Sand screening machine capable of preventing filter screen from being blocked for building construction

A technology for building construction and filter clogging. It is applied in the direction of filter screen, solid separation, grille, etc. It can solve the problems of slowing down the progress of the project, high manual labor consumption, and the inability to carry out sand screening operations, so as to prevent clogging and improve filtration. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

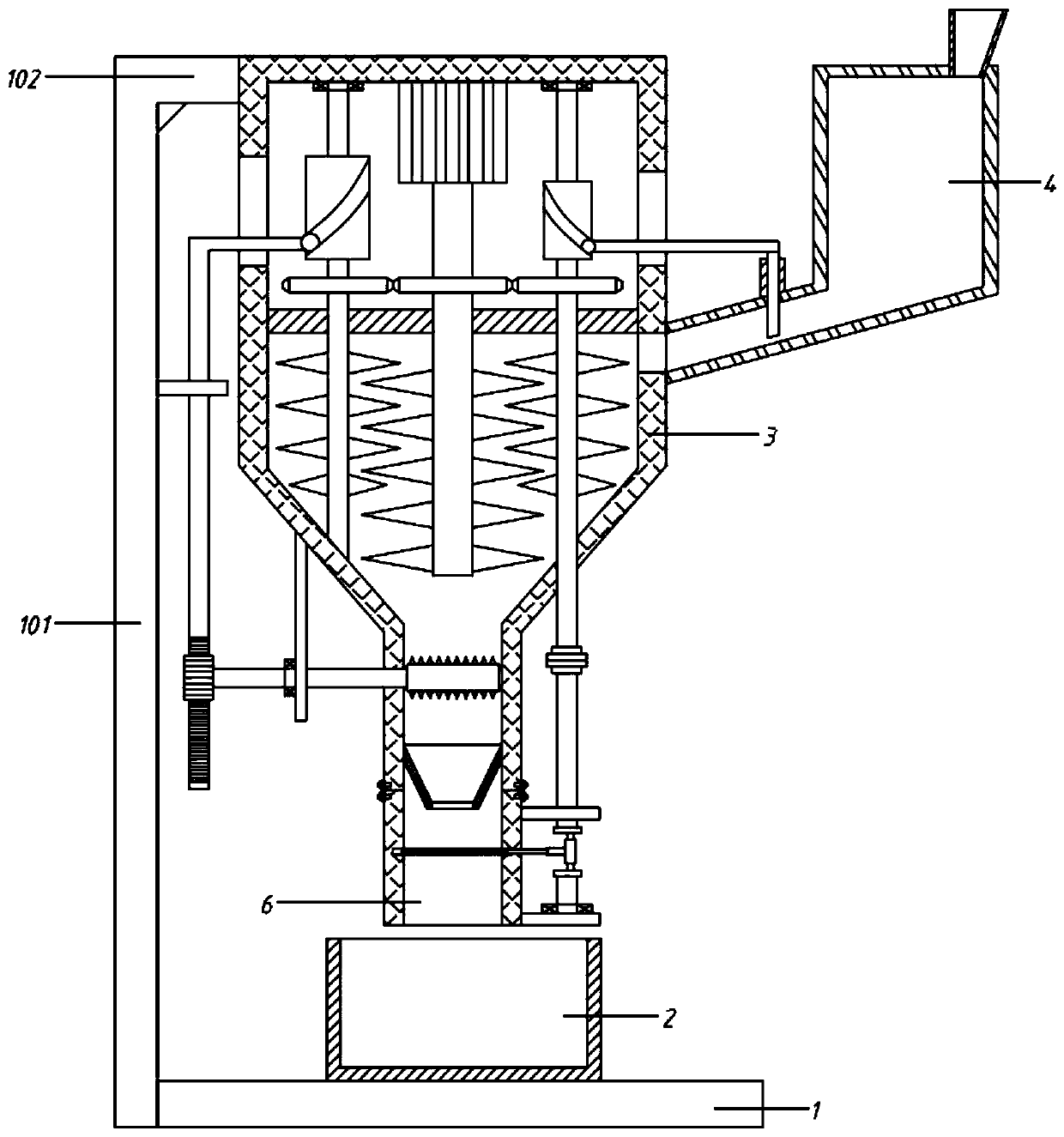

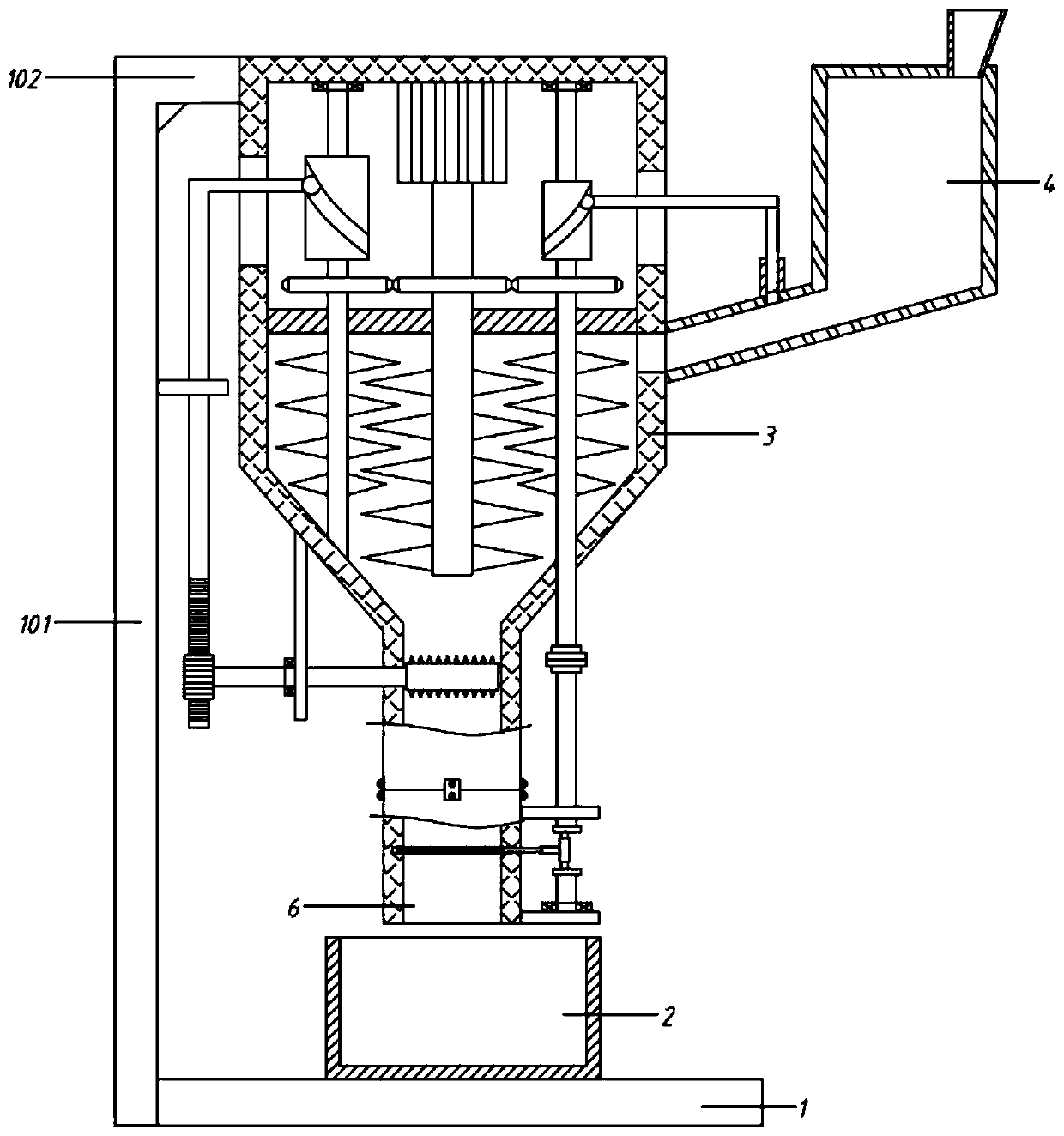

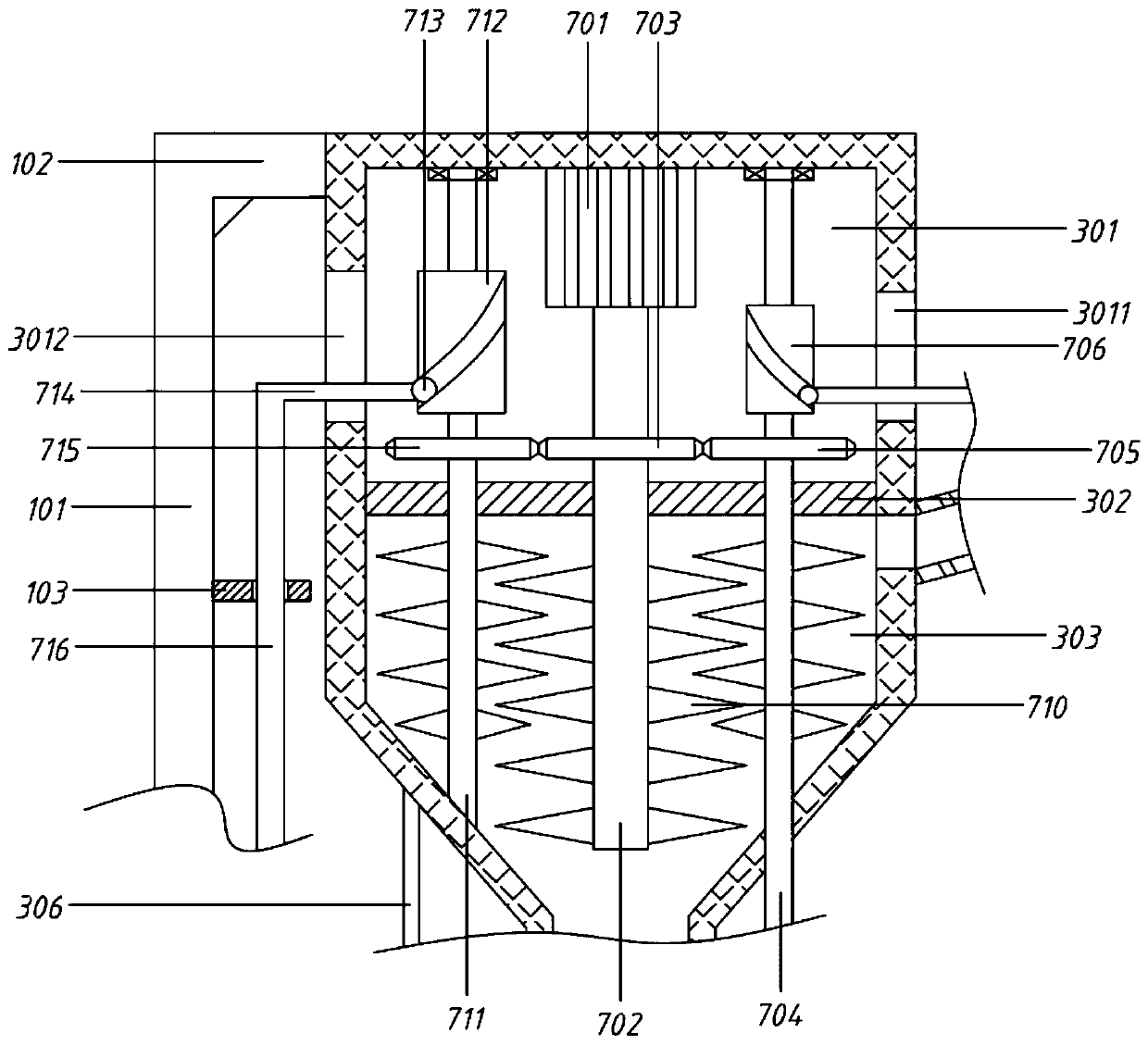

[0051] A sand screening machine for building construction that can prevent filter screens from clogging, comprising a housing 3 and a filter pipe 6;

[0052] A partition 302 is fixed inside the housing 3, which divides the inner cavity of the housing 3 into a transmission chamber 301 and a crushing chamber 303;

[0053] A servo motor 701 is installed on the top of the transmission chamber 301, and the output end of the servo motor 701 is connected with a vertical No. 1 rotating shaft 702 downward. The No. 1 rotating shaft 702 passes through the partition 302 and extends into the crushing chamber 303; The second rotating shaft 704 is installed in parallel, the first rotating shaft 702 is equipped with a first gear 703, the first gear 703 is located above the partition 302, the second rotating shaft 704 is correspondingly equipped with a second gear 705, the second gear 705 and the first gear 703 Engagement, the second rotating shaft 704 also passes through the partition 302 and...

Embodiment 2

[0057] A sand screening machine for building construction that can prevent filter screens from clogging, comprising a housing 3 and a filter pipe 6;

[0058] A partition 302 is fixed inside the housing 3, which divides the inner cavity of the housing 3 into a transmission chamber 301 and a crushing chamber 303;

[0059] A servo motor 701 is installed on the top of the transmission chamber 301, and the output end of the servo motor 701 is connected with a vertical No. 1 rotating shaft 702 downward. The No. 1 rotating shaft 702 passes through the partition 302 and extends into the crushing chamber 303; The second rotating shaft 704 is installed in parallel, the first rotating shaft 702 is equipped with a first gear 703, the first gear 703 is located above the partition 302, the second rotating shaft 704 is correspondingly equipped with a second gear 705, the second gear 705 and the first gear 703 Engagement, the second rotating shaft 704 also passes through the partition 302 and...

Embodiment 3

[0064] A sand screening machine for building construction that can prevent filter screens from clogging, comprising a housing 3 and a filter pipe 6;

[0065] A partition 302 is fixed inside the housing 3, which divides the inner cavity of the housing 3 into a transmission chamber 301 and a crushing chamber 303;

[0066] A servo motor 701 is installed on the top of the transmission chamber 301, and the output end of the servo motor 701 is connected with a vertical No. 1 rotating shaft 702 downward. The No. 1 rotating shaft 702 passes through the partition 302 and extends into the crushing chamber 303; The second rotating shaft 704 is installed in parallel, the first rotating shaft 702 is equipped with a first gear 703, the first gear 703 is located above the partition 302, the second rotating shaft 704 is correspondingly equipped with a second gear 705, the second gear 705 and the first gear 703 Engagement, the second rotating shaft 704 also passes through the partition 302 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com