Automated forage cutting equipment used for breeding industry

A cutting equipment and aquaculture technology, applied in the field of automatic forage cutting equipment for aquaculture, can solve the problems of slow cutting speed, tool damage, inconvenient transportation of products, etc., and achieve the effect of reducing forage residue and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

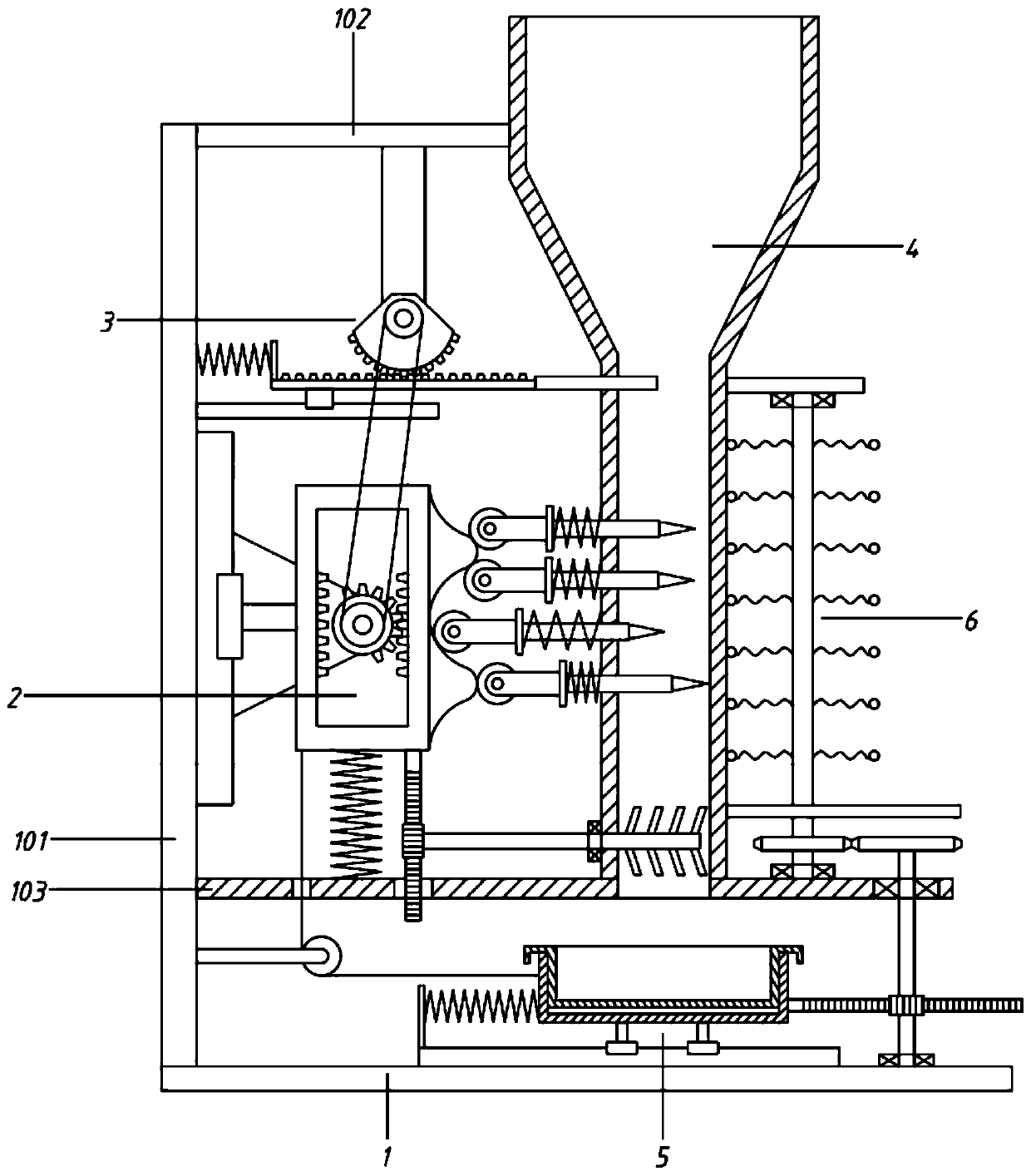

[0051] An automatic forage cutting equipment for aquaculture, comprising a casing 4 and a cutting assembly 2;

[0052] The shell 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and the top of the feeding hopper 402 is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 is provided with a feeding port;

[0053] The cutting assembly 2 is arranged on the left side of the feeding tube 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass cutting mechanism; the inner sides of the left and right sides of the rectangular frame 201 are processed with teeth, and the incomplete gear 204 is installed in the rectangular frame 201, and is connected with the teeth. Intermittent fit; the incomplete gear 204 is externally connected with a servo motor; a number of protrusions 205 are processed on the right outer side of the rectangular frame 201; the grass cutting mechanism is hori...

Embodiment 2

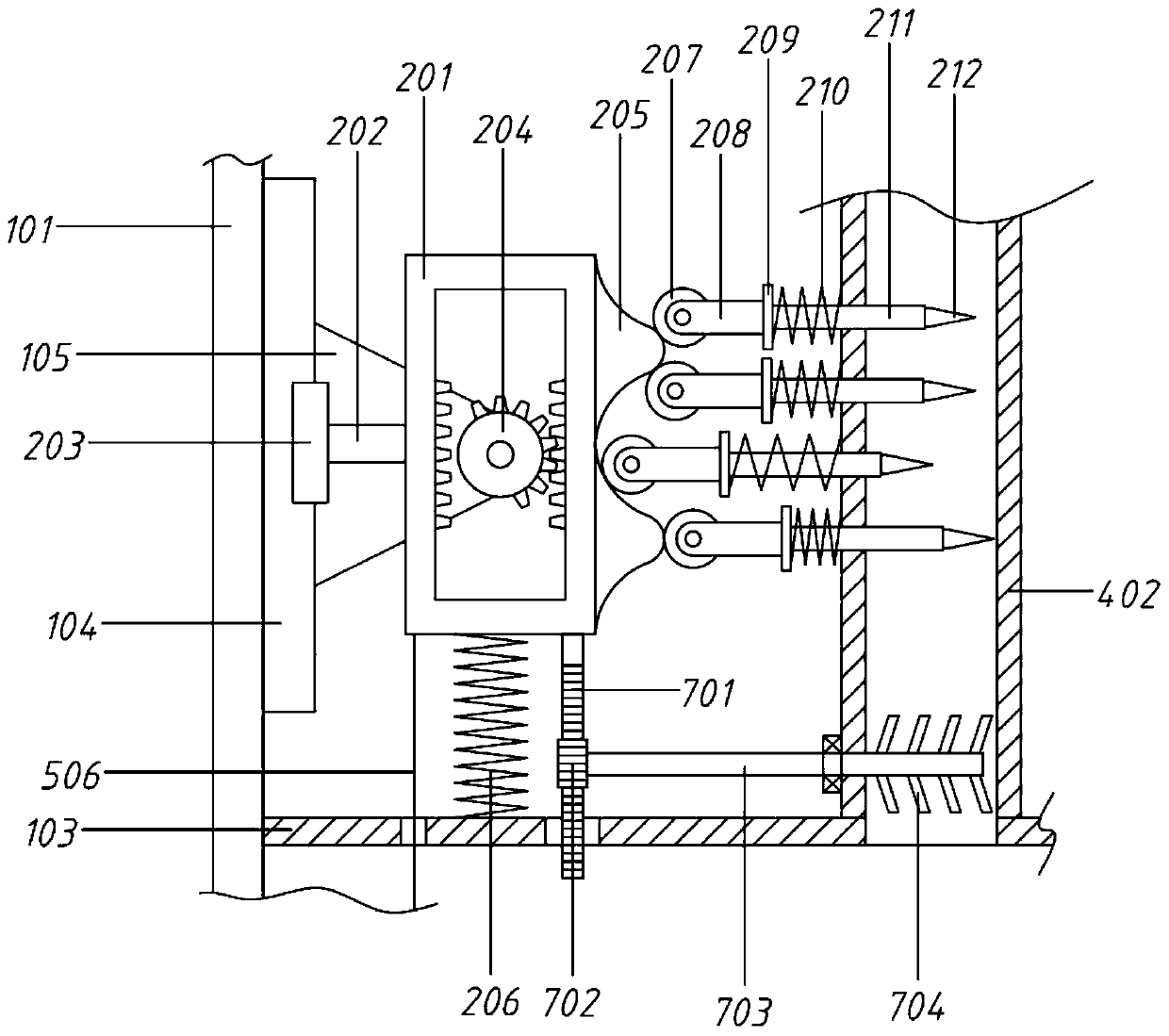

[0056] An automatic forage cutting equipment for aquaculture, comprising a casing 4 and a cutting assembly 2;

[0057] The shell 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and the top of the feeding hopper 402 is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 is provided with a feeding port;

[0058] The cutting assembly 2 is arranged on the left side of the feeding tube 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass cutting mechanism; the inner sides of the left and right sides of the rectangular frame 201 are processed with teeth, and the incomplete gear 204 is installed in the rectangular frame 201, and is connected with the teeth. Intermittent fit; the incomplete gear 204 is externally connected with a servo motor; a number of protrusions 205 are processed on the right outer side of the rectangular frame 201; the grass cutting mechanism is hori...

Embodiment 3

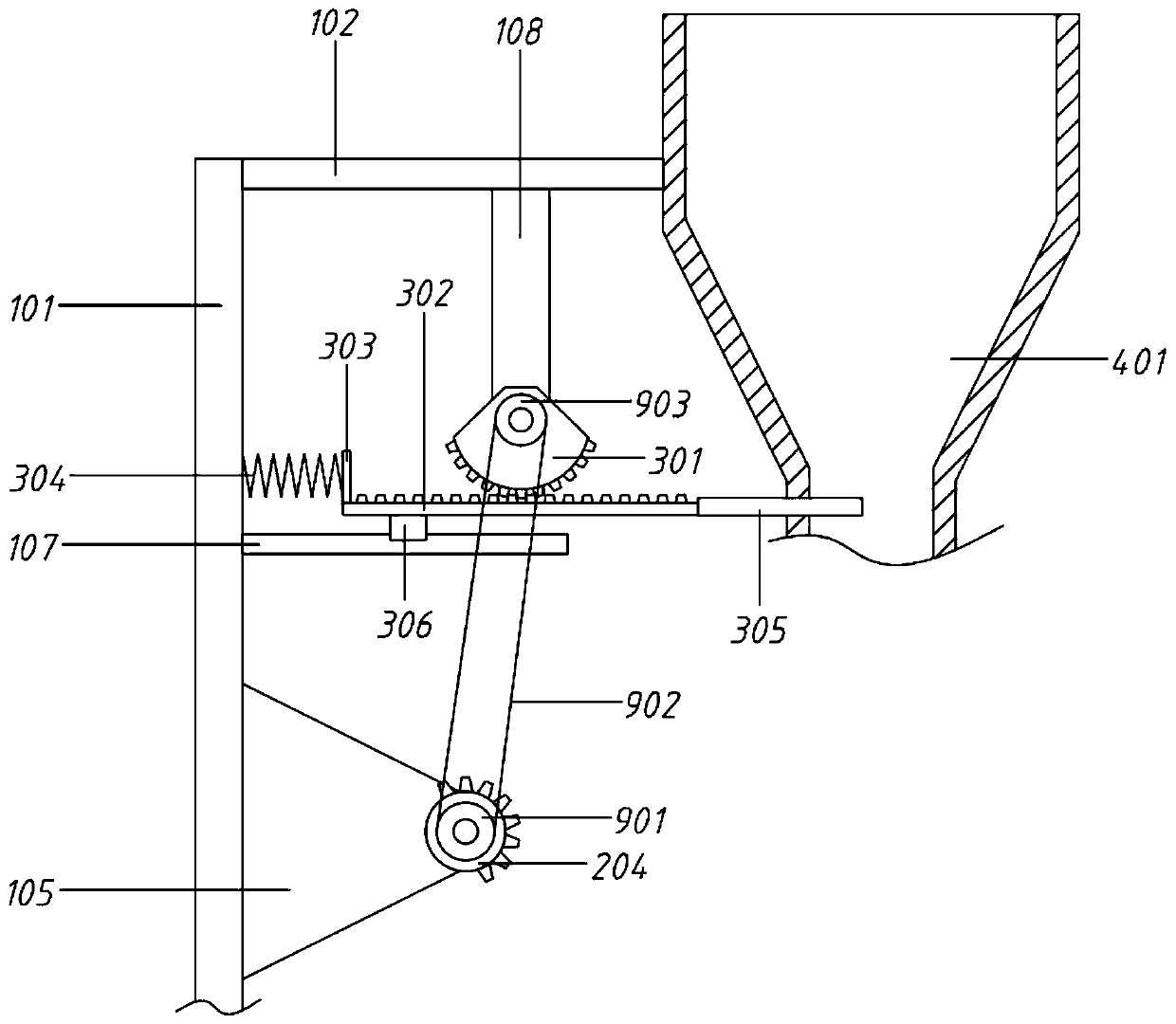

[0063] An automatic forage cutting equipment for aquaculture, comprising a casing 4 and a cutting assembly 2;

[0064] The shell 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and the top of the feeding hopper 402 is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 is provided with a feeding port;

[0065] The cutting assembly 2 is arranged on the left side of the feeding tube 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass cutting mechanism; the inner sides of the left and right sides of the rectangular frame 201 are processed with teeth, and the incomplete gear 204 is installed in the rectangular frame 201, and is connected with the teeth. Intermittent fit; the incomplete gear 204 is externally connected with a servo motor; a number of protrusions 205 are processed on the right outer side of the rectangular frame 201; the grass cutting mechanism is hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com