Urea terminated butadiene polymers and butadiene acrylonitrile copolymers

A polybutadiene acrylonitrile and polymer technology, applied in the field of butadiene acrylonitrile copolymers, can solve the problems of accelerated curing reaction, lower glass transition temperature, no generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

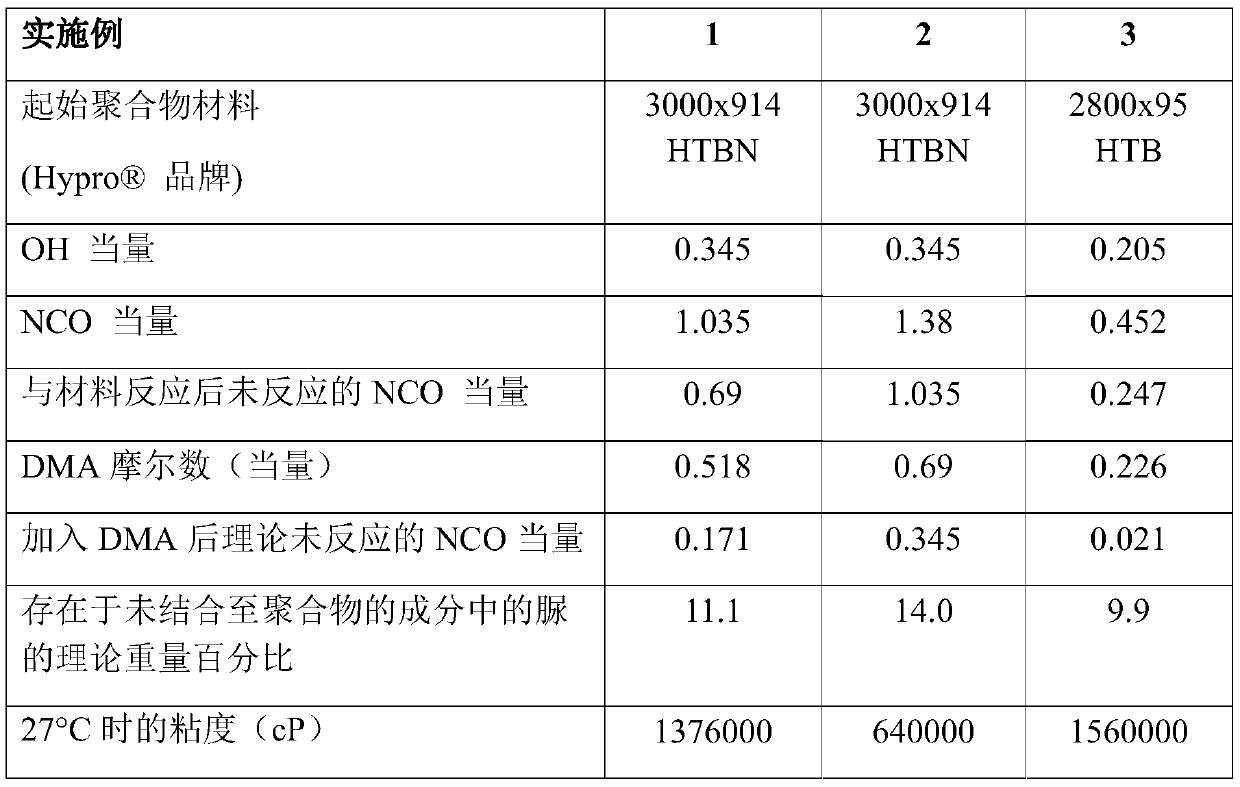

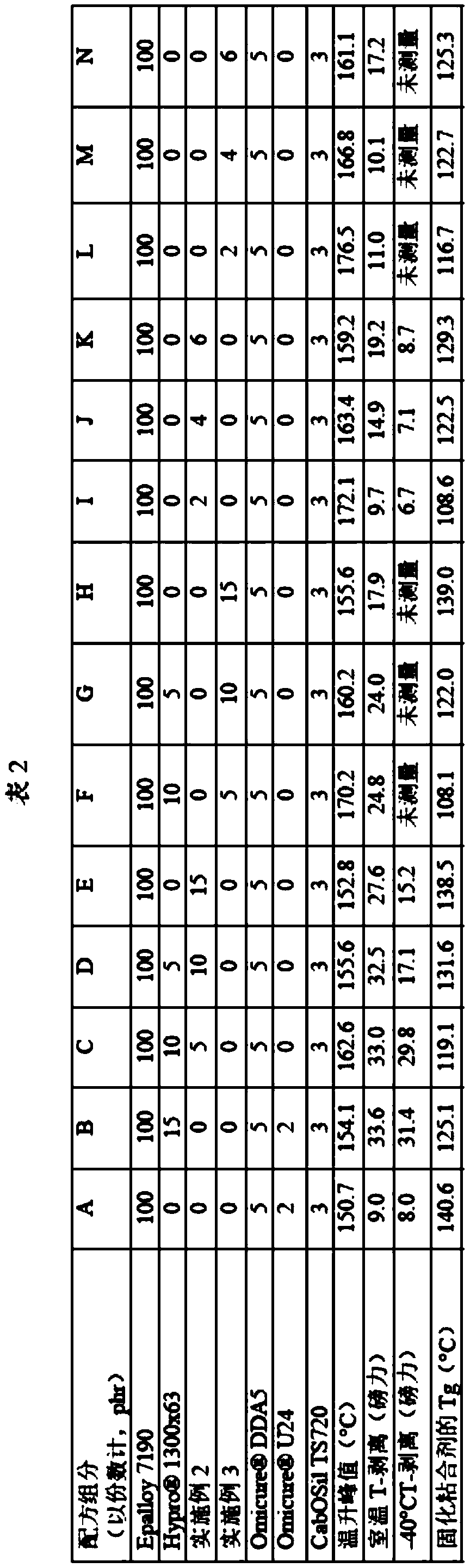

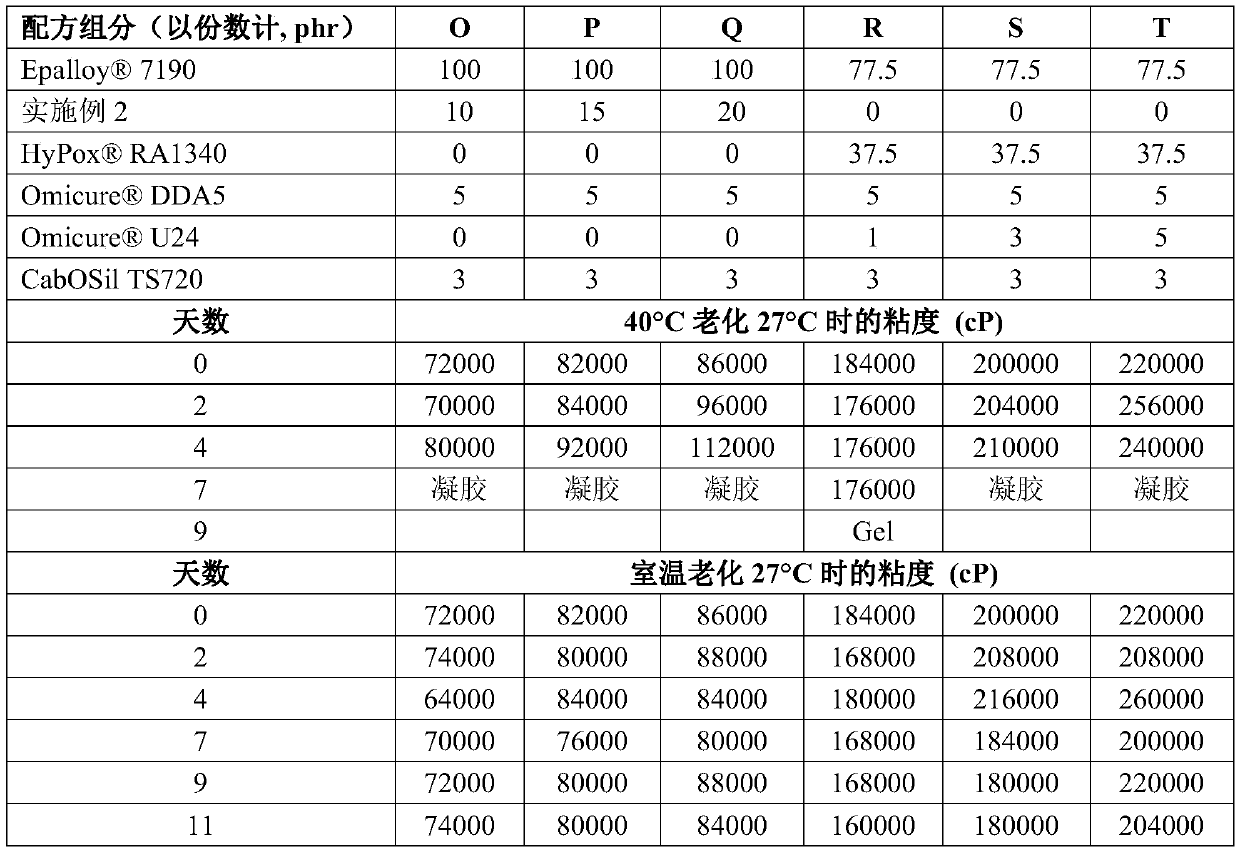

[0047] Example 1 shows the use of 3000x914HTBN (Example 1 and Example 2) or 2800x95HTB (Example 3) Starting Material Synthesis of urea-terminated polymers of the invention using the general method described in this application. Table 1 reflects the variation of the reaction stoichiometry and the amount of starting material. The urea-terminated polymers of the present invention were prepared using various amounts (expressed as equivalents (moles of reactive groups)) of polymeric material, diisocyanate (NCO) and dimethylamine described below.

[0048] 500 g of the indicated polymeric material was weighed into a 3 necked round bottom flask equipped with mechanical stirring and vacuum distillation. The flask was heated to 100°C in an oil bath with stirring under vacuum and allowed to degas for a period of 1 hour before reducing the temperature to 45°C. After the oil bath reached 45°C, 300 g of xylene was added, and the reaction mixture was stirred for 20 minutes until homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com