A galvanized and dipped malleable steel pipe fitting

A technology of zinc malleable steel pipe and malleable steel pipe, applied in the field of galvanized dipped malleable steel pipe fittings, can solve the problem of inability to withstand acid and alkaline environment corrosion, improve the rust prevention effect, widen the scope of use and environmental adaptability, and achieve good The effect of acid and alkali resistance protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

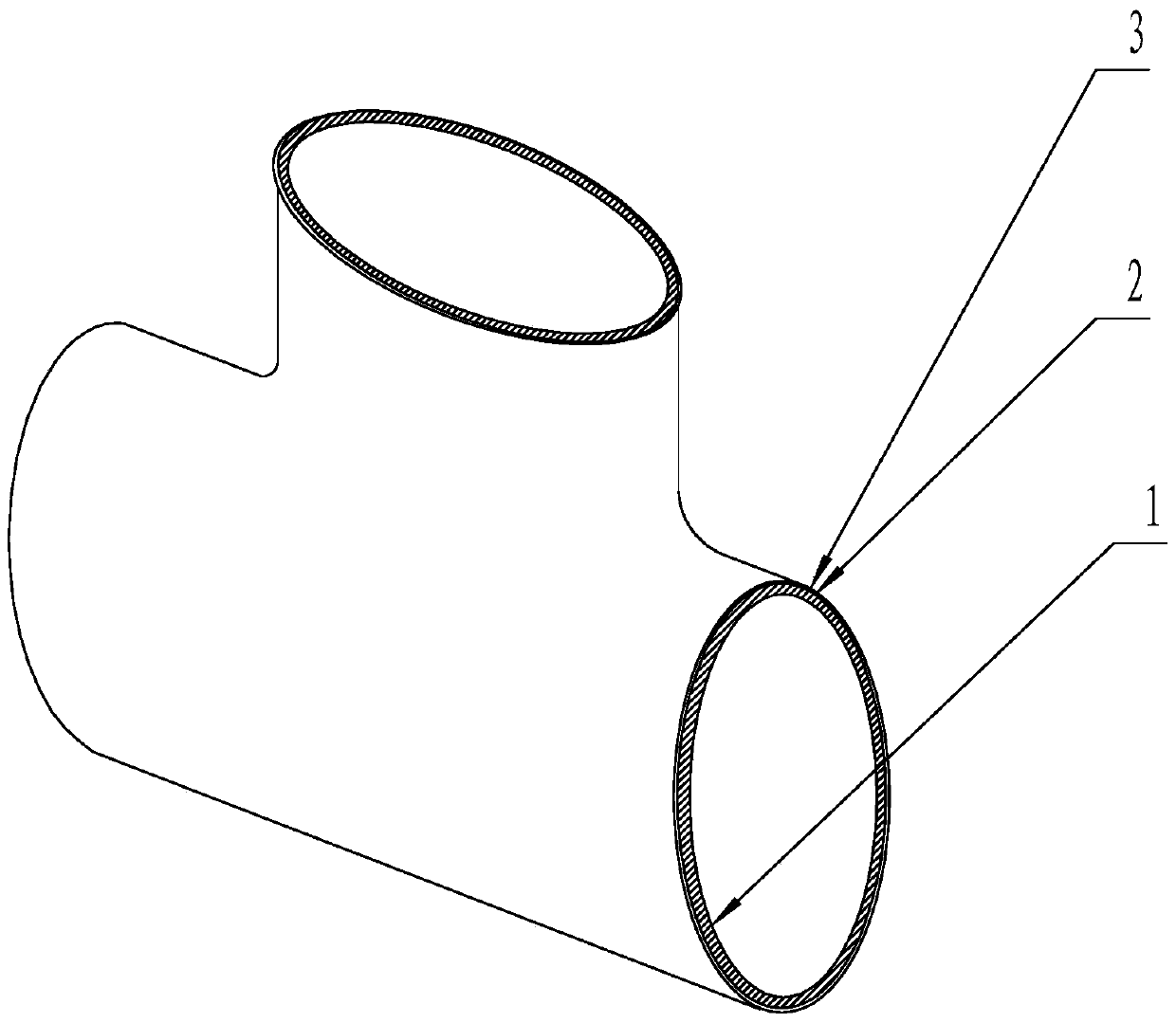

[0022] Such as figure 1 As shown, a galvanized and varnished malleable steel pipe fitting includes a malleable steel pipe fitting base 1, which is characterized in that the surface of the malleable steel pipe fitting base 1 has a galvanized layer 2 and a dipping paint layer 3 in sequence, and the galvanized layer 2 is an inner layer , The dipping paint layer 3 is the outer layer; the thickness of the galvanized layer 2 is 50μm; the thickness of the dipping paint layer 3 is 40um, the adhesion is ≤1, and the impact resistance is ≥70kg.cm;

[0023] The preparation method of the galvanized and varnished malleable steel pipe fittings includes the following steps:

[0024] A. Steps for shot blasting of malleable steel pipe base 1: the shot blasting time of malleable steel pipe 1 is 30 minutes, so that the surface of malleable steel pipe 1 can reach the national standard, which is the corrosion grade of steel surface before coating and A Sa 3 in the rust removal grade of GB8923-88. Grade...

Embodiment 2

[0035] Such as figure 1 As shown, a galvanized and varnished malleable steel pipe fitting includes a malleable steel pipe fitting base 1, which is characterized in that the surface of the malleable steel pipe fitting base 1 has a galvanized layer 2 and a dipping paint layer 3 in sequence, and the galvanized layer 2 is an inner layer , The dipping paint layer 3 is the outer layer; the thickness of the galvanized layer 2 is 80μm; the thickness of the dipping paint layer 3 is 70um, the adhesion is ≤1, and the impact resistance is ≥70kg.cm;

[0036] The preparation method of the galvanized and varnished malleable steel pipe fittings includes the following steps:

[0037] A. Steps for shot blasting of malleable steel pipe base 1: The shot blasting time of malleable steel pipe base 1 is 40 minutes, so that the surface of malleable steel pipe 1 can reach the national standard, which is the corrosion grade of steel surface before coating and A Sa 3 in the rust removal grade of GB8923-88. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com