Switchable combination working line for grain screening and impurity removing

A working line and grain technology, which is applied in grain processing, grain milling, sieving, etc., can solve the problems of low automation, energy consumption, and inability to improve the work efficiency of shrubbery removal, so as to improve work efficiency and high automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

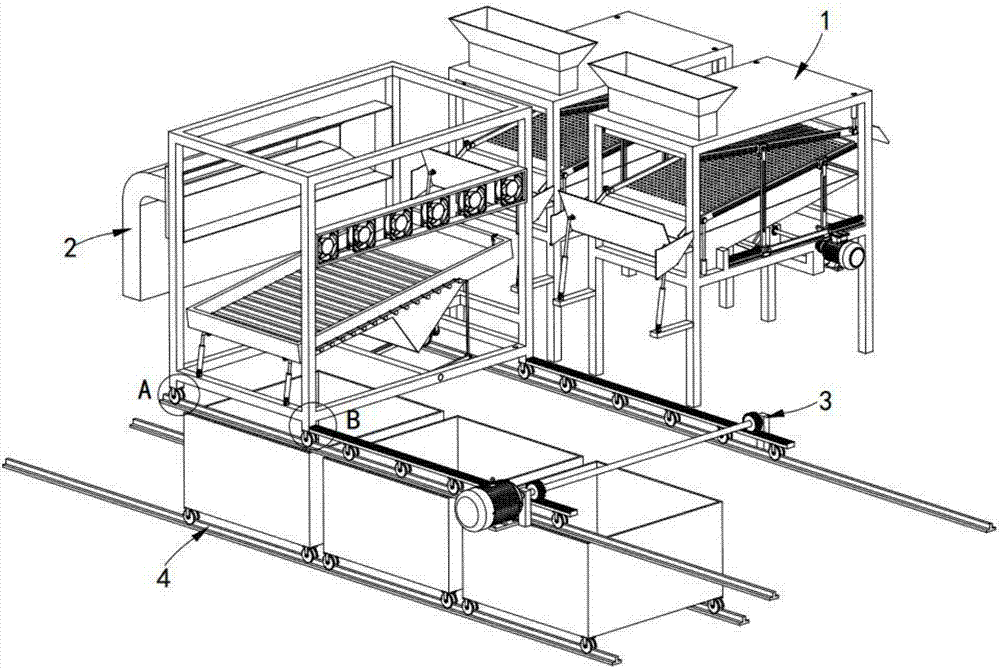

[0084] Such as figure 1 , figure 2 and image 3 As shown, a switchable combined working line for grain screening and impurity removal includes a symmetrically arranged resonance screening mechanism 1, Shibuya screening mechanism 2, switching mechanism 3 and storage mechanism 4, and the resonance screening mechanism 1 is set in Shibuya screening mechanism. The front side of mechanism 2, which is used for screening grain;

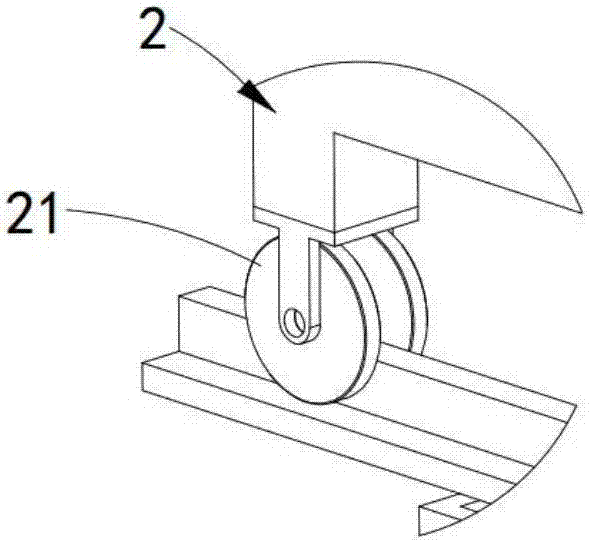

[0085] A plurality of first traveling wheels 21 are arranged below the Shibuya screening mechanism 2, and the Shibuya screening mechanism 2 is driven by the switching mechanism 3 to switch to remove impurities from the grain output by the resonance screening mechanism 1;

[0086] The switching mechanism 3 is arranged on one side of the Shibuya screening mechanism 2, which includes a rack 31 symmetrically arranged at the front and rear ends of the Shibuya screening mechanism 2, and is connected to the Shibuya screening mechanism 2 through the rack 31 , and...

Embodiment 2

[0153] Figure 17 It is a schematic structural diagram of Embodiment 2 of a grain screening and impurity removal switchable combined working line of the present invention; Figure 17 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0154] Such as Figure 17 As shown, a switchable combined working line for grain screening and impurity removal can also rigidly connect the symmetrically arranged resonance screening mechanism 1. By installing the first traveling wheel 21 under the resonance screening mechanism 1, the switching mechanism 3 It is arranged on one side of the resonance screening mechanism 1, and is connected with the resonance screening mechanism 1 through a gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com