Black core malleable cast iron and manufacturing method thereof

A manufacturing method and technology of cast iron, applied in the direction of improving process efficiency, etc., can solve the problems of increasing manufacturing cost of black-core malleable cast iron, and achieve the effects of shortening time, improving mechanical strength, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

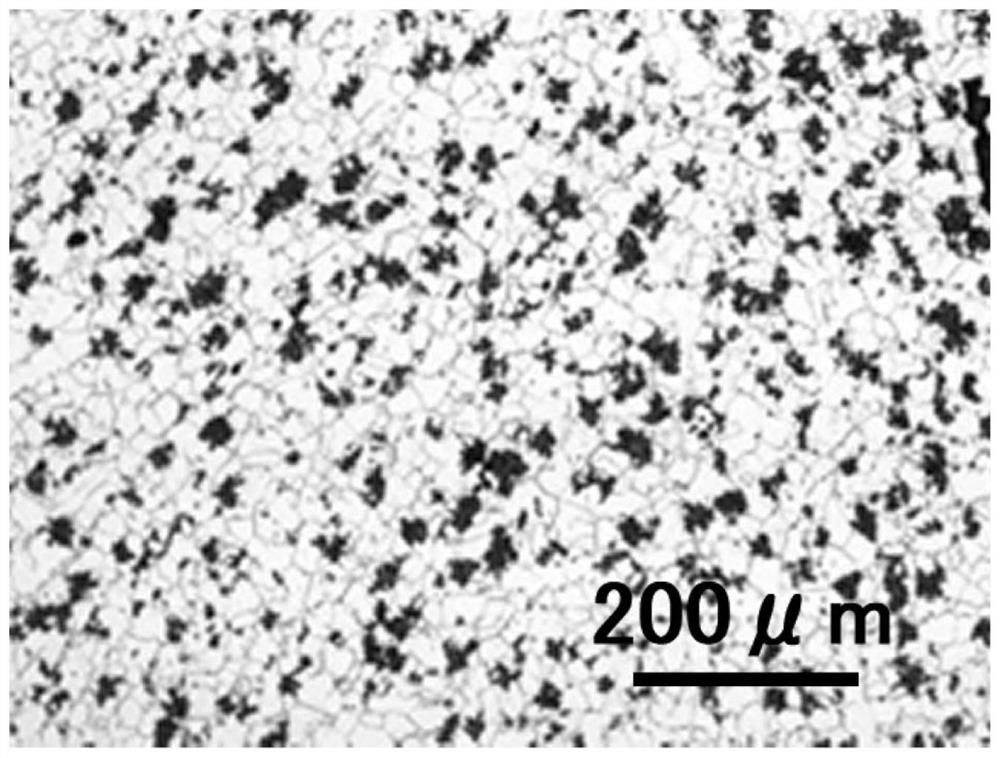

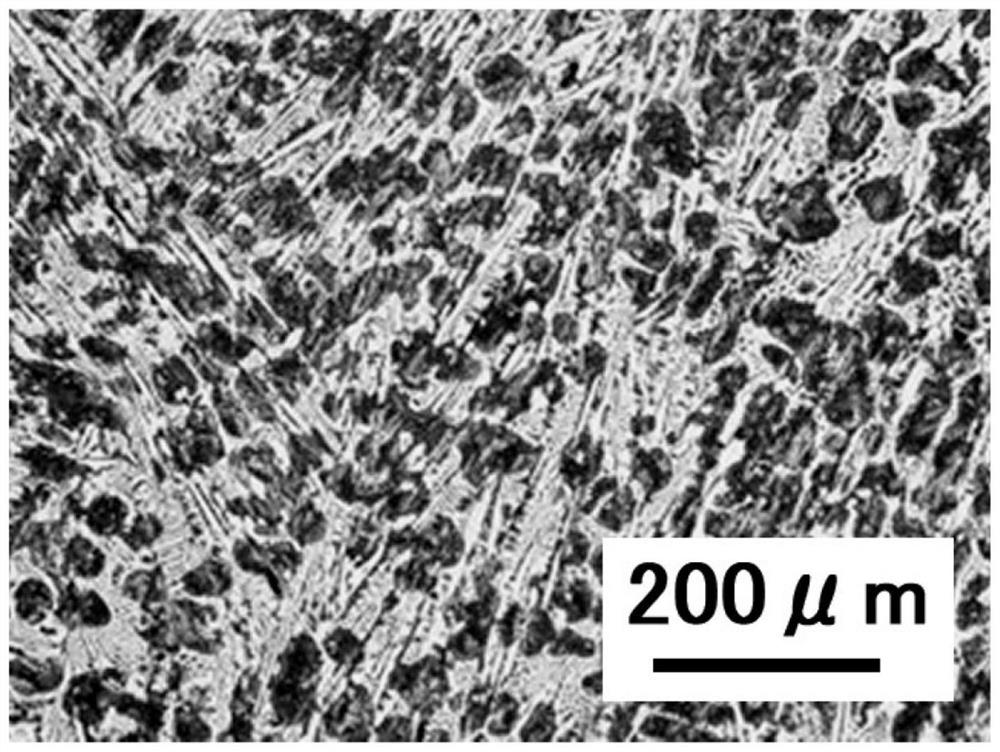

Image

Examples

no. 1 Embodiment >

[0134] In the first example, the influence of the addition amount of boron to the molten metal containing a certain amount of nitrogen on the metal structure and mechanical strength of black-core malleable cast iron was studied.

[0135] The molten metal blended so as to contain 3.0% by mass of carbon, 1.5% of silicon, iron, and unavoidable impurities as the remainder was released to a 700kg ladle, and added at 6 levels ranging from 56g to 336g. 18% boron iron boron was stirred, and then immediately poured into the mold for casting, to obtain 6 kinds of cast irons with different boron content. The obtained cast iron contained 110 ppm of nitrogen from the raw materials and 0.35% of manganese from the raw materials in addition to the above-mentioned amounts of carbon and silicon.

[0136] Next, the cast iron obtained by casting was heated from room temperature to 980° C. over 45 minutes and held for 1 hour to perform first-stage graphitization. Next, after cooling the temperatu...

no. 2 Embodiment >

[0150] In the second example, the influence when the graphitization time was prolonged compared with the first example was examined. The same cast iron before graphitization as in Sample Nos. 3 to 6 of the first example was heated from room temperature to 980° C. over 1 hour and 10 minutes and held for 1 hour and 20 minutes to perform first-stage graphitization. Next, after cooling the temperature of the cast iron to 760°C, the second-stage graphitization was performed while cooling from 760°C to 720°C over 1 hour and 20 minutes, and four black-core malleable cast iron samples of Sample Nos. 8 to 11 were produced. The same evaluation as in Example 1 was performed on the produced sample. These evaluation results are collectively shown in Table 2.

[0151] [Table 2]

[0152]

[0153] According to Table 2, all of the sample Nos. 8 to 11 satisfying the ranges of the boron and nitrogen contents of the present embodiment satisfy the range of the particle size numbers of the pre...

no. 3 Embodiment >

[0157] In the third example, a method for adjusting the nitrogen content and whether or not the scrap of cast iron and black-heart malleable iron according to the present embodiment can be reused as raw materials were examined. The target component composition of the sample was 3.0% by mass of carbon, 1.5% of silicon, 70 ppm of boron, and 160 ppm of nitrogen. An electric furnace was used for melting of the raw materials, and the mass of the raw materials used in the primary melting was set to 50 kg.

[0158] Sample No. 12 in the third example used an alloy produced in an electric furnace as a raw material used for melting. The content of boron in the alloy was 33 ppm, and the content of nitrogen was 76 ppm. 50 kg of this alloy was melted, and 16 g of ferroboron with a boron content of 16%, 100 g of manganese nitride with a nitrogen content of 28%, and 100 g of manganese nitride with a nitrogen content of 28% were added to the obtained molten metal in order to adjust the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com