymers and butadiene acrylonitrile copolymers

Urea-terminated polybutadiene polymers and polybutadiene acrylonitrile copolymers useful as both accelerators and tougheners are disclosed for use in epoxy formulations cured with dicyandiamide. The inventive urea-terminated polymers achieve comparable toughness in cured epoxy formulations when compared to that achieved with traditional polymeric or rubber tougheners with little to no change in glass transition temperature. Viscosity improvement and stability over time are also an advantage. A method of preparation emphasizing aspects of reaction stoichiometry is also disclosed.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

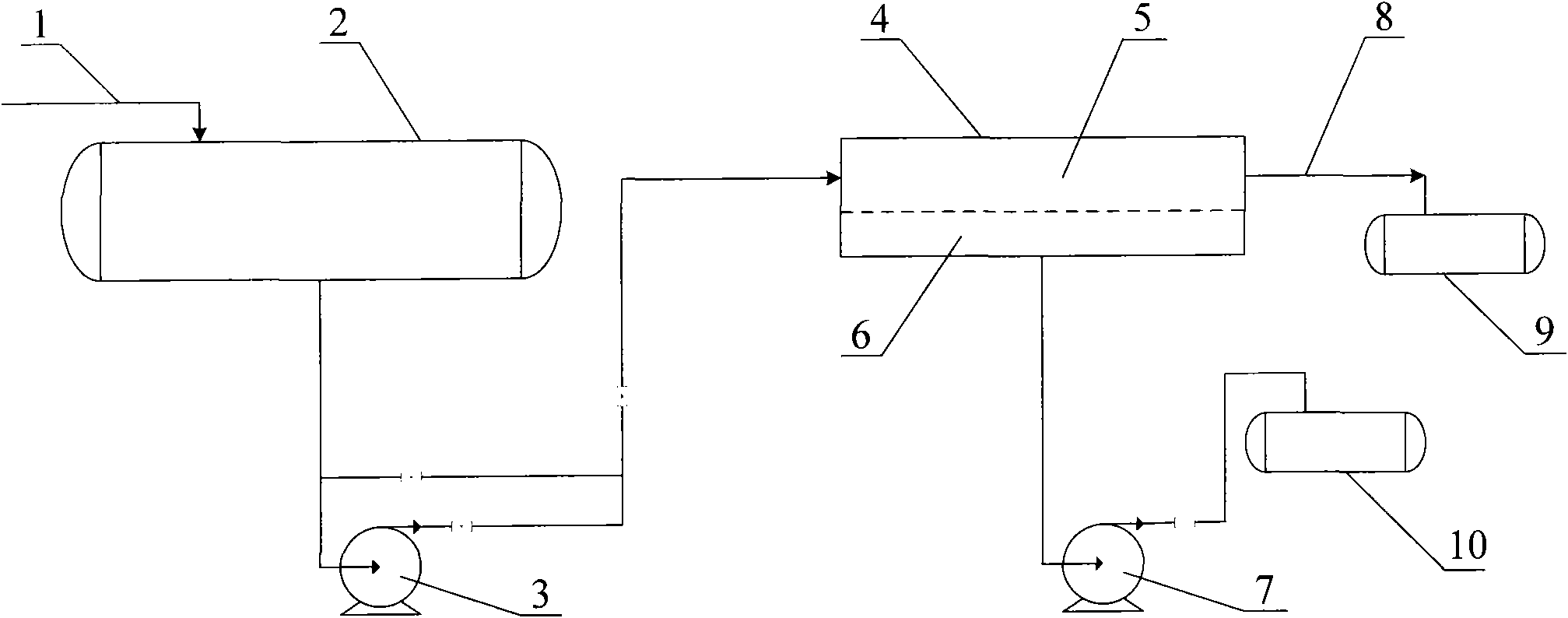

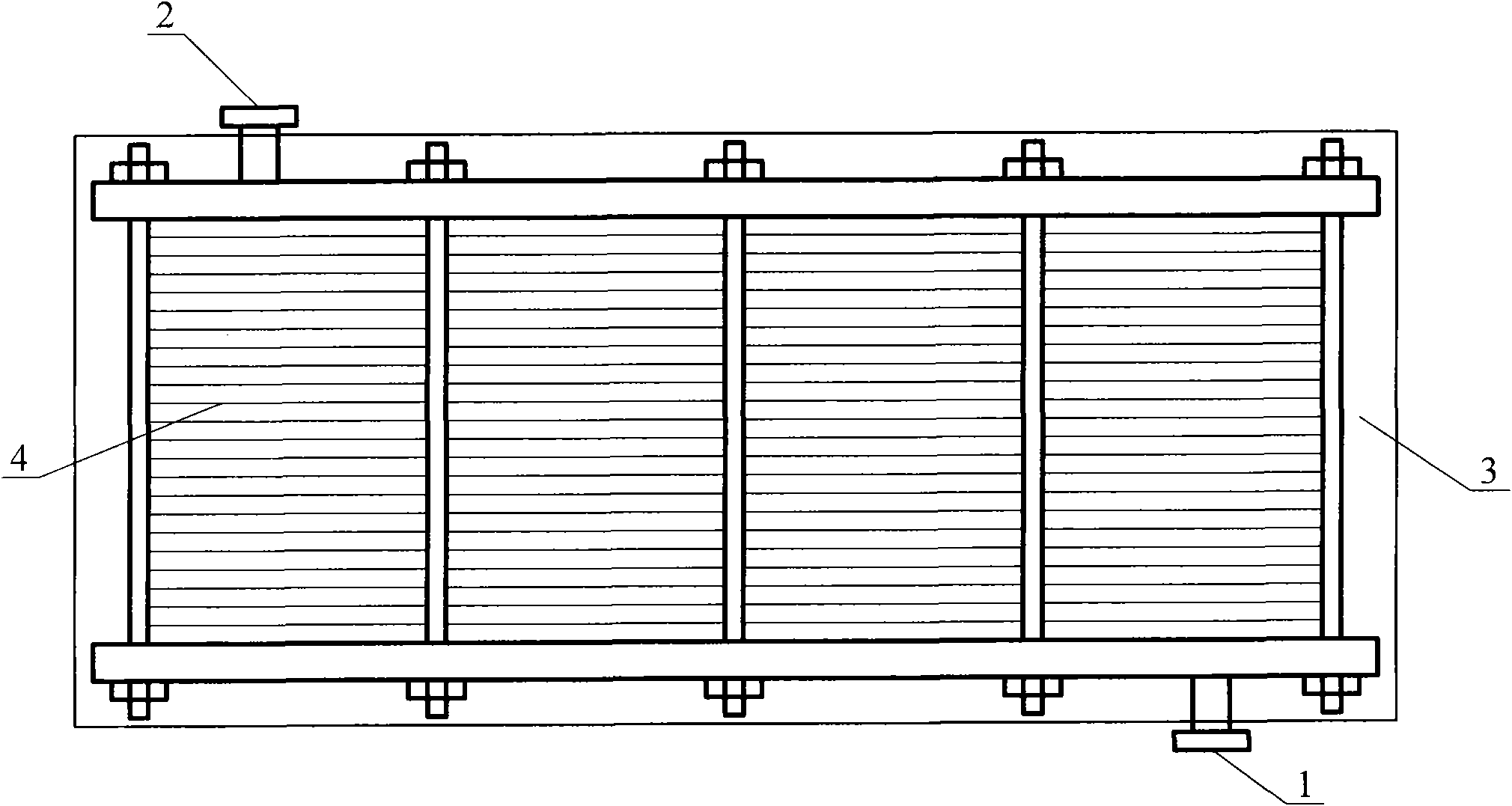

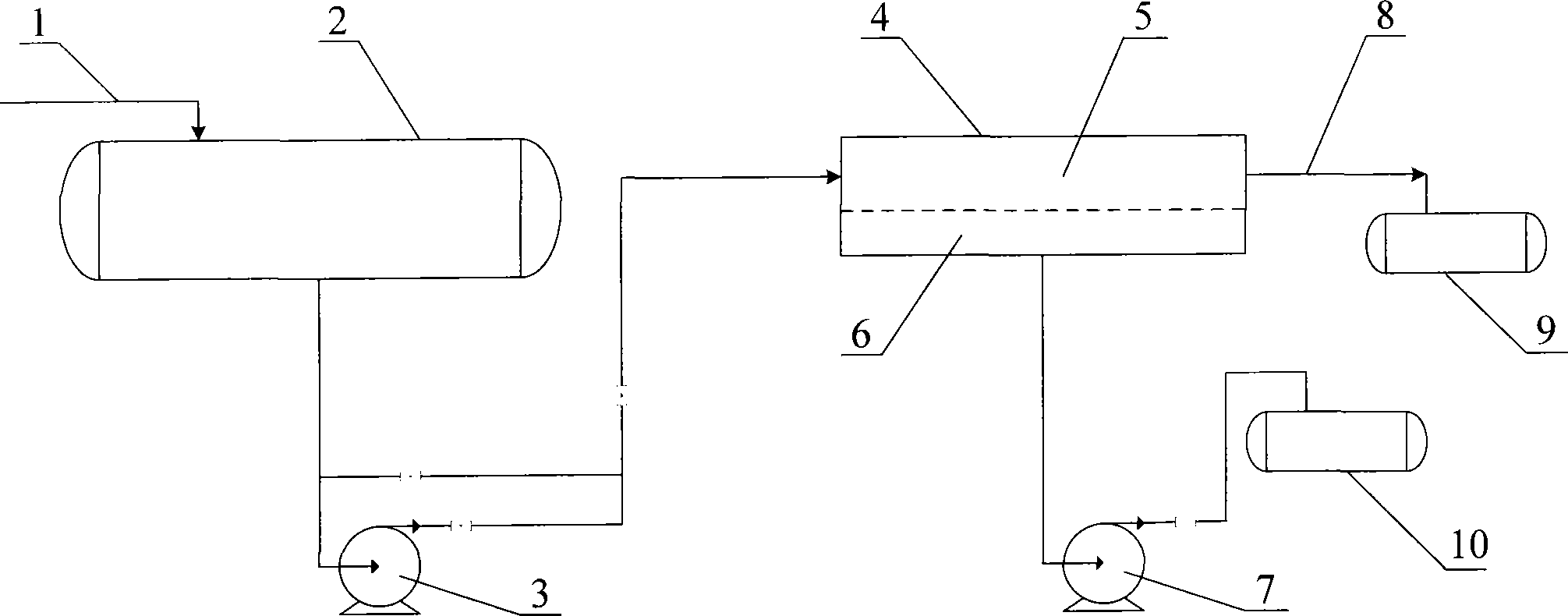

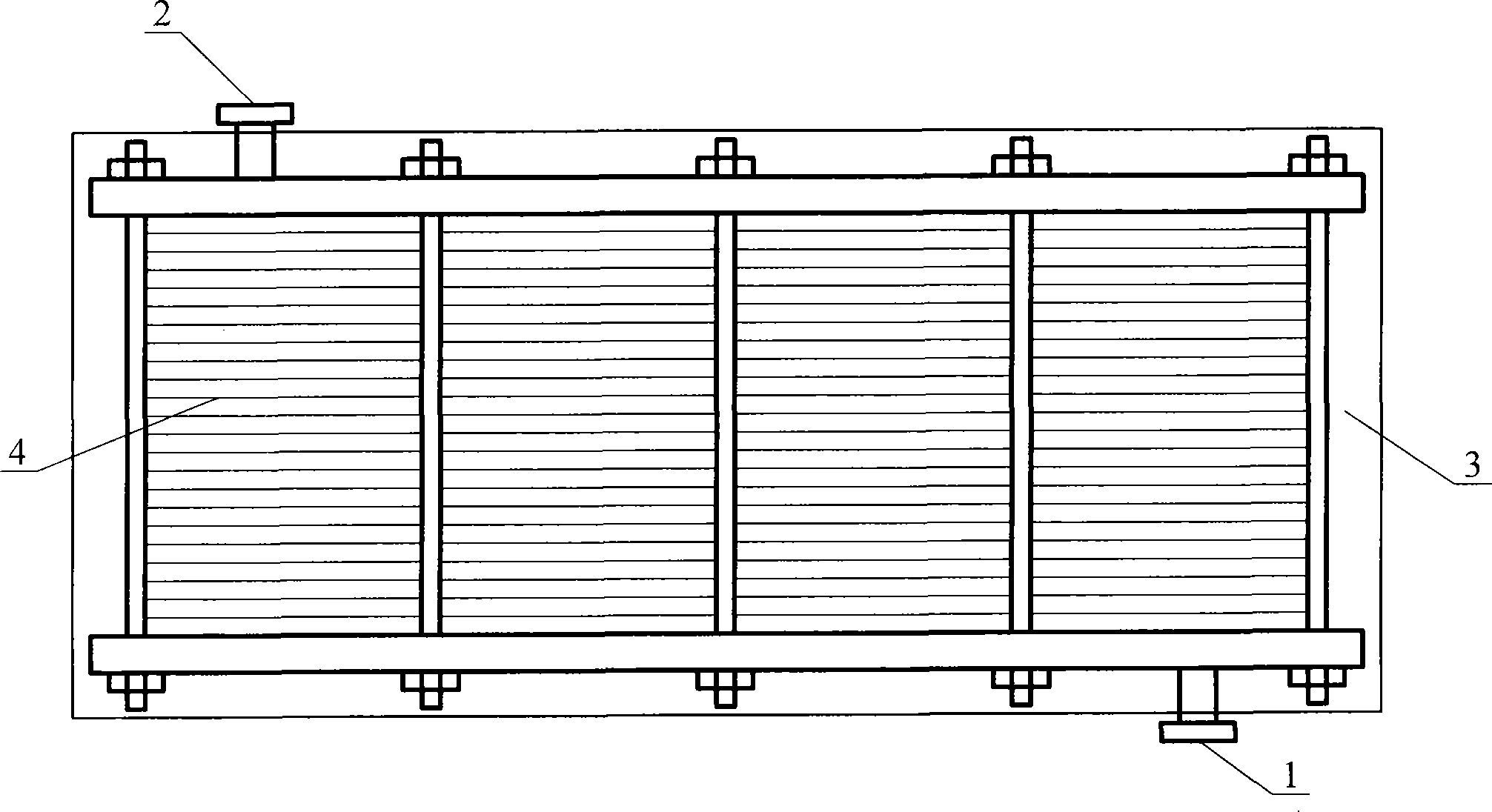

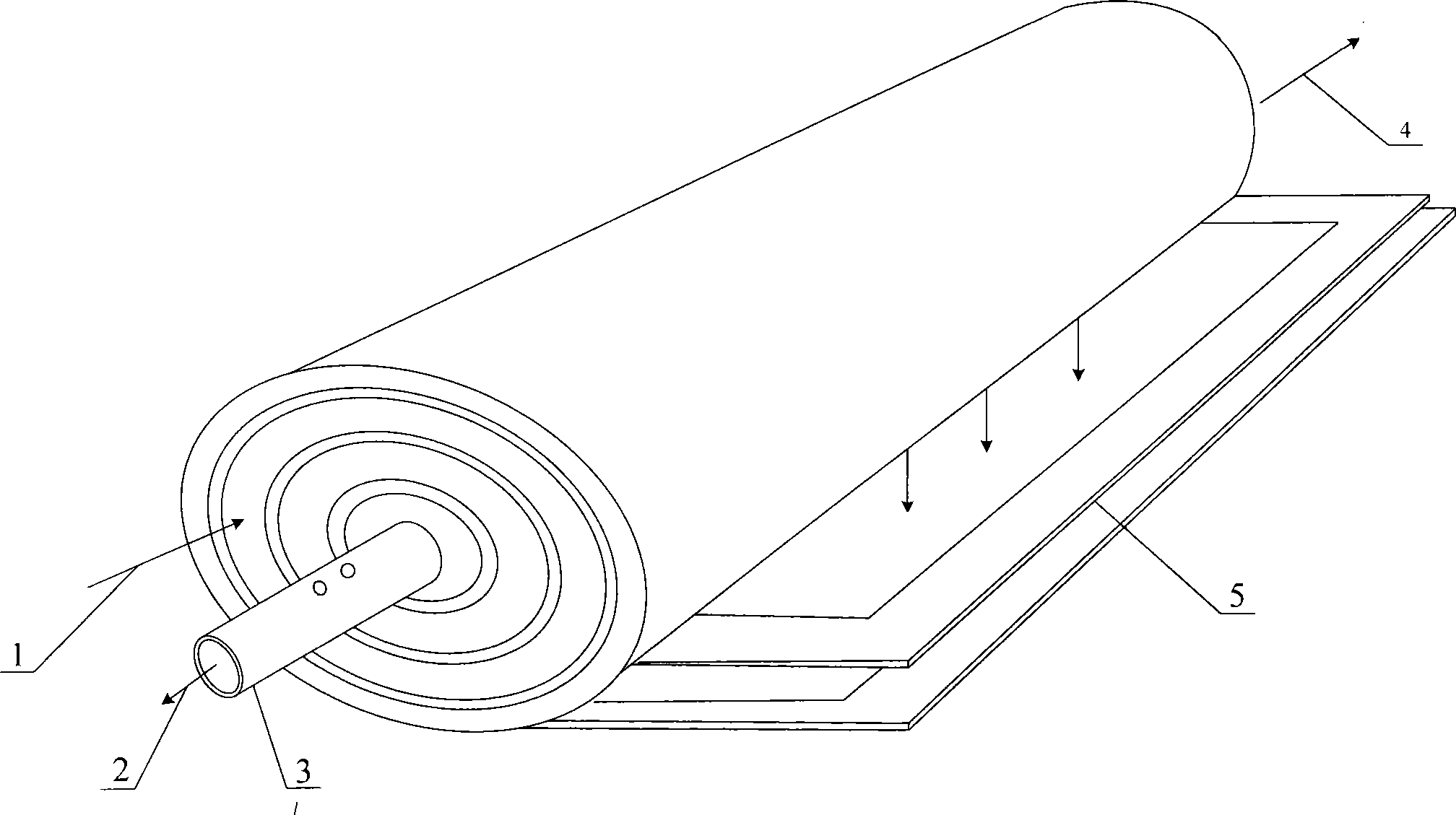

Desulfuration method of environmental-friendly liquefied petroleum gas

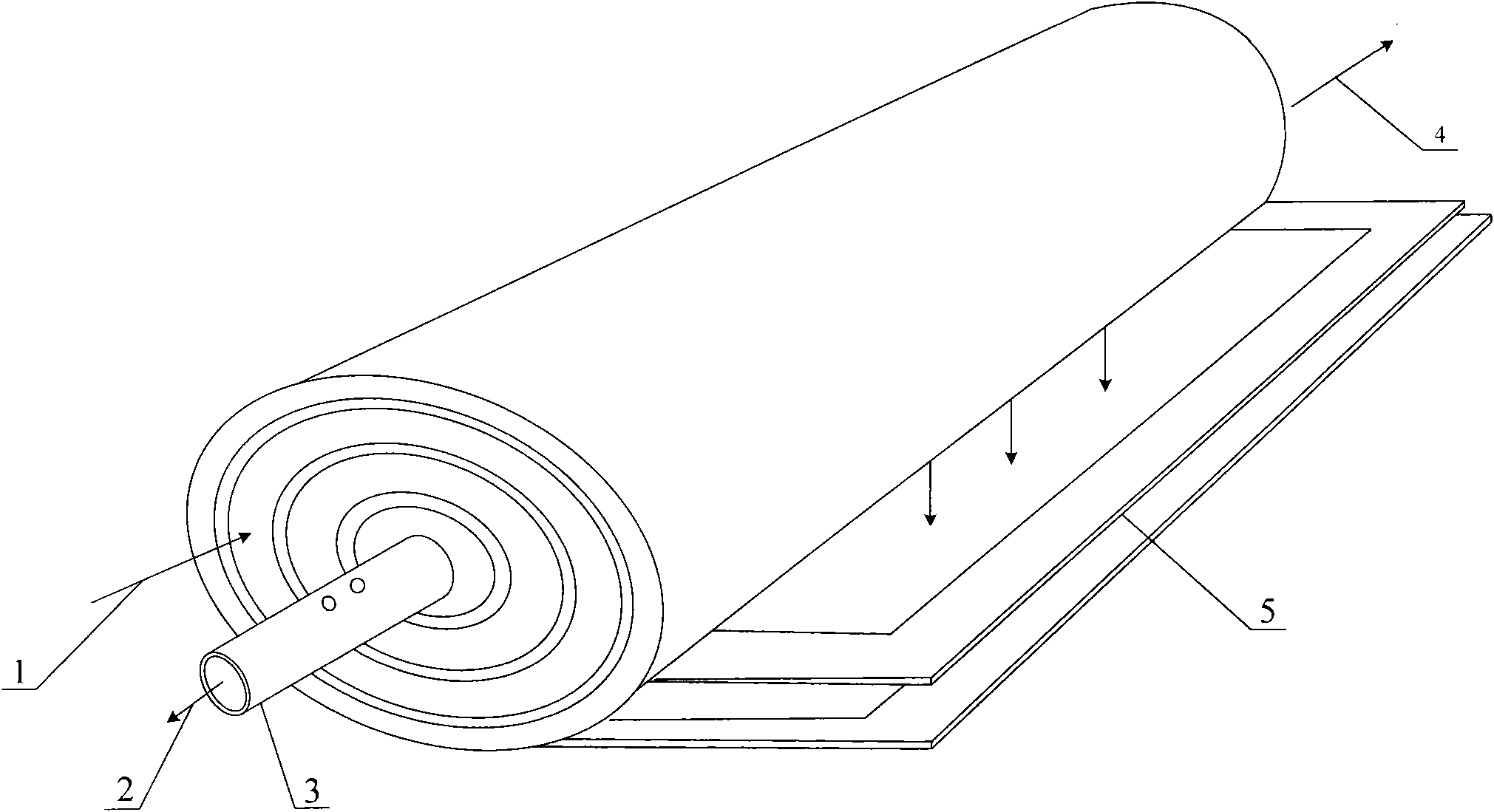

ActiveCN101591580ALarge amount of processingIncrease flow rateGaseous fuelsPolybutadiene acrylonitrileBasal membrane

The invention provides a desulfuration method of environmental-friendly liquefied petroleum gas. In the invention, after alcohol amine elution is carried out on the liquefied petroleum gas to remove the sulfureted hydrogen, the membrane separation technique is adopted for desulfuration in the complete absence of alkali, desulfurating agent or catalyst; The membrane separator adopts a plate-and-frame membrane separator and / or a spiral-wound membrane separator, the membrane material is the composite membrane composed of polyvinylidene fluoride basal membrane and telechelic hydroxyl polybutadiene-acrylonitrile membrane. The invention is characterized by high efficiency, environmental protection, easy operation and low operating cost and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

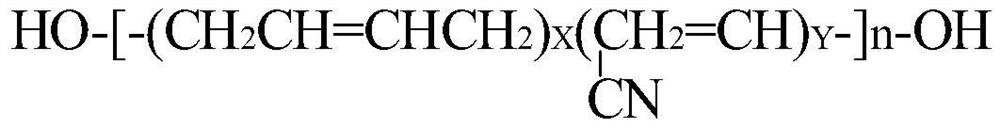

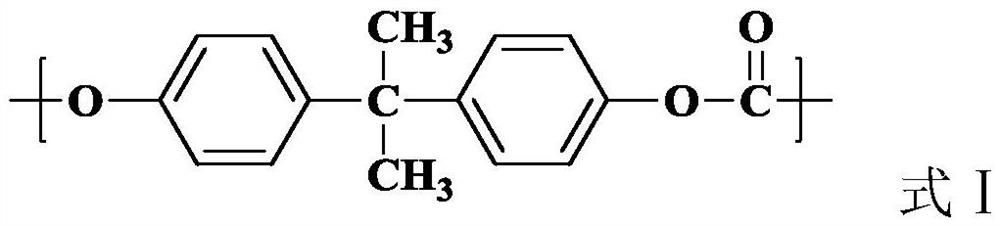

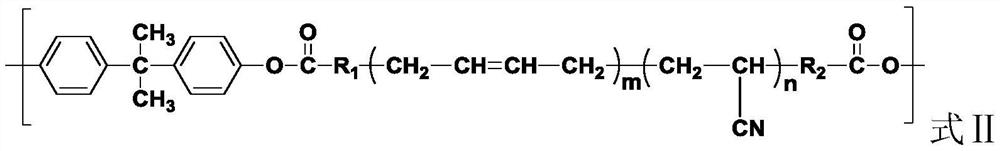

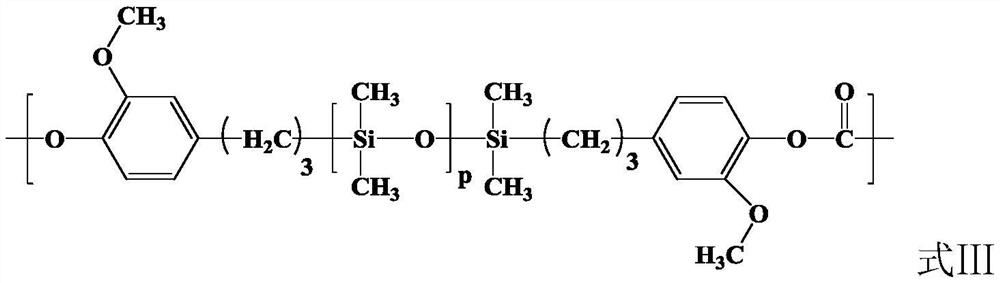

Copolymerized polycarbonate and preparation method thereof

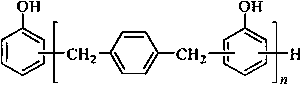

ActiveCN113999381AImprove anti-dripping performanceIncreased nitrile contentEndcappingPolymer science

The invention discloses copolymerized polycarbonate and a preparation method thereof. The copolymerized polycarbonate comprises a polycarbonate chain segment, a polybutadiene acrylonitrile chain segment, a polysiloxane chain segment, a branched group obtained by reacting with a branching agent, and a cyanophenyl end-capping group obtained by reacting with an end-capping agent. The copolymerized polycarbonate is excellent in intrinsic flame retardant and has good chemical resistance and low-temperature impact resistance.

Owner:WANHUA CHEM GRP CO LTD

Lightweight polycarbonate composition and preparation method thereof

The invention discloses a lightweight polycarbonate composition which comprises following raw materials, by weight, 50-90 parts of polycarbonate, 10-50 parts of polybutadiene-acrylonitrile-styrene copolymer resin, 0.2-2 parts of chemical foamer with the decomposition temperature from 200 DEG C to 260 DEG C and 0.1-1.0 part of antioxidant. The invention further provides a preparation method for the lightweight polycarbonate composition. The method includes: weighing the raw materials according to the parts by weight, feeding the raw materials into a twin-screw extruder by a metering device after the raw materials are fully mixed in a medium-speed mixer, fusing for extruding, and cooling in a die for forming. The lightweight polycarbonate composition and the preparation method thereof are fewer in kinds of the raw materials and simple in production process, the polycarbonate and the polybutadiene-acrylonitrile-styrene copolymer resin are added into the chemical foamer, so that the obtained lightweight polycarbonate composition has the advantage of low density while excellent mechanical performances are maintained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

High-elasticity epoxy resin encapsulating material and preparation method thereof

InactiveCN105331049AIncrease elasticityImprove mechanical propertiesCross-linkPolybutadiene acrylonitrile

The invention discloses a high-elasticity epoxy resin encapsulating material. The high-elasticity epoxy resin encapsulating material comprises components in parts by weight as follows: 30-60 parts of epoxy resin, 2-5 parts of polypropylene fiber, 10-15 parts of polymethyl methacrylate, 5-10 parts of carboxyl terminated polybutadiene-acrylonitrile, 1-3 parts of precipitated silica, 5-12 parts of a reactive diluent, 1-5 parts of a cross-linking agent and 3-7 parts of a curing agent. The invention further discloses a preparation method of the high-elasticity epoxy resin encapsulating material. The high-elasticity epoxy resin encapsulating material has good elasticity, good insulation and heat resistance, excellent corrosion resistance and good impact resistance; added compound elastic particles are non-toxic, have a large specific surface area and can effectively improve the mechanical properties of materials; a preparation method is simple, conditions are easy to control, no toxic substances are released in the preparation process, and environmental protection is facilitated.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

Desulfuration method of environmental-friendly liquefied petroleum gas

ActiveCN101591580BLarge amount of processingIncrease flow rateDispersed particle separationGaseous fuelsPolybutadiene acrylonitrileOperating cost

The invention provides a desulfuration method of environmental-friendly liquefied petroleum gas. In the invention, after alcohol amine elution is carried out on the liquefied petroleum gas to remove the sulfureted hydrogen, the membrane separation technique is adopted for desulfuration in the complete absence of alkali, desulfurating agent or catalyst; The membrane separator adopts a plate-and-frame membrane separator and / or a spiral-wound membrane separator, the membrane material is the composite membrane composed of polyvinylidene fluoride basal membrane and telechelic hydroxyl polybutadiene-acrylonitrile membrane. The invention is characterized by high efficiency, environmental protection, easy operation and low operating cost and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Urea terminated butadiene polymers and butadiene acrylonitrile copolymers

Urea-terminated polybutadiene polymers and polybutadiene acrylonitrile copolymers useful as both accelerators and tougheners are disclosed for use in epoxy formulations cured with dicyandiamide. The inventive urea-terminated polymers achieve comparable toughness in cured epoxy formulations when compared to that achieved with traditional polymeric or rubber tougheners with little to no change in glass transition temperature. Viscosity improvement and stability over time are also an advantage. A method of preparation emphasizing aspects of reaction stoichiometry is also disclosed.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Asphalt polyurethane waterproof coating and preparation method thereof

ActiveCN113528001BReduce polarityGood compatibilityPolyurea/polyurethane coatingsBituminous coatingsPolymer sciencePolyolefin

The application discloses an asphalt polyurethane waterproof coating and a preparation method thereof. The main raw materials of the asphalt polyurethane waterproof coating include, in parts by weight: polyether polyol, 15-25 parts; polyolefin polyol, 2-10 parts; Diisocyanate, 2 to 6 parts; asphalt, 5 to 20 parts. This application utilizes hydroxyl-terminated polybutadiene acrylonitrile to partially replace traditional polyether polyol, reacts it with isocyanate, and introduces non-polar butadiene and highly polar acrylonitrile into the synthetic polyurethane prepolymer. This kind of chain segment greatly enhances the compatibility between polyurethane prepolymer and asphalt, and the prepared asphalt polyurethane coating has better compatibility and adhesion with asphalt coil.

Owner:KESHUN WATERPROOF TECH CO LTD

Floor connecting structural adhesive and preparation method thereof

PendingCN113831887AStrong mildew resistanceAvoid destructionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceButadiene Dioxide

The invention relates to a floor connecting structural adhesive, which is prepared from the following raw materials: MDI, N330, polyether glycol and hydroxyl polybutadiene acrylonitrile, and the floor connecting structural adhesive also contains inorganic filler, a thixotropic agent, a coupling agent, a mildew preventive and an accelerant. According to the floor connecting structural adhesive and the preparation method thereof, the mildew preventive is added into the structural adhesive in the process of preparing the structural adhesive, so that the finished structural adhesive is higher in mildew resistance and is not easily influenced by a humid environment, and the structure of the structural adhesive is not damaged by mildew due to the fact that the mildew does not breed; the waterproof performance and the structural strength of the structural adhesive can be kept stable after the structural adhesive is used for a long time. By adding hydroxyl polybutadiene acrylonitrile and MDI in the preparation process, the toughness of the structural adhesive can be improved, so that the structural adhesive is prevented from being damaged by thermal expansion and cold contraction at the ground joint. Through the synergistic effect of the polyether glycol and the thixotropic agent, the structural strength and toughness can be further improved.

Owner:HEMEI (ZHEJIANG) AUTOMOBILE CO LTD

A kind of polyurethane resin and its preparation method and application

The invention provides a polyurethane resin and its preparation method and application. The raw materials for the preparation of the polyurethane resin include polyester polyol, polybutadiene diol (HTPB), polybutadiene acrylonitrile diol (HTBN), expanded The combination of chain agent and aliphatic diisocyanate; by introducing low-polarity HTPB and HTBN into the raw materials for preparation, together with polyester polyol and aliphatic isocyanate, the overall polarity of the final polyurethane resin is greatly reduced, and it is promoted. The compatibility of TPR material makes it have high bonding fastness with TPR material without adding binder in the injection molding process, which has important research significance.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

A kind of high polyaxial impact polycarbonate composition and preparation method thereof

The invention relates to a high multi-axis impact polycarbonate composition and a preparation method of the high multi-axis impact polycarbonate composition. The composition comprises the following components in parts by weight: 50-70 parts of polycarbonate resin PC, 25-50 parts of polybutadiene-acrylonitrile-styrene copolymer resin ABS, 2-10 parts of toughening agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method of the high multi-axis impact polycarbonate composition comprises the following steps of: dividing raw material into parts A and B, wherein the part A comprises the PC, the antioxidant and the lubricant while the part B comprises the ABS and the toughening agent; and respectively premixing the parts A and B in a high-speed mixer, subsequently adding the premixed materials into a double-screw extruder, feeding the part A from a primary feeding opening and feeding the part B from a secondary feeding opening, fusing and extruding at 200-280 DEG C with the rotation speed of the screw extruder at 200-600rpm and the pressure at 2-3MPa, then fusing, extruding and pelleting to obtain the product. Compared with the prior art, through the special toughening agent, PC and processing technologies, the multi-axis impact performance of the polycarbonate composition provided by the invention is improved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com