Degradable polyurethane material with active oxygen responsiveness and preparation method of degradable polyurethane material

A polyurethane material, responsive technology, applied in medical science, prosthesis, tissue regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Active oxygen responsive degradable polyurethane material (PCL / HDI 2:1), including soft segment and hard segment, the soft segment is polyε-caprolactone diol with a number average molecular weight of 2000, and the hard segment The segment is an aliphatic diisocyanate HDI and a ROS-responsive ketal thiol diamine chain extender.

[0036] has the following structure

[0037]

[0038] Its preparation includes the following steps:

[0039] Take 2.0213g of PCL with a number average molecular weight of 2000 and add it to a dry three-necked flask. Calculate the molar number of hydroxyl groups in the PCL to be 2.0213mmol. Distill under reduced pressure at 110°C for 1 hour to remove residual moisture and blow in nitrogen. After cooling down to 70°C, add 20mL of anhydrous N,N-dimethylformamide solvent to dissolve, add 0.3320g HDI, 0.004mmol catalyst dibutyltin dilaurate, and react at 70°C under nitrogen protection for 3h. Take 0.192g of the small molecule thioketaldiamine, di...

Embodiment 2

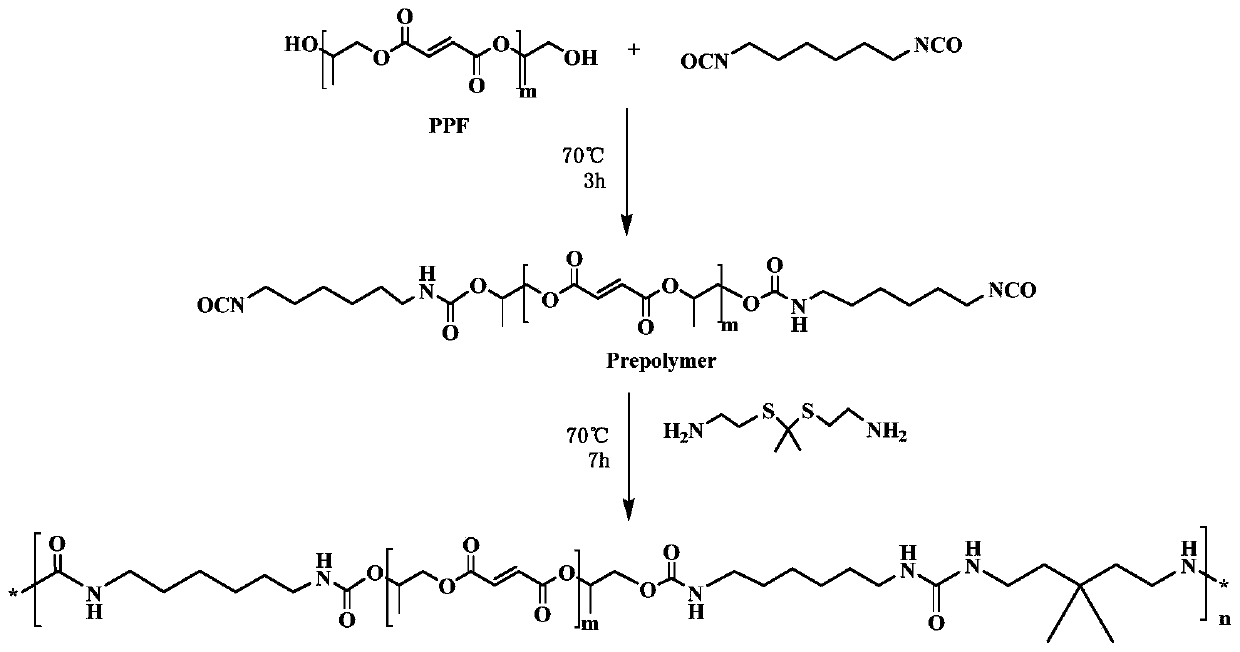

[0043] Active oxygen responsive degradable polyurethane material (PPF / HDI 2:1), including a soft segment and a hard segment, the soft segment is poly(trimethylene fumarate PPF) with a molecular weight of 1000, and the hard segment is fat Family diisocyanate HDI and ROS responsive ketal thiol diamine chain extender.

[0044] has the following structure:

[0045]

[0046] Its preparation includes the following steps:

[0047] Take 2.0368g of PPF with a number-average molecular weight of 1000 and add it to a dry three-necked flask. The calculated number of hydroxyl groups in PPF is 3.54mmol. Distill under reduced pressure at 110°C for 1h to remove residual moisture, and then blow in nitrogen. After cooling down to 70°C, add 20mL of anhydrous N,N-dimethylformamide solvent to dissolve, add 0.5950g HDI, 0.007mmol catalyst dibutyltin dilaurate, and react at 70°C under nitrogen protection for 3h. Take 0.3430g of thioketaldiamine small molecule, dissolve it in 3.5mL of anhydrous N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com