Shaking type feed screening machine based on cylindrical cam driving

A technology of cylindrical cam and screening machine, which is applied in the direction of feed, filter screen, solid separation, etc. It can solve the problems of low screening speed, unfavorable absorption, inconvenient replacement and cleaning, etc., and achieves the effect of simple and convenient operation and guaranteed use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

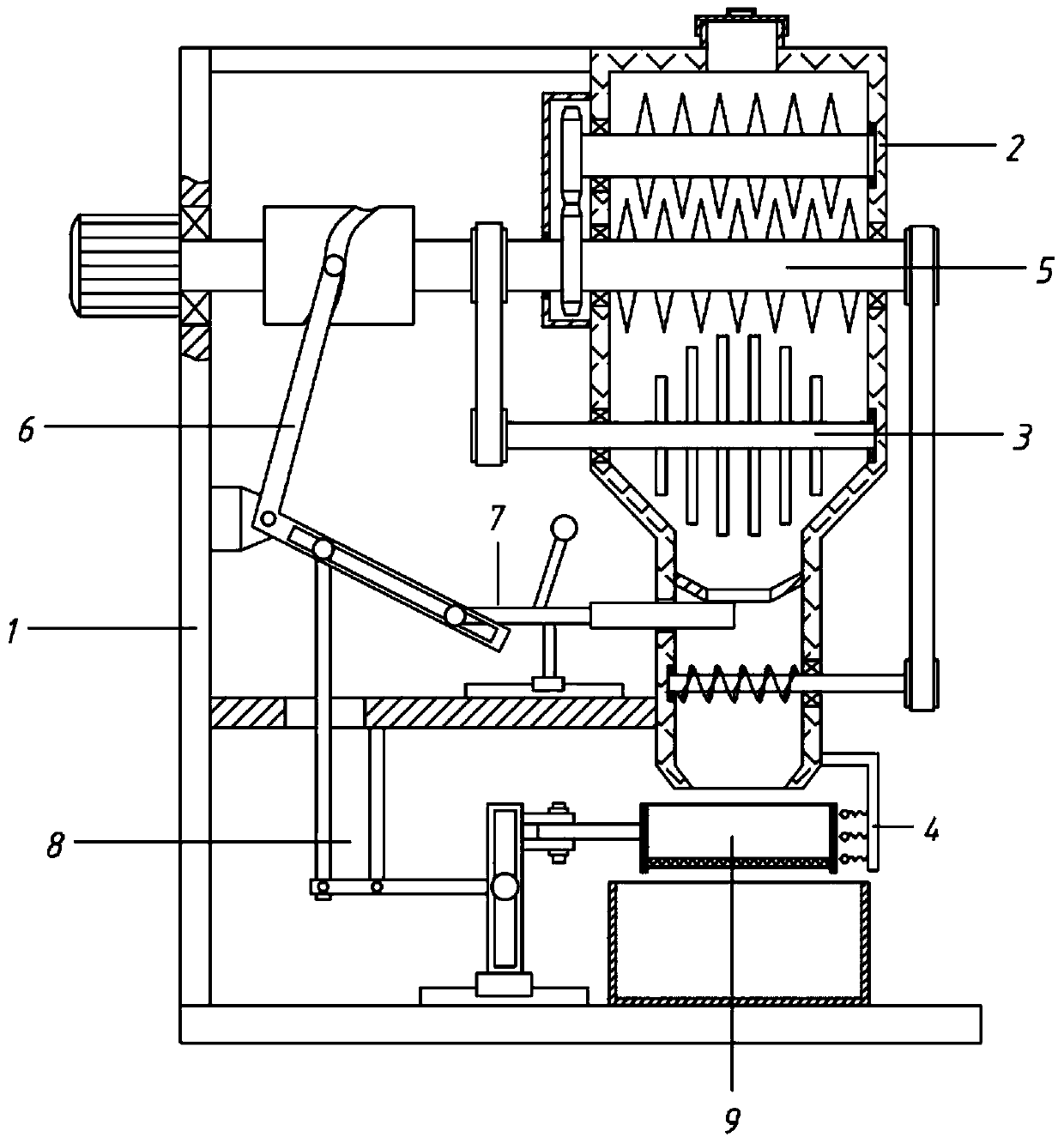

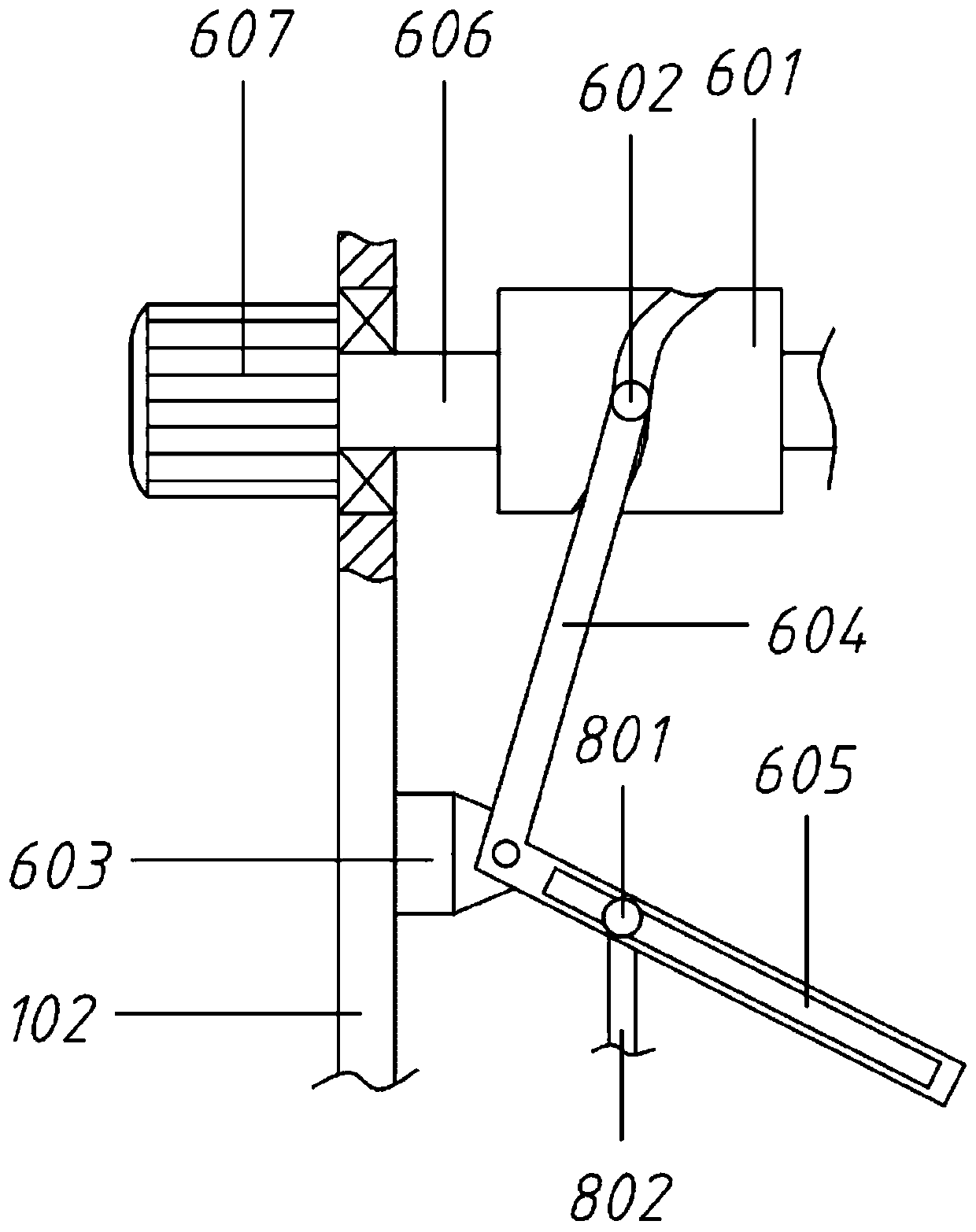

[0057] A swaying feed screening machine driven by a cylindrical cam, comprising a frame 1, a barrel 2, a cam assembly 6, a swaying assembly 8 and a filter assembly 9;

[0058] The frame 1 includes a base 101, a vertical plate 102, a top plate 103 and a support plate 104, the vertical plate 102 is fixed on the left end of the base 101, the top of the vertical plate 102 is connected to the top plate 103 to the right, and the lower section of the vertical plate 102 is fixed to the right with a support plate 104 ; The top left side of the barrel 2 is connected to the top plate 103, and the left side of the bottom end of the barrel 2 is connected to the support plate 104;

[0059] The cam assembly 6 is arranged on the vertical plate 102, and the shaking assembly 8 is arranged below the cam assembly 6; the filter assembly 9 is arranged under the barrel 2, and is connected to the right side of the shaking assembly 8; the cam assembly 6 acts on the shaking assembly 8, making the shakin...

Embodiment 2

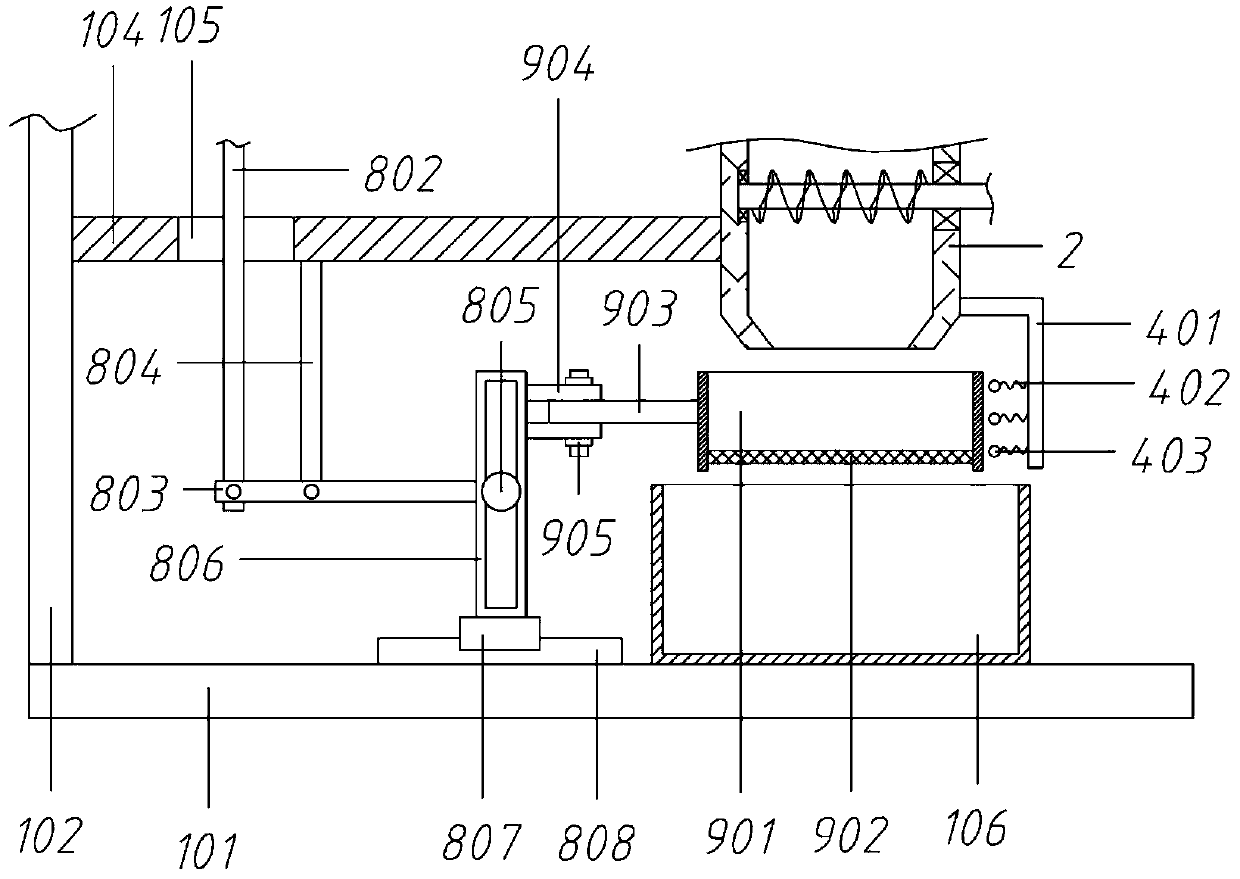

[0061] A swaying feed screening machine driven by a cylindrical cam, comprising a frame 1, a barrel 2, a cam assembly 6, a swaying assembly 8 and a filter assembly 9;

[0062] The frame 1 includes a base 101, a vertical plate 102, a top plate 103 and a support plate 104, the vertical plate 102 is fixed on the left end of the base 101, the top of the vertical plate 102 is connected to the top plate 103 to the right, and the lower section of the vertical plate 102 is fixed to the right with a support plate 104 ; The top left side of the barrel 2 is connected to the top plate 103, and the left side of the bottom end of the barrel 2 is connected to the support plate 104;

[0063] The cam assembly 6 is arranged on the vertical plate 102, and the shaking assembly 8 is arranged below the cam assembly 6; the filter assembly 9 is arranged under the barrel 2, and is connected to the right side of the shaking assembly 8; the cam assembly 6 acts on the shaking assembly 8, making the shakin...

Embodiment 3

[0074] On the basis of embodiment 2,

[0075] It also includes a collision assembly 4; the collision assembly 4 is arranged on the right side of the bottom end of the barrel 2, and includes a 7-type plate 401, a type of spring 402 and a small ball 403;

[0076] The left end of the transverse section of the 7-type plate 401 is connected with the barrel 2, and the left side of the longitudinal section is uniformly connected with a type of spring 402, and the left end of the type spring 402 is equipped with a small ball 403.

[0077] Specifically, the filter assembly 9 shakes from side to side, and when it moves to the right, it collides with the small ball 403 and generates vibration, which accelerates the filtering by the filter screen 902 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com