Vibrating diaphragm of sound production device, and sound production device thereof

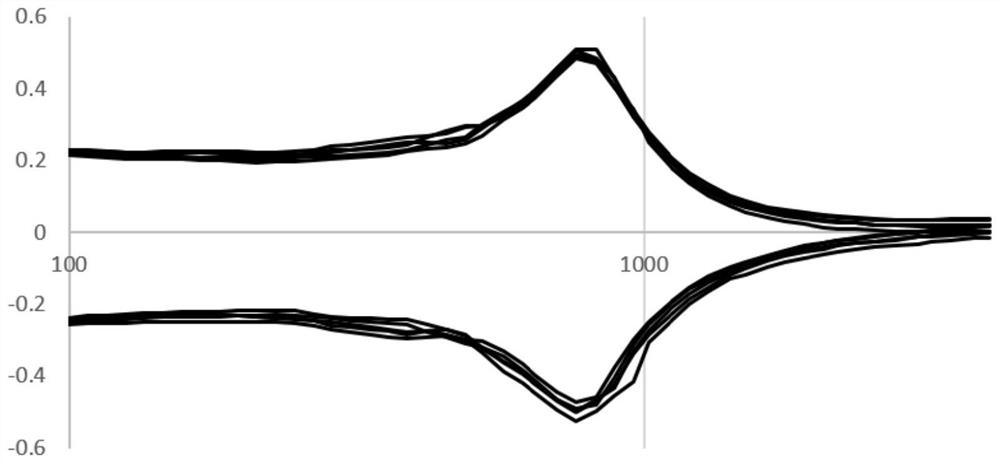

A sound-generating device and film technology, applied in the field of electroacoustics, can solve the problems of low material damping performance, bonding failure, low reliability, etc., and achieve the effects of good vibration consistency, improved damping performance, and reduced polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

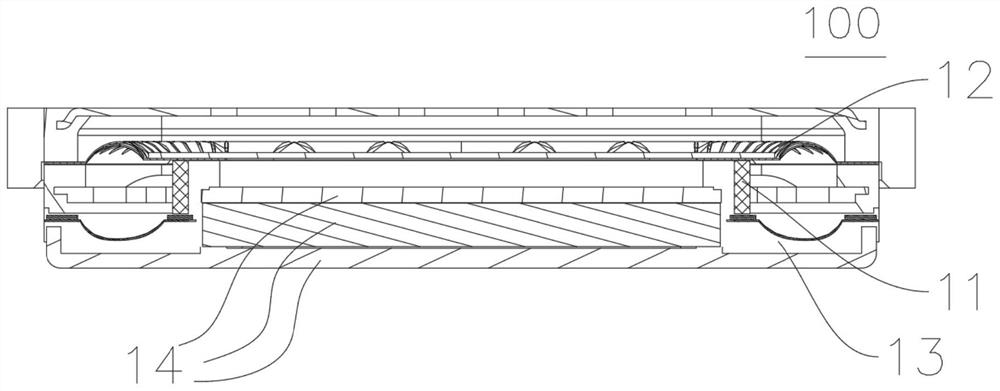

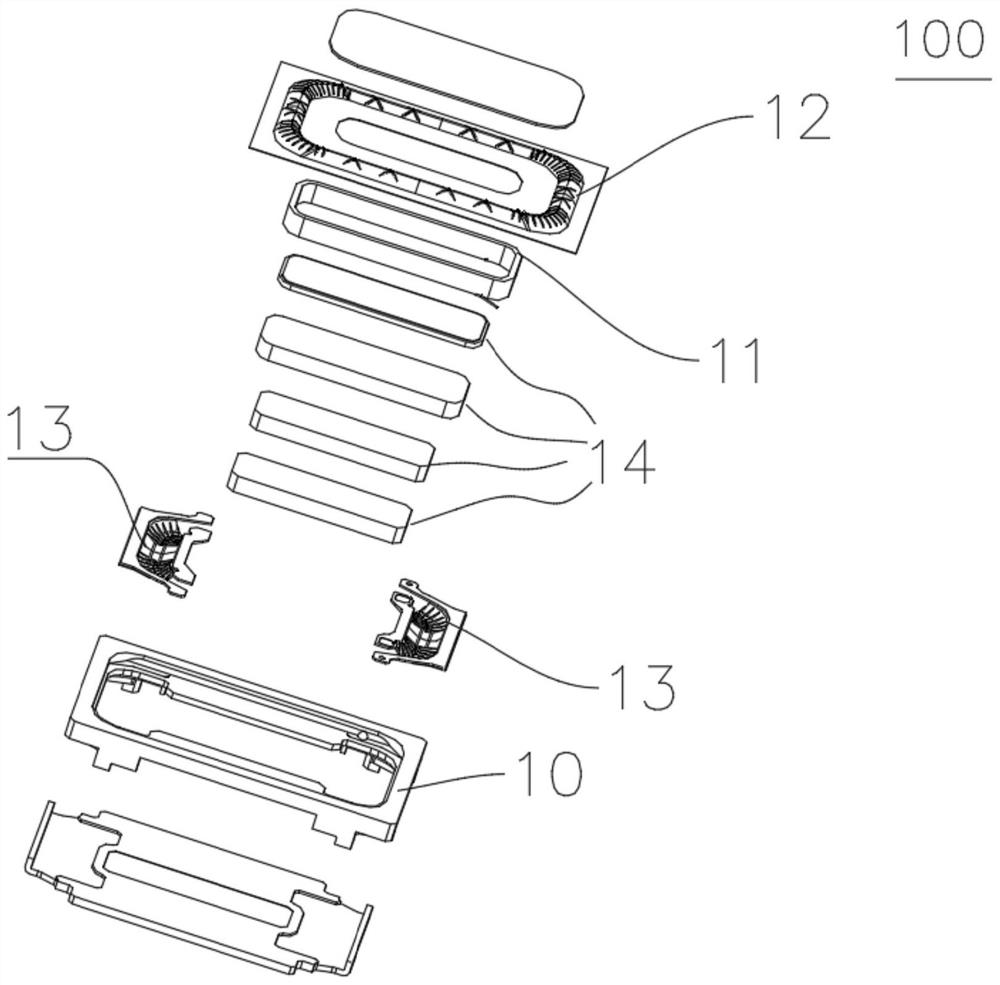

Examples

preparation example Construction

[0065] According to an embodiment of the present invention, there is also provided a method for preparing a diaphragm of a sound generating device, including the following steps: S1, adding a reactant to the base rubber. S2. Carrying out cross-linking molding of the base rubber and a reactant to form a vibrating membrane. Among them, the base rubber is EPDM rubber and / or EPDM rubber, and the reactant is one of polyacrylate, polyethylene-acrylate, polyethylene-vinyl acetate and hydrogenated polybutadiene-acrylonitrile or more.

[0066] Thus, by adding reactants (polyethylene-acrylate and / or polyacrylate and / or polyethylene-vinyl acetate and / or hydrogenated polybutadiene-acrylonitrile) to the base polymer (EPDM and (or binary ethylene propylene rubber), the reactant can form an effective mutual transmission network structure with EPDM rubber and / or binary ethylene propylene rubber molecules, the molecular chain entanglement increases, and the internal friction resistance betwee...

Embodiment 1

[0079] The reactant (polyethylene-acrylate) which accounts for 3% of the total amount of the base rubber and the reactant is cross-linked with 70A EPDM rubber, and after vulcanization, the diaphragm material is formed and assembled into a product.

[0080] Among them, the formula of 70A EPDM rubber is as follows:

[0081] In parts by mass, 100 parts of EPDM; 1 part of sulfur; 3.5 parts of accelerator; 50 parts of carbon black; 20 parts of paraffin oil;

Embodiment 2

[0083] The reactant (polyethylene-acrylate) which accounts for 5% of the total amount of the base rubber and the reactant is cross-linked with 70A EPDM rubber, and after vulcanization, the diaphragm material is formed and assembled into a product.

[0084] Among them, the formula of 70A EPDM rubber is as follows:

[0085] In parts by mass, 100 parts of EPDM; 1 part of sulfur; 3.5 parts of accelerator; 50 parts of carbon black; 20 parts of paraffin oil;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com