Tracking type dynamic bottle cap marking method

A tracking, bottle cap technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor feeding effect of bottle caps, unable to achieve synchronous tracking of bottle caps and bottle cap transfer devices, etc., to save Power, push and slewing fit with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

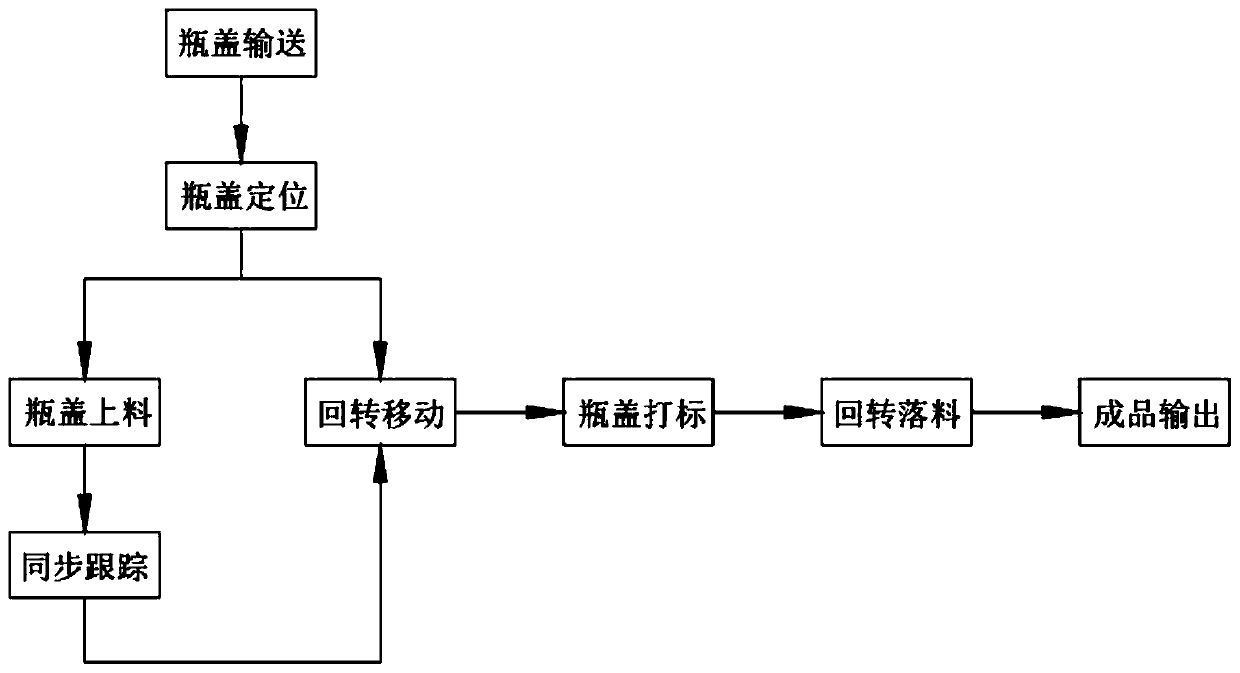

[0050] like figure 1 As shown, a tracking dynamic bottle cap marking method includes the following steps:

[0051] Step 1, bottle cap conveying, several bottle caps 10 after production and processing are entered into the bottle cap feeding track 422 and linearly transported backward in the bottle cap feeding track 422;

[0052] Step 2, bottle cap positioning, the bottle caps 10 transported in the bottle cap feeding track 422 in step 1 are transported to the pusher barrel 423, and enter the pusher barrel 423 from the feed port 422...

Embodiment 2

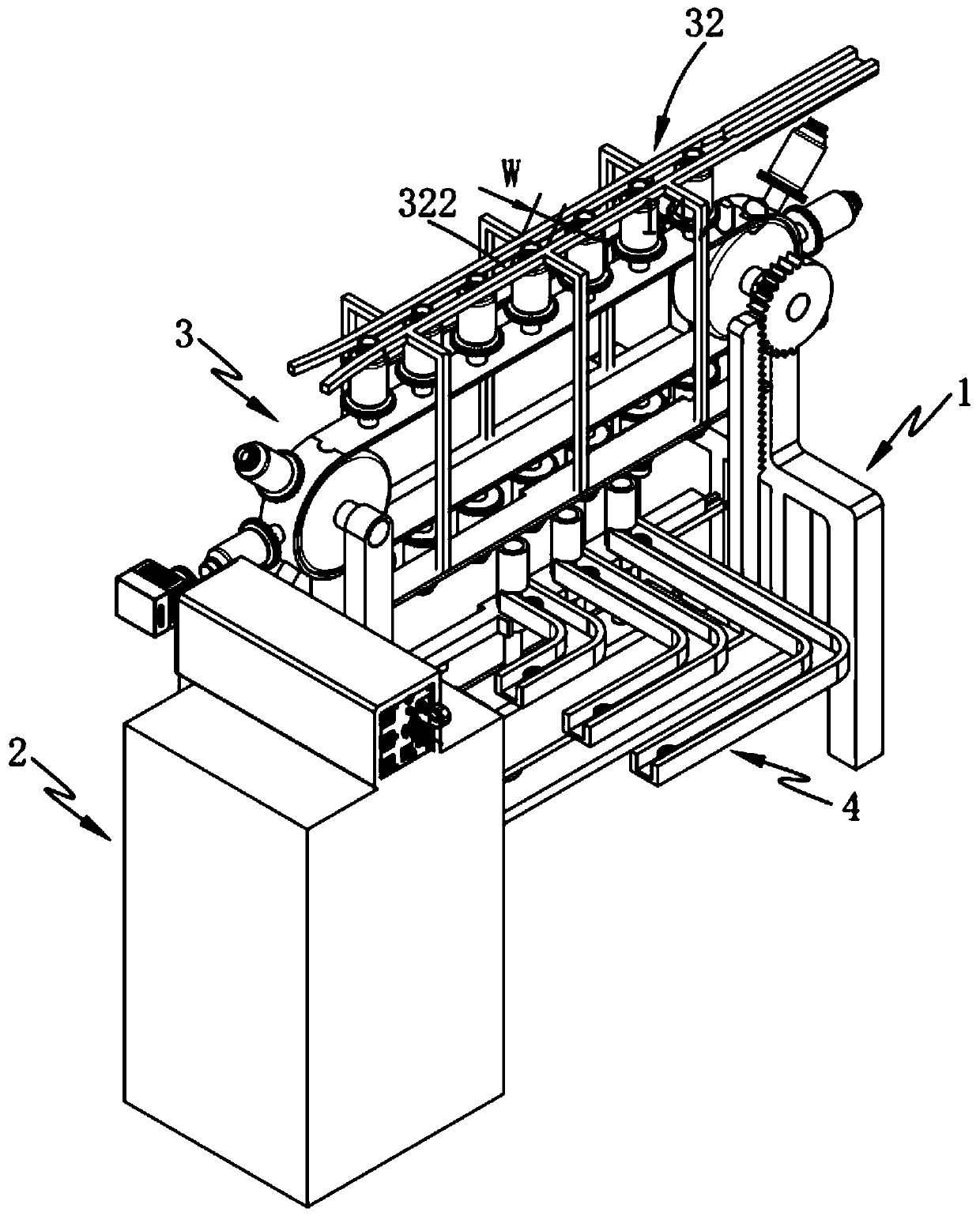

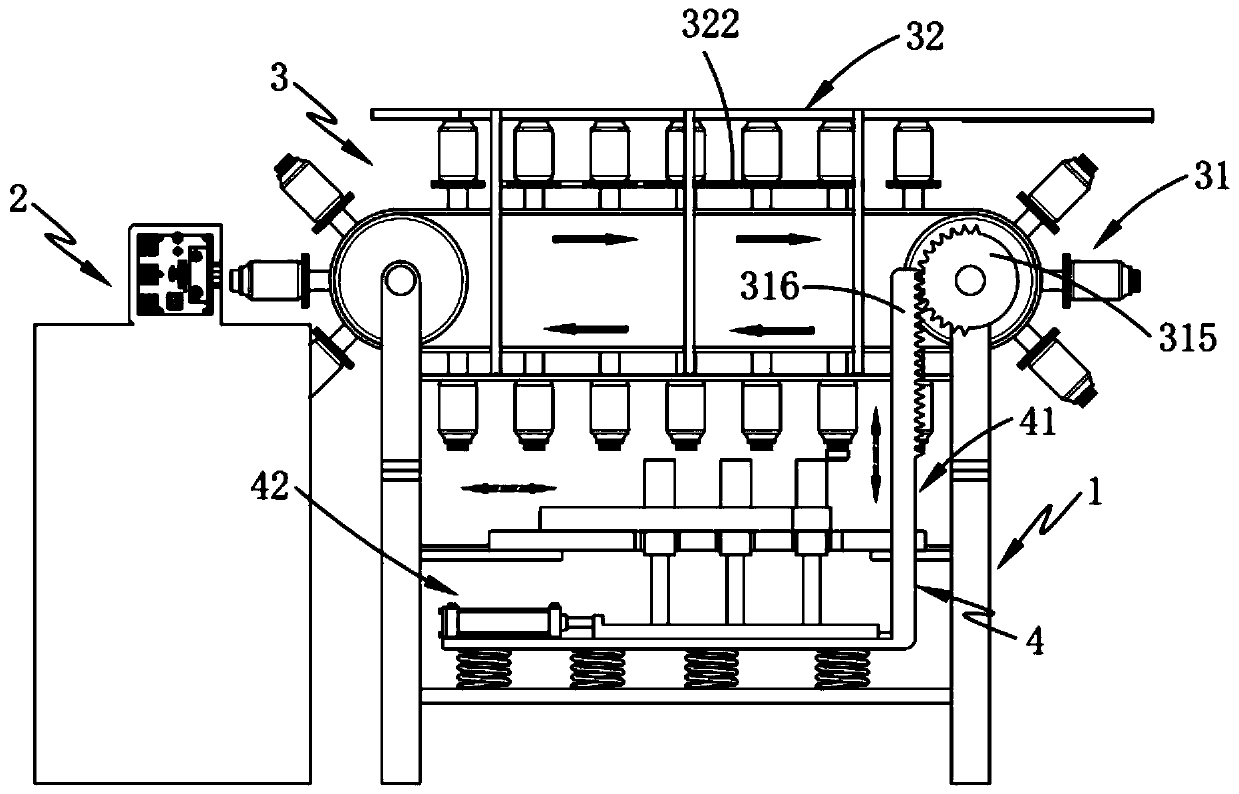

[0069] The present invention also provides a tracking type bottle cap marking equipment, such as figure 2 and 3 As shown, including bracket 1 and marking device 2, also includes:

[0070] Rotary device 3, said rotary device 3 is rotated and arranged on both ends of the length direction of said support 1, said rotary device 3 includes a rotary assembly 31 and an output assembly 32 arranged above said rotary assembly 31, said rotary assembly 31 Transport the bottle caps 10 that need to be marked in a rotary manner, and enter the output assembly 32 for outward output after marking at the marking device 2 during transportation; and

[0071] Feeding device 4, described feeding device 4 is slidably arranged on the described support 1, and this feeding device 4 comprises the interval pusher assembly 41 that is slidably arranged on the height direction of described support 1 and is slidably arranged on the interval pusher assembly 41. The tracking assembly 42 in the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com