Preparation method for corrosion-resistance ductile malleable iron material

A technology of cast iron and nodular graphite, which is applied in the field of preparation of corrosion-resistant nodular malleable cast iron materials, can solve the problems of waste of nickel and chromium, uneven corrosion resistance, uneven special compounds, etc., to reduce the cost of use, ensure smooth production, and reduce nickel and the effect of the use of chrome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

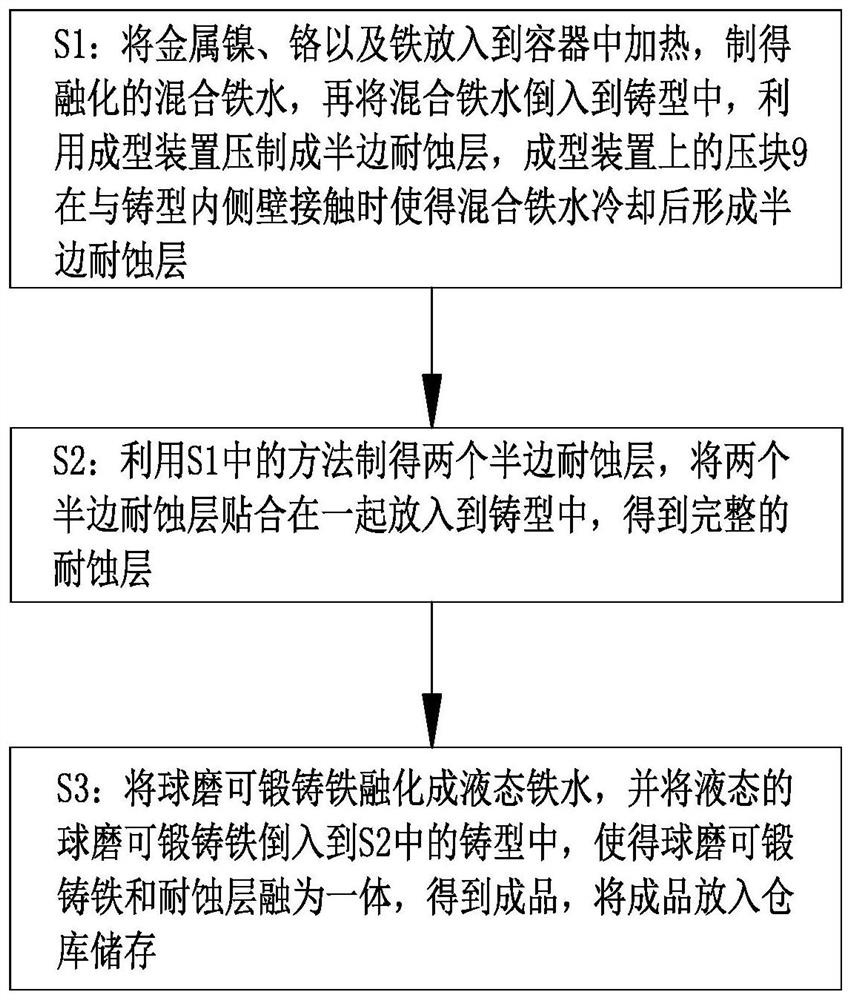

[0026] Such as Figure 1 to Figure 5 Shown, a kind of preparation method of corrosion-resistant nodular graphite malleable iron material of the present invention, comprises the following steps:

[0027] S1: Put metal nickel, chromium and iron into the container and heat to obtain melted mixed molten iron, then pour the mixed molten iron into the mold, and use the forming device to press the half-side corrosion-resistant layer, and the briquette on the forming device 9. When the molten iron is in contact with the inner wall of the mold, the half-side corrosion-resistant layer is formed after cooling, and the sheet-shaped corrosion-resistant layer is obtained by pressing the molding device, so that the corrosion-resistant layer is distributed on the surface of the ductile cast iron material, and it is combined with the ductile cast iron The material is integrated, which can still play a protective role when forging the ductile cast iron material, while reducing the use of nickel...

specific Embodiment approach

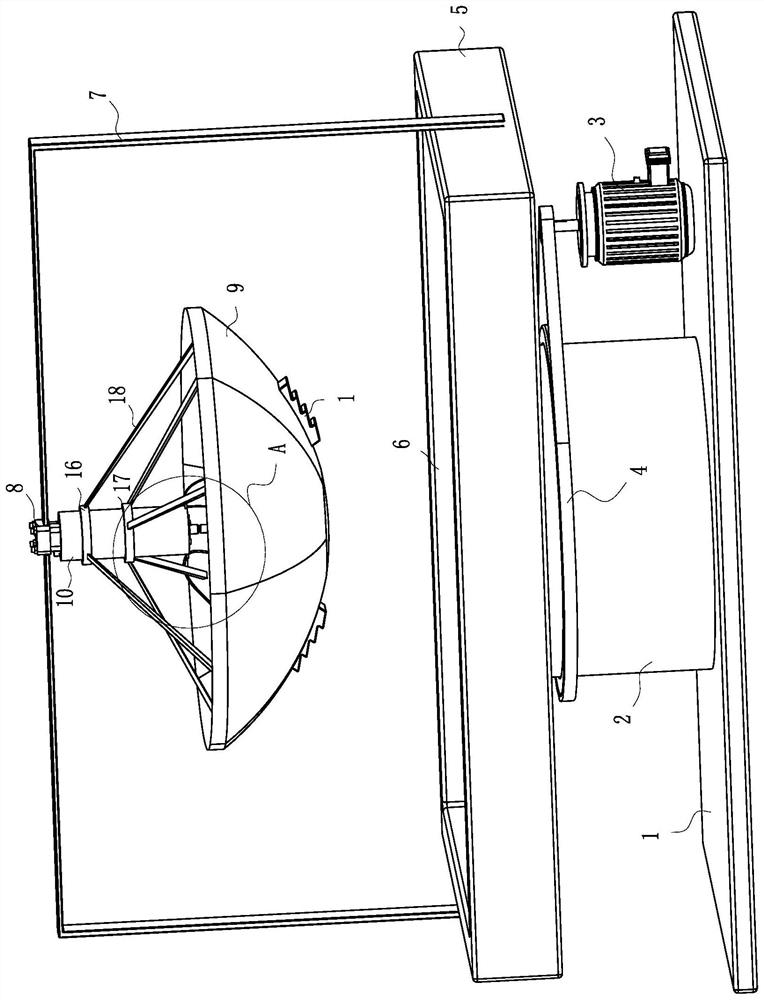

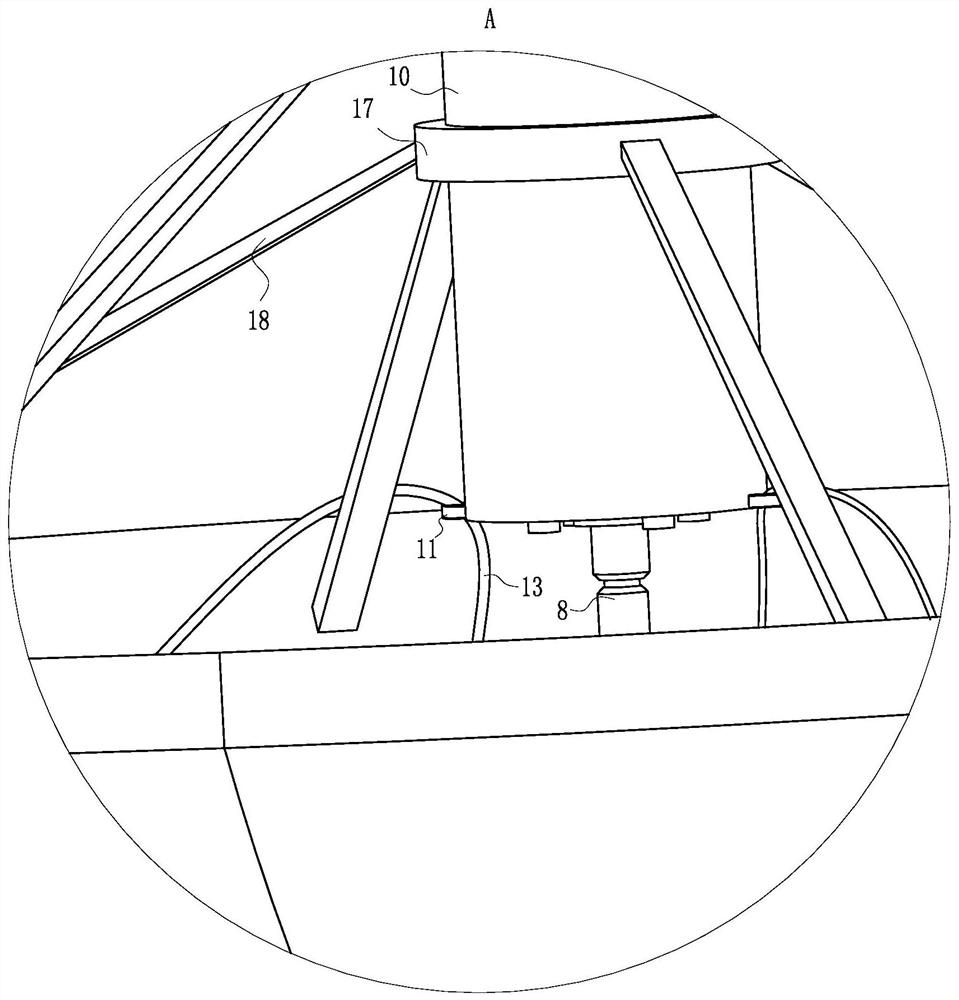

[0031] As a specific embodiment of the present invention, the outer wall of the push rod motor 8 is fixed with a circular ring 10, and the bottom end of the circular ring 10 is symmetrically fixed with more than two iron rings 11, and the side wall of the pressure block 9 is There are more than two through holes on the top, and a slider 12 is slidably installed at the through hole, and a steel wire rope 13 is fixed on the end of the slider 12 facing the push rod motor 8, and the end of the steel wire rope 13 away from the slider 12 passes through the iron The ring 11 is fixedly connected to the output shaft end of the drive motor 3; when in use, if the bottom of the inner cavity of the mold is a flat structure, it is difficult for the mixed molten iron entering the inner cavity of the mold to be distributed on the inner wall of the mold, and the pressure The block 9 is subject to greater resistance during the pressing down process, thereby causing a greater workload on the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com