Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Malleable iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Malleable iron is cast as white iron, the structure being a metastable carbide in a pearlitic matrix. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Carbon agglomerates into small roughly spherical aggregates of graphite leaving a matrix of ferrite or pearlite according to the exact heat treatment used. Three basic types of malleable iron are recognized within the casting industry: blackheart malleable iron, whiteheart malleable iron and pearlitic malleable iron.

Corrosion-resistant malleable nodular cast iron material and preparation method thereof

InactiveCN102051548AImprove the strengthening and toughening effectImprove toughnessMalleable ironCorrosion

The invention provides a corrosion-resistant malleable nodular cast iron material and a preparation method thereof. The corrosion-resistant malleable nodular cast iron material has good performance; and the preparation method is simple in process, low in production cost and suitable for industrial production. Malleable nodular cast iron is utilized as a substrate for the corrosion-resistant malleable nodular cast iron material, wherein metal wire clusters formed by mild steel wires and iron wires are distributed on the substrate; the diameter of the mild steel wires and the diameter of the iron wires are 1-2mm; the mild steel wires and the iron wires account for 5-40% of the material by volume; and the length of the mild steel wires in the material is equivalent to that of the iron wires in the material.

Owner:金湖中博物联网科技有限公司

Malleable iron-chromium-aluminum ferritic electrothermal alloy

The invention discloses a malleable iron-chromium-aluminum ferritic electrothermal alloy, which comprises the following chemical compositions in percentage by mass: less than or equal to 0.01 percent of C, less than or equal to 0.05 percent of N, less than or equal to 0.1 percent of Si, less than or equal to 0.08 percent of Mn, 21.5 to 31 percent of Cr, less than or equal to 3.0 to 6.0 percent of Al, less than or equal to 0.030 percent of P, less than or equal to 0.030 percent of S, and the balance of Fe and inevitable impurities. The malleable iron-chromium-aluminum ferritic electrothermal alloy not only has excellent corrosion resistance, but also has good toughness, lower cost than a nickel-chromium electric stove wire, service temperature 300 DEG C higher than the nickel-chromium electric stove wire and long service life.

Owner:JIANGSU XIHU SPECIAL STEEL

As-cast malleable cast iron cylinder sleeve produced through centrifugal casting and production process of as-cast malleable cast iron cylinder sleeve

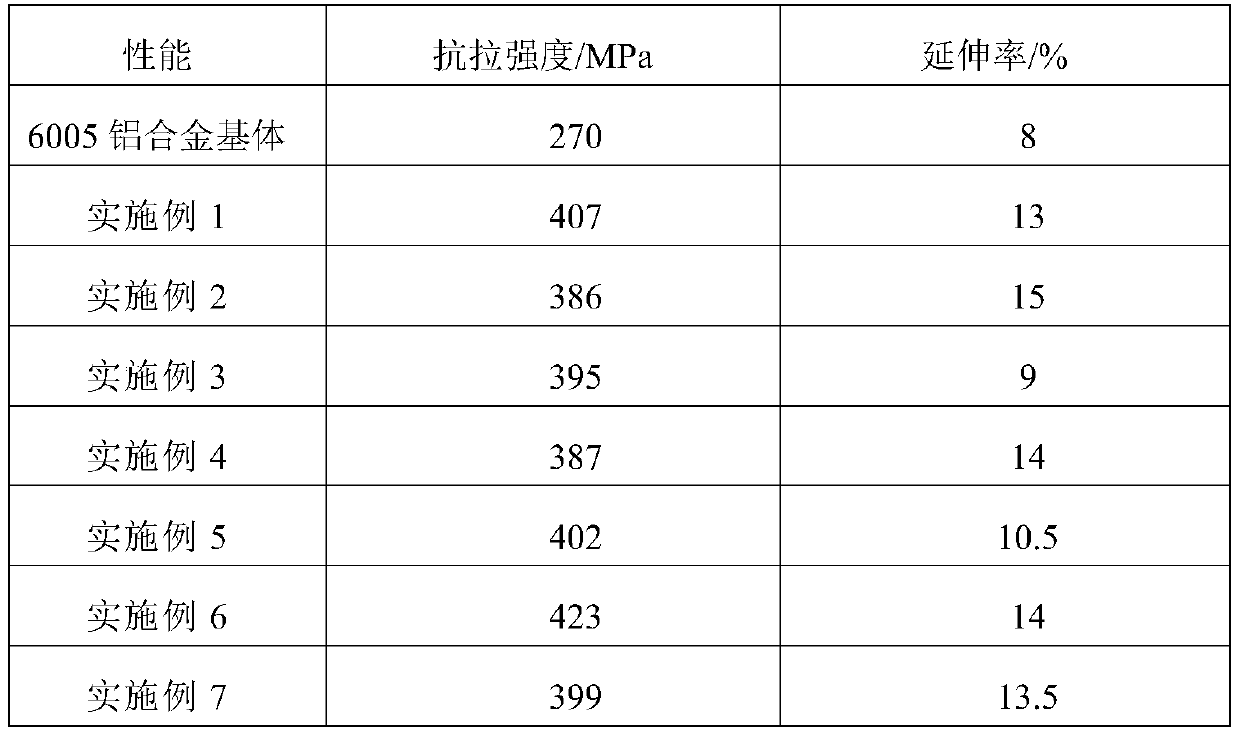

ActiveCN105401063AHigh tensile strengthHigh elongationFurnace typesHeat treatment furnacesChemical compositionManganese

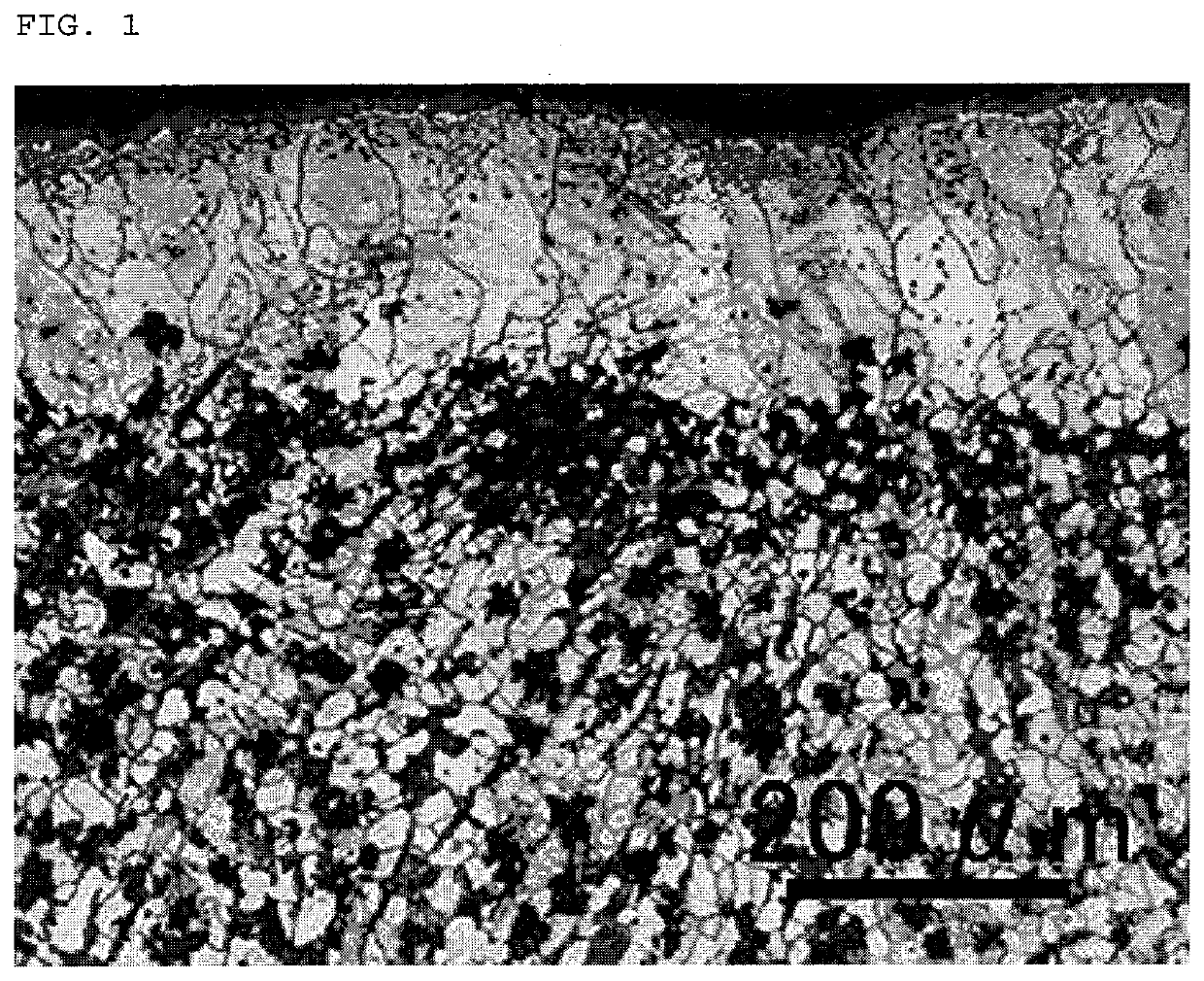

The invention relates to an as-cast malleable cast iron cylinder sleeve produced through centrifugal casting and a production process of the as-cast malleable cast iron cylinder sleeve. The as-cast malleable cast iron cylinder sleeve comprises the following chemical compositions in percent by weight: 2.7-3.2 percent of C, 1.8-2.2 percent of Si, more than 0 percent and less than 0.1 percent of P, more than 0.03 percent and less than 0.06 percent of S, 0.3-0.8 percent of Mn, 0.005-0.01 percent of B, 1.5-1.7 percent of Cu, 0.06-0.08 percent of Bi, 0.06-0.08 percent of rare earth, 0.002-0.004 percent of Al, and the balance of Fe. The metallographic phases of the cylinder sleeve adopt bulk graphite, more than 95% of pearlite and a small amount of ferrite. The cylinder sleeve is 500 MPa above in tensile strength, is larger than 230 HB in hardness, is larger than 2.0% in elongation, and has the advantages of short production cycle, low cost, high elongation, high tensile strength, and good abrasion resistance.

Owner:ZYNP GRP

Non-carcinogenic and non-sensitive metal Chinese pan

The invention relates to a non-carcinogenic and non-sensitive metal Chinese pan, which belongs to the technical field of metallography and cancer pathology, is applicable to cooling utensils, and is uniquely characterized in that the Chinese pan can collide with a truner and is operated in a wearing way. The World Health Organization and the cancer pathology prove that chromium and nickel are carcinogenic substances to the respiratory tract and are sensitive to a human body, and nickel is a first class carcinogenic substance. The Chinese pan is manufactured by low-carbon steel or low-carbon gray pig iron which does not contain stainless steel and contains chromium and nickel, malleable cast iron and spheroidal graphite cast iron, and can be assembled into an integrated structure by a plurality of stamping parts by means of forging, stamping, calendaring, casting, precision casting and welding when a Chinese pan body and two lug handles are made into a metal intergraded type, and the surface of the Chinese pan is covered by a layer of blue and black compact oxidation film by a blueing technology. Even if metal pan powder ground from the bottom in the Chinese pan enters into cooked food and is absorbed by the human body when vegetable is fired, the human body suffers from no nocuity and side effects, therefore, the potential carcinogenic and sensitive danger since chromium and nickel are absorbed by the human body to circulate in the human body along with blood when a stainless steel pan is used is eliminated. The Chinese pan is more attractive in appearance due to the blue and black compact oxidation film which is covered on the surface of the pan.

Owner:马兆瑞

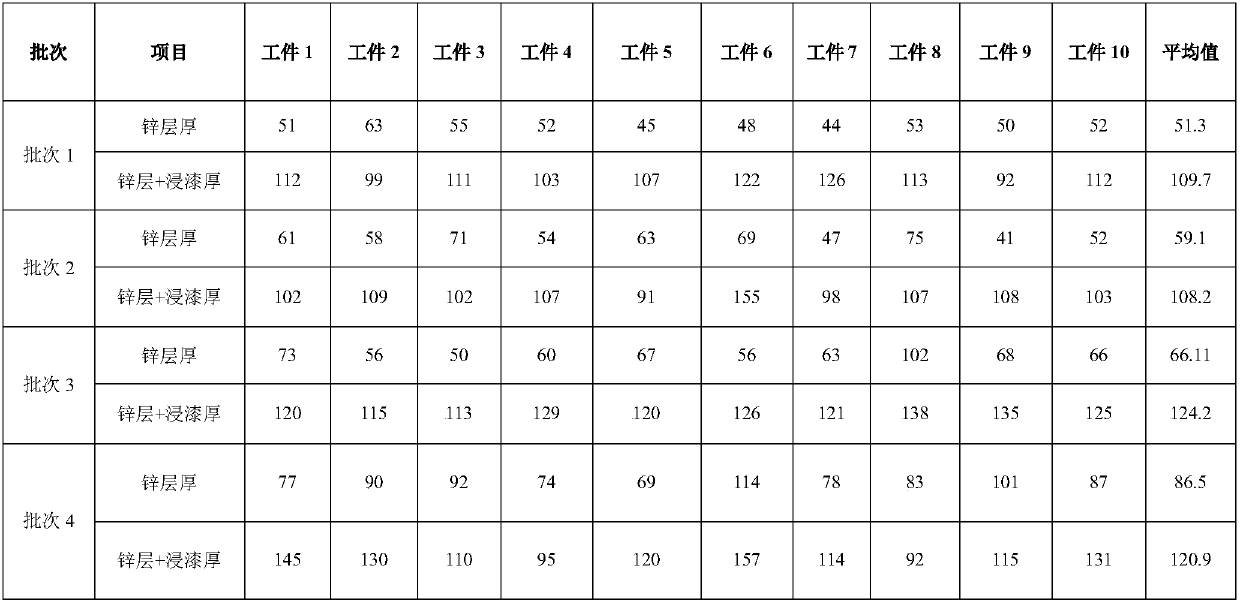

Method for reducing silicon reactivity of hot-dip galvanization of malleable cast iron

ActiveCN109750244AReduce thicknessImprove uniformityHot-dipping/immersion processesSurface engineeringAlloy

The invention belongs to the field of metal surface engineering, and particularly relates to a method for reducing the silicon reactivity of hot-dip galvanization of the malleable cast iron. An aqueous hydrogen peroxide solution with concentration of 25-35% is adopted to process the surface of the malleable cast iron, activity of silicon is effectively reduced, and then hot-dip galvanization is conducted in Zn-0.05wt.% Al alloy liquid at 450-570DEG C. The galvanization can be lowered, thickness of a clad layer of the malleable cast iron can be effectively reduced, and thickness uniformity of the clad layer of the malleable cast iron is obviously improved.

Owner:CHANGZHOU UNIV

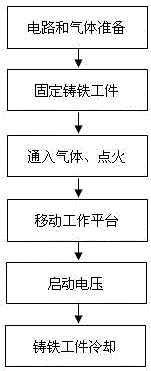

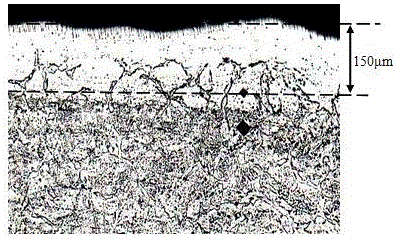

Surface modification method of cast iron

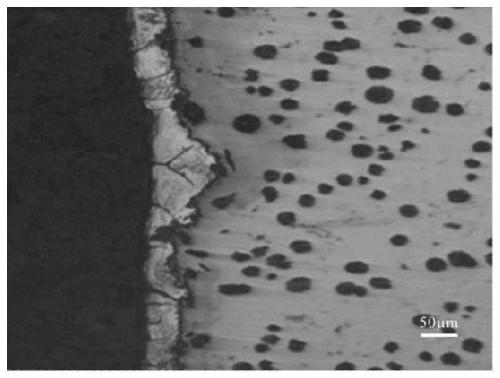

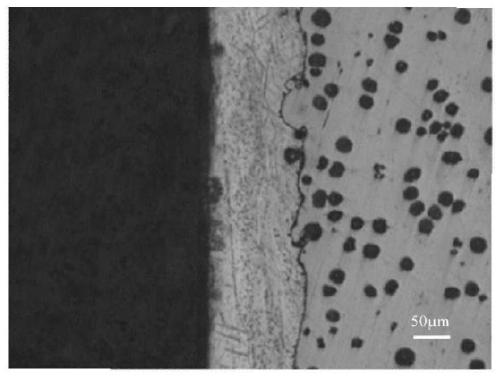

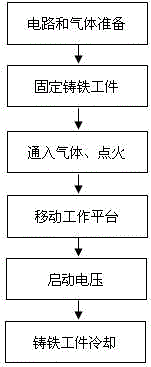

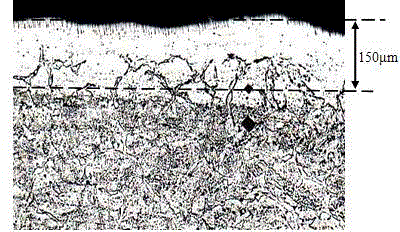

The invention relates to a surface modification method of cast iron, particularly a novel cast iron material surface modification technique by using electric explosion, gaseous detonation and plasma energy superposition, which performs modification treatment on the cast iron material surface by using high energy superposition. The method has the characteristics of one or two or more of the three surface modification techniques (plasma surface modification, gaseous detonation and electric explosion), can implement treatment in an atmospheric environment, has the advantages of low cost and high treatment efficiency, can form a 70-150-mu m-thick enhanced modified layer on the surface of the cast iron part, and can enhance the wearability, corrosion resistance and service life of the cast iron part by 1-6 times. The method is suitable for surface modification treatment of gray cast iron, malleable cast iron, nodular cast iron, vermicular cast iron and alloy cast iron parts, and can be widely used in the fields of mechanical industry, aviation manufacturing and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Molding sand for wet core during malleable iron pipe fitting casting

InactiveCN110479951AImprove wet compressive strengthImprove breathabilityFoundry mouldsFoundry coresPipe fittingReusability

The invention relates to the technical field of casting, in particular to molding sand suitable for a wet core during malleable iron pipe fitting casting. The molding sand is prepared from the following components of, in percentage by mass, 45%-55% of old sand, 35%-45% of fresh sand, 5%-8% of bentonite, 0.1%-0.4% of starch, 0.1%-0.4% of coal powder and 1%-3% of water. The fresh sand and the old sand are sequentially added into a sand mixer according to a ratio, then the coal powder and the bentonite are added, then the starch is added, finally the water is added, stirring is carried out in thesame direction, and after all the components are uniformly stirred, the molding sand is obtained. The molding sand can be used for core producing for the wet core, and the prepared wet core is high in reusability and strong in binding force. The wet core prepared by the molding sand is high in wet pressure strength, and good in collapsibility and good in air permeability after casting. The use ofthe core iron is cancelled, the waste of the core iron material is avoided, a sorting core iron working procedure is not needed, and the core making efficiency is further improved.

Owner:赤峰市建支管业有限公司

Ledeburite malleable cast iron with high tenacity

InactiveCN107541643ANovel componentsThe production process is reasonable and clearSolid state diffusion coatingStress concentrationLedeburite

The ledeburite malleable cast iron with high toughness belongs to the field of casting technology. It is composed of the following raw materials in mass percentage, C 0.07%, Si 0.25%, Mn 0.2%, S 0.01%, P 0.02%, Cr 2.2%, Mo 1.2%, V 0.65%, Nb 0.12%, RE 0.08%, Ni 0.14%, W 0.36%; the rest is Fe and impurities. The composition of the invention is novel, the service life is greatly improved, the use cost is greatly reduced, the use range is expanded, and the large impact load can be effectively solved. Surface carburizing treatment is carried out on it, and surface quenching treatment is carried out after carburizing, and its toughness and fatigue strength have been greatly improved. The stress on the surface is reduced, and the service life of malleable cast iron has been greatly improved, which meets the needs of various stress concentrations and high impact loads.

Owner:田静

A kind of surface modification method of cast iron

A method for surface modification of cast iron, which uses high-energy superposition to modify the surface of cast iron materials, specifically a new type of surface modification technology for cast iron materials using electric explosion, gas explosion, and plasma energy superposition. This technology has the characteristics of one, two or more of the three surface modification technologies of plasma surface modification, gas explosion and electric explosion, and can be processed in an atmospheric environment with low cost and high processing efficiency. A reinforced modified layer with a thickness of 70‑150 μm is formed on the surface of the parts, which can improve the wear resistance, corrosion resistance and service life of cast iron parts by 1‑6 times. The invention is suitable for surface modification treatment of gray cast iron, malleable cast iron, nodular cast iron, vermicular graphite cast iron and alloy cast iron parts, and can be widely used in the fields of machinery industry, aviation manufacturing and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

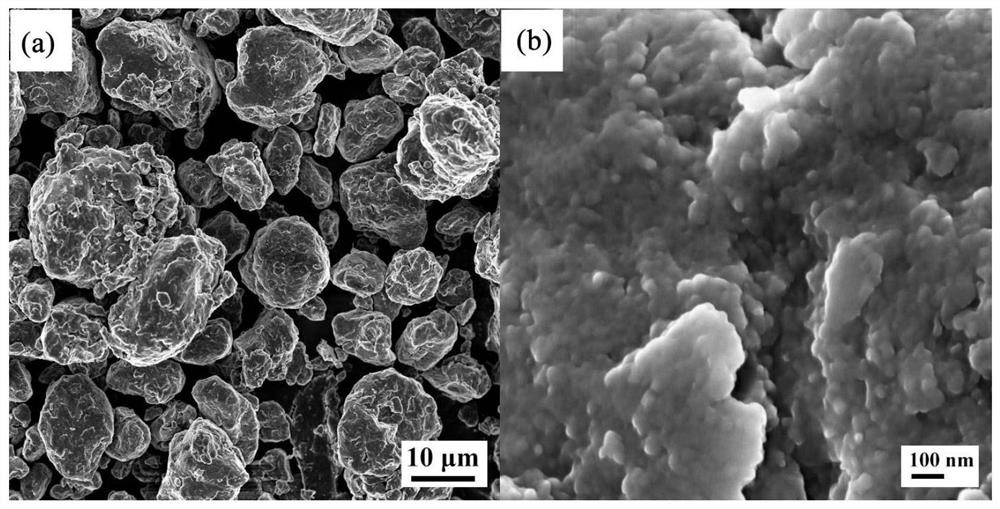

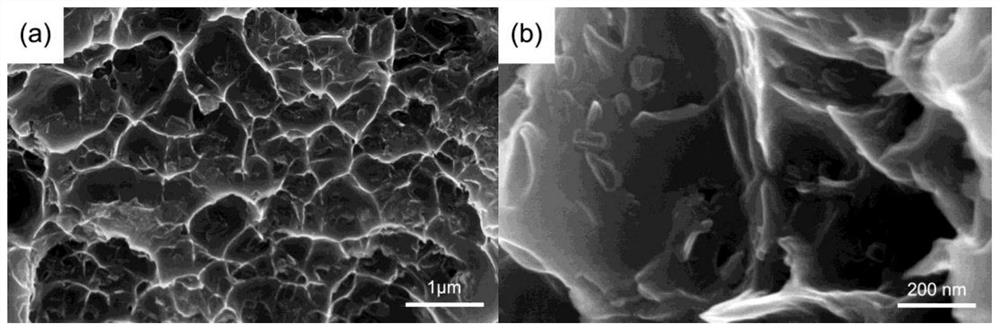

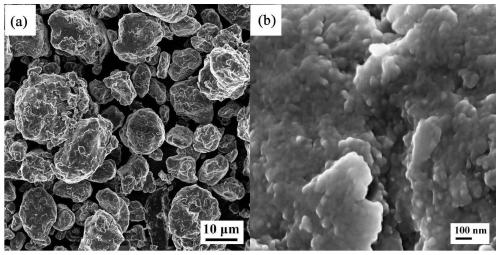

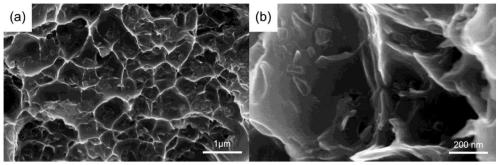

A nano-modified aluminum alloy material and its preparation method and energy-saving and environment-friendly power fittings produced therefrom

ActiveCN111455208BLow densityMeet security and stability performance requirementsCarbon nanotubeMalleable iron

The invention discloses a nano-modified aluminum alloy material and its preparation method and the energy-saving and environment-friendly electric fittings produced therefrom. The method comprises the following steps: 1) preparing silicon-coated carbon nanotubes: mixing silicon powder and carbon nanotubes Mechanical ball milling to fully mix silicon powder and carbon nanotubes to construct a core-shell structure to obtain silicon-coated carbon nanotubes; 2) Preparation of nano-modified aluminum alloy materials: adding silicon-coated carbon nanotubes obtained in step 1) to aluminum alloy Semi-solid stirring is carried out in the matrix, so that the added silicon-coated carbon nanotubes are uniformly dispersed in the aluminum alloy matrix, and then the temperature is raised for casting to obtain cast rods of nano-modified aluminum alloy materials. Compared with traditional malleable cast iron materials for electric fittings, the nano-modified aluminum alloy material prepared by the invention has the advantages of light weight, high strength and no galvanizing, and has higher strength than conventional aluminum alloys.

Owner:STATE GRID CORP OF CHINA +2

Abrasion resistant malleable cast iron material and preparation method thereof

InactiveCN102071377AImprove the strengthening and toughening effectImprove wear resistanceMalleable ironMetal

The invention provides an abrasion resistant malleable cast iron material and a preparation method thereof. The material has good performance, and the preparation method for the material is simple in process and low in production cost, and is suitable for industrial production. The abrasion resistant malleable cast-iron material takes malleable cast iron as a matrix; a metal wire group formed by high carbon steel wires and iron wires is distributed in the matrix; both the diameter of the used high carbon steel wires and the diameter of the used iron wires are 1 to 2 millimeters; the material contains 5 to 40 volume percent of the high carbon steel wires and the iron wires; and the diameter of the metal wire group is 10 to 15 centimeters.

Owner:金湖中博物联网科技有限公司

Nano modified aluminum alloy material and preparation method thereof and energy-saving environmental-friendly electric power hardware fitting manufactured thereby

ActiveCN111455208ALow densityMeet security and stability performance requirementsNanotubeMalleable iron

The invention discloses a nano modified aluminum alloy material and a preparation method thereof and an energy-saving environmental-friendly electric power hardware fitting manufactured thereby. The method comprises the following steps of 1) preparing a silicon coated nanotube: mixing silicon powder with a carbon nano tube and mechanically ball-milling the mixture, wherein the silicon powder and the carbon nano tube are mixed fully to construct a core-shell structure to obtain the silicon coated nanotube; and 2) preparing a nano modified aluminum alloy material: adding the silicon coated nanotube obtained in the step 1) into an aluminum alloy matrix for semi-solid state stirring, wherein the added silicon coated carbon nano tube is dispersed in the aluminum alloy matrix uniformly, and thenraising the temperature and carrying out pouring to obtain a nano modified aluminum alloy material cast rod. Compared with a malleable cast iron material for a conventional electric power hardware fitting, the prepared nano modified aluminum alloy material has the advantages of being light in weight, high in strength and free of galvanizing and is higher than a conventional aluminum alloy in strength.

Owner:STATE GRID CORP OF CHINA +2

Forgeable ferrite cast iron

The invention relates to forgeable ferrite cast iron, which is characterized by comprising the following components by weight percent: 95.00 to 95.50 percent of iron, 2.30 to 2.55 percent of carbon, 1.50 to 1.80 percent of silicon, 0.45 to 0.65 percent of manganese, less than 0.20 percent of sulfur, less than 0.06 percent of phosphorus, 0.005 to 0.012 percent of bismuth and less than 0.06 percent of chromium. According to the principle of low carbon, medium or high silicon, reasonable manganese and sulfur ratio, strict control of bismuth and chromium, and as low phosphorus and sulfur as possible, the forgeable ferrite cast iron mixed according to the proportioning proposal has better mechanical property and machining property.

Owner:HENGYANG FENGSHUN AXLE CO LTD

White-core malleable cast iron decarburization process

The invention relates to the technical field of cast iron decarburization, and provides a white-core malleable cast iron decarburization process which comprises the following steps of S1, preparing raw materials, a casting and a decarburizing agent; S2, feeding the raw materials into a furnace, putting the casting into a heat treatment furnace, adding the decarburizing agent for material mixing; and sealing the heat treatment furnace after the materials are mixed, wherein the decarburizing agent is one or more of oxide scale, iron ore, building sand and limestone; S3, conducting heat treatment: in the heating process, heating the mixed materials in the heat treatment furnace in sequence for 5 to 24 hours, and controlling the temperature after heating to be 1000 DEG C to 1100 DEG C; in the heat preservation process, maintaining the heated temperature for 20 to 80 h; in the cooling process, reducing the temperature to 650 DEG C or below; and S4, discharging the product from the furnace, and opening a furnace door of the heat treatment furnace. Through the technical scheme, the problem that the scrap rate of cast iron is higher than 5 percent in the prior art is solved.

Owner:TANGSHAN XINYE TECH

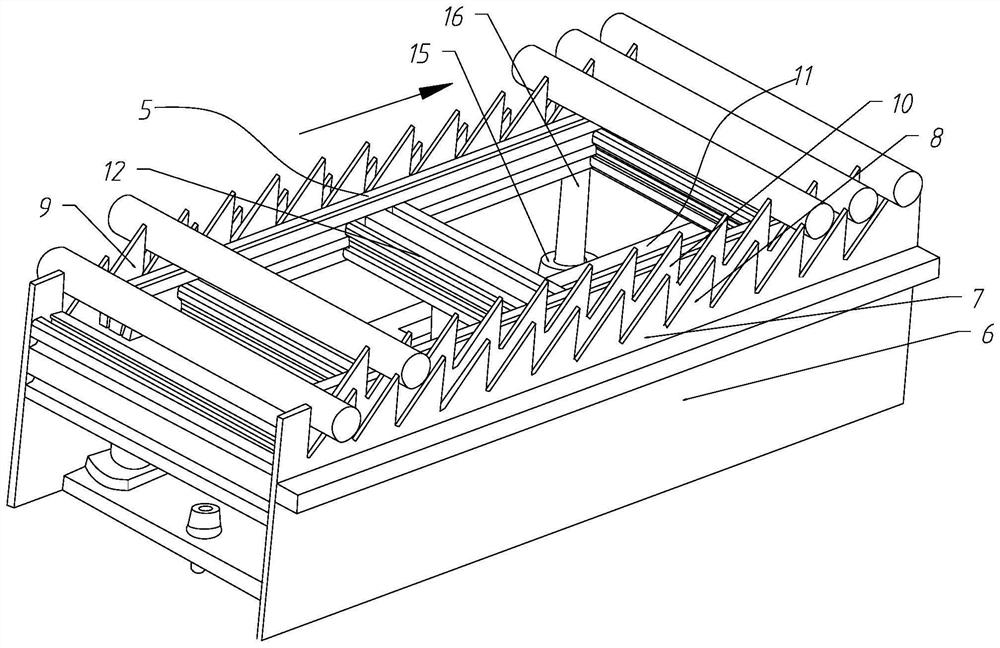

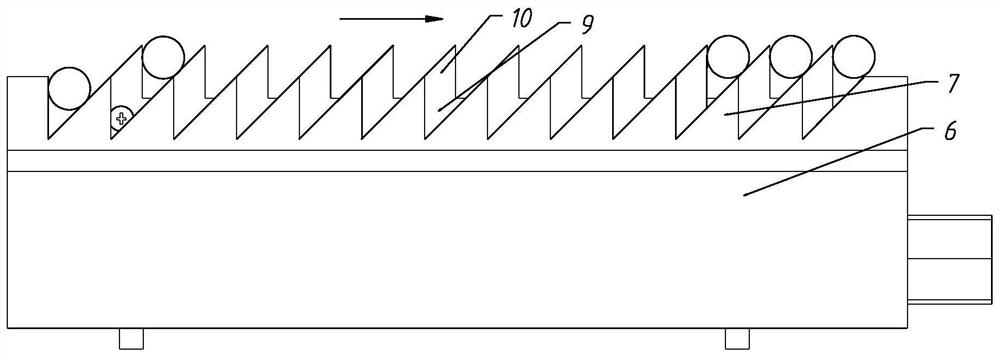

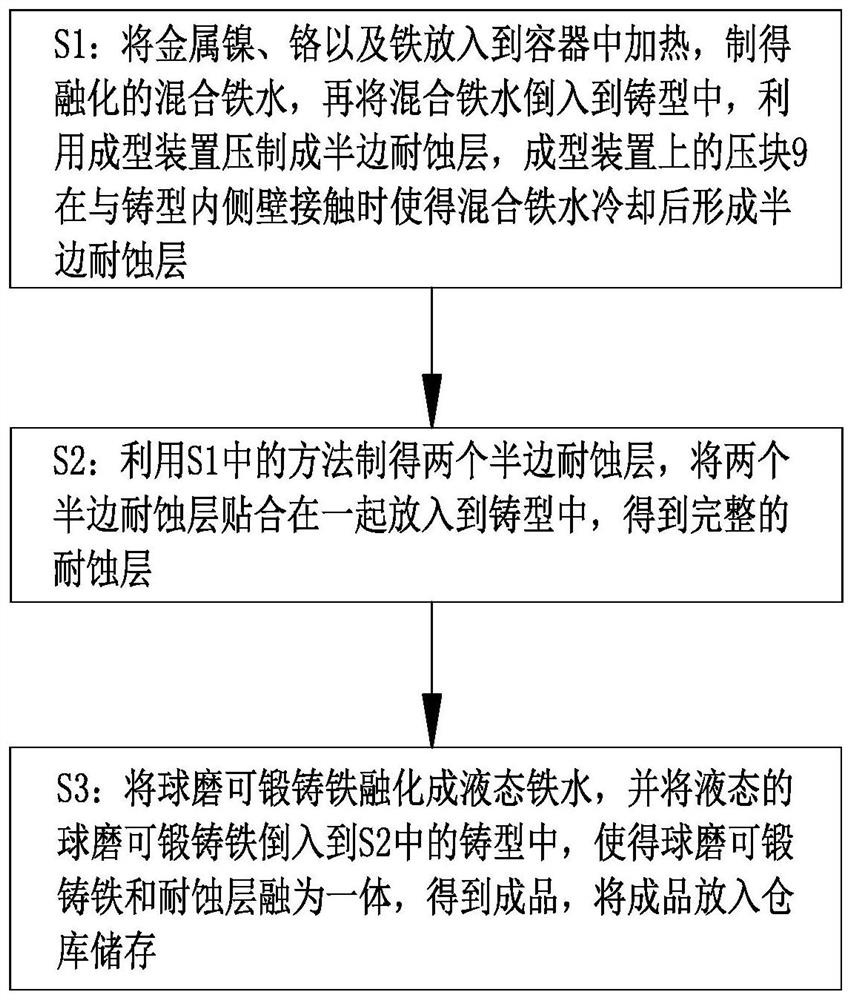

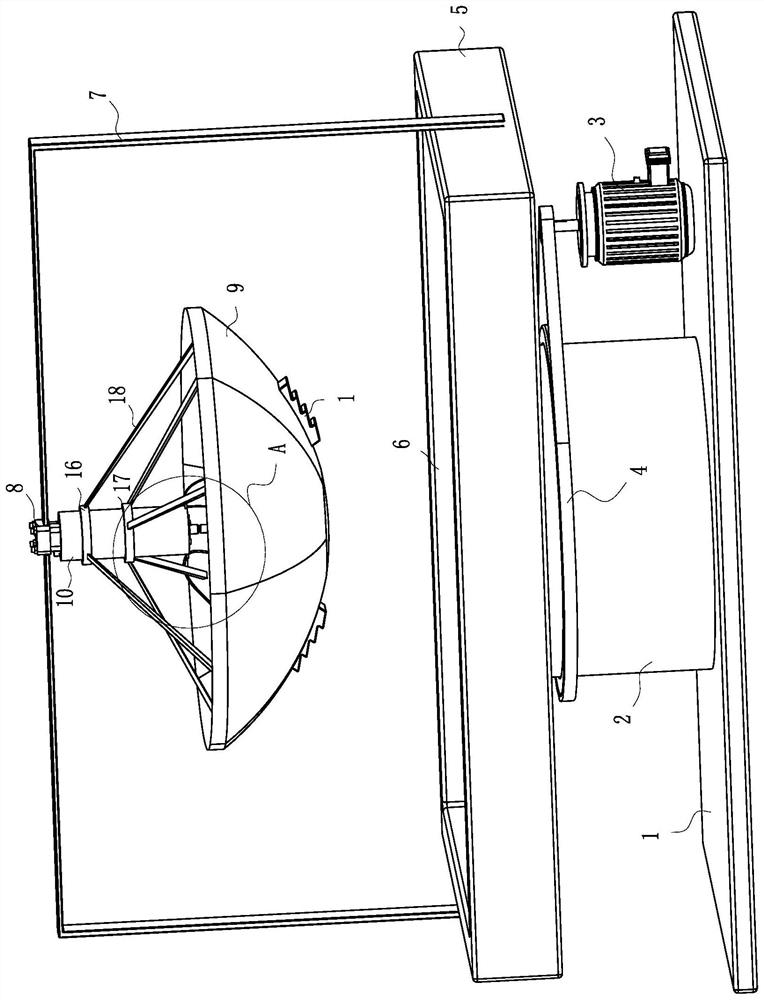

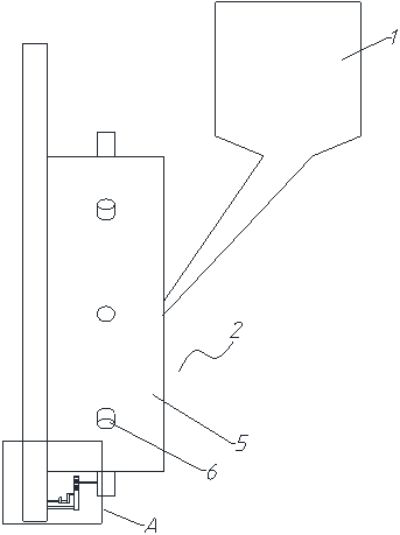

Preparation method for corrosion-resistance ductile malleable iron material

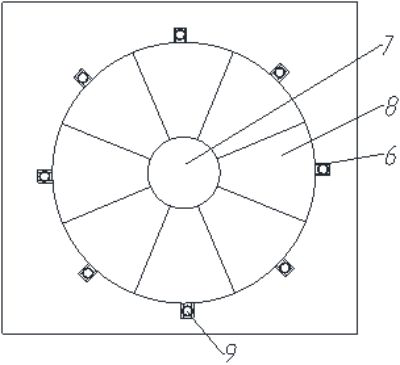

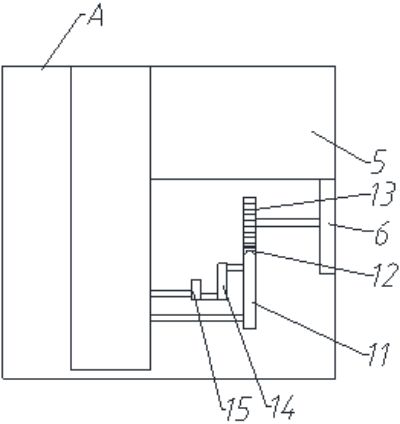

The invention belongs to the technical field of material preparation, particularly to a preparation method for a corrosion-resistance ductile malleable iron material. A molding apparatus used in the method comprises a base plate; a rotation shaft is rotatably mounted at the top end of the base plate; a drive motor is fixed at the top end of the base plate; a rotation wheel is fixed at the top endof the drive motor; a rotation ring is fixed on the surface of the rotation shaft; a synchronous belt is movably connected between the rotation wheel and the rotation ring; a placement table is fixedat the top end of the rotation shaft; a placement tank is provided at the top end of the placement table, and is used for placing a casting mold; and two brackets are fixed on the side walls of the placement table. A flaky corrosion resistance layer is pressed in the invention, is distributed on the surface of the ductile malleable iron material, and is fused with the ductile malleable iron material together; a protection effect can still be achieved when the ductile malleable iron material is forged; and moreover, the use of nickel and chromium is reduced, the use cost is reduced, and the characteristics of the ductile malleable iron material are retained to the greatest extent.

Owner:长沙圆丹动力科技有限公司

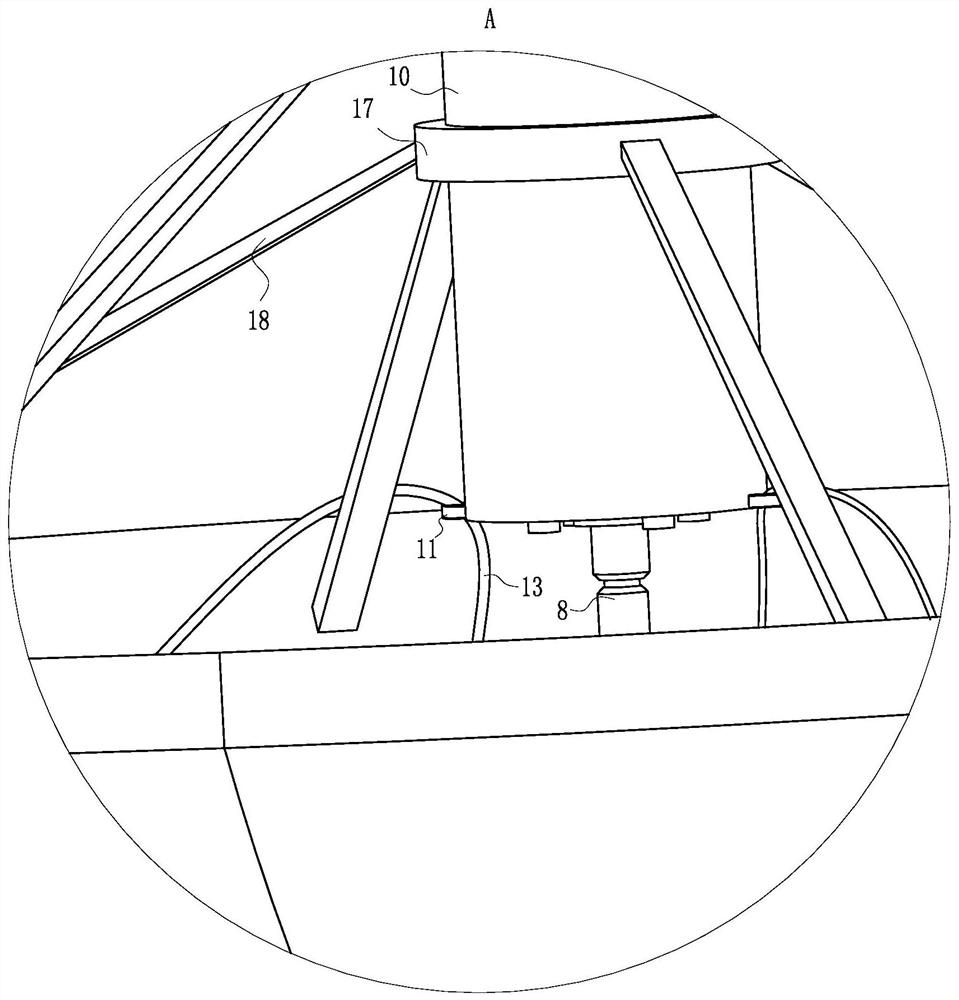

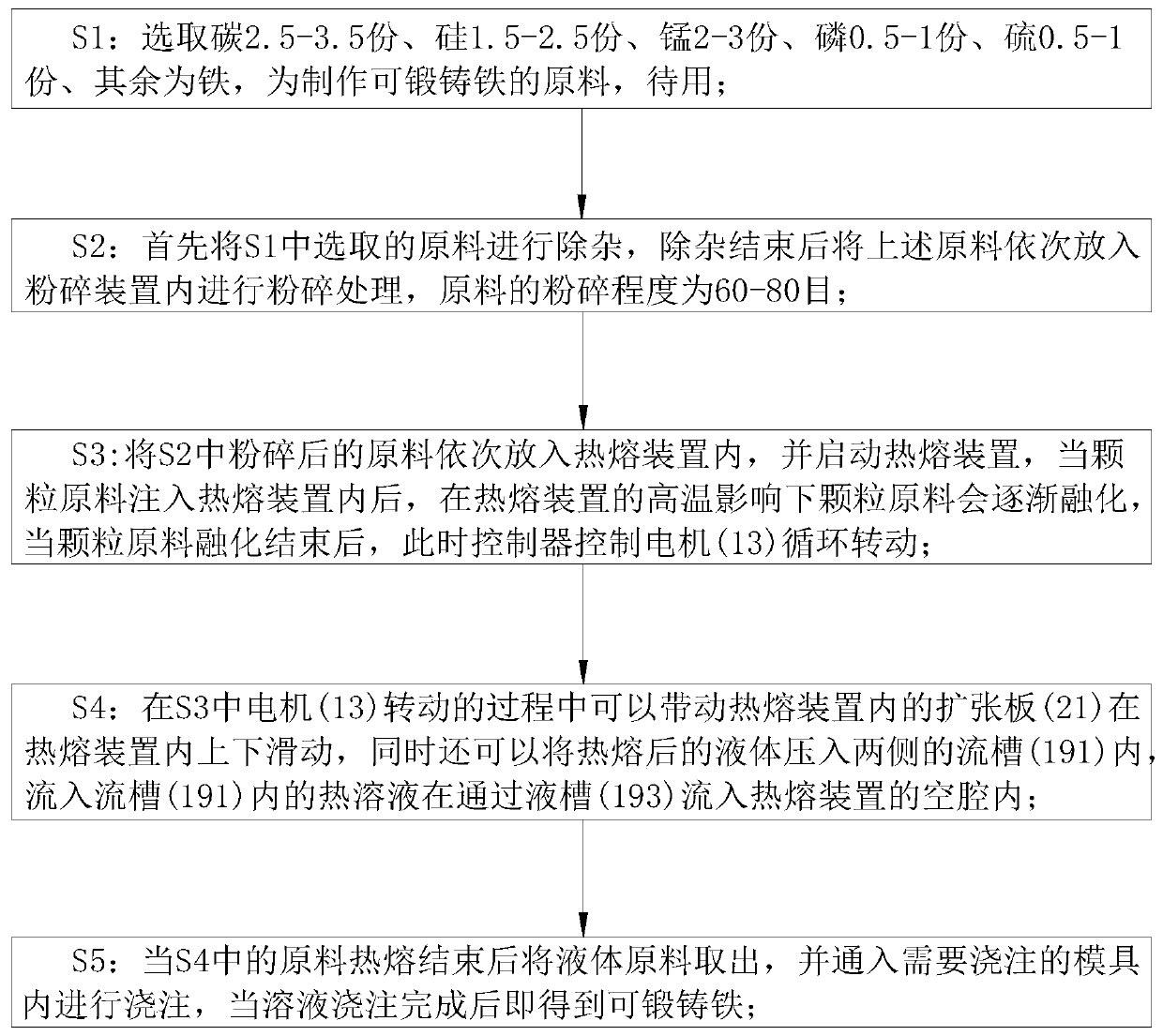

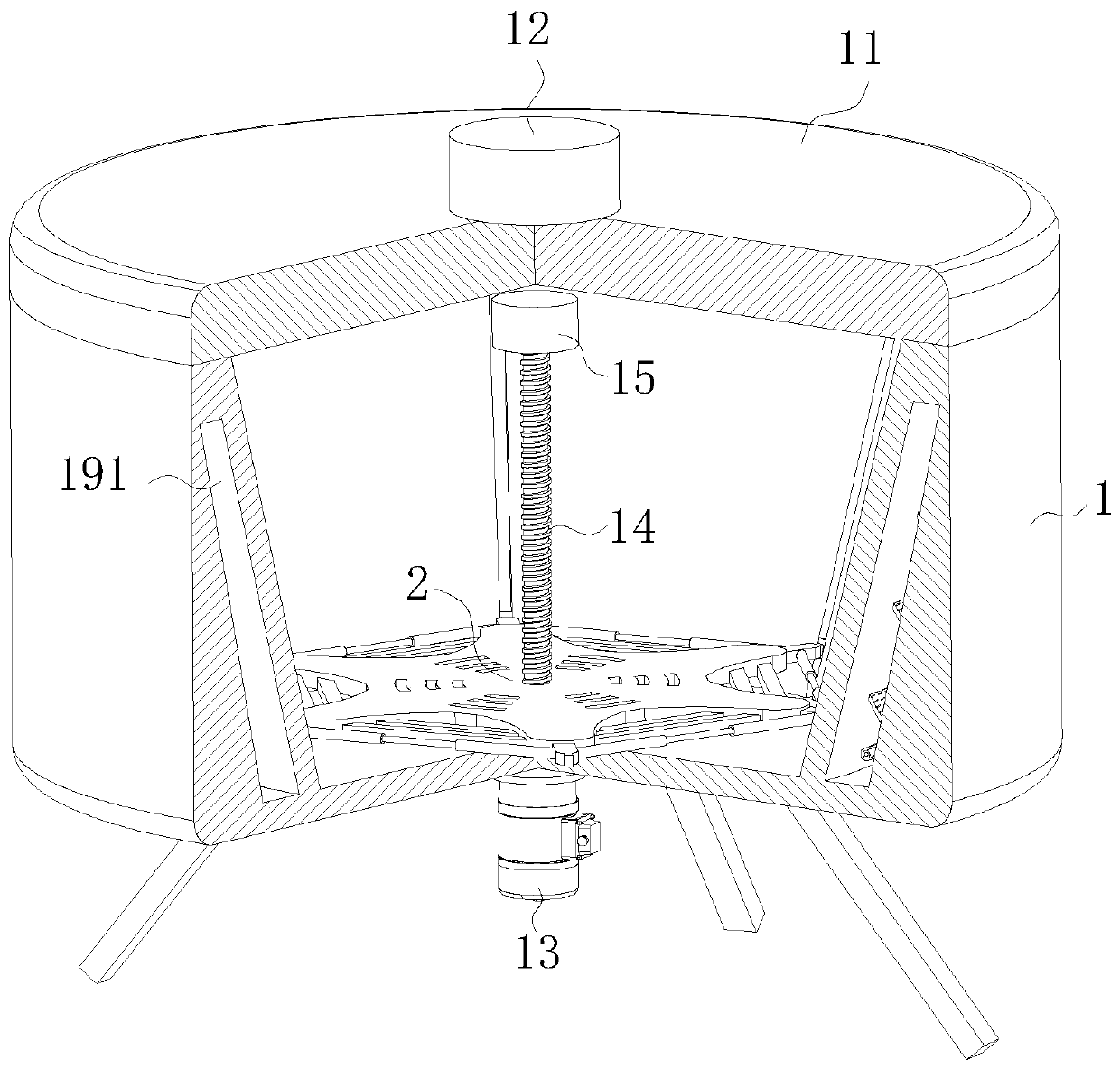

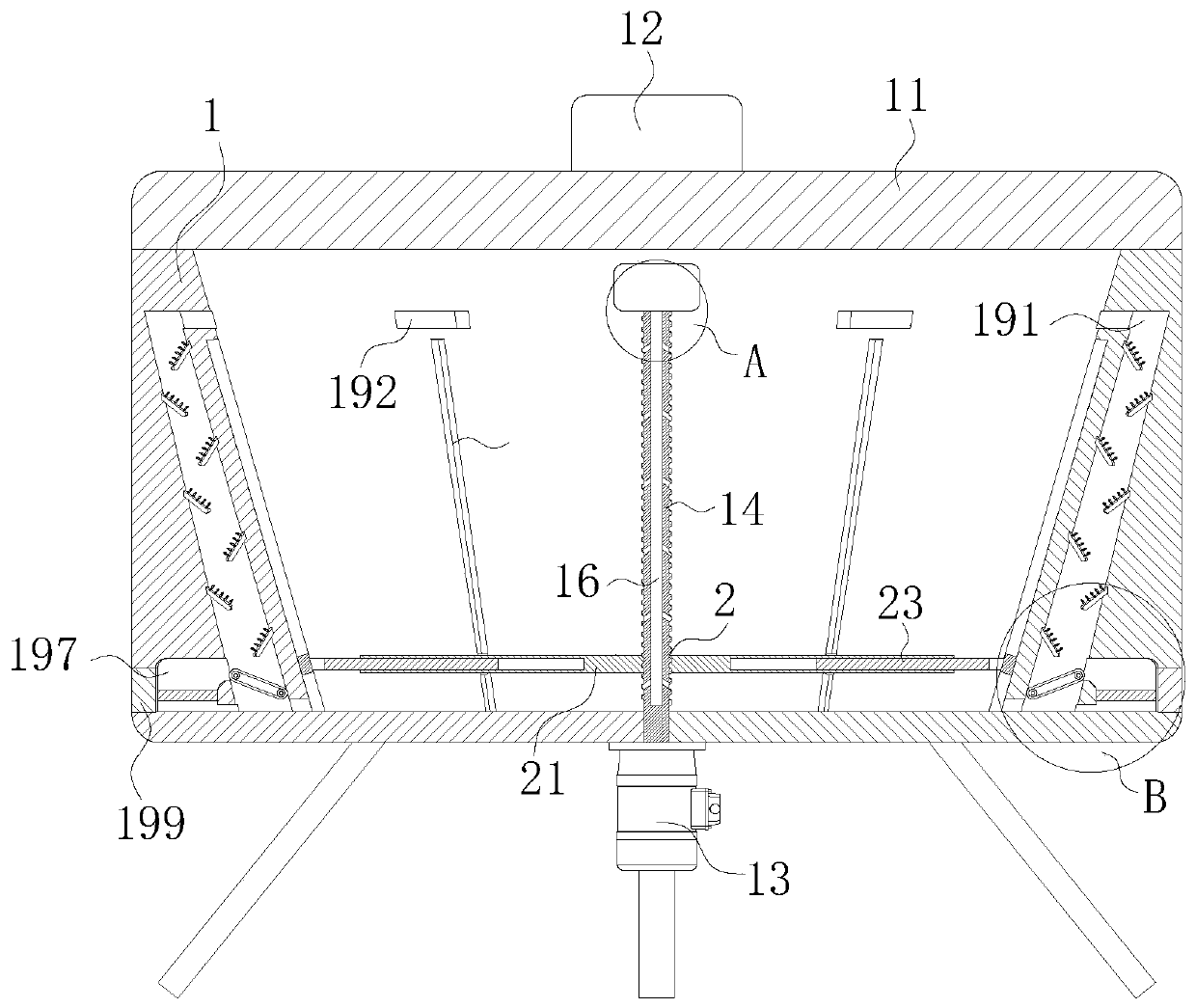

High-toughness ledeburite malleable cast iron

The invention belongs to the technical field of malleable cast iron, and particularly relates to high-toughness ledeburite malleable cast iron. The hot melting device comprises a hot melting box and an impurity removing mechanism; a box cover is mounted on the top end surface of the hot melting box; a supercharger is installed on the upper surface of the box cover and electrically connected with the controller through a wire; a cavity in the hot melting box is designed to be inclined; and the bottom end surface of the hot melting box is fixedly connected with a motor; a lead screw is fixedly connected to a driving shaft of the motor. The device is mainly used for solving the problems that according to an existing hot melting device, a raw material is usually placed in the hot melting device for hot melting, then gas doped in a raw material is exhausted in a stirring mode, however, the gas doped in a raw material cannot be completely exhausted in the mode, a cavity exists in poured malleable cast iron, and the casting quality of the malleable cast iron is influenced; and meanwhile, impurities in molten iron need to be manually removed in the hot melting process of the raw material,so that a certain danger is caused to workers, and meanwhile, the impurities are not thoroughly removed.

Owner:山东惠宇汽车零部件有限公司 +1

Heat-resistant malleable cast iron material and preparation method thereof

InactiveCN102051546BImprove the strengthening and toughening effectImprove heat resistanceCarbon steelMalleable iron

The invention provides a heat-resistant malleable cast iron material and a preparation method thereof. The heat-resistant malleable cast iron material has good performance; and the preparation method is simple in process, low in production cost and suitable for industrial production. Malleable cast iron is utilized as a substrate for the heat-resistant malleable cast iron material, wherein metal wire clusters formed by medium carbon steel wires and iron wires are distributed on the substrate; the diameter of the medium carbon steel wires and diameter of the iron wires are 1-2mm; the medium carbon steel wires and the iron wires account for 5-40% of the material by volume; and the diameter of the metal wire clusters is 10-15cm.

Owner:金湖中博物联网科技有限公司

Heat-resistant malleable cast iron material and preparation method thereof

InactiveCN102051546AImprove the strengthening and toughening effectImprove heat resistanceCarbon steelMalleable iron

The invention provides a heat-resistant malleable cast iron material and a preparation method thereof. The heat-resistant malleable cast iron material has good performance; and the preparation method is simple in process, low in production cost and suitable for industrial production. Malleable cast iron is utilized as a substrate for the heat-resistant malleable cast iron material, wherein metal wire clusters formed by medium carbon steel wires and iron wires are distributed on the substrate; the diameter of the medium carbon steel wires and diameter of the iron wires are 1-2mm; the medium carbon steel wires and the iron wires account for 5-40% of the material by volume; and the diameter of the metal wire clusters is 10-15cm.

Owner:金湖中博物联网科技有限公司

Abrasion resistant malleable cast iron material and preparation method thereof

InactiveCN102071377BImprove the strengthening and toughening effectImprove wear resistanceMalleable ironMetal

The invention provides an abrasion resistant malleable cast iron material and a preparation method thereof. The material has good performance, and the preparation method for the material is simple in process and low in production cost, and is suitable for industrial production. The abrasion resistant malleable cast-iron material takes malleable cast iron as a matrix; a metal wire group formed by high carbon steel wires and iron wires is distributed in the matrix; both the diameter of the used high carbon steel wires and the diameter of the used iron wires are 1 to 2 millimeters; the material contains 5 to 40 volume percent of the high carbon steel wires and the iron wires; and the diameter of the metal wire group is 10 to 15 centimeters.

Owner:金湖中博物联网科技有限公司

Method for producing malleable iron pipe fittings using recycled waste

ActiveCN106756441BImprove matrix tissueDecrease phenomenonProcess efficiency improvementSmelting processFerrosilicon

Owner:HEBEI JIANZHI CASTING GROUP

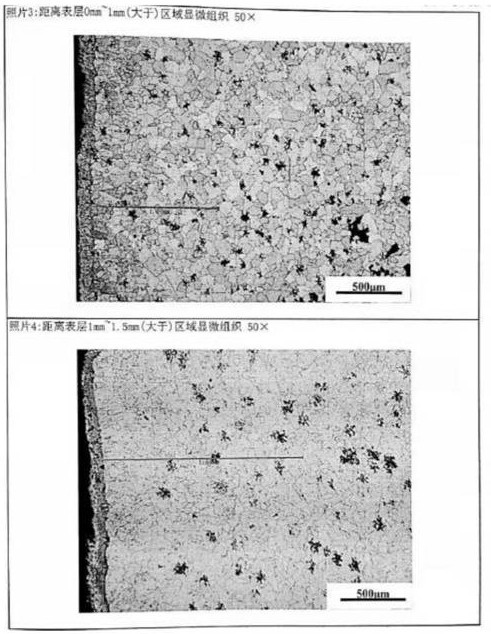

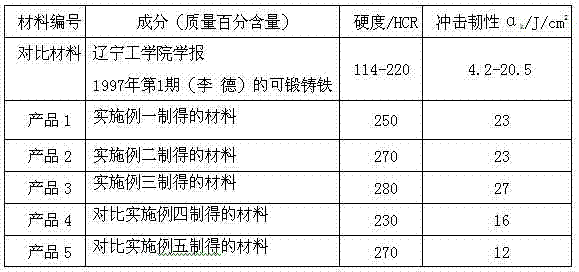

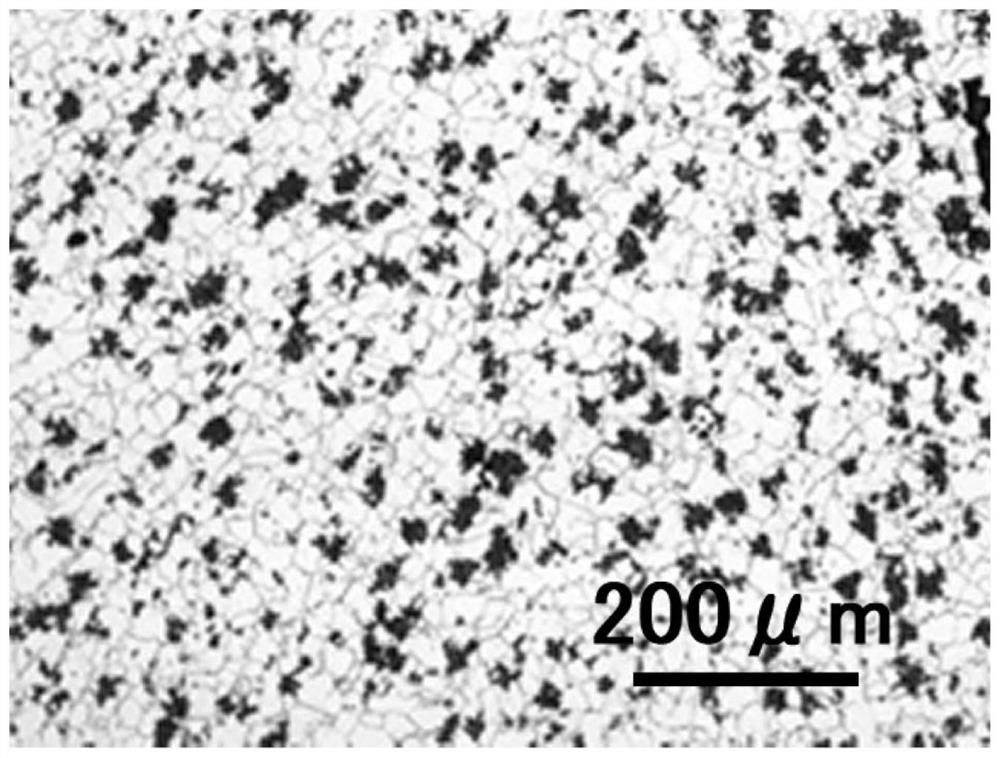

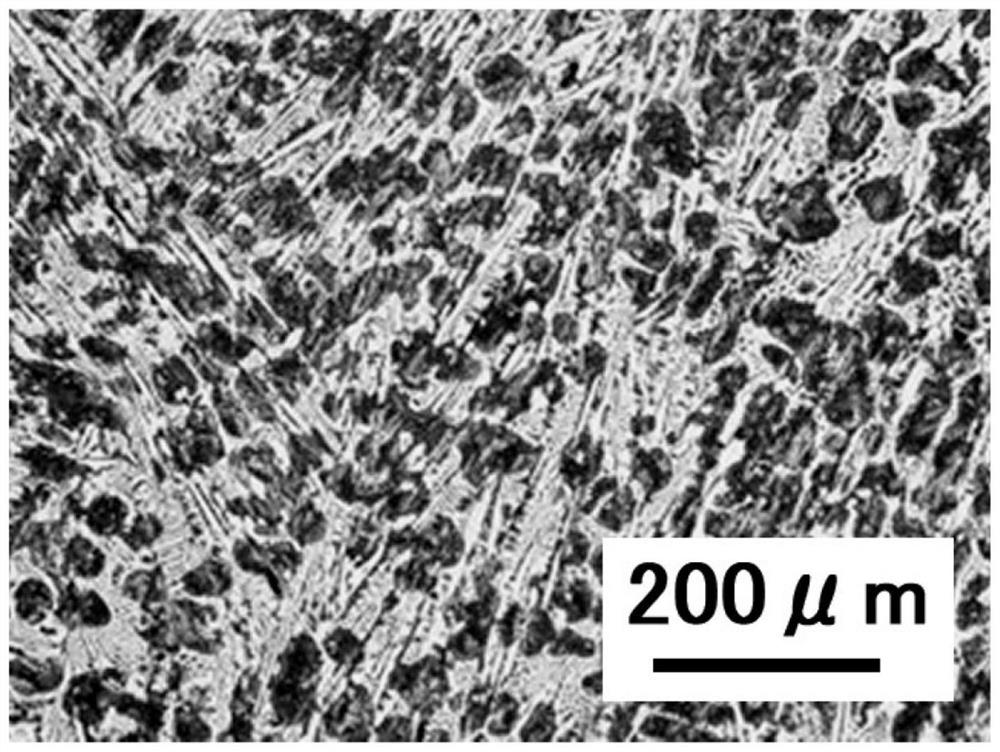

Black core malleable cast iron and manufacturing method thereof

PendingCN114846162AImprove qualityHigh mechanical strengthProcess efficiency improvementGraphiteMalleable iron

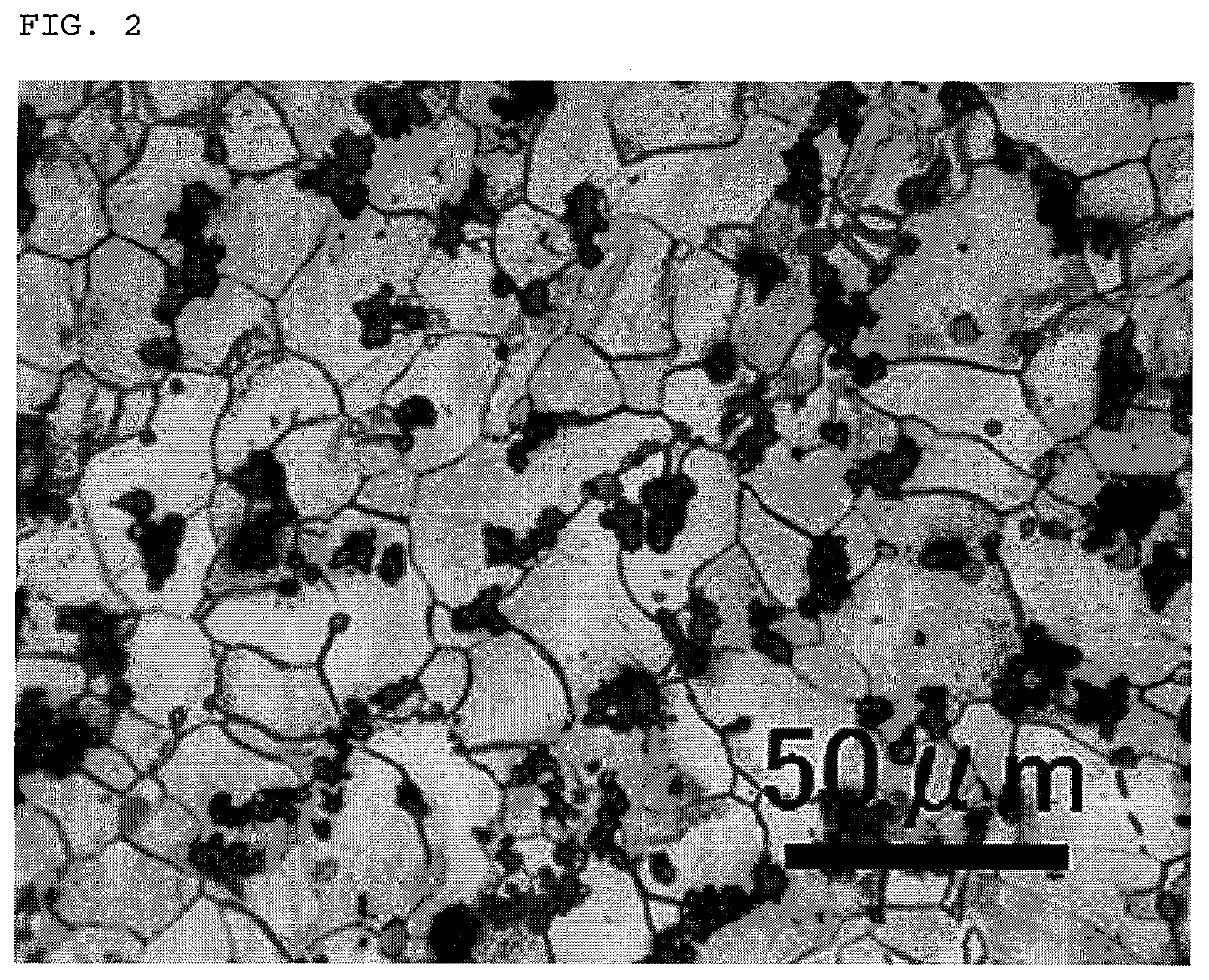

A black core malleable cast iron according to an embodiment of the present invention has a ferrite matrix and bulk graphite contained in the matrix, and contains, in mass ratio, 50 ppm to 100 ppm of boron and 65 ppm to 200 ppm of nitrogen, and the crystal grain size of the matrix is 8.0 to 10.0 in terms of grain size numbers as quantized by comparison between a metallographic structure picture and a standard crystal grain size map.

Owner:株式会社博迈立铖

Production process of white heart malleable cast iron

The present invention relates to the technical field of cast iron technology, and proposes a white-heart malleable cast iron production process, including S1. Mixing and smelting raw materials and additives to obtain high-carbon molten iron; S2. Casting high-carbon molten iron at a suitable temperature into a coated sand mold shell, cooling and forming Obtaining a shaped green body; S3. Trimming the burrs and gates of the shaped green body; S4. Performing decarburization annealing on the trimmed green body to obtain a casting; S5. Deburring and shot blasting the casting. Through the above technical solution, the problem that the traditional process in the prior art is not suitable for producing white-heart malleable cast iron is solved.

Owner:TANGSHAN XINYE TECH

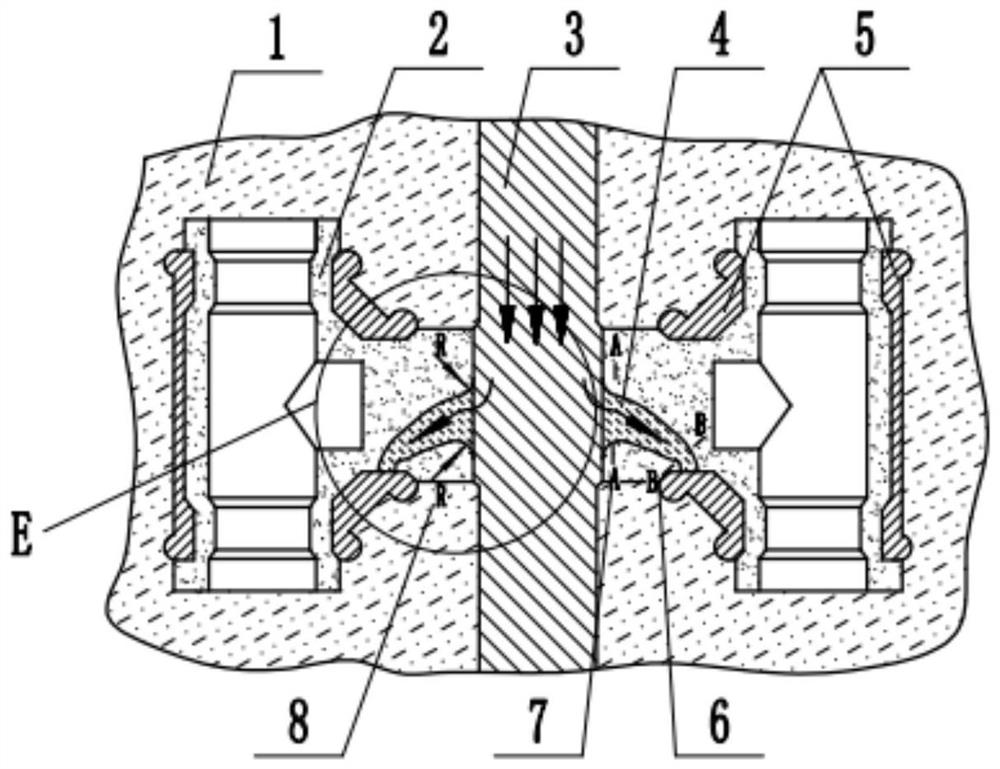

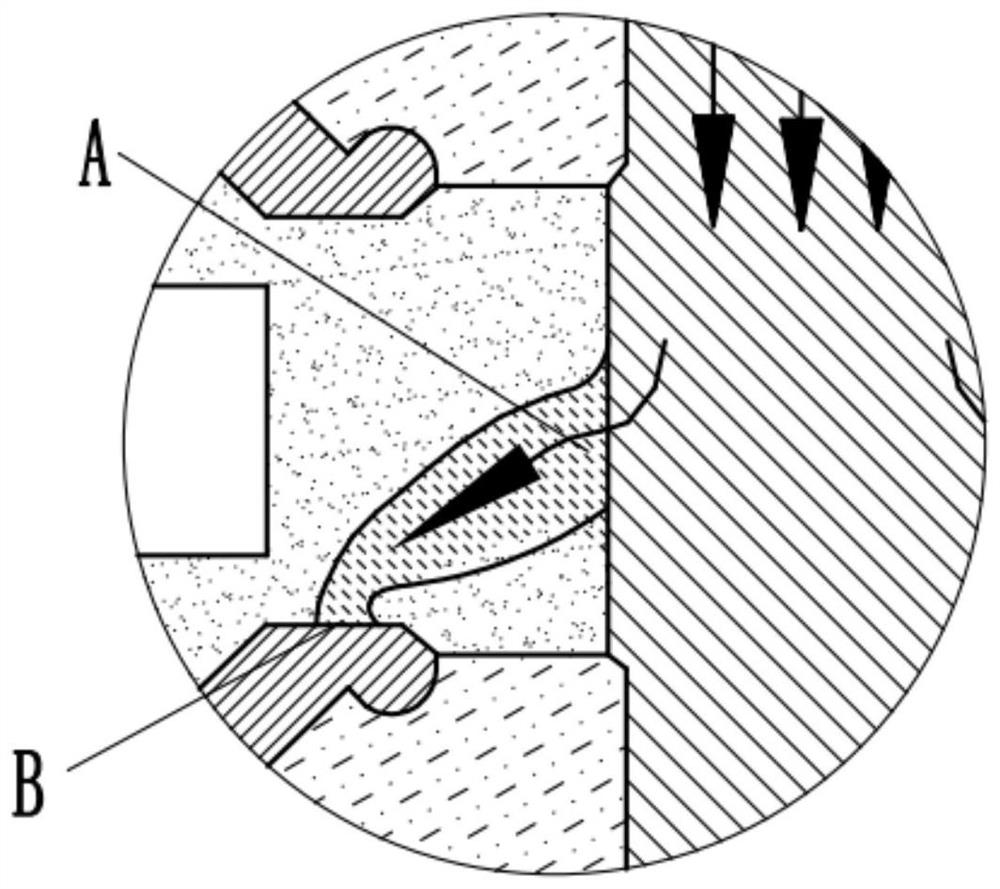

Sand core with built-in pouring gate

PendingCN111940685AQuality assuranceIncrease productivityFoundry mouldsFoundry coresClassical mechanicsEngineering

A sand core with a built-in pouring gate comprises a resin sand core arranged in a sand mold; the pouring gate is arranged in the resin sand core; one end A of the pouring gate arranged in the resin sand core is connected with a runner in the sand mold, the other end B of the pouring gate is connected with a cavity of a malleable cast iron connecting piece, and the section of the pouring gate is arranged in the direction of a pouring gate channel in a variable-section mode; the pouring gate channel is in a curve shape, and the other end B of the pouring gate is located in a to-be-machined inner hole section area M of the cavity of the malleable cast iron connecting piece. Due to the arrangement of the pouring gate of the resin sand core, the defects that the end face of a casting is rough,sand holes exist, residues are easily generated at the pouring gate, stubbles are large and the like in the prior art are overcome, and meanwhile the production efficiency of subsequent machining isimproved.

Owner:TANGSHAN XINYE TECH

High-performance motorcycle brake disc material and preparation method

ActiveCN111850384AImprove high temperature strengthImprove wear resistanceBraking discsFurnace typesHigh wear resistanceUltimate tensile strength

Motorcycle brake disc materials are required to have high mechanical strength, excellent wear resistance, low density and good heat dissipation performance. At present, brake discs made of a single material like malleable cast iron or gray cast iron or alloy steel cannot meet actual comprehensive performance requirements. The invention discloses a high-performance motorcycle brake disc material. Firstly, alloy powder comprising 2-2.5% of C, 4.0-4.5% of Cr, 3.5-4.0% of Mo, 8.5-9% of V, 1-2% of W, 2-3% of Co and the balance Fe is prepared; then, the alloy powder is sintered into a porous body with certain strength and porosity; then, the porous body is infiltrated with aluminum alloy to obtain a dense bulk material; and then, suitable heat treatment is performed to obtain a high-performancemotorcycle brake disc finally. The microstructure of the material is a dual-communicating structure, the iron-based alloy can provide high high-temperature resistance strength and wear resistance, andthe aluminum alloy can provide high thermal conductivity and low density, so the final material has excellent comprehensive performance such as high wear resistance, high-temperature strength, high thermal conductivity and low density.

Owner:河南中钻新材料有限公司

Method for Producing Plated Black Heart Malleable Cast Iron Member, Plated Black Heart Malleable Cast Iron Member, and Pipe Join

ActiveUS20200248279A1Reduce the burden onHot-dipping/immersion processesCorrosion preventionEngineeringMechanical engineering

Owner:HITACHI METALS LTD

Surface pretreatment method for improving quality of malleable cast iron hot-dip galvanizing coating

ActiveCN110616392AReduce thicknessReduced reactivity to siliconHot-dipping/immersion processesSurface engineeringPretreatment method

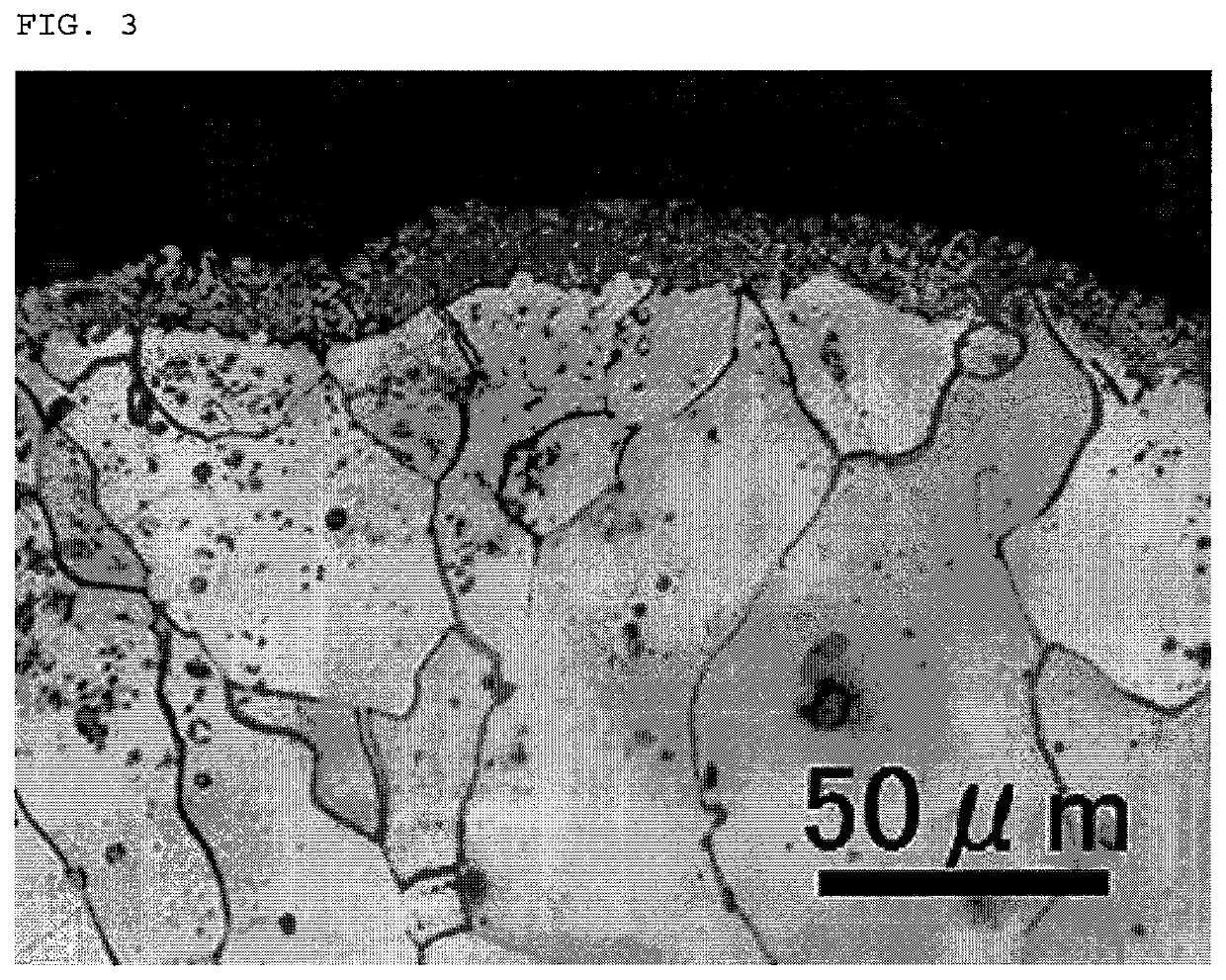

The invention belongs to the field of metal surface engineering, and particularly relates to a surface pretreatment method for improving the quality of a malleable cast iron hot-dip galvanizing coating. According to the main step of the surface pretreatment method, a malleable cast iron part is buried into a sodium bicarbonate powder bed, so that the malleable cast iron part is placed in an oxidizing atmosphere to be subjected to surface oxidizing pretreatment, and the aim of effectively inhibiting the activity of silicon on the surface of the cast iron part is achieved. Compared with malleable cast iron which is not pretreated. The plating thickness difference of different positions of the malleable cast iron part and the average thickness value are remarkably reduced, the plating qualityis obviously improved, and the surface pretreatment method has wide application prospects in the galvanization industry.

Owner:CHANGZHOU UNIV

Method for producing malleable iron pipe by using reclaiming waste

ActiveCN106756441AImprove matrix tissueDecrease phenomenonProcess efficiency improvementSmelting processFerrosilicon

The invention relates to a method for producing a malleable iron pipe by using reclaiming waste. The method is characterized in that a medium frequency furnace smelting process is adopted, foundry pig iron with waste machine iron, and raw materials include, by weight, 45-55 parts of foundry returns, 10-30 parts of waste rolled steel, 20-35 parts of the machine iron, 0.6-1 part of a carburetant, 0.25-0.5 part of ferrosilicon and 0-10 parts of malleable cast iron chippings. According to the method, the raw material structure and the matching process are optimized, the matrix structure of a cast workblank piece is improved, the product performance is stabilized, the phenomenon of casting grey pieces is reduced, and the rejection rate of cast products is reduced.

Owner:HEBEI JIANZHI CASTING GROUP

A kind of preparation method of corrosion-resistant nodular malleable iron material

The invention belongs to the technical field of material preparation, in particular to a preparation method of a corrosion-resistant ductile malleable iron material. A forming device used in the method comprises a bottom plate, a rotating shaft is rotatably installed on the top of the bottom plate, and a driving motor is fixed on the top of the bottom plate A rotating wheel is fixed on the top of the drive motor, a rotating ring is fixed on the surface of the rotating shaft, a synchronous belt is movably connected between the rotating wheel and the rotating ring, a placing table is fixed on the top of the rotating shaft, and the top of the placing table is There is a placing groove, the placing groove is used for placing the casting mold, and two brackets are fixed on the side wall of the placing platform; the invention presses and produces a sheet-shaped corrosion-resistant layer, so that the corrosion-resistant layer is distributed on the surface of the ductile malleable iron material, and is compatible with the ductile malleable cast iron material. The ductile malleable iron material is integrated into one, and it can still protect the ductile malleable iron material when forging, and at the same time reduce the use of nickel and chromium, reduce the cost of use, and retain the characteristics of the ductile malleable iron material to the maximum extent.

Owner:长沙圆丹动力科技有限公司

A galvanized and dipped malleable steel pipe fitting

ActiveCN105154805BImprove environmental adaptabilityImprove rust resistanceHot-dipping/immersion processesEpoxyPipe fitting

The invention discloses a galvanized and dipped varnish malleable steel pipe fitting. A galvanized and dipped malleable steel pipe fitting, comprising a malleable steel pipe fitting base body, the surface of the malleable steel pipe fitting base body has a galvanized layer and a varnish layer in turn, the galvanized layer is an inner layer, and the varnish layer is an outer layer; the thickness of the galvanized layer is 50‑80μm; the thickness of the impregnated paint layer is 40‑70um, the adhesion is ≤ grade 1, and the impact resistance is ≥70kg.cm. In the present invention, since the galvanized malleable steel pipe fittings are impregnated with epoxy resin, the thickness of the galvanized layer of the present invention reaches 50-80 μm; the thickness of the impregnated paint layer reaches 40-70 μm, the adhesion is ≤ grade 1, and the impact resistance is ≥ 70 kg .cm; galvanized and dipped malleable steel pipe fittings also overcome the problem that galvanized malleable steel pipe fittings cannot withstand acidic and alkaline environment corrosion; also solve the problem of the surface color of traditional malleable steel galvanized pipe fittings and other pipelines and their connectors used in conjunction with it The problem of color mismatch; at the same time, it also improves the antirust effect of galvanized and dipped malleable steel pipe fittings.

Owner:JINAN MEIDE CASTING CO LTD

Preparation method of light-weight high-strength nano-modified aluminum alloy material

InactiveCN114367659AHigh strengthLow densityFoundry mouldsFoundry coresUltimate tensile strengthNanotube

The invention discloses a preparation method of a light-weight and high-strength nano-modified aluminum alloy material, which comprises the following steps: step 1, preparing Mg-Si coated nanotubes, mixing magnesium powder, silicon powder and carbon nanotubes, and then mechanically grinding, so that the silicon powder and the carbon nanotubes are fully mixed, and constructing a core-shell structure to obtain magnesium-silicon coated carbon nanotubes; and 2, preparing a nano modified aluminum alloy material: adding the magnesium-silicon coated carbon nanotubes obtained in the step 1) into an aluminum alloy, stirring to uniformly disperse the added silicon coated carbon nanotubes in an aluminum alloy matrix, and then performing heat treatment casting to obtain a nano modified aluminum alloy material cast rod. According to the invention, the Al-Mg-Si alloy is adopted, so that the strength of the alloy fitting is greatly improved. Compared with a traditional malleable cast iron material for electric power fittings, the nano-modified aluminum alloy material provided by the invention has the advantages of light weight, high strength and no zinc plating.

Owner:江苏东恒光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com