Polyurethane resin as well as preparation method and application thereof

A technology of polyurethane resin and polyester polyol, which is applied in the field of polyurethane resin, can solve problems such as the inability to realize TPR sole injection molding, and achieve the effects of promoting compatibility, reducing overall polarity, and easy softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

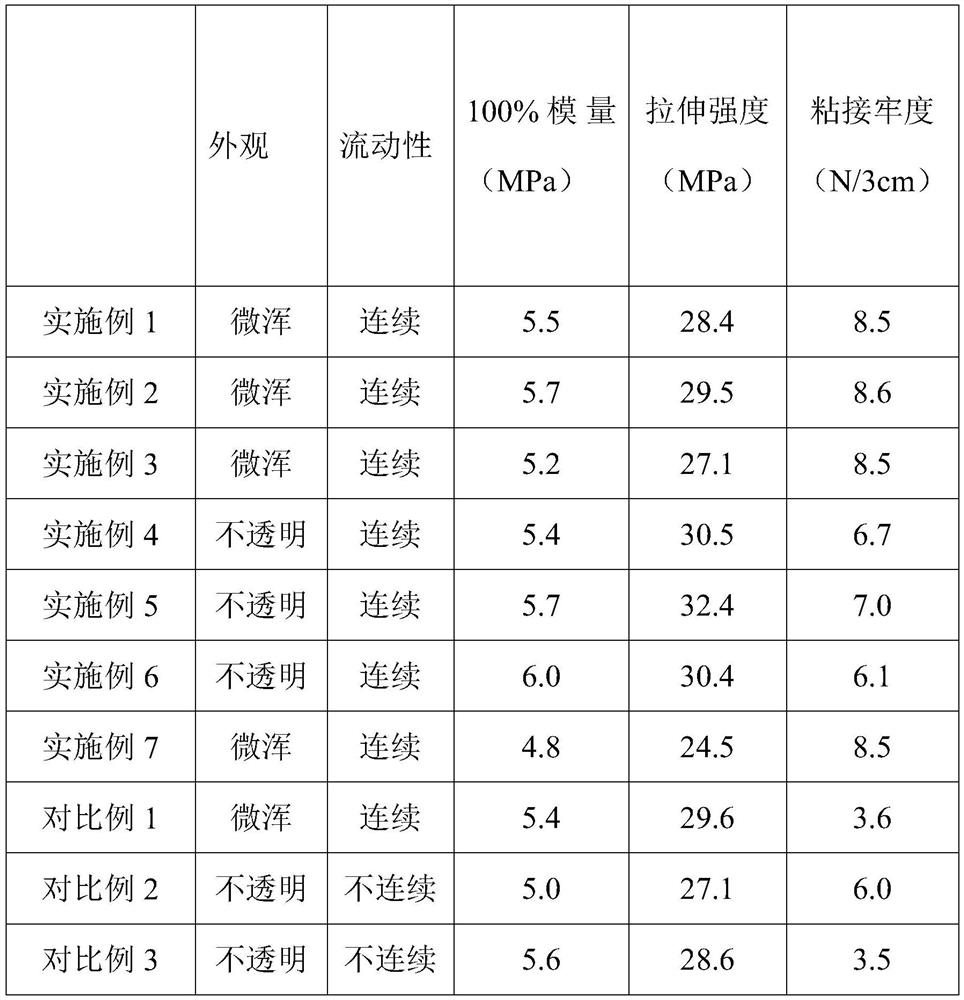

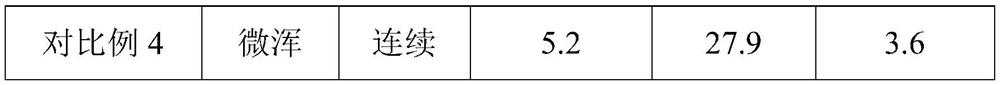

Examples

Embodiment 1

[0057] A kind of polyurethane resin, its preparation method comprises the steps:

[0058] (1) 2-methyl-1,3-propylene adipate diol with a number average molecular weight of 1000, polybutadiene diol with a number average molecular weight of 1000, and polybutadiene diol with a number average molecular weight of 1000 at 55°C Polybutadiene acrylonitrile diol, 1,4-butanediol and phosphite antioxidant (BASF, Antioxidant 168) in N,N-dimethylformamide and toluene at a mass ratio of 2:1 Mix uniformly in the medium to obtain a mixture; wherein, the total molar weight of polyadipate 2-methyl-1,3-propylene glycol ester diol, polybutadiene diol and polybutadiene acrylonitrile diol and 1,4- The molar ratio of butanediol is 1:2, and the molar ratio of poly(2-methyl-1,3-propylene glycol adipate), polybutadiene diol and polybutadiene acrylonitrile diol is 7:3 :1;

[0059] (2) React the mixture obtained in step (1), 4,4'-dicyclohexylmethane diisocyanate and an organic bismuth catalyst (leading...

Embodiment 2

[0062] A kind of polyurethane resin, its preparation method comprises the steps:

[0063] (1) Polyneopentyl adipate diol with a number average molecular weight of 1000, polybutadiene diol with a number average molecular weight of 1000, and polybutadiene acrylonitrile with a number average molecular weight of 1000 at 50°C Diol, 1,4-butanediol and phosphite antioxidant (BASF, Antioxidant 168) were mixed uniformly in N,N-dimethylformamide and toluene with a mass ratio of 2:1 to obtain a mixture ; Wherein, the total molar weight of polyneopentyl adipate diol, polybutadiene diol and polybutadiene acrylonitrile diol and the mol ratio of 1,4-butanediol are 1:2, poly The mol ratio of neopentyl glycol adipate diol, polybutadiene diol and polybutadiene acrylonitrile diol is 5:3:2;

[0064] (2) react the mixture obtained in step (1), isophorone diisocyanate and organic bismuth catalyst (leading in the United States, BICAT8108) at 100°C for 2 hours to obtain a prepolymer;

[0065] (3) a...

Embodiment 3

[0067] A kind of polyurethane resin, its preparation method comprises the steps:

[0068] (1) 3-methyl-1,5-pentanediol adipate with a number average molecular weight of 1000, polybutadiene diol with a number average molecular weight of 1000, and a number average molecular weight of 1000 polybutadiene acrylonitrile diol, 1,4-butanediol and phosphite antioxidant (BASF, antioxidant 168) in N,N-dimethylformamide with a mass ratio of 2:1 Mix homogeneously with toluene to obtain a mixture; wherein, the total molar weight of polyneopentyl adipate diol, polybutadiene diol and polybutadiene acrylonitrile diol and the amount of 1,4-butanediol The molar ratio is 1:2, the molar ratio of polyadipate 3-methyl-1,5-pentanediol, polybutadiene diol and polybutadiene acrylonitrile diol is 4:1:1 ;

[0069] (2) react the mixture obtained in step (1), isophorone diisocyanate and organic bismuth catalyst (leading in the United States, BICAT8108) at 110 ° C for 1 hour to obtain a prepolymer;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com