Preparation method of hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer/carbon nanotube conductive composite film

A polybutadiene and carbon nanotube technology, which is applied in the field of preparation of conductive composite films, can solve the problems of long operation time, difficult formation of conductive films, easy occurrence of chapping, etc., and achieves the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Dissolve 14.6g of carboxyl-terminated polybutadiene-acrylonitrile copolymer with an average molecular weight of 2800 in 6mL of tetrahydrofuran solvent, add 35mL of triethanolamine and 1.8g of sodium bisulfate, and perform esterification reaction at 110°C for 4 hours, and the reaction is completed. The obtained product was washed with distilled water until it was neutral, and dried in vacuum at 110° C. for 7 days to obtain a modified hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer.

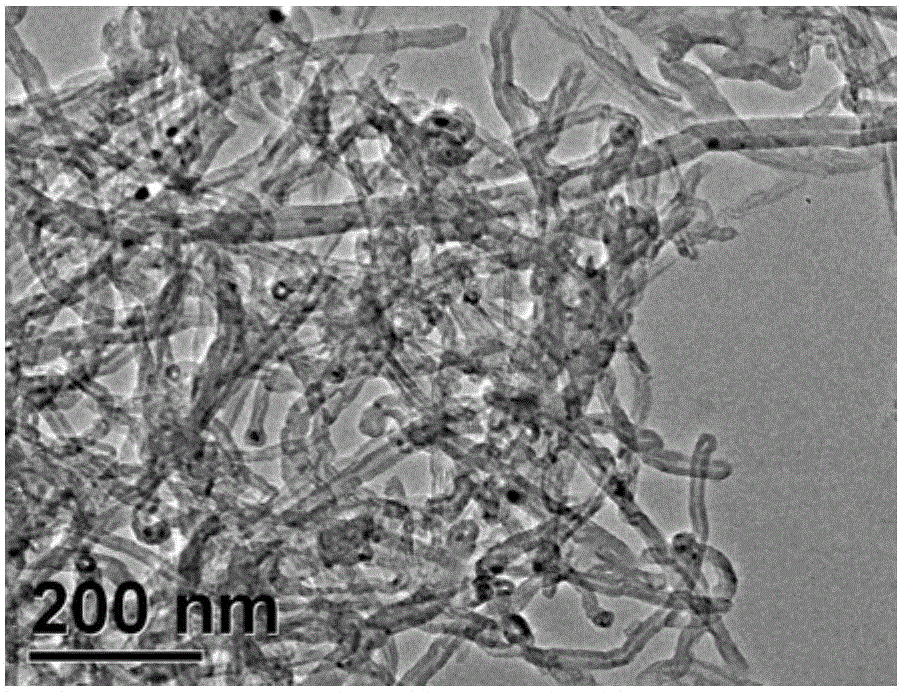

[0026] 2. Put 0.100 g of hydroxyl multi-walled carbon nanotubes (purchased from Chengdu Institute of Organic Chemistry, Chinese Academy of Sciences) in a 50 mL three-neck flask, add 5 mL of toluene, and ultrasonically disperse them with an ultrasonic cleaner for 2 hours to obtain a uniform carbon nanotube dispersion. The used hydroxyl multi-walled carbon nanotubes have an outer diameter of 30-50 nm, a length of 10-20 μm, and a hydroxyl content of 1.06%.

...

Embodiment 2

[0034] In step 3 of Example 1, 0.300 g of hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and 5 mL of toluene were added to a 50 mL three-necked flask, stirred evenly, and 8.0 μg of di-n-butyltin dilaurate, 31.4 μg of hexamethylene diisocyanate was heated up to 80°C and reacted at constant temperature for 2 hours to form a brown-yellow transparent solution. Other steps were the same as in Example 1 to obtain a hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conductive composite film.

Embodiment 3

[0036] In step 3 of Example 1, 0.186 g of hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and 5 mL of toluene were added to a 50 mL three-necked flask, stirred evenly, and 5.7 μg of di-n-butyltin dilaurate, 41.9 μg of hexamethylene diisocyanate was heated up to 80°C and reacted at constant temperature for 2 hours to form a brown-yellow transparent solution. Transfer the brown-yellow transparent solution in step 3 to the carbon nanotube dispersion obtained in step 2, react at 80°C for 2 hours, add 8 μL of 1,4-butanediol dropwise, and continue to react at 80°C for 2 hours to obtain a uniformly dispersed black suspension. Cloudy liquid. The other steps were the same as in Example 1 to obtain a hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conductive composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com