Preparing method for silver-plated fibers

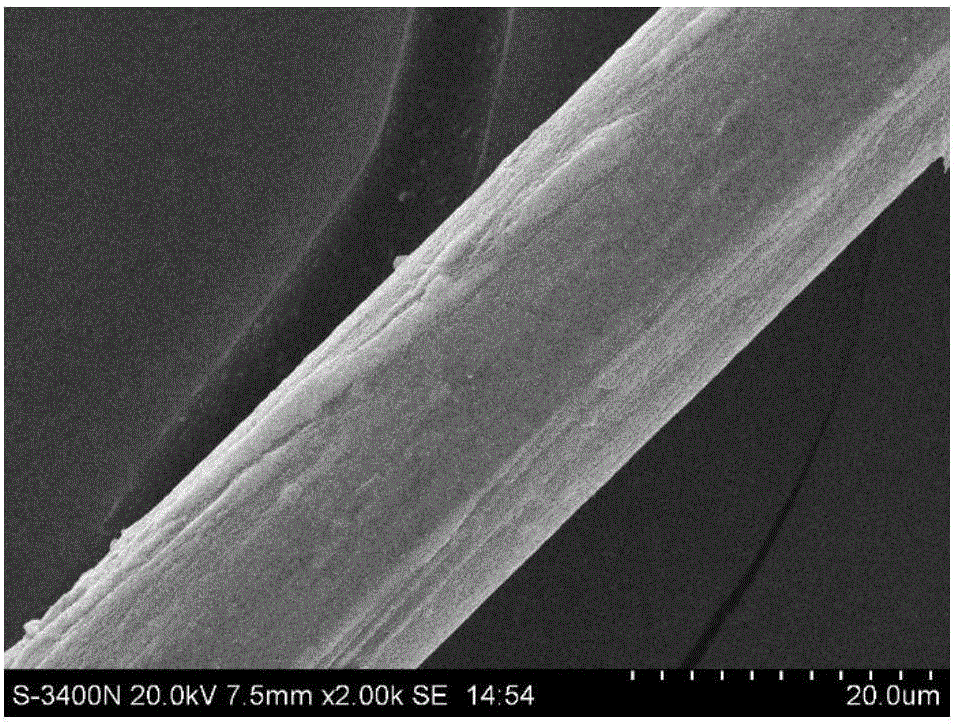

A silver-plated fiber and fiber technology, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of insufficient bonding force between the silver plating layer and the substrate fiber, and achieve excellent conductivity and antibacterial properties, not easy to peel off, Effect of increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method concrete process of silver-plated fiber is as follows:

[0022] In the first step, the polyester fiber is immersed in 5g / L sodium hydroxide aqueous solution, stirred and reacted at 130°C for 60 minutes, taken out, and rinsed with deionized water.

[0023] In the second step, immerse the fiber obtained in the first step into 10 g / L tin dichloride aqueous solution, take it out after soaking at room temperature for 2 minutes, and rinse it with deionized water.

[0024] In the third step, immerse the polyester fiber gained in the second step activation treatment in the silver salt solution, the composition of the silver salt solution is: silver nitrate 3g / L, ammoniacal liquor 3.5mL / L, formalin 1.3mL / L; 20- After stirring and reacting at 30°C for 180 minutes, take it out and rinse it with hot water.

[0025] Tests show that this silver-plated fiber has excellent antibacterial effect, and the antibacterial rate against Staphylococcus aureus is gr...

Embodiment 2

[0027] In the first step, the polyester fiber is immersed in 10g / L potassium hydroxide aqueous solution, stirred and reacted at 120°C for 90 minutes, taken out, and rinsed with deionized water.

[0028] In the second step, the fibers treated in the first step are immersed in 10 g / L tin dichloride aqueous solution, soaked at room temperature for 2 minutes, taken out, and rinsed with deionized water.

[0029] The 3rd step, the terylene fiber that second step activation process is immersed in the silver salt solution, the composition of this silver salt solution is: silver nitrate 7.5g / L, ammoniacal liquor 8.7mL / L, formalin 3mL / L; 20 Take it out after stirring and reacting at -30°C for 180 minutes, and rinse it with hot water.

[0030] Tests show that this silver-plated fiber has excellent antibacterial effect, and the antibacterial rate against Staphylococcus aureus is greater than 99.9%. It retains the characteristics of the original fiber, feels soft, and the plating layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com