Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Poly(propylene fumarate)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

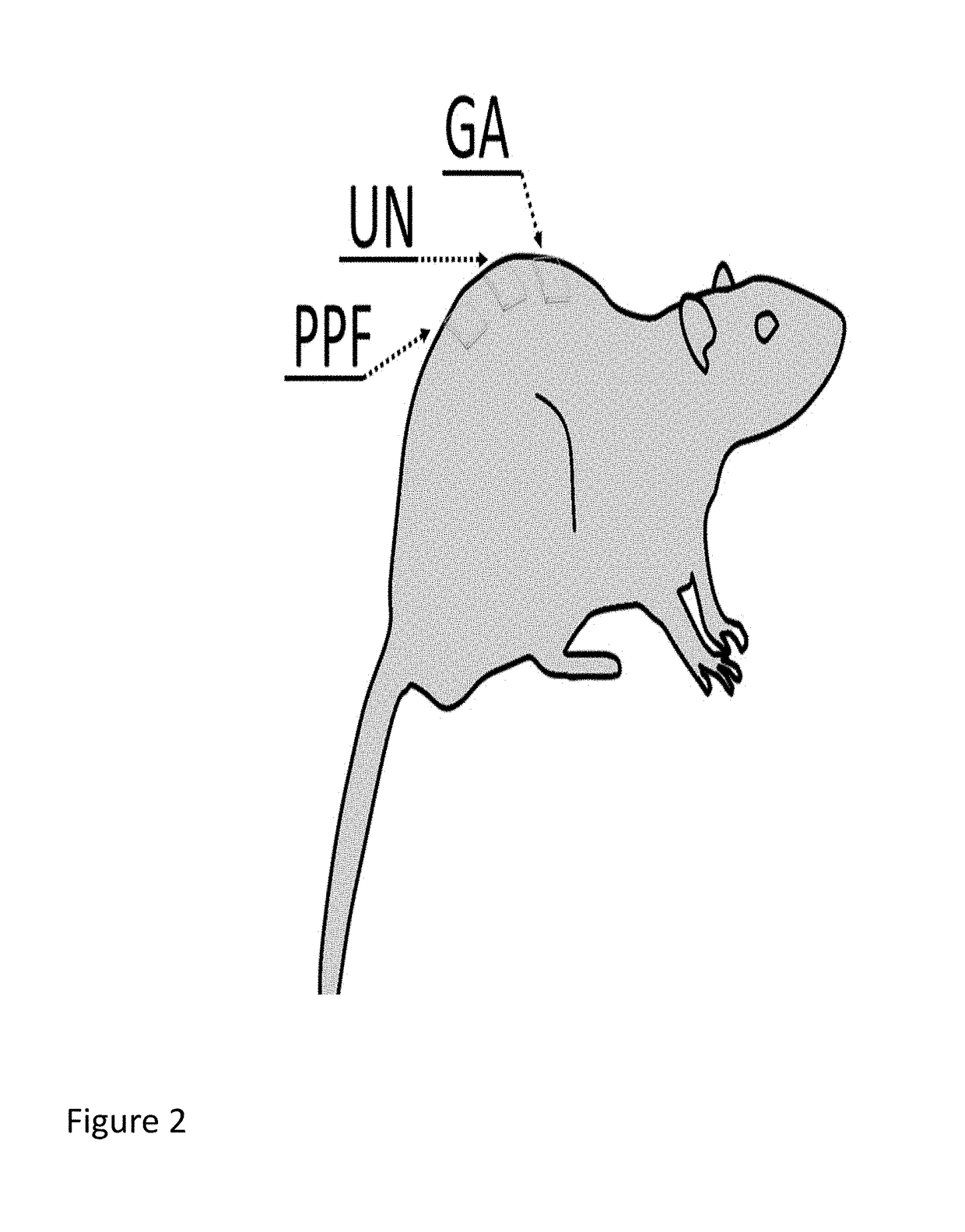

Poly(propylene fumarate) and its applications. Poly(propylene fumarate) (PPF) is a linear polyester based upon fumaric acid, a component of the Krebs cycle.

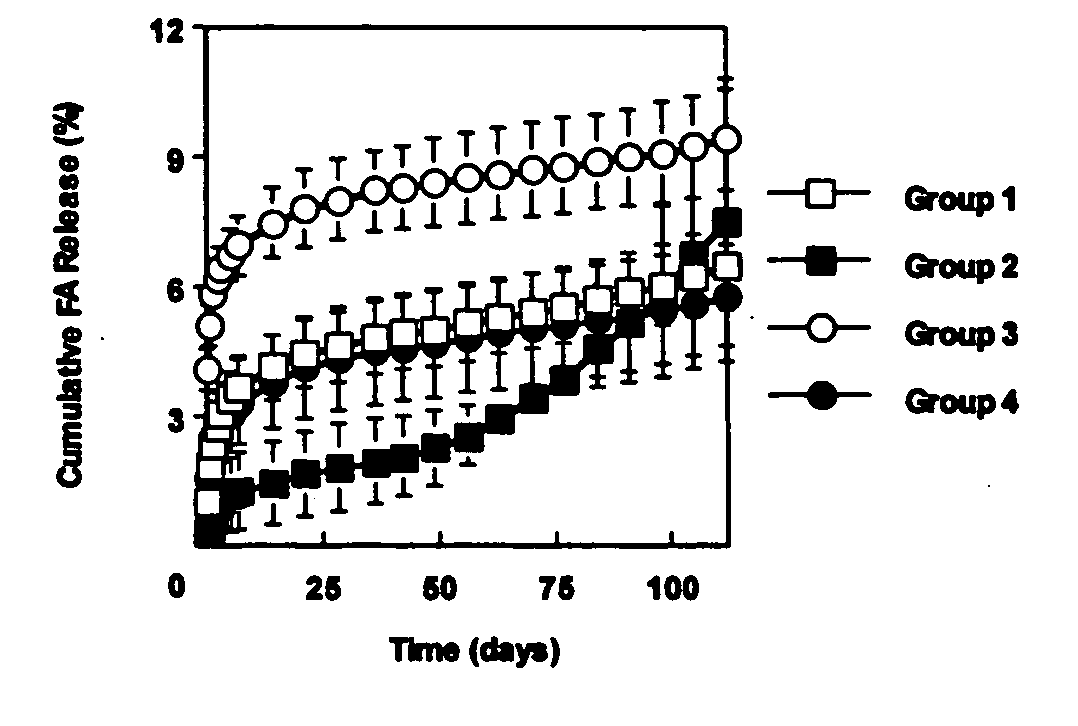

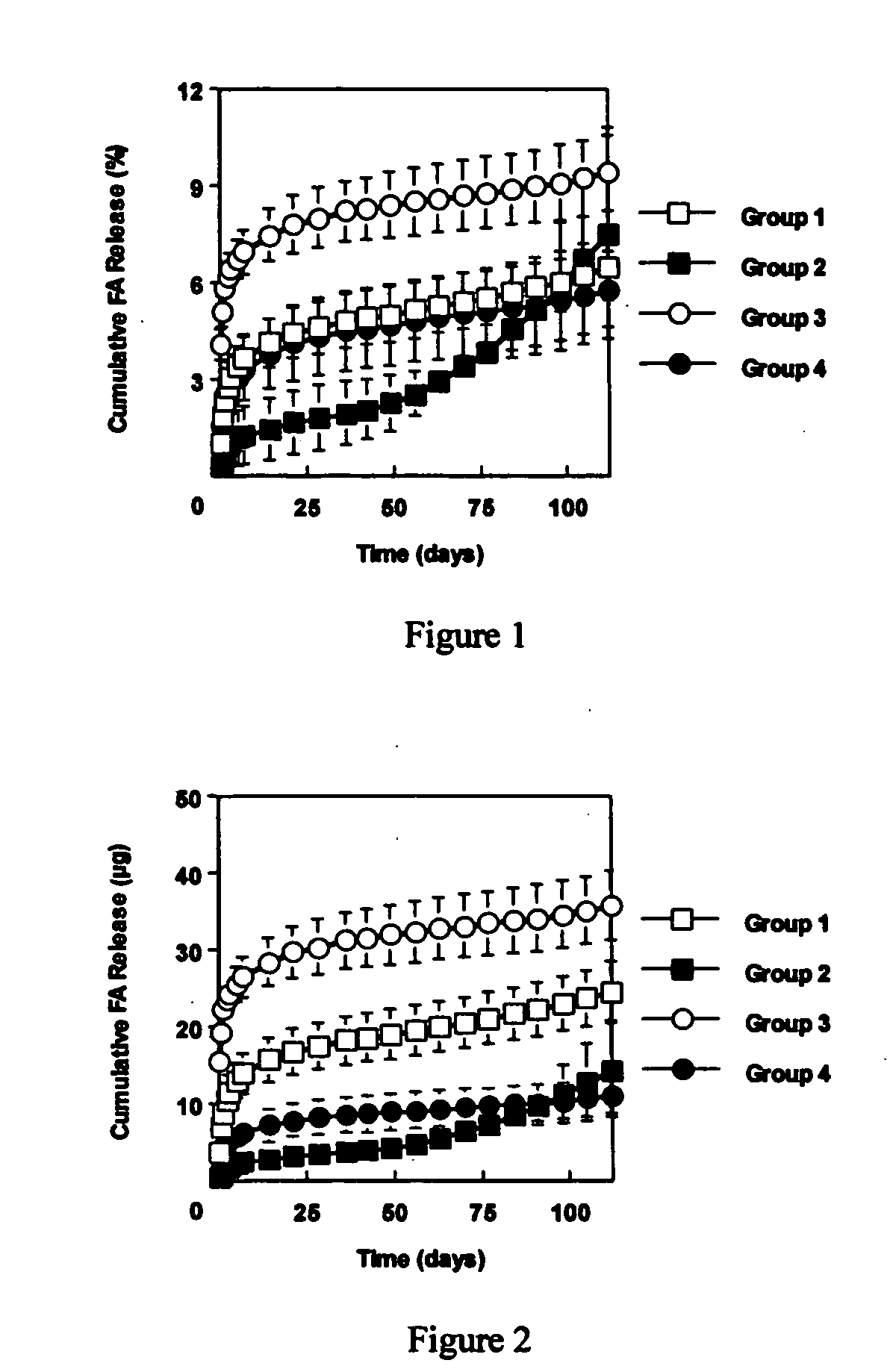

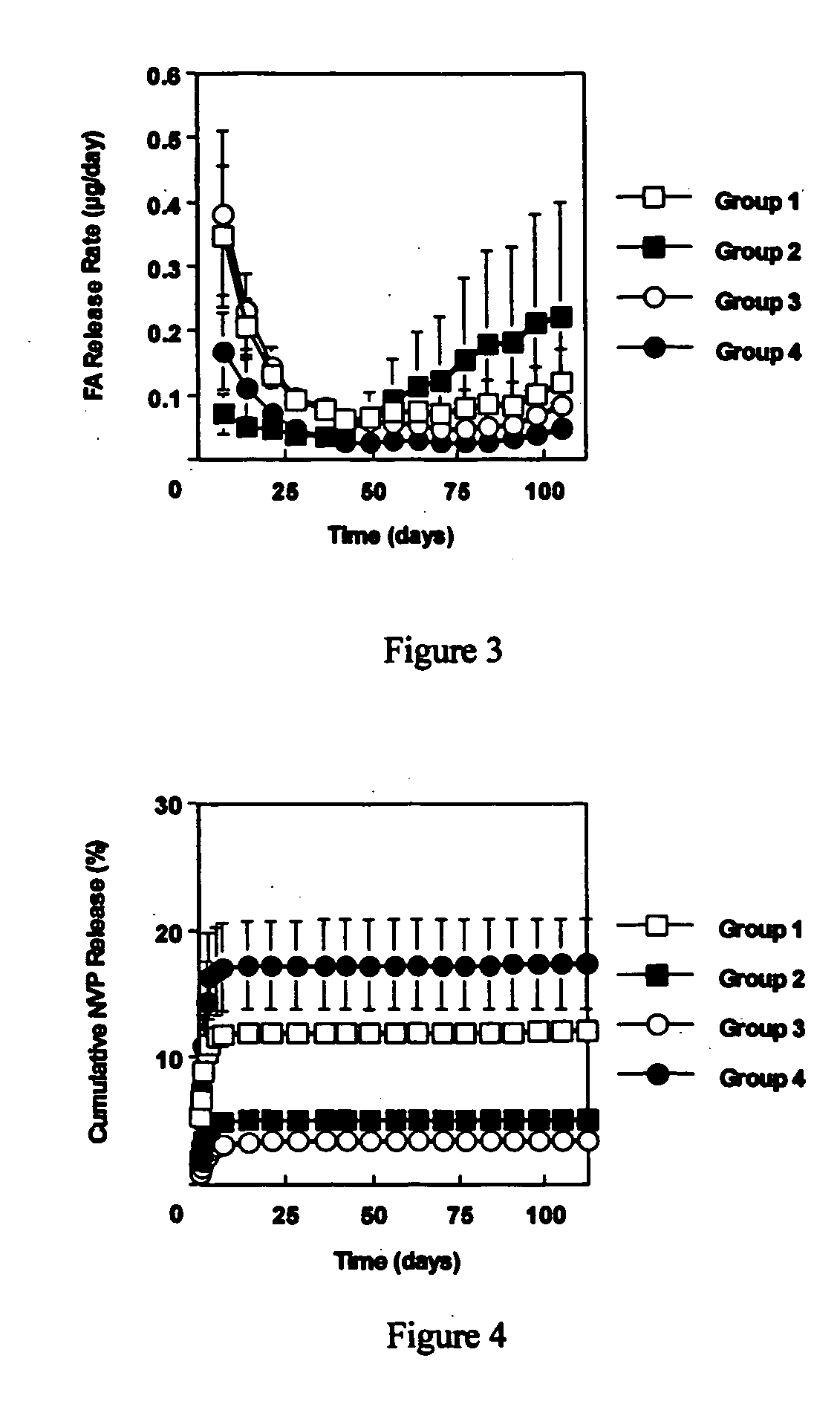

Injectable biodegradable drug delivery system

Compositions for delivering a pharmaceutically active agent to the eye, and / or for treating an ophthalmic disorder, are based on a fumarate polymer, especially a poly(propylene fumarate) polymer.

Owner:BAUSCH & LOMB INC +1

Hydrogel Porogents for Fabricating Biodegradable Scaffolds

InactiveUS20080206308A1Rheologic propertyElimination of porogen leaching stepPowder deliveryBiocideBiodegradable scaffoldBiodegradable hydrogels

Hydrogel microparticles with entrapped liquid are used as the porogen to reproducibly form interconnected pore networks in a porous scaffold. In one embodiment, a biodegradable unsaturated polymer, a crosslinking agent, and a porogen comprising biodegradable hydrogel microparticles are mixed together and allowed to form a porous scaffold in an mold or in a body cavity. Example biodegradable unsaturated polymers include poly(propylene fumarate) and poly(e-caprolactone-fumarate). The cosslinking agent may be a free radical initiator, or may include a free radical initiator and a monomer capable of addition polymerization. Example hydrogel microparticles include uncrosslinked or crosslinked collagen , an uncrosslinked or crosslinked collagen derivative, and an uncrosslinked or crosslinked synthetic biodegradable polymer such as oligo(poly(ethylene glycol) fumarate).

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

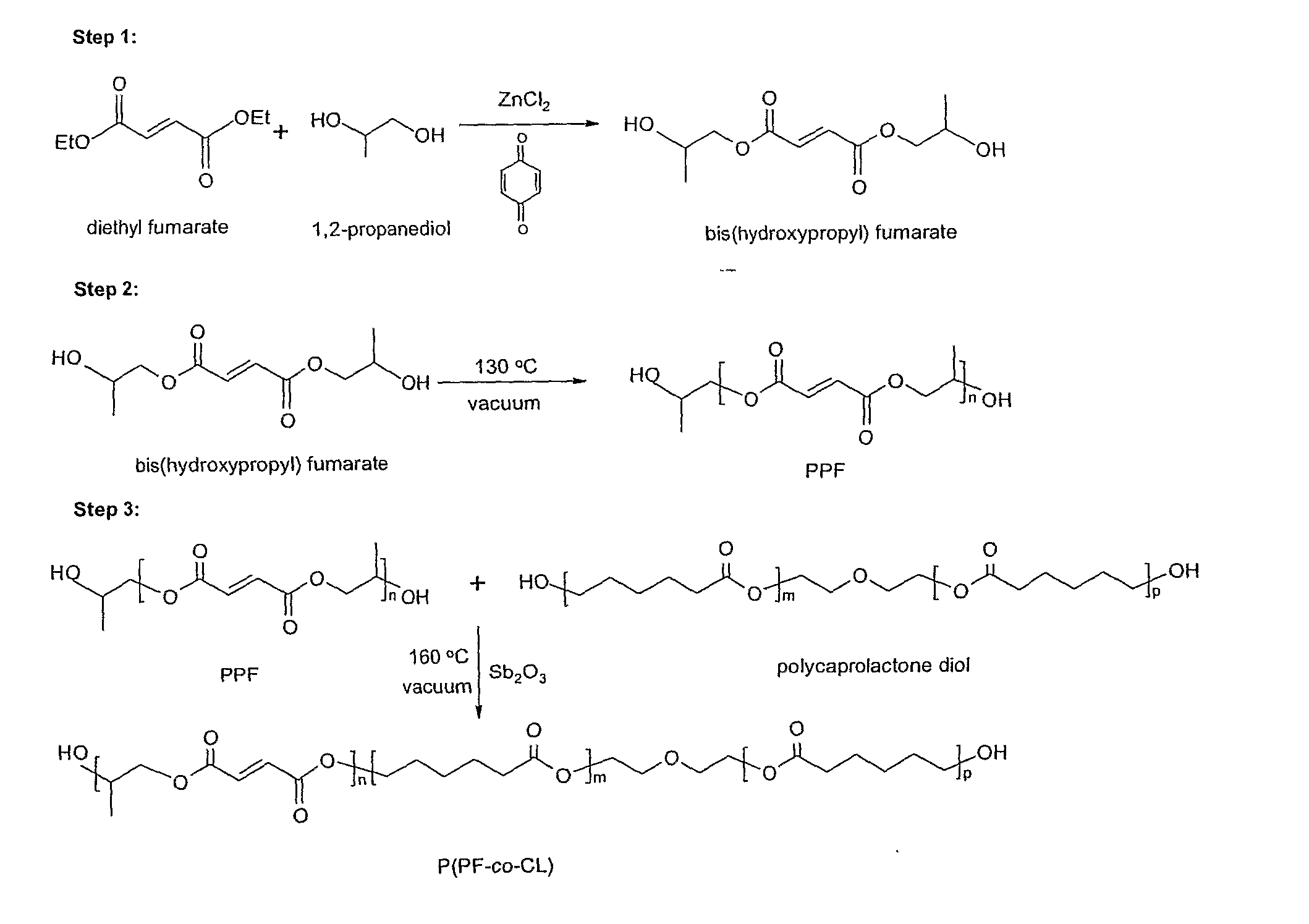

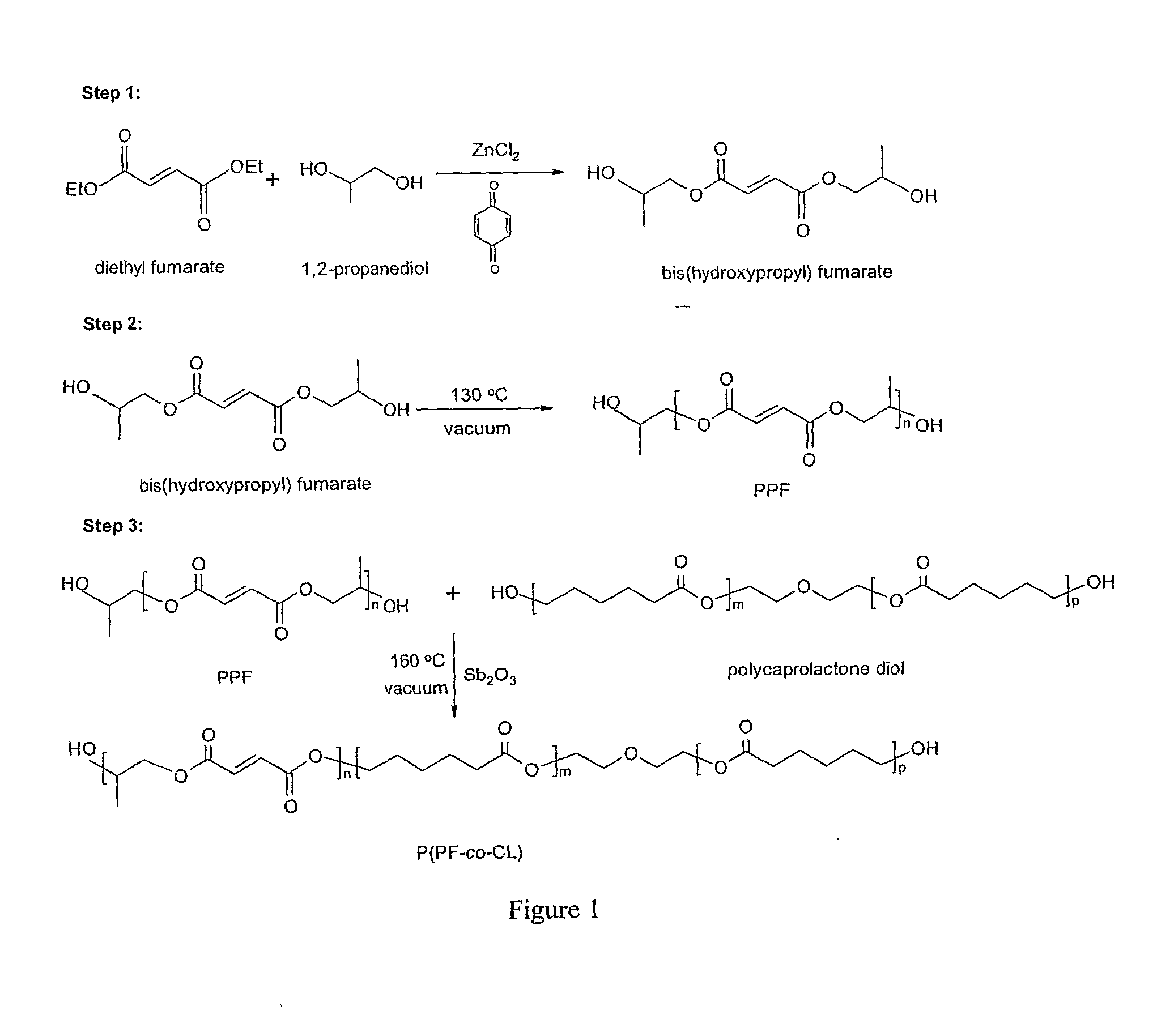

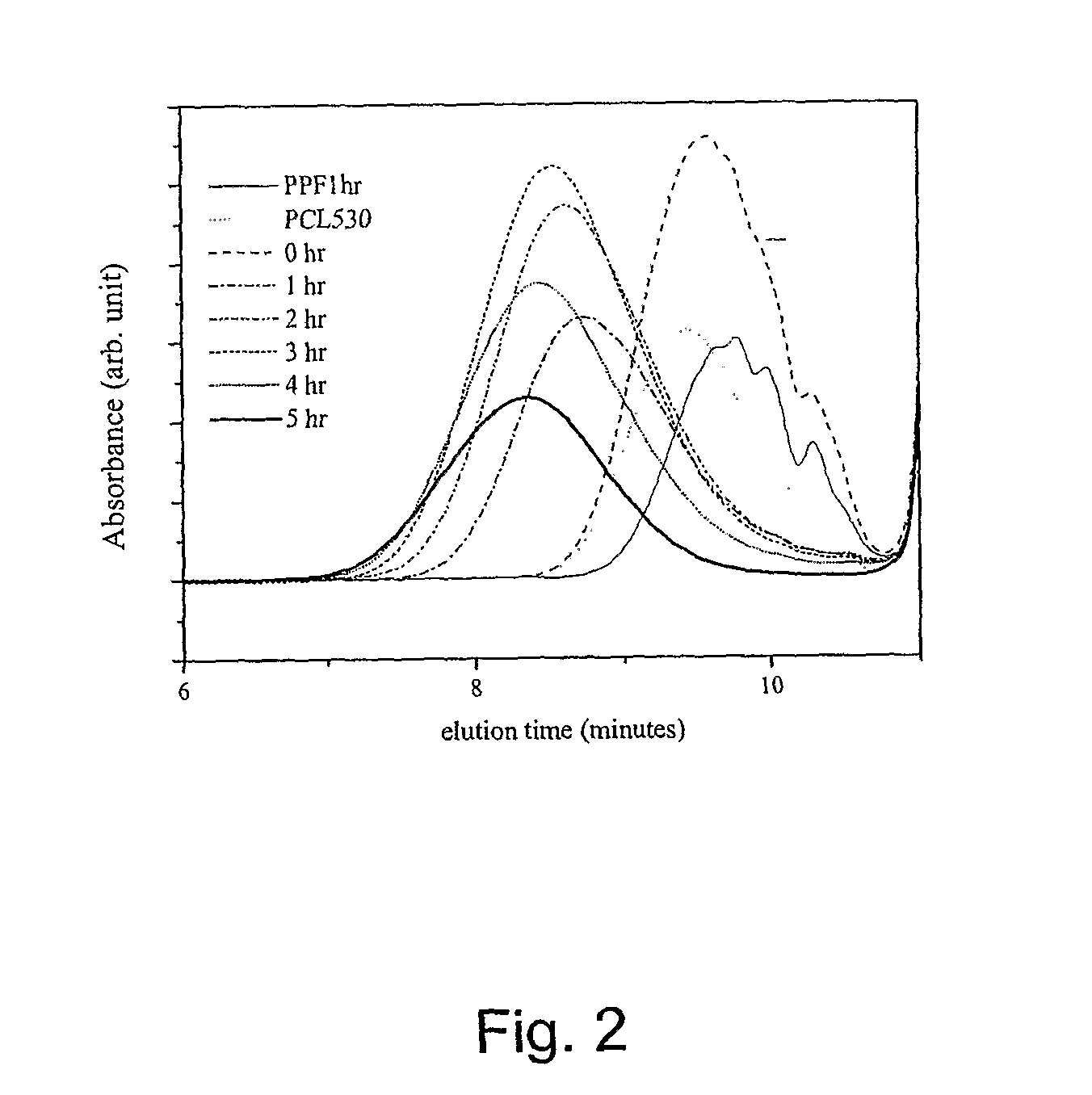

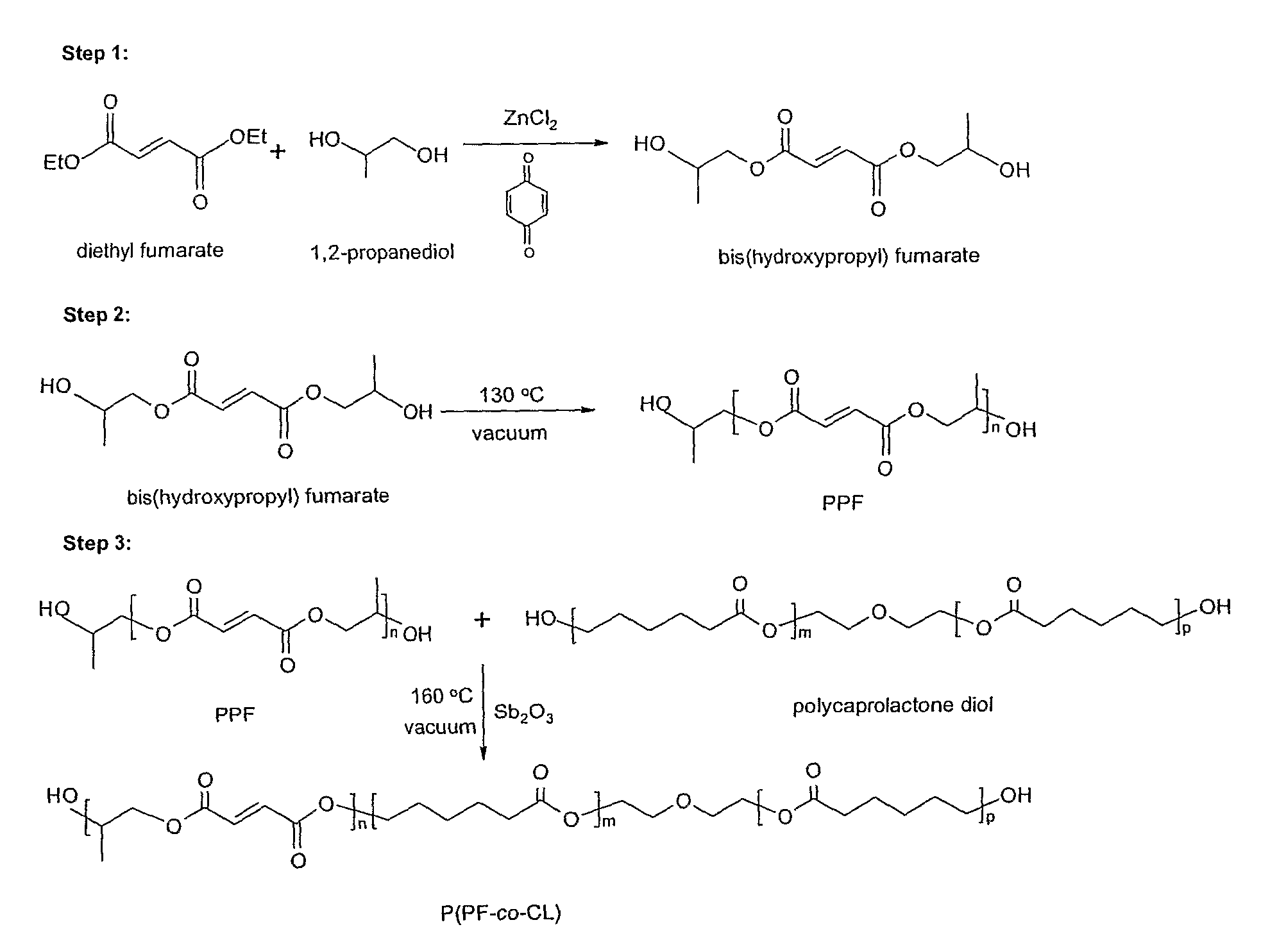

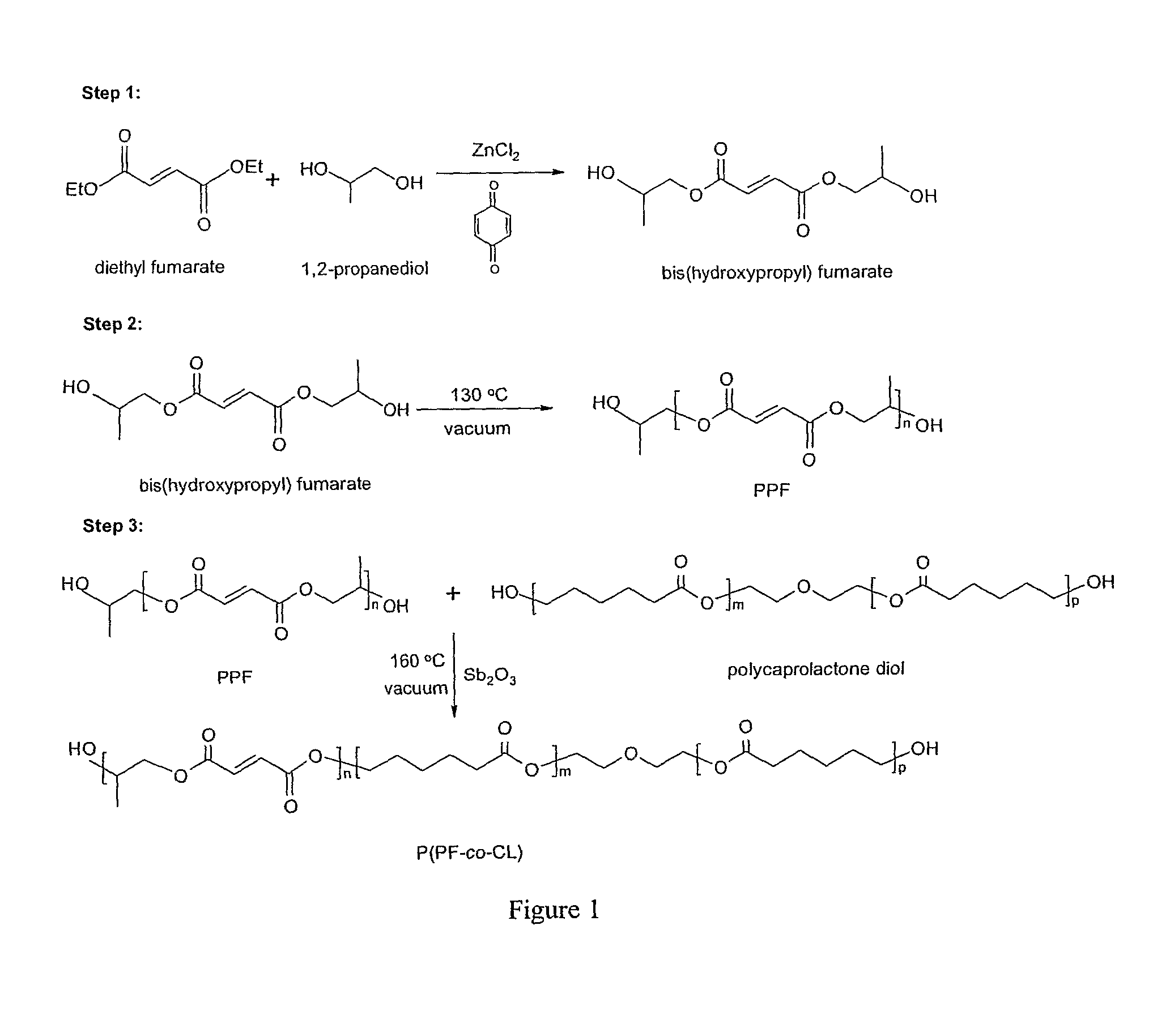

Block Copolymers of Polycarpolactone and Poly (Propylene Funarate)

InactiveUS20080004368A1High molecular weightMechanical crosslinkabilityPowder deliveryImpression capsPolymer scienceCross linker

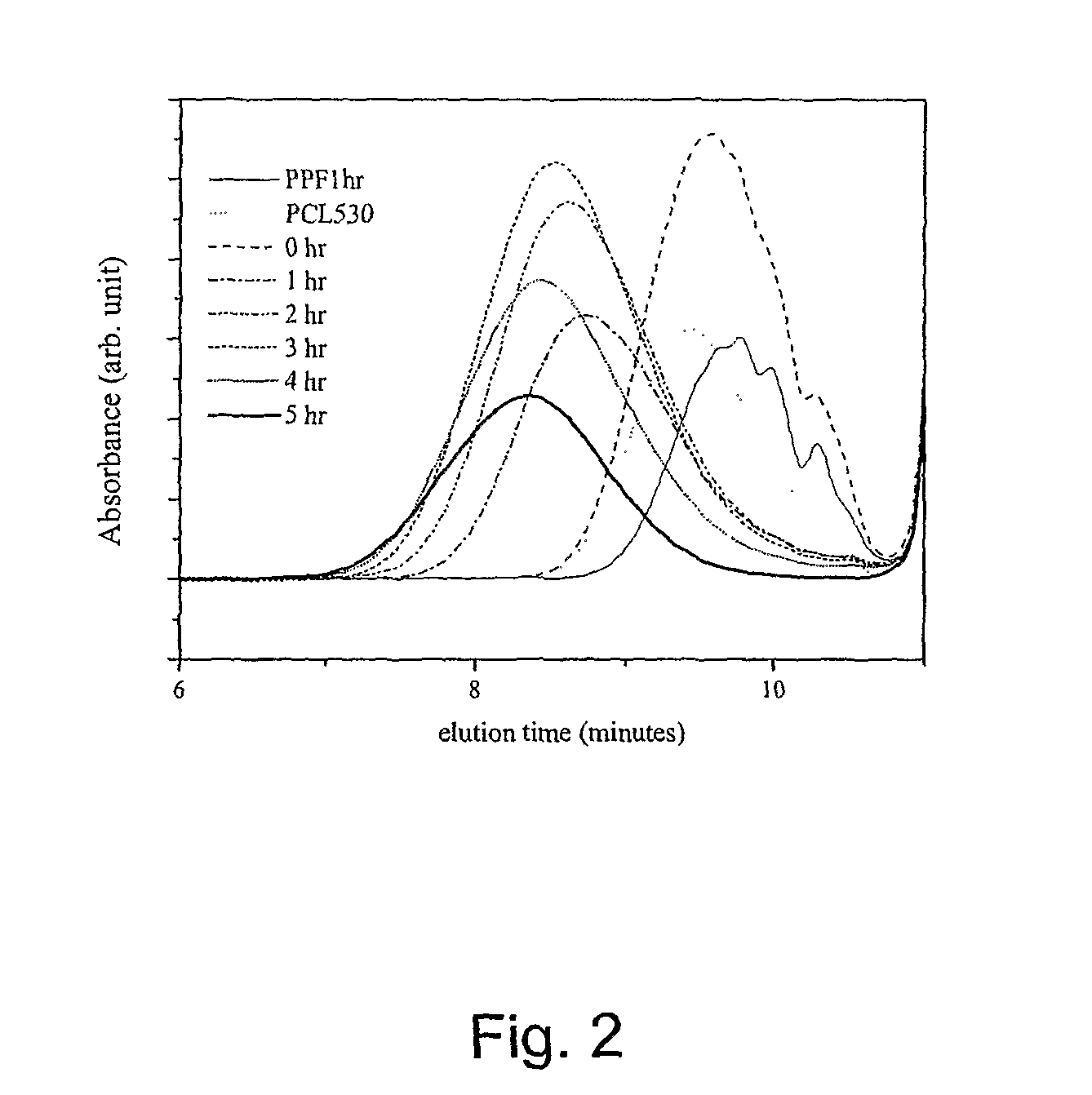

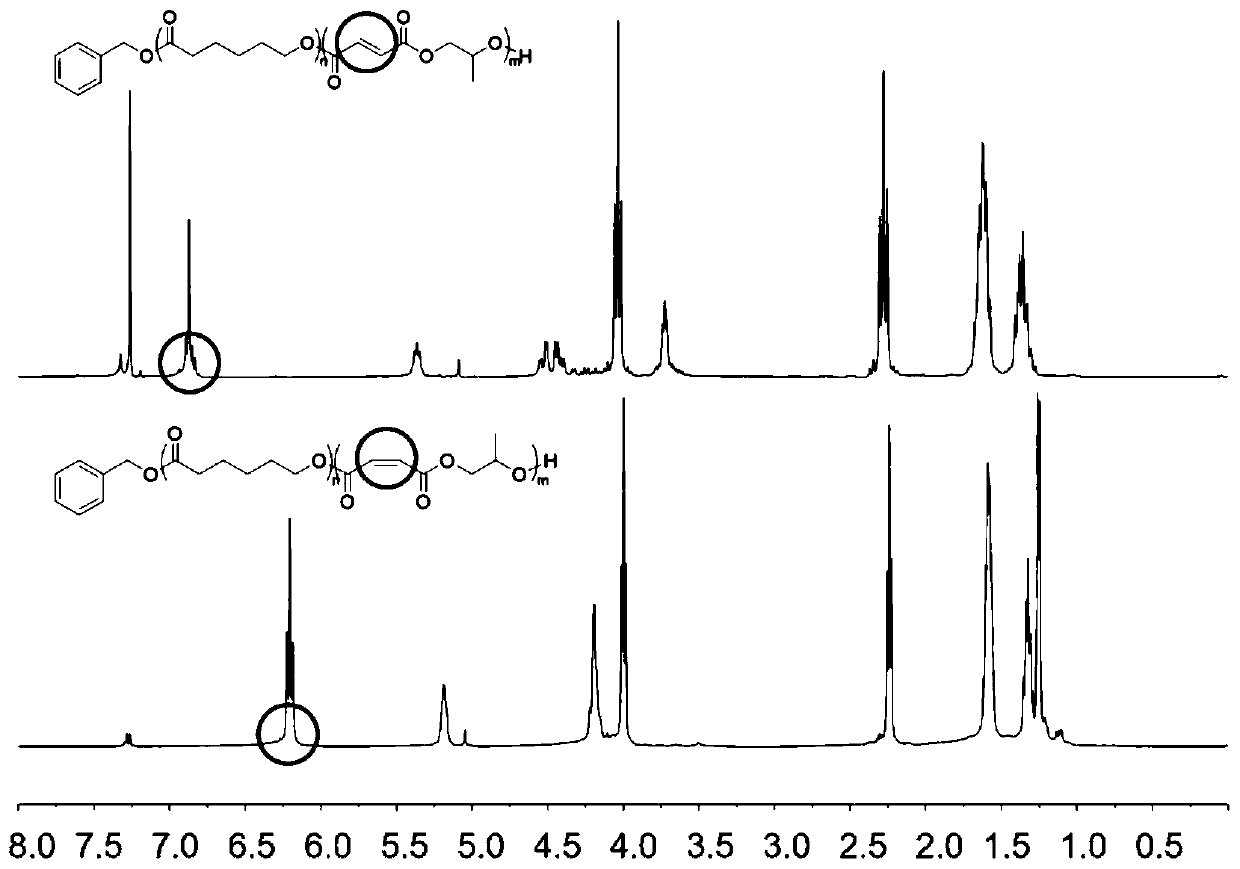

Poly(propylene fumarate) is copolymerized with poly(caprolactone) diol to produce a block copolymer of poly(propylene fumarate) and poly(ε-caprolactone). The biocompatible and bioresorbable block copolymer of poly(propylene fumarate) and poly(ε-caprolactone) is useful in the fabrication of injectable and in-situ hardening scaffolds for tissue and / or skeletal reconstruction. The block copolymer can be crosslinked by redox or photo-initiation, with or without an additional crosslinker. Thus, the copolymer is both self-crosslinkable (without the use of any crosslinkers) and photocrosslinkable (in the presence of UV light).

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

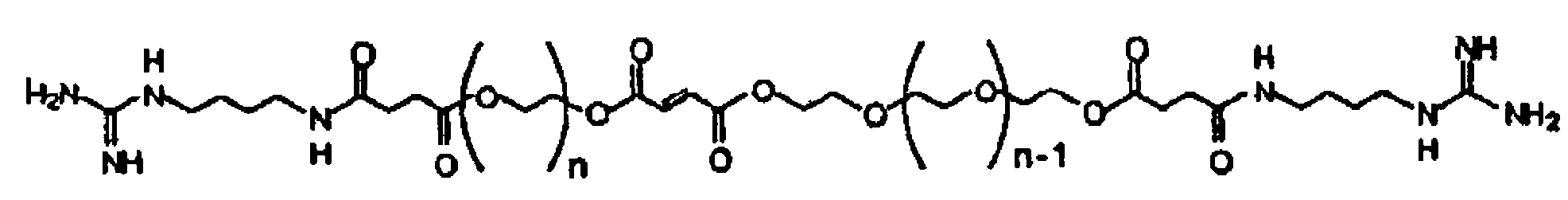

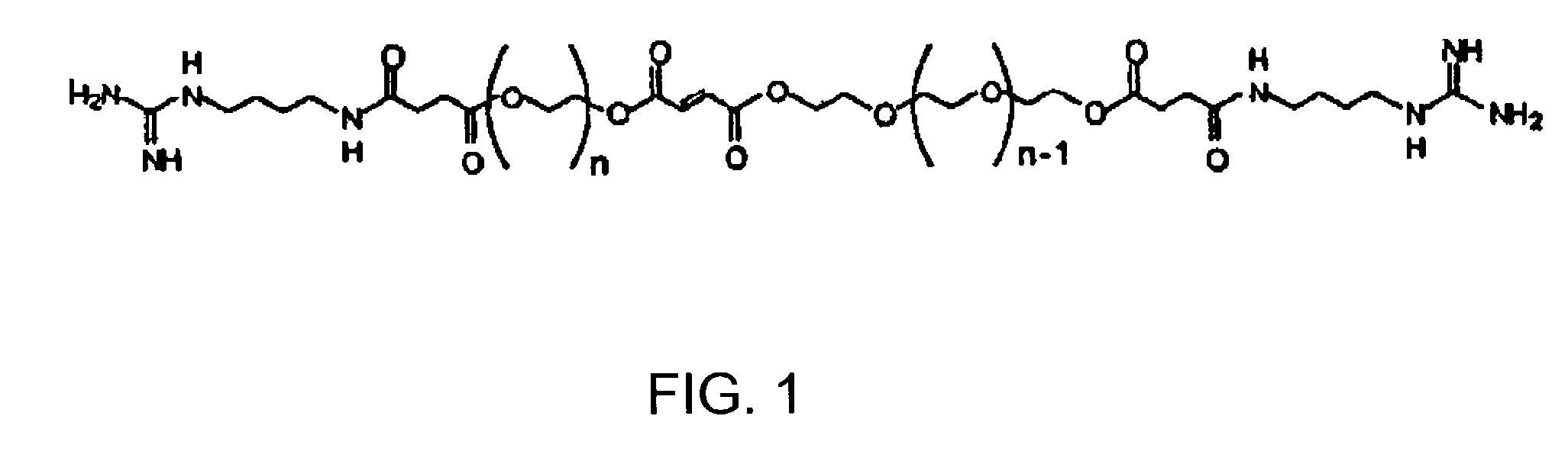

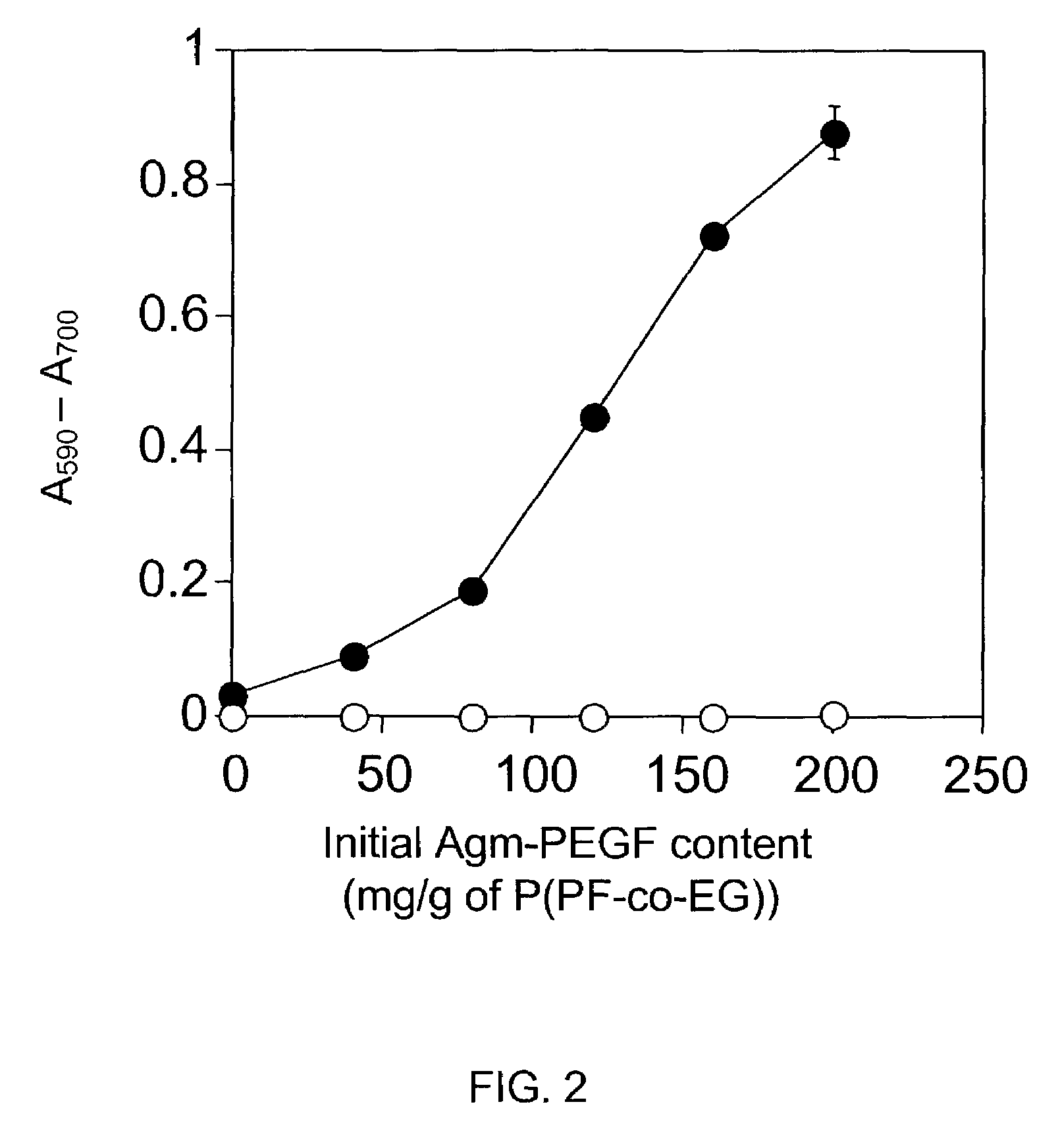

Synthesis and characterization of biodegradable cationic poly(propylene fumarate-co-ethylene glycol) copolymer hydrogels modified with agmatine for enhanced cell adhesion

InactiveUS7629388B2Improve cell adhesionSignificant positive effectBiocidePeptide preparation methodsCross-linkCell adhesion

A cross-linkable monomer comprises a fumaric acid functional group having a first end and a second end, a first spacer group affixed to said first end and comprising at least repeating unit, a first terminal group affixed to said first spacer group, a second spacer group affixed to said second end and comprising at least one ethylene glycol repeating unit, and a second terminal group affixed to said second spacer group. A hydrogel formed by cross-linking the present monomer and a method for making the monomer. A method for forming a hydrogel, comprises the steps of a) synthesizing a copolymer of poly(propylene fumarate) (PPF) and poly(ethylene glycol (PEG) so as to produce P(PF-co-EG), b) synthesizing a PEG-tethered fumarate (PEGF), c) coupling agmatine sulfate to the PEGF to produce PEGF modified with agmatine (Agm-PEGF), and d) cross-linking the P(PF-co-EG) from step a) with Agm-PEGF from step c).

Owner:RICE UNIV

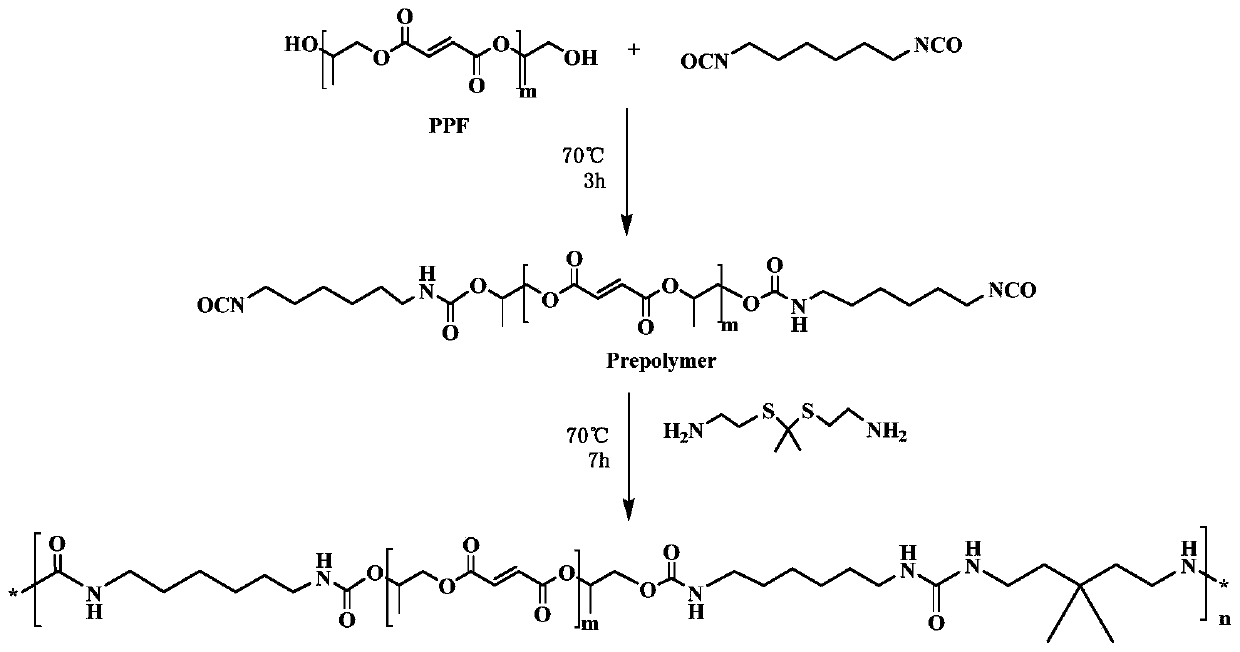

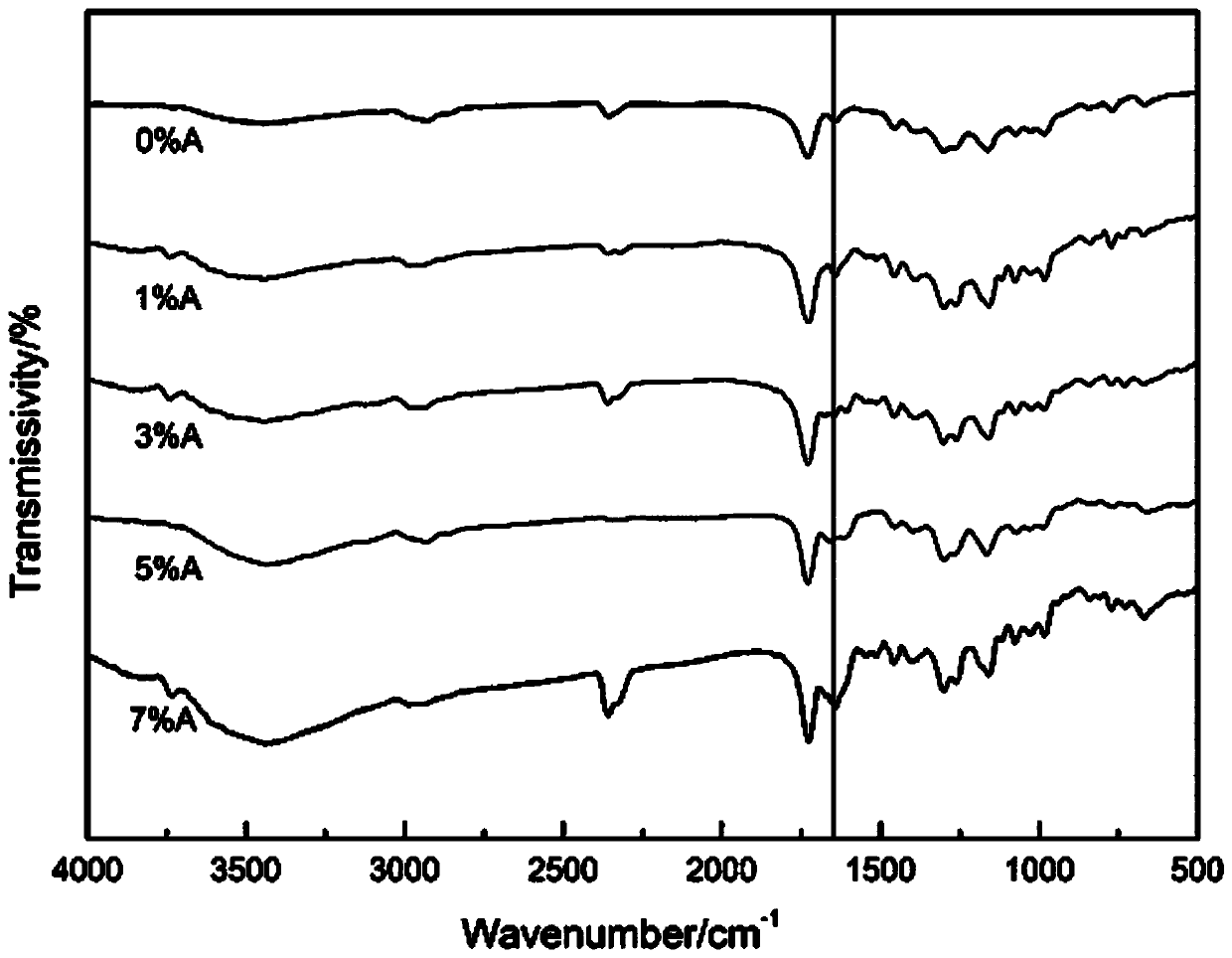

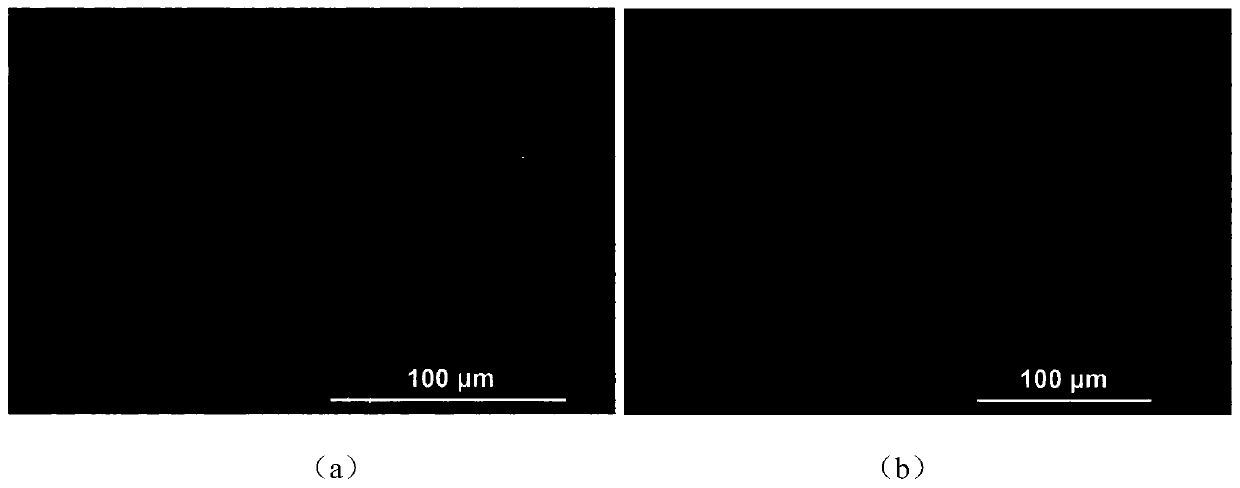

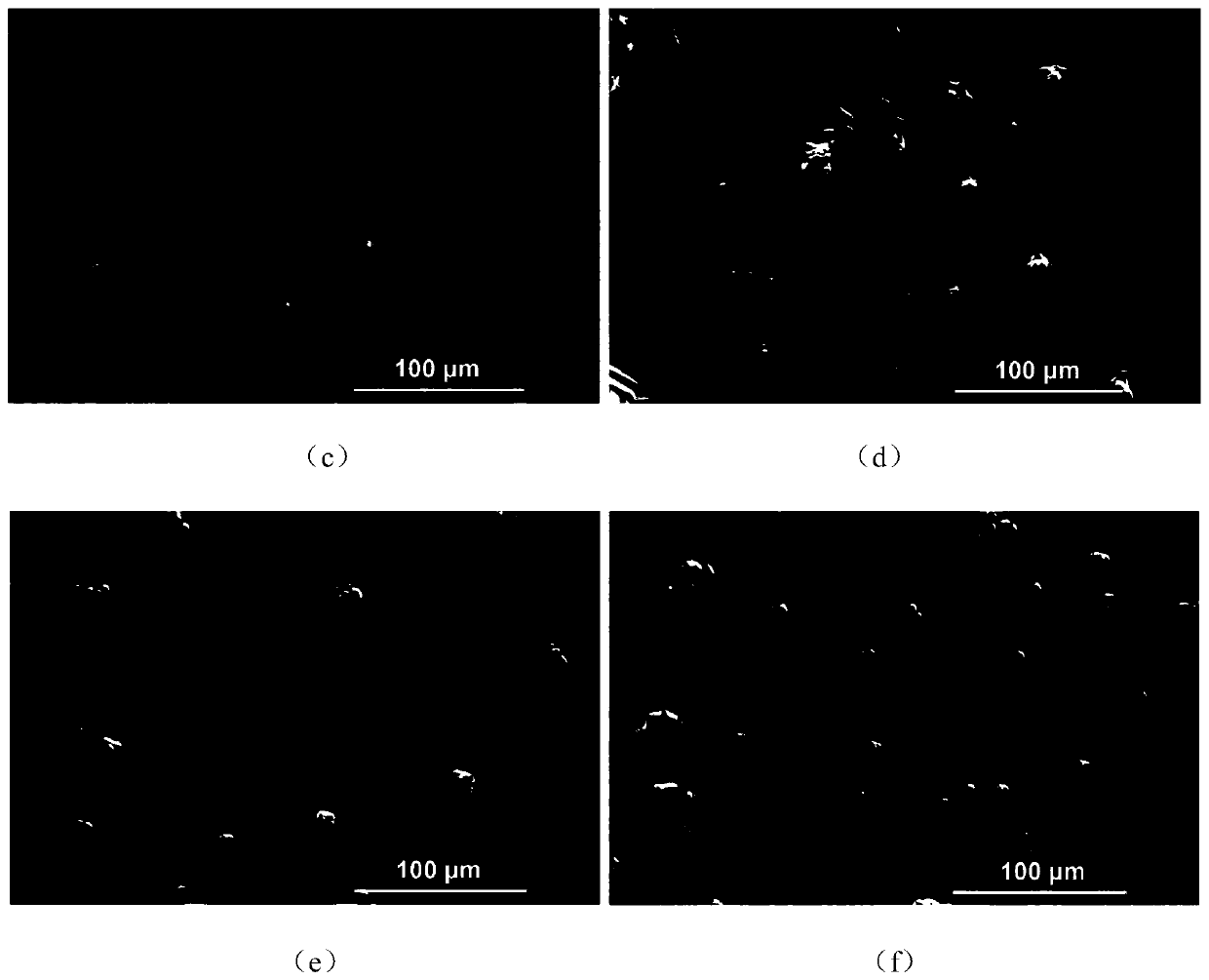

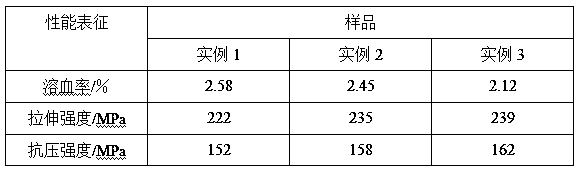

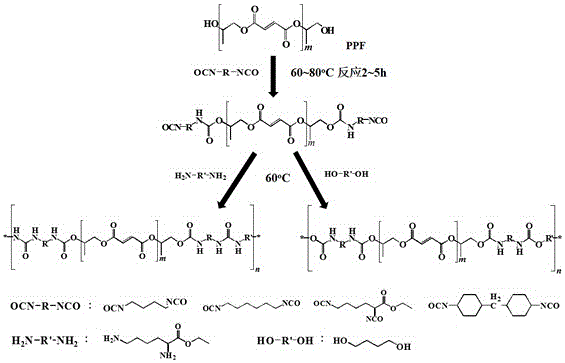

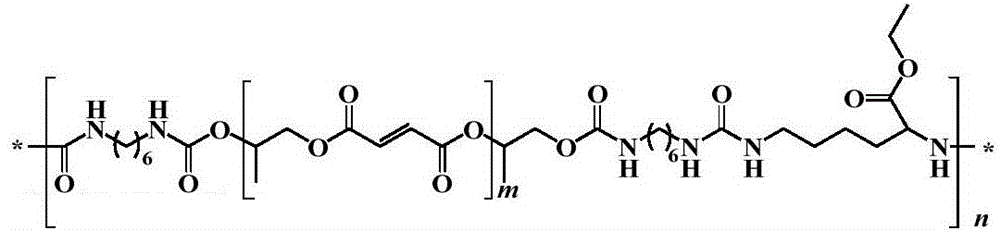

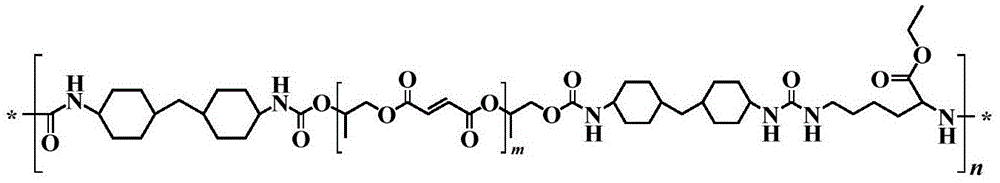

Degradable polyurethane material with active oxygen responsiveness and preparation method of degradable polyurethane material

ActiveCN109988280ADegradableWith mechanical propertiesTissue regenerationProsthesisBiocompatibility TestingOxygen

The invention discloses a degradable polyurethane material with active oxygen responsiveness and a preparation method of the degradable polyurethane material. The degradable polyurethane material comprises a biodegradable polyester glycol soft segment and a hard segment composed of saturated aliphatic diisocyanate and reactive oxygen responsive small molecular diamine. The material is prepared bytaking poly(epsilon-caprolaclone glycol) (PCL) or polypropylene glycol fumarate (PPF) as macromolecular diols, saturated aliphatic diisocyanate as a raw material and reactive oxygen responsive small molecular diamine as a chain extender and adopting a two-step chain extension method. A polyurethane elastomer prepared from the degradable polyurethane material has good biocompatibility and responsiveness to reactive oxygen, the material and a degradation product are harmless to human bodies, so that the degradable polyurethane material can be widely applied to the fields such as biological medicines and tissue engineering and can be used for bone repair and myocardium generation.

Owner:ZHEJIANG UNIV

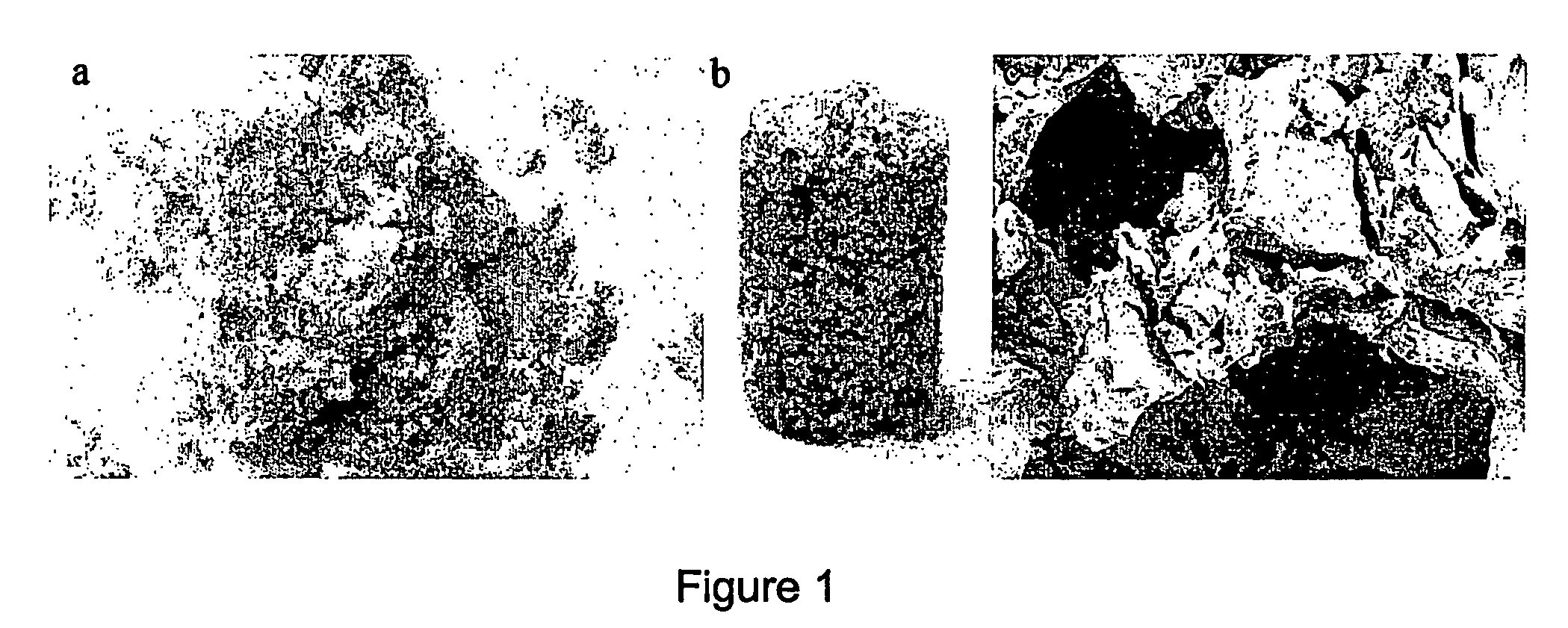

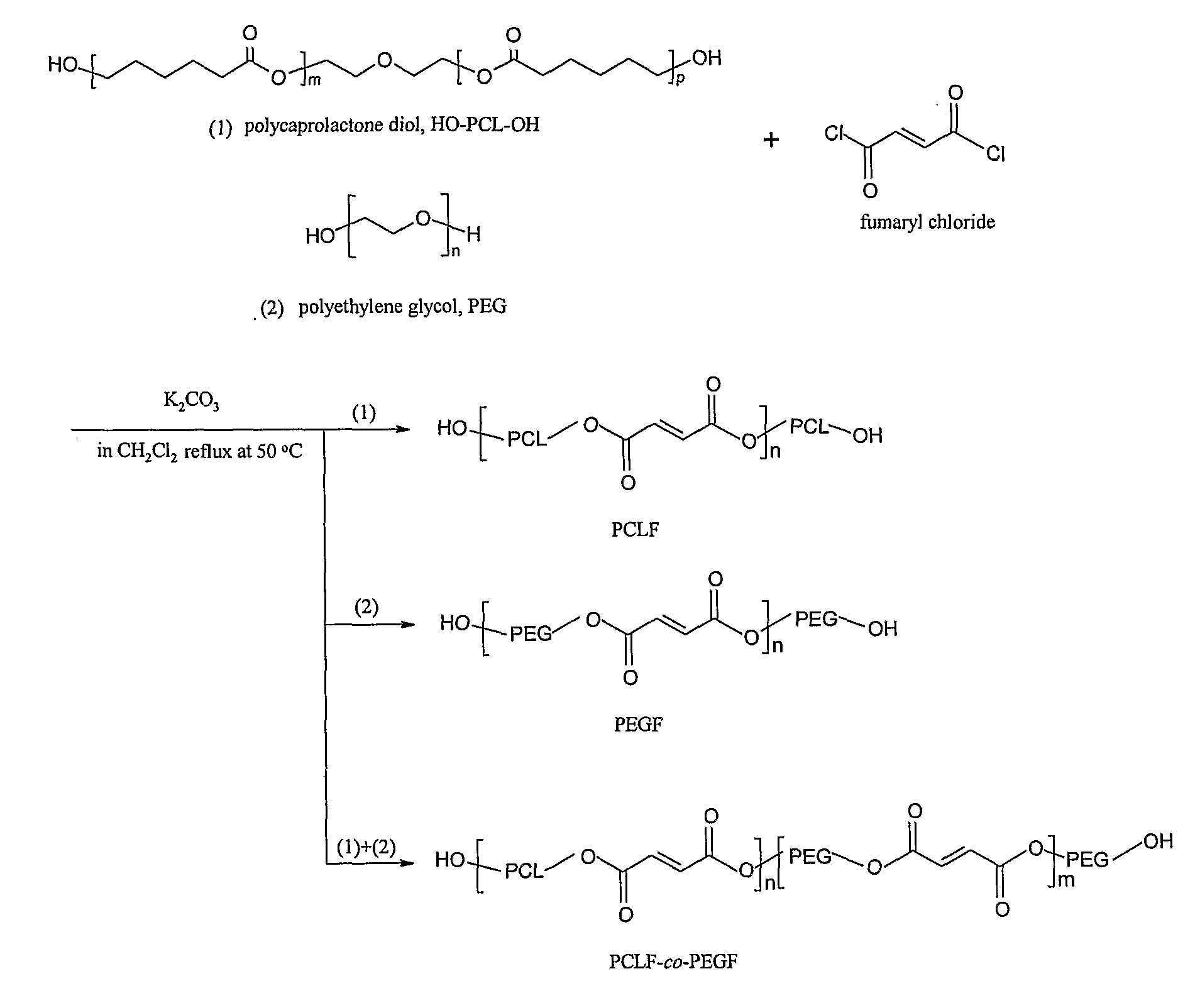

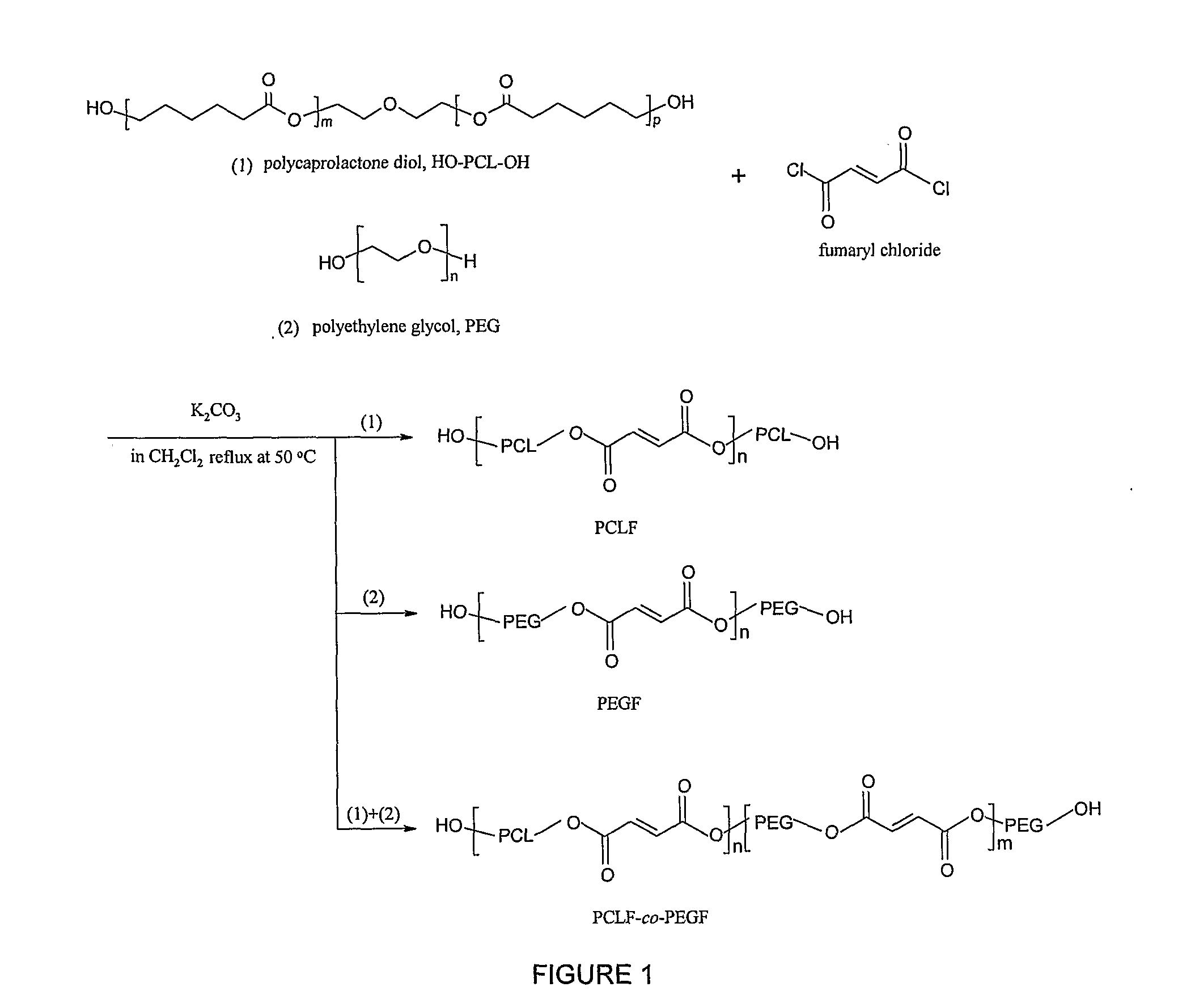

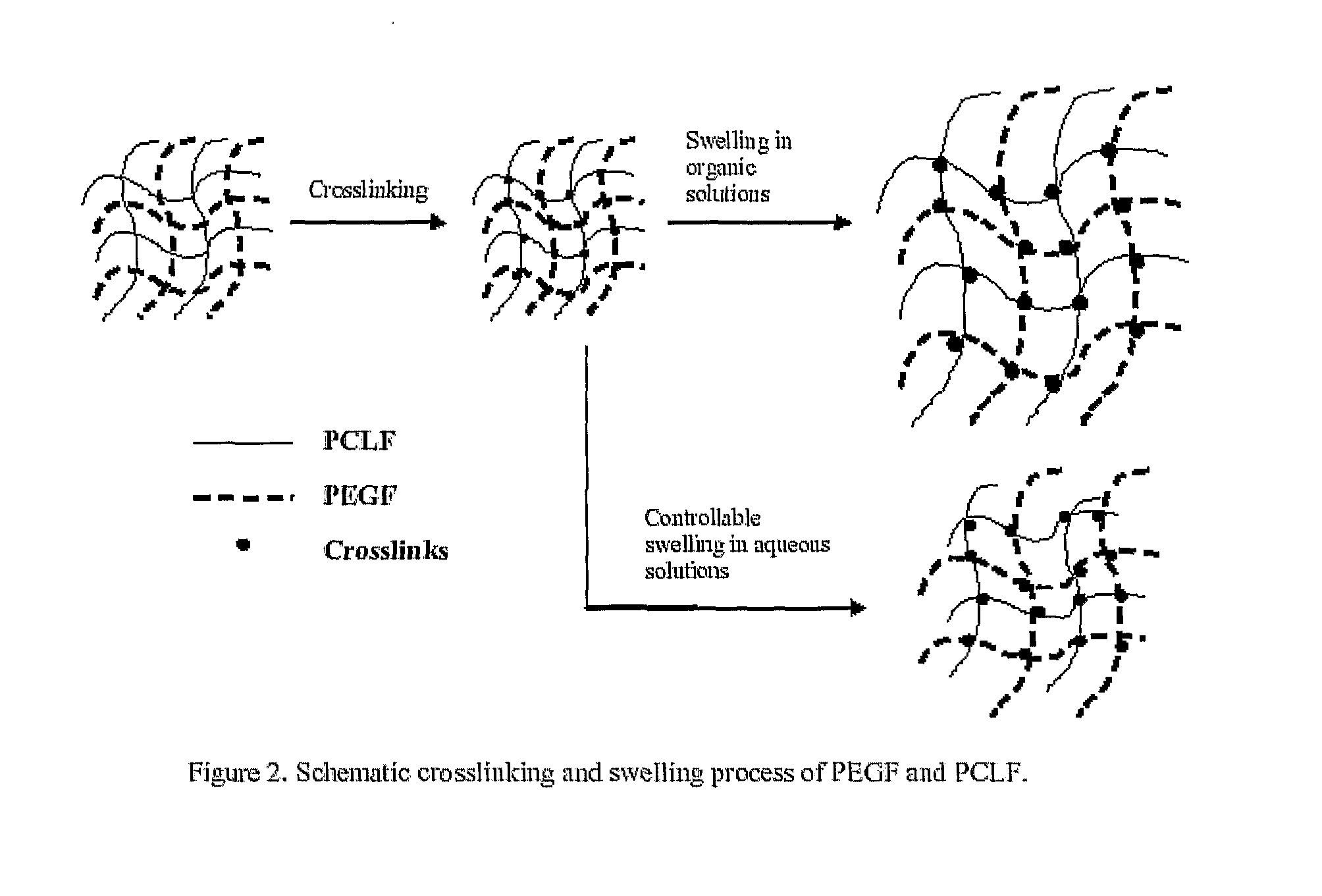

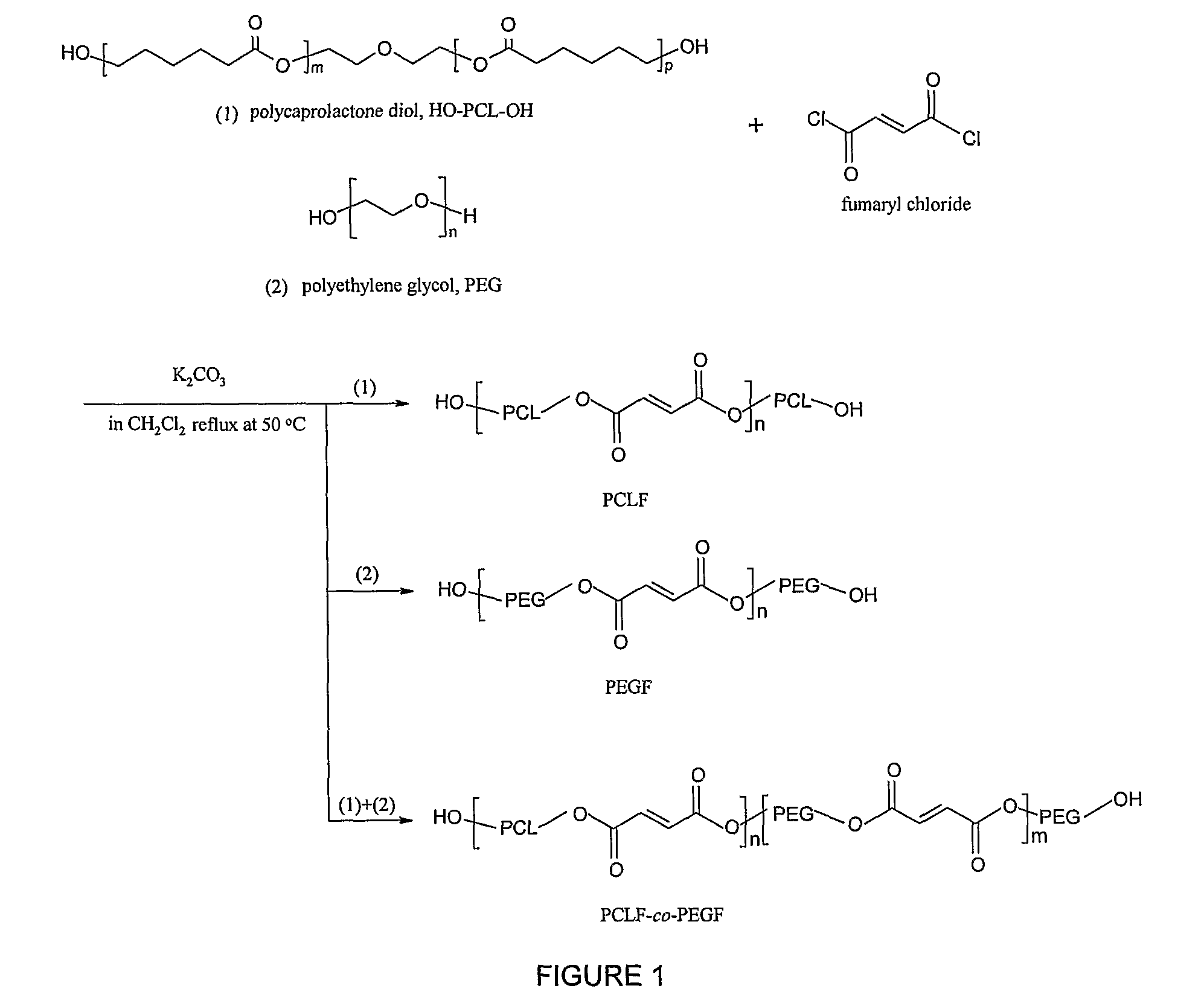

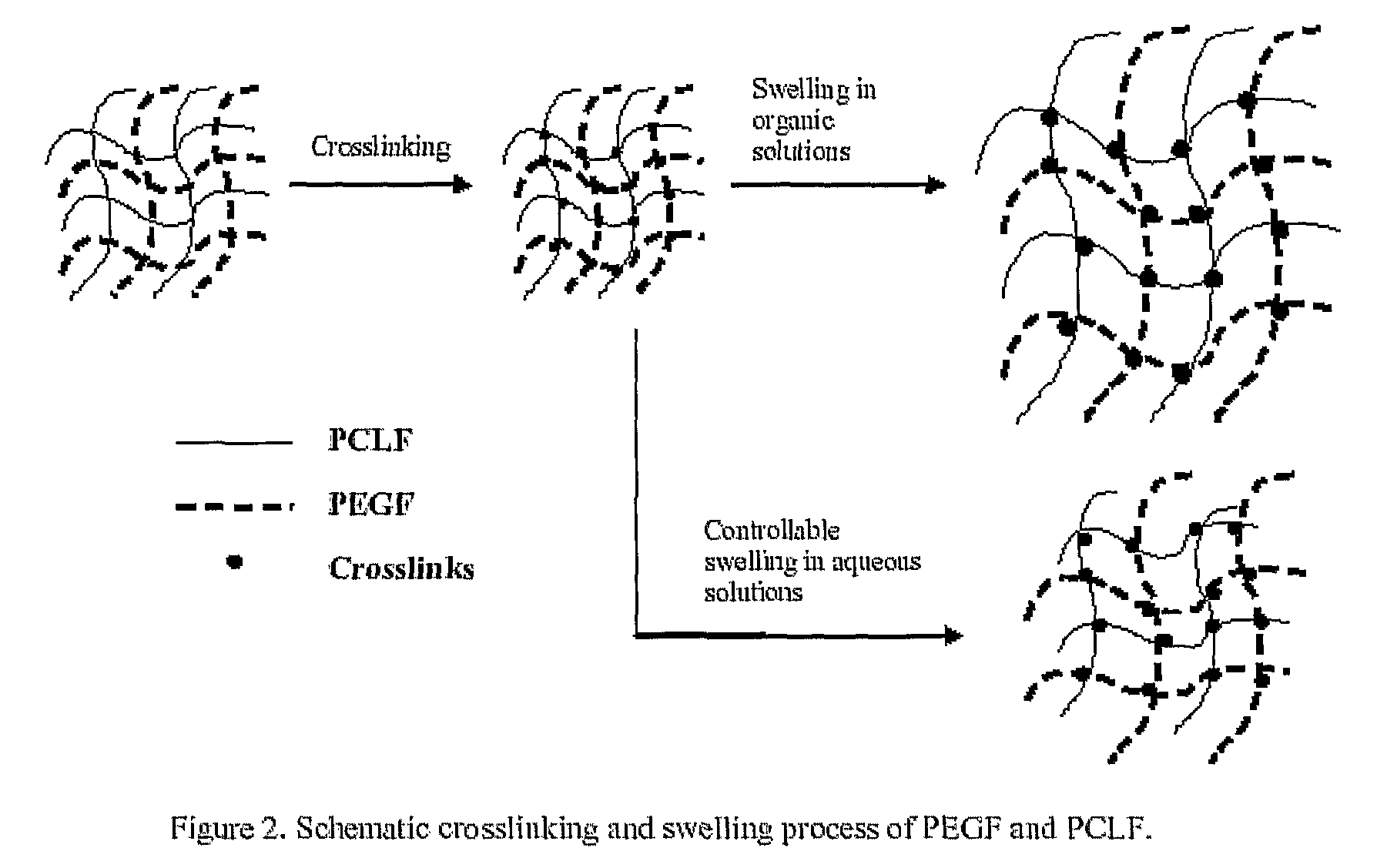

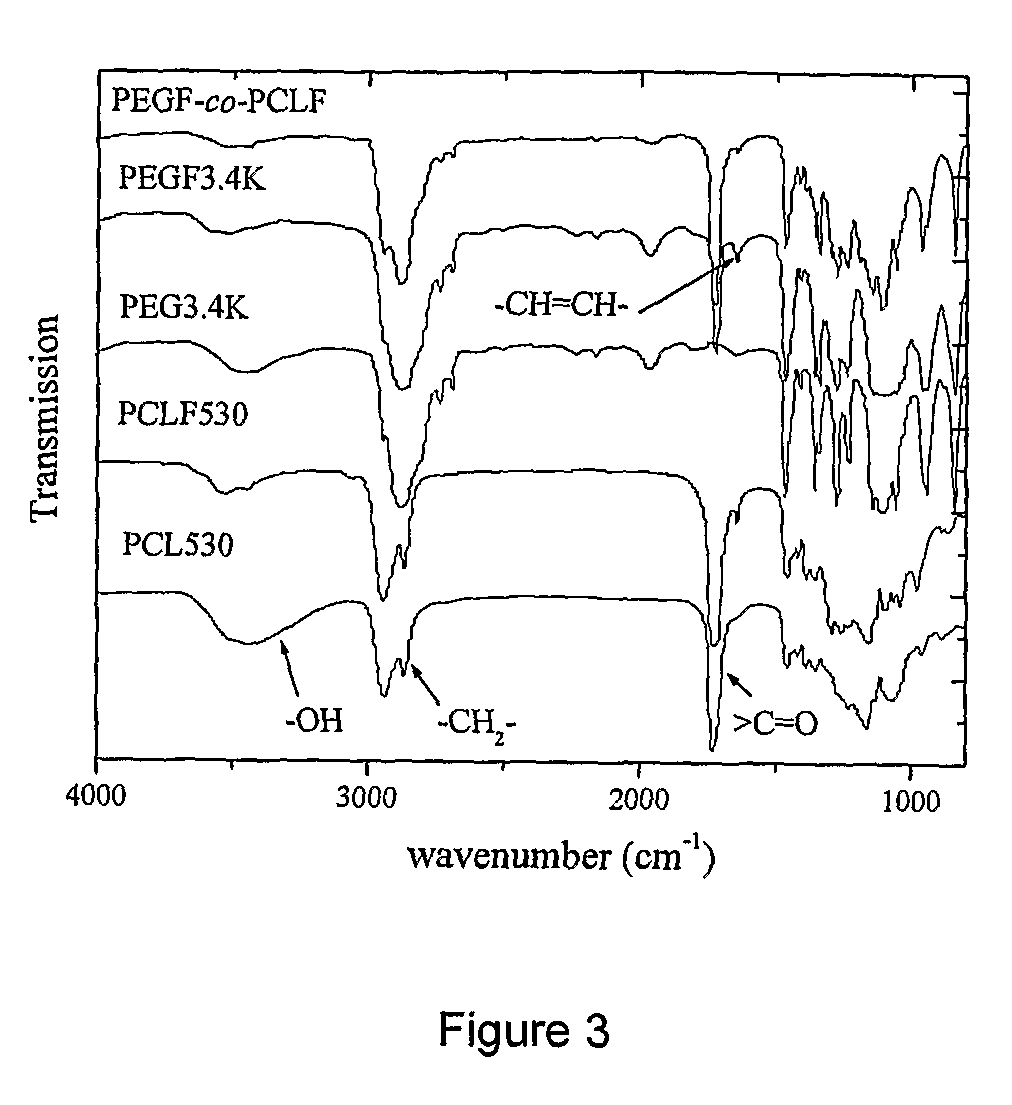

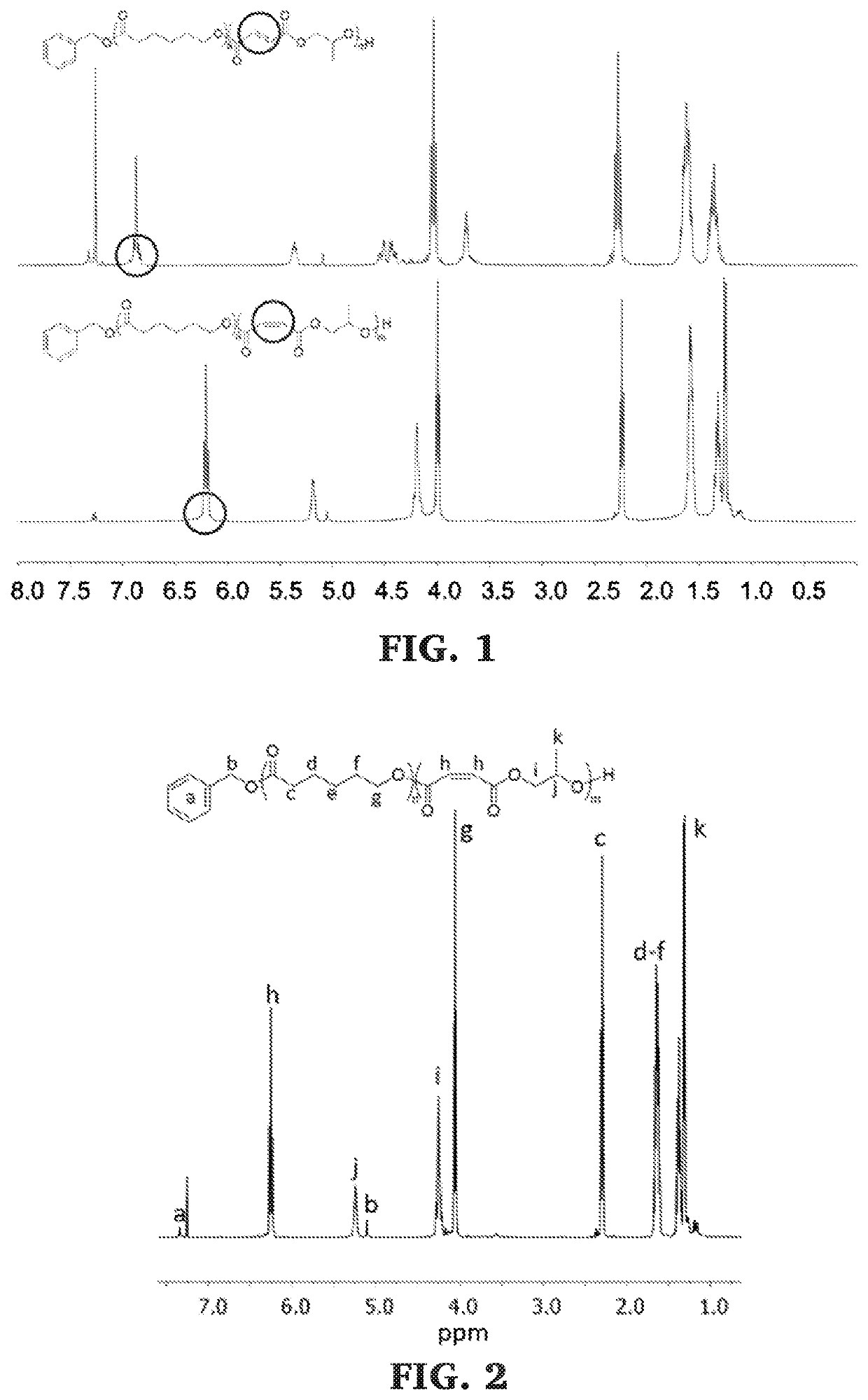

Hydrophilic/Hydrophobic Polymer Networks Based on Poly(Caprolactone Fumarate), Poly(Ethylene Glycol Fumarate), and Copolymers Thereof

InactiveUS20080262102A1Consume moreHigh molecular weightSurgical adhesivesTissue cultureControlled drugsHydrophobic polymer

Improved methods for preparing polyethylene glycol fumarate) are disclosed. Methods for chemically crosslinking or photocross-linking hydrophilic polyethylene glycol fumarate) with hydrophobic polymers such as poly(propylene fumarate) (PPF) and poly(caprolactone fumarate) (PCLF) to form various hydrogels (FIG. 1) with controllable hydrophilicity are also disclosed. The hydrogels are useful in the fabrication of injectable and in-situ hardening scaffolds for application in skeletal reconstruction. An injectable material including the hydrogels may be useful in controlled drug release.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Environment-friendly high-heat-stability LED (light-emitting diode) photosensitive packaging adhesive and preparation method thereof

ActiveCN104263305AHigh light transmittanceImprove thermal stabilityNon-macromolecular adhesive additivesOther chemical processesAdhesiveHeat stability

The invention provides an environment-friendly high-heat-stability LED (light-emitting diode) photosensitive packaging adhesive and a preparation method thereof. The end curing product of the packaging adhesive is a PPF / PPF-DA crosslinked curing body, namely propylene glycol polyfumarate / propylene glycol polyfumarate-diacrylate crosslinked curing body. The curing product has no toxicity; the intensity of illumination and the distance between the light source and sample are regulated to control the curing time within a short time, thereby greatly satisfying the requirement of LED packaging for curing time; and the packaging adhesive curing product has the advantages of higher light transmittance, higher heat stability and higher mechanical properties.

Owner:XI AN JIAOTONG UNIV

Block copolymers of polycarpolactone and poly (propylene funarate)

InactiveUS7816461B2Excellent characteristicsHigh strengthPowder deliveryImpression capsPolymer scienceCross linker

Poly(propylene fumarate) is copolymerized with poly(caprolactone) diol to produce a block copolymer of poly(propylene fumarate) and poly(caprolactone). The biocompatible and bioresorbable block copolymer of poly(propylene fumarate) and poly(caprolactone) is useful in the fabrication of injectable and in-situ hardening scaffolds for tissue and / or skeletal reconstruction. The block copolymer can be crosslinked by redox or photo-initiation, with or without an additional crosslinker. Thus, the copolymer is both self-crosslinkable (without the use of any crosslinkers) and photocrosslinkable (in the presence of photons such as UV light).

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

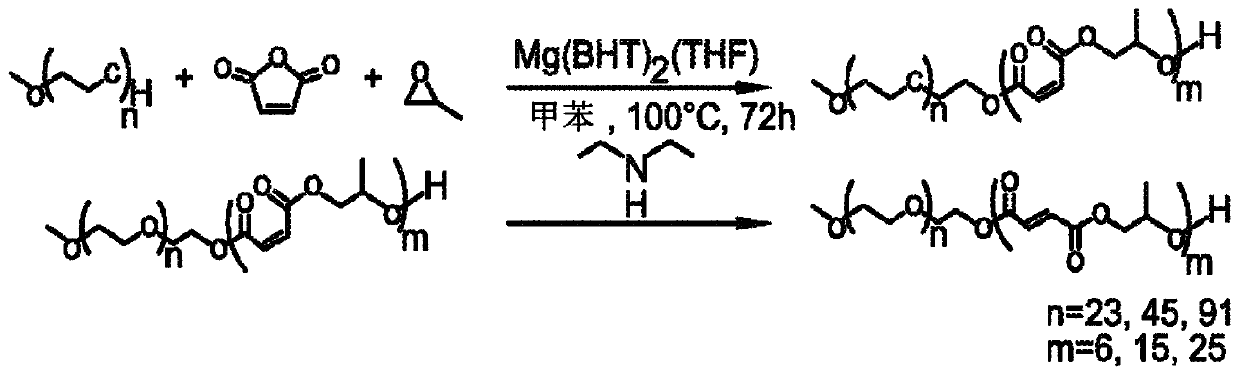

Block copolymers of lactones and poly(propylene fumarate)

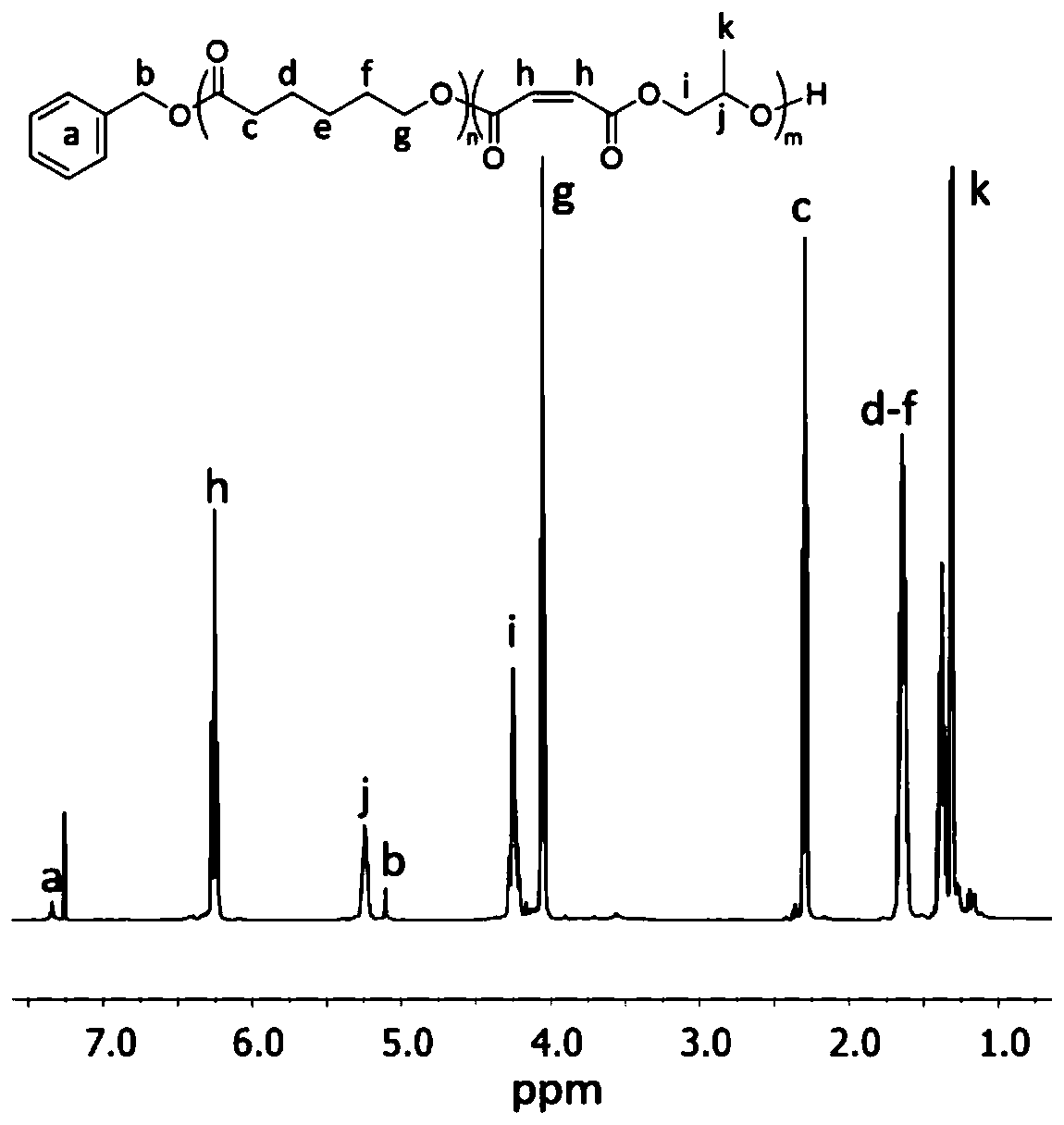

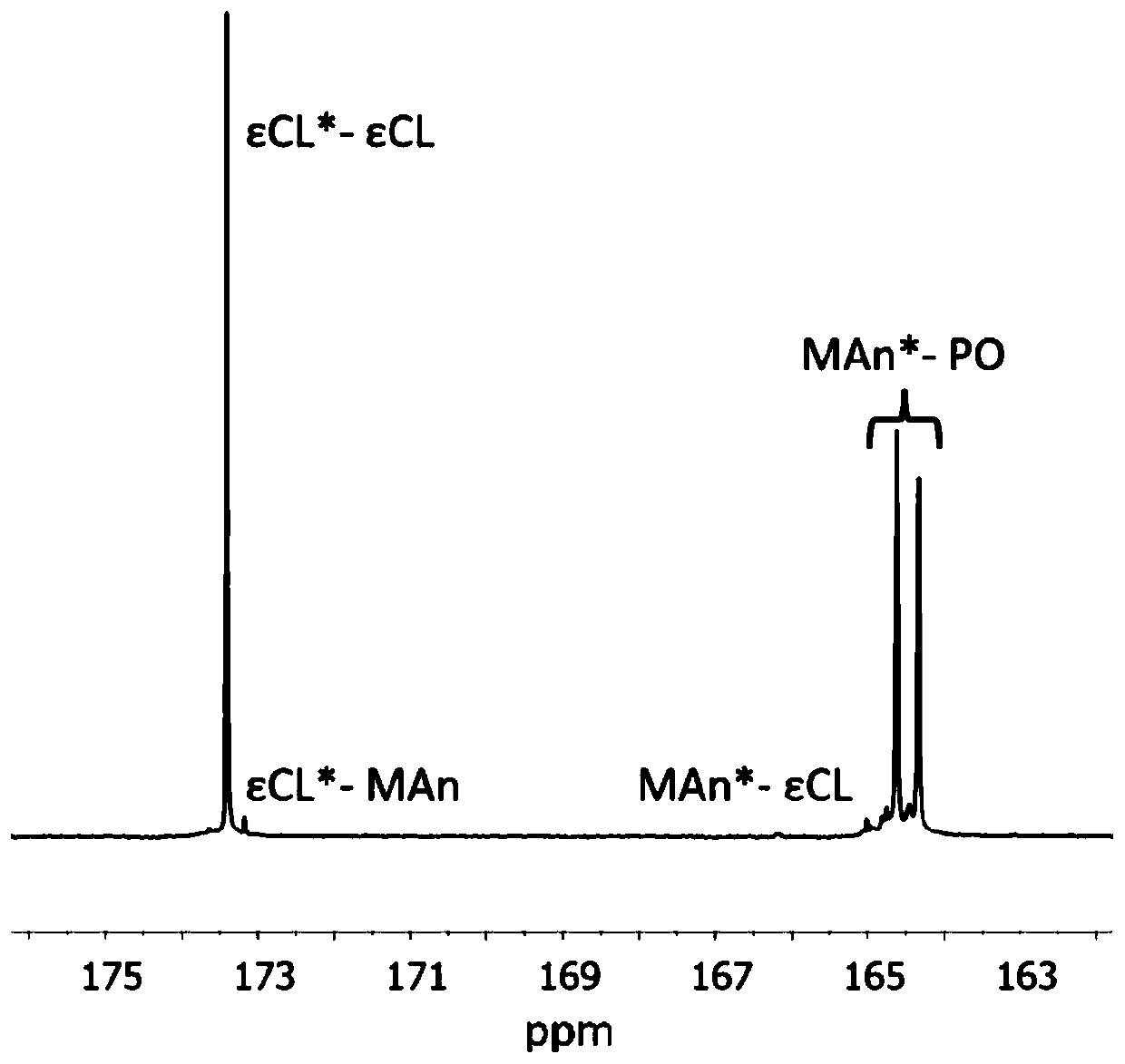

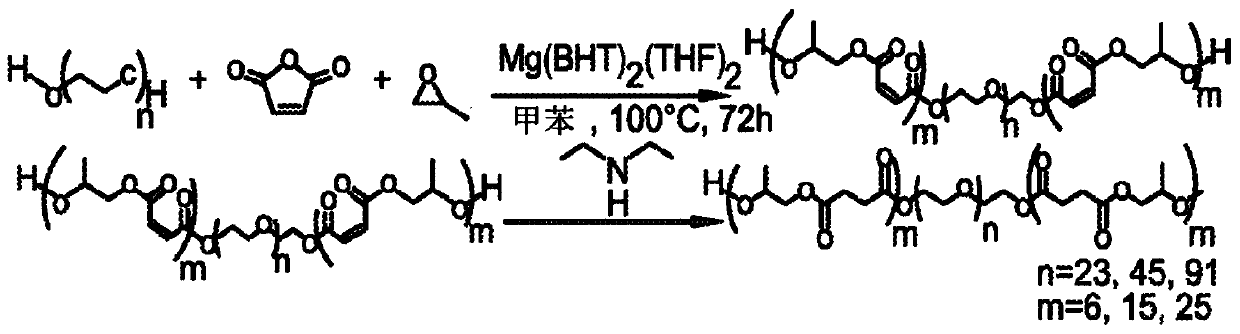

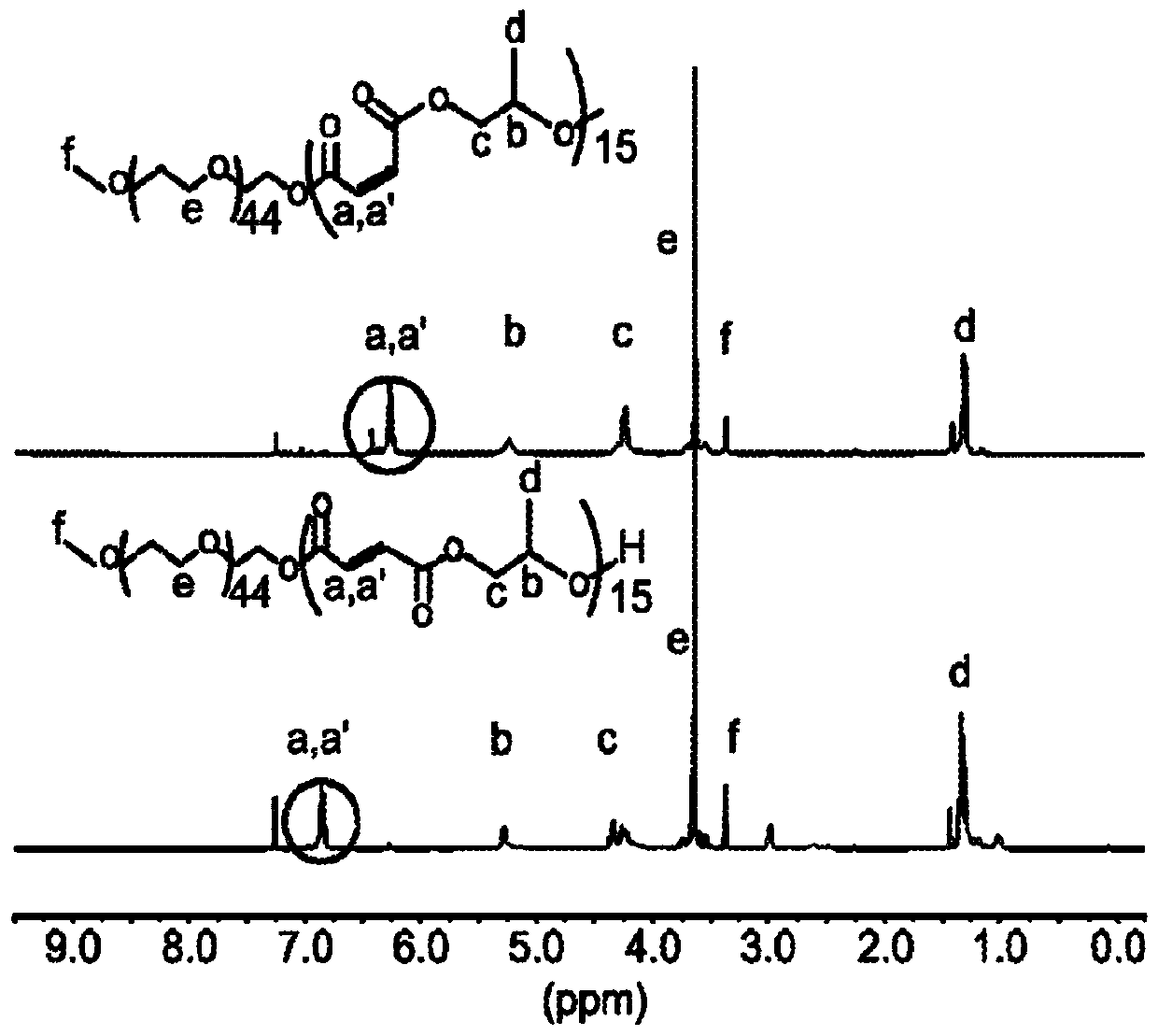

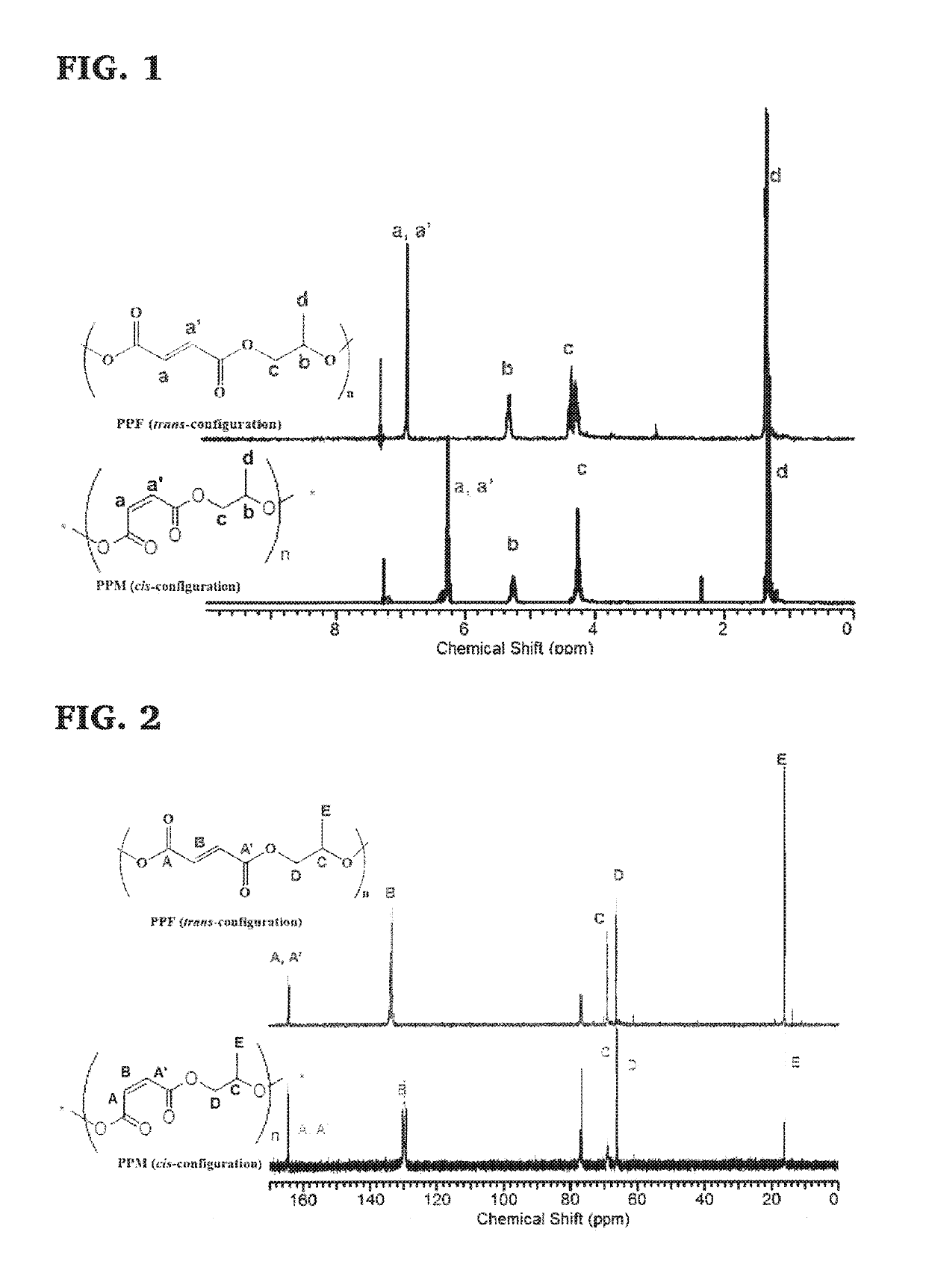

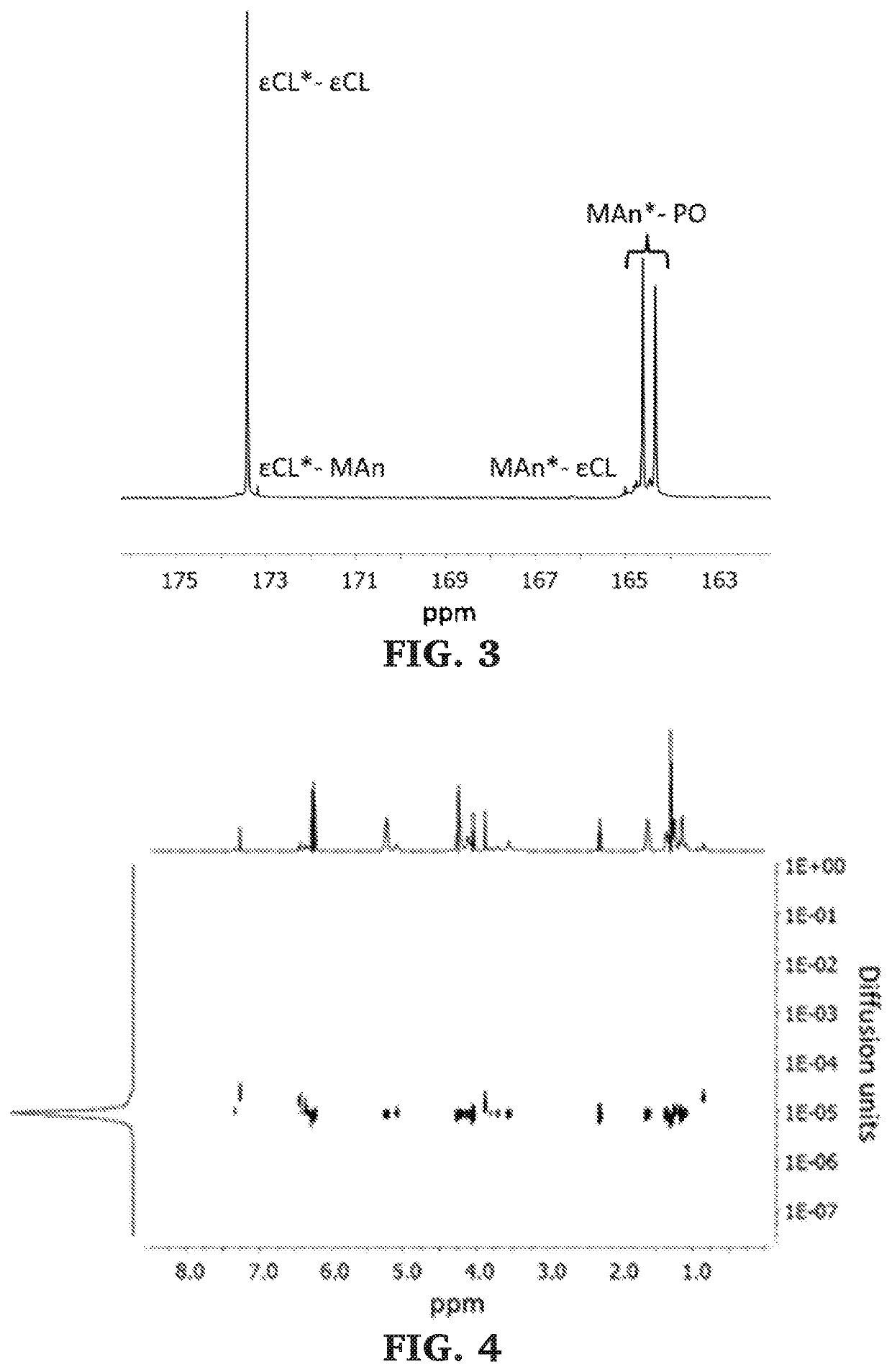

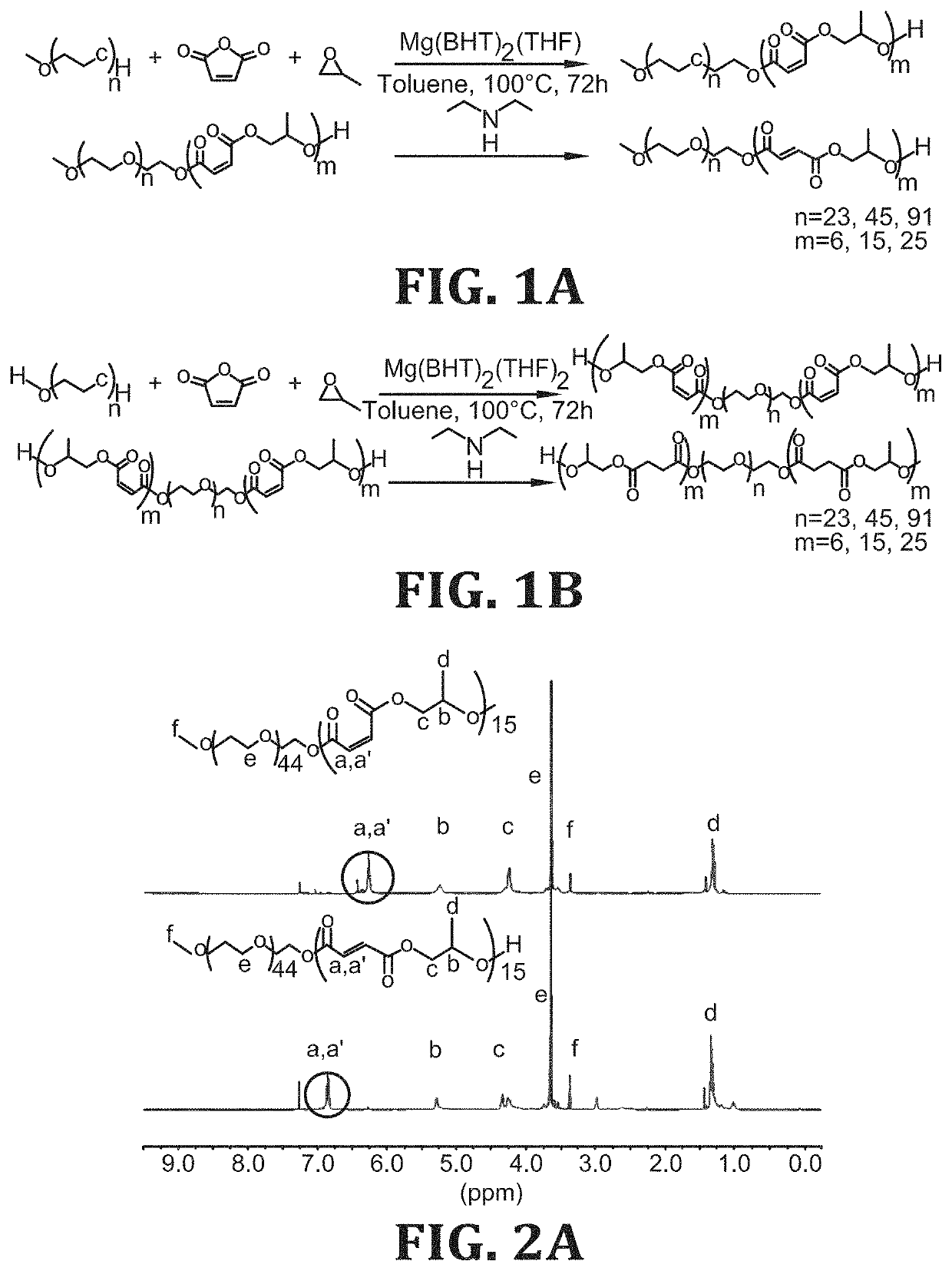

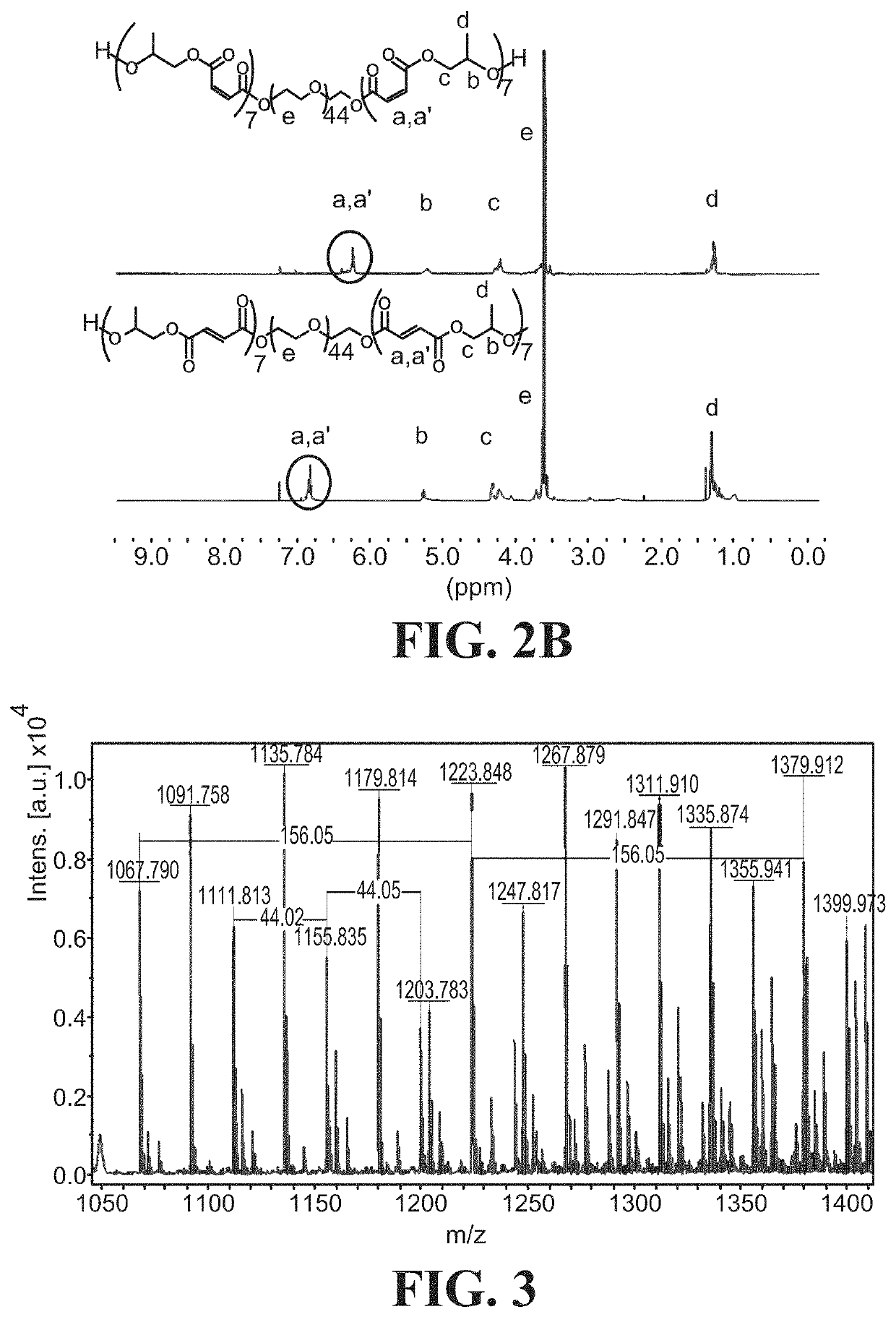

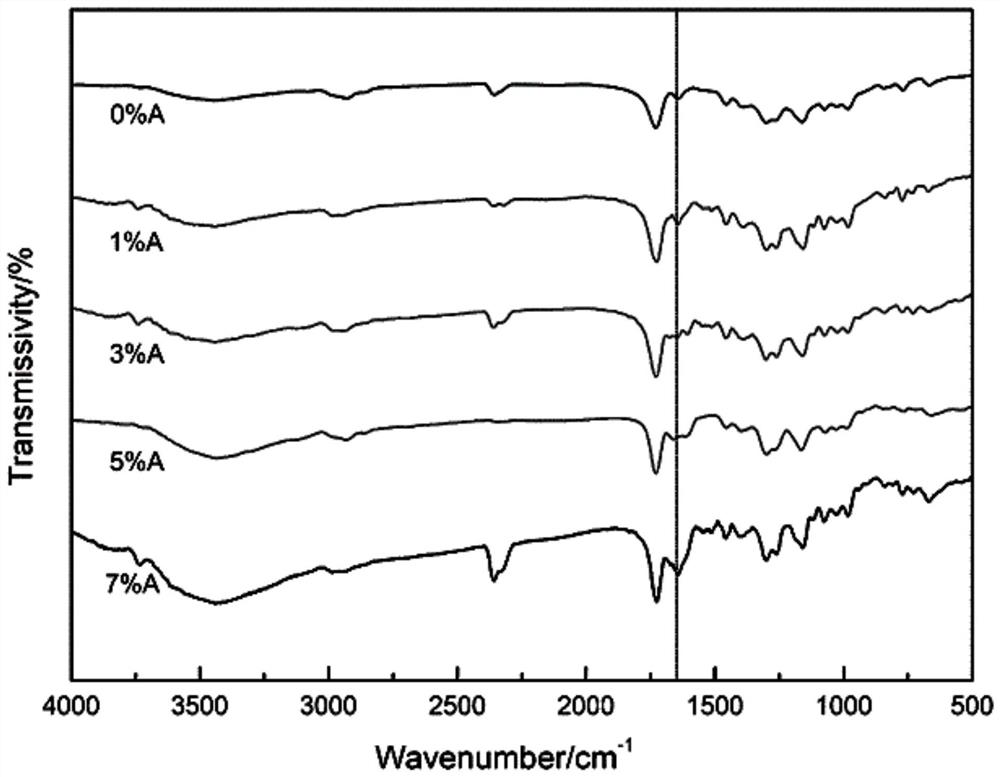

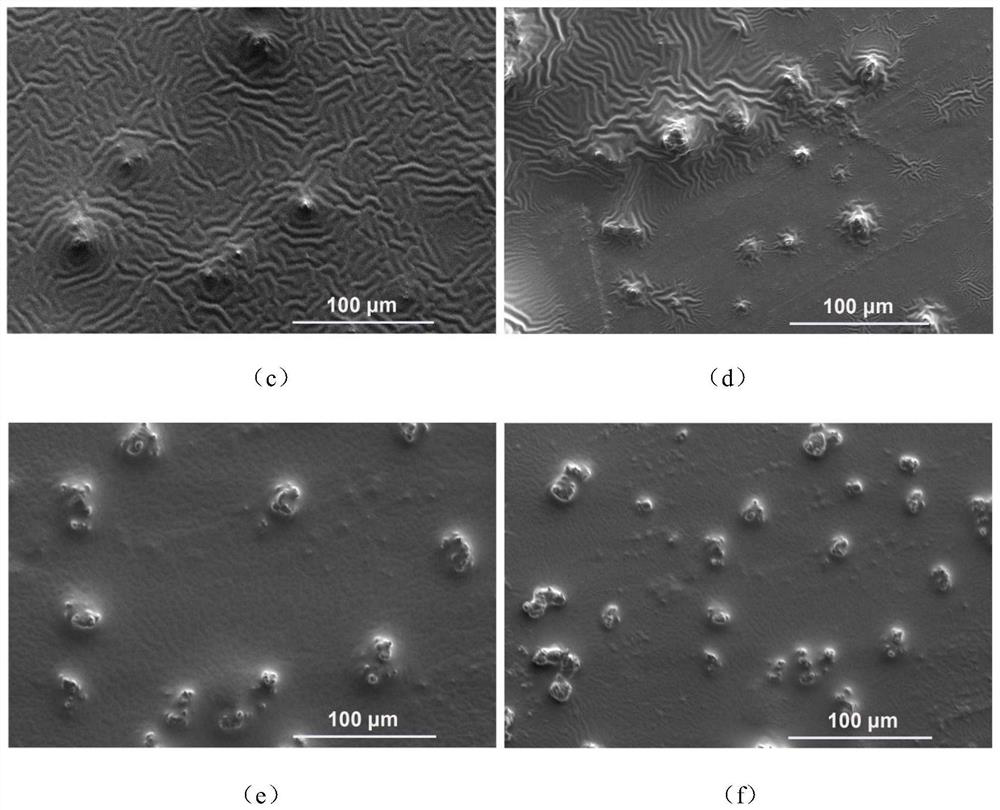

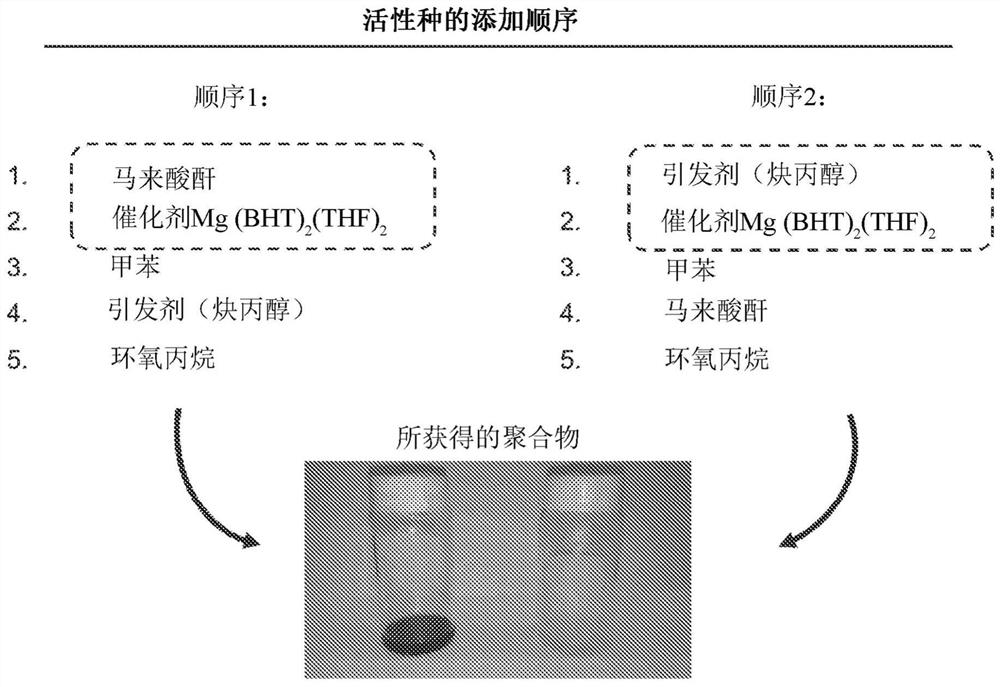

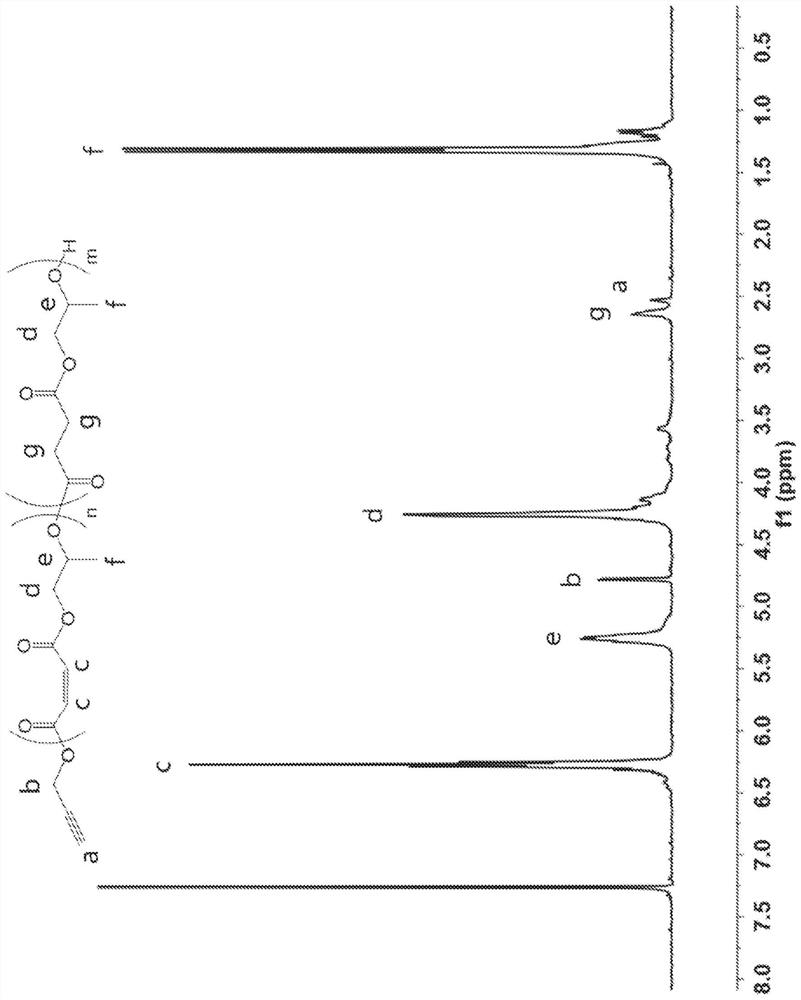

In various embodiments, the present invention provides well-defined biodegradable poly(lactone-b-propylene fumarate) diblock and triblock polymers formed using a novel one-pot, scalable ring-opening block-order copolymerization (ROBOCOP) technique that utilizes magnesium 2,6-di-tert-butyl-4-methylphenoxide (Mg(BHT)2(THF)2) to "switch" from the ROP of cyclic esters to the ROCOP of maleic anhydride(MAn) and propylene oxide (PO) to produce PPF based block copolymers for application in additive manufacturing and patient specific regenerative medicine. These block copolymers are fully resorbable and can be photochemically crosslinked in a number of applications, including 3D printing. By adding the lactone block to the PPF polymer, the viscosity of the resulting block copolymer at working temperatures can be precisely controlled and the quantity of the reactive diluent in printable resins can be reduced or eliminated.

Owner:THE UNIVERSITY OF AKRON

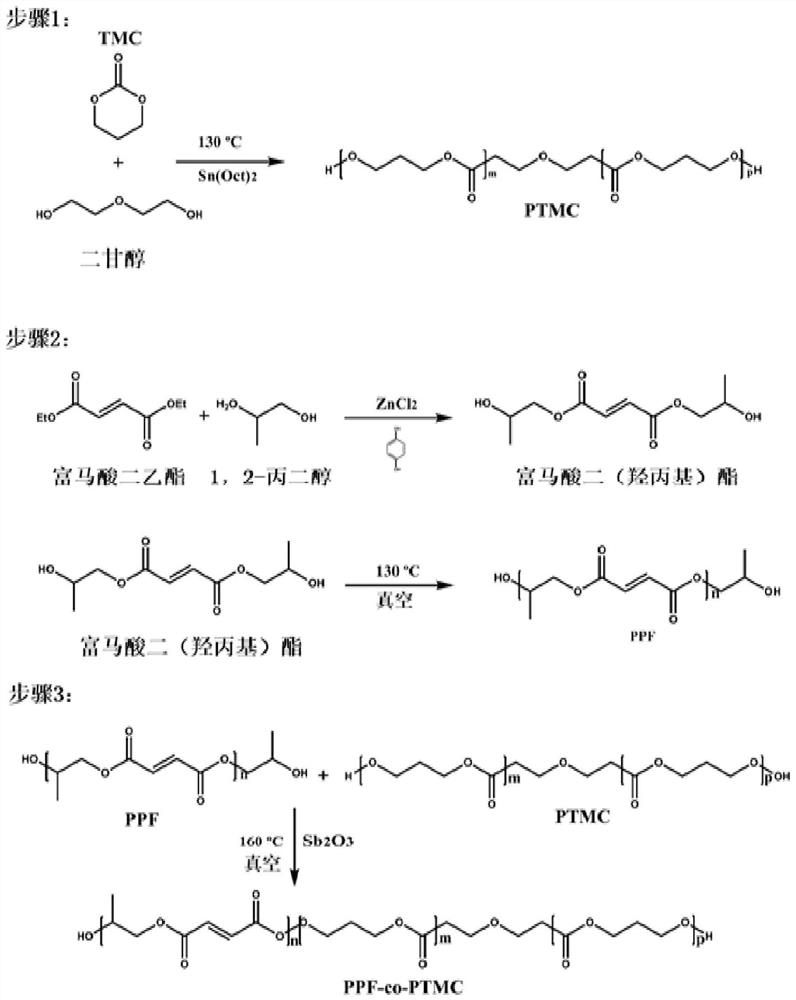

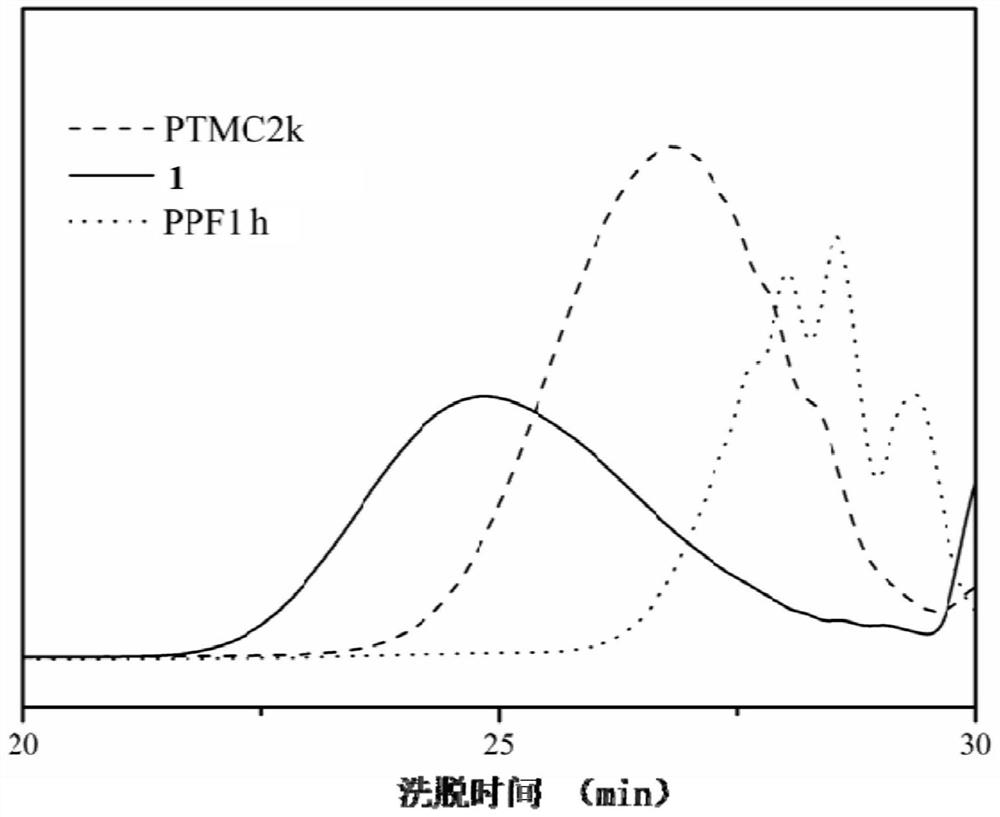

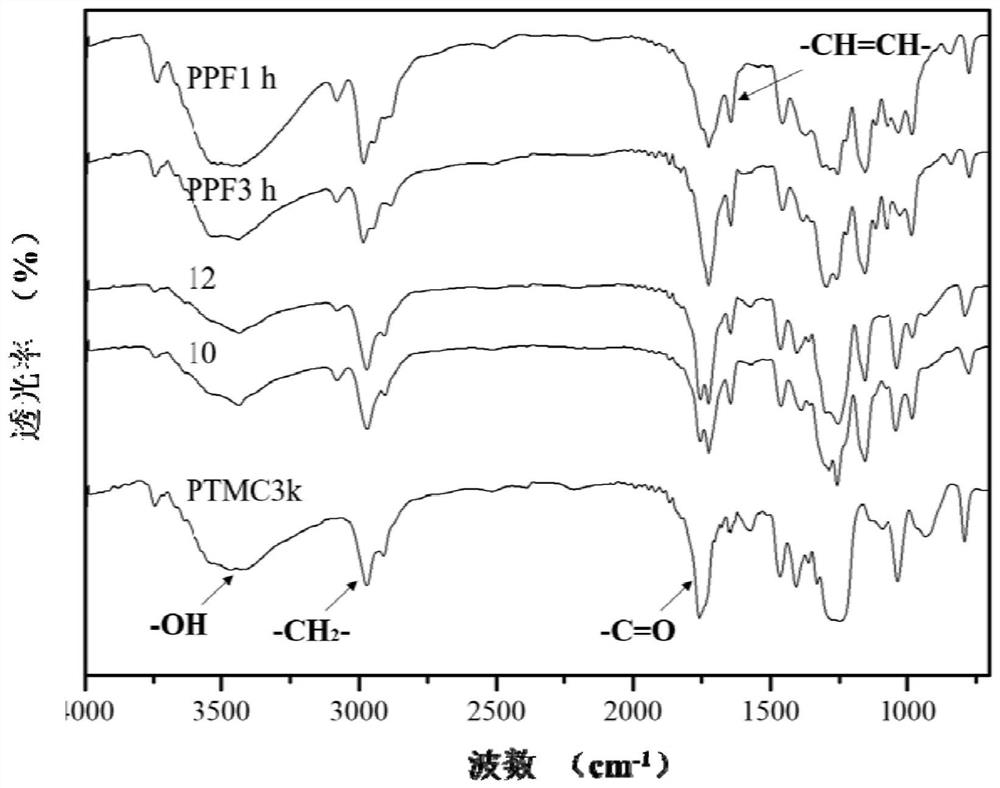

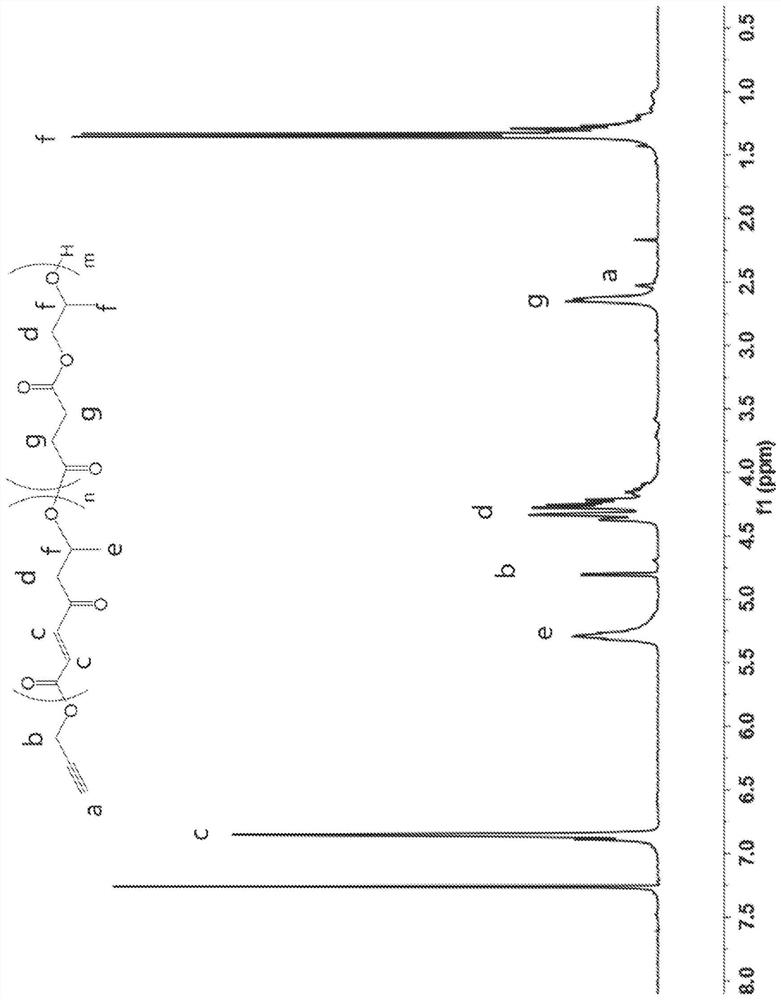

Novel crosslinkable and degradable multi-block copolymer, preparation method and application thereof

ActiveCN112175191ARegulatory performanceFlexible performance adjustmentTissue regenerationProsthesisPolymer scienceTrimethylene carbonate

The invention relates to the technical field of high polymer material synthesis, and discloses a novel crosslinkable and degradable multi-block copolymer, the chemical structural formula of which is shown as formula (I) in the specification, wherein in the formula (I), n is greater than or equal to 3 and less than or equal to 22; m+p is greater than or equal to 4 and less than or equal to 110; andm, n and p are positive integers. The preparation method of the novel crosslinkable and degradable multi-block copolymer comprises the following steps of: uniformly mixing polypropylene fumarate andpoly(trimethylene carbonate), and carrying out reaction at 150-170DEG C for 4-6h to obtain the copolymer. The physical, chemical and degradation properties of the novel crosslinkable and degradable multi-block copolymer provided by the invention can be adjusted by changing the molecular weights and component ratios of PPF and PTMC; oxidation-reduction or ultraviolet crosslinking curing molding canbe carried out, and the performance of a finally molded product can be flexibly regulated and controlled by regulating and controlling a polymer crosslinking network. The copolymer can be used as a tissue engineering material for bone, cartilage and nerve regeneration.

Owner:SUN YAT SEN UNIV

Hydrophilic/hydrophobic polymer networks based on poly(caprolactone fumarate), poly(ethylene glycol fumarate), and copolymers thereof

InactiveUS8912247B2Consume moreHigh molecular weightCosmetic preparationsImpression capsHydrophobic polymerPoly(ethylene glycol fumarate)

Improved methods for preparing polyethylene glycol fumarate) are disclosed. Methods for chemically crosslinking or photocross-linking hydrophilic polyethylene glycol fumarate) with hydrophobic polymers such as poly(propylene fumarate) (PPF) and poly(caprolactone fumarate) (PCLF) to form various hydrogels (FIG. 1) with controllable hydrophilicity are also disclosed. The hydrogels are useful in the fabrication of injectable and in-situ hardening scaffolds for application in skeletal reconstruction. An injectable material including the hydrogels may be useful in controlled drug release.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

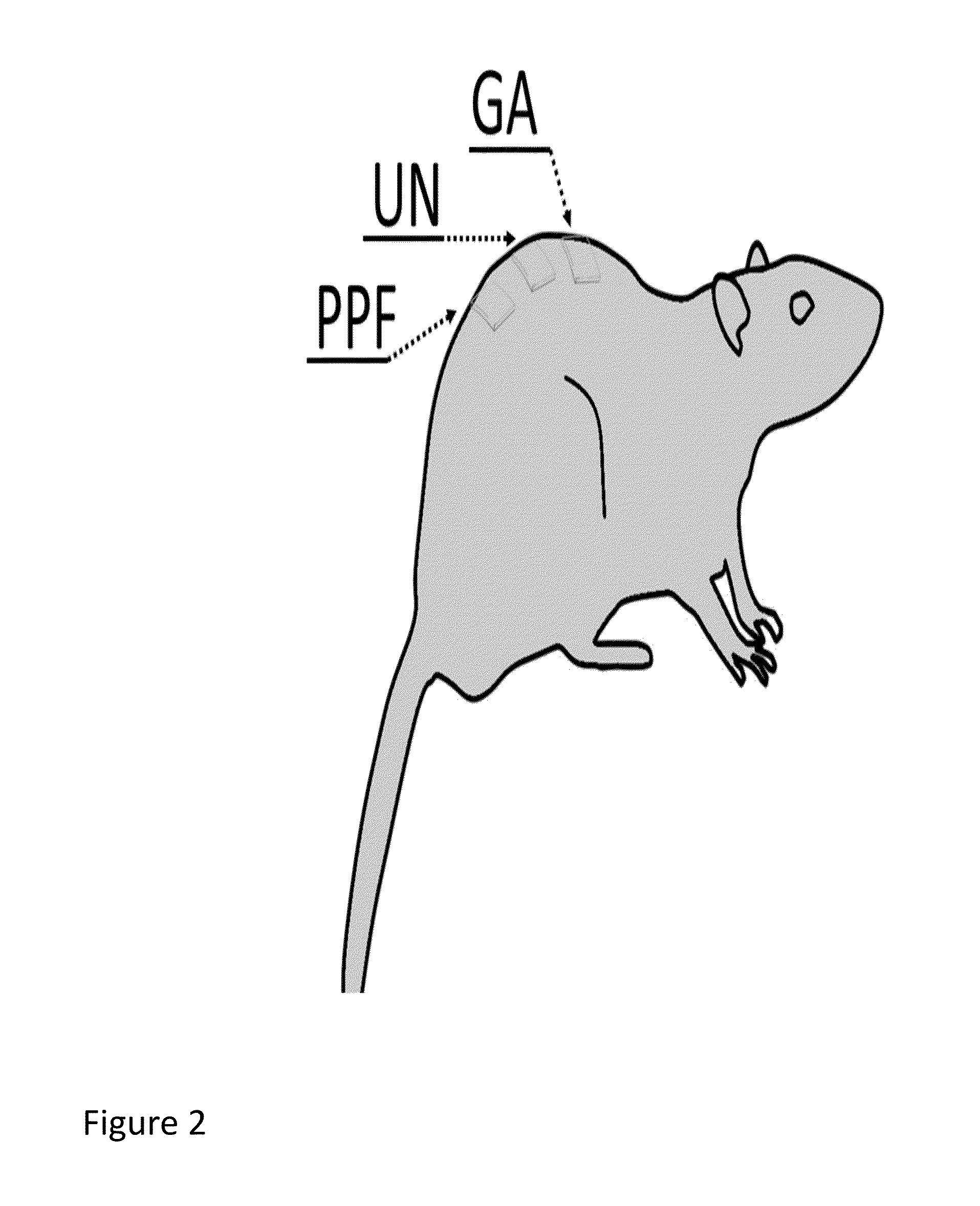

Polymer-tissue hybrid biomaterials and methods of making and using same

Provided are hybrid biomaterials comprising one or more layers of cross-linked poly(propylene fumarate) and / or cross-linked copolymer comprising a plurality of cross-linked propylene fumarate moieties. The layers may further comprise a plurality of microparticles, a plurality of micropores, or both a plurality of microparticles and a plurality of micropores encapsulated within the cross-linked poly(propylene fumarate) and / or cross-linked copolymer comprising a plurality of cross-linked propylene fumarate moieties. One of the layers is disposed on a compliant matrix dense tissue substrate (e.g., a pericardium tissue substrate). The hybrid biomaterials can be used, for example, in method of repairing tissue defects.

Owner:UNIV OF MARYLAND

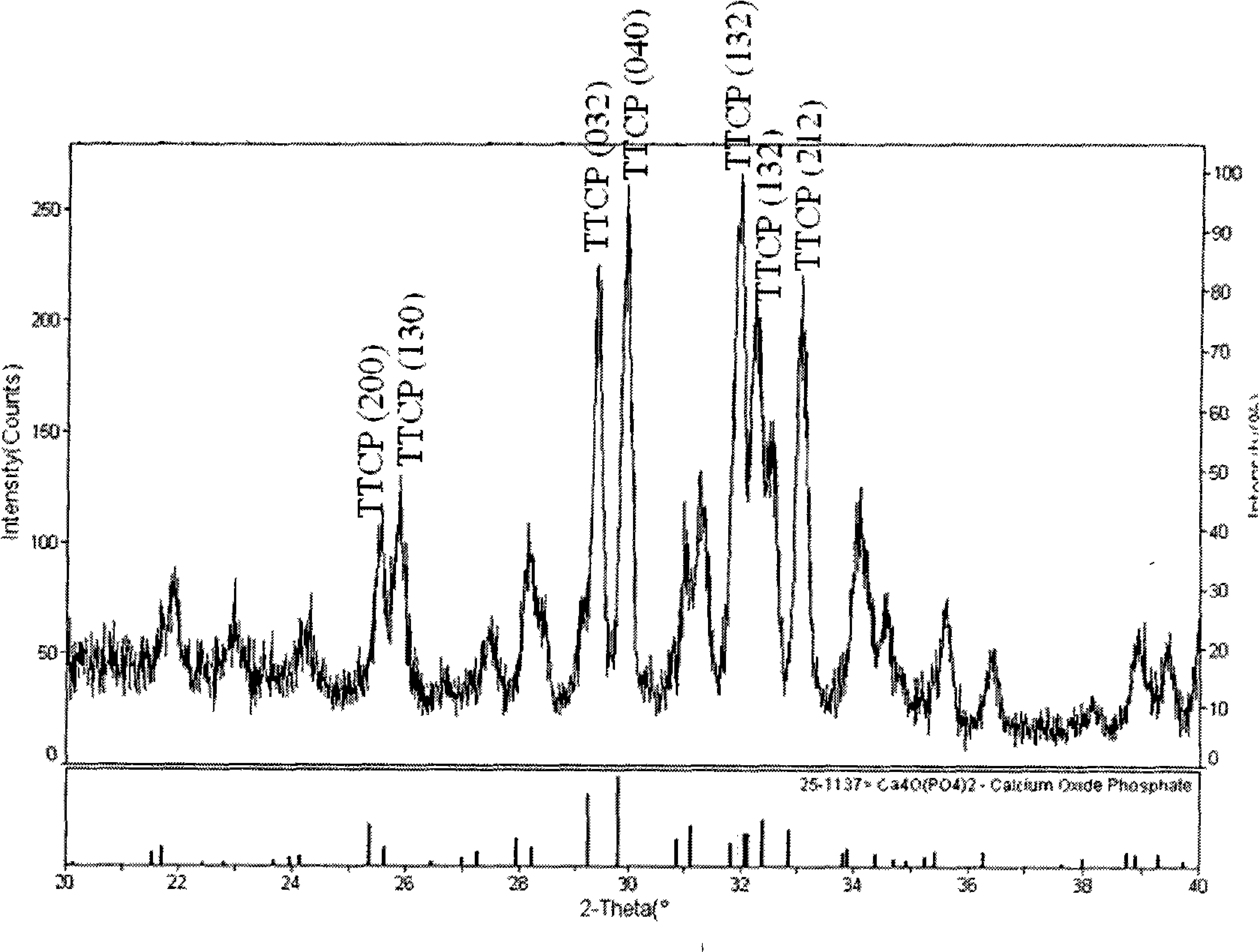

Bio-Degenerable Bone Cement and Manufacturing Method thereof

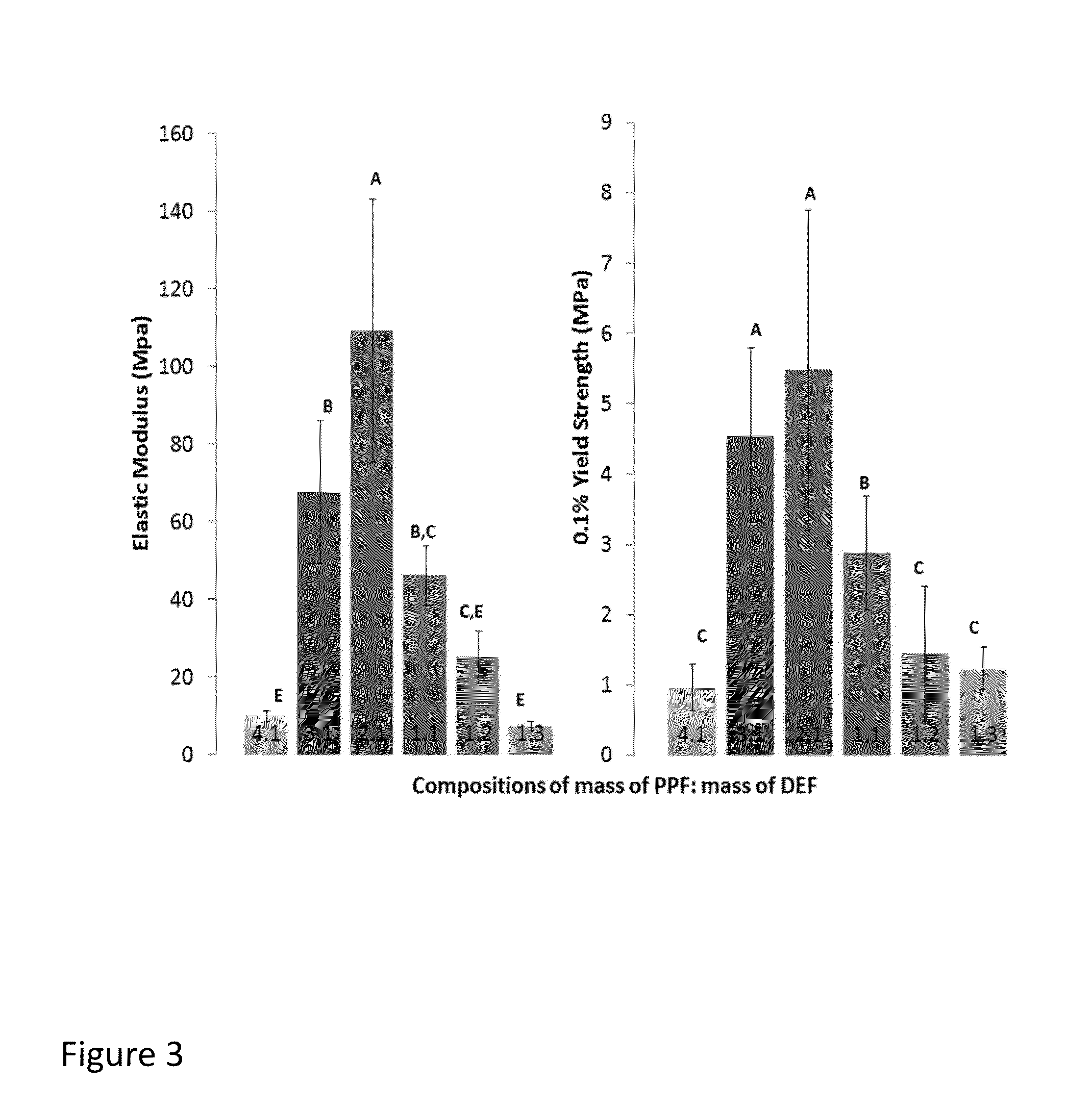

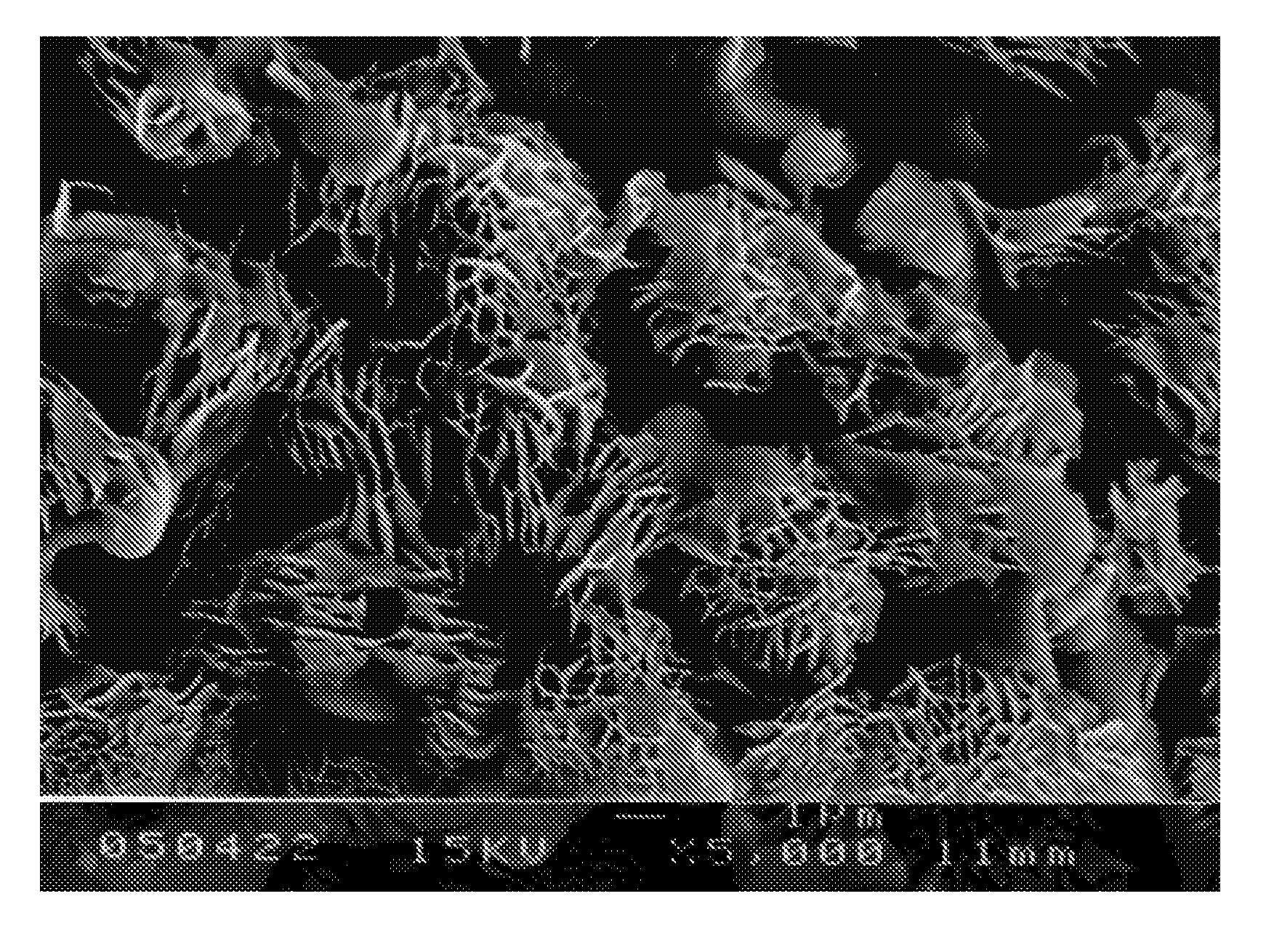

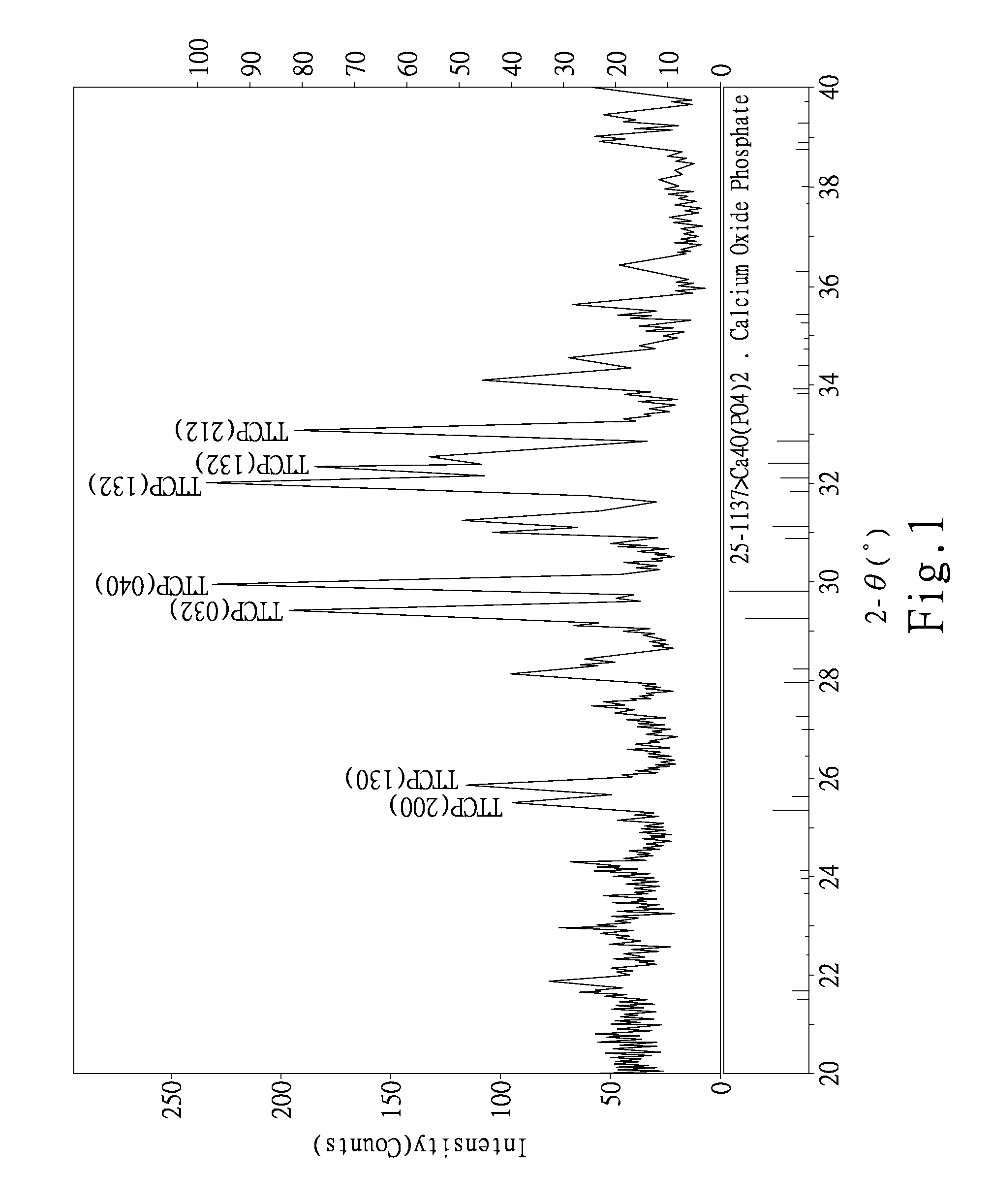

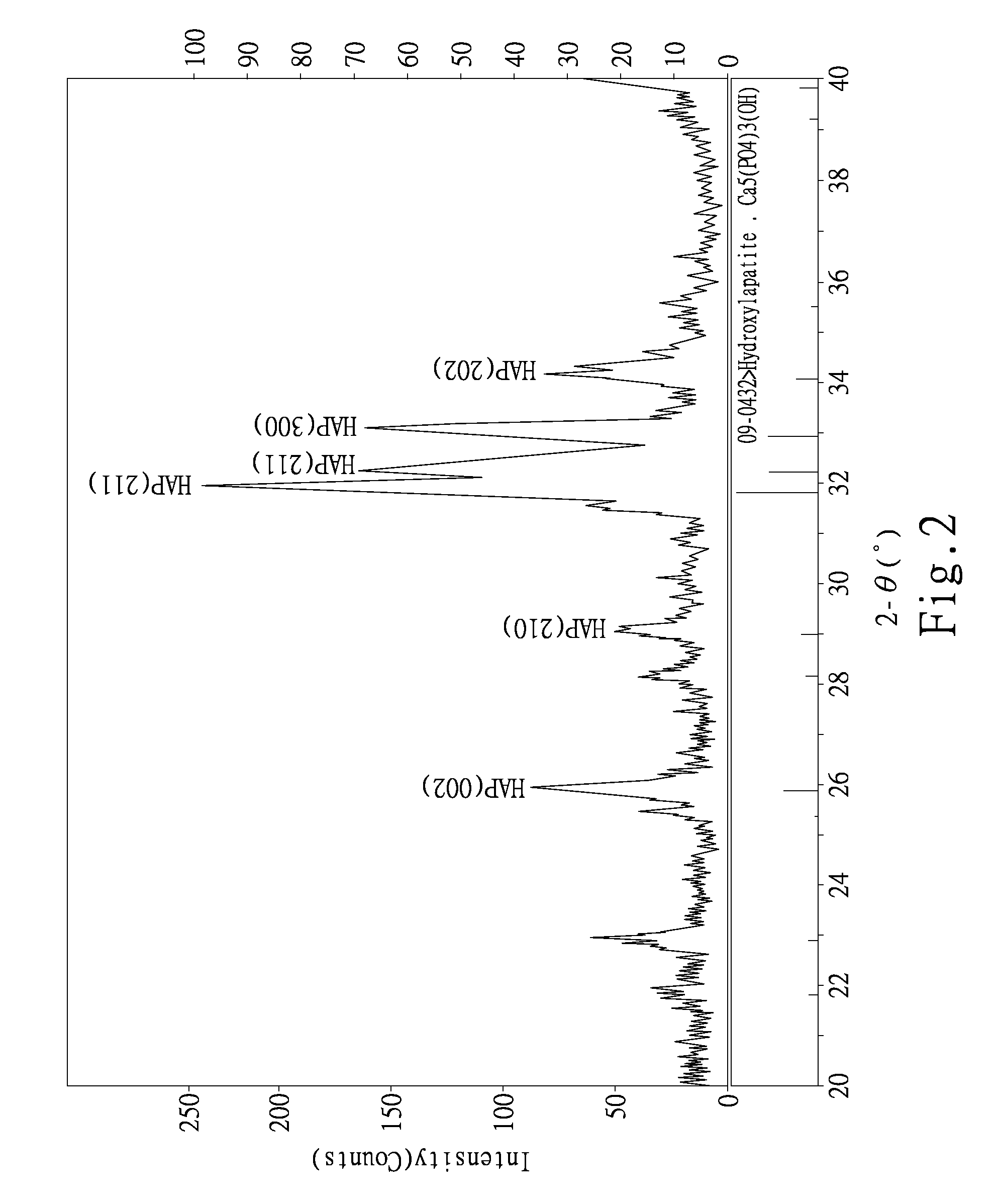

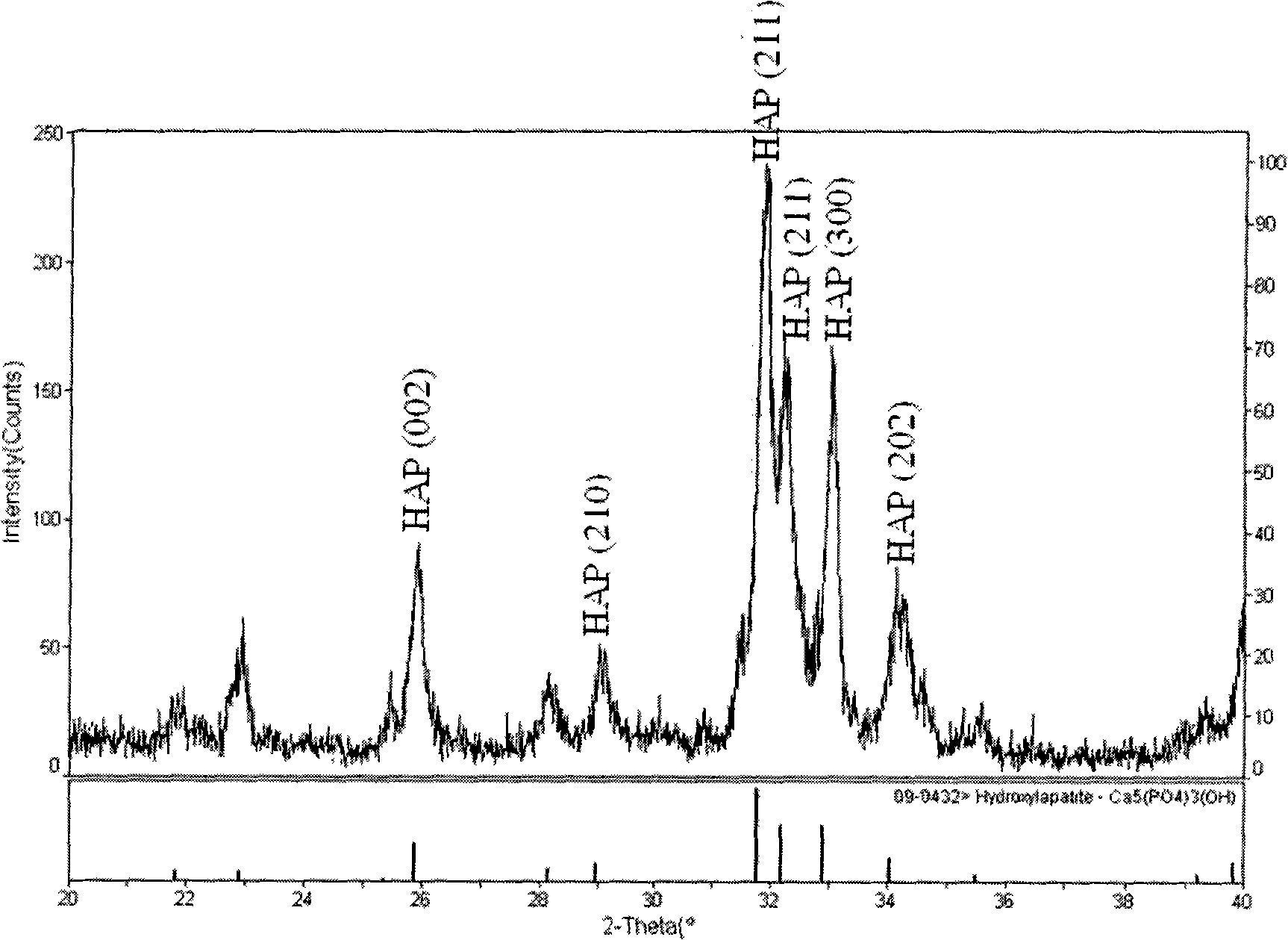

InactiveUS20090036564A1Improve mechanical propertiesGood biocompatibilityImpression capsDentistry preparationsCalcium biphosphateCompressive strength

A bio-degenerable bone cement is made of a mixture of poly (propylene fumarate) (PPF) and a diphasic material of tetra-calcium phosphate (TTCP) / dicalcium phosphate anhydrous (DCPA). The bone cement produced by a manufacturing method is injectable, bio-degenerable and non-penetrable to radioactive rays and features the advantages of a compressive strength close to the strength of bones, a low polymerization temperature, and a high biological compatibility.

Owner:PURZER PHARMA

Adenine-reinforced degradable soft tissue adhesive as well as preparation method and use method thereof

ActiveCN110680951AHigh glass transition temperatureImprove adhesion strengthSurgical adhesivesUltraviolet lightsBiocompatibility

The invention discloses an adenine-reinforced degradable soft tissue adhesive as well as a preparation method and a use method thereof, and the preparation method comprises the following steps: step 1, putting PPF, PPF-DA and Adenine powder into a solvent, and uniformly stirring to obtain a mixture A; step 2, removing the solvent in the mixture A to obtain a mixture B; 3, adding a photoinitiator BAPO solution into the mixture B, and uniformly mixing the materials to obtain a mixture C; and step 4, removing the solvent in the mixture C to obtain the adenine-reinforced degradable soft tissue adhesive. When in use, ultraviolet light is adopted to carry out photocuring on the material. According to the invention, adenine is introduced into a poly propylene fumarate-based material in a dispersive distribution manner, and meanwhile, the bonding performance, degradation performance and biocompatibility of the material are improved. The problems that in the prior art, the adhesion strength between a PPF-based material and soft tissue is low, and application of the PPF-based material to a soft tissue adhesive is limited are solved.

Owner:XI AN JIAOTONG UNIV

Synthesis and characterization of well defined poly(propylene fumarate) and poly(ethylene glycol) block copolymers

In one or more embodiments, the present invention provides a low molecular weight, non-toxic, resorbable poly(ethylene glycol)(PEG)-block-poly(propylene fumarate) (PPF) diblock copolymers and poly(propylene fumarate) (PPF)-block-poly(ethylene glycol)(PEG)-block-poly(propylene fumarate) (PPF) triblock copolymers (and related methods for their making and use) that permits hydration for the formationof such things as hydrogels and has constrained and predictable material properties suitable for 3D printing and drug delivery applications. Using continuous digital light processing (cDLP) hydrogelsthe diblock and triblock copolymers can be photochemically printed from an aqueous solution into structures having a 10-fold increase in elongation at break compared to traditional diethyl fumarate (DEF) based printing. Furthermore, PPF-PEG-PPF triblock hydrogels have also been found in vitro to be biocompatible across a number of engineered MC3T3, NIH3T3, and primary Schwann cells.

Owner:THE UNIVERSITY OF AKRON

Poly-butyl glycol fumaric acid ester-based material for environment-friendly LED packaging adhesive and preparation method of poly-butyl glycol fumaric acid ester-based material

ActiveCN105860908AHigh light transmittanceHigh refractive indexNon-macromolecular adhesive additivesCross-linkPolymer science

The invention provides a poly-butyl glycol fumaric acid ester-based material for an environment-friendly LED packaging adhesive and a preparation method of the poly-butyl glycol fumaric acid ester-based material. A final curing product is a PBF / PPF-DA cross-linking solidified body, namely, a poly-butyl glycol fumaric acid ester / poly-butyl glycol fumaric acid ester diacrylic ester cross-linking solidified body, the solidified product is free of toxicity, the solidification time can be controlled within a relatively short time range by adjusting the lighting intensity and the distance between a light source and a sample, the requirements of LED packaging on the solidification time can be greatly met, and the solidified product is relatively good in light transmittance, refractive index, thermal stability and mechanical property.

Owner:XI AN JIAOTONG UNIV

High-barrier high polymer thin-film material and preparation method thereof

The invention discloses a high-barrier high polymer thin-film material and a preparation method thereof. The high-barrier high polymer thin-film material comprises the following components by weight: 15-30 parts of polyethylene, 15-25 parts of polyvinyl chloride, 2-5 parts of diethyl phthalate, 2-6 parts of polycarbonate, 4-12 parts of polyvinyl alcohol, 3-6 parts of dipropylene glycol dibenzoate, 4-9 parts of poly propylene fumarate, and 3-7 parts of polypropylene glycol adipate. The preparation method comprises the following steps: high-speed mixing, screw rod extruding, film blowing modeling, cooling and the like. The prepared high-barrier high polymer thin-film material has strong airtight performance and high tensile strength, and is convenient to use, and wide in application range.

Owner:苏州凯欧曼新材料科技有限公司

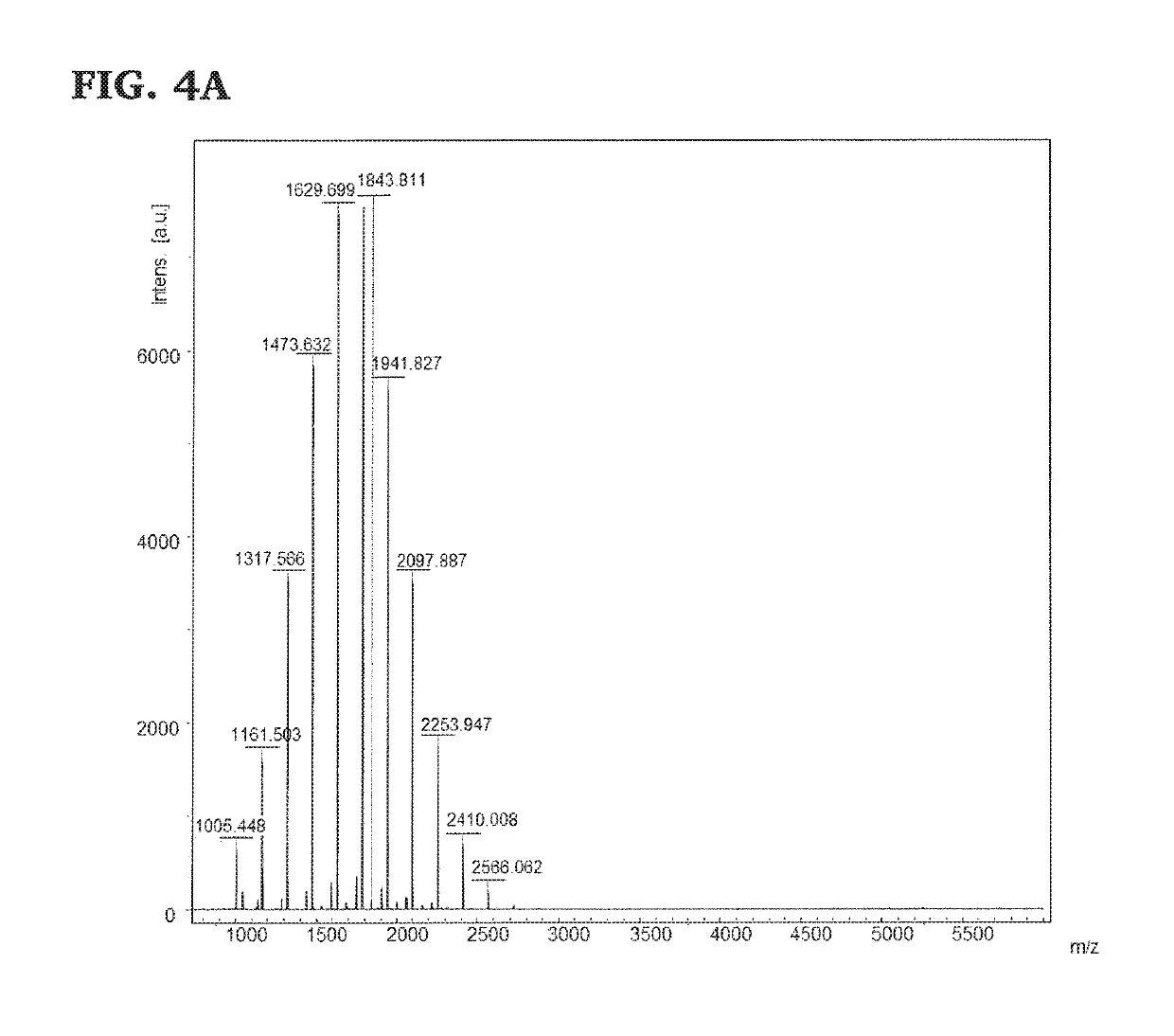

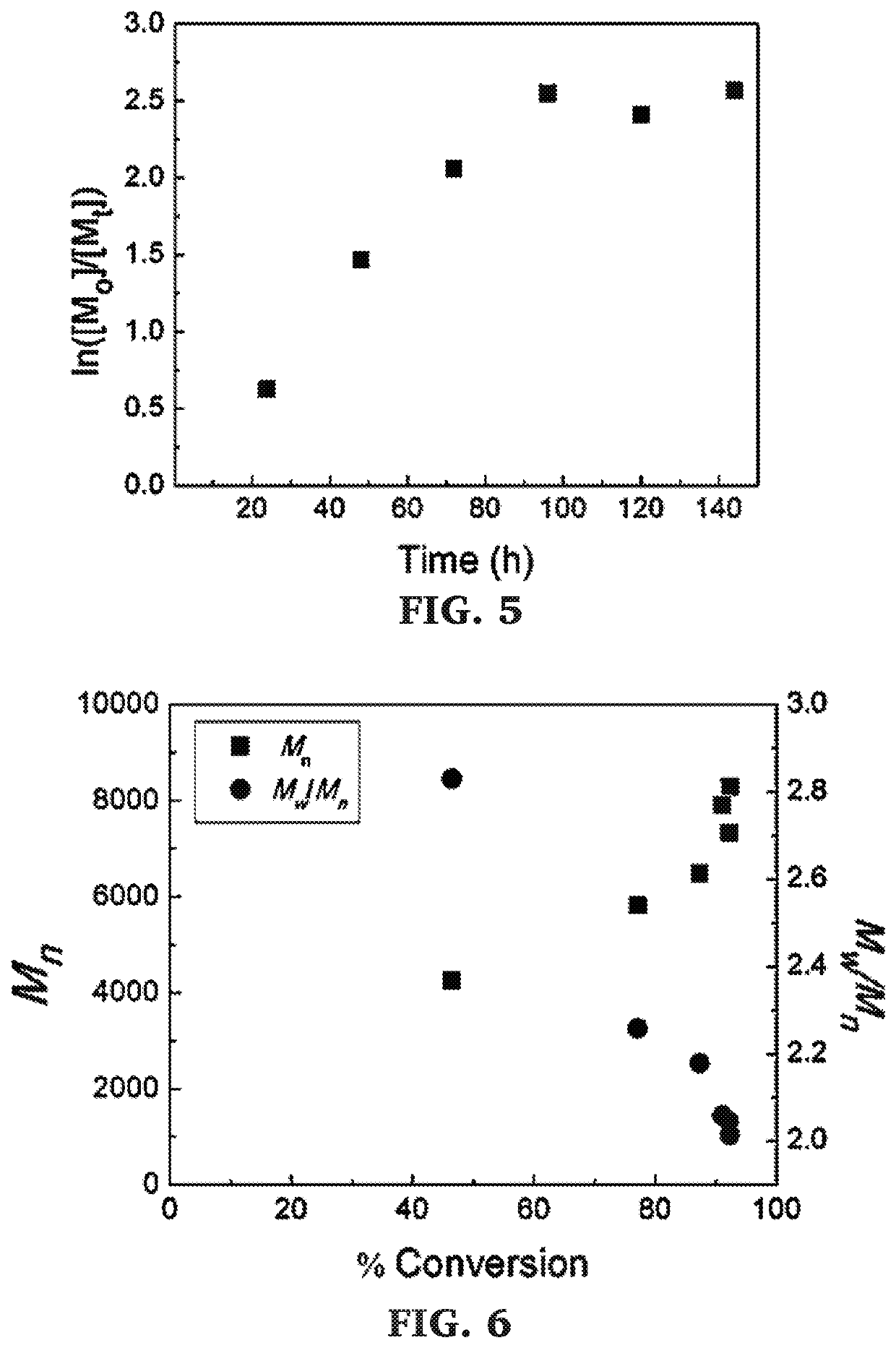

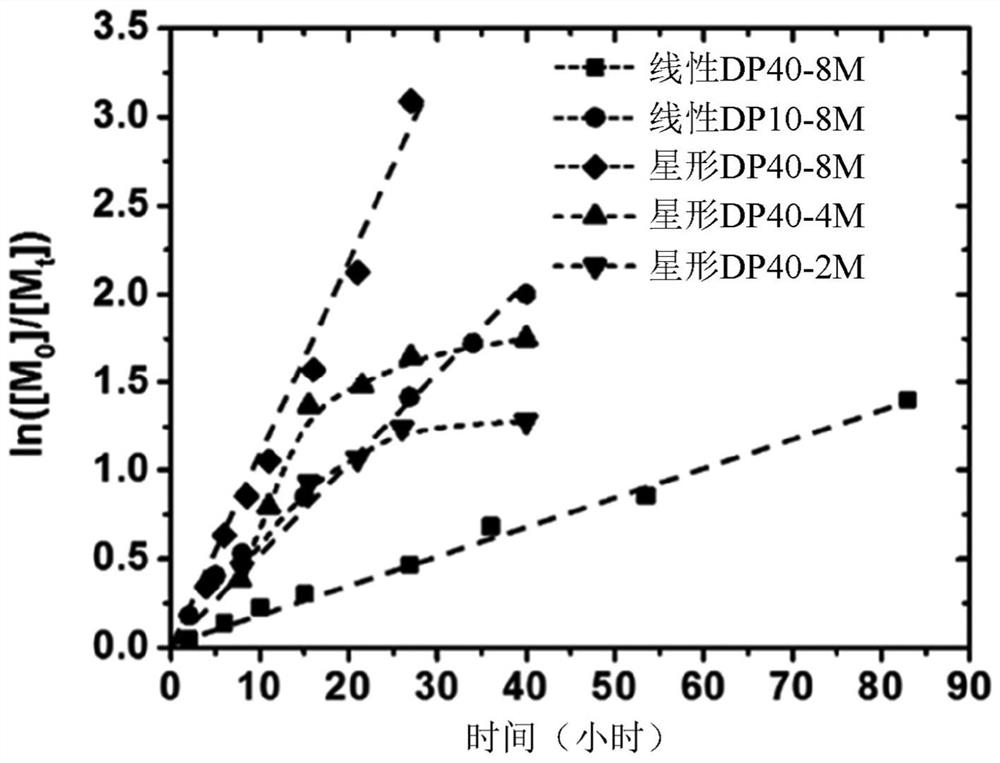

Well-defined degradable poly(propylene fumarate) polymers and scalable methods for the synthesis thereof

ActiveUS10465044B2Constrained and predictable material propertyCheap to makeAdditive manufacturing apparatusProsthesisSynthesis methodsOxygen

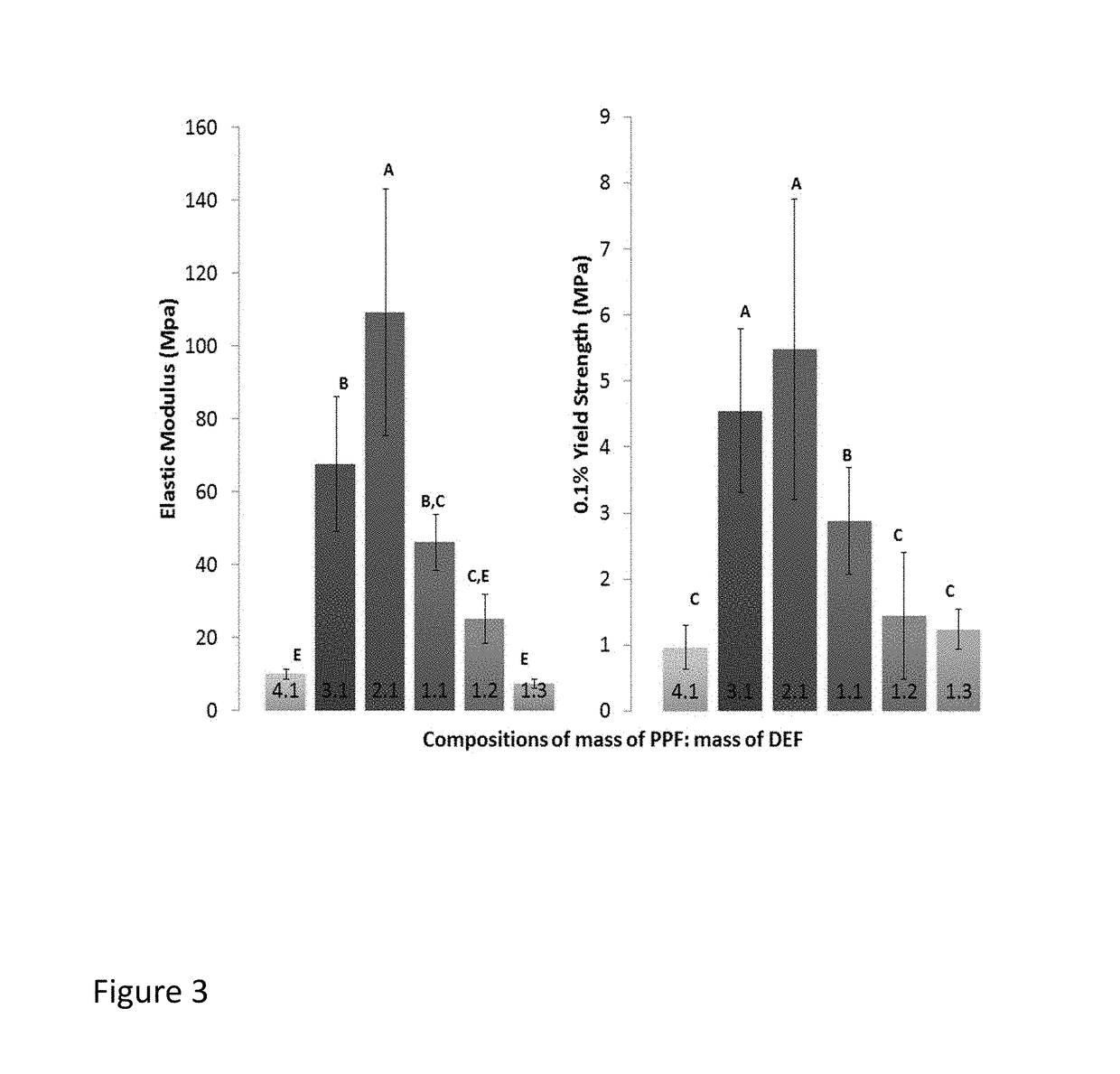

Method for making poly(propylene fumarate) (PPF) polymer made by ring-opening polymerization of propylene oxide and maleic anhydride in the presence of magnesium ethoxide initiator, wherein PPF is specifically designed for us in 3D manufacturing of medical devices. PPF polymers have a number average molecular weight (Mn) of from about 450 Daltons to about 3400 Daltons; a molecular mass distribution (m) of from 1.0 to 2.0; and contains less than 1% w / w of poly(maleic anhydride-co-propylene oxide) polymer chains particularly. PPF polymers are non-toxic, degradable, and resorbable and can be used in tissue scaffolds and medical devices that are implanted within a living organism.

Owner:THE UNIVERSITY OF AKRON +1

Absorbable cervical intervertebral fusion cage and preparation method thereof

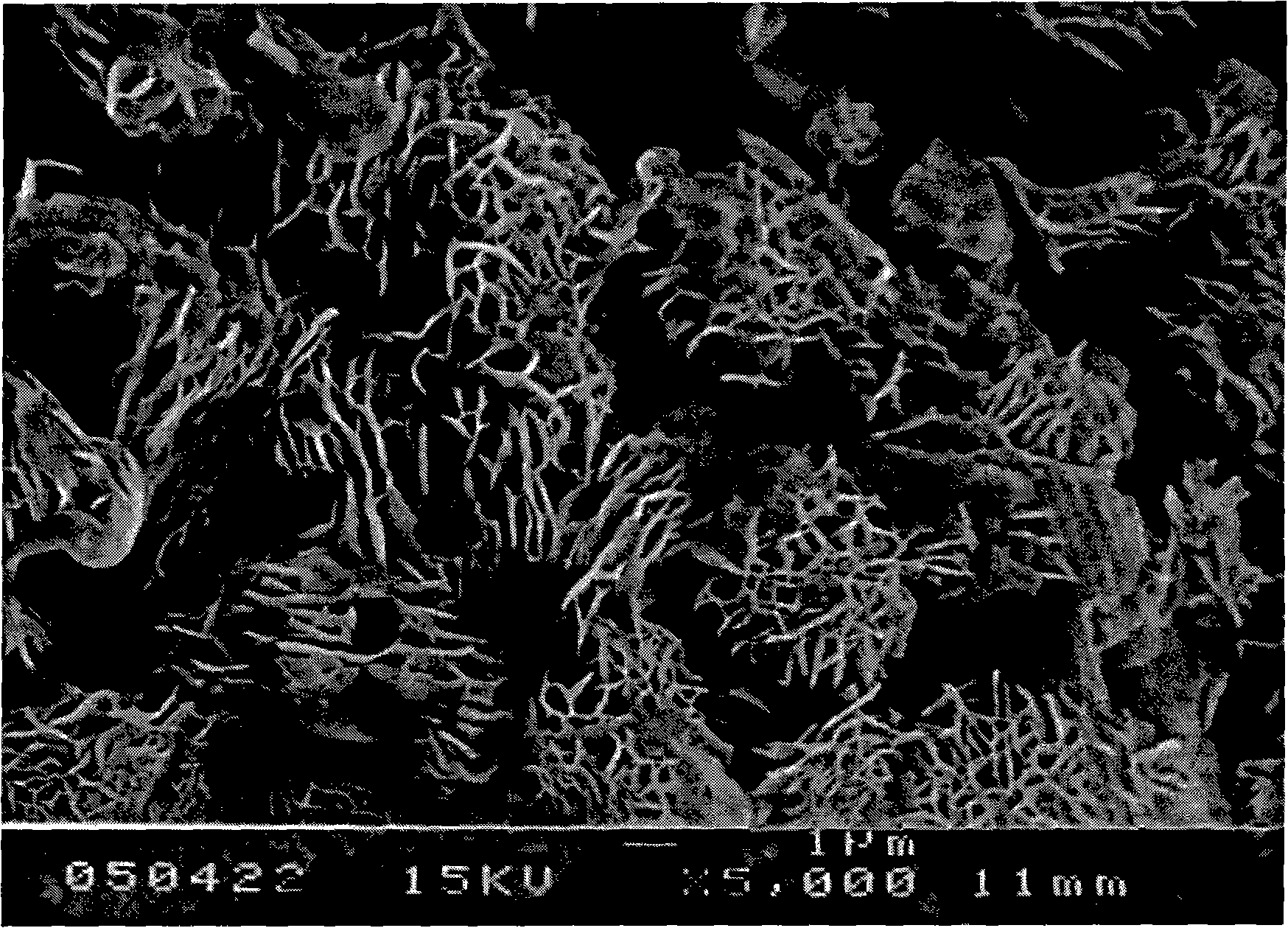

InactiveCN108309517AImprove biological activityNo stress shieldingSpinal implantsX-rayPolymethyl methacrylate

The invention discloses an absorbable cervical intervertebral fusion cage and a preparation method thereof. The fusion cage is a bionic intervertebral fusion cage made from nano-hydroxyapatite and poly propylene fumarate polymer composites; the preparation method of the fusion cage comprises the steps that a PPF / DEF mixed solution is prepared in proportion, BAPO is added, then the nano-hydroxyapatite is added, the prepared mixed solution is injected into a fusion cage polymethyl methacrylate mould, and is prepared into a fusion cage prototype after ultraviolet irradiation polymerization, and finally punching and teeth making are carried out on the fusion cage prototype. The fusion cage has bone induction activity and absorbability in vivo, can be degraded in vivo gradually until the humanbody adsorbs the fusion cage completely, the fusion situation after surgery can be observed through X ray, and the fusion cage is applied to anterior cervical intervertebral fusion fixed cases. The absorbable cervical intervertebral fusion cage and the preparation method thereof have the advantages that the preparation method is simple, a better interface combination between inorganic components and high polymer materials can be ensured, the mechanical strength of the prepared polymer is higher than that of a thermo-crosslinking method, and the mechanical strength and elasticity modulus of thepolymer are more close to cancellous bone of the human body.

Owner:中国人民解放军新疆军区总医院

Bone cement with biological decomposability and preparation method thereof

The invention relates to a bone cement with biological decomposability and a preparation method thereof. Macromolecular poly propylene fumarate (PPF) and the double-phase material of tracalcium phosphate (TTCP) / anhydrous calcium hydrophosphate (DCPA) are mixed to derive the bone cement material with biological decomposability. The bone cement material derived by the preparation method of the invention has the advantages of syringeability, biological decomposability, radiation imperviousness, compressive strength closer to bone strength, lower polymeric temperature, high biological compatibility, etc.

Owner:PURZER PHARMA

Block copolymers of lactones and poly(propylene fumarate)

PendingUS20200231760A1Printable resinImprove suppression propertiesAdditive manufacturing apparatusProsthesisPolymer scienceMeth-

In various embodiments, the present invention provides well-defined biodegradable poly(lactone-b-propylene fumarate) diblock and triblock polymers formed using a novel one-pot, scalable ring-opening block-order copolymerization (ROBOCOP) technique that utilizes magnesium 2,6-di-tert-butyl-4-methylphenoxide (Mg(BHT)2(THF)2) to “switch” from the ROP of cyclic esters to the ROCOP of maleic anhydride (MAn) and propylene oxide (PO) to produce PPF based block copolymers for application in additive manufacturing and patient specific regenerative medicine. These block copolymers are fully resorbable and can be photochemically crosslinked in a number of applications, including 3D printing. By adding the lactone block to the PPF polymer, the viscosity of the resulting block copolymer at working temperatures can be precisely controlled and the quantity of the reactive diluent in printable resins can be reduced or eliminated.

Owner:THE UNIVERSITY OF AKRON

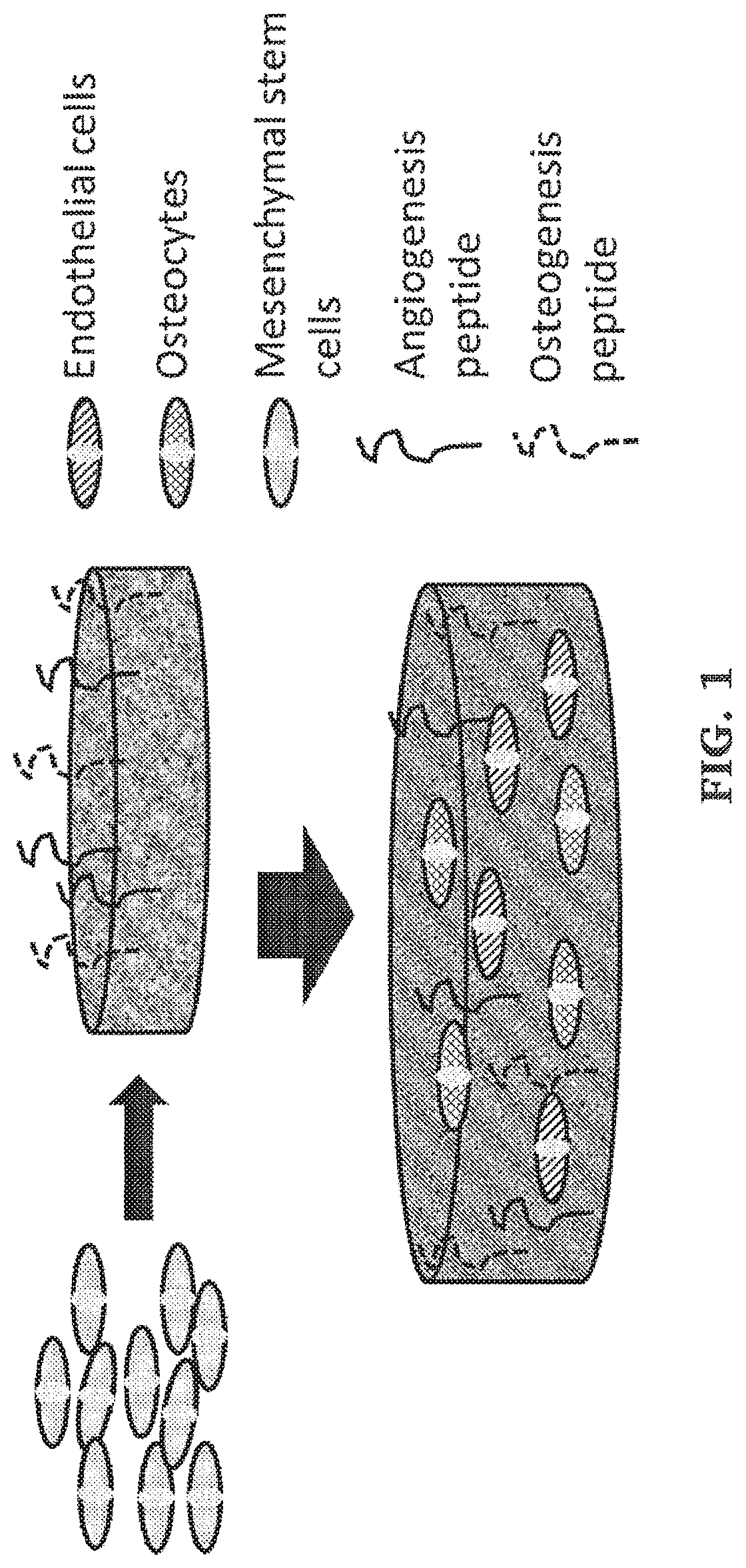

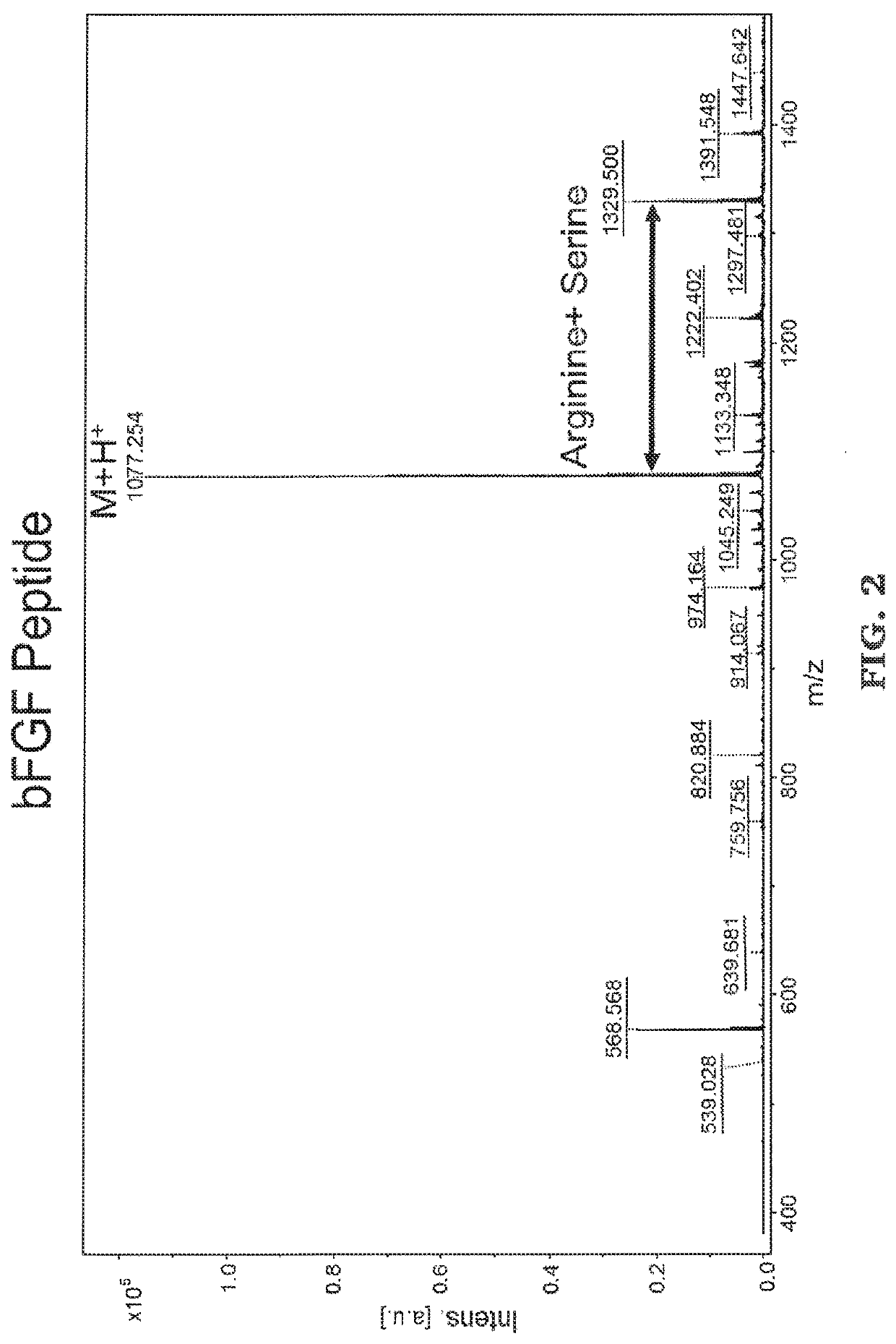

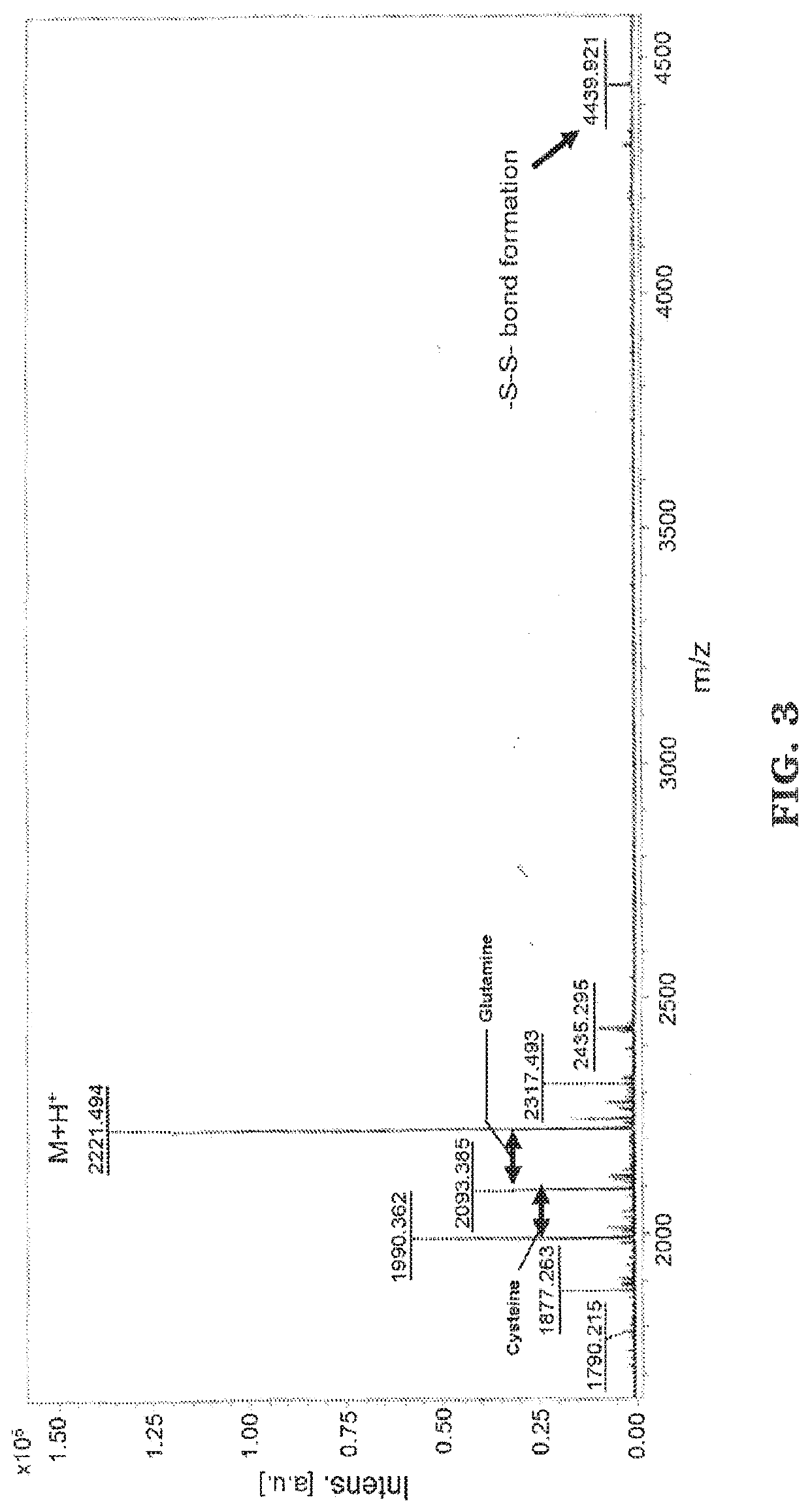

Post-3d printing functionalization of polymer scaffolds for enhanced bioactivity

In various aspects, the present invention is directed to novel bioactive peptide loaded poly(propylene fumarate) (PPF) tissue scaffolds and related methods for their making and use. In various embodiments, these bioactive peptide loaded poly(propylene fumarate) tissue scaffolds are formed by forming a PPF structure or matrix using photochemical 3-D printing techniques and then loading that printed PPF structure or matrix with a bioactive peptides or other bioactive compounds that have, or have been functionalized to have, a thiol functional group at or near its terminus. The thiol groups on the bioactive peptides or other compound will react with exposed alkene functional groups on the PPF polymer matrix via a thiol-ene “click” reaction, thereby binding these bioactive peptides or other compounds to the tissue scaffolds. The bioactive peptide loaded PPF tissue scaffolds of the present invention are particularly useful in repairing bone defects.

Owner:THE UNIVERSITY OF AKRON

Preparation method of high-compatibility magnesium-based biocomposite material

InactiveCN108210993AIncrease free energyImprove hydrophilicityAnodisationPharmaceutical delivery mechanismHigh cellFree energies

The invention relates to a preparation method of a high-compatibility magnesium-based biocomposite material, and belongs to the technical field of magnesium alloy materials. According to the method, poly (propylene fumarate) is used as a raw material and as a coating porous gel to modify the surface of a magnesium alloy material. Since the porous gel is used as a carrier, a network gel structure can be effectively formed, cell adsorption specific surface area is enlarged, and a large number of cells can be accommodated, so that the carrier has a high cell capacity, and the porous structure effectively adsorbs phosphorylcholine. The phosphorylcholine is used for surface modification to significantly enhance the surface free energy and hydrophilicity of the magnesium alloy material and effectively improve the compatibility of the magnesium-based biomaterial with the cells.

Owner:王建东

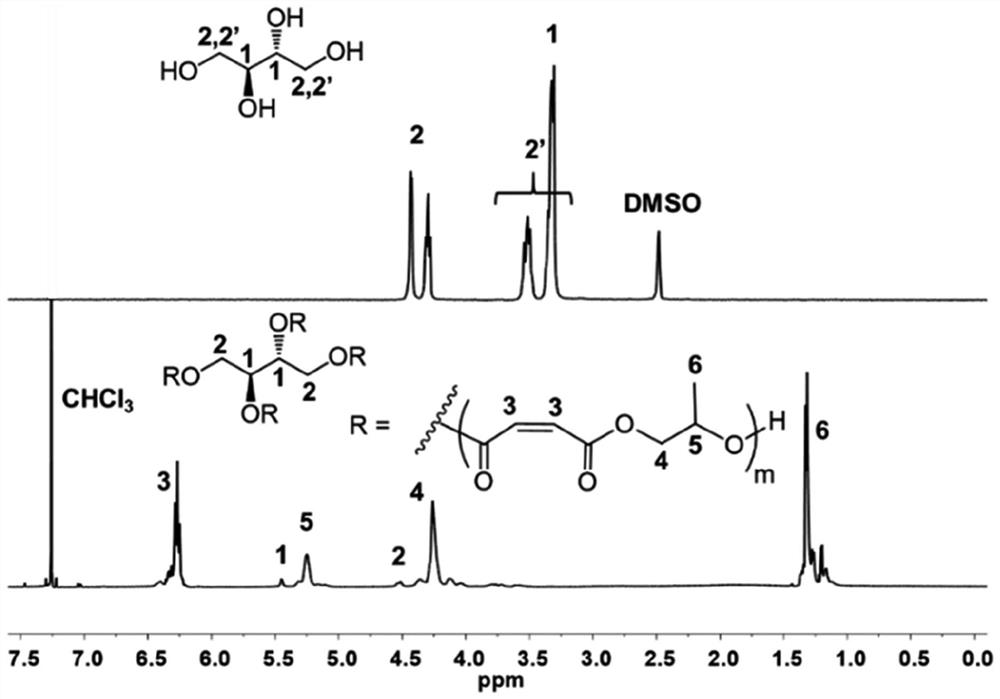

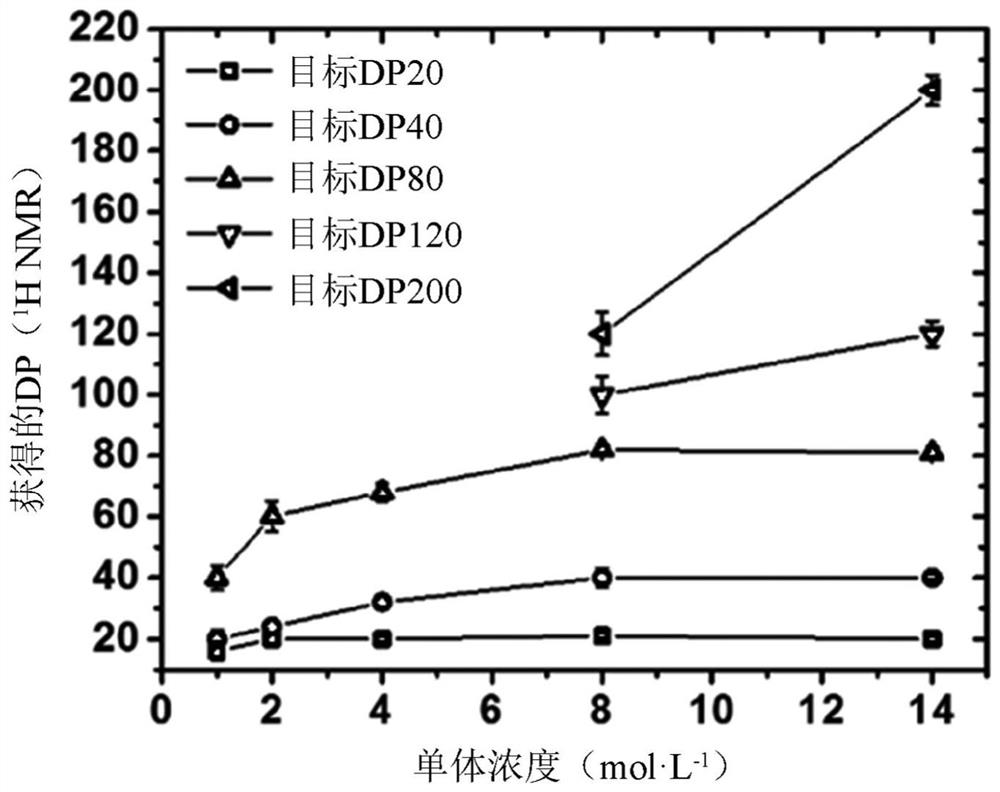

Star-shaped poly(propylene fumarate) copolymers for 3D printing applications

Owner:THE UNIVERSITY OF AKRON

Polymer-tissue hybrid biomaterials and methods of making and using same

Provided are hybrid biomaterials comprising one or more layers of cross-linked poly(propylene fumarate) and / or cross-linked copolymer comprising a plurality of cross-linked propylene fumarate moieties. The layers may further comprise a plurality of microparticles, a plurality of micropores, or both a plurality of microparticles and a plurality of micropores encapsulated within the cross-linked poly(propylene fumarate) and / or cross-linked copolymer comprising a plurality of cross-linked propylene fumarate moieties. One of the layers is disposed on a compliant matrix dense tissue substrate (e.g., a pericardium tissue substrate). The hybrid biomaterials can be used, for example, in method of repairing tissue defects.

Owner:UNIV OF MARYLAND

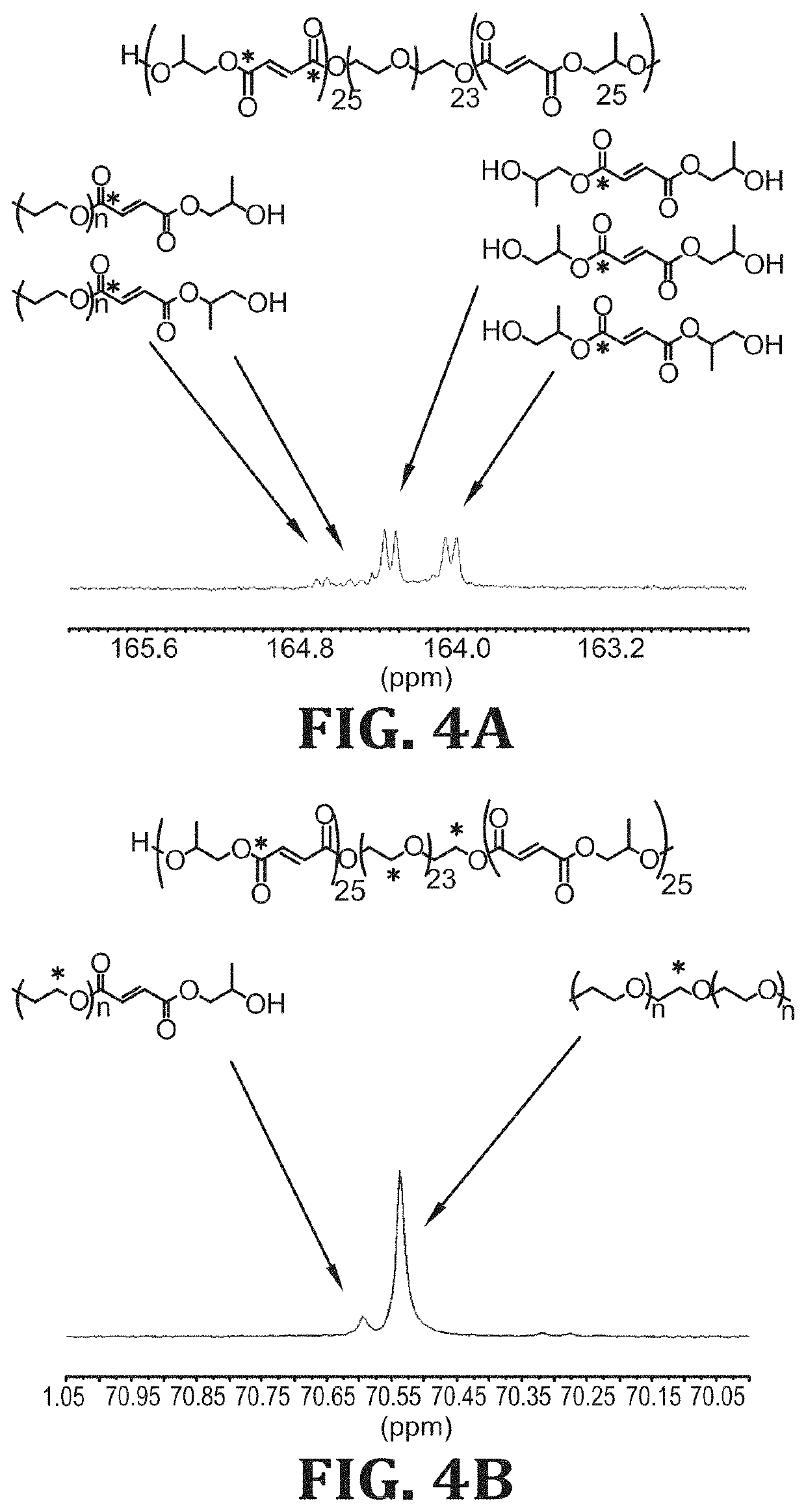

Synthesis and characterization of well defined poly(propylene fumarate) and poly (ethylene glycol) block copolymers

In one or more embodiments, the present invention provides a low molecular weight, non-toxic, resorbable poly(ethylene glycol) (PEG)-block-poly(propylene fumarate) (PPF) diblock copolymers and poly(propylene fumarate) (PPF)-block-poly(ethylene glycol) (PEG)-block-poly(propylene fumarate) (PPF) triblock copolymers (and related methods for their making and use) that permits hydration for the formation of such things as hydrogels and has constrained and predictable material properties suitable for 3D printing and drug delivery applications. Using continuous digital light processing (cDLP) hydrogels the diblock and triblock copolymers can be photochemically printed from an aqueous solution into structures having a 10-fold increase in elongation at break compared to traditional diethyl fumarate (DEF) based printing. Furthermore, PPF-PEG-PPF triblock hydrogels have also been found in vitro to be biocompatible across a number of engineered MC3T3, NIH3T3, and primary Schwann cells.

Owner:THE UNIVERSITY OF AKRON

A kind of biodegradable unsaturated polyurethane material and preparation method thereof

Owner:ZHEJIANG UNIV

A kind of adenine enhanced degradable soft tissue adhesive and its preparation and use method

ActiveCN110680951BReduce the use effectWell mixedSurgical adhesivesPolymer scienceUltraviolet lights

Owner:XI AN JIAOTONG UNIV

Poly(propylene fumarate)-based copolymers for 3D printing applications

ActiveCN113039234AAdditive manufacturing apparatusAdditive manufacturing with liquidsPolymer scienceSuccinic anhydride

In various embodiments, the present invention is directed to a PPF-based copolymer for 3D printing applications and methods for its making and use. These copolymers have a viscosity in a printable viscosity range and allow light transmittance at curing wavelengths. In various embodiments, a lower viscosity copolymers are obtained by substitution of a portion of maleic anhydride with succinic anhydride and then forming a poly(propylene fumarate-co-succinate) copolymer by the copolymerization of maleic anhydride and succinic anhydride with propylene oxide via Mg(BHT)2(THF)2 catalyzed ring opening copolymerization (ROCOP). Because of their lower viscosities, these copolymers require less, if any, diethyl fumarate (DEF) to prepare the 3D printing resin, while the mechanical properties can still be adjusted as with a PPF polymer prepared without the succinic anhydride.

Owner:THE UNIVERSITY OF AKRON

Polybutylene fumarate-based material for environment-friendly LED encapsulation glue and preparation method thereof

ActiveCN105860908BHigh light transmittanceHigh refractive indexNon-macromolecular adhesive additivesCross-linkPolymer science

The invention provides a poly-butyl glycol fumaric acid ester-based material for an environment-friendly LED packaging adhesive and a preparation method of the poly-butyl glycol fumaric acid ester-based material. A final curing product is a PBF / PPF-DA cross-linking solidified body, namely, a poly-butyl glycol fumaric acid ester / poly-butyl glycol fumaric acid ester diacrylic ester cross-linking solidified body, the solidified product is free of toxicity, the solidification time can be controlled within a relatively short time range by adjusting the lighting intensity and the distance between a light source and a sample, the requirements of LED packaging on the solidification time can be greatly met, and the solidified product is relatively good in light transmittance, refractive index, thermal stability and mechanical property.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com