Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Feeding difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

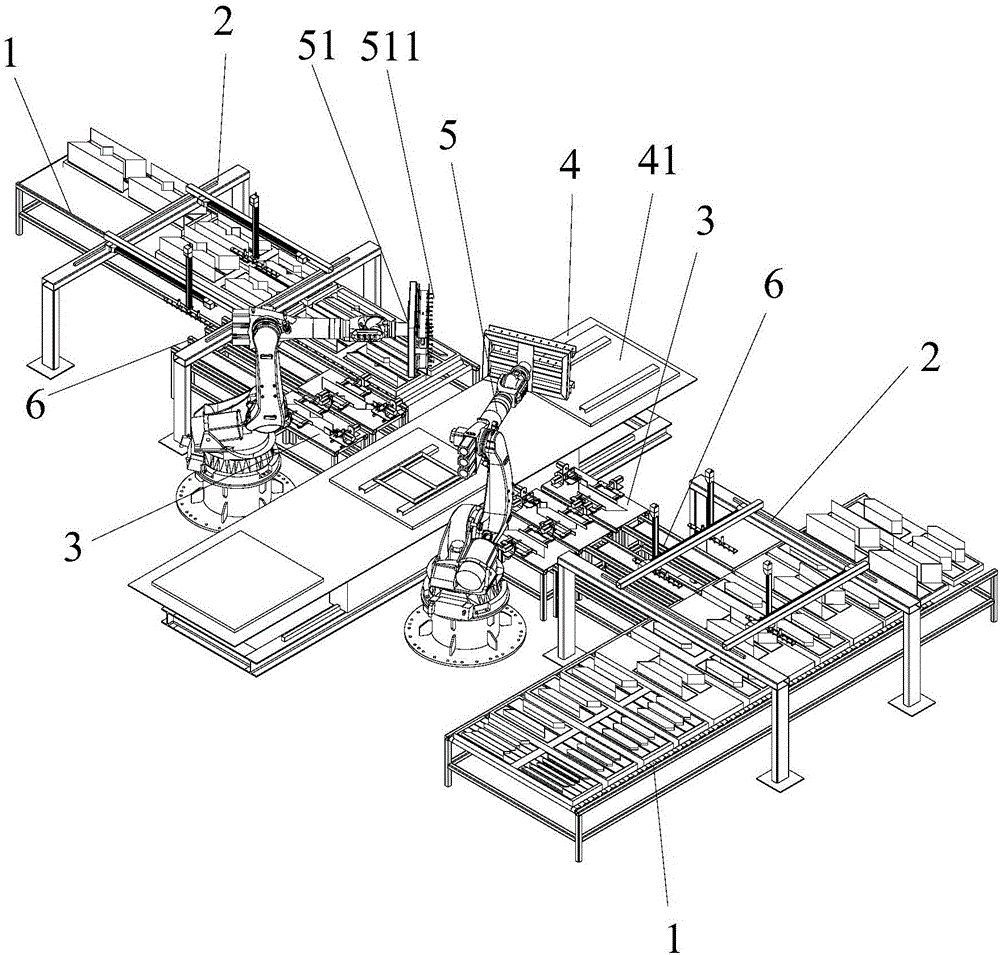

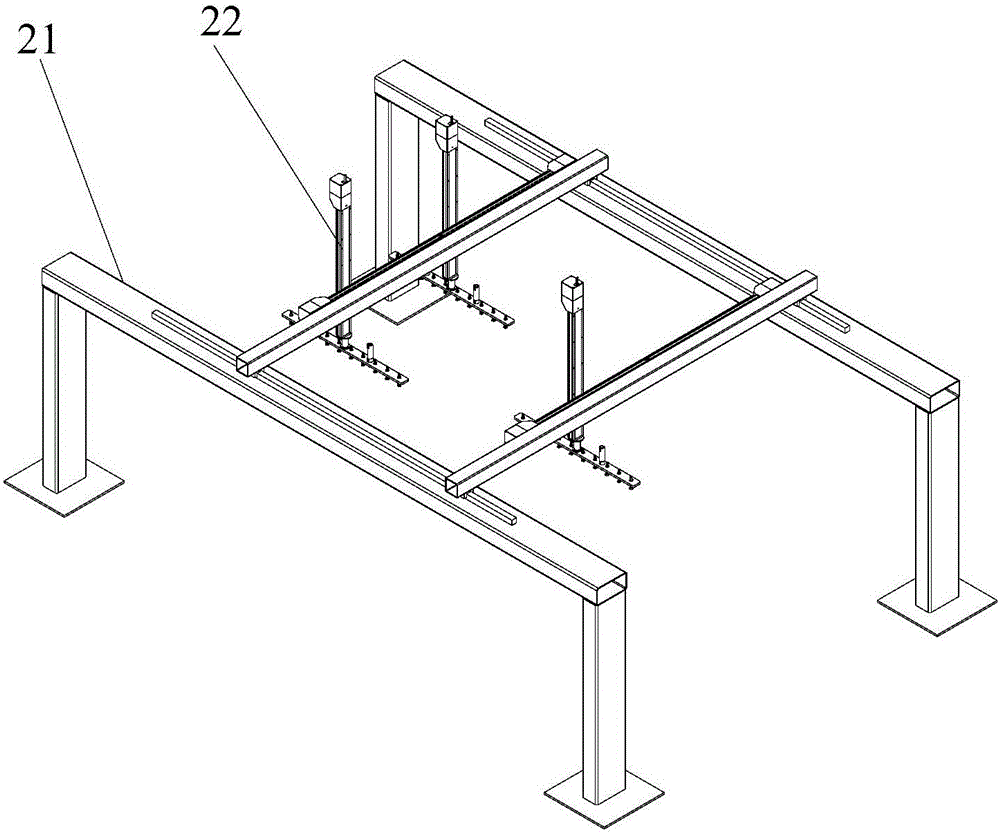

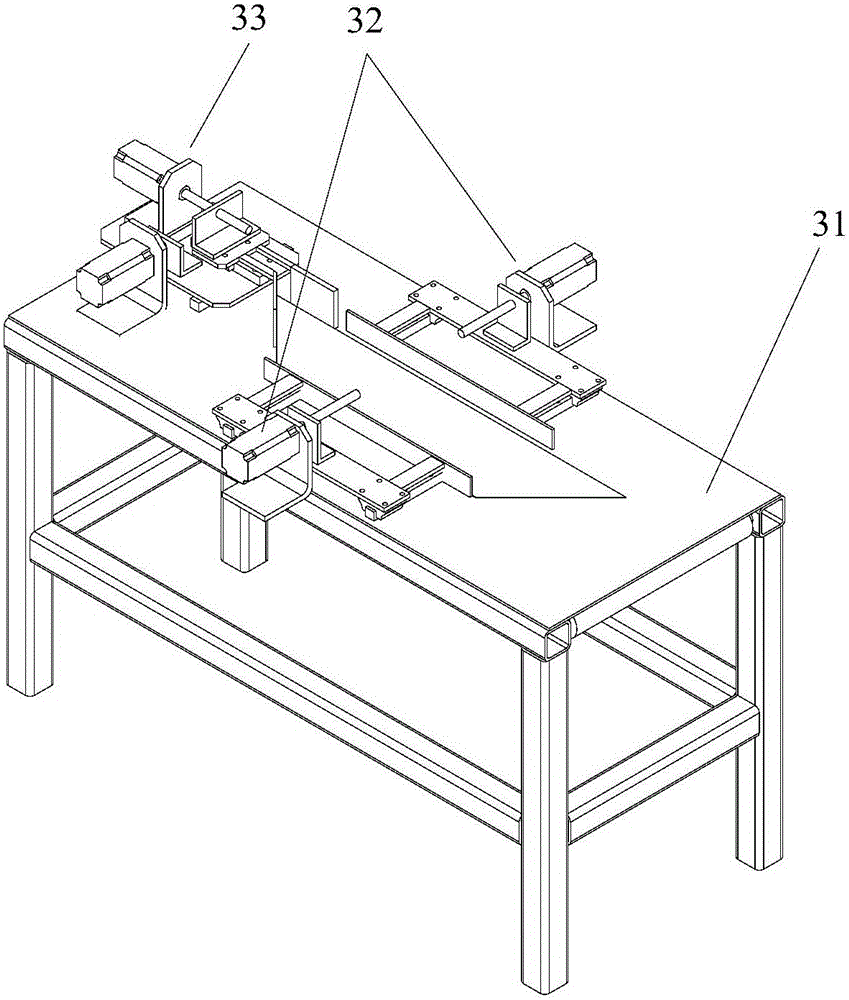

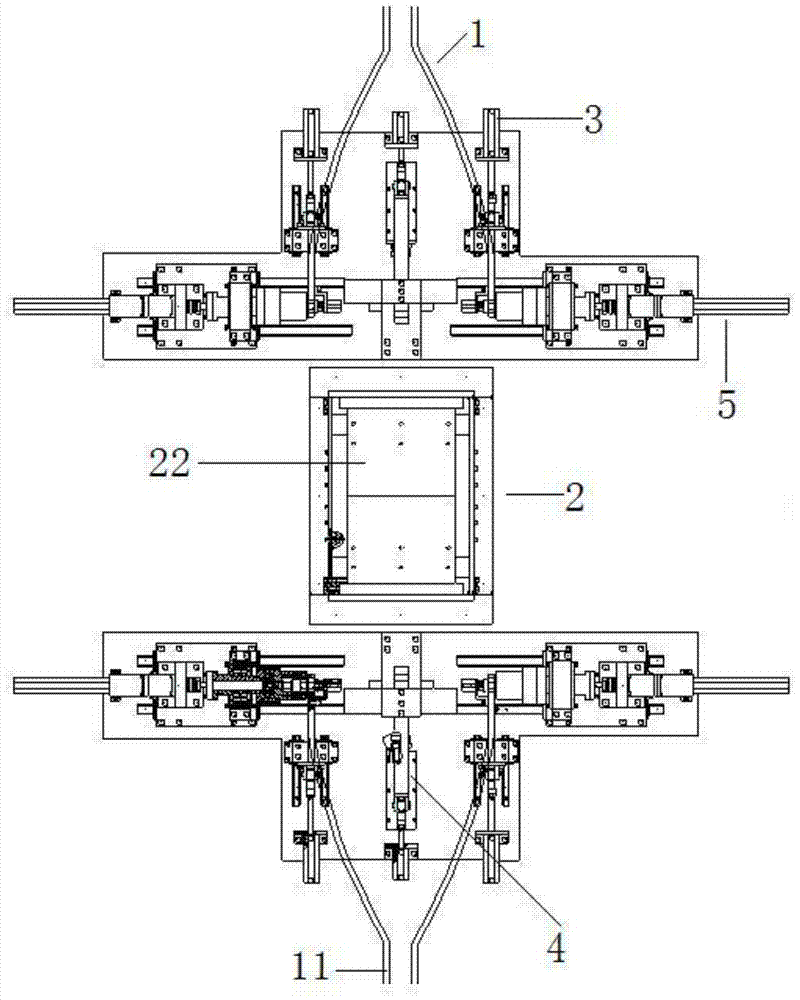

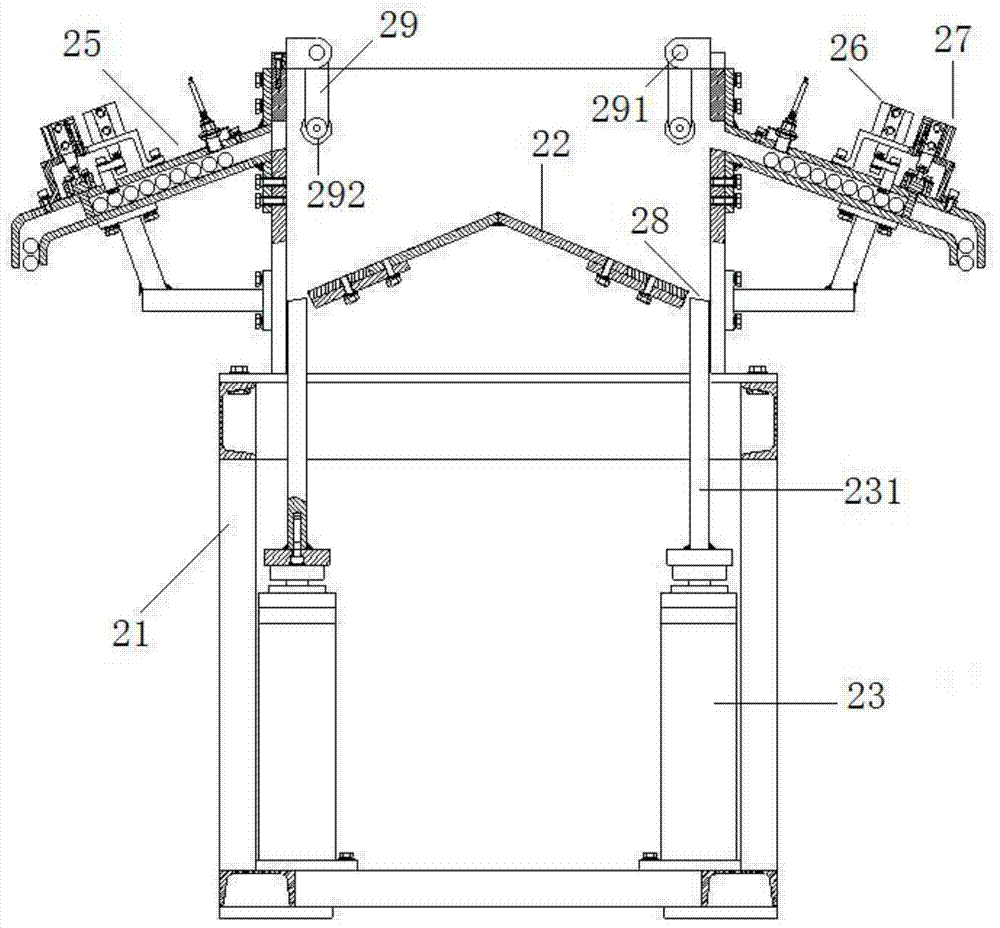

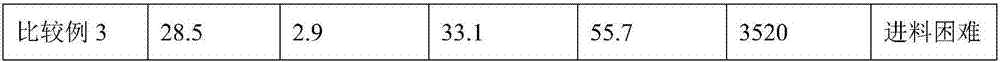

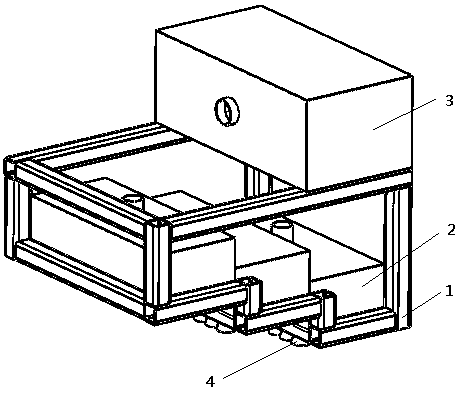

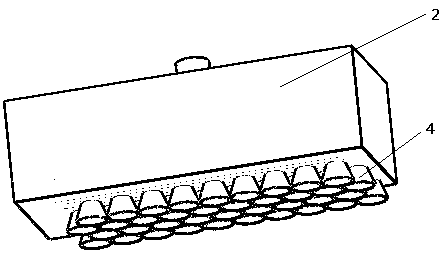

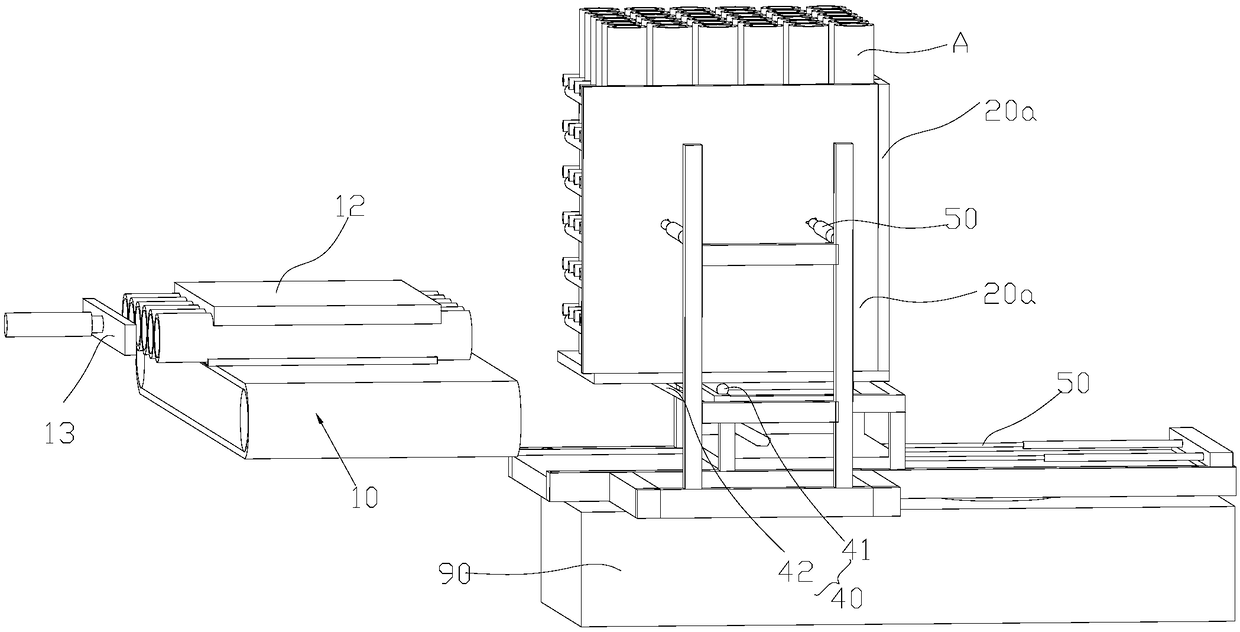

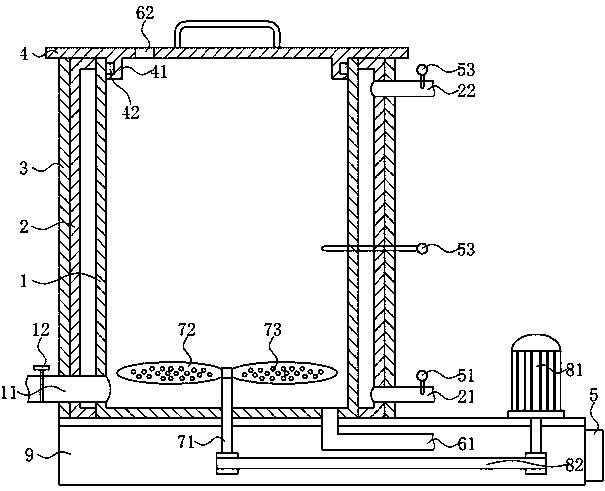

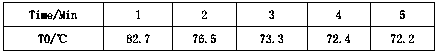

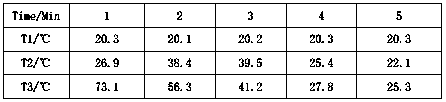

Automatic laminated sheet assembly method and system

ActiveCN105702445AReduce the difficulty of front-end loadingImprove processing efficiencyConveyorsTransformers/inductances detailsTransformerAssembly line

The invention discloses an automatic laminated sheet assembly method and system. The method comprises the steps as follows: components for forming laminated sheets in the same layer are grouped according to the structures and the shapes of the laminated sheets in the same layer in an assembly part of requiring laminated sheet assembly; the grouped components are transferred by an assembly line for laminated sheet assembly respectively; the grouped components are primarily grabbed and transferred to a positioning platform; multiple components in the same group are synchronously grabbed and are accurately positioned; the accurately positioned components in the same group are synchronously grabbed and are stacked on a laminated sheet worktable; and cyclic stack is carried out until the laminated sheet assembly is ended. The front-end feeding difficulty is lowered; multiple sheets are grabbed once; the processing efficiency is improved; relatively large processing size and model of the assembly part can be covered; the intelligent degree is high; and the automatic laminated sheet assembly method and system are especially suitable for the laminated sheet assembly of silicon steel sheets for a transformer core.

Owner:CHANGSHA CTR ROBOTICS

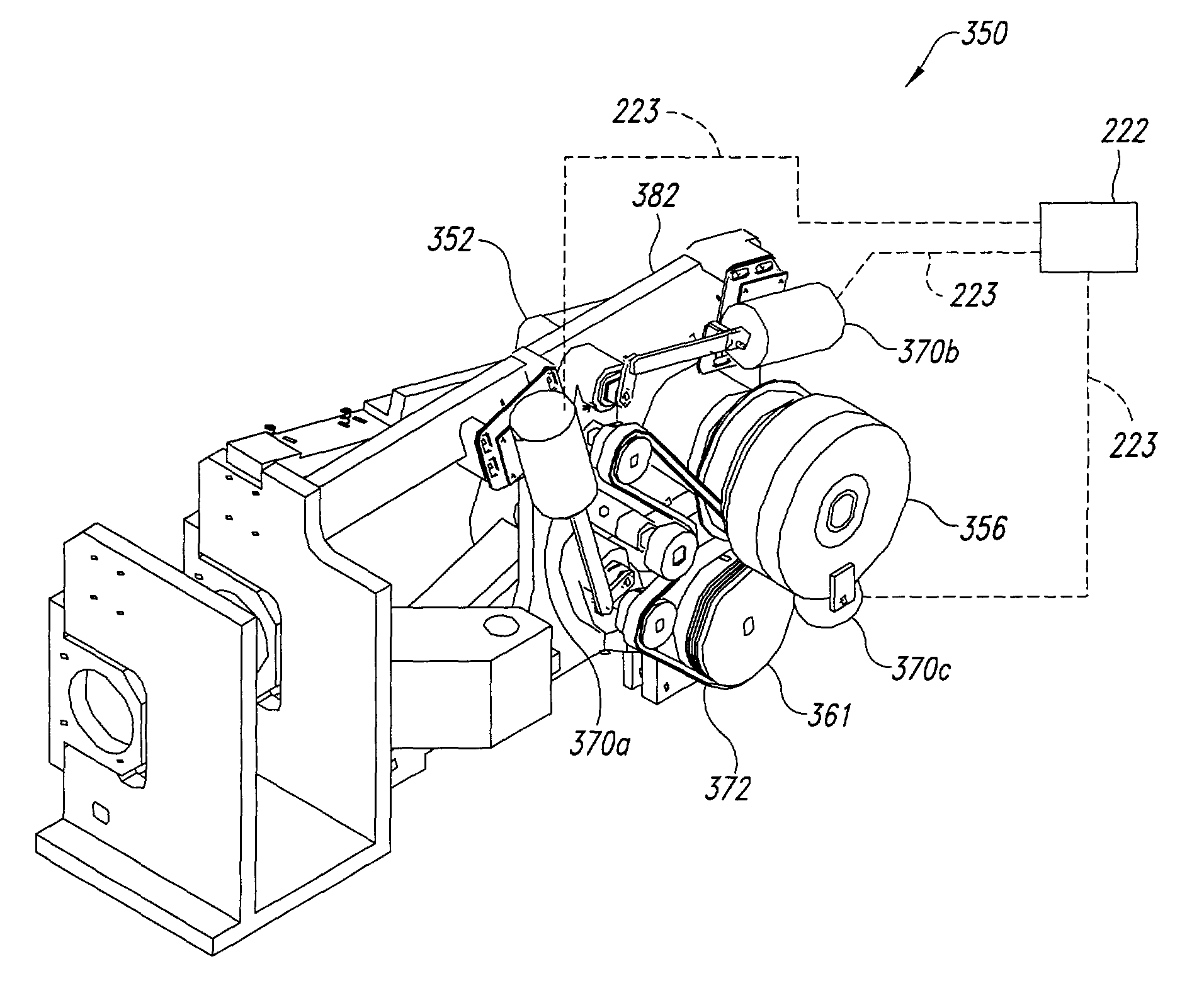

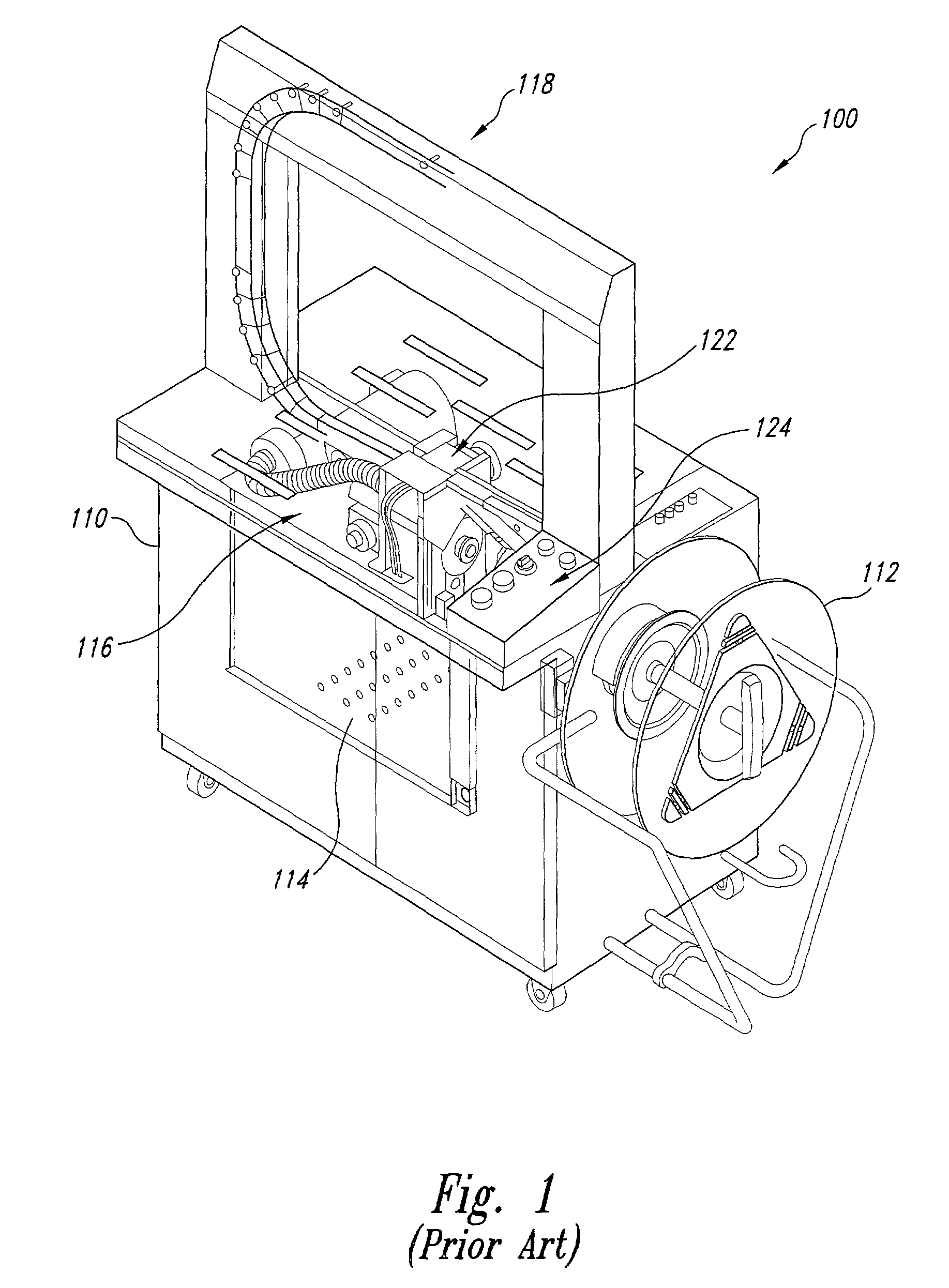

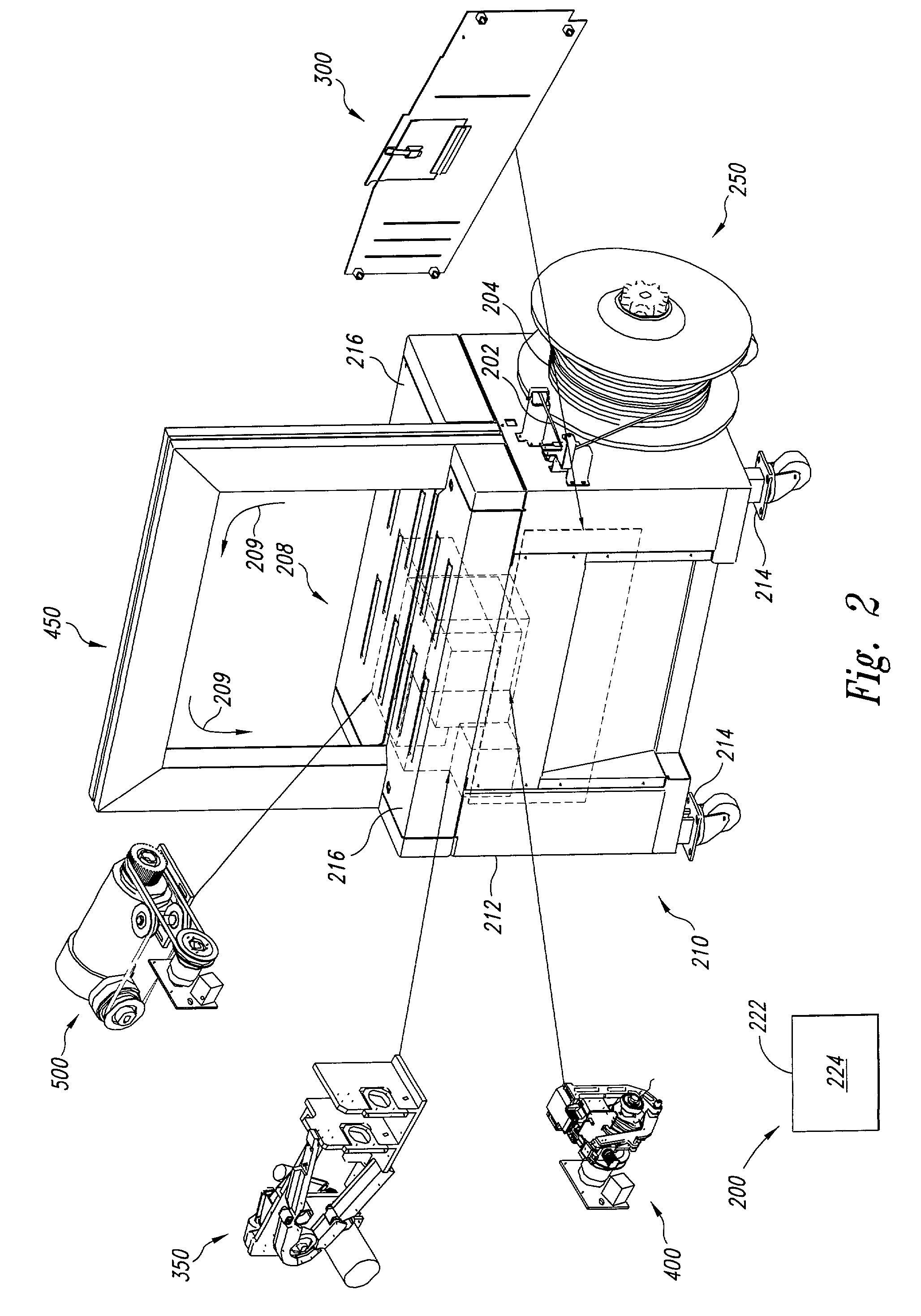

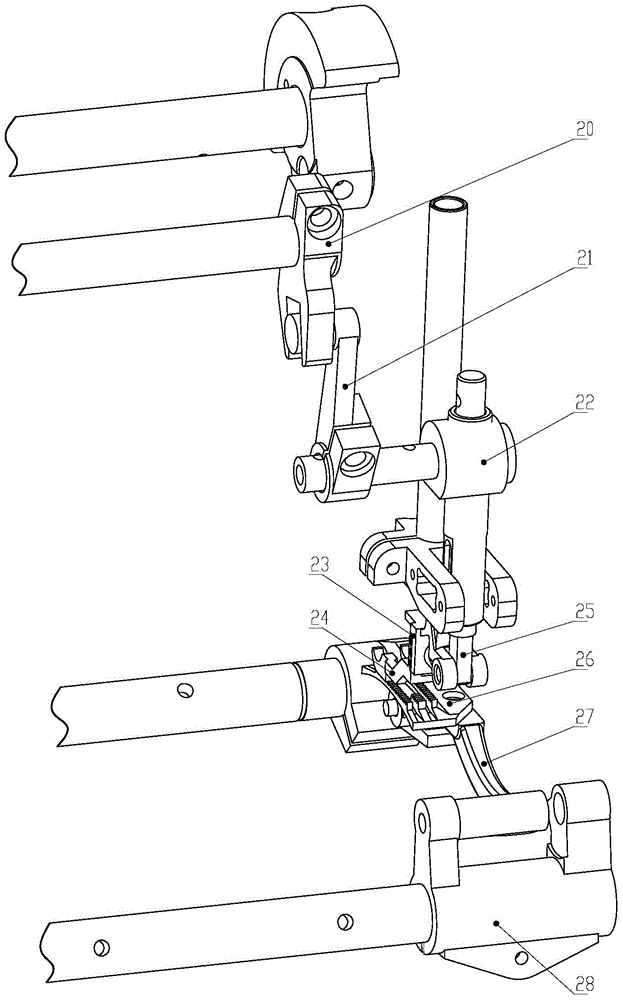

Control mechanism for a feed and tension unit in a strapping apparatus

InactiveUS20020129717A1Easy to changeVariability in apparatusBinding material applicationBundling machine detailsDrive wheelFeed drive

Apparatus and methods for applying flexible straps around objects include a feed and tension unit a feed drive wheel and a feed pinch wheel, a primary tension drive wheel and a primary tension pinch wheel, and a secondary tension drive wheel and a secondary tension pinch wheel, wherein at least one of the pinch wheels is controllably biased against the respective drive wheel by a solenoid that is controlled in two stages: a first stage that provides a full feed or tensioning force and a second stage that provides a reduced feed or tensioning force by altering the pulse width modulation of the solenoid. In another embodiment, the three sets of wheels of the feed and tension unit are configured to provide a simplified "V-shaped" strap path that reduces bending of the strap, thereby reducing friction and consequent feeding difficulties. In another embodiment, the feed and tension unit includes inner and outer guides that form a strap channel through the feed and tension unit to provide easy access to the strap path for clearing the strap path in the event of a jam. In another embodiment, a track assembly includes a plurality of sections providing modularity of construction. Each section includes a backplate attached to at least one support member, and a slotted cover pivotably attached to the at least one support member proximate the backplate and moveable between an open position spaced apart from the backplate and a closed position proximate the backplate. In another embodiment, a cutting assembly for severing strap material includes a press platen and a cutter having a first cutting blade along a first edge thereof and a second cutting blade along a second edge thereof, the cutter being removably and variably engaged to the press platen.

Owner:SAMUEL MANU TECH

Method for producing wood-plastic composite material

The invention relates to a method for preparing wood-plastic composite materials. The method comprises the following steps: 1) thoroughly mixing 50-100 weight parts of wood powder with 40-200 weight parts of fillers with a high-speed mixer, adding 1-20 weight parts of finishing agents into the high-speed mixer, and stirring at 80-120 DEG C for 10-20 min; 2) adding 10-20 weight parts of addition agents in the resulting powder mixture, stirring for 3-6 min to allow uniform dispersion; 3) delivering the resulting mixture produced in the step 2) to a fluidized bed dryer for drying until the water content is below 3%, granulating by using a ring mould pellet mill to obtain pressed pellets; and 4) mixing resin granules with pellets at a weight ratio of 1:(1-2) and extrusion-molding to obtain the final product. The preparation method is implemented by pressing and pelletizing wood powder, mixing wood pellets with plastic granules and conducting extrusion processing, overcomes material feeding difficulties, and can double the yield and increase production capacity.

Owner:中山市森朗环保装饰建材有限公司

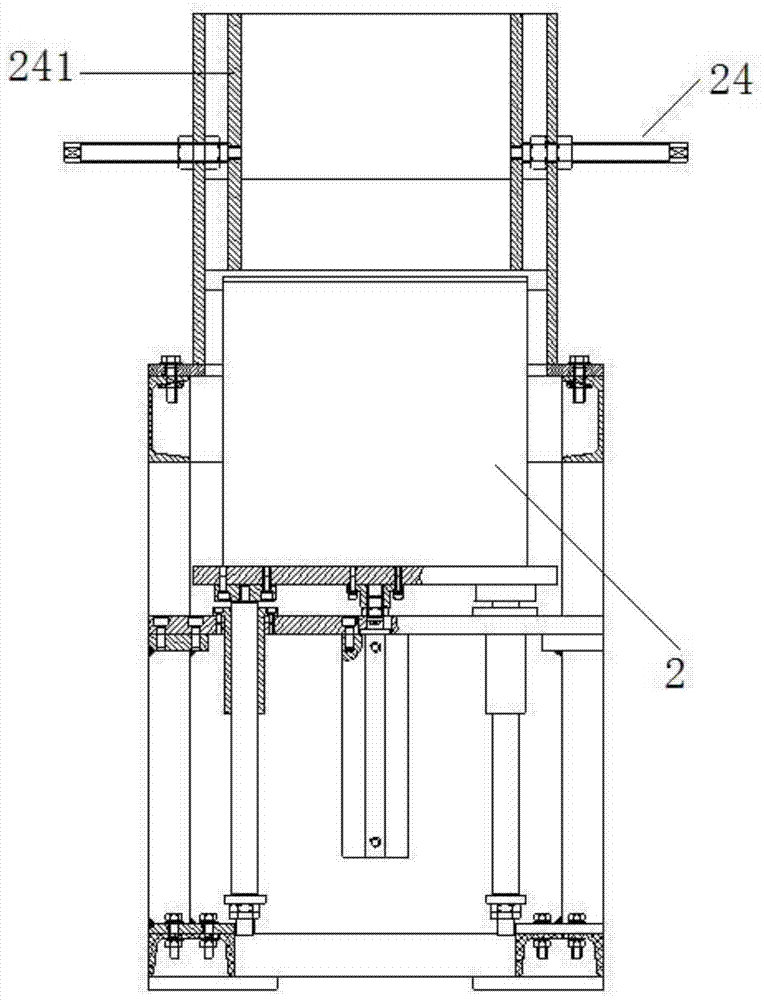

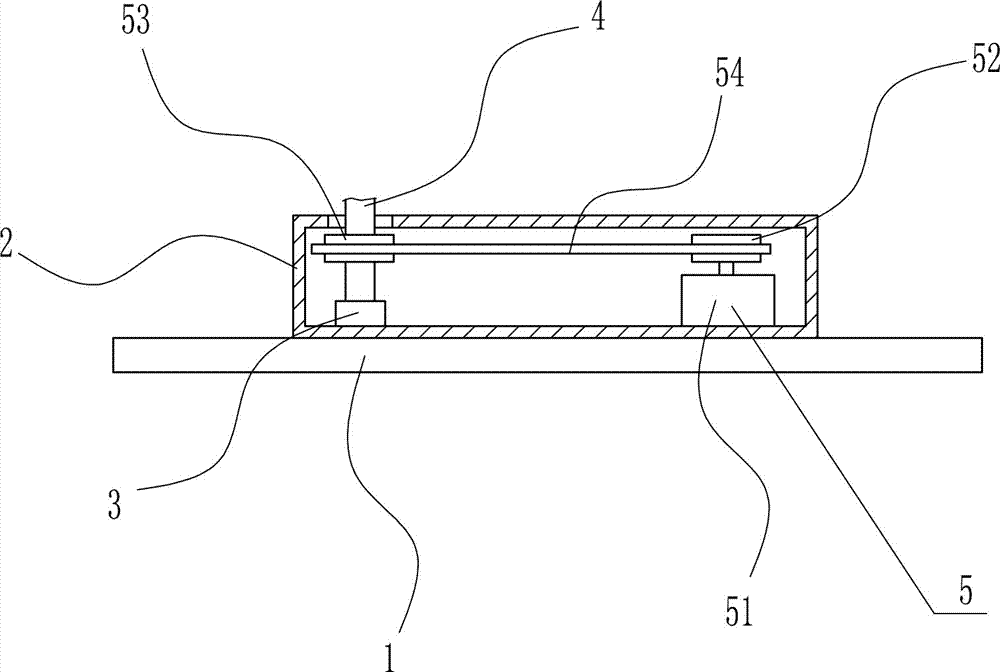

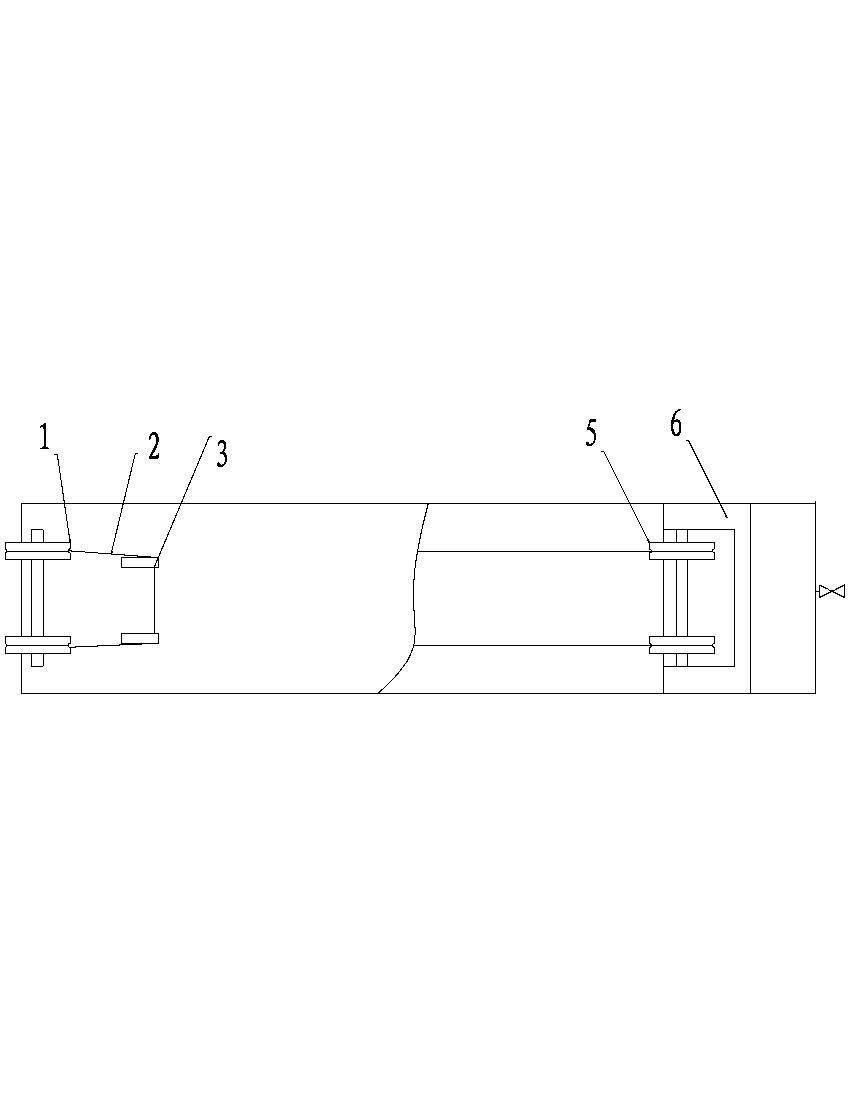

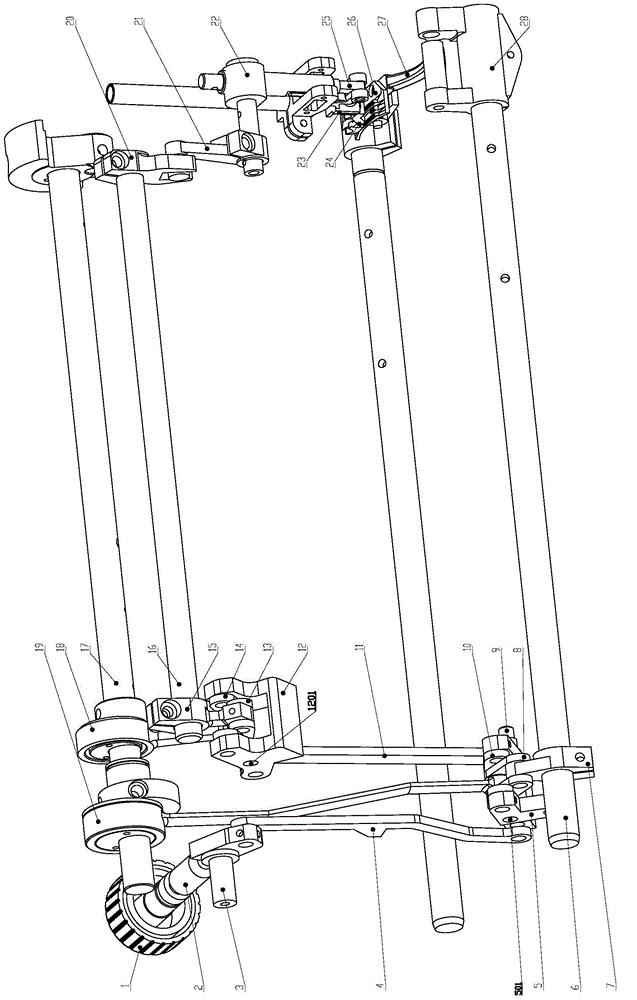

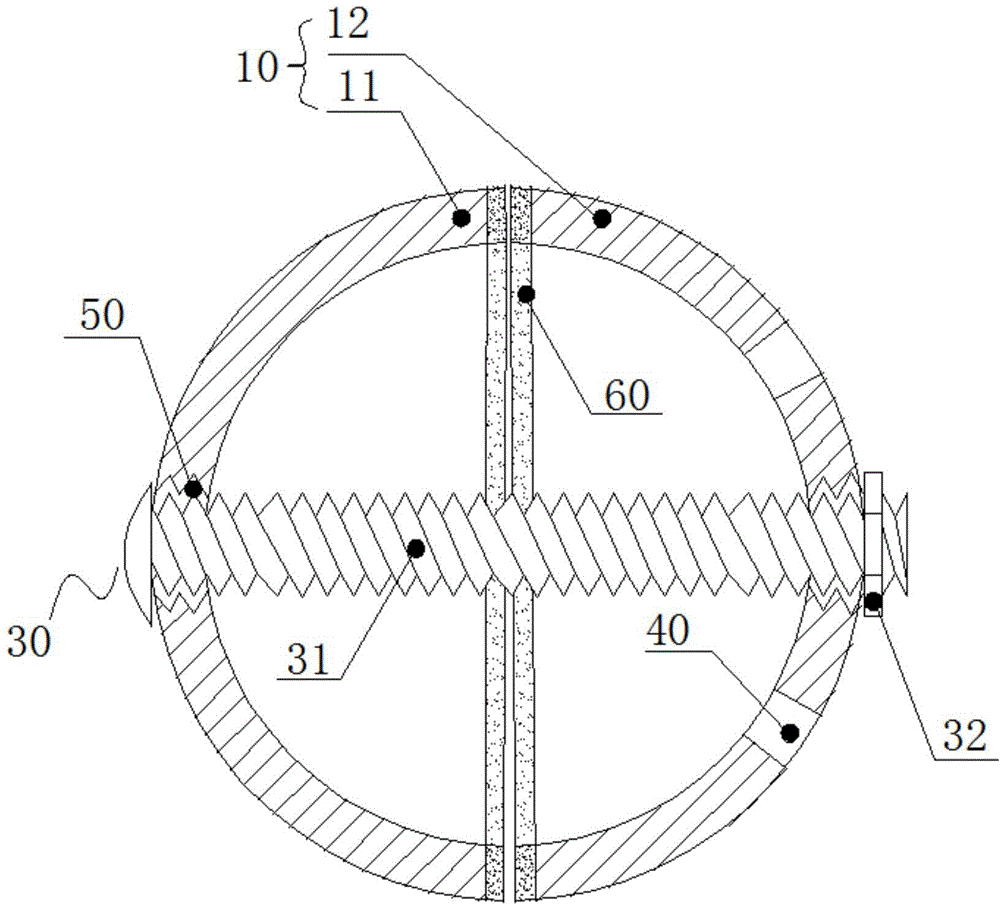

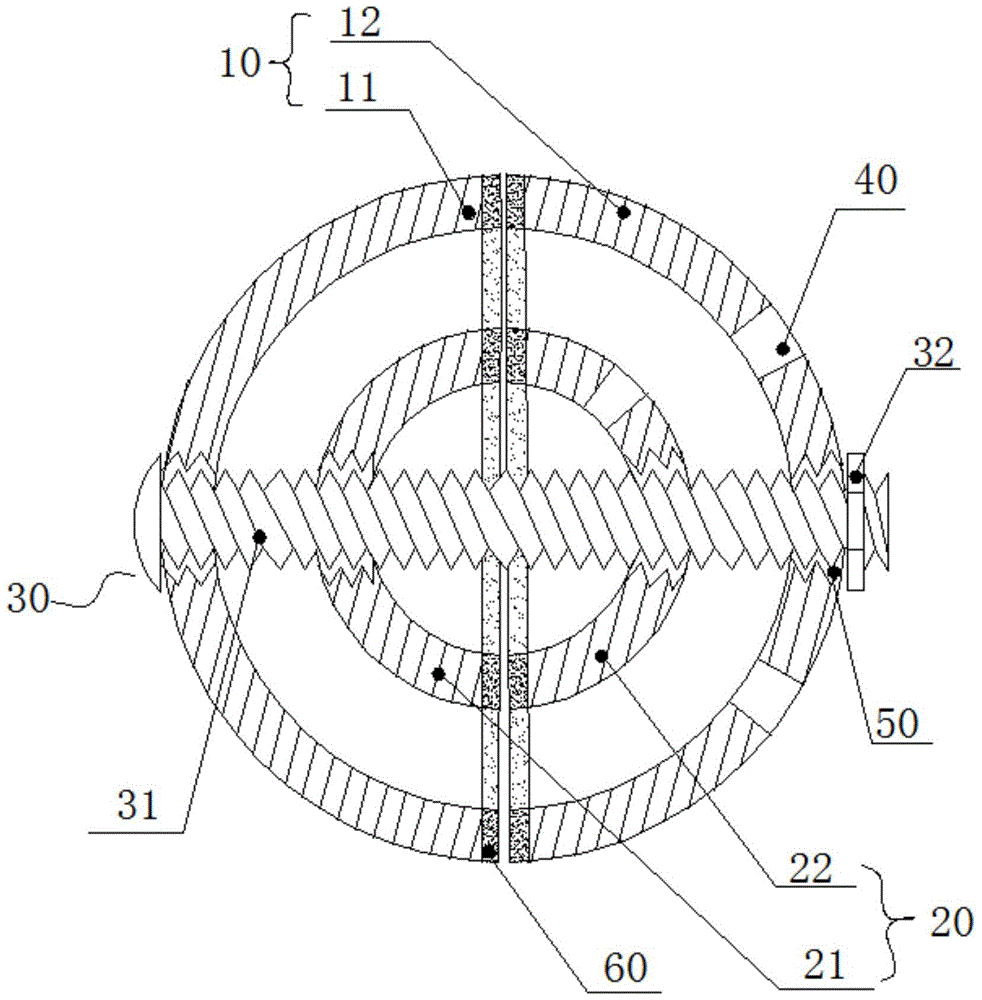

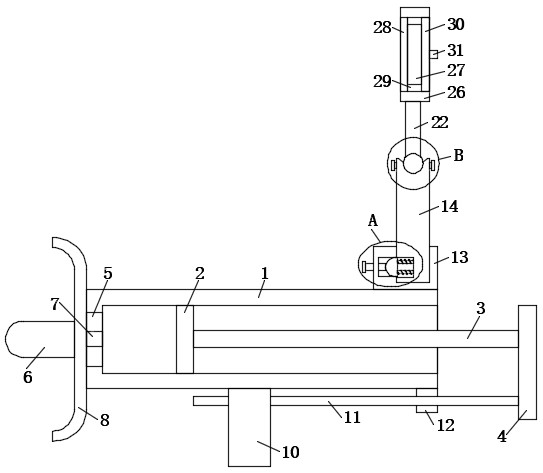

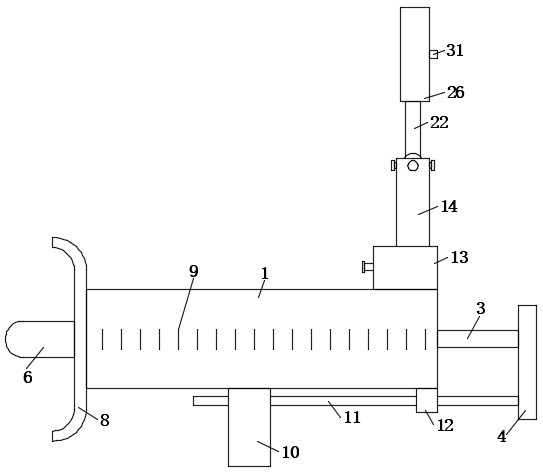

Screw rod and nut assembling device

ActiveCN104275593AReduced precision requirementsFeeding operation is simple and fastMetal working apparatusEngineeringSelf adjustment

The invention discloses a screw rod and nut assembling device, and aims to provide an assembling device which is reasonable whole structure distribution, is capable of completing feeding through simple, low-requirement operation, enabling the automatic adjusting capacity to be obtained during a feeding process and carrying out effective and accurate positioning after the feeding is completed, has a quick positioning process, is unlikely to cause additional damage and is capable of ensuring the smoothness and the stability of the whole assembling process. The screw rod and nut assembling device comprises a nut feeding device, a screw rod feeding device, an upper nut device, an upper screw rod device and a screwing device. The screw rod and nut assembling device disclosed by the invention has the beneficial effects that the screw rod and nut assembling device can be suitable for feeding screw rods in multiple length specifications in sequence; the feeding operation is simple and quick, adaptive adjustment can be automatically carried out during a follow-up blanking process, the blanking position is accurate, and the feeding difficulty is low; two-end assembling of the multiple screw rods can be simultaneously carried out, and the production efficiency is increased; the error amount can be adapted to through self adjustment of a buffer spring, the requirement on accurate feeding amount of an air cylinder is reduced, and better security is provided for the stability of the assembling process.

Owner:HANGHOU ACAD OF MACHINERY SCI & TECHCO

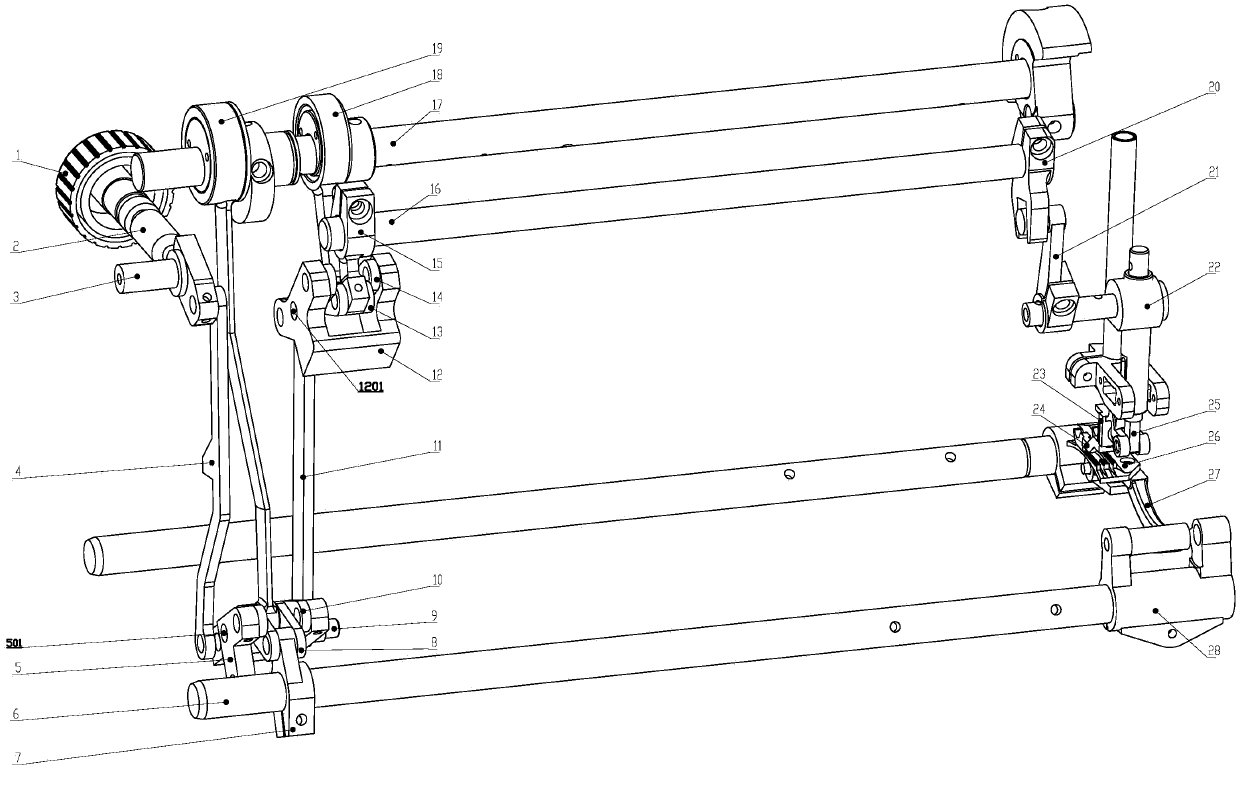

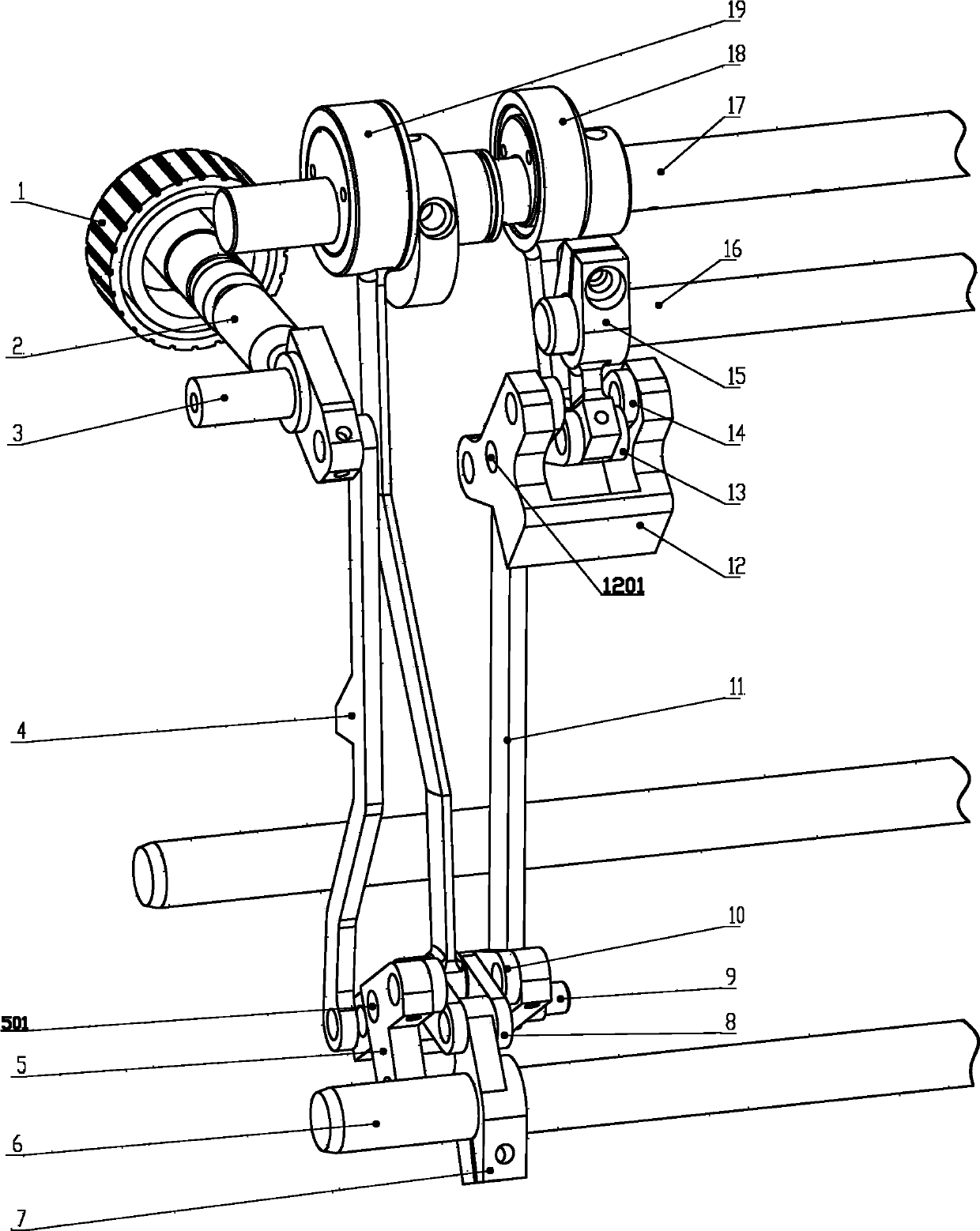

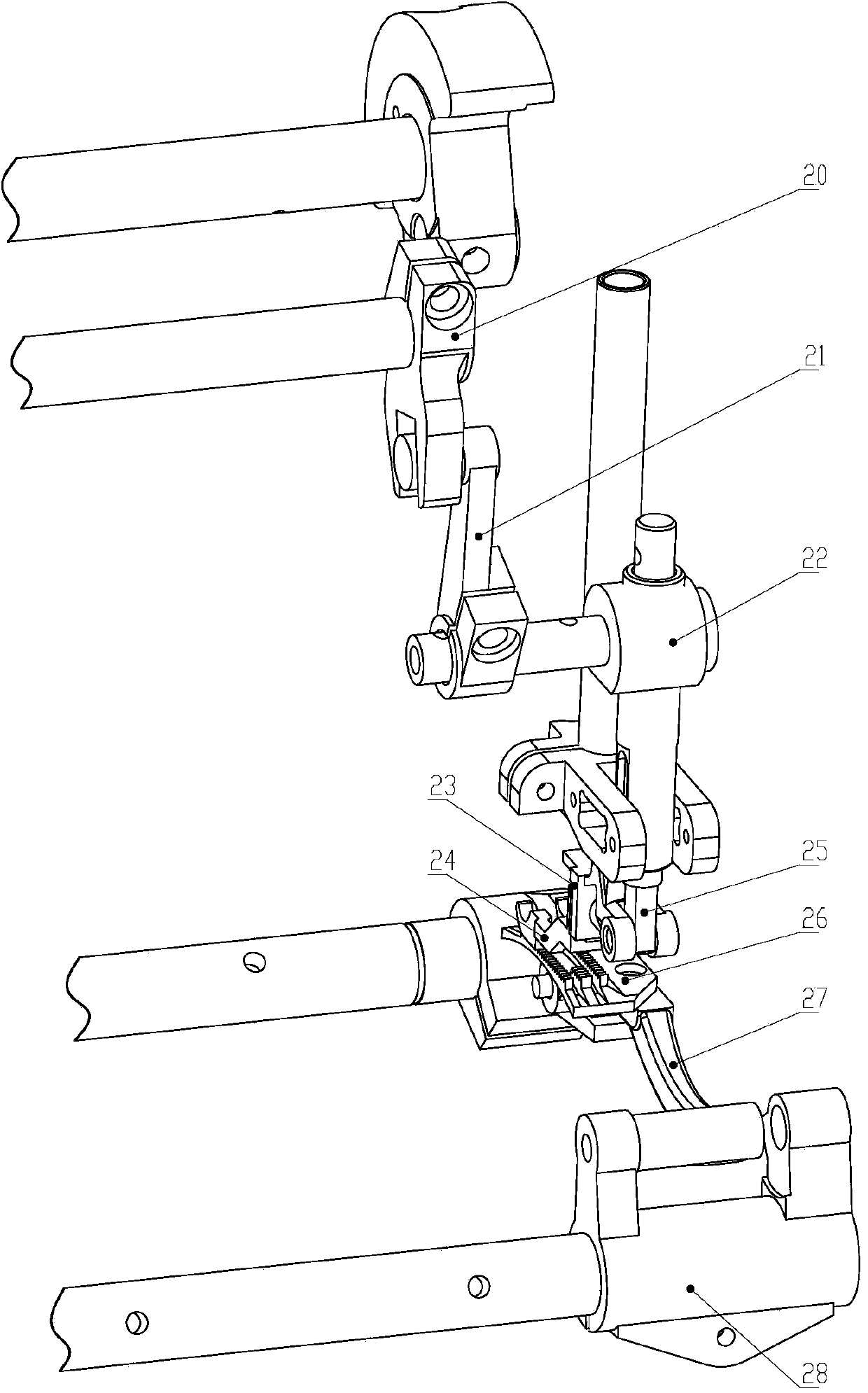

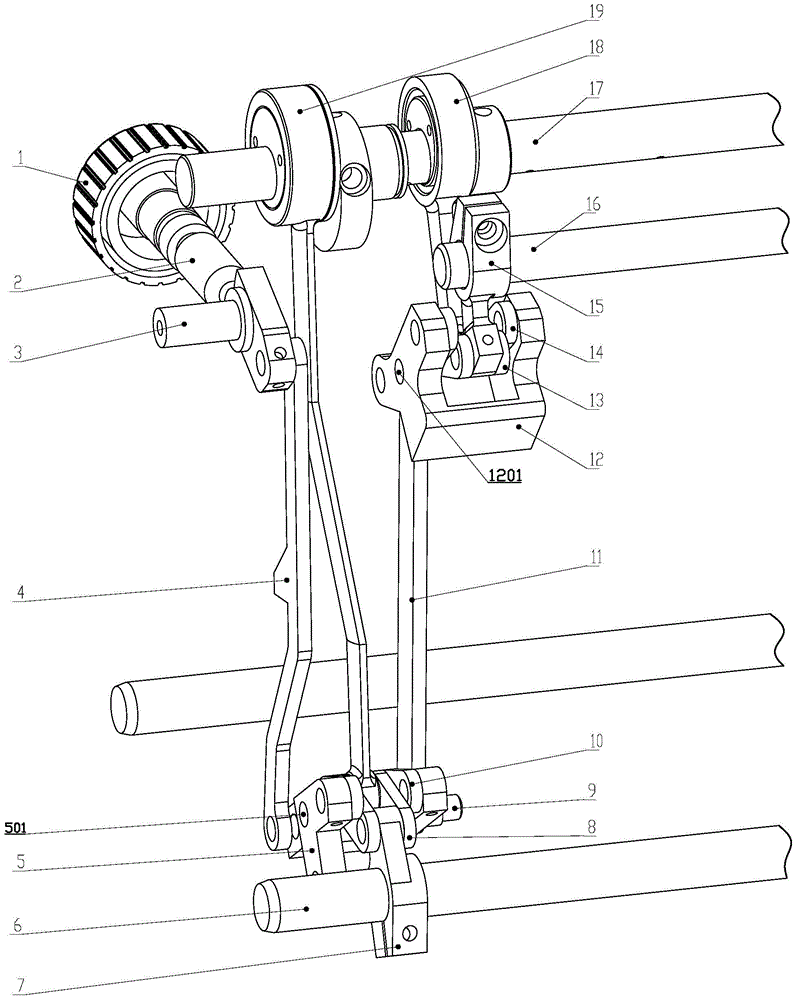

Upper and lower synchronous feeding mechanisms of thin-material lockstitch sewing machine and feeding method thereof

The invention relates to upper and lower synchronous feeding mechanisms of a thin-material lockstitch sewing machine and a feeding method thereof. The mechanisms are designed aiming at that the similar product mechanisms are not easy to adjust and high in synchronous feeding difficulty. The design key points of the mechanisms are that the upper pin shaft hole of an upper feeding oscillating plate seat is connected to the housing of the lockstitch sewing machine through a pin shaft, while swinging around the pin shaft, the upper feeding oscillating plate seat drives the upper synchronous feeding mechanism to change the swing amplitude so as to change the distance of travel of upper feeding teeth, a lower feeding oscillating plate seat swings around the pin shaft and thus drives the lower feeding mechanism to change the swing amplitude and also to change the distance of travel of lower feeding teeth, a synchronous connecting rod eccentric pin and a synchronous connecting rod are provided so that the upper and lower feeding teeth move synchronously, and under the error influence of the upper synchronous feeding mechanism and the lower synchronous feeding mechanism, the center distance of the synchronous connecting rod is adjusted by the synchronous connecting rod eccentric pin so that the upper synchronous feeding mechanism and the lower synchronous feeding mechanism run synchronously. The manufacturing cost of the upper and lower synchronous feeding mechanisms of the thin-material lockstitch sewing machine is low, the feeding method is feasible, the labor efficiency is effectively improved, and therefore, the upper and lower synchronous feeding mechanisms and the feeding method are suitable for popularization and application.

Owner:NINGBO SANHEXIN AUTOMATION

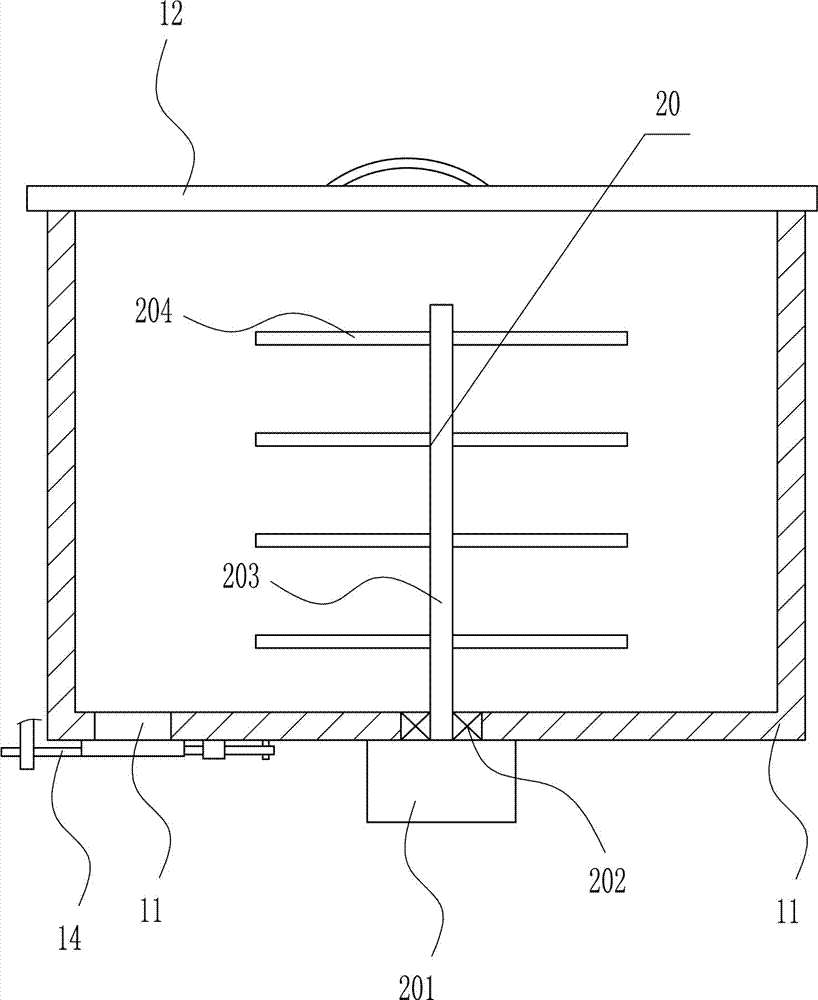

Discharging device for mixing in chemical petroleum refining

InactiveCN107159051ARealize lifting functionLeak evenlyRotary stirring mixersMixer accessoriesPetroleumPersonnel safety

The invention relates to a discharging device, in particular to a discharging device for mixing in chemical petroleum refining and aims to realize low feeding difficulty, high feeding efficiency and capability of guaranteeing personnel safety in feeding. The discharging device comprises a base, a shell, a first bearing seat, a first rotating shaft, a rotating device, a 7-shaped frame, a second bearing seat, a second rotating shaft, a lifting rod, a lifting device, a transport tank and the like. The shell is arranged in the middle of the top of the base, and the first rotating shaft is mounted on a bearing of the first bearing seat which is arranged at the bottom of the inner left portion of the shell. The discharging device has advantages of simplicity in operation, time saving, labor saving and high safety. By manhole control, semiautomatic rotating discharging and stirring for mixing, high practicality and high safety are realized.

Owner:曾河锦

Vacuum ejection device with energy storage function

InactiveCN102589346AEven by forceImprove stress conditionBows/crossbowsStress conditionsConstant force

The invention provides a vacuum ejection device with an energy storage function. A capacity-variable vacuum chamber consisting of a barrel and a piston is used as an energy storage body, and the size of the capacity of the vacuum chamber is changed by the aid of a chord rope via a pulley system, so that mechanical energy is stored or released. The vacuum ejection device realizes a constant-force spring effect, constant-force input and output of energy storage and releasing of the ejection device are realized, chord feeding difficulty is reduced, and an object is ejected stably. Simultaneously, the stress condition of the chord rope is improved.

Owner:杨中华

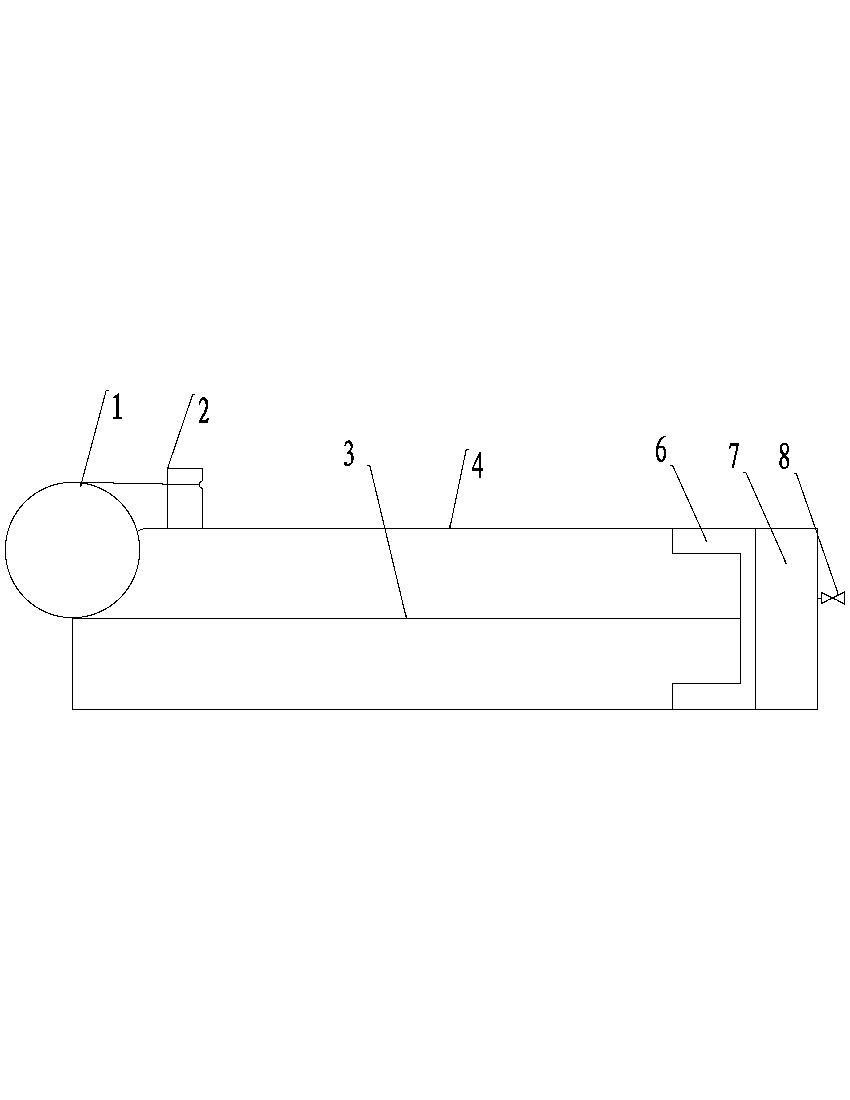

Continuous feeding device for solution method centrifugal spinning

InactiveCN105155000ASuitable for mass productionSimple structureSpinning head liquid feederFilament/thread formingDrive shaftInjection pump

The invention relates to the field of centrifugal spinning, and aims to provide a continuous feeding device for solution method centrifugal spinning. The device comprises a motor, a spinning jet and a hose fixing base. The motor is arranged on a rack. One end of a transmission shaft is connected to the motor, and the other end of the transmission shaft is connected with the spinning jet. The hose fixing base is fixed to the rack through a supporting rod, and a longitudinal through hole is formed in the hose fixing base. Two bearings are arranged at the two ends of the through hole respectively. The transmission shaft is installed in a flange bearing and coincides with the center line of the through hole. A rubber hose penetrates through an inclined through hole formed in one side of the hose fixing base, a feeding port of the rubber hose is connected to an outlet of an injection pump, and a discharging port of the rubber hose stretches into a cavity of the spinning jet in a suspended mode without making contact with the inner wall of the cavity or the transmission shaft. The continuous feeding device can feed a spinning solution to the spinning jet or a horizontal disc continuously, and therefore the situation that the development of solution method centrifugal spinning is limited by feeding difficulty will not occur. The continuous feeding device is simple in structure, small in occupied space, low in cost, high in adaptability, capable of improving production efficiency and suitable for batch production.

Owner:ZHEJIANG SCI-TECH UNIV

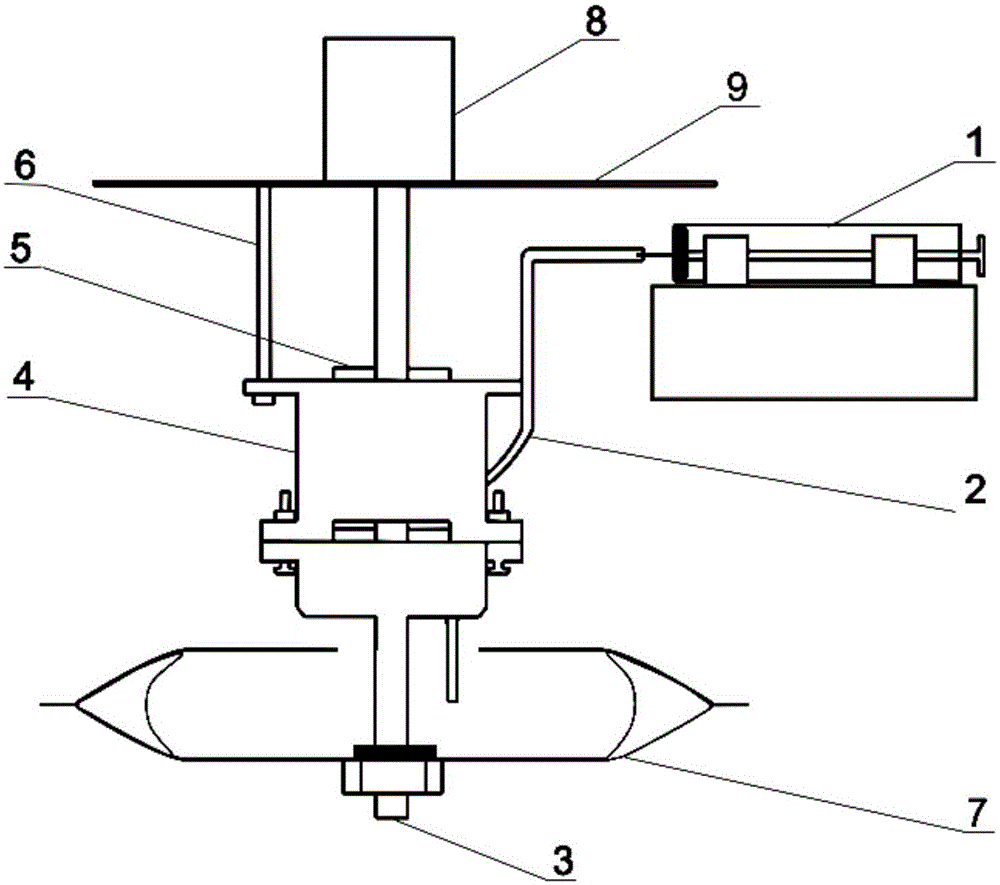

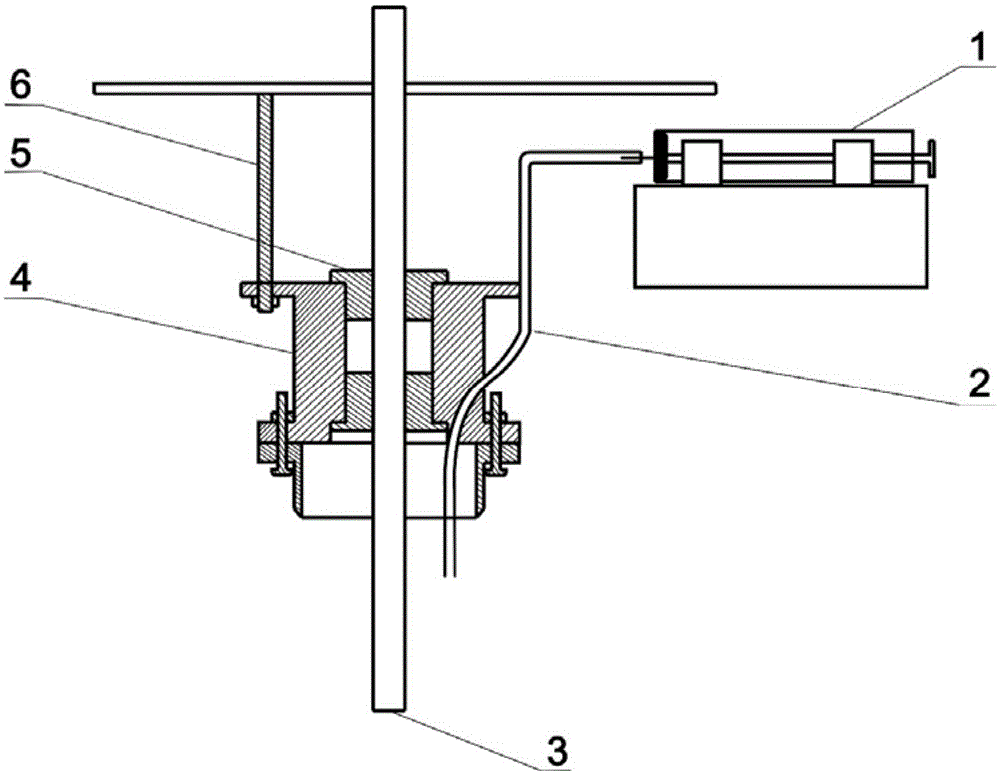

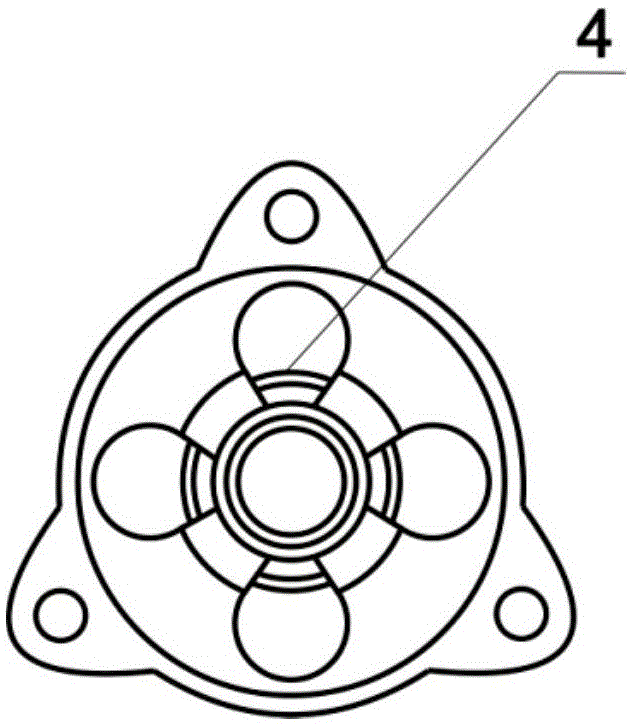

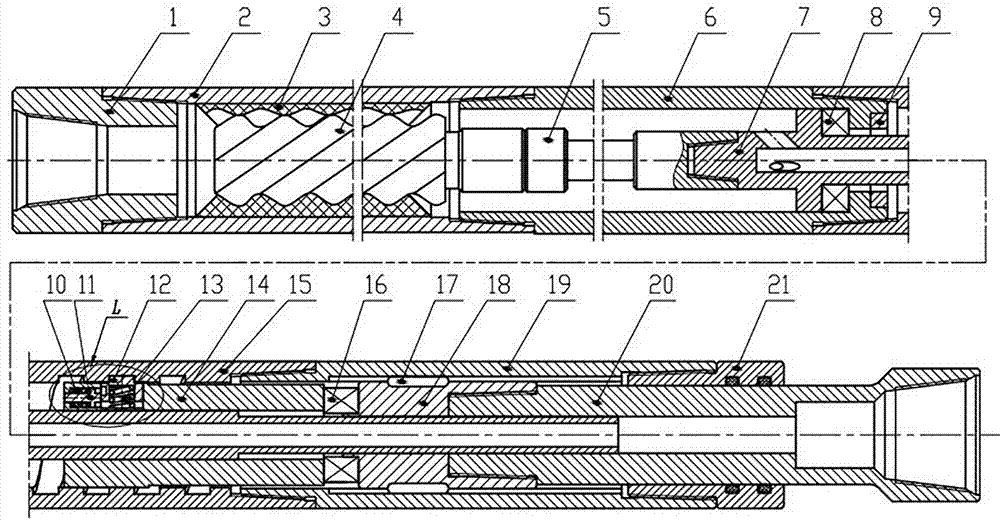

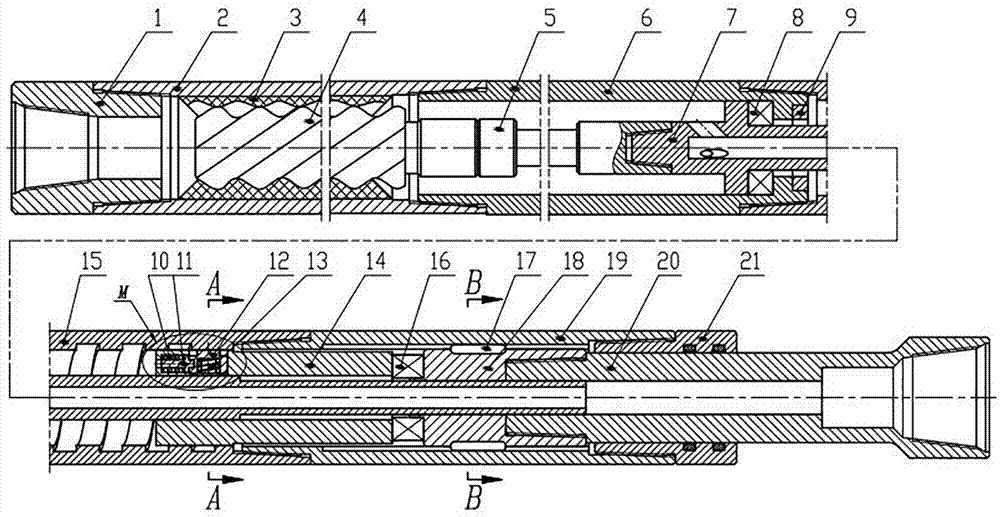

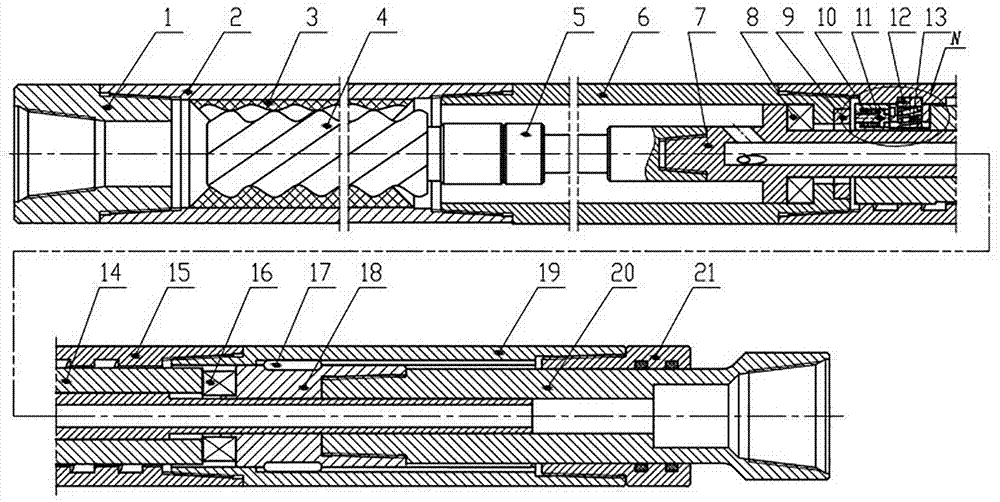

Pressurized propulsion tool for horizontal well

InactiveCN106958429AMeet the needs of advancementWith zoom effectConstructionsRotary-drilling machinesWell drillingAxial thrust

The invention relates to a pressurized propulsion tool for horizontal well drilling in an oil and gas industry. The pressurized propulsion tool solves the problem of depressurization and feeding difficulties of horizontal drill string. The technical scheme comprises that a upper sub is connected with a upper drill string by threading and a output shaft is connected with a lower drill string by threading; upper end of a stator shell is connected with the lower end of the upper sub by threading, and the lower end of the stator shell is connected with the upper end of a universal shaft shell by threading; the upper end of the universal shaft shell is connected with the lower end of a screw rotor by threading, and the lower end of the universal shaft shell is connected with the upper end of a center tube by threading; a magnetic ring is embedded in the end face of a raised steps which is in the lower end of the universal shaft shell; a locking pin and a spring a are integrally arranged in a axial stepped hole of the upper end face of a propulsion cylinder, and a slider block and a spring b are integrally arranged in a radial counter bore of the upper part of the outer circumference of the propulsion cylinder; the lower end of a outer shell is connected with a release cap by threading. The pressurized propulsion tool utilizes the principle of the screw transmission, the output shaft can provide axial thrust, push the lower drill string feed-in, effectively extend the horizontal drilling length and improve the economic efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

Triplophysa venusta Zhu et Cao fingerling cultivation method

InactiveCN106106294ASolve cleanlinessSolve the contradiction of needing rich natural bait to overcome the difficulty of mouth feedingClimate change adaptationAnimal feeding stuffDiseaseWater quality

The invention relates to a seedling breeding method of Triplophysa venusta Zhu et Cao, which belongs to the technical field of fish breeding. The seedling cultivation method of Xiuli plateau loach includes: the temporary management of filmed larvae, the cultivation of open-mouthed fry, the artificial feeding of fry, the daily management in the middle and later stages, and the steps of fish disease prevention and control. The present invention has the advantages of: 1. Artificially bred rotifers are used as opening bait in the early stage of fish fry cultivation, which solves the contradiction that the beautiful plateau loach needs clean water and abundant natural bait to overcome the difficulty of opening the mouth. 2. The survival rate of fry is high, the growth is fast, the method is simple, easy to popularize, and the breeding cost is low. 3. It can effectively protect, develop and utilize the germplasm resources of Xiuli plateau loach.

Owner:YUNNAN HUADIAN LUDILA HYDROPOWER CO LTD +1

Upper and lower synchronous feeding mechanism and feeding method of thin material lockstitch sewing machine

The invention relates to upper and lower synchronous feeding mechanisms of a thin-material lockstitch sewing machine and a feeding method thereof. The mechanisms are designed aiming at that the similar product mechanisms are not easy to adjust and high in synchronous feeding difficulty. The design key points of the mechanisms are that the upper pin shaft hole of an upper feeding oscillating plate seat is connected to the housing of the lockstitch sewing machine through a pin shaft, while swinging around the pin shaft, the upper feeding oscillating plate seat drives the upper synchronous feeding mechanism to change the swing amplitude so as to change the distance of travel of upper feeding teeth, a lower feeding oscillating plate seat swings around the pin shaft and thus drives the lower feeding mechanism to change the swing amplitude and also to change the distance of travel of lower feeding teeth, a synchronous connecting rod eccentric pin and a synchronous connecting rod are provided so that the upper and lower feeding teeth move synchronously, and under the error influence of the upper synchronous feeding mechanism and the lower synchronous feeding mechanism, the center distance of the synchronous connecting rod is adjusted by the synchronous connecting rod eccentric pin so that the upper synchronous feeding mechanism and the lower synchronous feeding mechanism run synchronously. The manufacturing cost of the upper and lower synchronous feeding mechanisms of the thin-material lockstitch sewing machine is low, the feeding method is feasible, the labor efficiency is effectively improved, and therefore, the upper and lower synchronous feeding mechanisms and the feeding method are suitable for popularization and application.

Owner:NINGBO SANHEXIN AUTOMATION

Low-light culturing method for giant salamanders

InactiveCN105340833APromote growth and developmentReduce morbidityClimate change adaptationAnimal feeding stuffGiant salamanderEconomic benefits

The invention discloses a low-light culturing method for giant salamanders. The low-light culturing method is characterized in that giant salamanders are cultured in a low-light culturing plant after being incubated, wherein the low-light culturing plant is provided with a window, and sunshine can directly shoot into the low-light culturing plant; culture ponds for culturing different sizes of giant salamanders are arranged in the low-light culturing plant, and ultraviolet lamps for irradiating the culture ponds are further arranged in the low-light culturing plant; the peripheries and the bottoms of the culture ponds are smooth; giant salamanders are cultured by virtue of deep well water, and the average water temperature all the year round is 16-20 DEG C; no noise reduction facility is arranged in the low-light culturing plant. According to the low-light culturing method for the giant salamanders, the giant salamanders are fed in a low-light indoor environment after being incubated, so that the giant salamanders can adapt to low-light and noisy environments, the living habit of the giant salamanders is changed, the construction cost and the management cost of a culturing site are effectively lowered, the feeding difficulty of the giant salamanders is reduced, and the economic benefit is increased.

Owner:GUANGYUAN SHUNFA AGRI DEV CO LTD

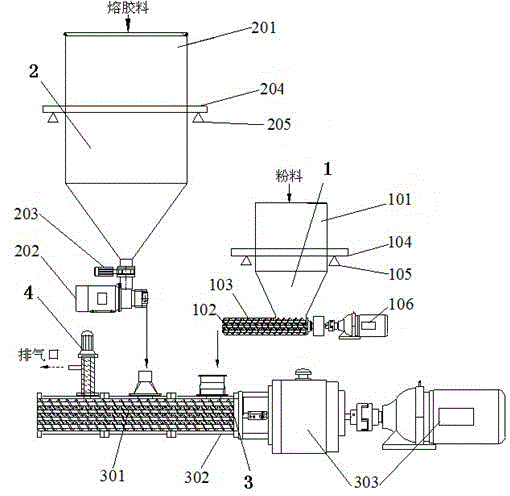

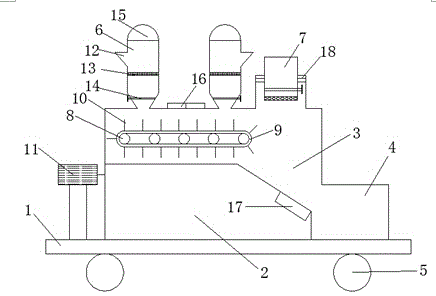

Multi-screw measurement feeding and mixed conveying system

The invention discloses a multi-screw measurement feeding and mixed conveying system. The multi-screw measurement feeding and mixed conveying system comprises a heterodromous multi-screw powder body measurement feeder, a colloid measurement feeder, a homonymous multi-screw mixed conveyer and a homonymous dual-screw air exhaust device; the homonymous multi-screw mixed conveyer comprises a machine barrel; the machine barrel comprises a first barrel body, a second barrel body and a third barrel body which are connected sequentially; a feeding opening is formed in the upper side of the first cylinder body, and is in flexible connection and sealing with the powder body measurement feeder; a colloid charge opening is formed in the upper side of the second barrel body, the colloid charge opening distributes colloid by adopting a pours plate and enables the colloid to be dropped uniformly on the surface of the powder body in the barrel body; an air exhaust opening is formed in the upper side of the third barrel body, and is connected with the homonymous dual-screw air exhaust device so as to exhaust moisture from the machine barrel. The multi-screw measurement feeding and mixed conveying system thoroughly solves the difficulties of nanoscale inorganic powder body feeding difficulty and easiness in scattering, improves the production efficiency, reduces the energy consumption, and has the advantages of high automatic degree, high precision and good seal property.

Owner:江苏诚盟装备股份有限公司

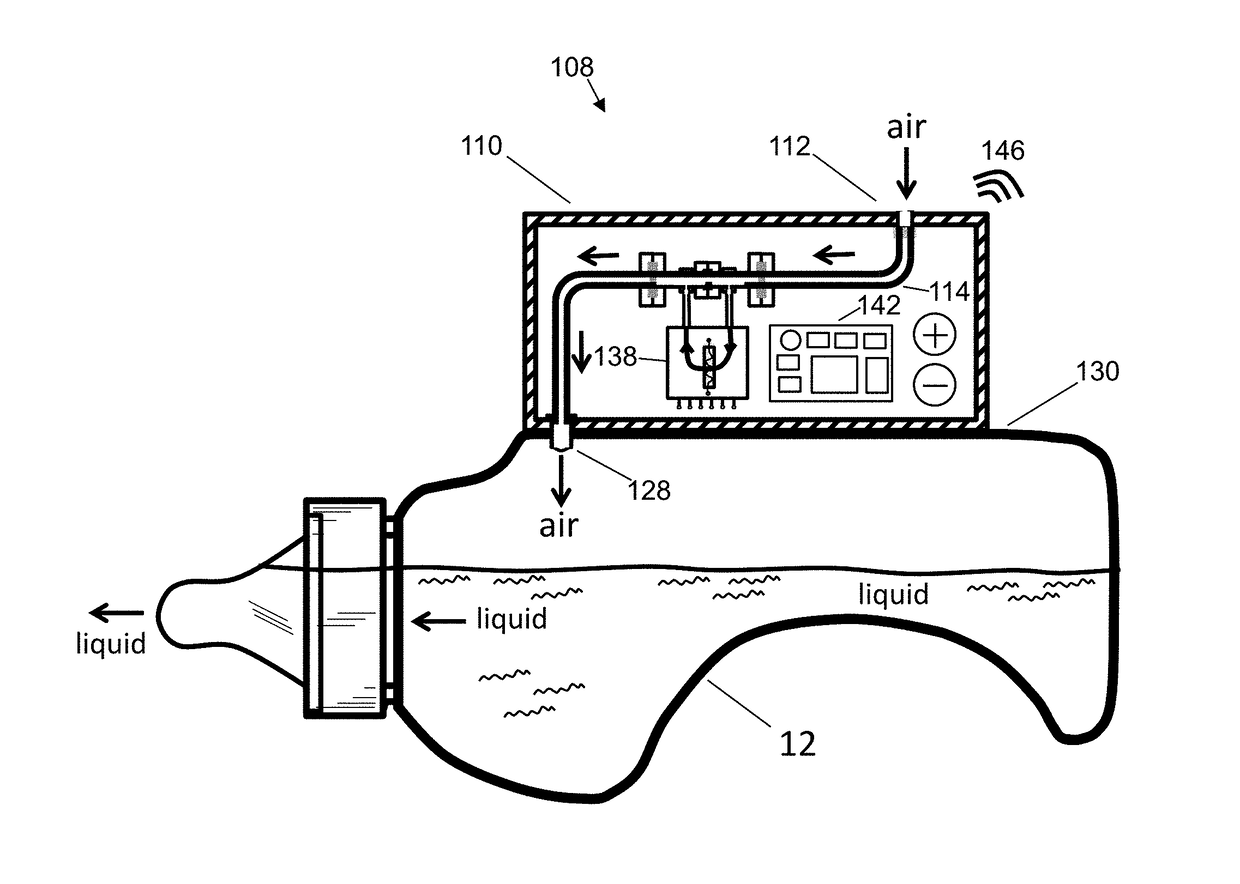

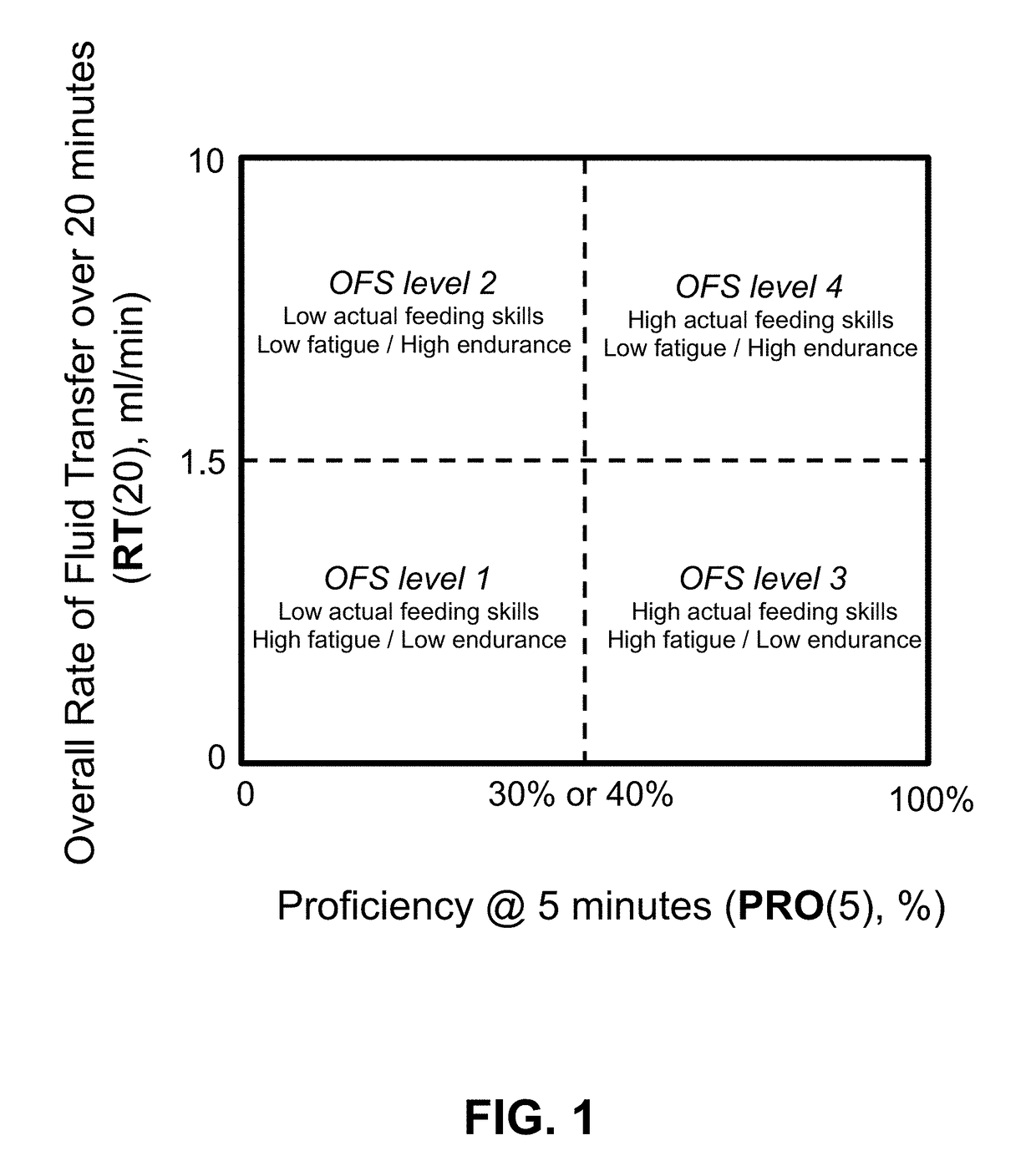

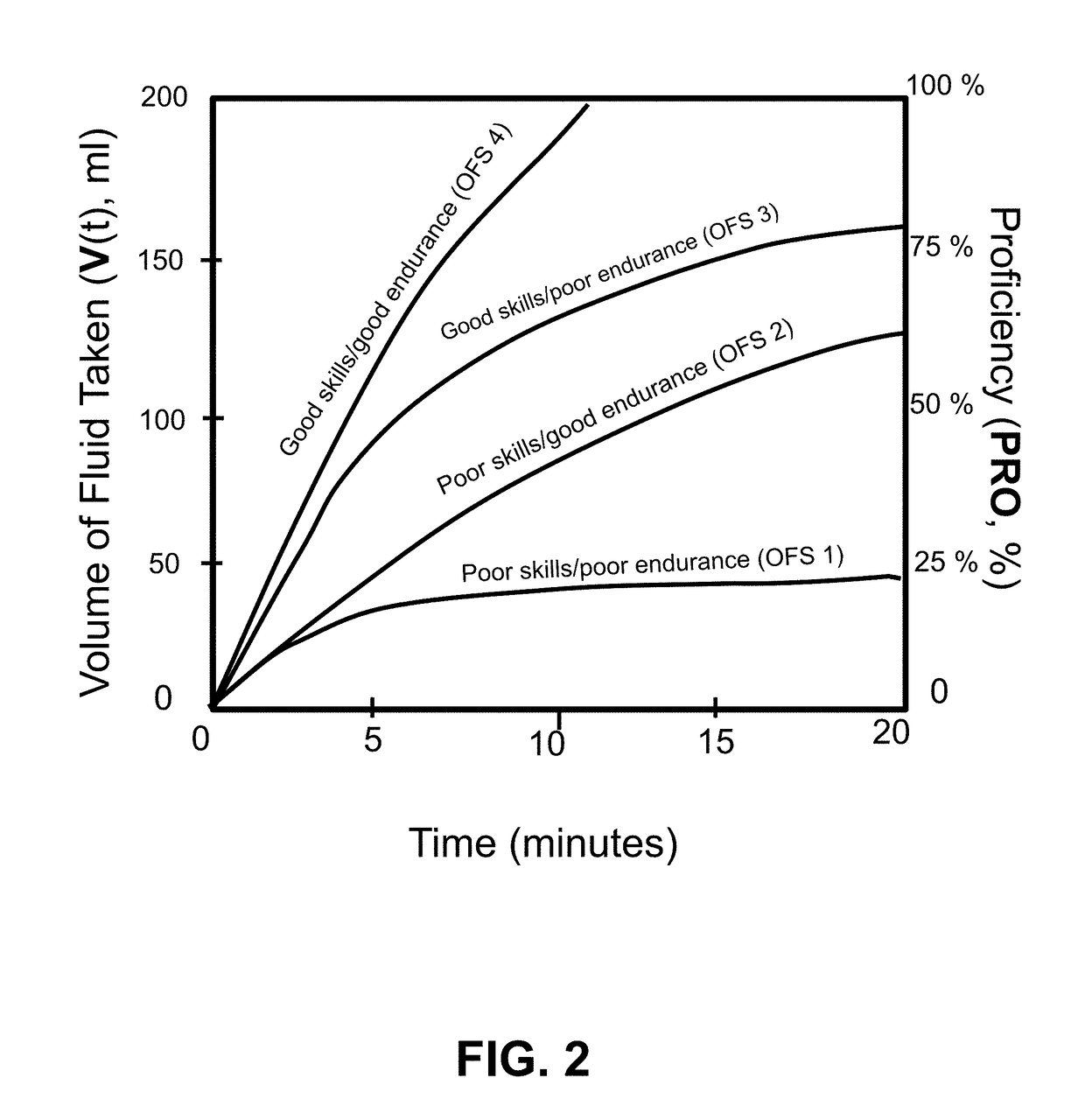

System and methods for assessing oral feeding skills during oral feeding

ActiveUS20180211558A1Optimize feeding performance and safety and competencyFeeding-bottlesDiagnostic recording/measuringMedicineSkill sets

The present invention relates to systems and methods for assessing and improving an infant's oral feeding skills. The system comprises a “smart” baby feeding device comprising an instrumented baby bottle with a removable, battery-powered monitoring module wirelessly connected to a remote device (e.g., smart phone, tablet, laptop, PC). The purpose of the remote device is to monitor (in real time) and measure the frequency and quality of feedings of new-born babies to help optimize feeding development by providing real-time feeding performance information back to the caregiver. The information collected is of assistance in minimizing feeding difficulties and correcting feeding deficiencies.

Owner:LAU CHANTAL

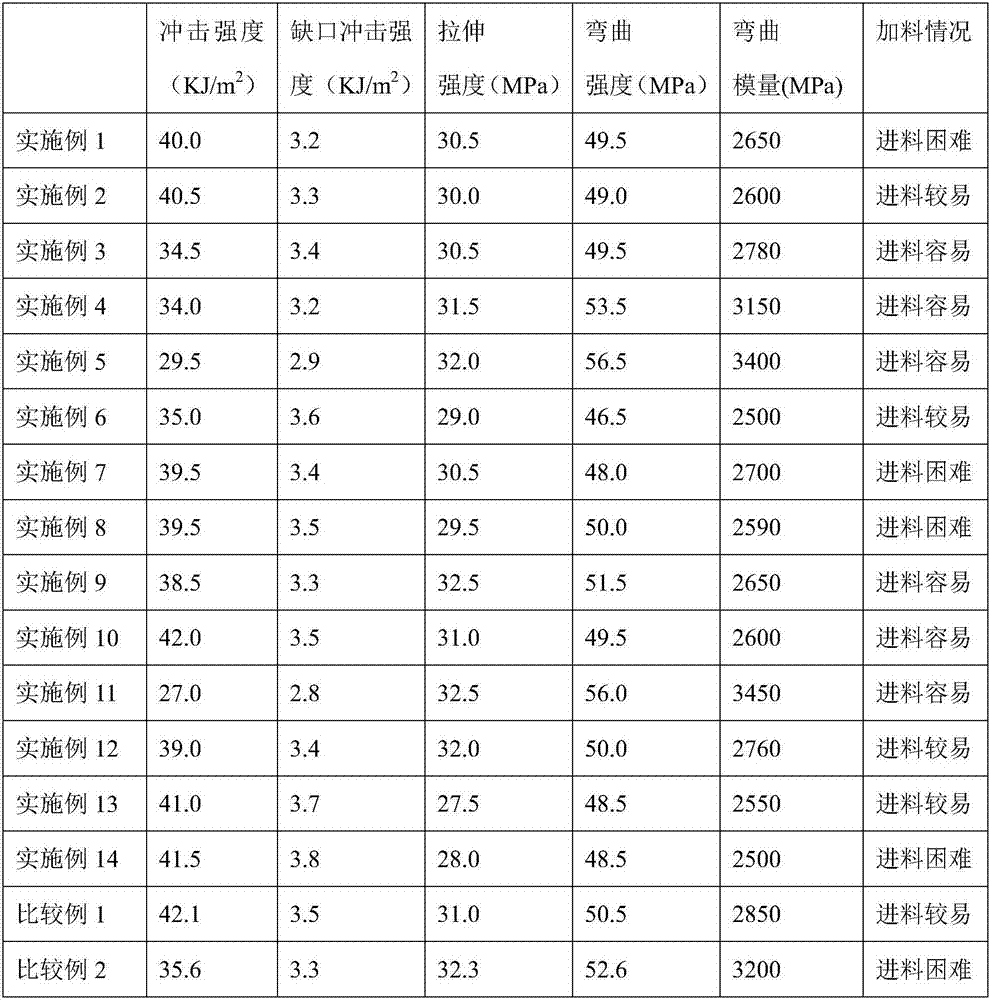

High-heat-resistant polypropylene composite material and preparation method thereof

The invention discloses a high-heat-resistant polypropylene composite material, which is prepared from the preparation raw materials including polypropylene, talcum powder and antioxidants and is also prepared from the following preparation raw materials in percentage by weight: 0.1 to 10 percent of polyethylene wax and 1 to 15 percent of polytetrafluoroethylene. The invention also discloses a preparation method of the high-heat-resistant polypropylene composite material. The proper amount of polyethylene wax and polytetrafluoroethylene are used, so that the dispersing capability of the talcum powder in a polypropylene composite material system can be obviously improved, and the prepared polypropylene composite material maintains a high-heat-resistant characteristic. The prepared polypropylene composite material ensures the feeding smoothness; meanwhile, all items of mechanical properties of the material are basically not influenced. The provided method for overcoming the feeding difficulty of the polypropylene composite material has the advantages that the preparation process is simple; the technical transformation on an extruding machine is not needed; the method can be easily realized in the practical production process.

Owner:谢炳

Profiling air suction cutting type saffron thread harvesting device

PendingCN108738686ASolve the problem of severe jitterIncrease success ratePicking devicesCut flowersPulp and paper industry

The invention provides a profiling air suction cutting type saffron thread harvesting device, which comprises a machine frame part, a profiling cover part, a cutting part and a negative pressure collecting box part, wherein the machine frame part is used for fixing various components; the profiling cover is arranged at the front end of the machine frame; the cutting part is arranged above the profiling cover; an air suction collecting opening is formed in the operation position of the cutting part; the negative pressure collecting part is arranged above the machine frame. In the process that the whole device forwards moves, a flower ball firstly touches the profiling cover; under the effect of the air pressure in an air suction collecting opening, the flower ball enters the profiling coverand realizes the temporary fixation of the flower ball under the effects of the air pressure and the profiling cover. The cutting operation on the fed flower threads can be realized through a crescent reciprocating cutter; the cut flower threads enter a negative pressure collecting box under the negative pressure effects; the whole set flower thread harvesting process can be completed. The flowerthread suction is assisted by using the air suction and the profiling cover; the problems of serious flower ball shaking and flower thread feeding difficulty can be effectively solved; the large-scale blind picking is realized; the harvesting efficiency is improved.

Owner:SHIHEZI UNIVERSITY

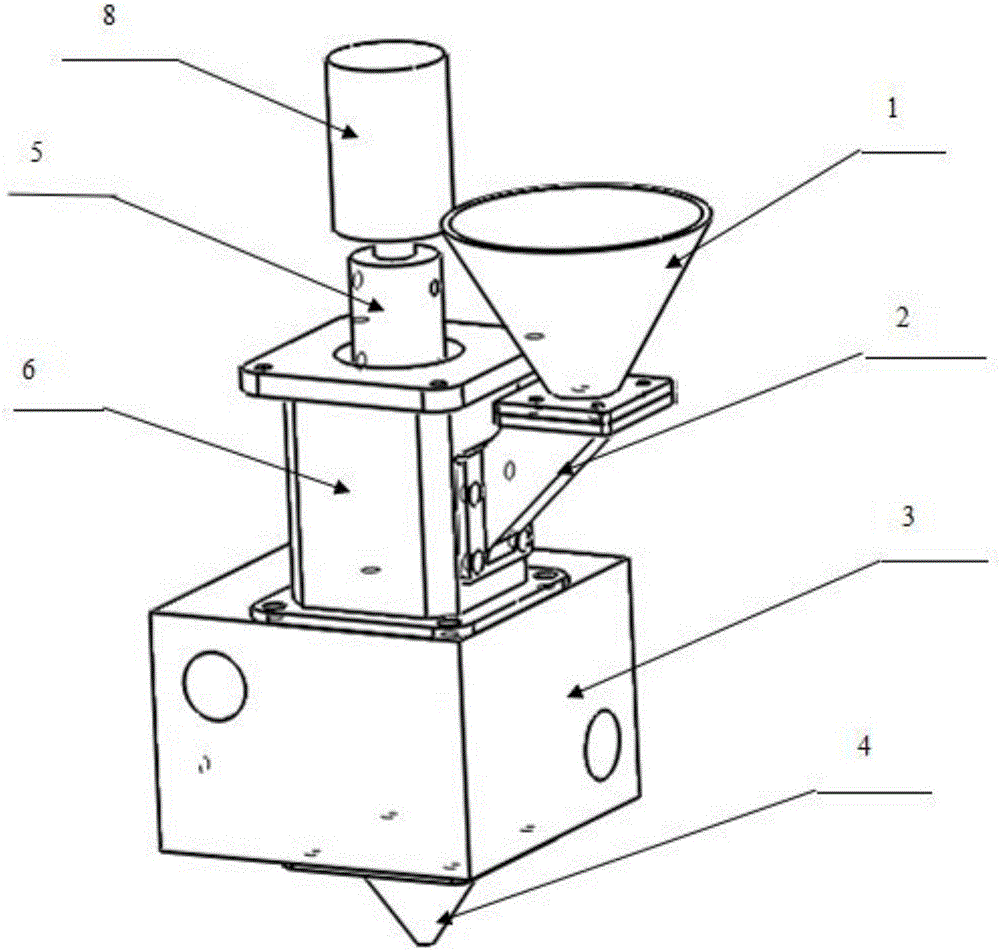

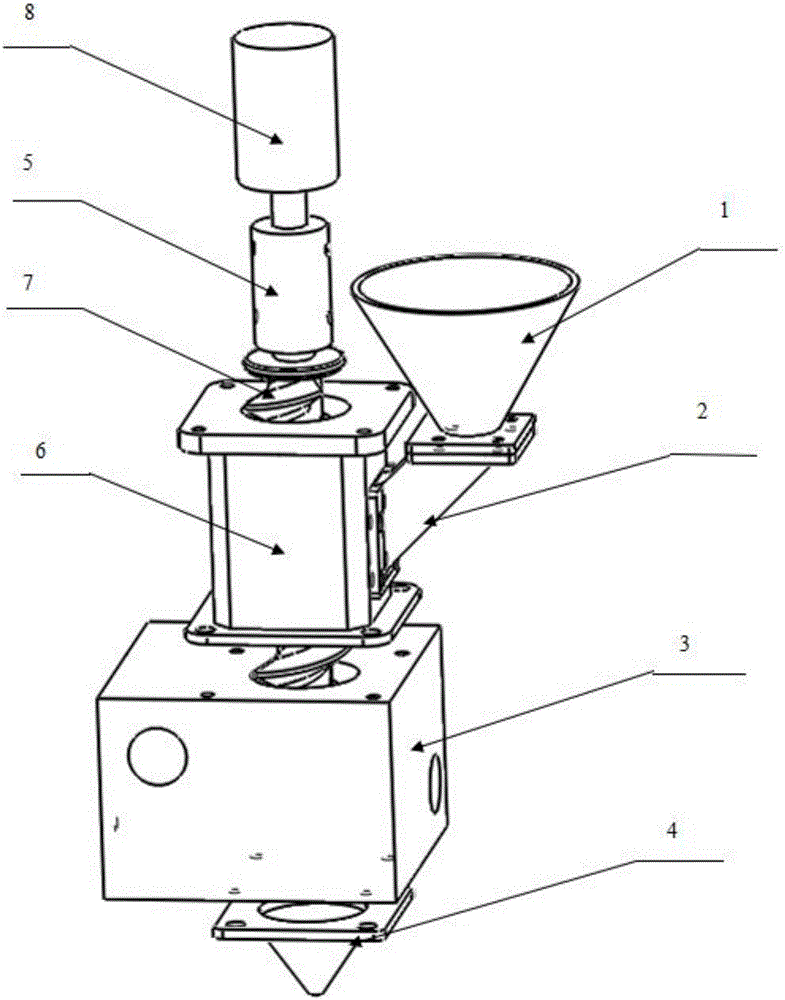

Three-dimensional waxing, supply and extrusion integrated nozzle structure

InactiveCN105058794ASimple structureSolve feeding difficultiesAdditive manufacturing apparatusWaxHeater Rod

The invention discloses a three-dimensional waxing, supply and extrusion integrated nozzle structure. The structure comprises a conveying drum fixed on the upper surface of a mobile slide block, wherein a conveying hole communicated with the conveying drum is formed in the mobile slide block; a screw rod is installed in the conveying drum, and is driven by a motor; the motor is fixed at the top of the conveying drum; the screw rod is inserted in the conveying hole of the mobile slide block; a nozzle is arranged below the conveying hole of the mobile slide block, and is fixedly connected to the lower surface of the mobile slide block; heating rods are arranged around the conveying hole of the mobile slide block, and are inserted into the mobile slide block; an inclined conveying pipe is fixed at one side of the conveying drum; and a discharge hopper is fixed at the top of the conveying pipe. The three-dimensional waxing, supply and extrusion integrated nozzle structure simplifies the structure of an extruded wax supply device of a three-dimensional waxing printer, solves the problem of feeding difficulty of molten wax, and improves the printed product precision. The three-dimensional waxing, supply and extrusion integrated nozzle structure is simple in structure, low in manufacturing cost and convenient for operation.

Owner:TIANJIN UNIV

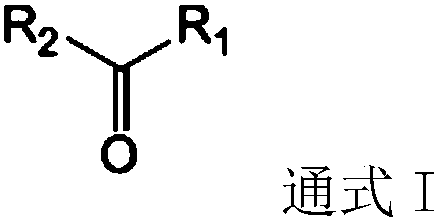

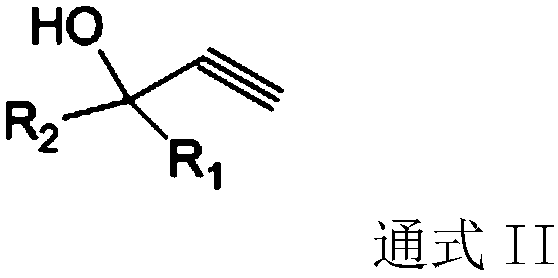

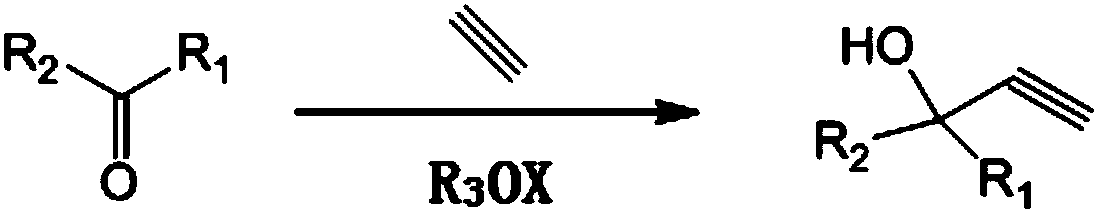

Method for efficiently preparing alkynol

ActiveCN108863717AHigh purityImprove conversion rateOrganic compound preparationHydroxy compound preparationDistillationPotassium hydroxide

The invention relates to a method for efficiently preparing alkynol, belongs to the field of preparation of chemical intermediates and chemicals, and particularly relates to a preparation method of alkynol. The preparation method comprises the following steps that 1, alkali metal is added into an anhydrous alcohols solvent; an alcohol-alkali metal solution is prepared; 2, a compound I is added into the alcohol-alkali metal solution; uniform stirring is performed; cooling is performed to be 0 DEG C or below; 3, acetylene is introduced through being metered at normal pressure; alkynol is obtained; 4, the alkynol solution after reaction is neutralized by ammonium chloride and a same alcohol mixed suspension system; 5, the neutralized mixed suspension system is filtered; after alcohols are recovered from filter liquid, reduced pressure distillation is performed to obtain an alkynol product. The method overcomes the defect that under the existing harsh reaction conditions of high pressure,liquid ammonia and the like, the solid potassium hydroxide feeding difficulty is avoided; under the ordinary pressure condition, the ketone compounds are converted into alkynol at high conversion rate. The method has the advantages of high conversion rate, simple process and good product purity.

Owner:PANJIN GELIN KAIMO TECH CO LTD

Breeding method of Rillengrundel

InactiveCN102835340ASolve the problem of not ingesting any feedSolve the problem of lootingClimate change adaptationPisciculture and aquariaZooplanktonAquatic product

The invention discloses a breeding method of Rillengrundel (Parapocryptes serperaster (Richardson)), relates to an aquaculture method, and provides the breeding method of Rillengrundel. The breeding method comprises the steps of: preparing a cultivation pool; collecting and cultivating a parent fish; carrying out natural oviposition and manual handling, and cultivating fish fry by rich water. Theproblem that the parent fish of Rillengrundel does not eat any feed in a cement pit is solved by directionally cultivating diatom in an earthen basin; planktonic animals are killed by trichlorphon for creating a good mouth-open feeding environment for larval fishes of Rillengrundel; the problem that the larval stage feed of the larval fishes of Rillengrundel is grabbed by the planktonic animals is sloved; ostrea rivularis is bred in the earthen basin by a hanging method; the problem of the larval stage feed source in the earthen basin of the larval fishes of Rillengrundel is solved; the problem of mouth-open feeding difficulty of the larval fishes of Rillengrundel is solved, and a positive and effective way is provided to improve the breeding quantity of Rillengrundel.

Owner:XIAMEN UNIV

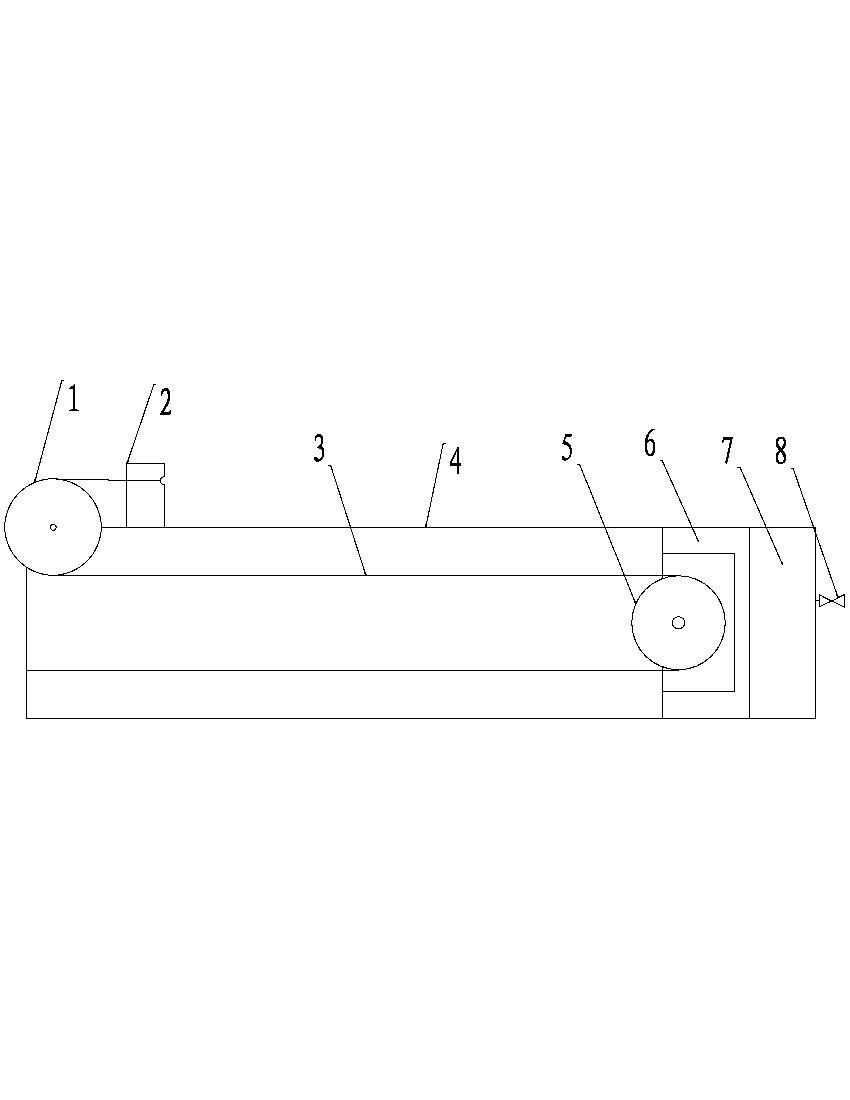

Machining automatic feeding device and method

InactiveCN109592308AEasy to realize intermittent feedingRealize intermittent feedingConveyorsFriction forceMachining

The invention discloses a machining automatic feeding device and method. The technical problem that in the prior art, machining feeding difficulty achieves intermittent conveying is solved. The machining automatic feeding device comprises a feeding bottom plate, a mounting frame is arranged above the feeding bottom plate, a rotating shaft, a cam and a power mechanism are arranged on the mounting frame, the cam is arranged on the rotating shaft, a rubber layer is arranged on a protruding part of the cam, the power mechanism is used for driving the cam on the rotating shaft to rotate, accordingto the machining automatic feeding device, in the rotating process of the cam, the protruding part of the cam continuously makes contact with a machining material on a feeding bottom plate, the rubberlayer located on the protruding part exerts large horizontal friction force to the machining material, the machining material is pushed to be continuously conveyed to the machining station forwards,and in the feeding process, due to cam feeding through friction between the protruding part and the machining material, machining material intermittent forward conveying is achieved.

Owner:HENAN XINDAXIN SCI & TECH

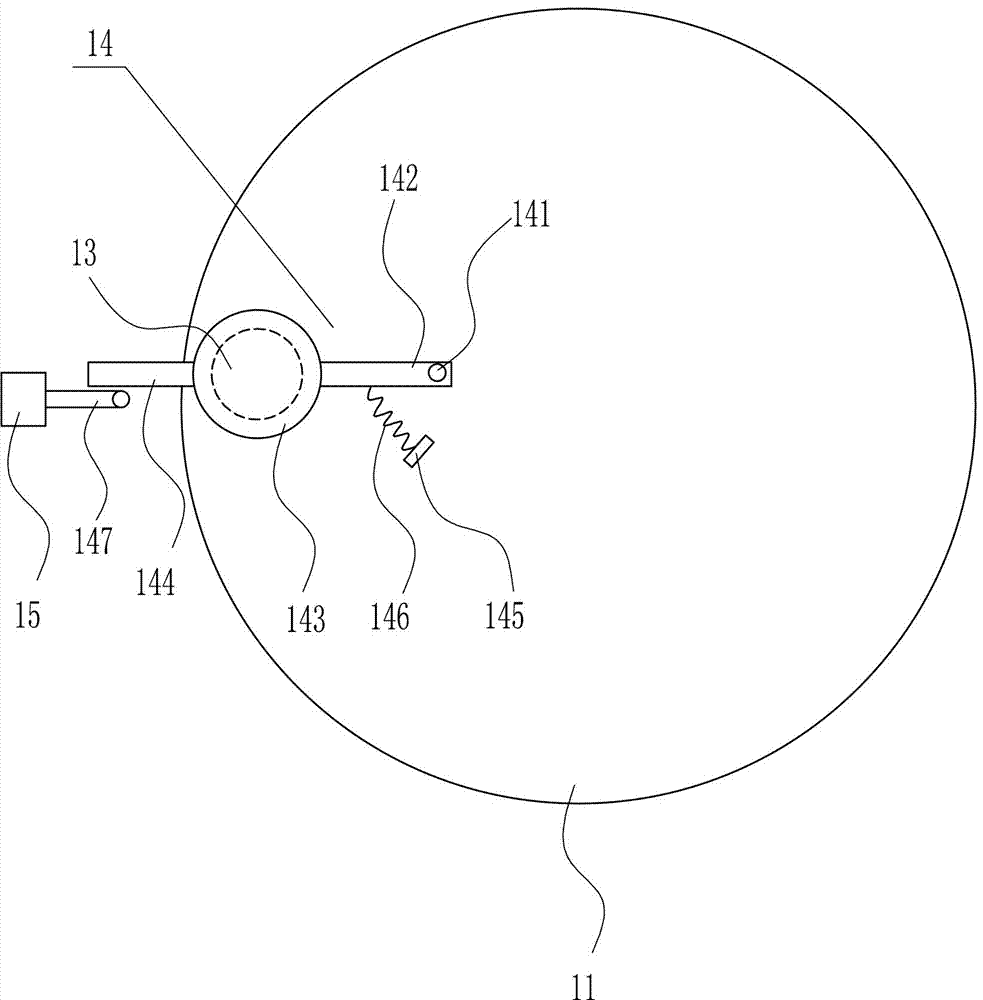

Food distribution ball

ActiveCN105613330AImprove intelligencePrevent leakageAnimal feeding devicesTaming and training devicesEngineeringCompanion animal

The invention discloses a food distribution ball comprising at least two spheres and a fixing shaft. The sizes of the at least two spheres are different. Each sphere has at least one food distribution hole. Each sphere can be split into two hemisphere housings. The sphere with a larger diameter sleeves the sphere with a smaller diameter. An internal thread through hole is formed in the bottom of each housing. The fixing shaft comprises a bolt and a nut. The fixing shaft is threadedly connected to the internal thread through hole through the bolt. The fixing shaft penetrates through the at least two sleeved spheres, and is locked with the nut, such that the fixing shaft is detachably connected with the spheres. The food distribution ball comprises at least two spheres, and the number of spheres can be selected according to needs. The spheres are sleeved mutually, such that a layered food distribution ball is formed. A pet can play with the food distribution ball. With the food distribution ball, feeding difficulty can be increased gradually. The food distribution ball provides fun and freshness, and assists in developing pet intelligence.

Owner:山东未来城建筑工程有限公司

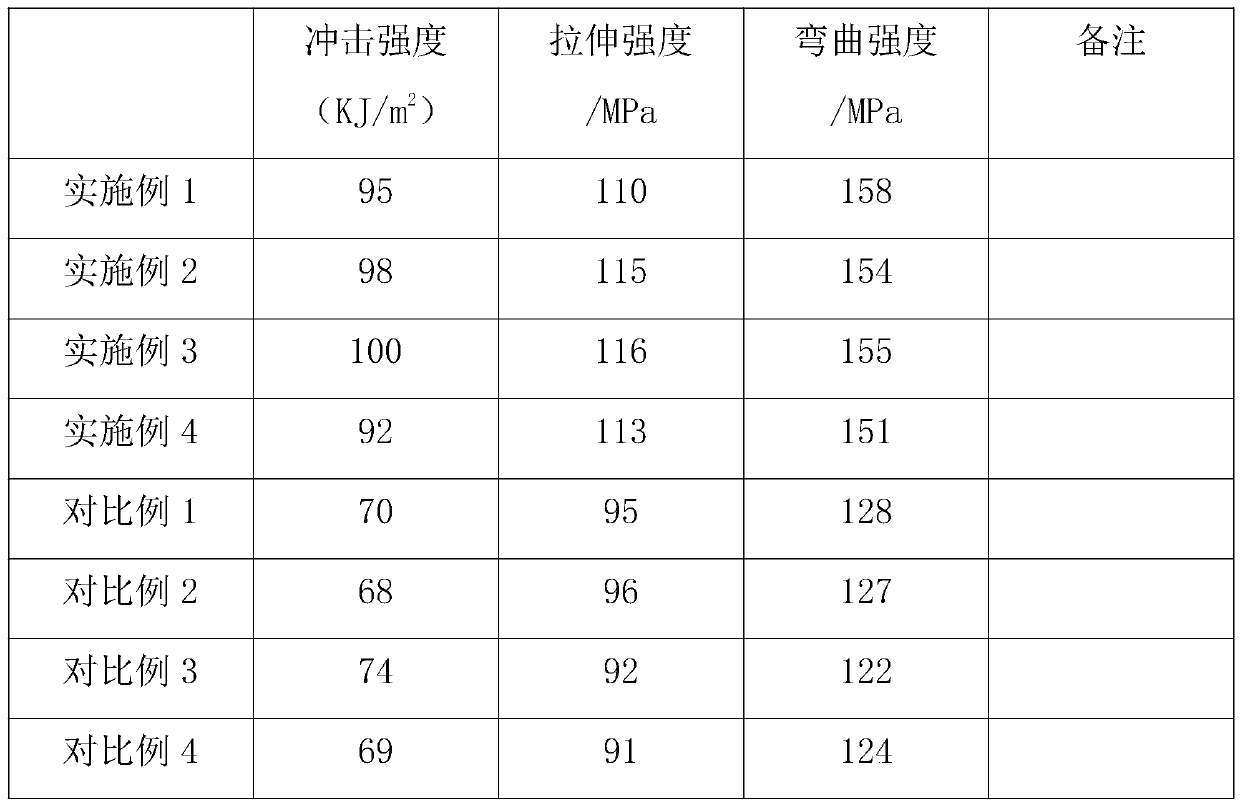

Preparation and application methods of small-grain-size polyimide powder

The invention provides a preparation method of a small-grain-size polyimide powder. The preparation method of the small-grain-size polyimide powder comprises the following steps of dissolving diamineinto organic solvent, then adding in dianhydride for reaction for 3-7 hours, then adding in water separating agent, increasing the temperature to 140-160 DEG C, inletting and mixing in inert gas for dewatering for 6-12 hours, cooling down to 70-90 DEG C, pouring the hot reaction liquid into separated solution, cooling down to 0-35 DEG C for crystallization, and performing filtering and drying to obtain the small-grain-size polyimide powder. The preparation method of the small-grain-size polyimide powder has the advantage that the fine powder is directly obtained after reaction is completed, sothat crushing and screening can be saved, granularity can be uniform, production devices can be simplified, the problem of feeding difficulty during processing can be solved, and industrial values can be achieved. The prepared small-grain-size polyimide powder can be fed into a double-screw extruder for extrusion pelletizing to obtain polyimide granules, which are then injection-molded into standard mechanical testing sample bars for standard mechanical testing, thereby improving the overall mechanical performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

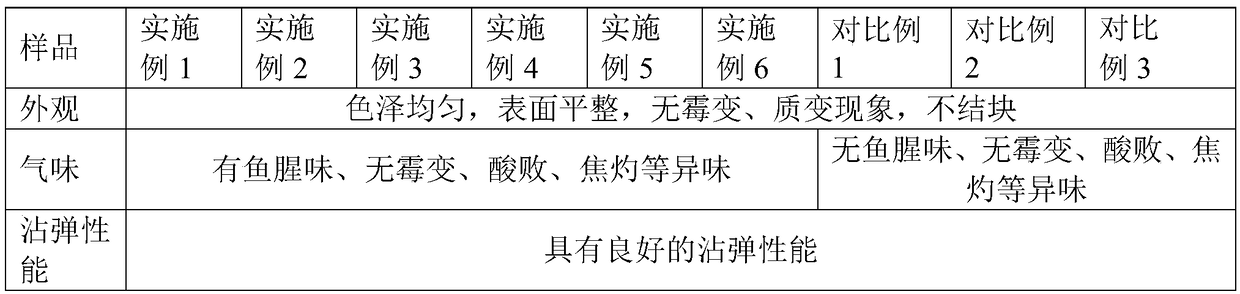

Frog feed and preparation method thereof

InactiveCN108813127AEasy to feedIncrease profitFood processingAnimal feeding stuffAnimal scienceBullfrog

Relating to the field of culture feed, the invention discloses a frog feed and a preparation method thereof, and solves the problem that some feed is unpopular with bullfrogs in the prior art. The feed comprises the following components: 25-45wt% of bait, 10-15wt% of bran, 10-15wt% of rice bran, 5-10wt% of allicin, 2-10wt% of B vitamins, 5-10wt% of yeast tablets, 5-10wt% of grease, and 10-20wt% ofa Chinese herbal feed additive. Specifically, the bait includes at least two of shrimp shell meal, fish steak meal, crab shell meal and dried scallop meal; and the Chinese herbal feed additive includes at least two of bighead atractylodes rhizome powder, Chinese yam, radix isatidis and Schisandra chinensis. The feed can be easily accepted by bullfrogs, has small feeding difficulty, can achieve waste utilization, and saves resources.

Owner:厦门同欣荣饲料科技有限公司

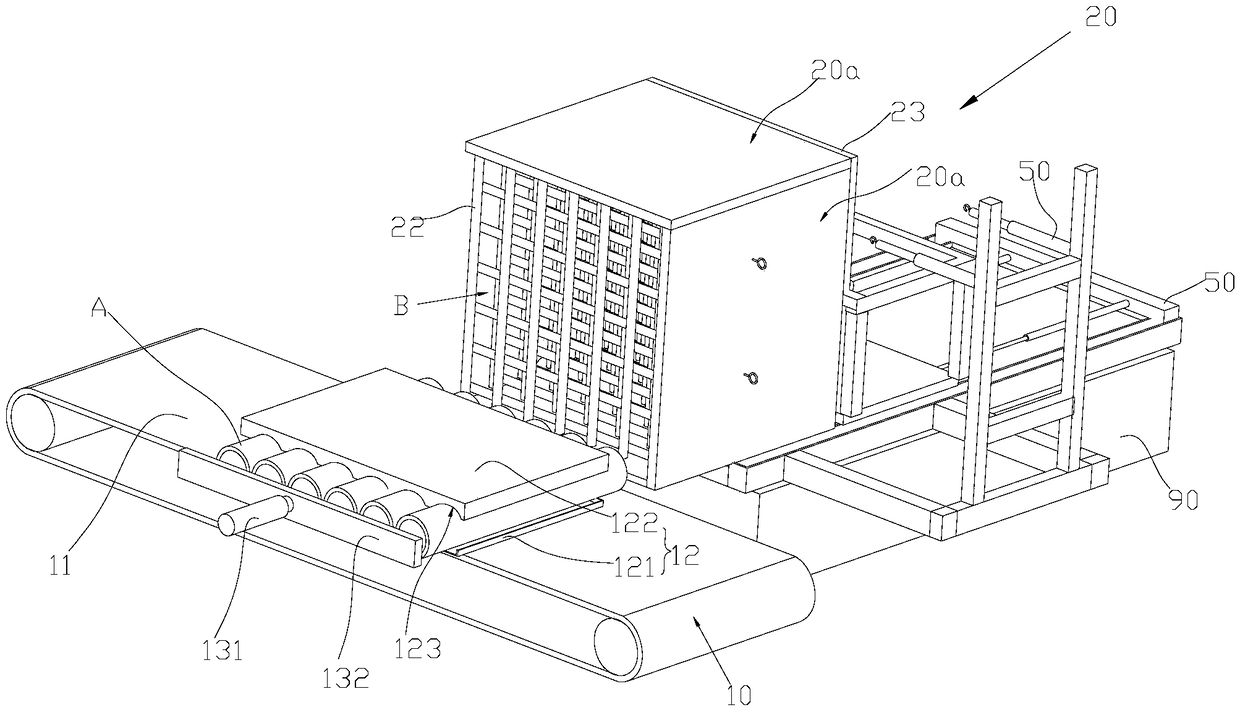

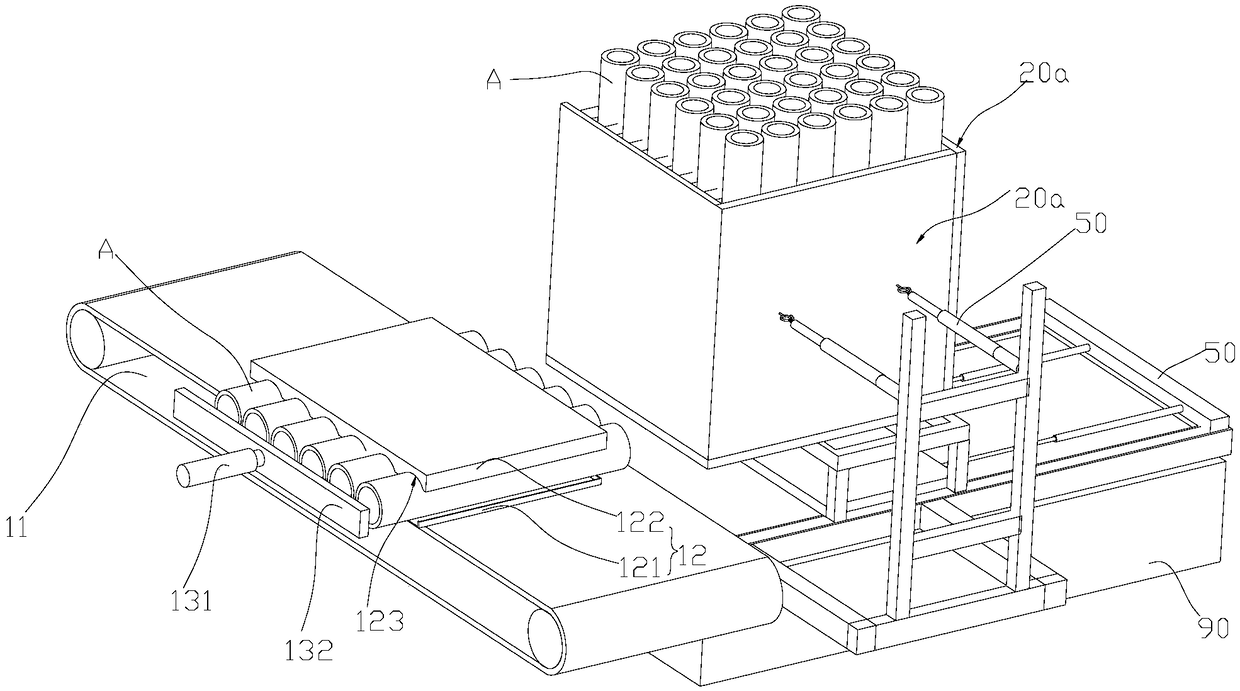

Transfer mechanism

ActiveCN108820853AEasy to insertPrecise positioningConveyorsConveyor partsEngineeringTransfer mechanism

The invention relates to the field of pipe surface treatment, in particular to a transfer mechanism. The transfer mechanism is provided with a plurality of round or rectangular tubular regions B usedfor containing to-be-treated tubes A, one end of each tubular region B is open, and the other end of each tubular region B is closed; the section size of the tubular regions B is slightly larger thanthe outer diameter of the to-be-treated tubes A, and the tubular regions B form a square shape; the section size of the tubular regions B is adjustable, and the minimum value of the section size is slightly larger than the outer diameter of the to-be-treated tubes A. During feeding of the transfer mechanism, the section size of the tubular regions B is adjusted to the maximum value, the tubes canbe inserted into the tubular regions B very easily, the feeding difficulty is reduced, and the feeding efficiency is improved. After tube feeding is finished, the section size of the tubular regions Bis adjusted, so that the tubes are firmly locked in the tubular regions B. According to the structure that the section size of the tubular regions B is adjustable, the requirement for quick feeding can be met, the tubes can also be positioned, and thereof the transfer mechanism can be widely applied to the fields such as feeding and transferring of the tubes.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Mixing method for hydrolytic sensitive high polymer material and modified assistant and blender mixer

PendingCN107899459AAvoid molten sticky situationsAvoid situations where it absorbs moisture from the airRotary stirring mixersTransportation and packagingBLENDER/MIXERPolymer science

The invention discloses a mixing method and a blender mixer, in particular to the mixing method for a hydrolytic sensitive polymer material and a modified assistant and the blender mixer, and belongsto the technical field of modification of high polymer materials. The mixing method for the hydrolytic sensitive polymer material and the modified assistant comprises the following steps: taking the modified assistant and a dried hydrolytic sensitive high polymer material with heat as to-be-mixed materials; adding the to-be-mixed materials into the blender mixer, stirring and mixing the to-be-mixed materials by using a stirring mechanism of the blender mixer; in the process of stirring and mixing, introducing dry gas into the blender mixer to replace the air in the blender mixer and carrying out heat exchange on the materials and a heat-exchanging layer in the blender mixer at the same time. By adopting the mixing method disclosed by the invention, the agglomeration phenomenon of the materials in the blender mixer can be avoided, so that the problem of feeding difficulty of a feeder in the subsequent process is avoided; the condition that high-temperature materials absorb the moisturein the air can be avoided and the performance of a product prepared by modified materials is more excellent.

Owner:SICHUAN SUNSHINE PLASTICS

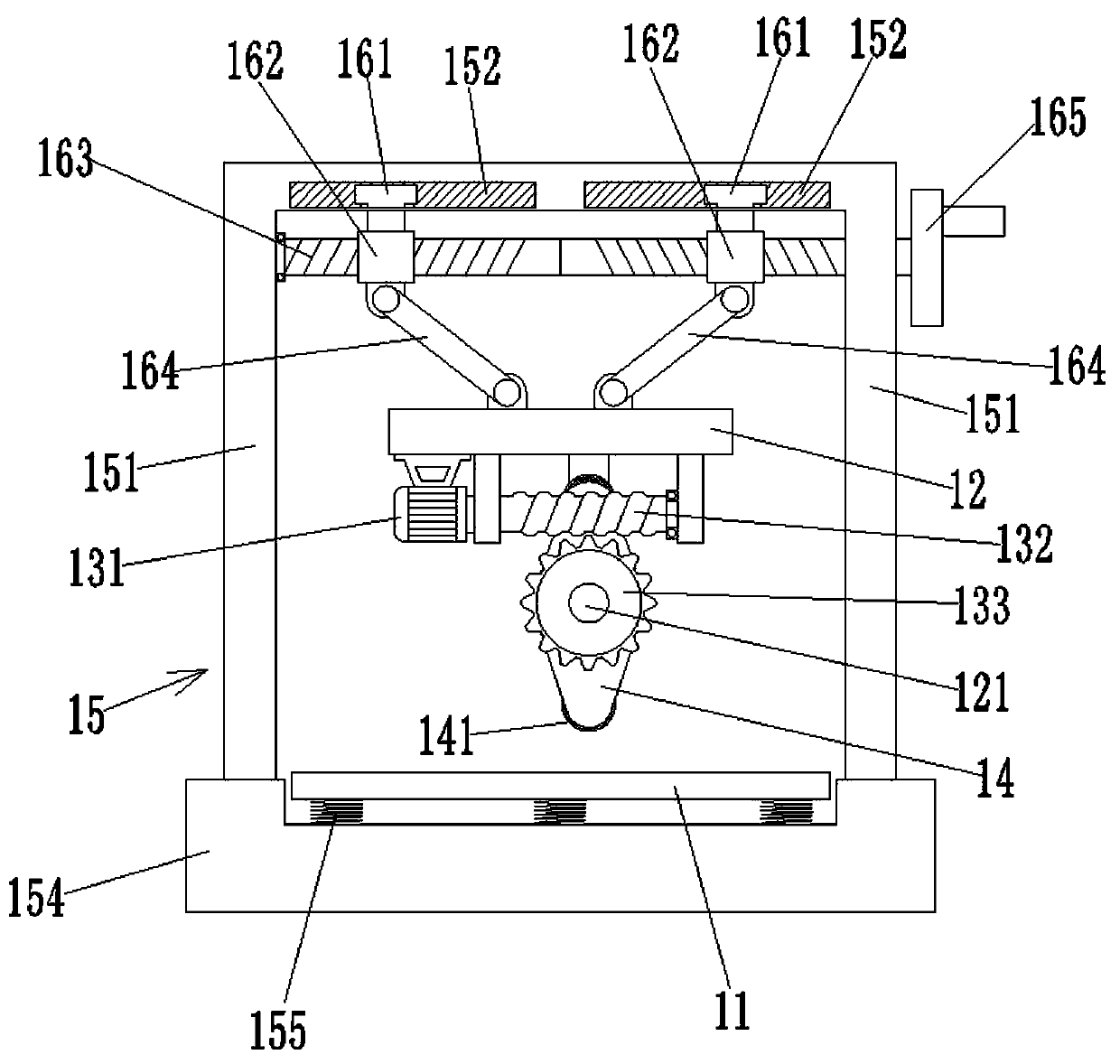

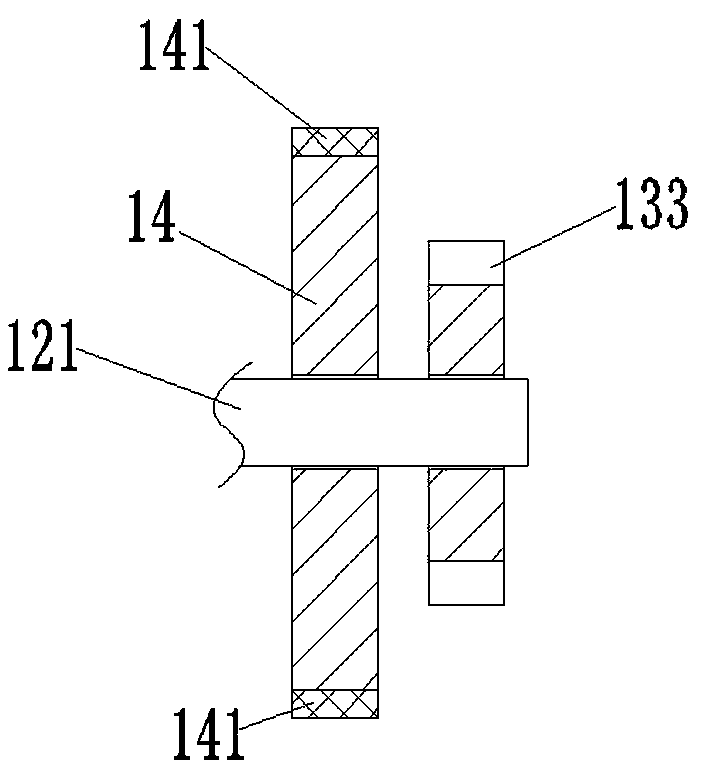

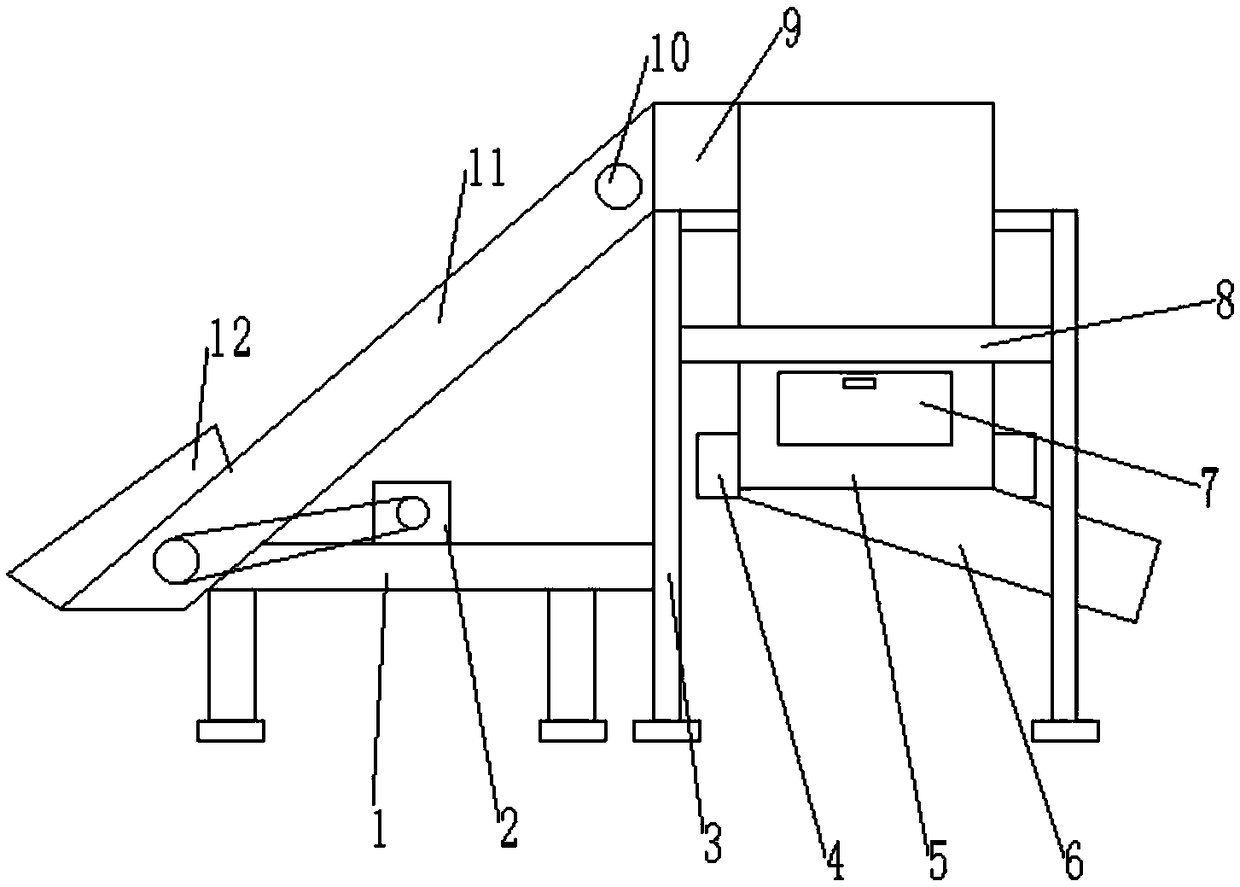

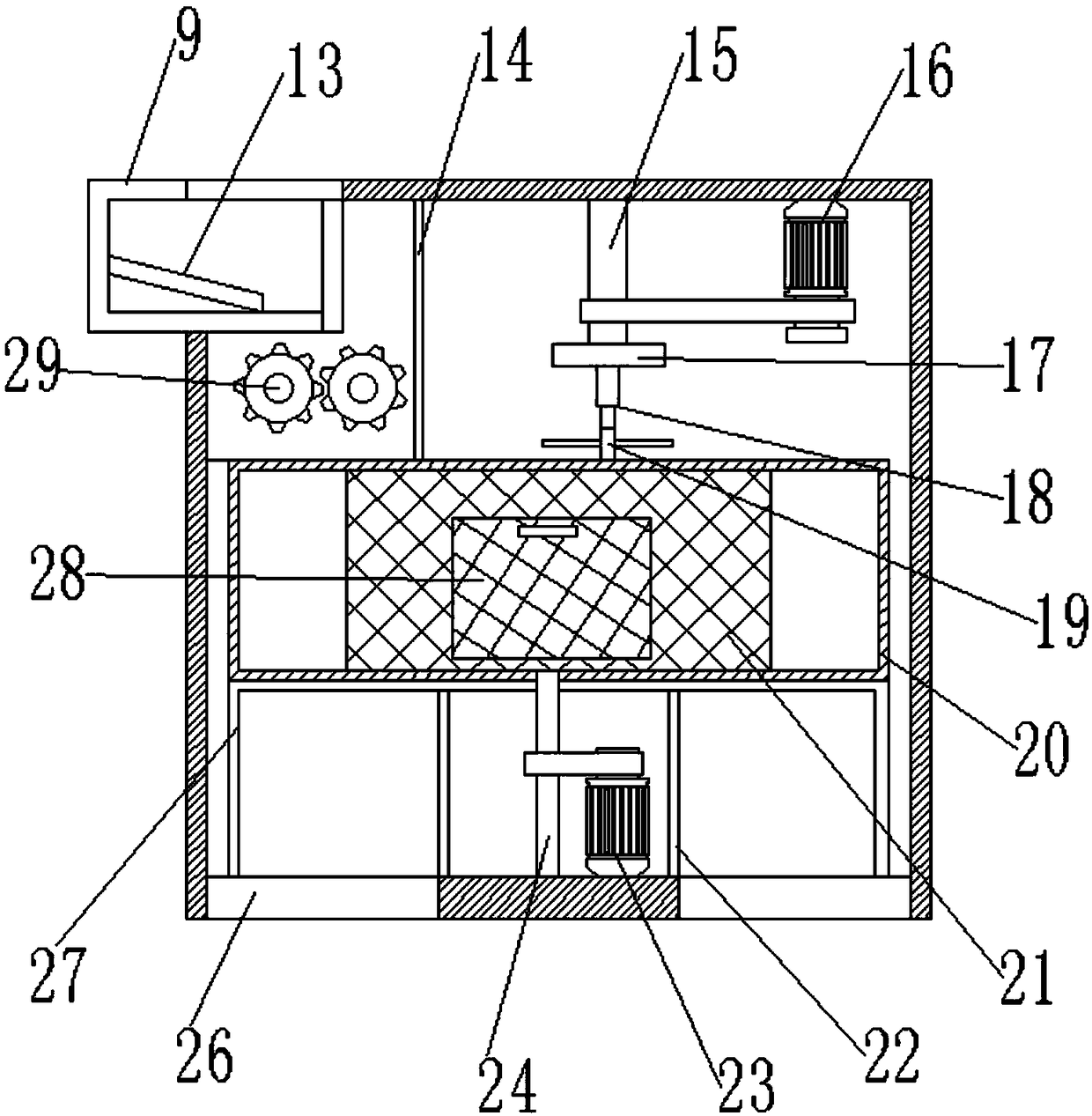

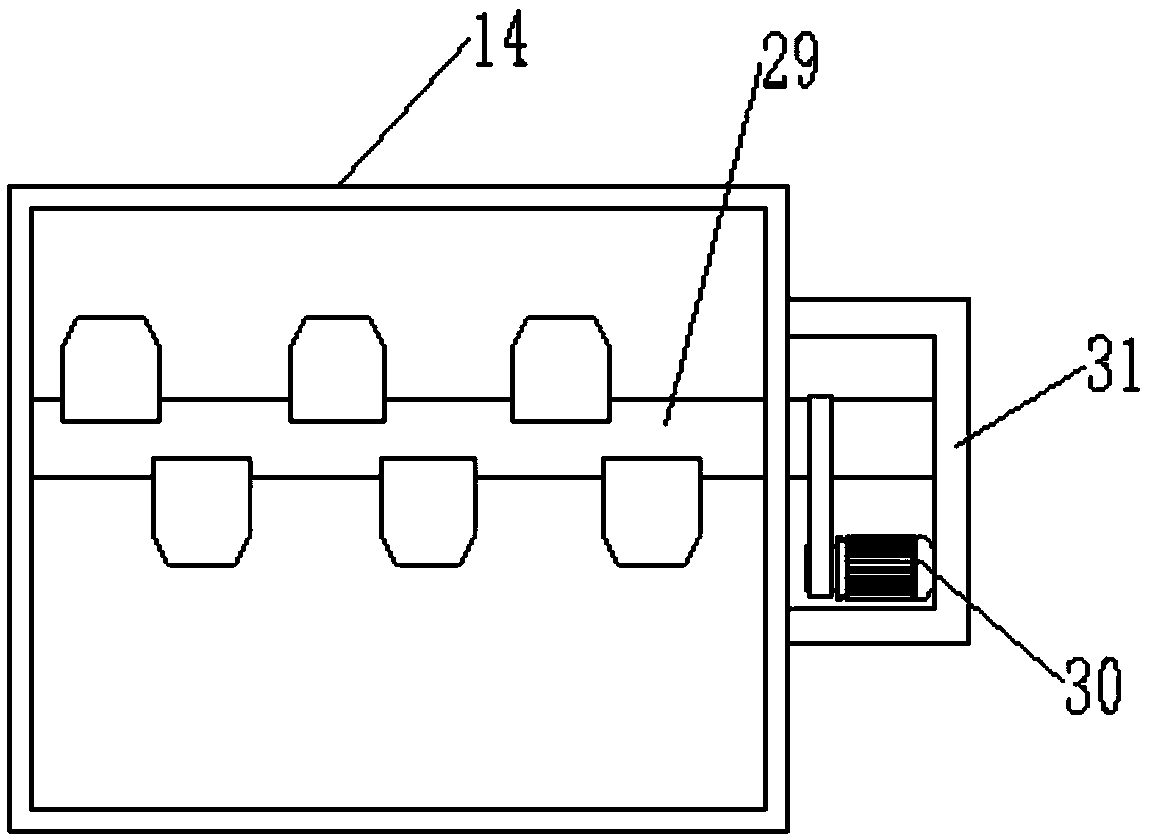

Even discharging building sand screening device

InactiveCN108855355AStop the flying phenomenonReduce the difficulty of feedingRotary stirring mixersTransportation and packagingArchitectural engineeringFeeding difficulty

The invention belongs to the technical field of building projects, and particularly relates to an even discharging building sand screening device. In order to solve the problems that an existing building sand screening device is uncontrollable in discharging and single in function, the even discharging building sand screening device in the scheme comprises a tank body, strengthening supports are welded to the outer walls of the two sides of the tank body, supporting columns are welded to the outer walls of the two sides of the strengthening supports, one connecting table is welded to the outerwalls of one sides of the two supporting columns, supporting legs are welded to the four corners of the outer wall of the bottom of the connecting table, a dustproof cover is welded to the outer wallof one side of the connecting table, a feeding opening is formed in the outer wall of one side of the dustproof cover, a feeding hopper is welded to the inner wall of the feeding opening, a driving roller and a driven roller are arranged inside the dustproof cover, the two ends of the driving roller and the two ends of the driven roller are fixed to the outer walls of the two sides of the dustproof cover through bearings. By means of the even discharging building sand screening device, feeding is carried out in a manner of a conveying belt, the feeding difficulty is reduced, the manpower strengthen is reduced, stirring in the sand screening process can be achieved, and the phenomenon that a screen net is blocked by sand is avoided.

Owner:郑州靓岛建筑设计有限公司 +1

Feed processing and producing feeding device

The invention provides a feed processing and producing feeding device. The feed processing and producing feeding device is mainly used for the field of feed processing and producing. The feed processing and producing feeding device comprises a base plate, a support, a conveying pipe, feeding buckets, a mixing bucket and universal wheels. The support is arranged on the upper surface of the base plate, the conveying pipe is arranged in the support, the three feeding buckets are arranged on the upper surface of the support and include two large-material buckets and one small-material bucket, a conveying device is arranged inside the conveying pipe, the tail end of the conveying pipe is bent downwards and connected with the mixing bucket, and the lockable universal wheels are arranged on the lower surface of the base plate. According to the feed processing and producing feeding device, multiple materials can be fed at the same time; in addition, it can be avoided that in the feeding process, dust in smashed materials floats around, and the environment is polluted, and the body health of an operator cannot be affected; as a mesh screen is additionally arranged in the device, large-particle substances which do not meet requirements can be removed; after a vibration exciter is additionally arranged, the pipe can be prevented from being blocked in the conveying process; as the small-material bucket is arranged, small materials can be added while large materials are added, feeding time is saved, and feeding difficulty is lowered.

Owner:TIANJIN MUJIA FEED CO LTD

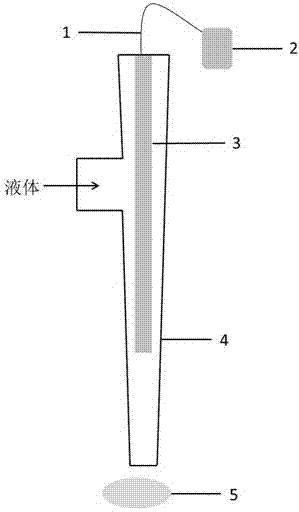

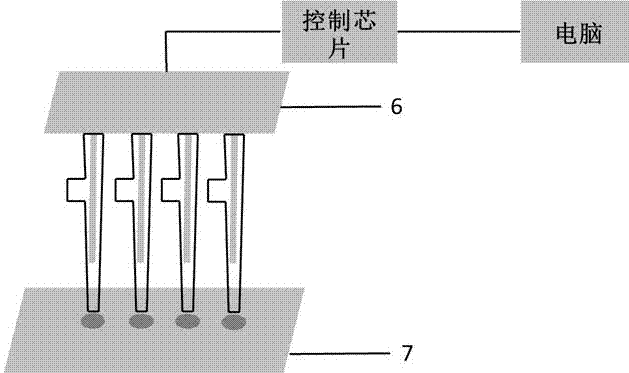

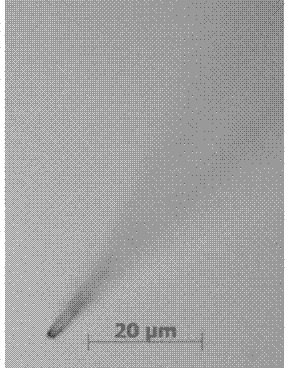

Ultra-trace liquid sample feeding device

ActiveCN107199062AIncrease profitSolve the difficulty of adding samplesBurettes/pipettesFluid controllersHeat conductingCapillary Tubing

The invention belongs to the technical field of biochemical experiments and in particular relates to an ultra-trace liquid sample feeding device. The ultra-trace liquid sample feeding device provided by the invention comprises a capillary tube, a mini-type heat conducting device, a heating source and a trace liquid pump, wherein the inner diameter of the capillary tube is 1 to 10 microns and the outer diameter of the capillary tube is 2 to 20 microns; a liquid inlet is formed in a side wall of the capillary tube; the mini-type heat conducting device is arranged in the capillary tube; the heating source is connected with the mini-type heat conducting device and is used for heating the mini-type heat conducting device; the trace liquid pump is used for pumping ultra-trace liquid into the capillary tube from the liquid inlet. The plurality of capillary tubes can be arranged to form an array sample feeding device. According to the ultra-trace liquid sample feeding device provided by the invention, liquid distribution of the ultra-trace liquid is carried out by utilizing a heat expansion principle of the mini-type heat conducting device, so that picoliter-grade liquid sample distribution is realized. By adopting the ultra-trace liquid sample feeding device, the sample feeding difficulty of the ultra-trace liquid of an existing trace sample feeding device is overcome; picoliter-grade sample feeding can be realized and the utilization rate of a trace valuable sample is improved.

Owner:FUDAN UNIV

Medicine feeding machine for nursing of department of pediatrics

InactiveCN111658537AStrong resistanceReduce difficultyOral administration deviceNursing careEngineering

The invention discloses a medicine feeding machine for nursing of department of pediatrics. The medicine feeding machine comprises an injector, wherein a piston is arranged in the injector, a push rodis fixedly mounted on the piston, one end of the push rod extends to the outer side of the injector, a push block is fixedly mounted at one end, away from the piston, of the push rod, a mounting block is in threaded connection to one end of the injector, a rubber suction nozzle is fixedly mounted on the mounting block, a communicating opening is formed in the mounting block and mutually communicates with the rubber suction nozzle, graduation lines are uniformly formed in the injector, a guiding device is connected to the pushing block, and an attention diverting device is mounted on the injector. The attention diverting device is mounted on the injector, so that when the injector is used for feeding medicines for babies, a cellphone for playing video can be used for attracting attention of the babies, the condition that when the babies pay attention to take medicines bitter in taste, the babies can make strong resistance, can be avoided, the medicine feeding difficulty can be greatlyreduced, the design is reasonable, and the practical effect is good.

Owner:王晓蕾

Pharmaceutical composition used for curing infantile dental ulcer and preparation method for pharmaceutical composition

ActiveCN105168500AHeat-clearing and detoxifyingWith sore swellingAerosol deliveryDigestive systemGel preparationOral canker sores

The invention provides a pharmaceutical composition used for curing infantile dental ulcer and a preparation method for the pharmaceutical composition. The pharmaceutical composition comprises the following components in parts by weight: 80 to 120 parts of sweet wormwood, 80 to 120 parts of pericarpium zanthoxyli, 80 to 120 parts of mint and 10 parts of camphor; the pharmaceutical composition can be made into a membrane preparation and a gel preparation. The pharmaceutical composition provided by the invention has effects of oral local antivirus, sterilization, anti-inflammation, convergence, analgesia and detumescence, and is mainly used for stopping pain of oral wounds, improving symptoms, relieving edema, improving infantile feeding difficulty caused by pain and promoting the oral wounds to be healed soon.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com