Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261results about How to "Realize intermittent feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

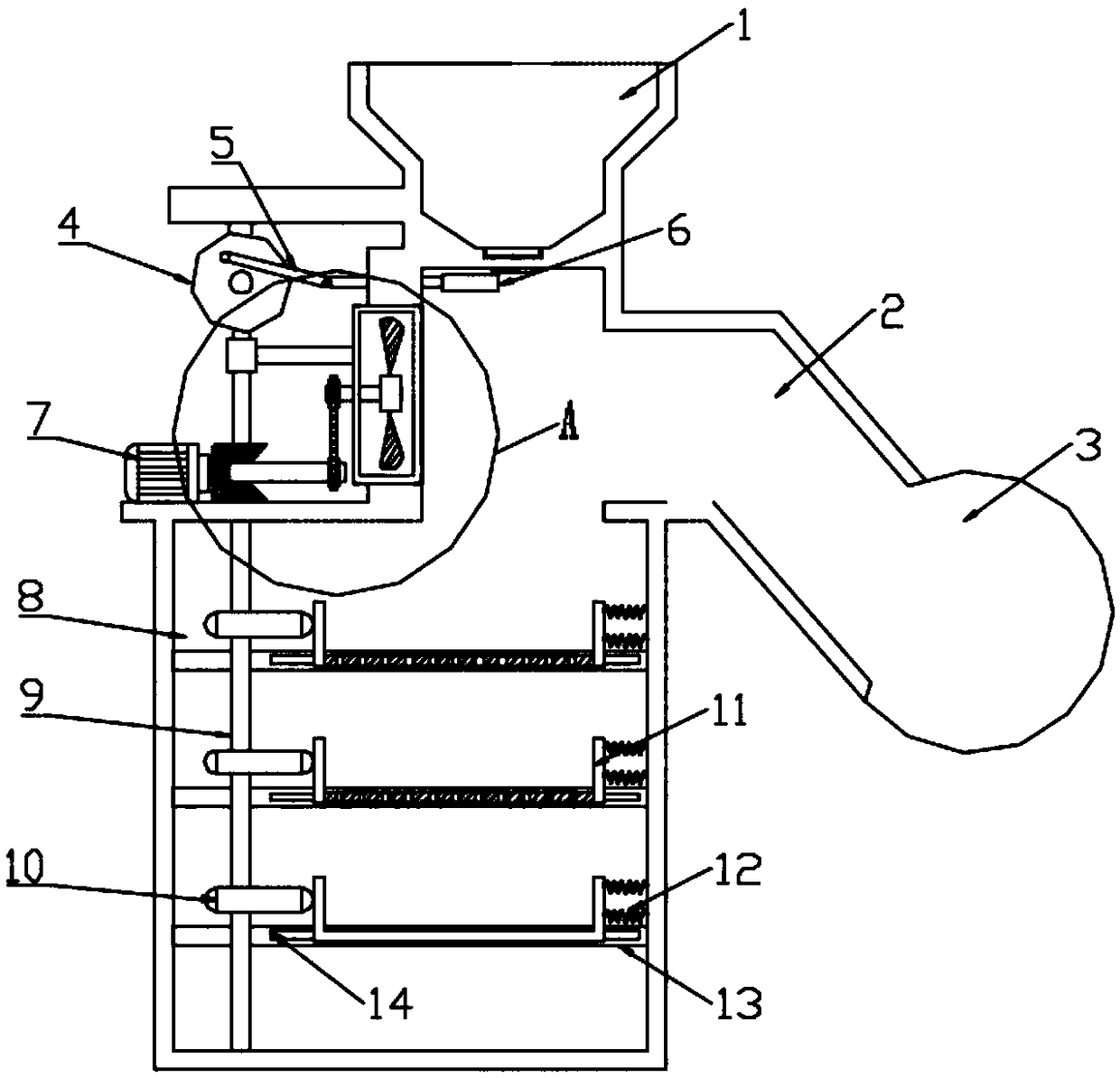

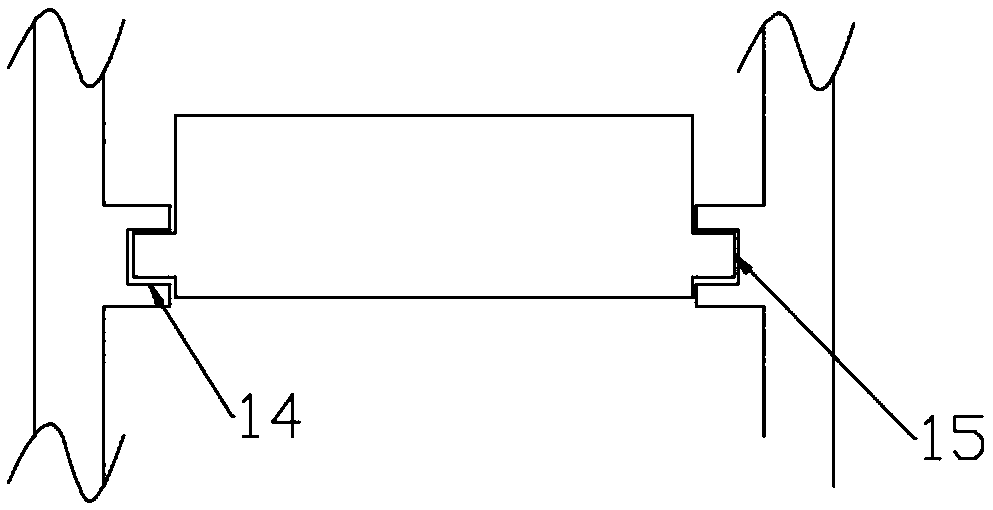

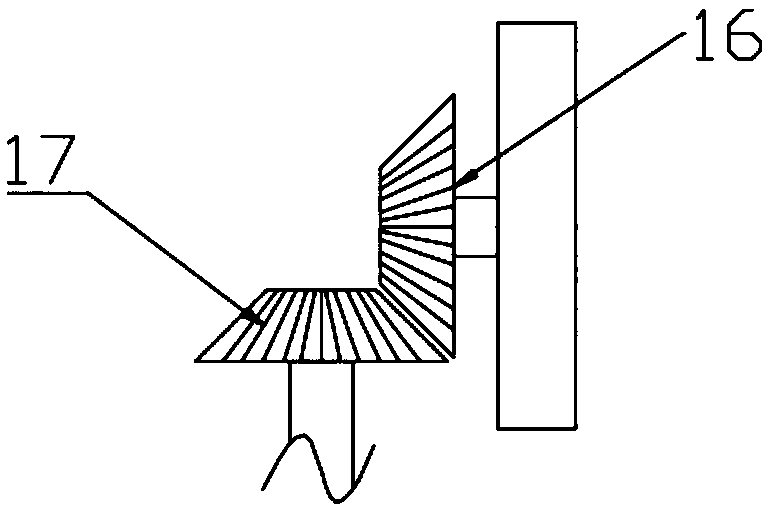

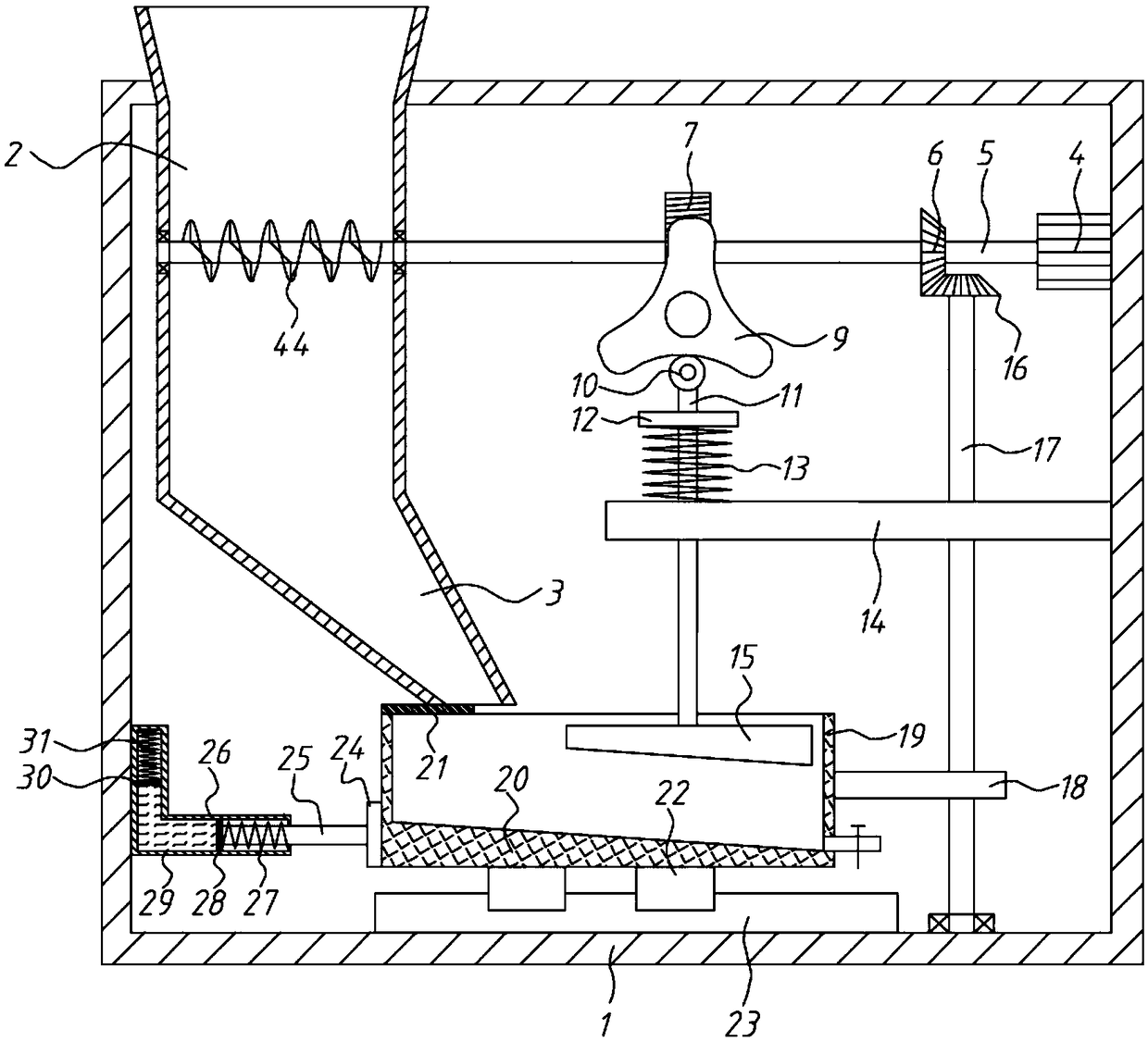

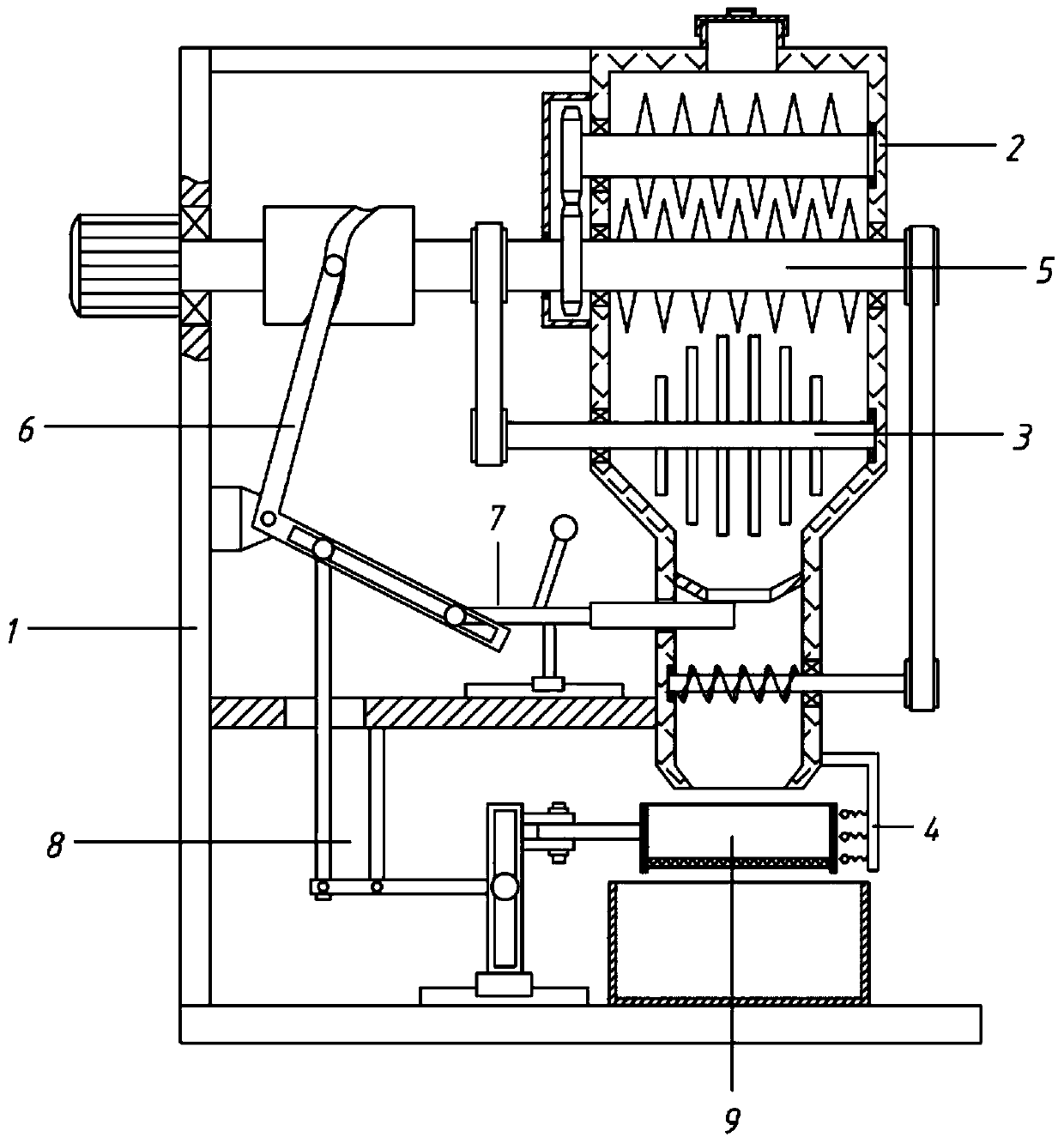

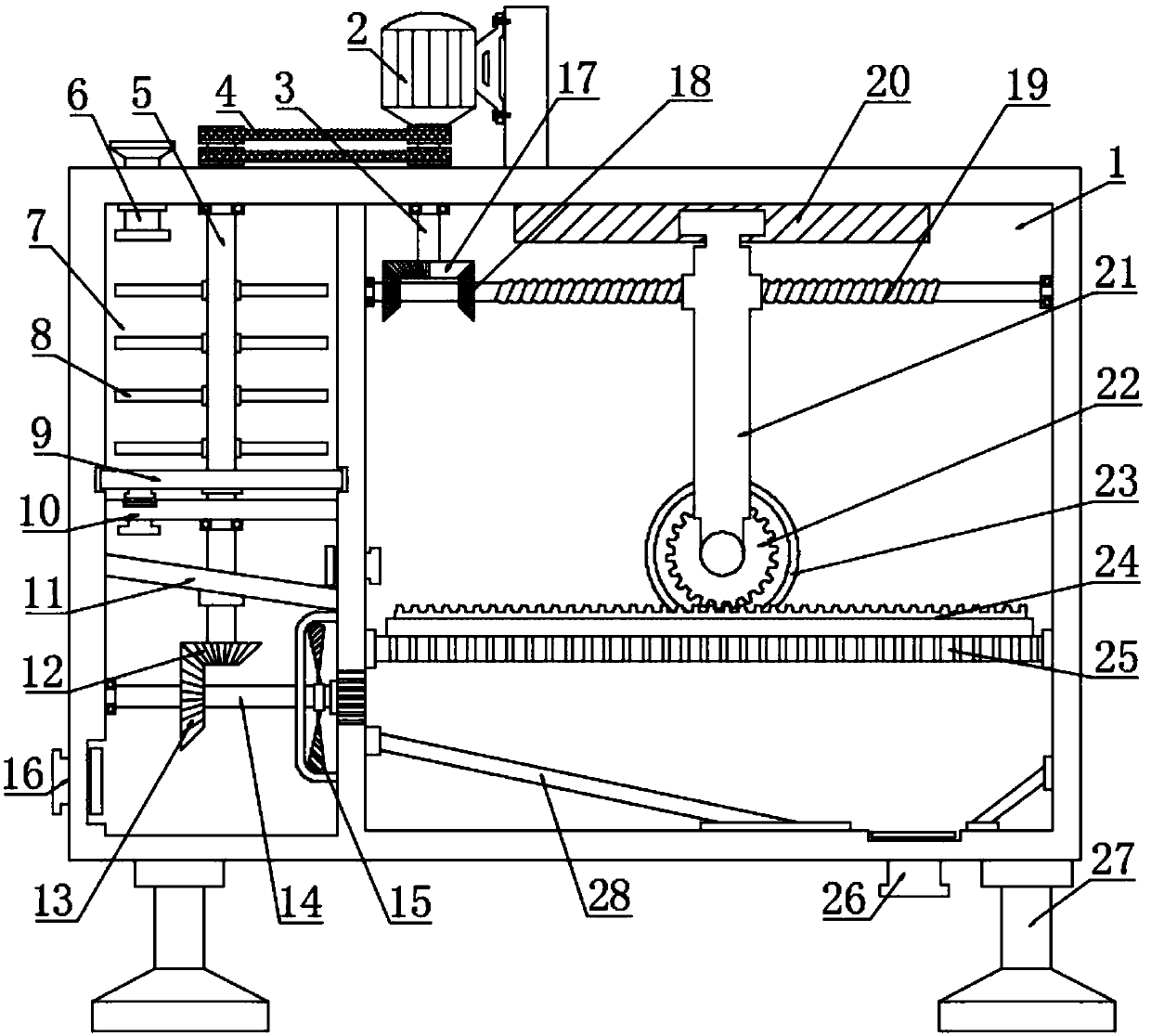

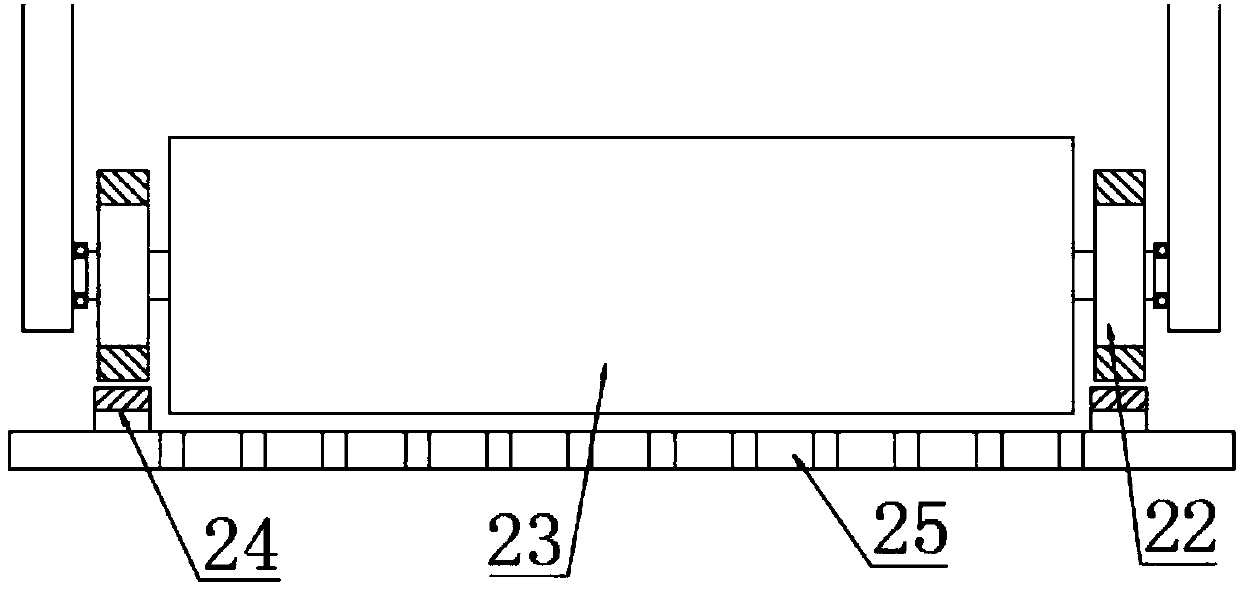

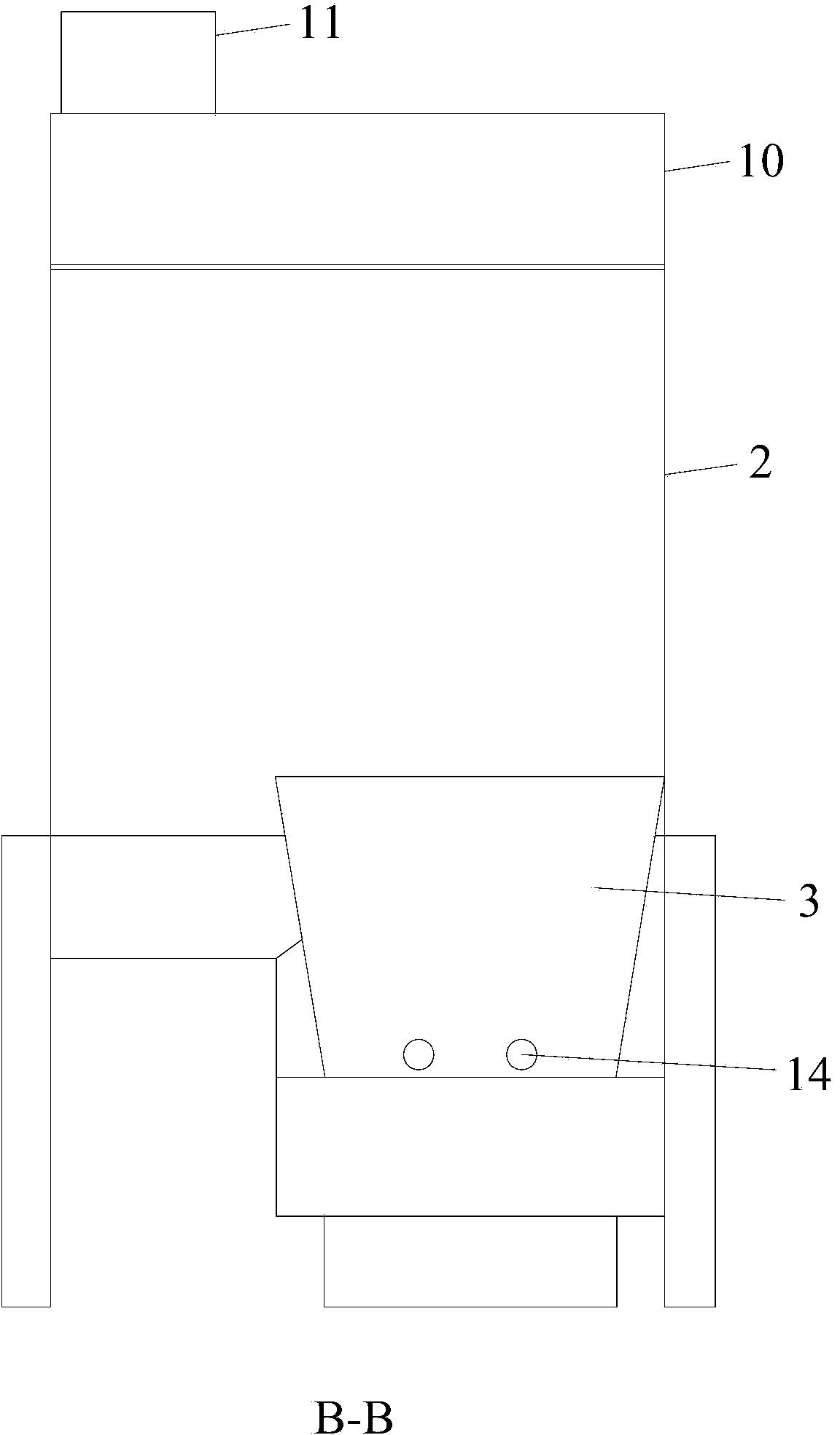

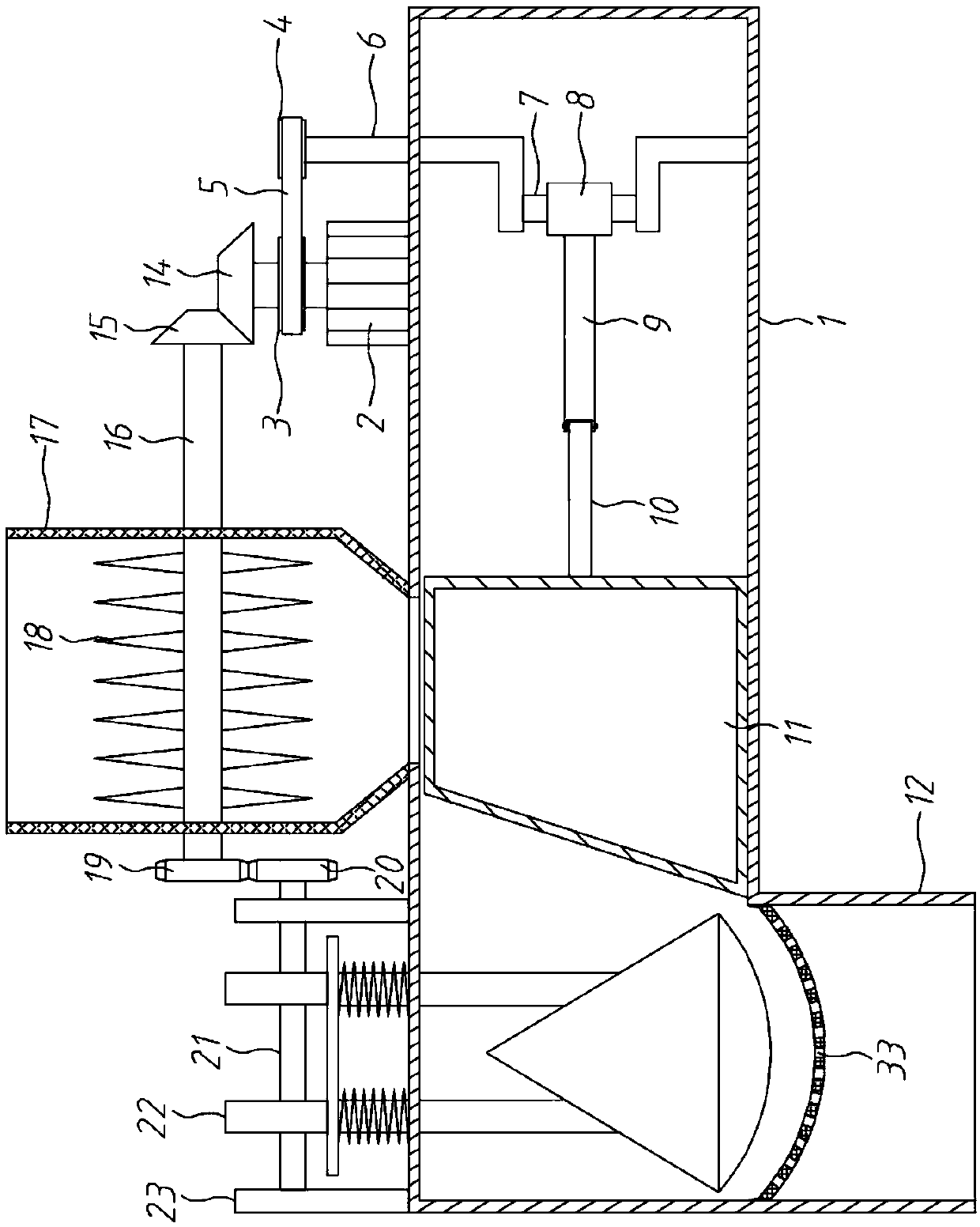

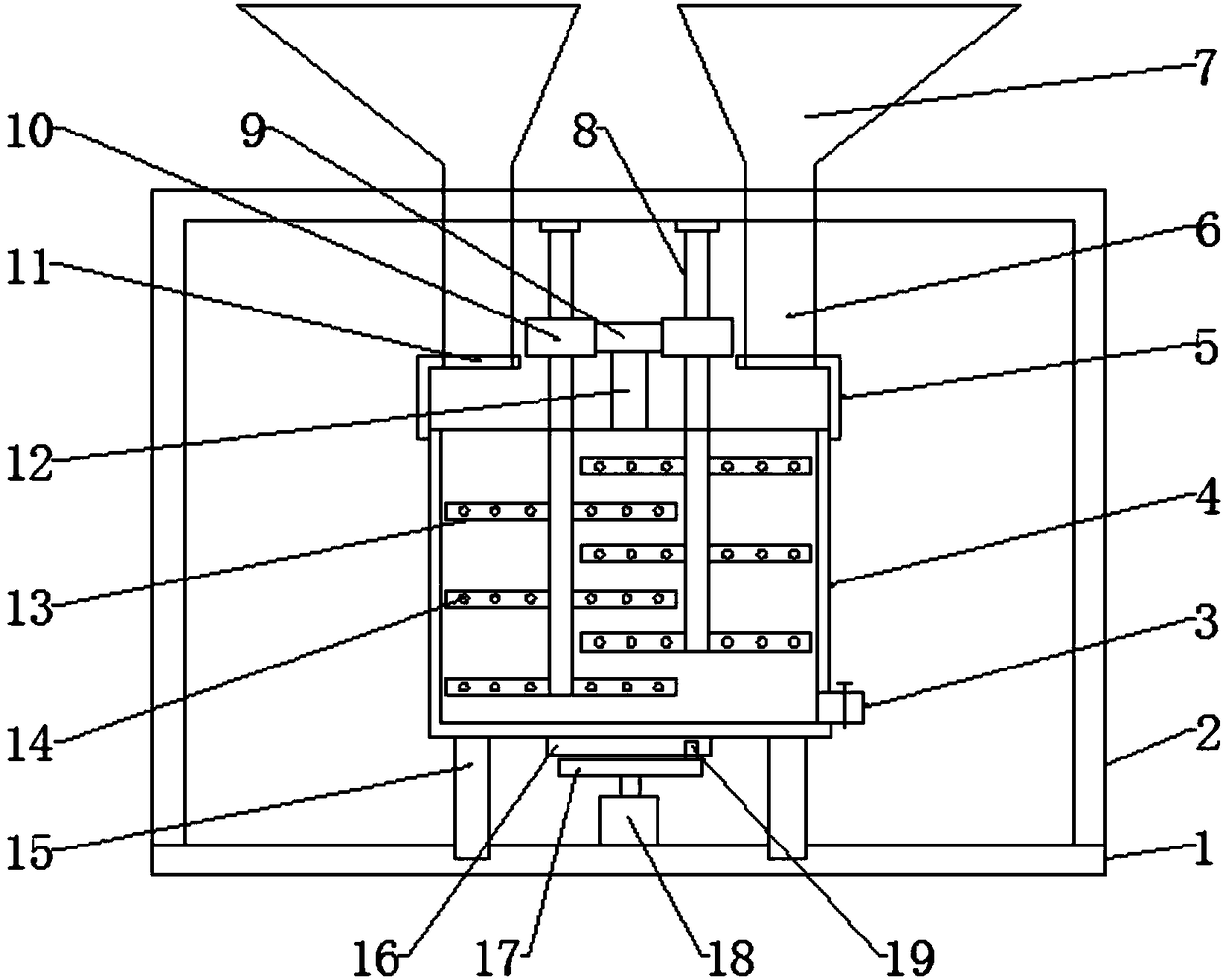

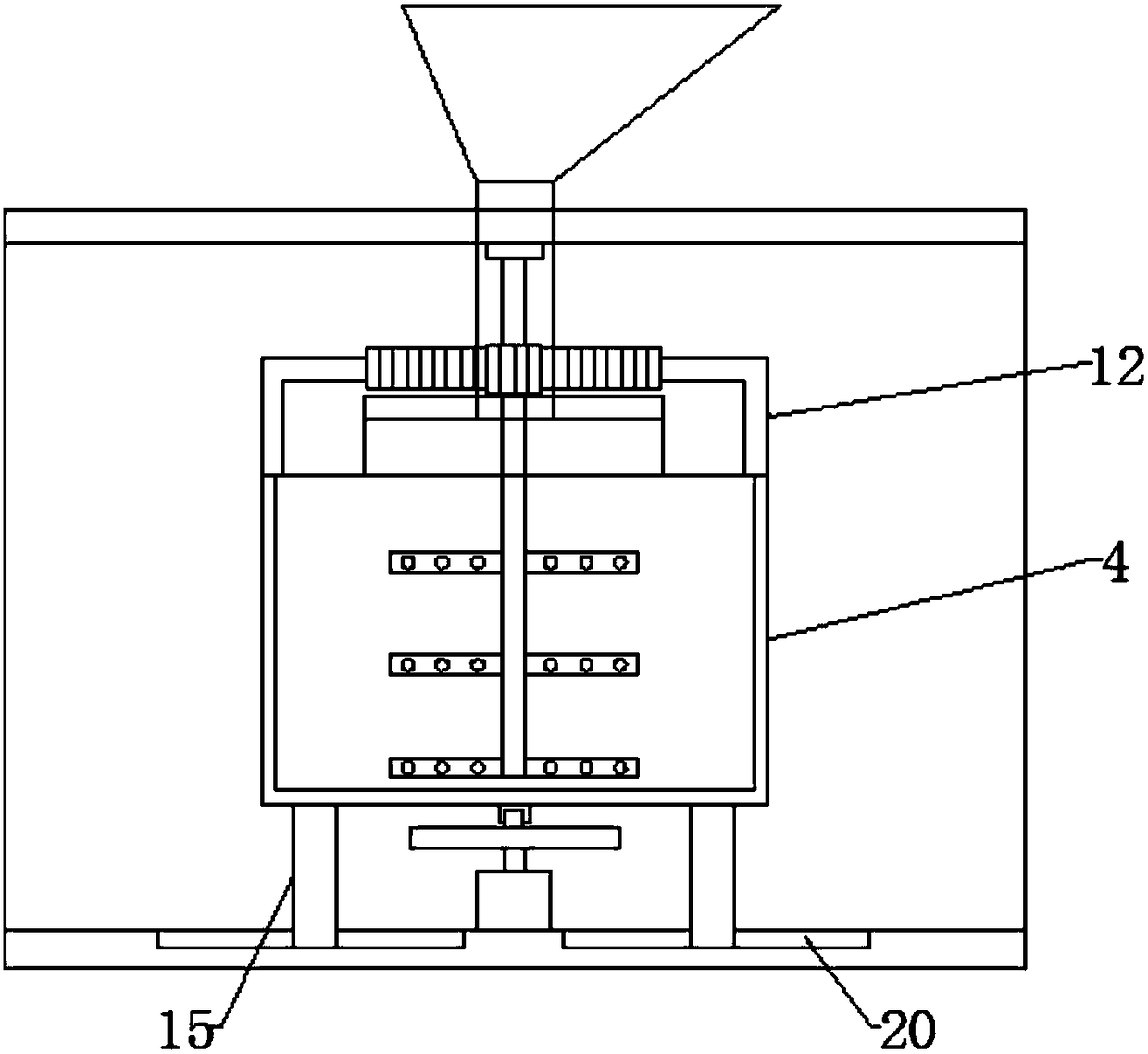

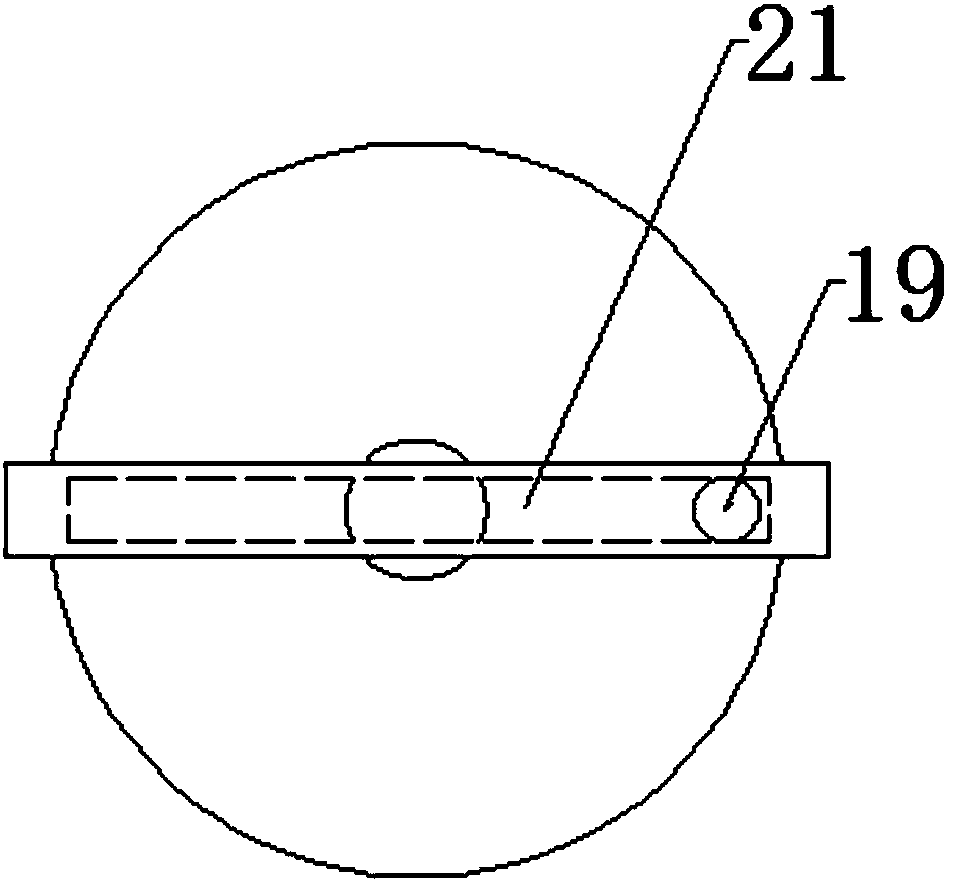

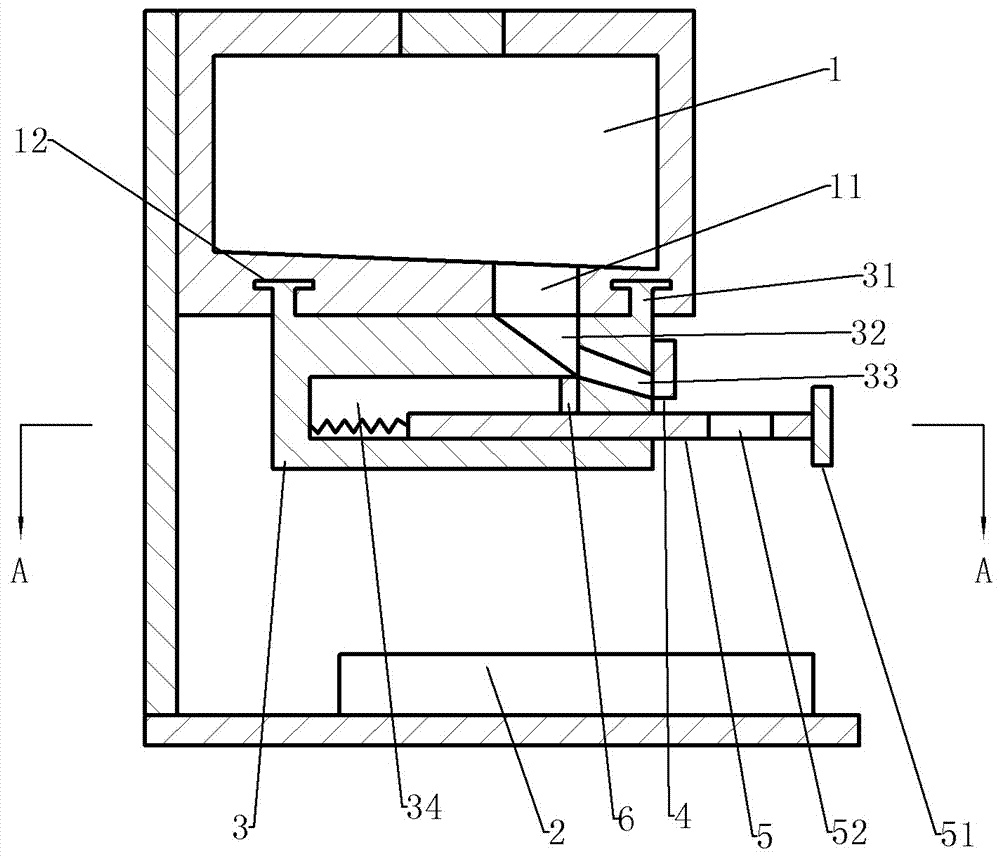

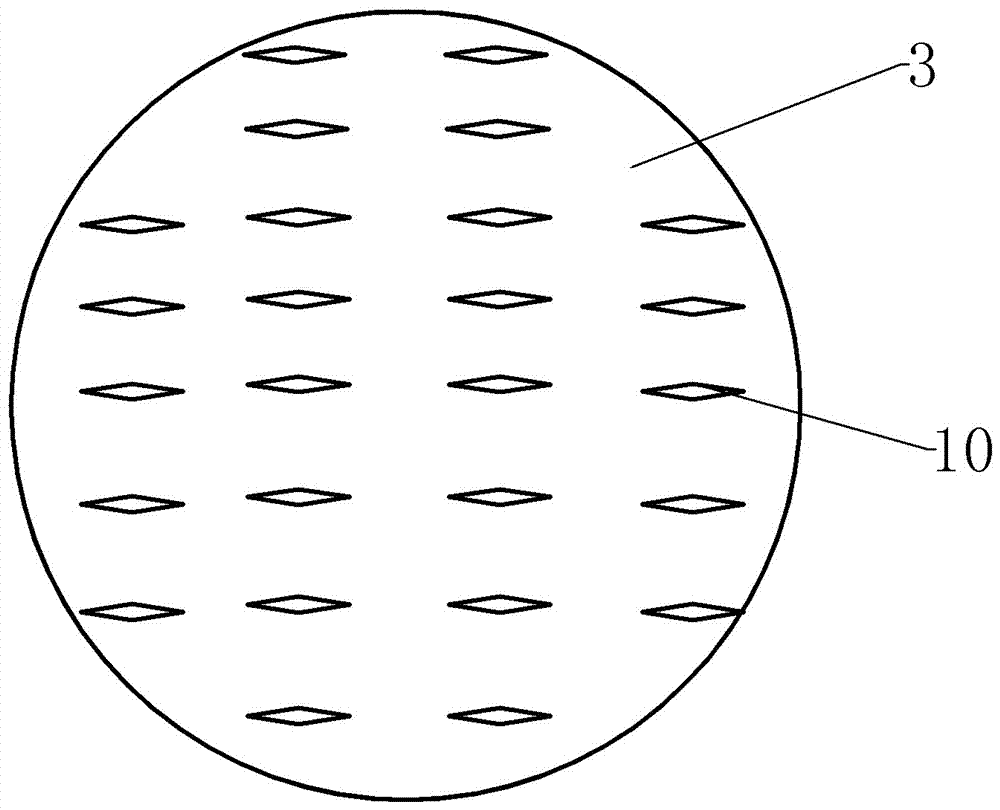

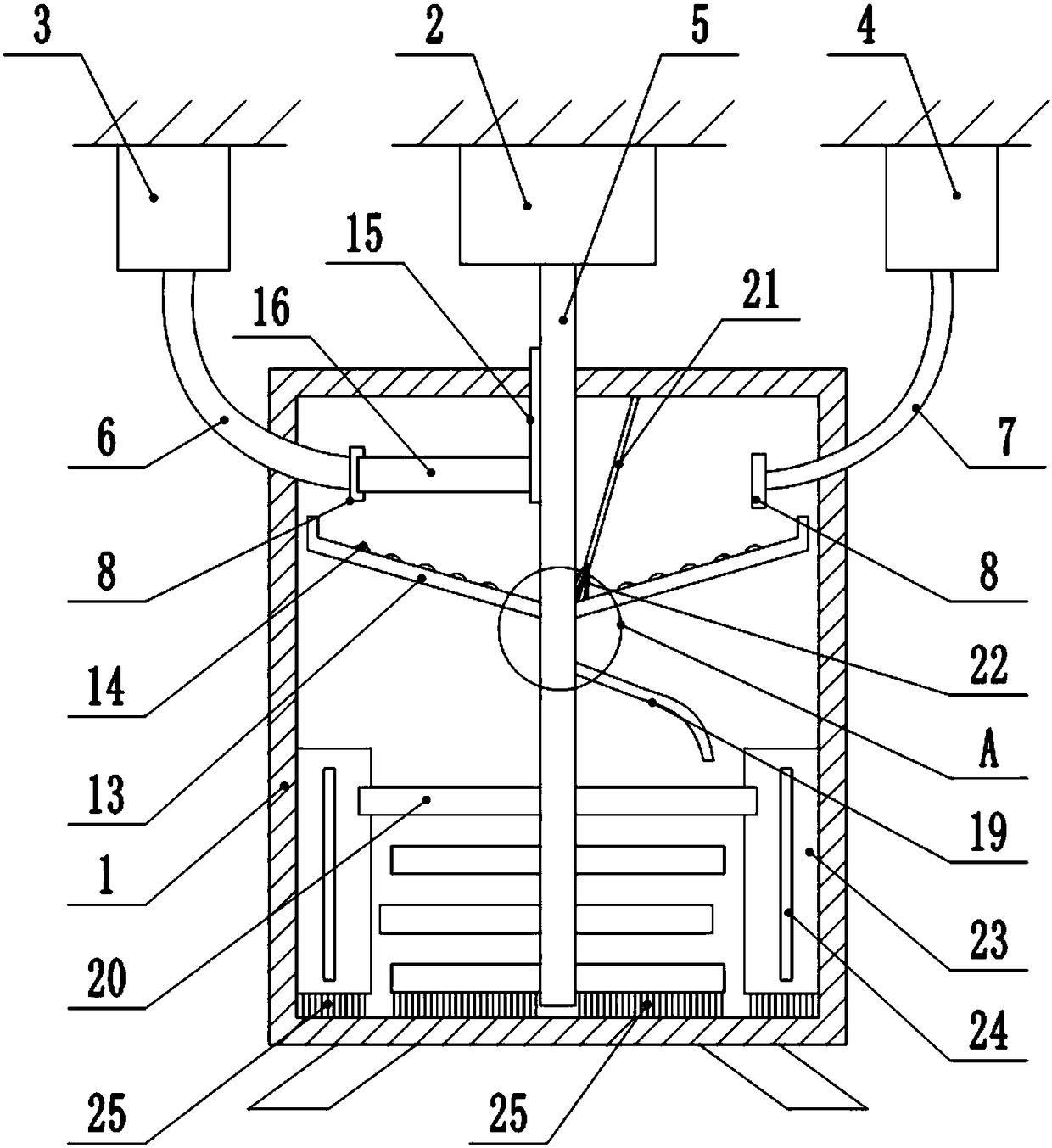

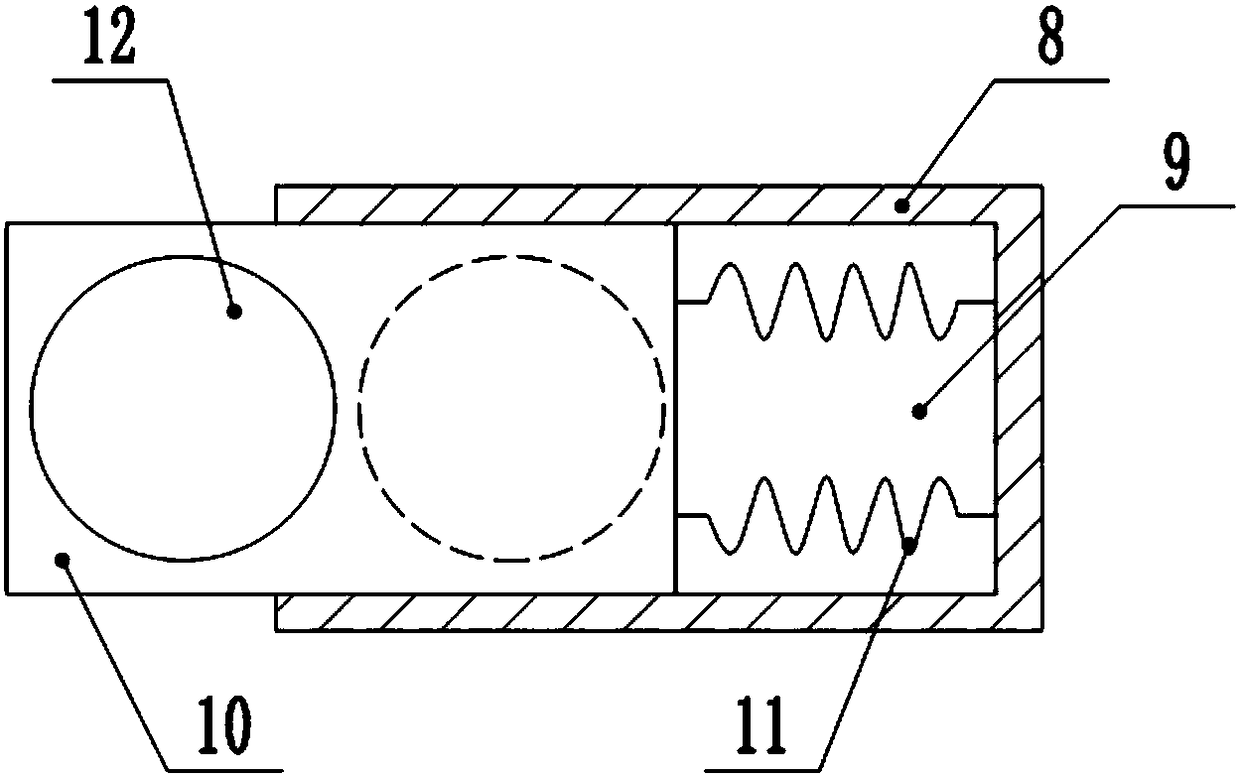

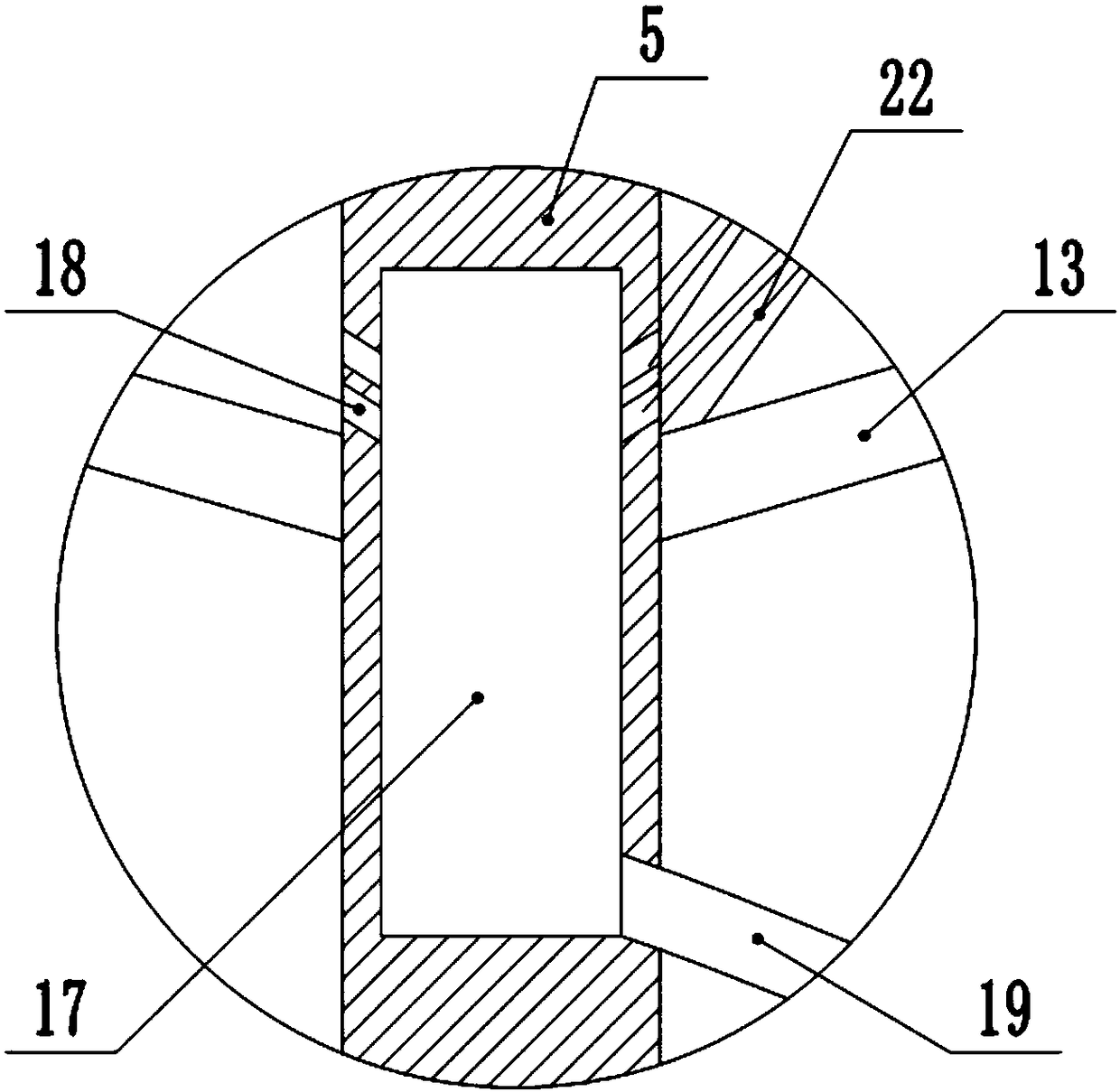

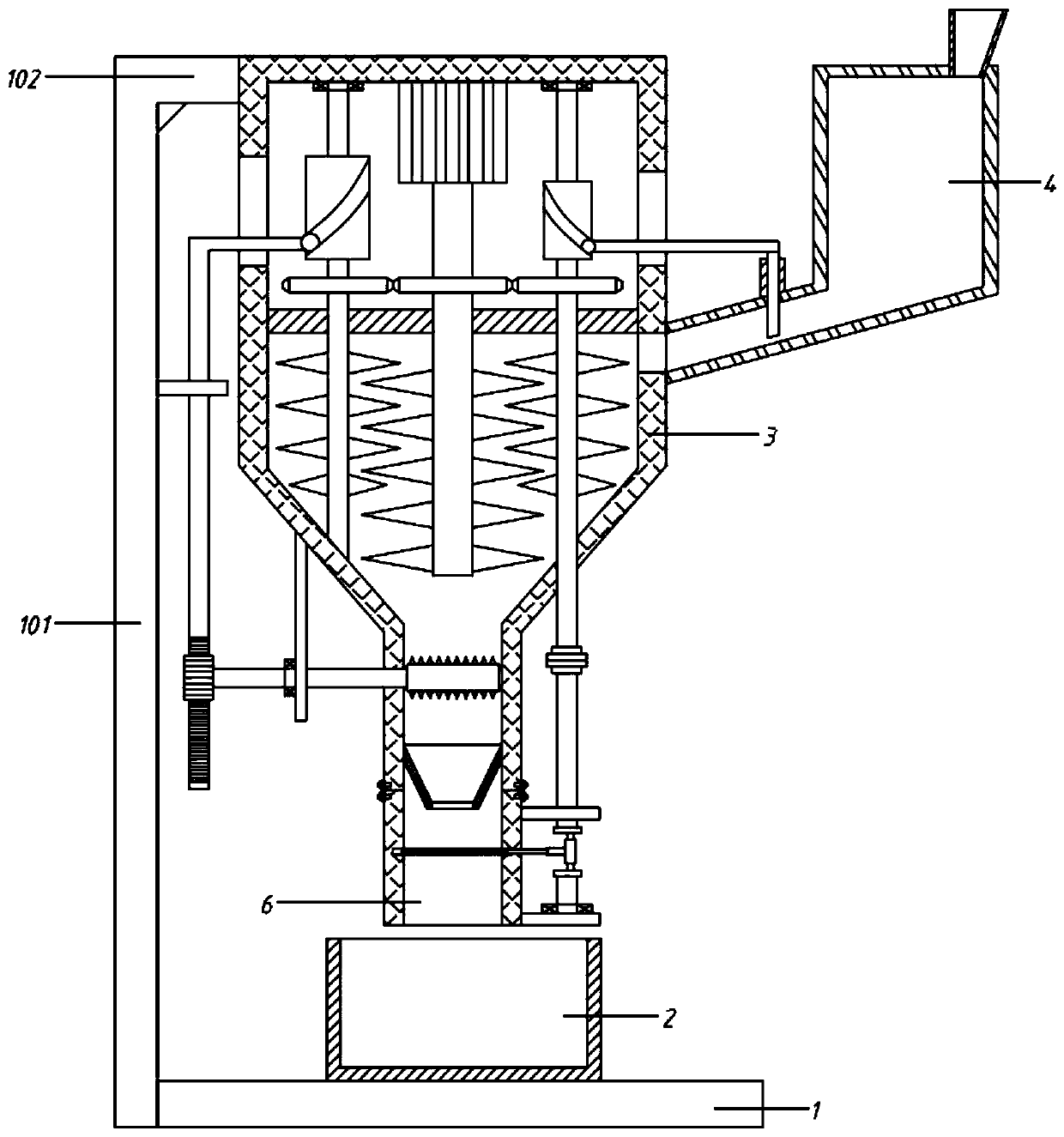

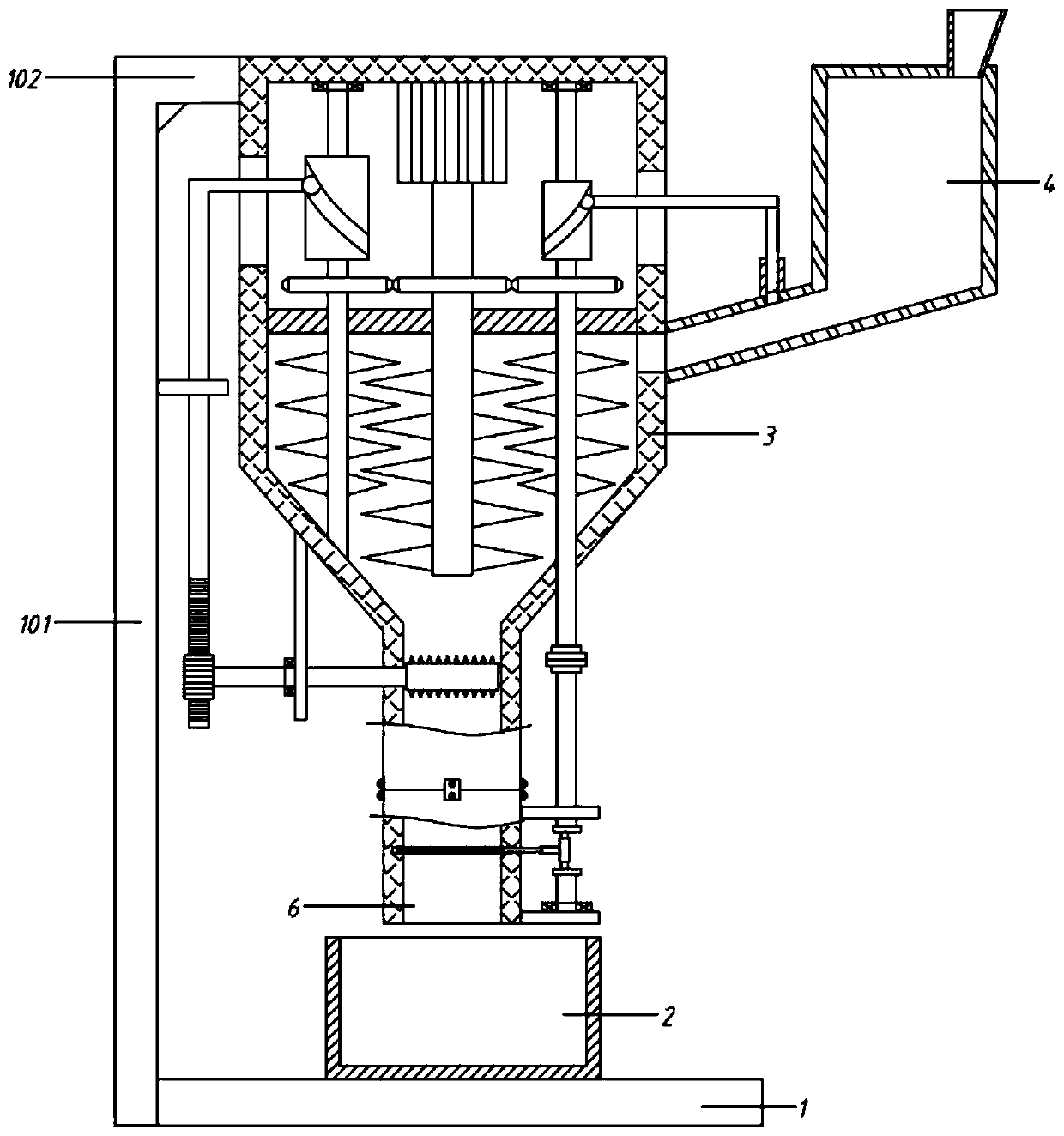

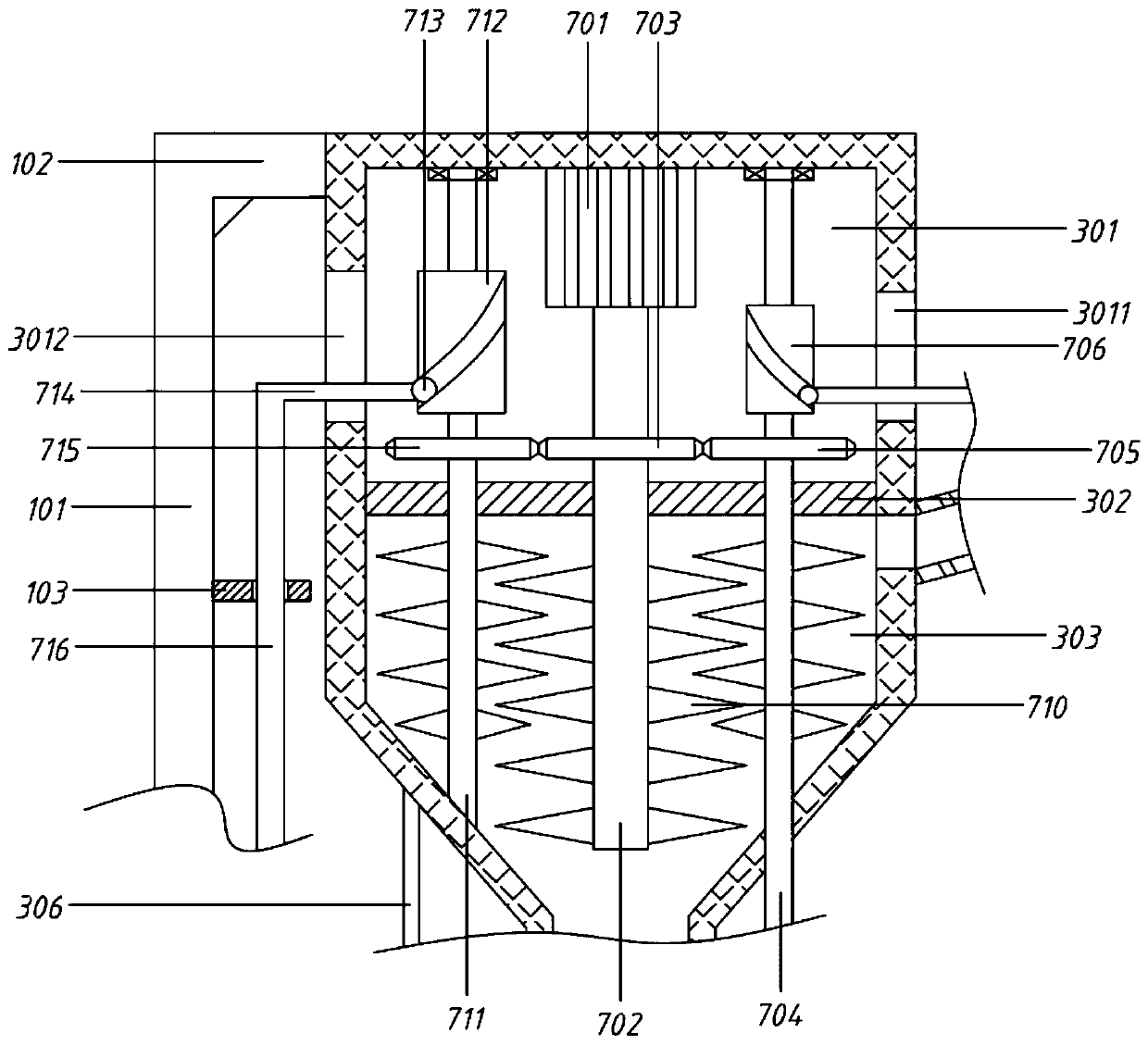

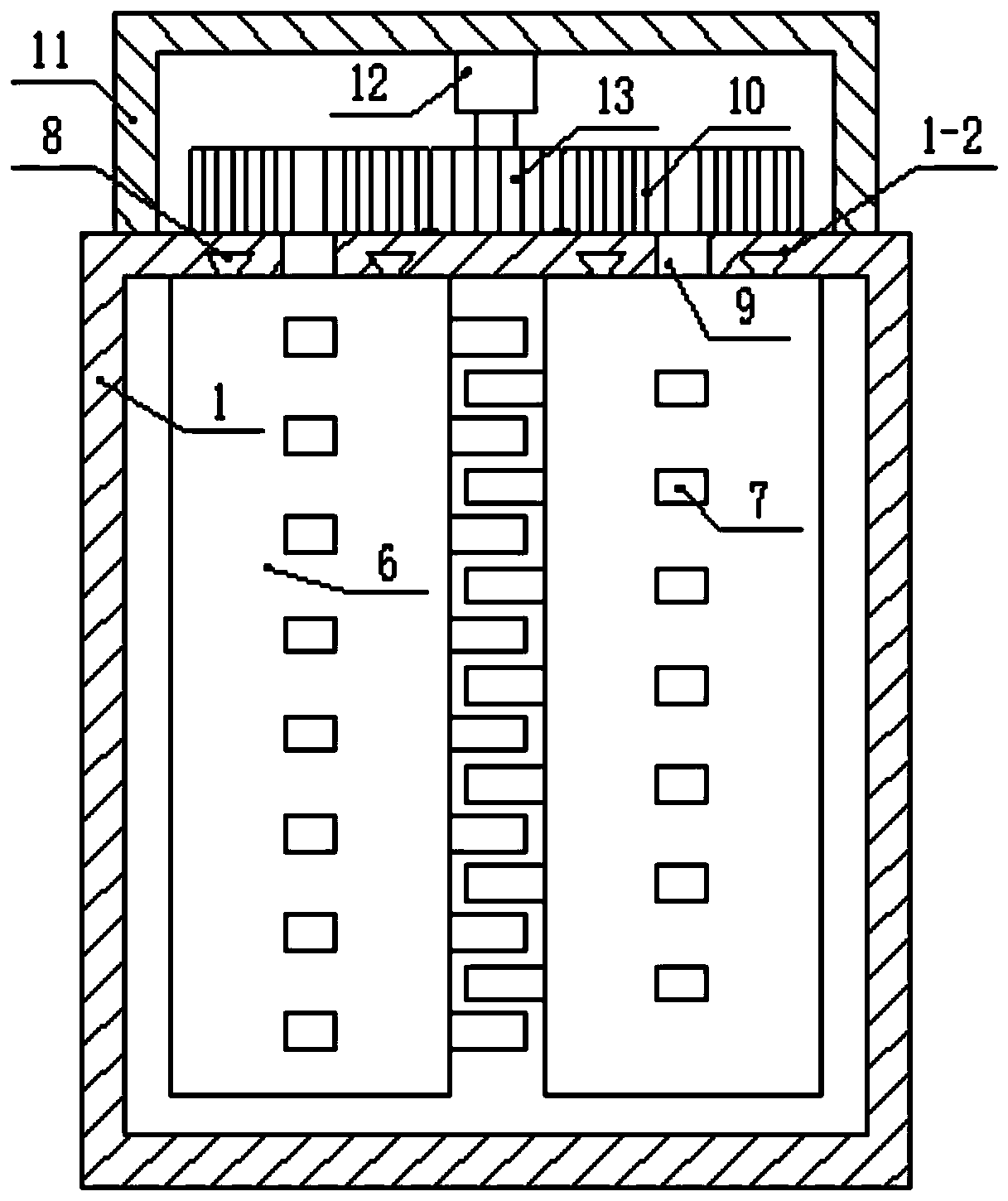

Dust raising, screening and impurity removing device for unhusked rice

InactiveCN108816756ARealize intermittent feedingAvoid affecting the effect of impurity removalSievingGas current separationEngineeringFan blade

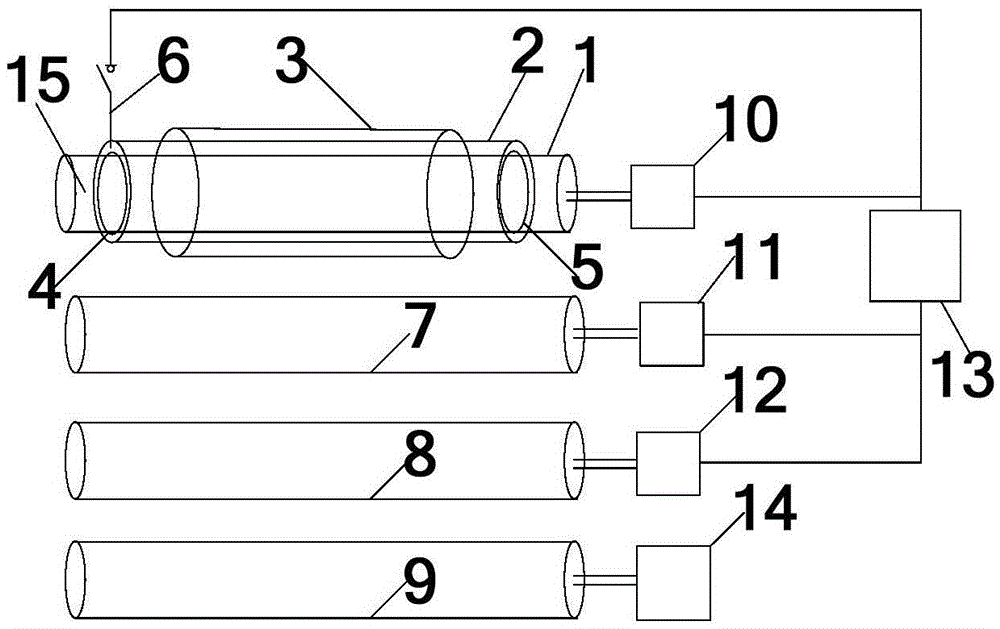

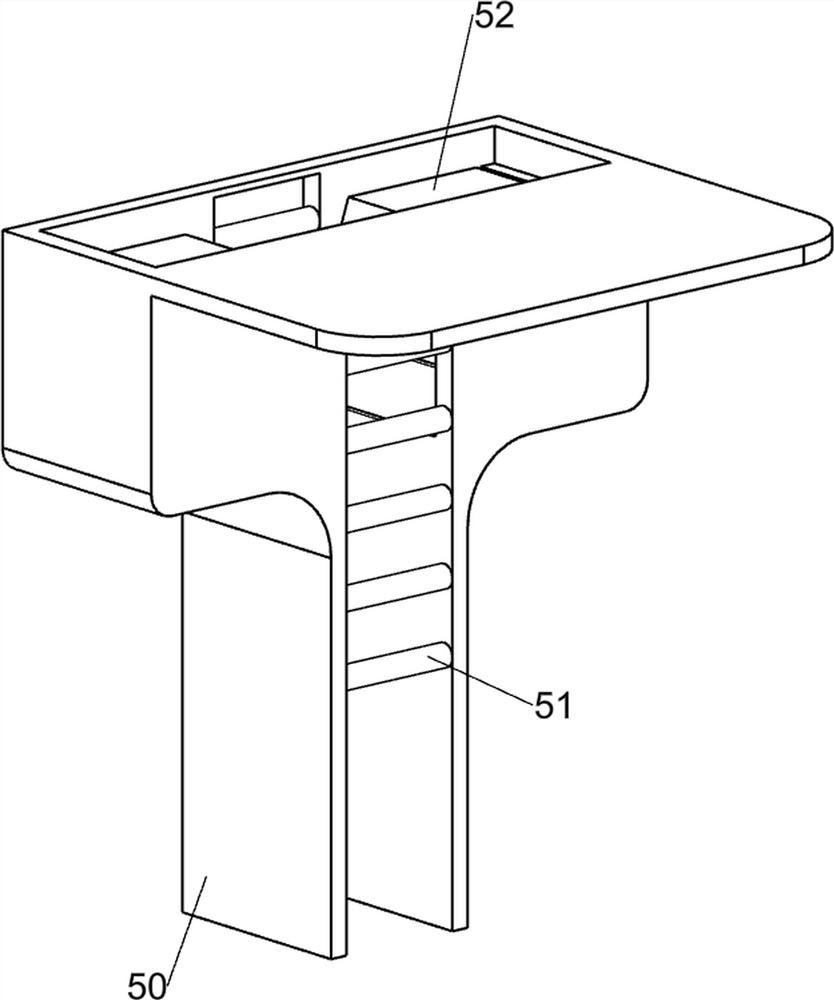

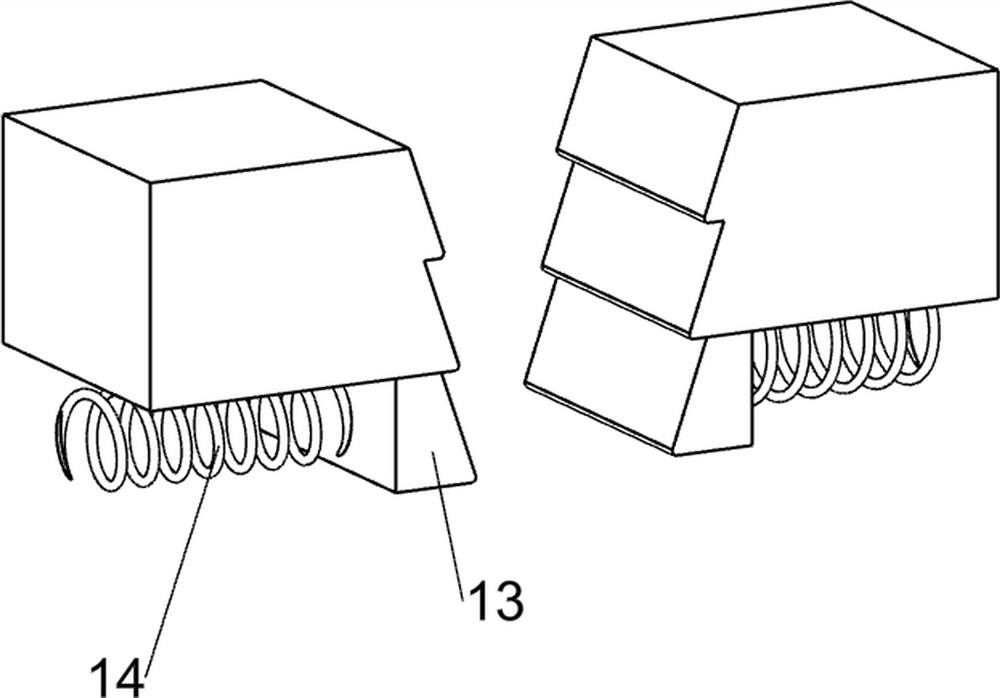

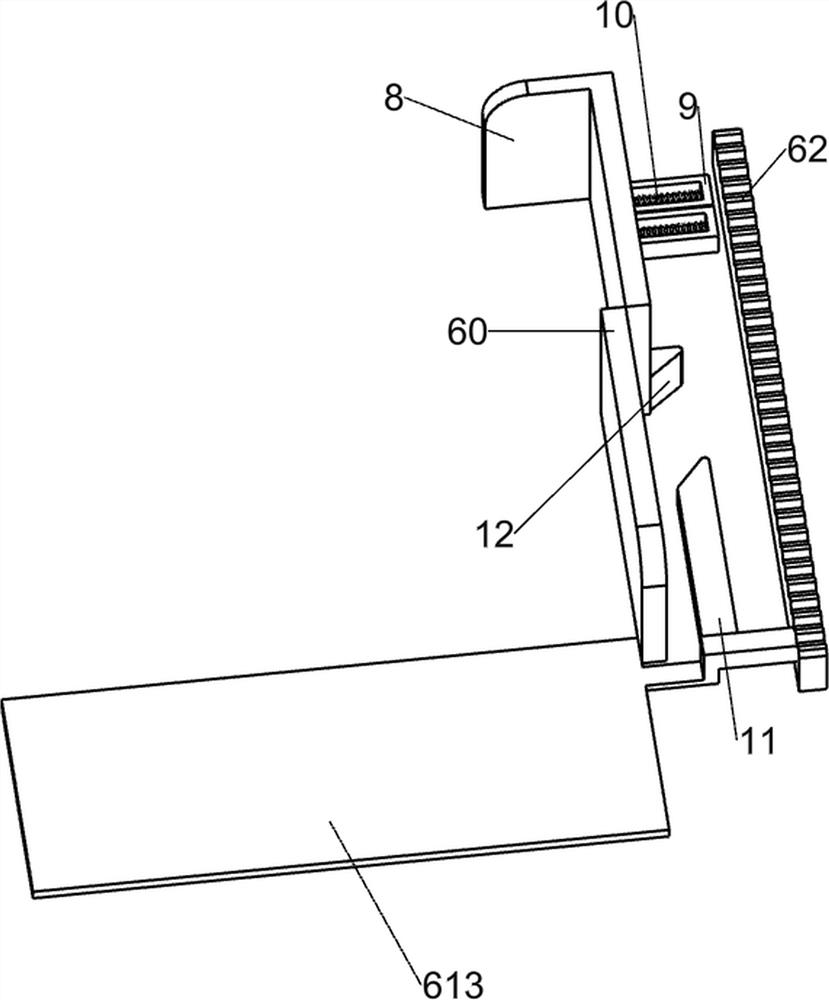

The invention discloses a dust raising, screening and impurity removing device for unhusked rice. The device comprises a feeding hopper, a blocking mechanism, a dust raising cavity, a motor, a screening cavity and screen plates; the feeding hopper is arranged at the upper end of the dust raising cavity, the lower end of the dust raising cavity communicates with the screening cavity, and the blocking mechanism is arranged at the lower end of the feeding hopper; fan blades are arranged on the left side of the dust raising cavity, and a rotating shaft located at the left ends of the fan blades isrotationally connected with an output shaft of the motor through a belt; and three groups of supporting plates are symmetrically arranged on the inner side of the screening cavity, each screen plateis arranged on the inner sides of every two symmetric supporting plates, screen holes are formed in the bottoms of the screen plates on the three groups of supporting plates correspondingly, and the left ends of the screen plates abut against eccentric wheels fixedly arranged on a rotary shaft. According to the dust raising, screening and impurity removing device for the unhusked rice, the designis novel, the eccentric wheels mutually cooperate with springs to drive the three screen plates to synchronously move left and right in a reciprocating mode when the eccentric wheels rotate, so that the screening efficiency is high; and meanwhile, the three screen plates can effectively remove large-particle impurities and small-particle impurities in the unhusked rice, so that the screening efficiency is high, and the practicability is high.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

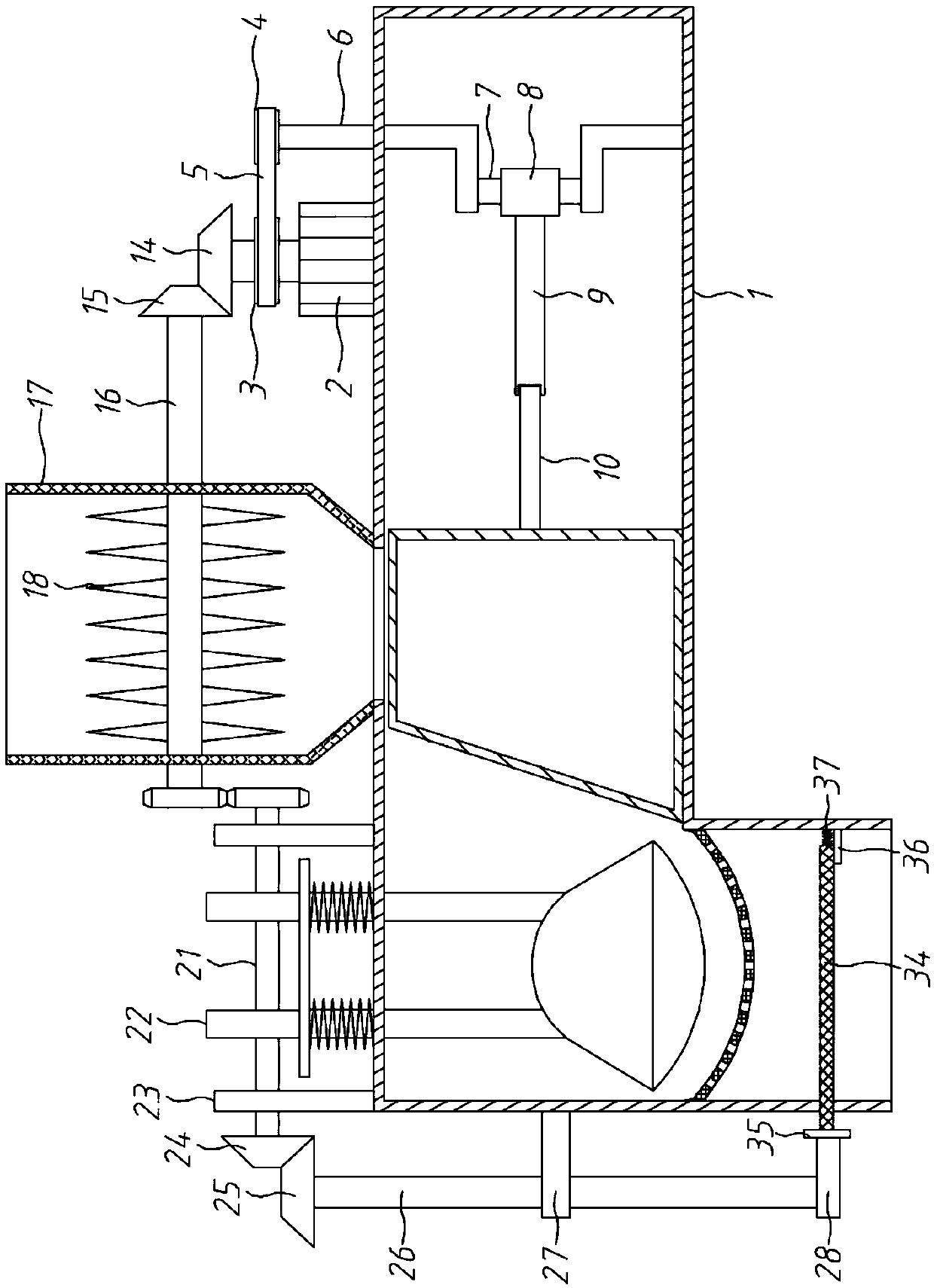

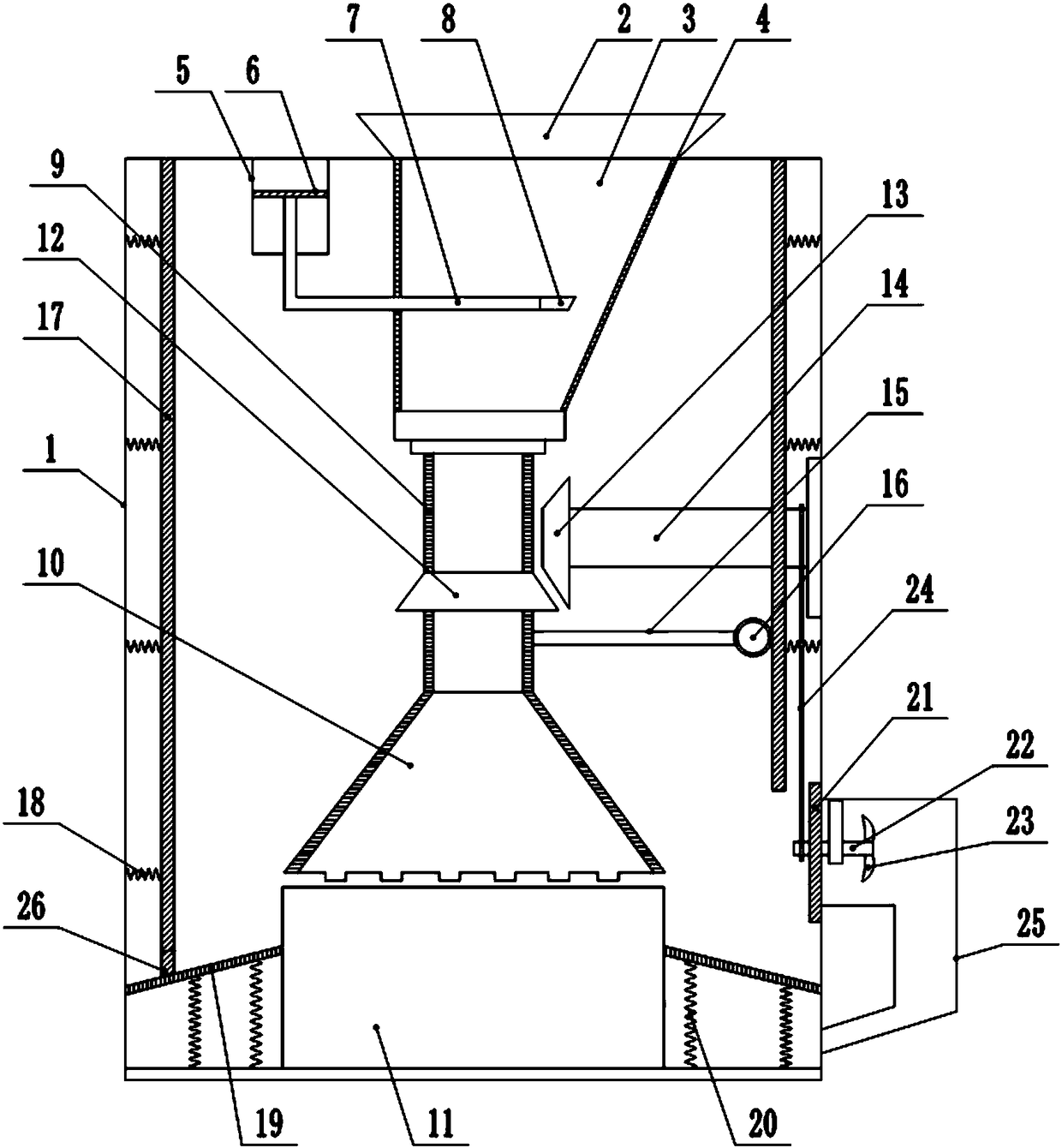

Efficient coal multi-stage crushing equipment for coal mine exploitation

InactiveCN111036376ARealize multi-stage crushingImprove crushing effectGrain treatmentsCoalMining engineering

The invention relates to the technical field of coal crushing equipment, in particular to efficient coal multi-stage crushing equipment for coal mine exploitation. A first rotating shaft is driven bya servo motor to rotate, on one hand, the first rotating shaft drives a second d rotating shaft to rotate through a transmission belt, crushing cutters interact, and coal in a feeding hopper is crushed; on the other hand, the first rotating shaft directly drives a grinding end to grind coal falling into a grinding channel through a feeding pipe, and therefore multi-stage crushing is achieved, andthe crushing effect and efficiency are improved; the first rotating shaft further drives a third rotating shaft to rotate through the transmission belt, a moving block moves up and down in the axial direction, a baffle is driven to move, the feeding pipe is intermittently opened or sealed, and intermittent feeding is achieved; and a push-pull assembly is arranged, a cylinder cam rotates along withthe first rotating shaft, a wedge block is driven by a connecting rod to move up and down, a push-pull rod drives a blocking plate to work in cooperation with a spring, and blocking and material pushing are completed.

Owner:安徽信典网络科技有限公司

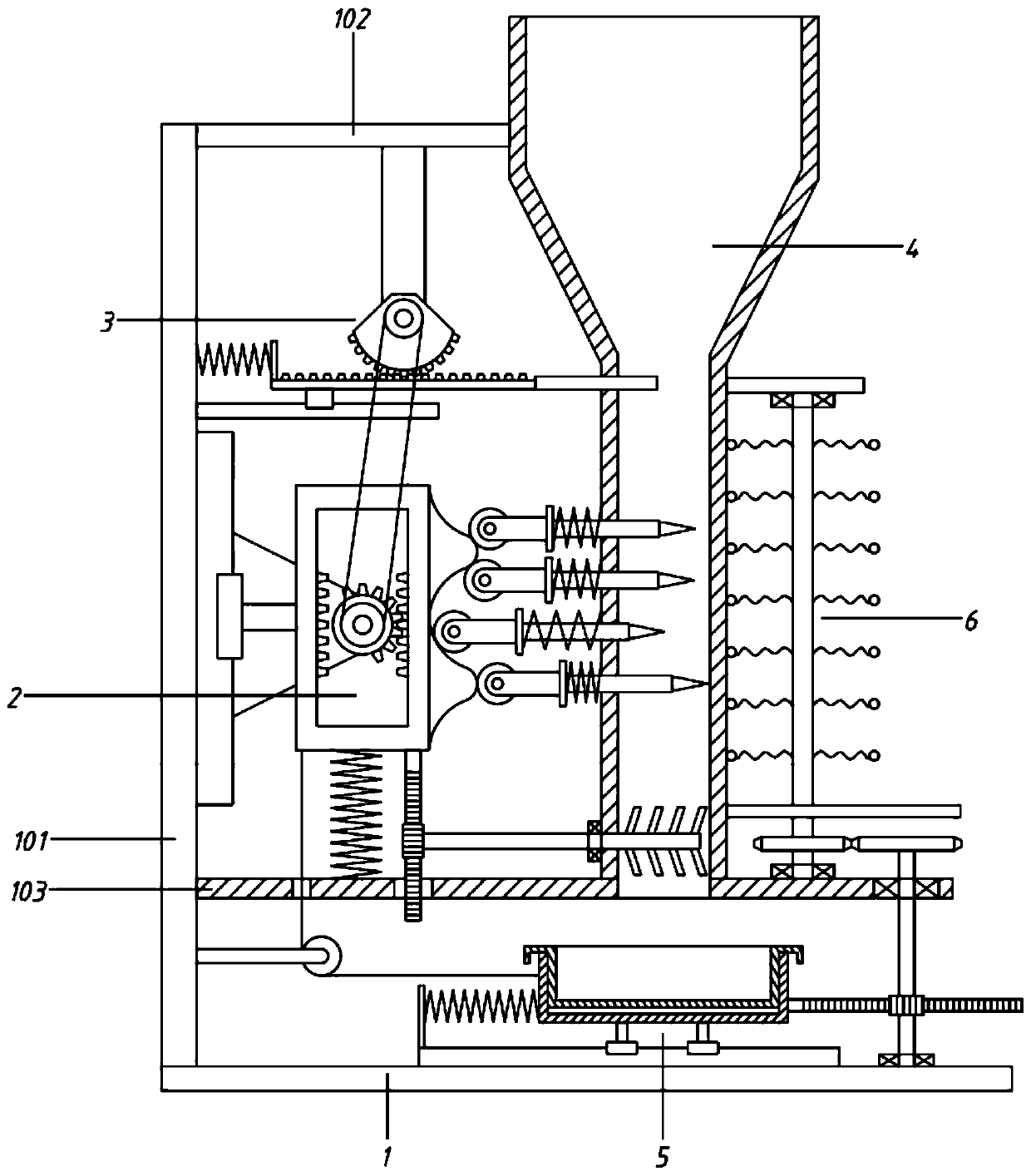

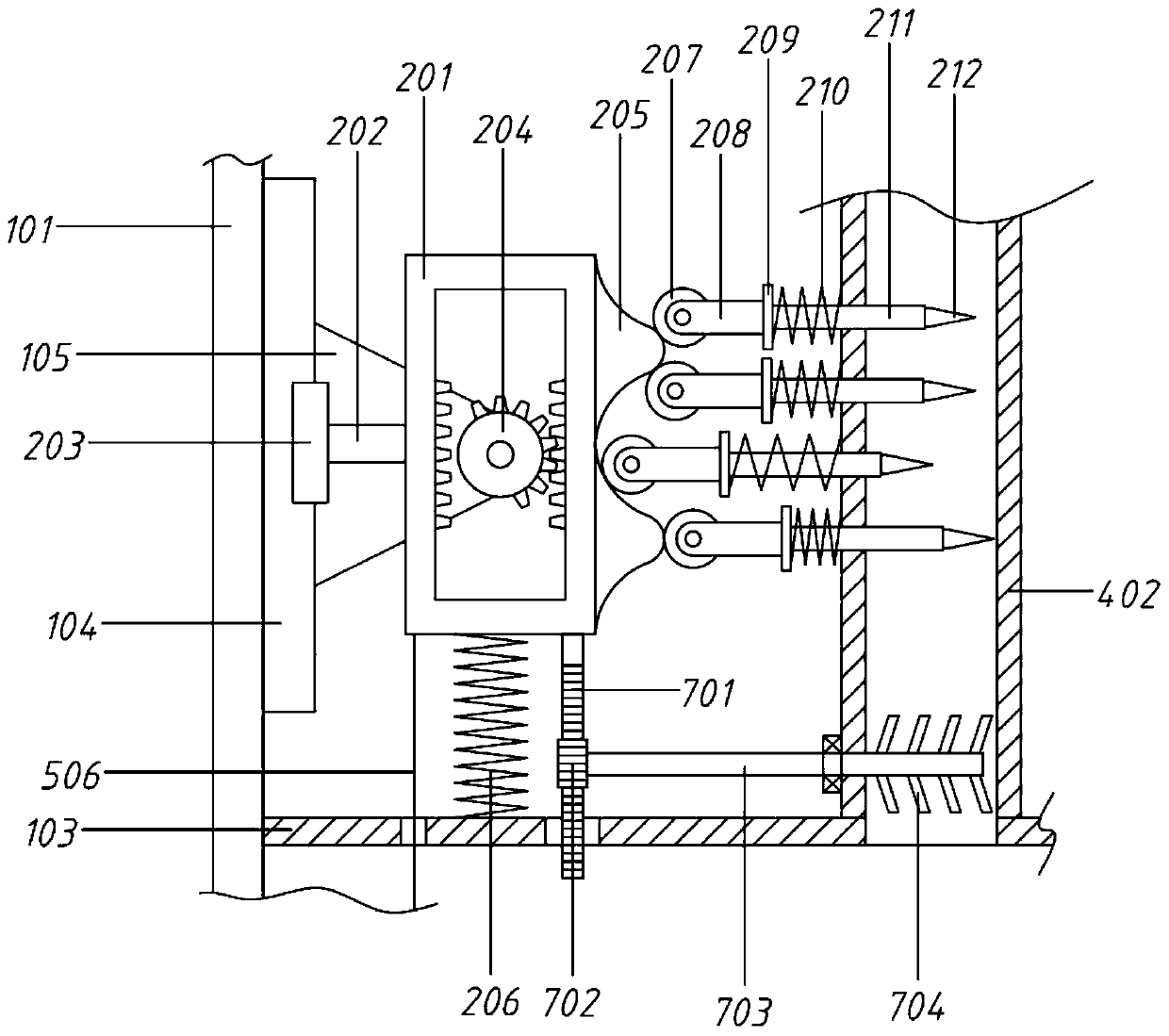

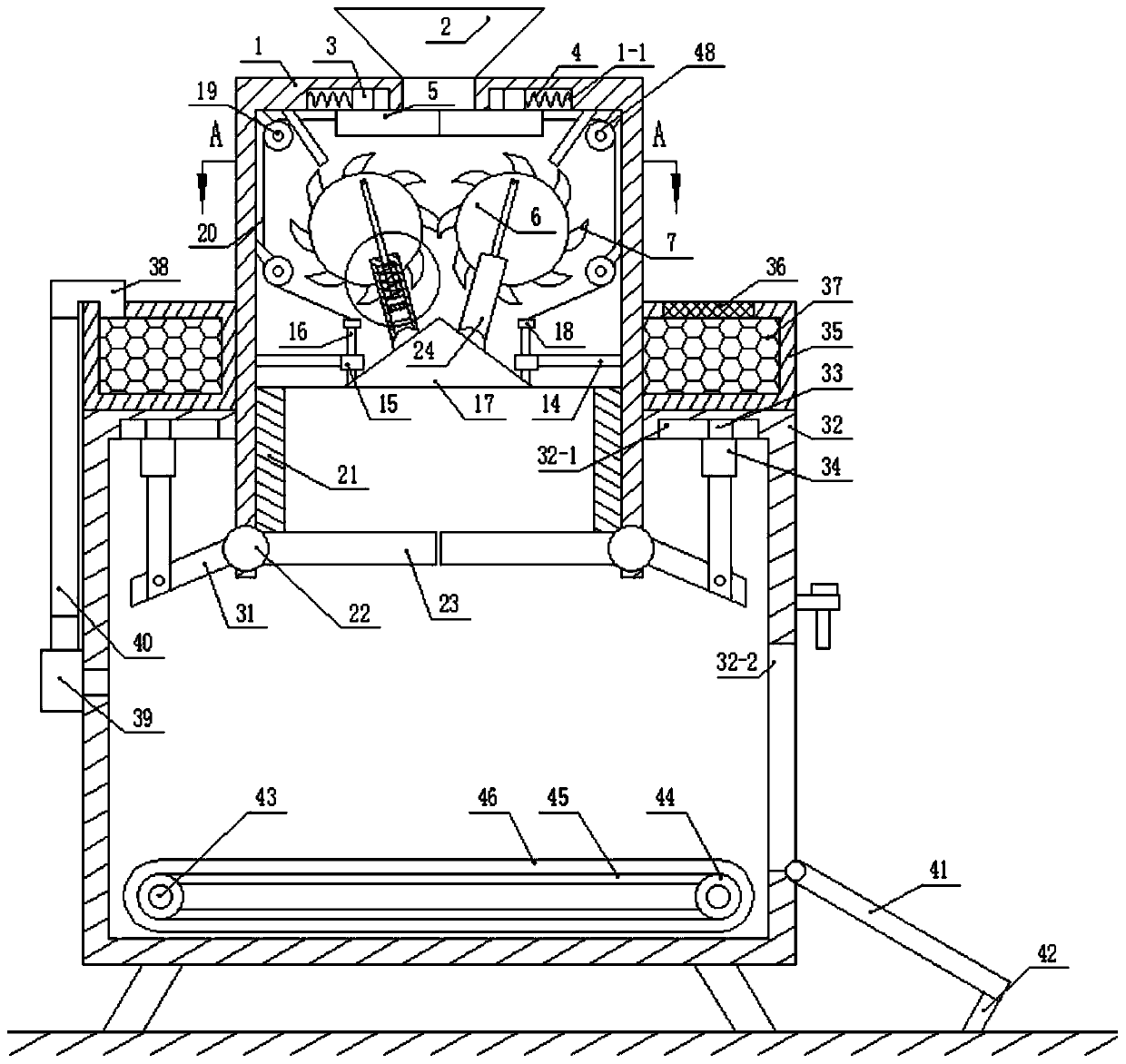

Environmentally-friendly efficient recovery crusher for waste injection molded parts

InactiveCN109333878AHas multiple functionsRealize intermittent feedingPlastic recyclingGrain treatmentsReciprocating motionEngineering

The invention relates to the technical field of waste injection molded part recovery, in particular to an environmentally-friendly efficient recovery crusher for waste injection molded parts. A firstshaft is driven by a drive motor to rotate to exert multiple effects that firstly, a second shaft is driven by transmission of bevel gears to rotate, so that a disc-shaped cam acts on a crushing basket, and cooperates with a piston barrel at the right side to make the crushing basket do reciprocating motion along a sliding rail, and therefore, the action region of a crushing tip is changed; secondly, a triangular cam is driven by a worm gear and a worm to rotate, and through functions of a roller and a first spring, the crushing tip is driven to vertically move to crush the injection molded parts in the crushing basket; thirdly, a spiral auger is also arranged on the inner section, located in a feed hopper, of the first shaft, and the waste injection molded parts firstly undergo the crushing action of the spiral auger when being put into the feed hopper, and then, fall into the crushing basket and are crushed; and fourthly, the outlet of a guide hopper is blocked by a baffle when the baffle is in an initial state, and during reciprocating motion of the crushing basket, the baffle moves along with the crushing basket to realize intermittent discharging.

Owner:李明军

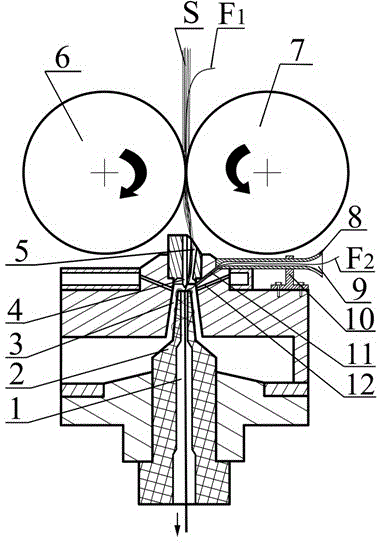

A kind of eddy current composite spinning method for producing fancy yarn

InactiveCN103215700BRealize intermittent feedingRealize feeding with periodic change in tensionContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a vortex composite spinning method for producing structured yarns, which belongs to the technical field of textile processing. According to the method, a yarn conveying channel which forms an included angle of 15-65 degrees with a guide pin is formed on each vortex spinning device outer tube of a vortex spinning machine; the yarn conveying channel is positioned on the same side as a front rubber roll; a yarn outlet of the yarn conveying channel is positioned at the fiber outlet of a fiber conveying channel and the yarn inlet of a yarn channel; the yarn inlet of the yarn conveying channel is communicated with a yarn leading channel of a yarn leading tube; and decorative yarns F2 are directly fed into the yarn inlet of the yarn channel without passing through a front jaw, and are wound on the surfaces of vortex core-spun yarns formed by F1 and short fiber rods S, so that the vortex composite structured yarns are formed. Due to the adoption of the method, short fibers produced in the conventional vortex spinning process can be prevented from being taken away by air flow, the fiber falling rate of short fibers is lowered, the yarn forming capacity during vortex composite spinning is improved greatly, end breakage of resultant yarns is eliminated, the requirements of vortex resultant yarns on a short fiber raw material are lowered, and the spinnable fiber raw material range of the vortex spinning is expanded greatly.

Owner:WUHAN TEXTILE UNIV +1

Beef processing equipment

The invention relates to the field of beef processing, in particular to beef processing equipment. The beef processing equipment comprises a workbench, a power mechanism and a processing mechanism. The processing mechanism comprises a connecting rod, a hammerhead, clamping jaws, hollow transverse rods and storage tubes. The connecting rod is connected to the power mechanism, one end of the connecting rod is abutted against a cam, and the other end of the connecting rod is hinged to the hammerhead. One end of each clamping jaw is hinged to the hammerhead, a hinge column is hinged to the middle of each clamping jaw, and the lower end of each clamping jaw is made of an elastic material and abutted against the workbench in movement. The transverse rods are provided with slide grooves, and the hinge columns are positioned in the slide grooves respectively. Each storage tube is arranged at one end, close to the hammerhead, of the corresponding transverse rod, and the other end of each transverse rod is connected to the workbench through a vertical rod. A retaining plate is slidably connected in a cavity of each transverse rod, one end of each retaining plate is connected to the corresponding hinge column, and the other end of each retaining plate extends into the corresponding storage tube. The beef processing equipment is provided for solving the problem of workload increase caused by moving of a hammer plate in application of existing processing equipment to meat paste processing.

Owner:重庆市长寿区舒福食品有限公司

Shaking type feed screening machine based on cylindrical cam driving

The invention relates to the technical field of feed screening equipment, in particular to a shaking type feed screening machine based on cylindrical cam driving. According to the shaking type feed screening machine, a first rotating shaft is driven through a servo motor to drive a cylindrical cam to rotate, a roller drives a bent rod to swing, a first rod moves, a second rod also swings, and dueto the fact that the hinged position of the left section of the second rod serves as a rotating point, the right end swings to have displacement in the left-right direction; a fourth rod is limited bya first sliding block and a first sliding rail, so that the fourth rod moves left and right under the action of a third clamping block and drives a filter assembly to shake left and right, a filter screen filters and screens feed falling into a filter basket, and the use effect of the filter screen is guaranteed; and a collision assembly is further arranged, when the filtering assembly moves rightwards, the filtering basket collides with small balls to generate vibration, and filtering of the filtering screen is accelerated.

Owner:淮安湘大骆驼饲料有限公司

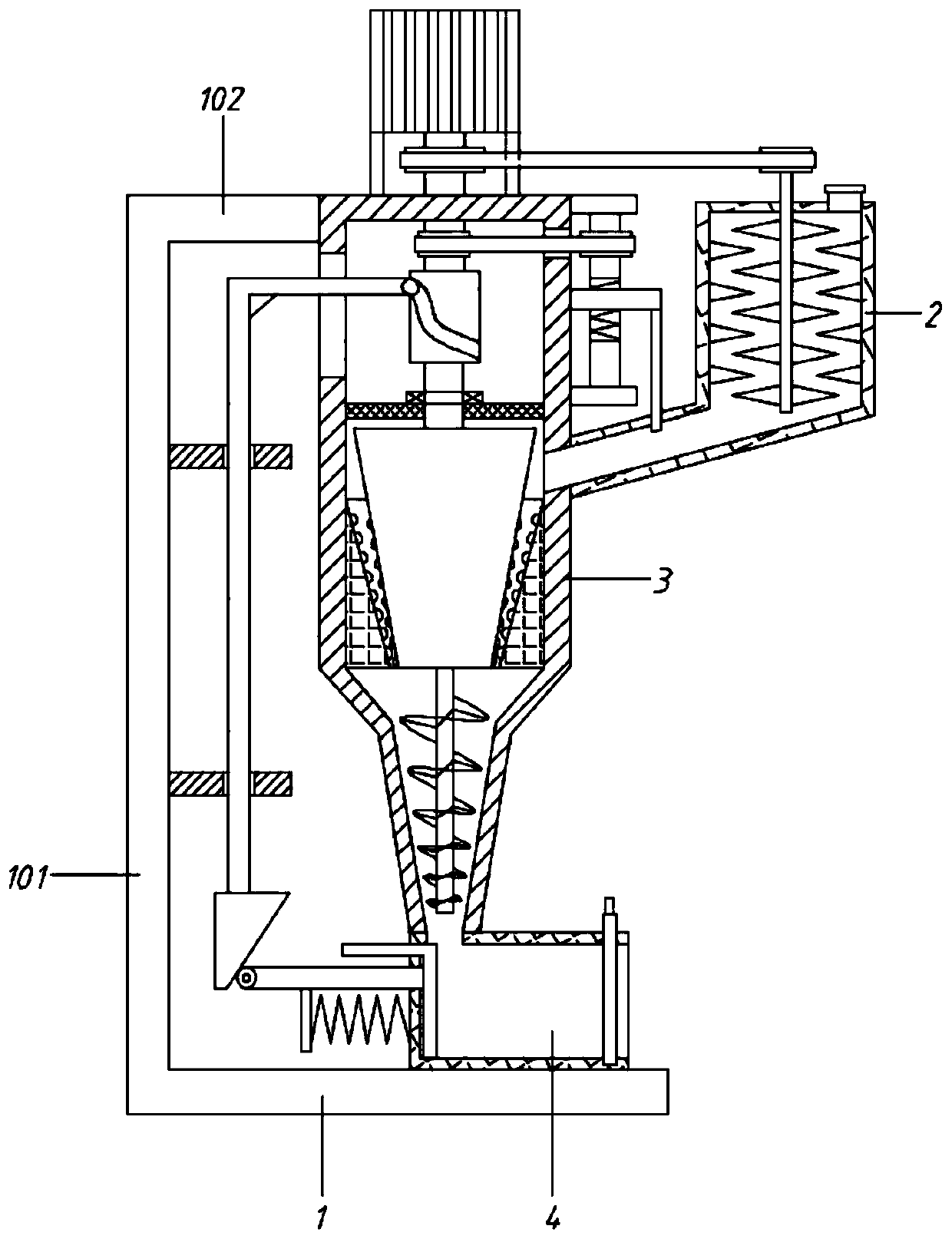

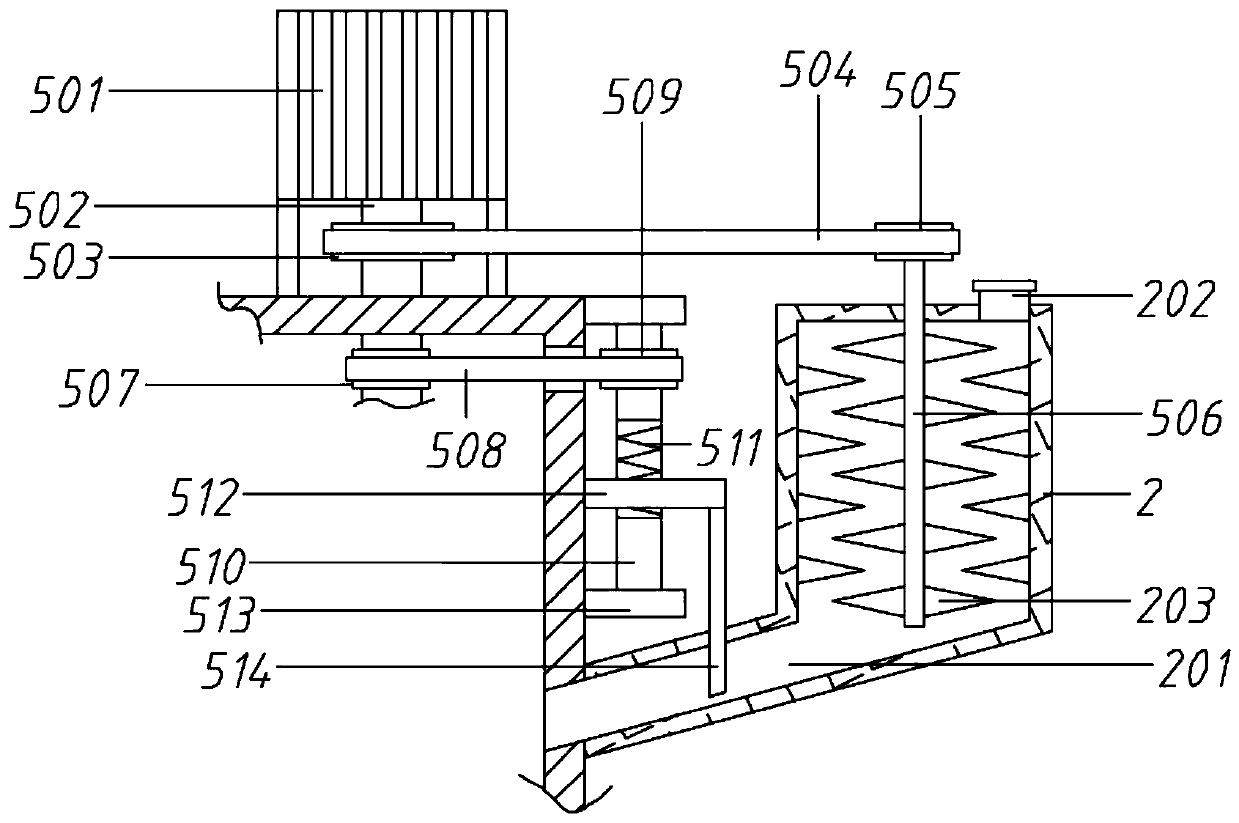

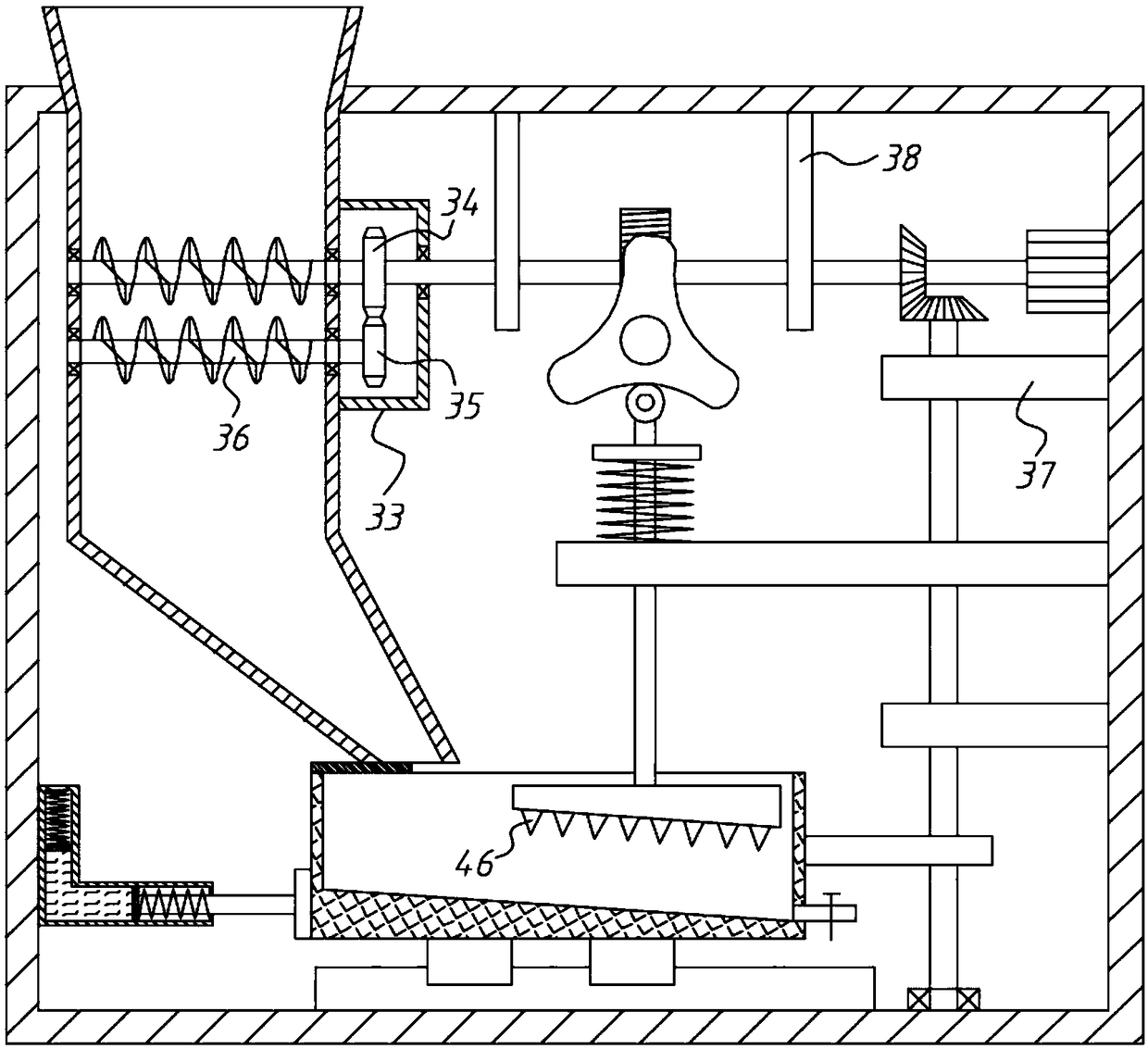

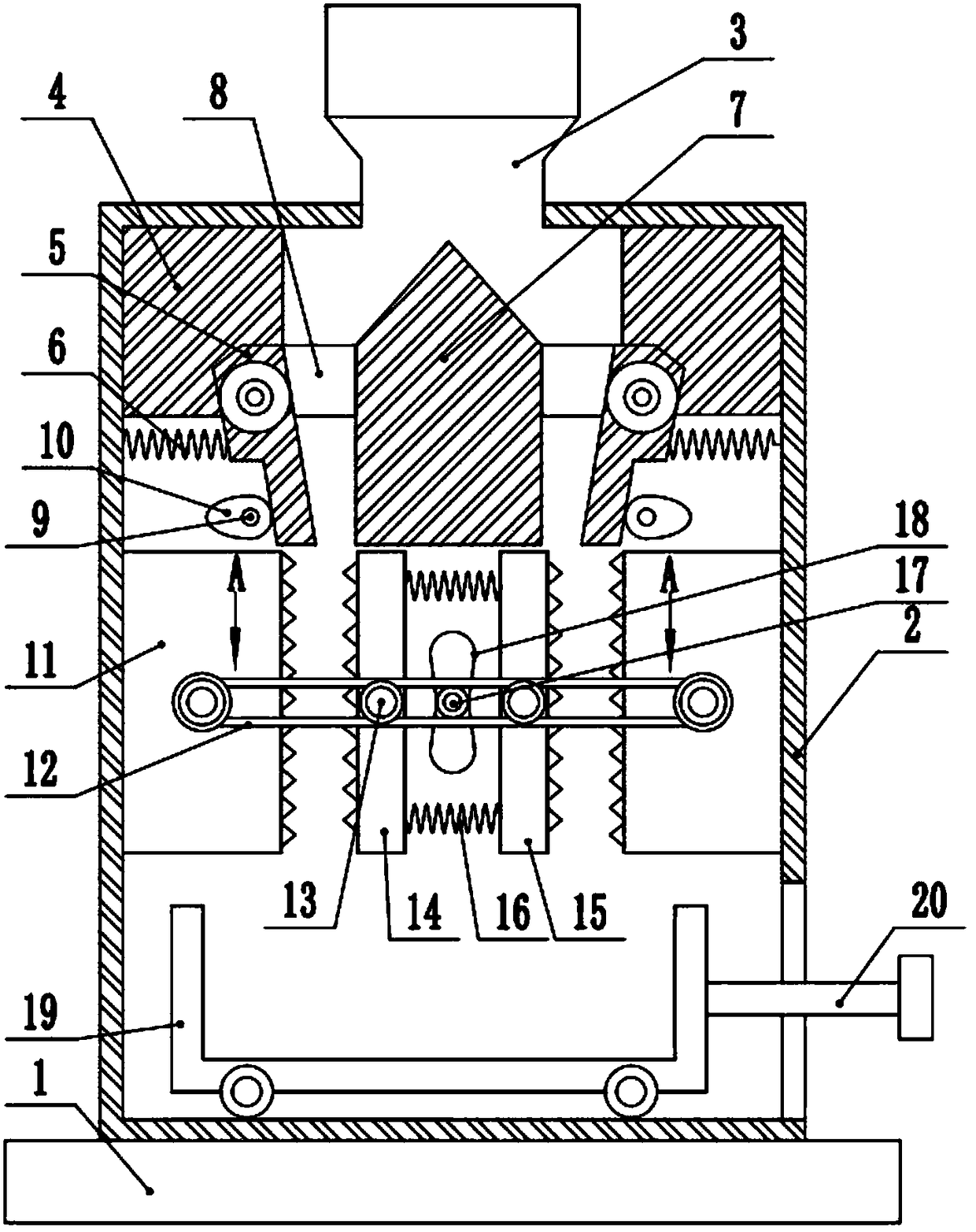

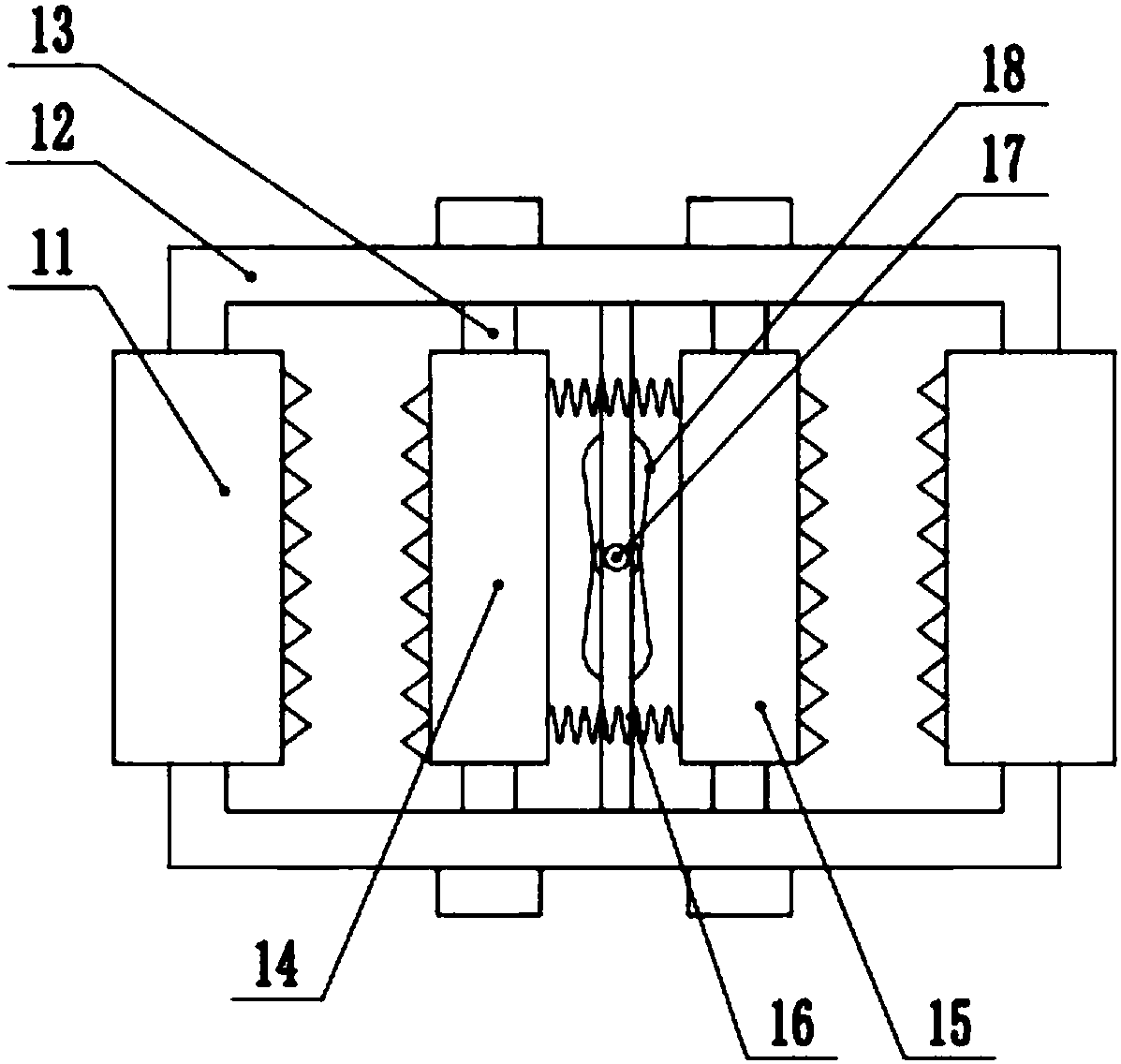

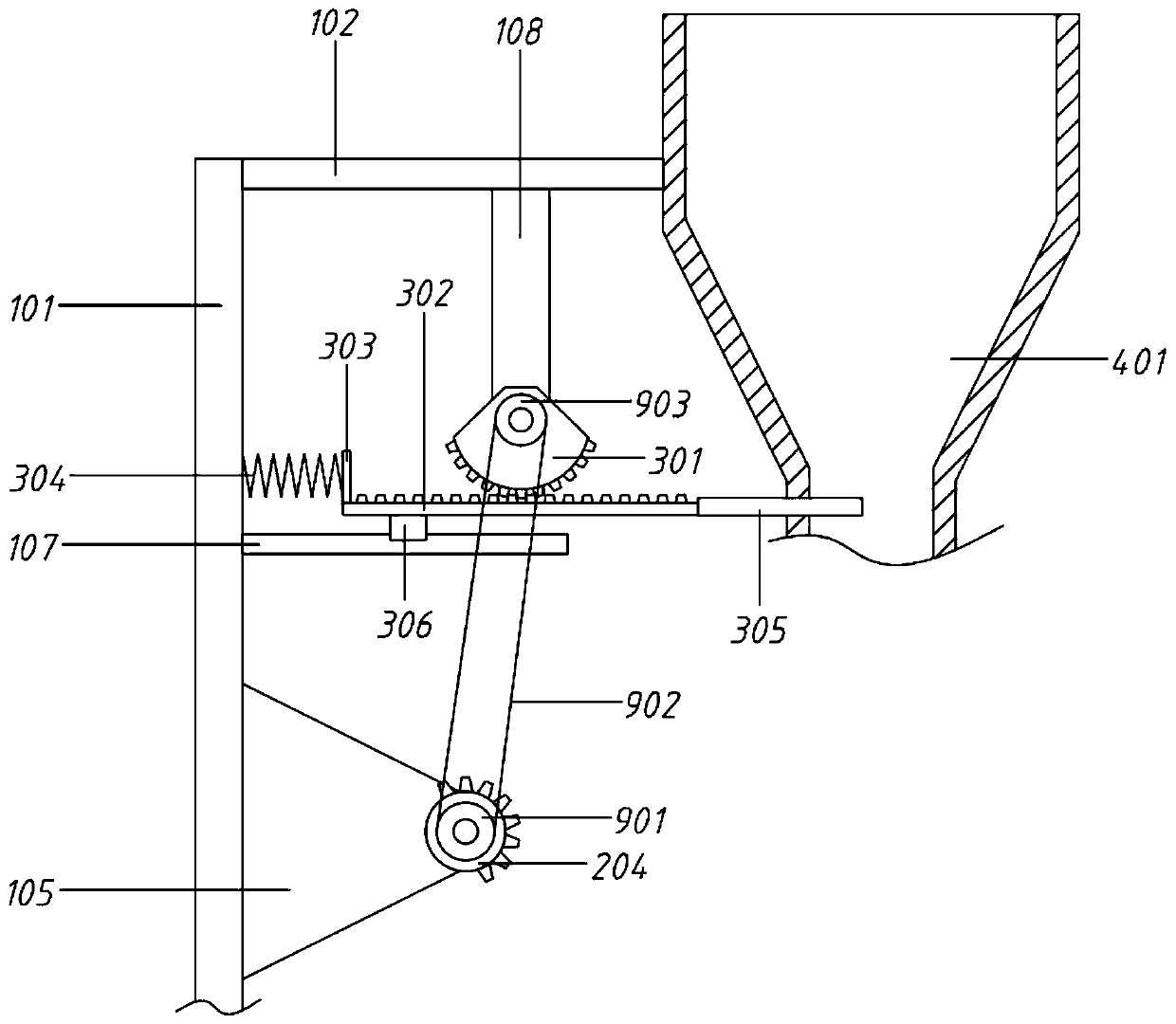

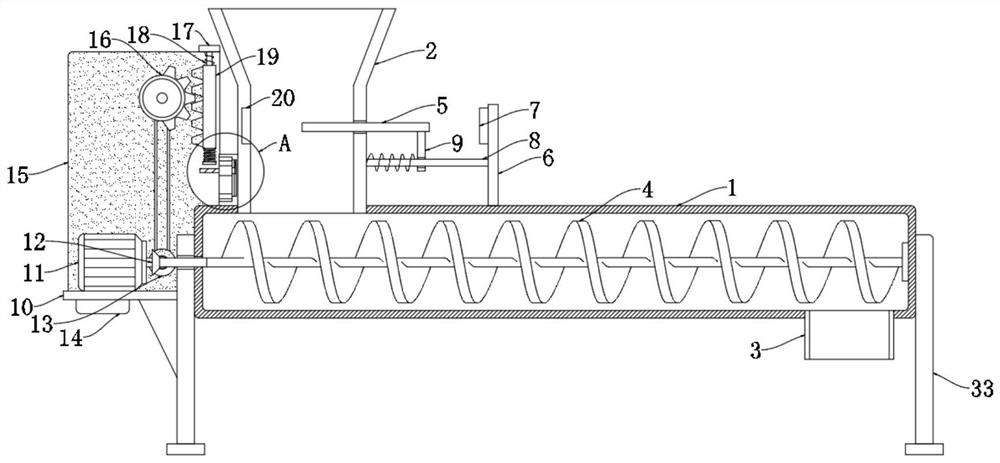

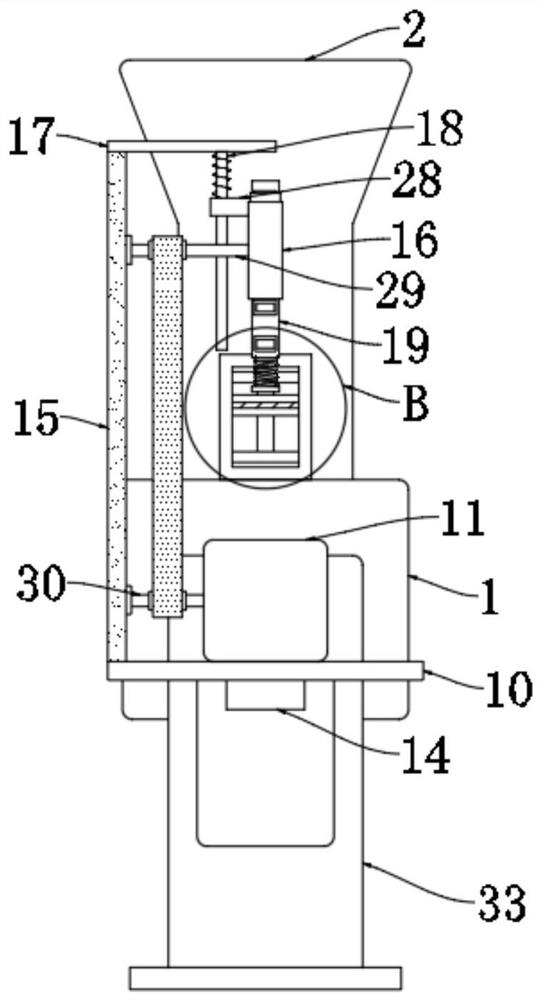

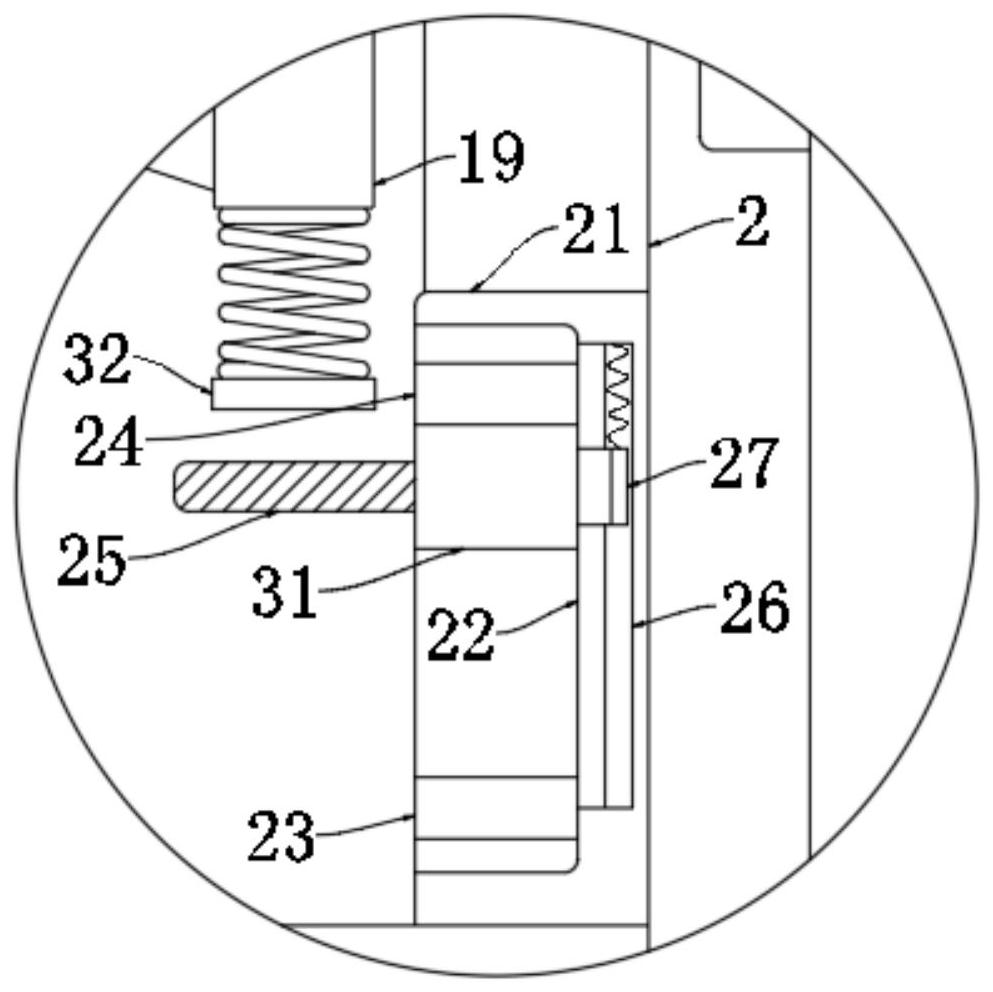

Cam-driven type intermittent feeding fodder smashing device

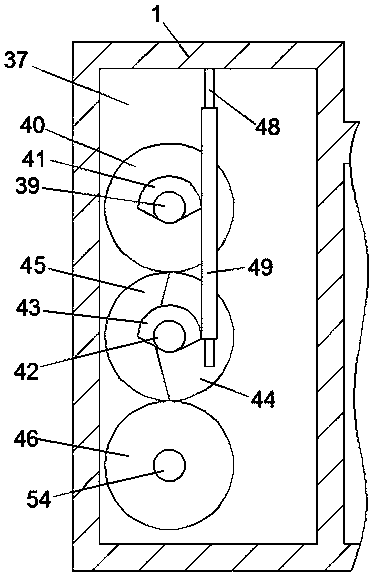

InactiveCN108160156ACrushed fullyRealize the effect of continuous extrusion and crushingFeeding-stuffGrain treatmentsInterference fitDrive motor

A cam-driven type intermittent feeding fodder smashing device comprises a base, a smashing tank, a rotating baffle, a first drive motor, a first cam, fixed smashing plates, a left smashing plate and aright smashing plate; the smashing tank is arranged on the base; the rotating baffle is rotationally installed on a fixed baffle through a rotating shaft; the fixed smashing plates are fixedly installed on the inner walls of the left side and the right side in the smashing tank through screws; and the left smashing plate and the right smashing plate are installed on a sliding shaft in an interference fit mode. The cam-driven type intermittent feeding fodder smashing device can achieve intermittent feeding, at the same time, the left smashing plate and the right smashing plate move towards thefixed smashing plates intermittently, accordingly continuous squeezing and smashing effects are achieved, discharging and smashing are conducted at the same time, and the situation that fodder is notsufficiently smashed as being discharged too much at a time is effectively avoided; and meanwhile, continuous pressing and squeezing can greatly improve the fodder smashing effect, the fodder can besmashed more sufficiently, and compared with manual grinding, more time and labor are saved, the structure is simple, and practicability is high.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

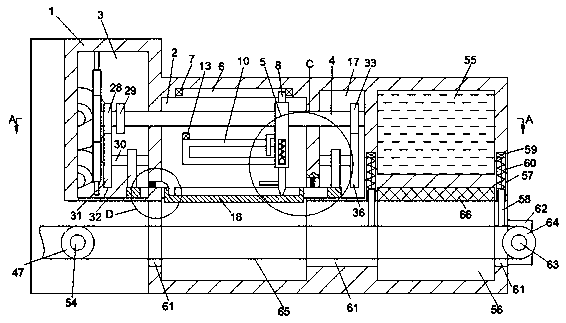

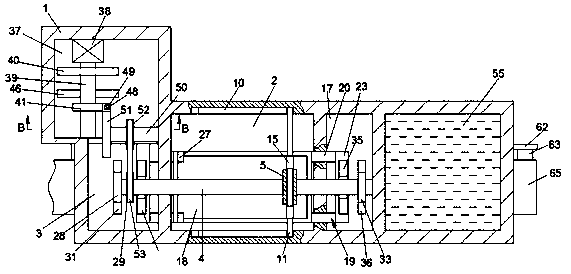

Lock beam molding cutting device

The invention provides a lock beam molding cutting device and belongs to the technical field of mechanical machining equipment. The lock beam molding cutting device comprises a power transmission mechanism, a feeding mechanism, a clamping mechanism and a cutting mechanism; the power transmission mechanism comprises a motor, a belt wheel I, a belt, a belt wheel II, a shaft, a worm and a turbine; the feeding mechanism comprises a crankshaft, a slider, a connection rod I, a connection rod II and a feeder; one end of the crankshaft is hinged to the slider; the clamping mechanism comprises a cam I, a push rod I, a swing rod I, a conical bush and a clamping pawl; the axes of the conical cam, the feeder and the clamping pawl are positioned in the same horizontal line; the conical cam is arranged right ahead of the feeder; the clamping pawl is arranged in the right front of the feeder; the other end of the crankshaft is fixed at the central position of the turbine. The centers of the cam I, the cam II and the turbine are coincided. The automatic feeding, clamping and cutting in the cutting process of a lock beam are realized, the structure is simple and the efficiency is high.

Owner:TONGXIANG XILIANG TIN CANS

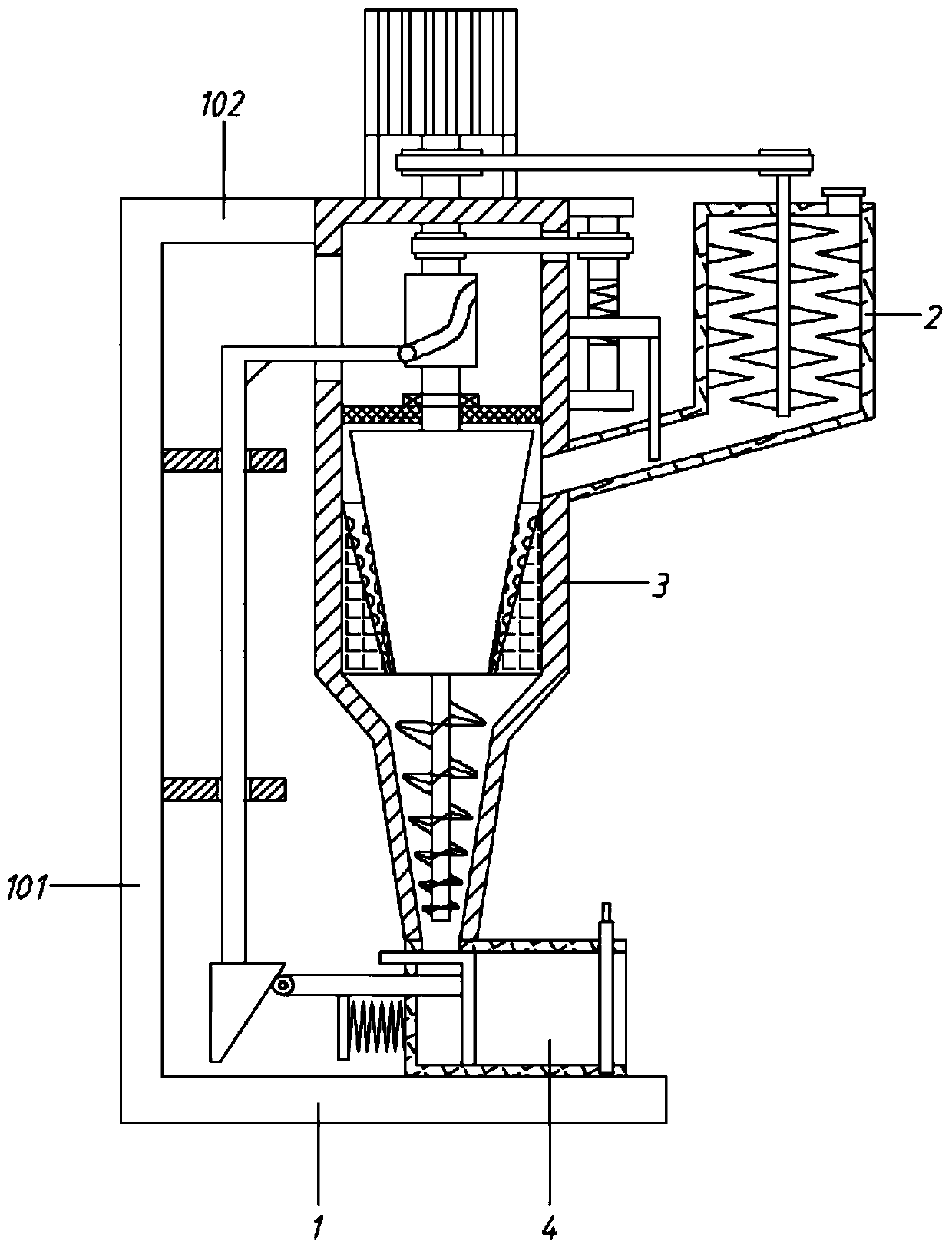

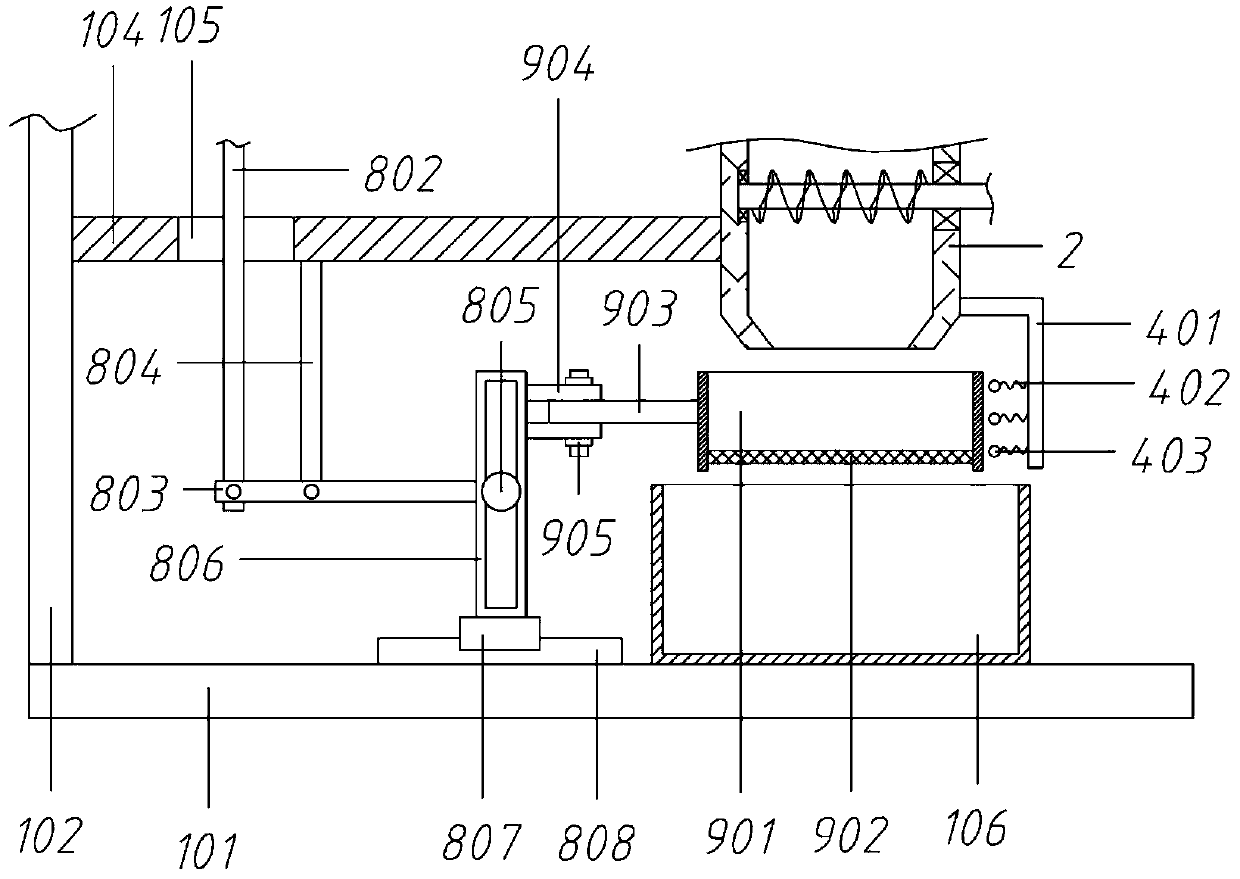

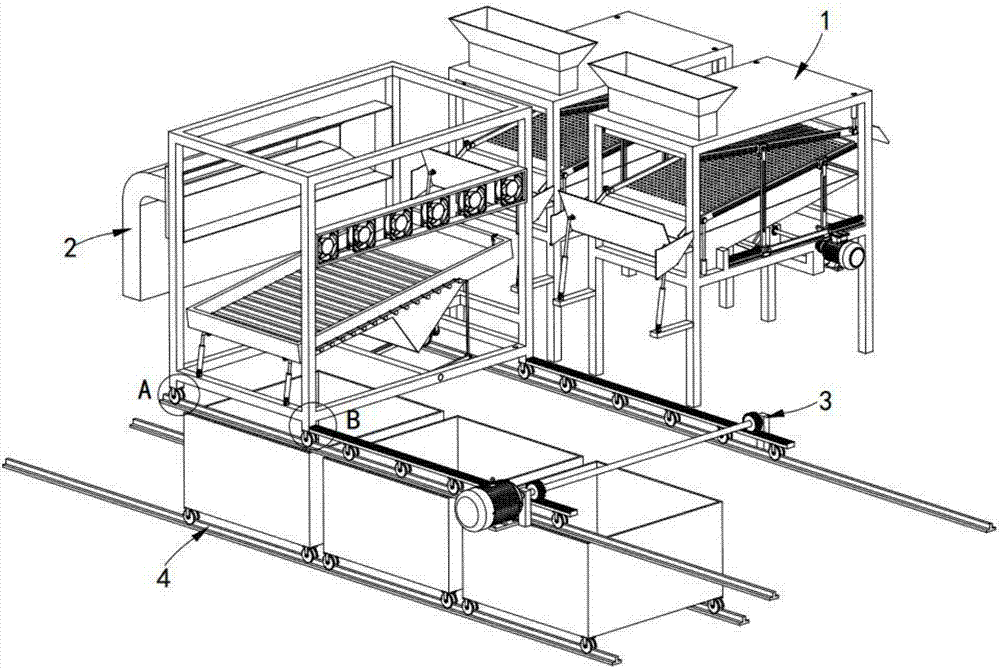

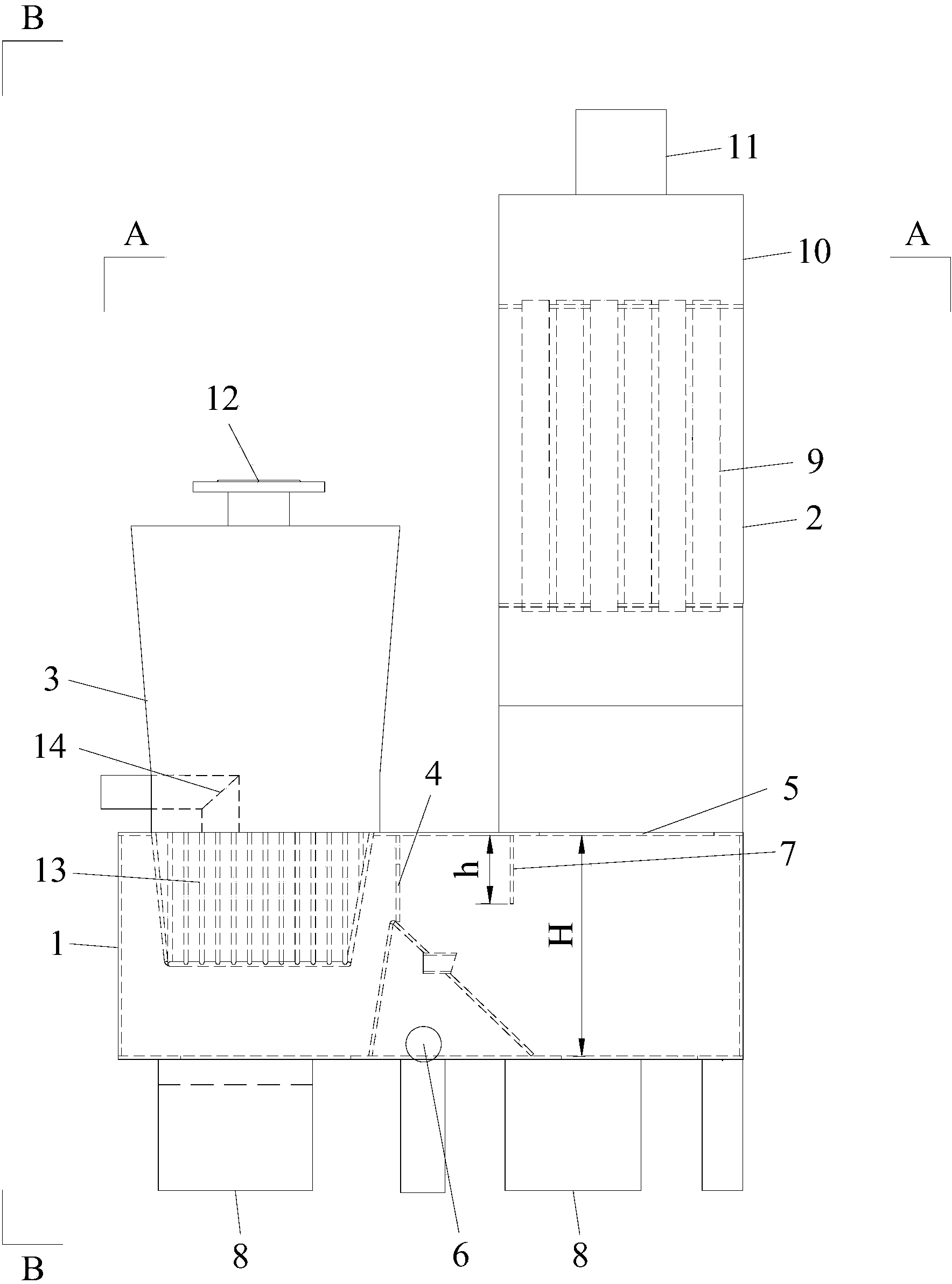

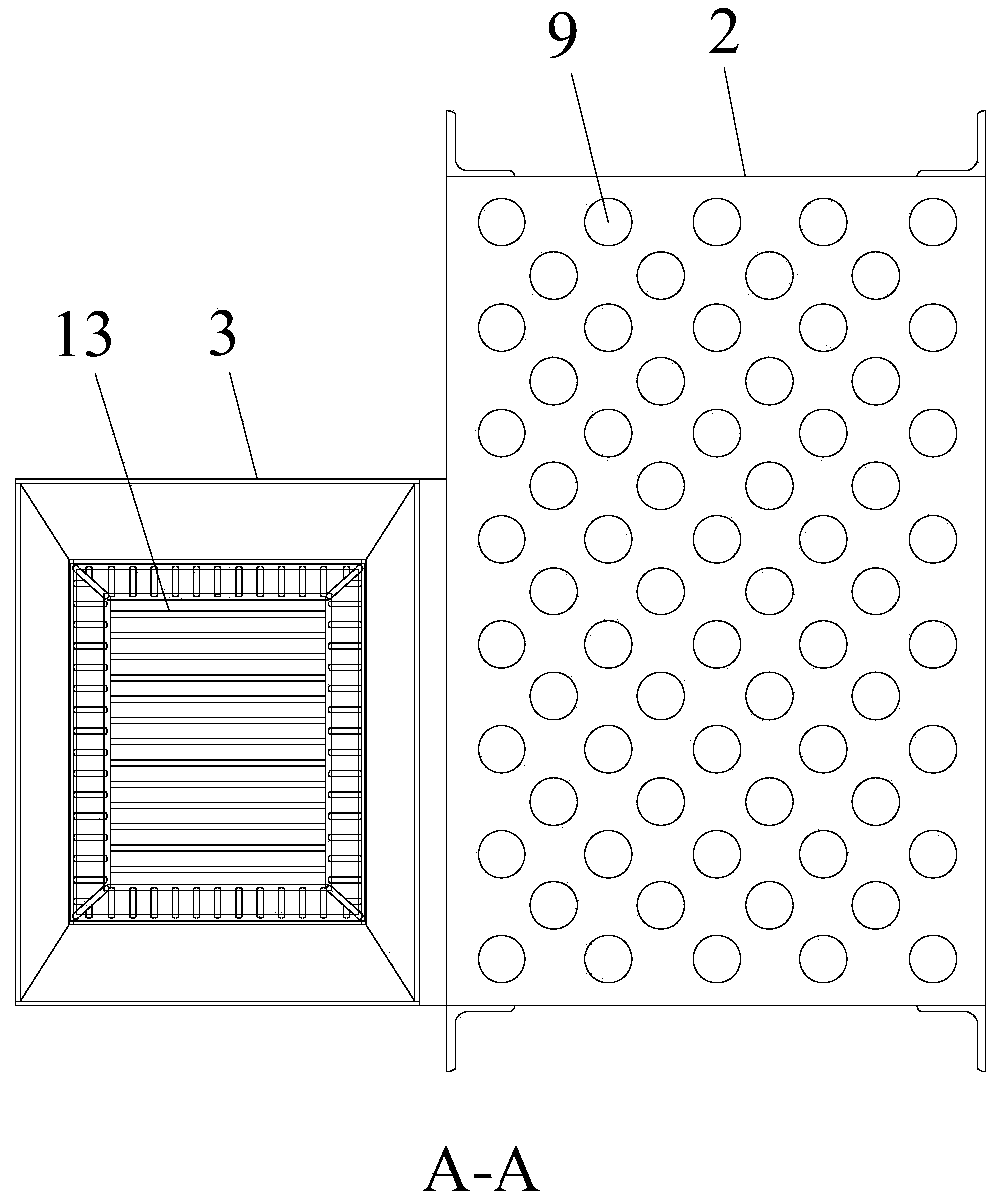

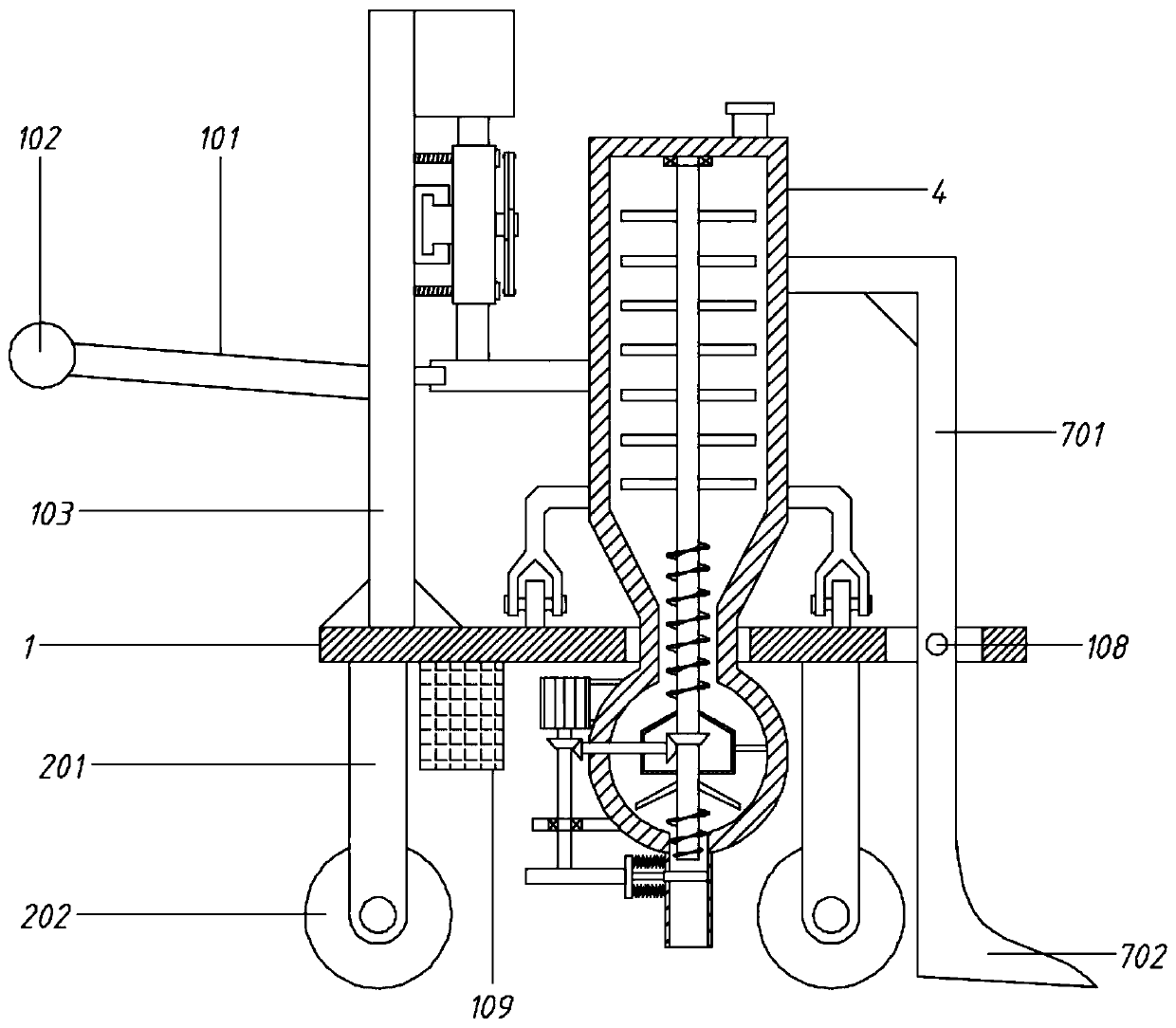

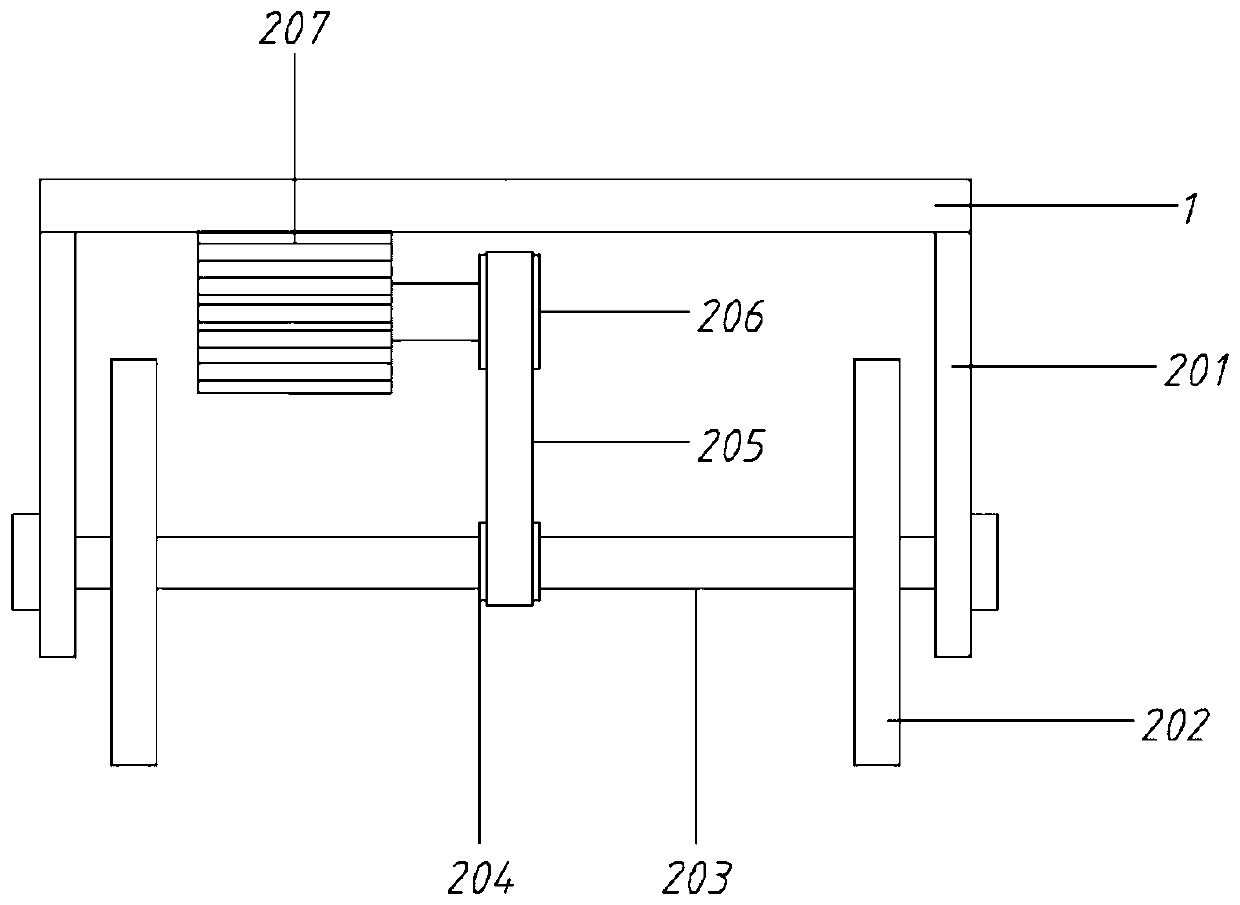

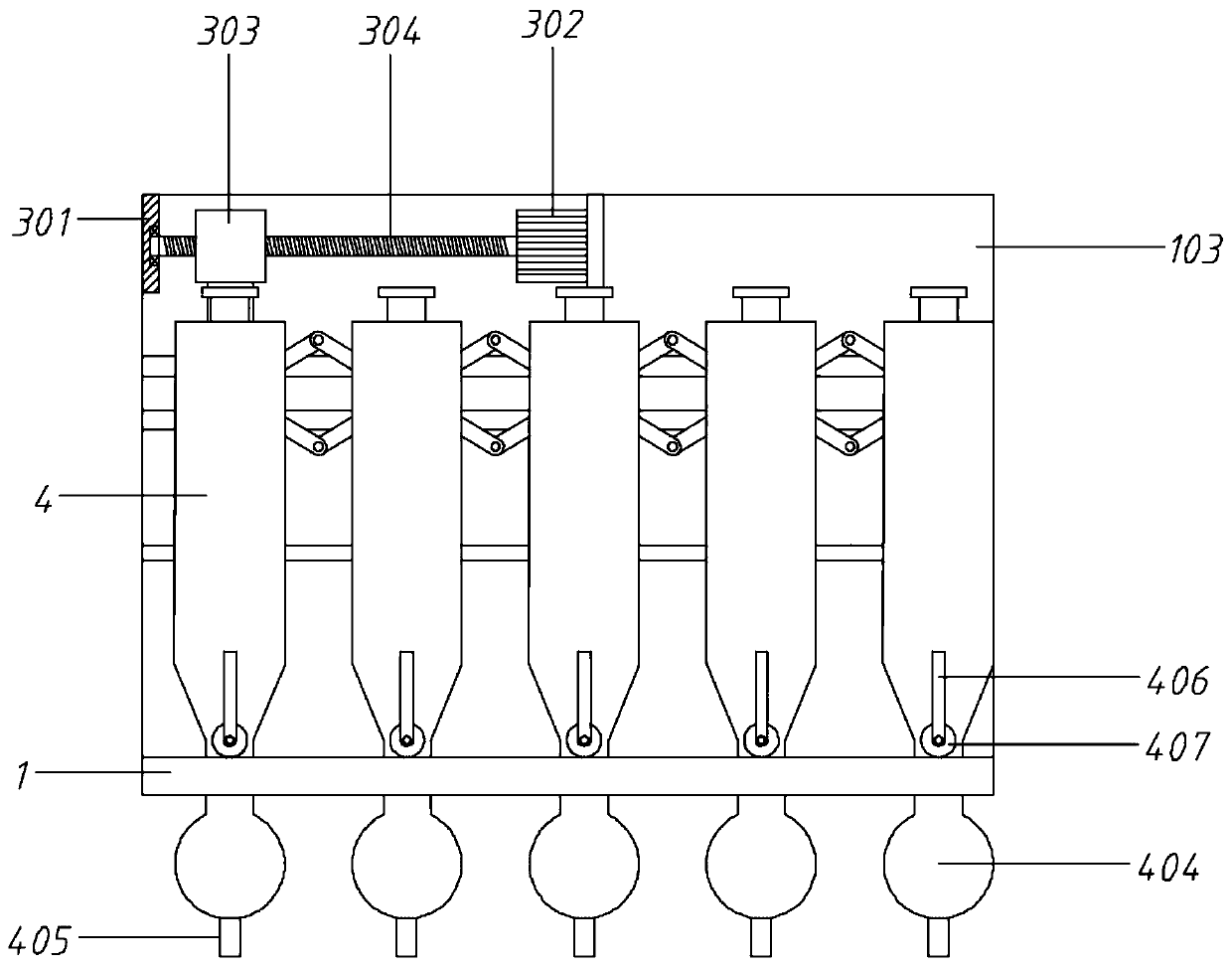

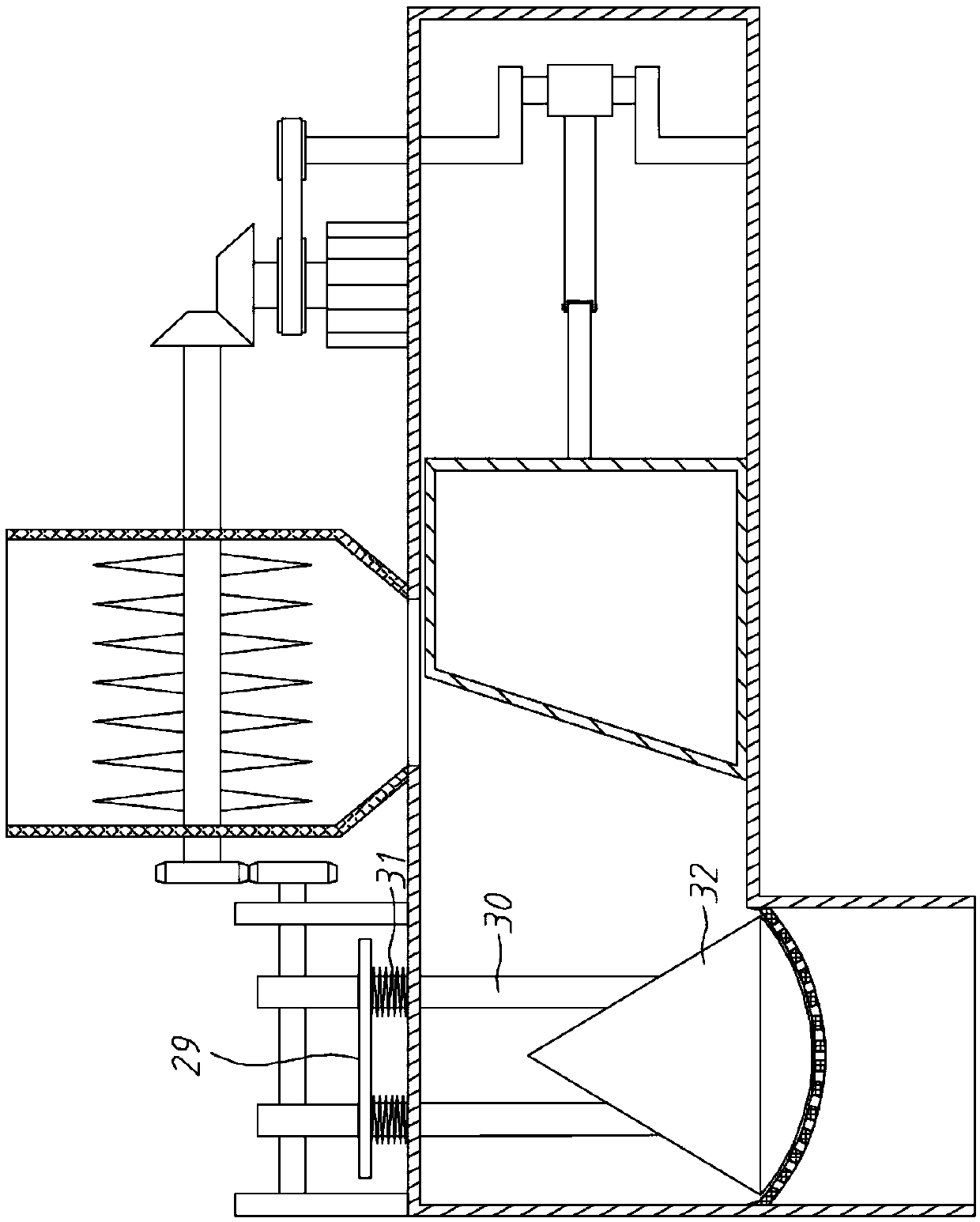

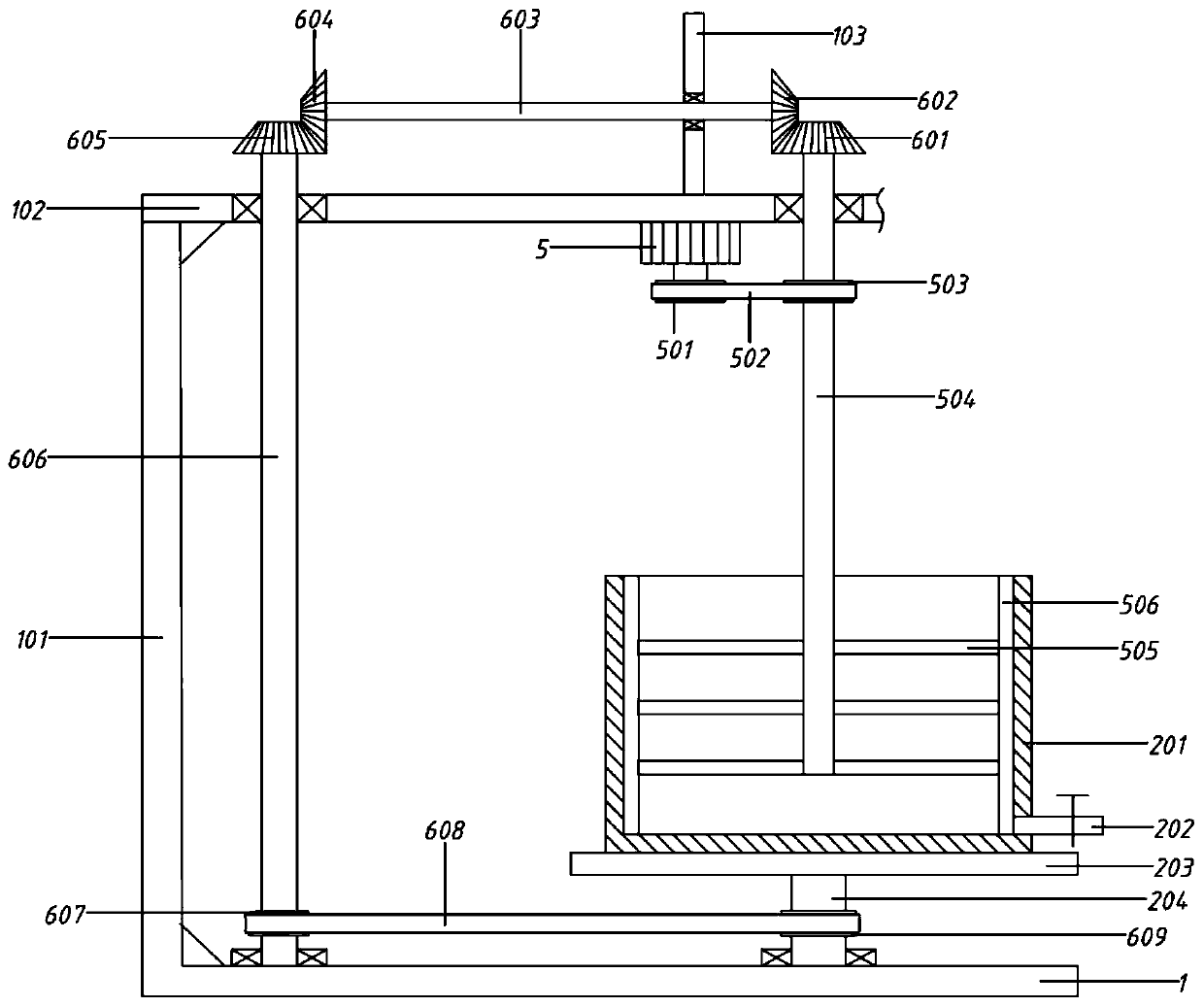

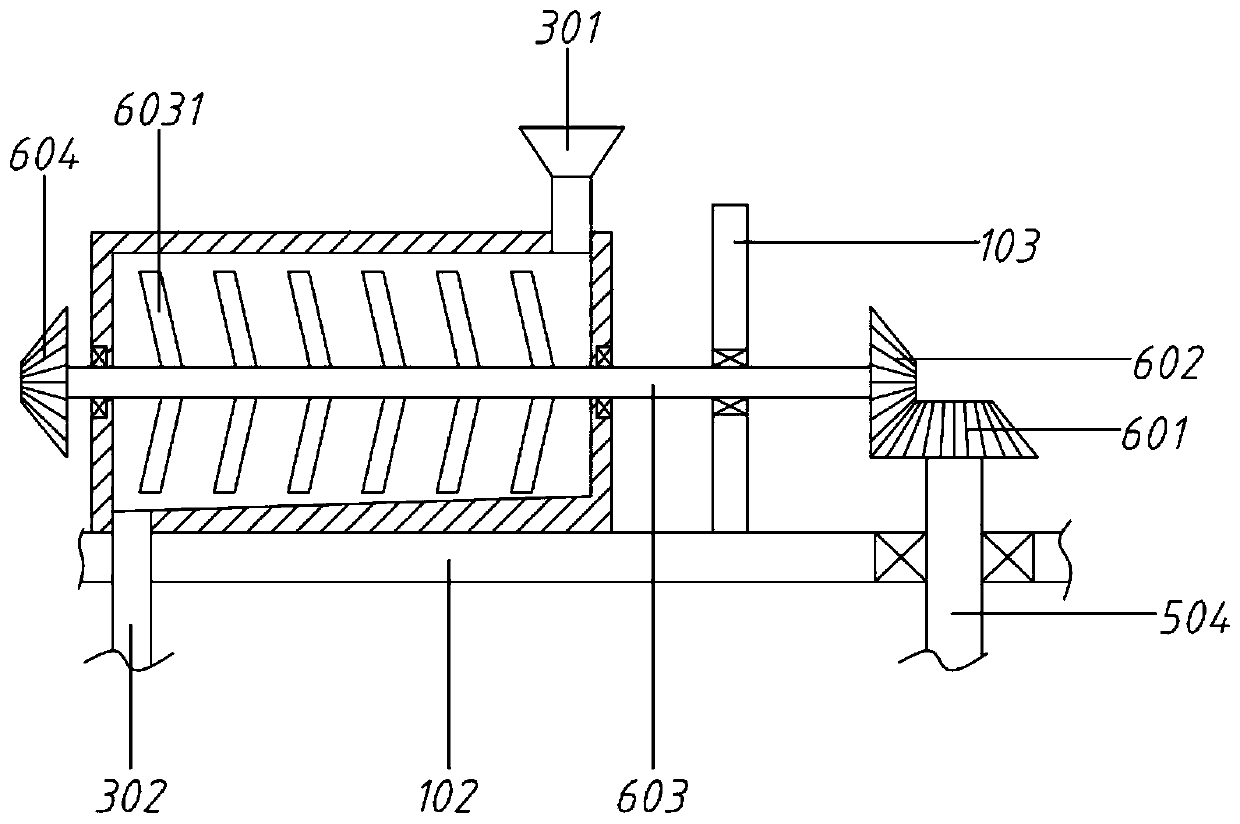

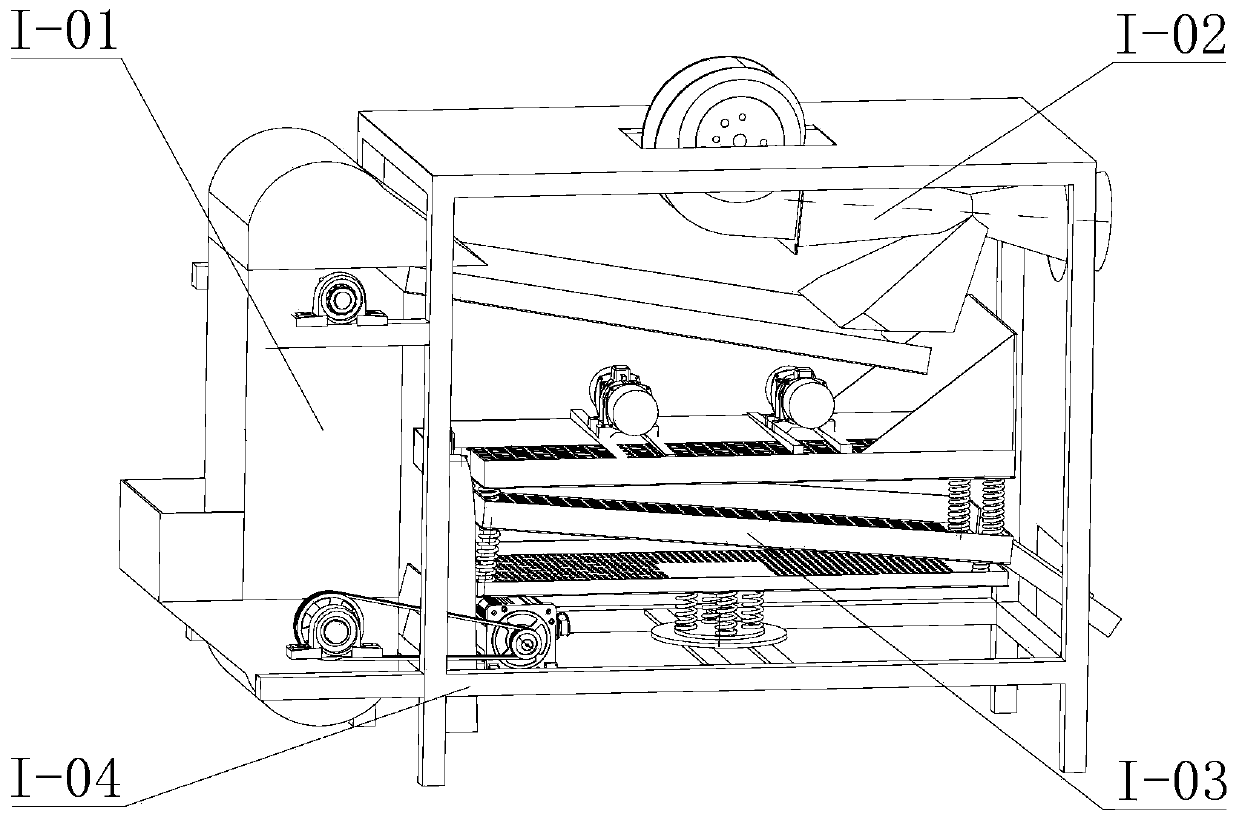

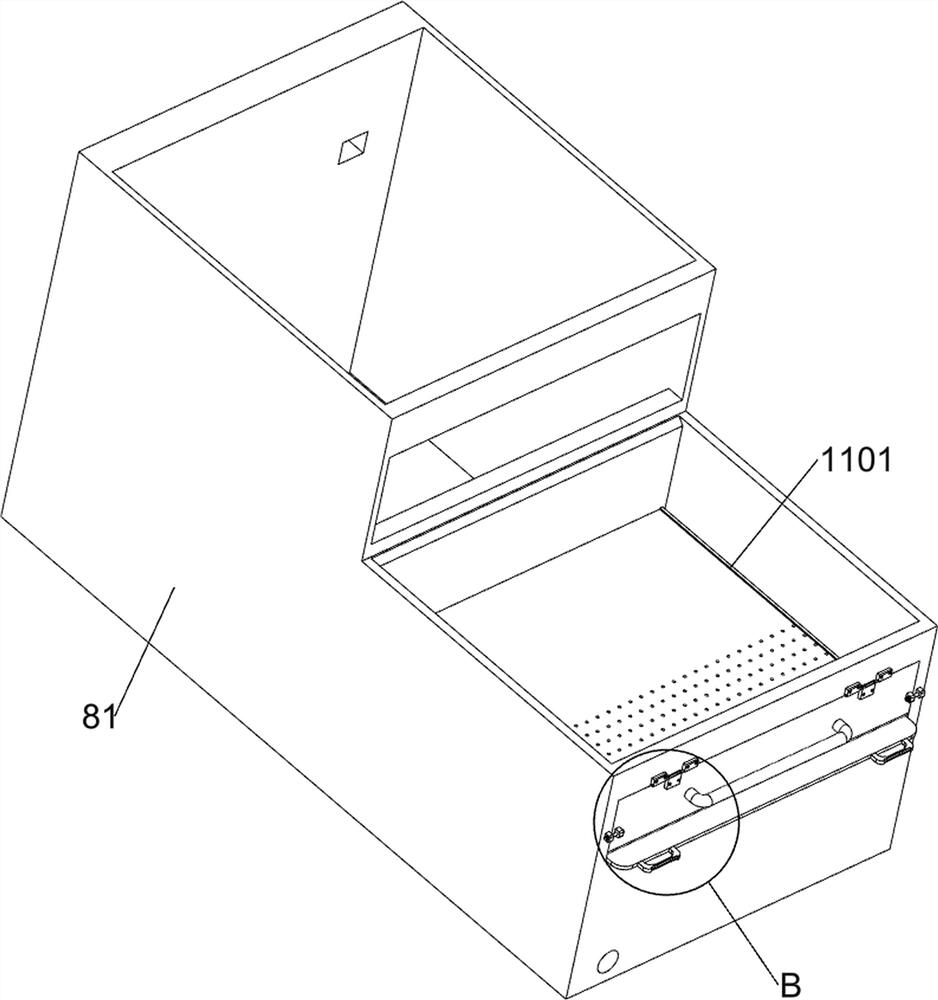

Switchable combination working line for grain screening and impurity removing

InactiveCN106903050ARealize automatic outputImprove work efficiencySievingGas current separationButt jointAgricultural engineering

The invention discloses a switchable combined working line for grain screening and impurity removal, which includes a symmetrically arranged resonance screening mechanism, a grain hulling mechanism, a switching mechanism and a storage mechanism. Docking with multiple resonance screening mechanisms, when the grain husking mechanism completes the removal of light impurities such as grain husks and shriveled grains from the output of the previous resonance screening mechanism, the grain husking mechanism can move laterally to the next resonance screening mechanism The rear side removes light impurities from the output grain, which doubles the work efficiency. At the same time, the grain hulling mechanism cooperates with the storage mechanism to realize the automatic output of the grain into the grain box, and when the grain box is full , can quickly switch grain boxes, high degree of automation.

Owner:奥林精密机械科技(长兴)有限公司

Siro-segment color yarn production device and production method

ActiveCN105483891ARealize intermittent feedingDrafting machinesYarnProgrammable logic controllerYarn

The invention provides a siro-segment color yarn production device and production method. A cotton-feeding roller is mounted at the rear portion of a rear roller and includes a roller shaft. A roller bushing is connected onto the roller shaft through bearings. One bearing is controlled to be in the on or the off state through an electromagnetic switch. A sleeve is fixedly connected to the outside of the roller bushing. The lengths of the roller shaft, the roller bushing and the sleeve decrease in order. The distances between the roller bushing and both ends of the roller shaft are equal. The distances between the sleeve and the both ends of the roller bushing are equal. The roller shaft, the rear roller, and a middle roller are respectively driven by a first server motor, a second server motor and a third server motor. The electromagnetic switch and the three server motors are connected through a programmable logic controller. During spinning, a first rove and a second rove are fed through the roller shaft at both ends of the roller bushing, a third rove and a fourth rove are fed through the roller bushing at both ends of the sleeve, and the corresponding server motors control the roller rotating speed to realize the siro spinning type interrupted feeding of the four roves.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

Notched steel plate punching equipment for buildings

InactiveCN112246939AAchieve the effect of automatic feedingRealize intermittent feedingMetal-working feeding devicesPositioning devicesPunchingArchitectural engineering

The invention relates to punching equipment, in particular to notched steel plate punching equipment for buildings. The notched steel plate punching equipment can push out a steel plate clamped on a punching block, can automatically feed the steel plate, and comprises a bottom plate, an air cylinder and the punching block, wherein the middle of the bottom plate is fixedly connected with an L-shaped rod; the air cylinder is installed on the L-shaped rod; and the punching block is connected to a piston rod of the air cylinder. According to the notched steel plate punching equipment, the effect that the steel plate clamped on the punching block can be pushed out and can be automatically fed is achieved, when the punching block moves downwards, a first rack and a feeding propelling plate can be driven to move leftwards through a series of transmissions, the lowermost steel plate can be pushed to the position below the punching block through leftward movement of the feeding propelling plate, then the feeding propelling plate is reset, and in this way, intermittent discharging is achieved.

Owner:李冰娜

Feed high-efficiency granulating device

InactiveCN107930535AAchieve recyclingIncrease productivityFeeding-stuffRotary stirring mixersDrive shaftTransmission belt

The invention discloses a feed high-efficiency granulating device. The feed high-efficiency granulating device is characterized in that a driving shaft is rotationally connected with the upper end ofa device body by a bearing; the upper part of the driving shaft is connected with the right side of a transmission belt in a rolling way; the left side of the transmission belt is connected with the upper end of a driven shaft in a rolling way; the upper part of the left end of the device body is provided with a material storage chamber; the driven shaft is rotationally connected with the materialstorage chamber by a bearing; the upper part of the driven shaft is fixedly connected with a stirring rod; a rotary disc is arranged at the upper end of a separating plate; the rotary disc is fixedlyconnected with the driven shaft; through holes are formed in the periphery of the rotary disc. The feed high-efficiency granulating device has the advantages that an air suction fan is rotated to suck the dust produced in the grinding and pressing process of a grinding and pressing cylinder, and the dust is discharged via an air exhaust port and is collected, so that the raw material can be recycled, thereby avoiding the waste; the feed raw material on a perforated plate is ground, pressed and granulated by the grinding and pressing cylinder which moves left and right and rotates, so that theproduction efficiency is high; the rotary driven shaft is used for driving the rotary disc to rotate, and then through holes in the rotary disc are communicated with a guide pipe on the separating plate in a reciprocating way, so that the intermittent material discharging effect is realized; the structural design is reasonable and suitable, the production efficiency of the feed is greatly improved, and the feed dust can be recycled.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

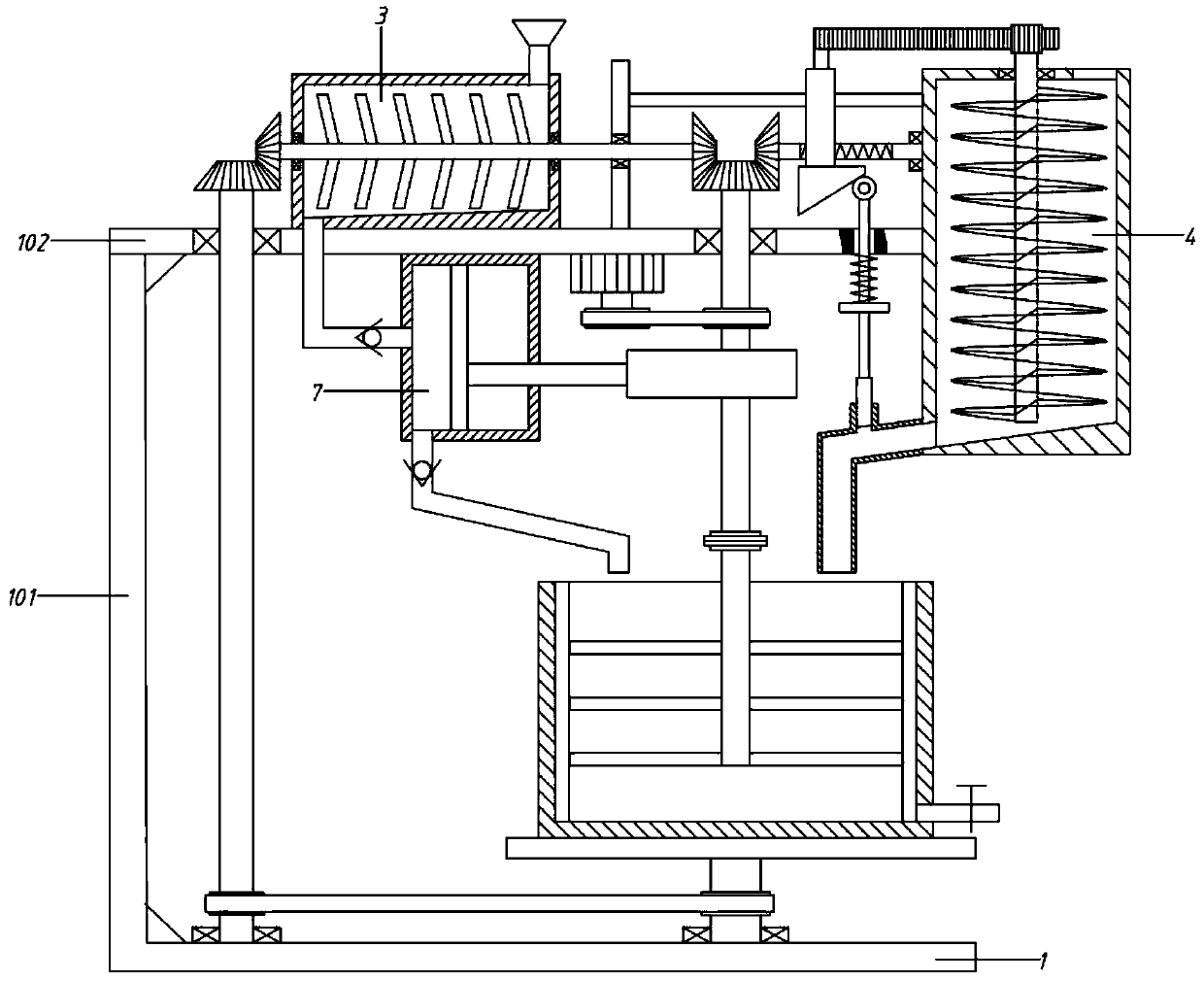

Environment-friendly gasification counter-flow combustion hot-blast stove

The invention discloses an environment-friendly gasification counter-flow combustion hot-blast stove. The environment-friendly gasification counter-flow combustion hot-blast stove comprises a combustion chamber, a heat exchange chamber and a gasification chamber for gasification and combustion of fuel. The combustion chamber is horizontally arranged, and both the gasification chamber and the heat exchange chamber are vertically arranged above the combustion chamber to form a gasification section type combustion U-shaped stove structure. The bottom of the gasification chamber and the bottom of the heat exchange chamber are connected with the combustion chamber through a first channel and a second channel respectively. The position, close to the first channel, of the inner side of a top plate of the combustion chamber stretches downwards to form a turbulent flow baffle. Positions, corresponding to the gasification chamber and the heat exchange chamber, of the bottom of the combustion chamber are respectively provided with a slag pit. The environment-friendly gasification counter-flow combustion hot-blast stove is simple in structure, convenient and quick to operate, high in combustion efficiency and small in environment pollution, and investment cost and operation cost are reduced.

Owner:GUANGDONG EMICRONET NEW ENERGY TECH

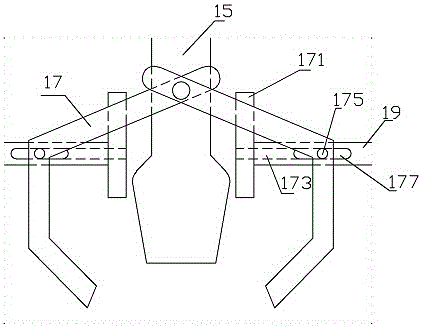

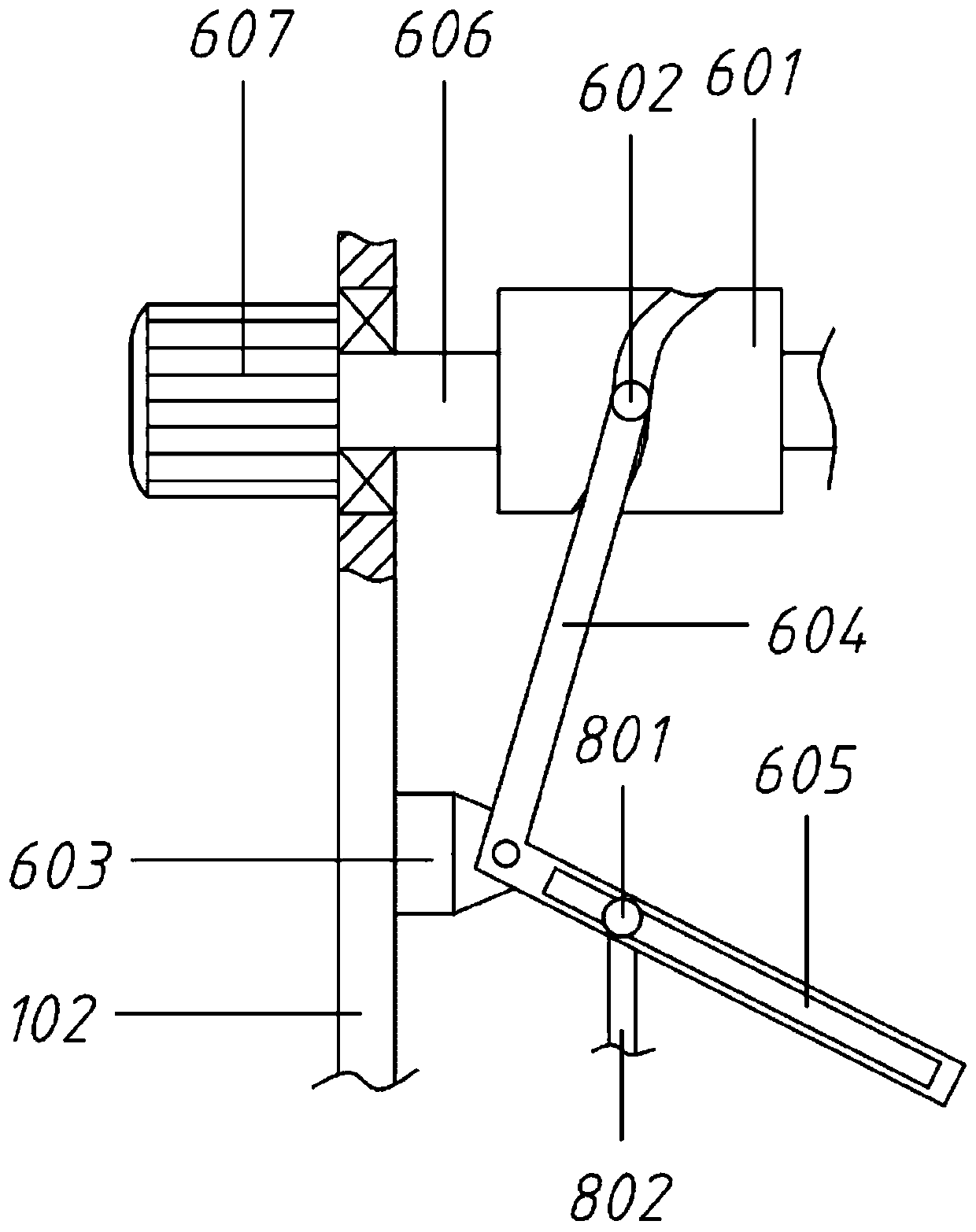

Agricultural sowing machine capable of adjusting sowing spacing

ActiveCN110959343AAdjust seeding spacingRealize synchronous isometric adjustmentSeed depositing seeder partsRegular seed deposition machinesSeederAgricultural engineering

The invention relates to the technical field of agricultural sowing equipment and particularly relates to an agricultural sowing machine capable of adjusting sowing spacing. A lead screw unit is employed as moving power, a lead screw rotates, and a traveling block moves along an axial direction of the lead screw, so that sliding bases are driven to move through one kind of links and are matched with a telescopic link group, and synchronous equidistant adjusting of the sliding bases is achieved; the sliding bases are connected with seed bins, the seed bins also move in a follow-up manner, and thus, adjustment on sowing spacing is achieved; multiple furrowing components are arranged and are connected with the seed bins in one-to-one correspondence, the seed bins move, and adjusting levers can move along a back and forth direction, so that furrowers can always correspond to a blanking pipe; and a relay bin is also provided with a movable plate for closing, a servomotor III is controlled to drive a cam to act on a pressing plate, the pressing plate also undergoes a spring action, so that the movable plate is driven to move left and right through a push-pull rod to close or open the blanking pipes, and thus, intermittent blanking is achieved.

Owner:苏州创小二智能科技有限公司

Automatic high-efficiency pounding machine for Chinese herbal medicine processing

The invention relates to the technical field of Chinese herbal medicine processing, in particular to an automatic high-efficiency pounding machine for Chinese herbal medicine processing. The automatichigh-efficiency pounding machine is driven through a single motor. On the one hand, the automatic high-efficiency pounding machine conducts driving through a driving wheel and a driving belt to drivea driven shaft I to rotate and drive a movable block to move left and right along a main cavity to implement intermittent discharging of Chinese herbal medicine; on another hand, the automatic high-efficiency pounding machine conducts driving through a bevel gear to drive a driven shaft II to rotate, and then smashing cutters conduct primary smashing on a Chinese herbal medicine material; additionally, the driven shaft II is driven through gears to drive a driven shaft III to rotate to drive a cam I to operate, the cam I acts on a pressing plate, and the pressing plate pulls a pounding head to move up and down through vertical connecting rods to pound Chinese herbal medicine falling onto a partition board; and moreover, the driven shaft III drives a rotary shaft IV to rotate through driving of the bevel gear and then drive a cam II to rotate and operate, and a filter screen moves left and right to conduct screening and filtering on Chinese herbal medicine particles on the filter screen.

Owner:安徽海神寿春药业有限公司

Double-side-rack type concrete mixing equipment

InactiveCN108214910AReduce stirring efficiencyStir wellCement mixing apparatusArchitectural engineering

Owner:南宁腾宁商品混凝土有限公司

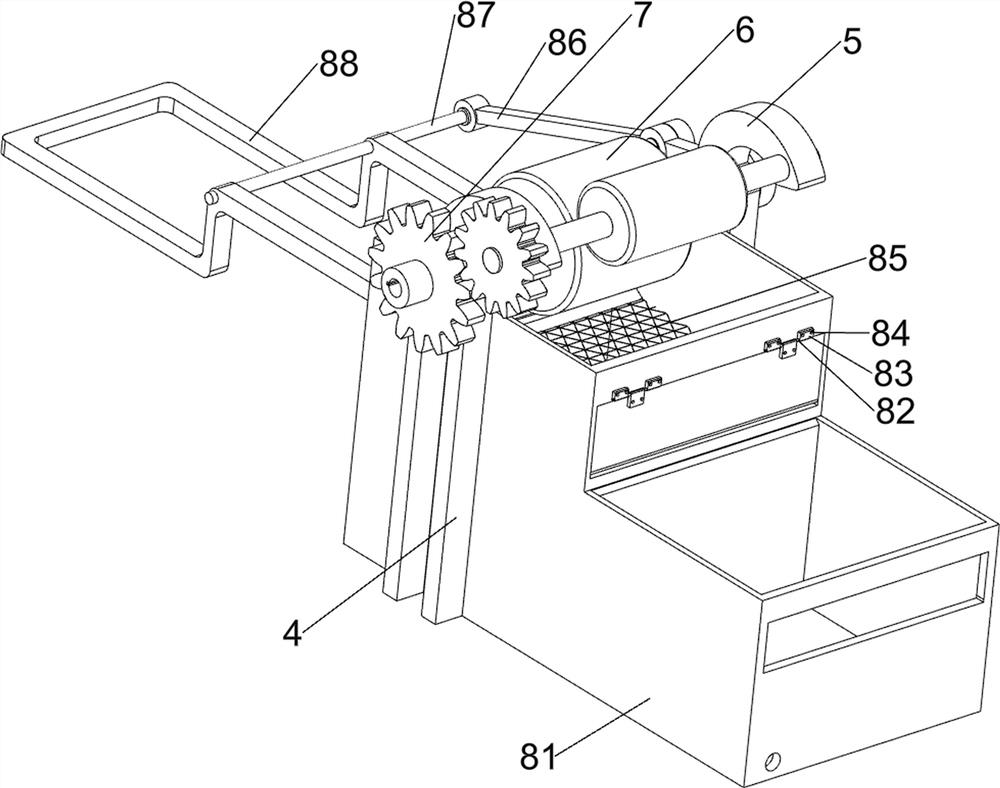

Automated forage cutting equipment used for breeding industry

The invention relates to the technical field of automated forage cutting equipment, in particular to automated forage cutting equipment used for breeding industry. An incomplete gear is employed to act on a rectangular framework of which the left inner side and the right inner side are each provided with teeth, and the incomplete gear rotates under the drive of a serve motor to drive the rectangular framework to move vertically, and thereby, protrusions act on a forage cutting mechanism to make the forage cutting mechanism move horizontally to automatically cut forage falling into a discharging pipe from a feed hopper, which is convenient and fast; still vertical movement of the rectangular framework is utilized to drive a second rack to move vertically, and the second rack acts on a second gear, and thereby, a second rotating shaft is driven to rotate to make a stirring rod stir the bottom end of the discharging pipe to avoid blockage; and while driving the incomplete gear, the servomotor further drives a sector gear through drive to rotate, and the sector gear cooperates with a first rack and a second spring to drive a movable plate to move horizontally, and thereby, an inlet ofthe discharging pipe is opened or sealed to realize intermittent discharging.

Owner:芜湖市千官康养农业科技有限责任公司

Feed trough for raising cattle

InactiveCN107484674APrevent diseaseRealize intermittent feedingAnimal feeding devicesEngineeringFodder

The invention belongs to the technical field of equipment for raising livestock and discloses a feed trough for raising cattle. The feed trough comprises a storage bin and a feeding trough, wherein a discharging hole is formed in the bottom part of the storage bin; the storage bin is rotationally connected with a laying-off disc; a storage trough is formed in the laying-off disc; a laying-off hole is formed in one side of the storage trough; an installing cavity is arranged on the laying-off disc, a pushing rod is connected in the installing cavity in a sliding manner, and a spring is arranged between the pushing rod and the installing cavity; the installing cavity is internally provided with a power supply and an installing block, the installing block is connected with an electromagnet in a sliding manner, the electromagnet is connected with a conducting strip which comprises a conducting part and an insulating part, and the power supply is provided with a conducting needle contacted with the insulating part; the pushing rod is provided with a magnet, and an iron plate is hinged to the laying-off disc; and magnetic needles are arranged at the bottom part of the laying-off disc. The feed trough disclosed by the invention solves the problems that polluted feed is remained in the feeding trough which is communicated with the storage bin so as to probably pollute the feed in the storage bin, so that and diseases are easily induced after next feeding of calves in the prior art.

Owner:贵州省潘念种养殖有限公司

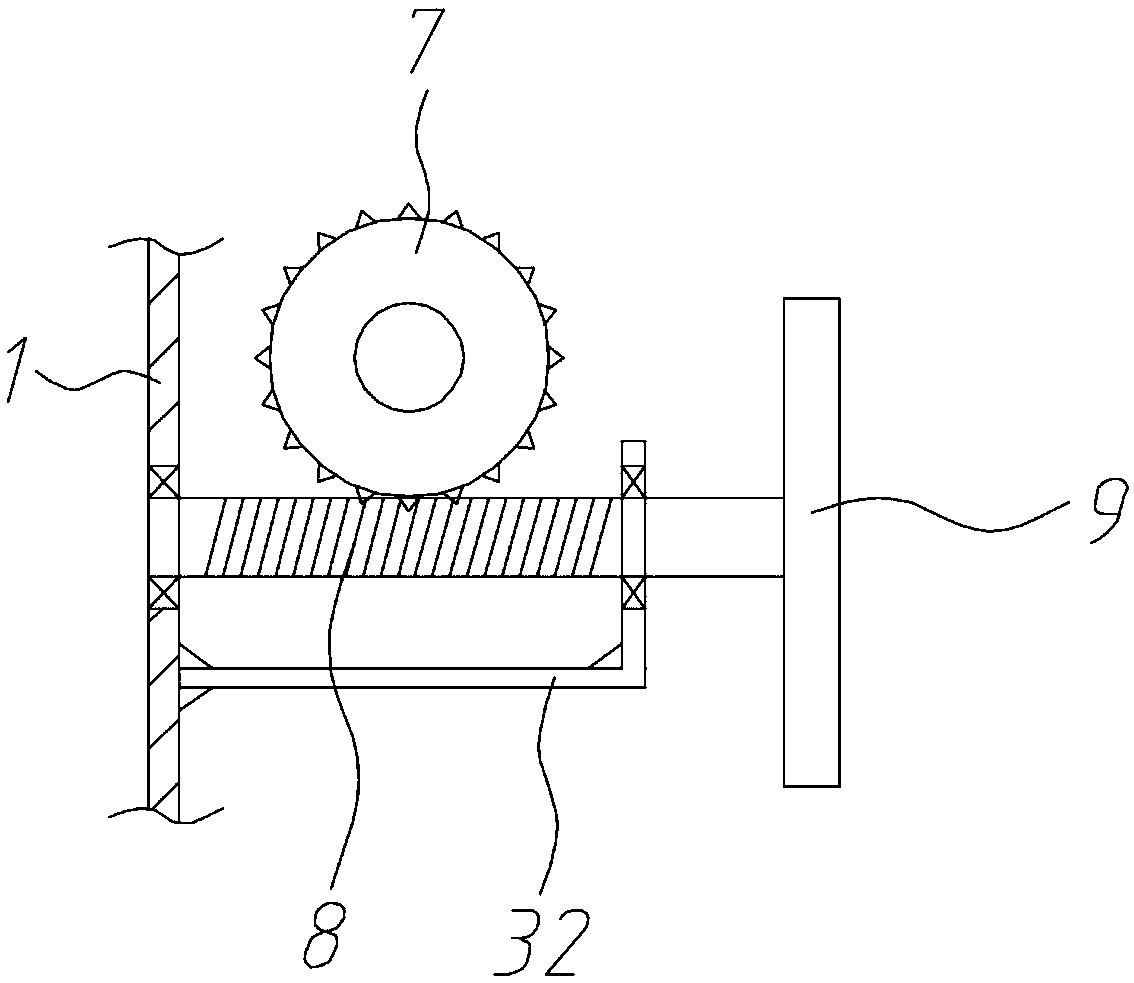

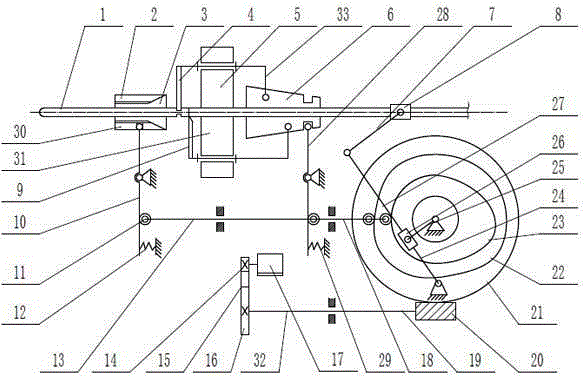

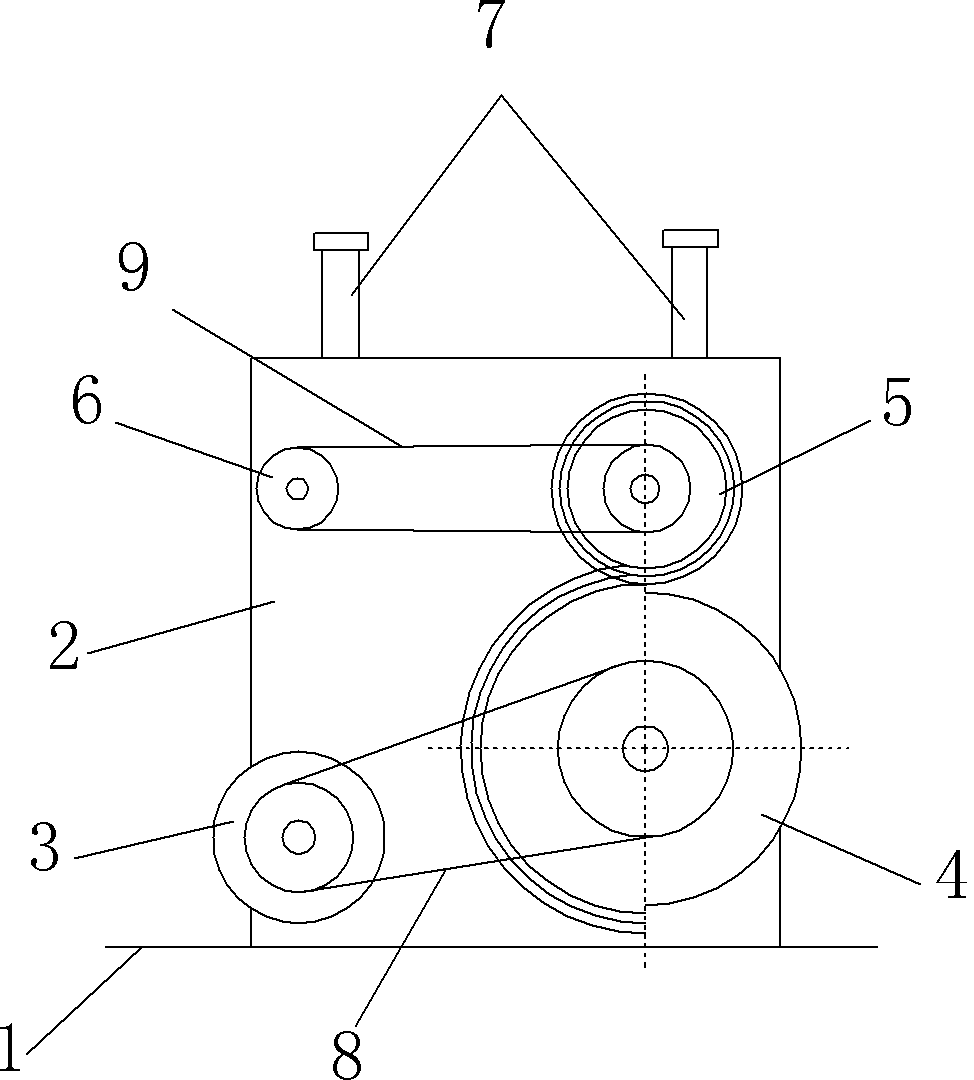

Intermittent feeding device for lathe

InactiveCN103659429ARealize intermittent movementRealize intermittent feedingMetal working apparatusLeather beltMachine tool

The invention discloses a feeding device for a lathe and particularly relates to an intermittent feeding device for a lathe. The intermittent feeding device comprises a base, a machine frame, a driving wheel, a driving gear, a driven gear and a driven wheel. The driving wheel, the driving gear, the driven gear and the driven wheel are arranged on a pin shaft of the machine frame. Two stand columns are arranged on the base. The machine frame is matched with a sliding column in a thread mode. The driving gear is a semi-gear. The driving wheel and the driving gear are in transmission through a chain. The driving gear and the driven gear are matched. The driven gear and the driven wheel are in transmission through a belt. According to the technical scheme, the intermittent feeding device for the lathe is simple in structure, and intermittent workpiece feeding can be achieved.

Owner:CHONGQING ZHIRUIDE TECH

Xiang pig feed mixing equipment

ActiveCN108465426ARealize intermittent feedingImprove uniformityFeeding-stuffTransportation and packagingEngineeringFeed additive

The invention relates to the field of livestock breeding equipment and in particular discloses Xiang pig feed mixing equipment which comprises a mixing tank, a motor and two storage chambers, whereinthe motor is arranged above the mixing tank; the output end of the motor is coaxially fixedly connected with a rotating shaft; the storage chambers are connected with discharge tubes; control mechanisms are mounted at discharge holes of the discharge tubes; the rotating shaft is hinged with push plates for opening the control mechanisms; holding discs are arranged below the discharge holes; a cavity is formed inside the rotating shaft; feeding holes are formed in the side wall of the rotating shaft; the feeding holes are communicated with the cavity and the mixing tank; a third discharge tubeis communicated with the bottom of the cavity; the rotating shaft is coaxially fixedly connected with a plurality of stirring blades; a plurality of vertically arranged rotating plates are hinged withthe side wall of the mixing tank along the circumference of the mixing tank; the rotating plates are pushed to rotate in the rotation process of the stirring blades. By adopting the equipment, primary mixing of feed with feed additives can be achieved through the holding discs, secondary mixing can be achieved through the stirring blades, meanwhile, feed on the side wall of the mixing tank can bestirred and mixed through rotation of the rotating plates, and the uniformity degree of the feed and the feed additives can be increased.

Owner:湖南俊旺科技饲料有限公司

Powder coating grinding equipment

The invention relates to powder coating grinding equipment. The powder coating grinding equipment comprises a grinding box and a feed hopper; the feed hopper communicates with a feeding passage; the bottom of the feeding passage is rotationally connected with a discharging pipe; the bottom of the discharging pipe is fixedly connected with an upper grinding disc; the bottom of the upper grinding disc is provided with a discharging hole; a lower grinding disc is arranged below the upper grinding disc; the discharging pipe is coaxially and fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is coaxially and fixedly connected with a horizontal shaft; the two sides of the inner wall of the grinding box are each provided witha discharging plate; a plurality of shaking springs are fixedly arranged between the discharging plates and the sidewall of the grinding box; the discharging pipe is further fixedly connected with ahorizontally-arranged push rod; the free end of the push rod leans against the discharging plates; the outer wall of the lower grinding disc is vertically and slidably connected with an obliquely-arranged filter plate; the bottom of the filter plate is fixedly connected with a support spring; a discharging mechanism is arranged at one side of the grinding box; the discharging mechanism comprises adriving shaft; and a belt is connected between the driving shaft and the horizontal shaft. The powder coating grinding equipment solves the problem about adhesion of power coatings.

Owner:重庆阿罗科技有限公司

Feeding device used for producing powder coating

InactiveCN111792325ARealize reciprocating motionRealize intermittent feedingPackagingConveyor partsReciprocating motionElectric machine

The invention discloses a feeding device used for producing powder coating. The feeding device comprises a material conveying cylinder. A feeding pipe is arranged on the upper wall of the material conveying cylinder in a communicating manner. A discharging pipe is arranged on the lower wall of the material conveying cylinder in a communicating manner. A baffle capable of sliding is arranged on theside wall of the feeding pipe in a penetrating manner. Supporting plates are fixedly connected to the side walls, close to the two ends, of the material conveying cylinder correspondingly. A placingplate is fixedly connected to the side wall of the supporting plate located on the left side. A power source is arranged on the lower wall of the placing plate. A motor is fixedly connected to the upper wall of the placing plate. An output shaft of the motor extends to the interior of the material conveying cylinder and is fixedly connected with a spiral conveying rod. According to the feeding device, reciprocating motion of the baffle can be achieved, intermittent discharging is achieved, the connecting portion of the feeding pipe and the spiral conveying rod can be prevented from being blocked by a large amount of powder coating, then it is ensured that the device can operate normally, the working efficiency of the equipment is improved greatly, a power source does not need to be arranged additionally to drive the baffle to move in a reciprocating manner, the purpose of saving resources is achieved, and thus the overall structure of the equipment is more reasonable.

Owner:郑现才

Preparation equipment capable of achieving uniform mixing for cosmetic production

InactiveCN111013474AWell mixedImprove mixing efficiencyRotating receptacle mixersTransportation and packagingSpiral bladeProcess engineering

The invention relates to the technical field of cosmetic mixing equipment, in particular to preparation equipment capable of achieving uniform mixing and used for cosmetic production. A servo motor isadopted to drive a second rotating shaft to rotate through transmission of a transmission wheel, so that materials are uniformly mixed by a stirring assembly; meanwhile, through bevel gear transmission, a fourth rotating shaft is driven to rotate, the fourth rotating shaft drives a rotating table to rotate through transmission of the transmission wheel, and therefore transmission of a mixing barrel is achieved; the rotating directions of the second rotating shaft and the rotating table are opposite, namely the stirring assembly and the mixing barrel rotate oppositely, so that the stirring andmixing efficiency is effectively improved; a liquid material barrel is further arranged, a third rotating shaft rotates to stir liquid raw materials in the liquid material barrel, and sedimentation is prevented; a solid material barrel is further arranged, solid raw materials in the solid material barrel are stirred through transmission in cooperation with the spiral blades, and hardening is prevented.

Owner:安徽职业技术学院

Granular fertilizer spraying equipment for pasture

InactiveCN108811650ASpray to achieveRealize intermittent feedingTransportation and packagingRotary stirring mixersAgricultural engineeringFan blade

The invention relates to granular fertilizer spraying equipment, in particular to the granular fertilizer spraying equipment for a pasture, and the granular fertilizer spraying equipment for the pasture is characterized by being capable of regulating the spraying distance and the spraying uniformity. The granular fertilizer spraying equipment for the pasture is characterized by comprising an L-shaped support, a first rolling wheel, a first installation seat, a second rolling wheel, a fertilizer outlet tank, a first bearing seat, a first rotating shaft, fan blades, a first bevel gear and the like, wherein the first rolling wheel is arranged at the right side of the bottom part of the L-shaped support; the left side surface of the L-shaped support is connected with the first installation seat; the first installation seat is provided with the second rolling wheel; the bottom part of the inner part of the L-shaped support is connected with the fertilizer outlet tank. According to the granular fertilizer spraying equipment provided by the invention, fertilizer falling into the fertilizer outlet tank can be thrown out through a second opening under high-speed rotation of the fan blades,so that spraying of the fertilizer can be realized; a spring has a buffer function, so that inertia generated during sudden stop and movement of other equipment can be prevented.

Owner:陈昌江

Sand screening machine capable of preventing filter screen from being blocked for building construction

The invention relates to the technical field of sand screening equipment, in particular to a sand screening machine capable of preventing a filter screen from being blocked for building construction.The sand screening machine capable of preventing the filter screen from being blocked for building construction has the advantages that a first rotating shaft is driven to rotate based on a servo motor, a second rotating shaft is driven to rotate through gear transmission, on one hand, coarse sand enters a crushing cavity from a feeding hopper, crushing is carried out under the action of a crushing cutter; on the other hand, the second rotating shaft further drives a fourth rotating shaft to rotate through a coupler, a crank throw rotates along with the fourth rotating shaft, a first connecting rod and a second connecting rod drive the filter screen to shake left and right, the filtering efficiency is improved, the filter screen is prevented from being blocked; the fact that a filter pipeis detachably connected with the shell is adopted in conjunction with the coupler connection mode of the fourth rotating shaft and the second rotating shaft, so that the filter pipe is integrally detached conveniently, the coarse sand is conveniently removed; and the second rotating shaft is used for driving a first cylindrical cam to rotate, a first supporting rod drives a baffle plate to move upand down, the baffle plate periodically enters and exits a feeding pipe, blocking or communicating for feeding are carried out, and intermittent feeding is achieved.

Owner:安徽乐秀信息科技有限公司

Film cutting device

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryGear driveGear wheel

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

Peanut whole-process production line and method

ActiveCN111317148AEfficient separationReduce the impactGas current separationSolid materialEngineeringProcess engineering

The invention provides a peanut whole-process production line and method. The peanut whole-process production line comprises a peanut cleaning system, a shell breaking system, a red skin removing system, a peanut kernel grading system, a superfine grinding system and a grading packaging system. The first process is peanut cleaning and impurity removing, peanut shell breaking is arranged behind peanut cleaning and impurity removing, peanut kernel red skin removing and peanut shell superfine grinding are respectively arranged behind the peanut shell breaking, peanut kernel grading is arranged behind the peanut kernel red skin removing, and peanut shell superfine powder grading packaging is arranged behind the peanut shell superfine grinding. By the peanut whole-process production line, peanut whole-process processing is completed, and peanut resources are fully utilized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Automatic silk-screen printing drying equipment

ActiveCN111002697AAchieve left and right movementRealize intermittent feedingScreen printersScreen printingEngineering

The invention discloses automatic silk-screen printing drying equipment. The equipment comprises a main machine body, wherein a working cavity is arranged in the main machine body, a first transmission cavity is formed on a left side of the working cavity, a second transmission cavity is formed on the right side of the working cavity, a screw rod is rotatably arranged in the working cavity and between the second transmission cavity and the first transmission cavity, a nut spirally matched with the screw rod is arranged on the screw rod in the working cavity, and a first guide groove is formedon an upper side wall of the working cavity. The equipment is advantaged in that a rack can be meshed with a fan-shaped gear I or a fan-shaped gear II, a scraper can move left and right, the scraper can be separated from a silk screen through a magnet, the silk screen can be moved upwards and separated from a workpiece while the scraper is separated from the silk screen, operation is easy and convenient, manufacturing cost is low, printing efficiency is high, intermittent feeding can be achieved, and the colored workpiece can be dried.

Owner:平湖佐越机械制造股份有限公司

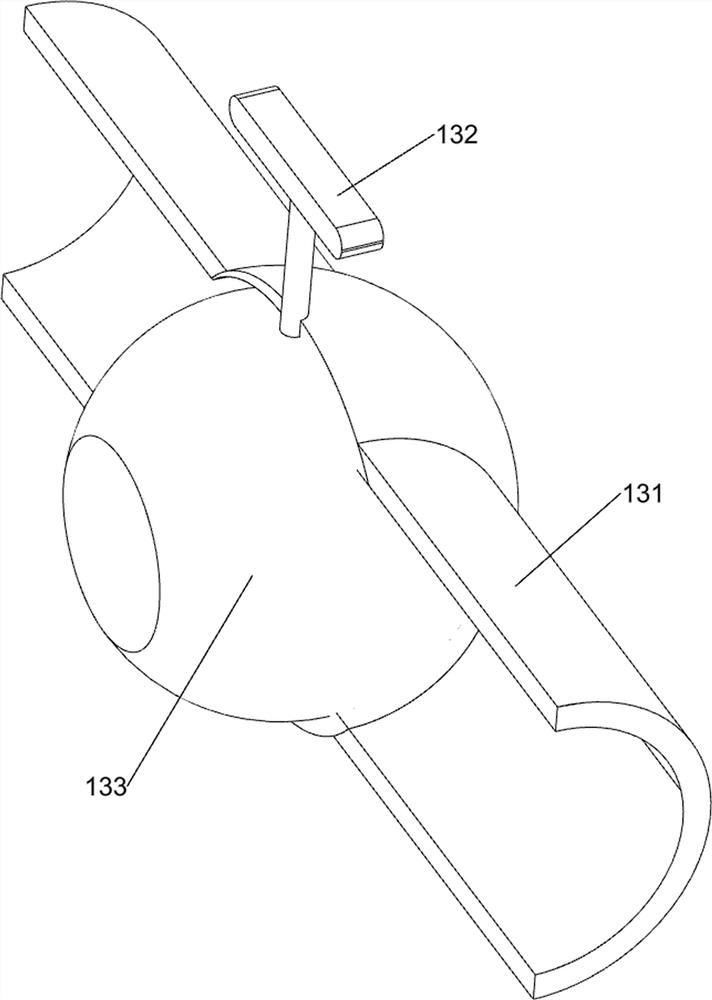

Sugarcane juicing equipment for agriculture and light industry

ActiveCN113068843AAchieve juicingRealize the collectionJuice extractionClimate change adaptationElectric machineryCane

The invention relates to juicing equipment, in particular to sugarcane juicing equipment for agriculture and light industry. The invention provides sugarcane juicing equipment for the agriculture and light industry that has good sealing performance and is convenient for people to collect bagasse. The sugarcane juicing equipment for the agriculture and light industry comprises a bottom plate, a motor, first supporting columns, a small roller and a large roller, wherein the top part of the bottom plate is provided with a supporting frame; the motor is arranged at the top part of the supporting frame; the first supporting columns are symmetrically arranged at the top part of the bottom plate; the small roller is rotationally arranged between the first supporting columns; and the large roller is rotationally arranged between the first supporting columns, and the large roller is connected with an output shaft of the motor. According to the sugarcane juicing equipment, juicing of a sugarcane is implemented with the cooperation of the small roller and the large roller; then, collection of sugarcane juice and bagasse is implemented with the cooperation of a pushing mechanism; and meanwhile, secondary juicing of the bagasse is implemented with the cooperation of a secondary juicing mechanism, and in such a manner, juice in the sugarcane can be thoroughly squeezed out.

Owner:艾文龙

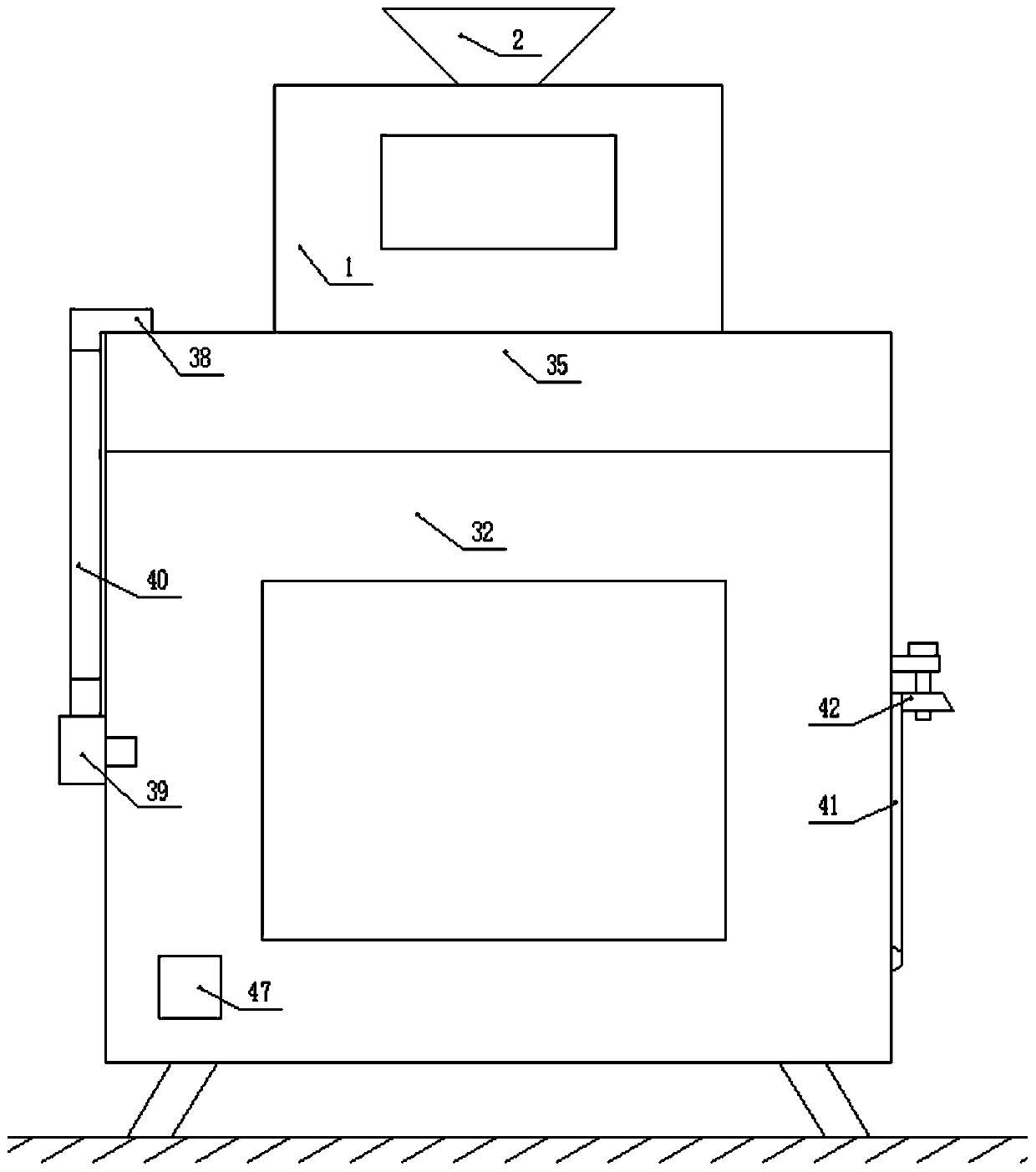

Waste treatment robot device capable of filtering irritant gas

ActiveCN111495529ARealize intermittent feedingStir wellDispersed particle filtrationDirt cleaningActivated carbonStructural engineering

The invention provides a waste treatment robot device capable of filtering irritant gas. The waste treatment robot device comprises a crushing barrel, a box body and an annular box, a feed hopper arranged at the top of the crushing barrel, two first baffles capable of horizontally sliding relatively arranged in the crushing barrel, two rollers with arc-shaped blades arranged in the crushing barrelat equal height, a balancing weight arranged below the rollers, and the balancing weight is linked with the first baffles; bottom openings of the crushing barrel are located in the box body, a conveying belt is arranged at the bottom of the box body and located under a transverse plate, a discharging hole is formed in the side wall, close to the output side of the conveying belt, of the box body,and a suction fan is fixed to the outer side wall of the box body; the outer wall of the crushing barrel is sleeved with the annular box in an attached mode, the annular box is filled with activatedcarbon, an air inlet is formed in one side of the annular box, an air outlet is formed in the other side of the annular box, and the air inlet is connected with the suction fan through a pipeline. While intermittent discharging is achieved, materials can be fully stirred and crushed conveniently, and the crushing rate of waste is increased.

Owner:SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com