Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Achieve secondary crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

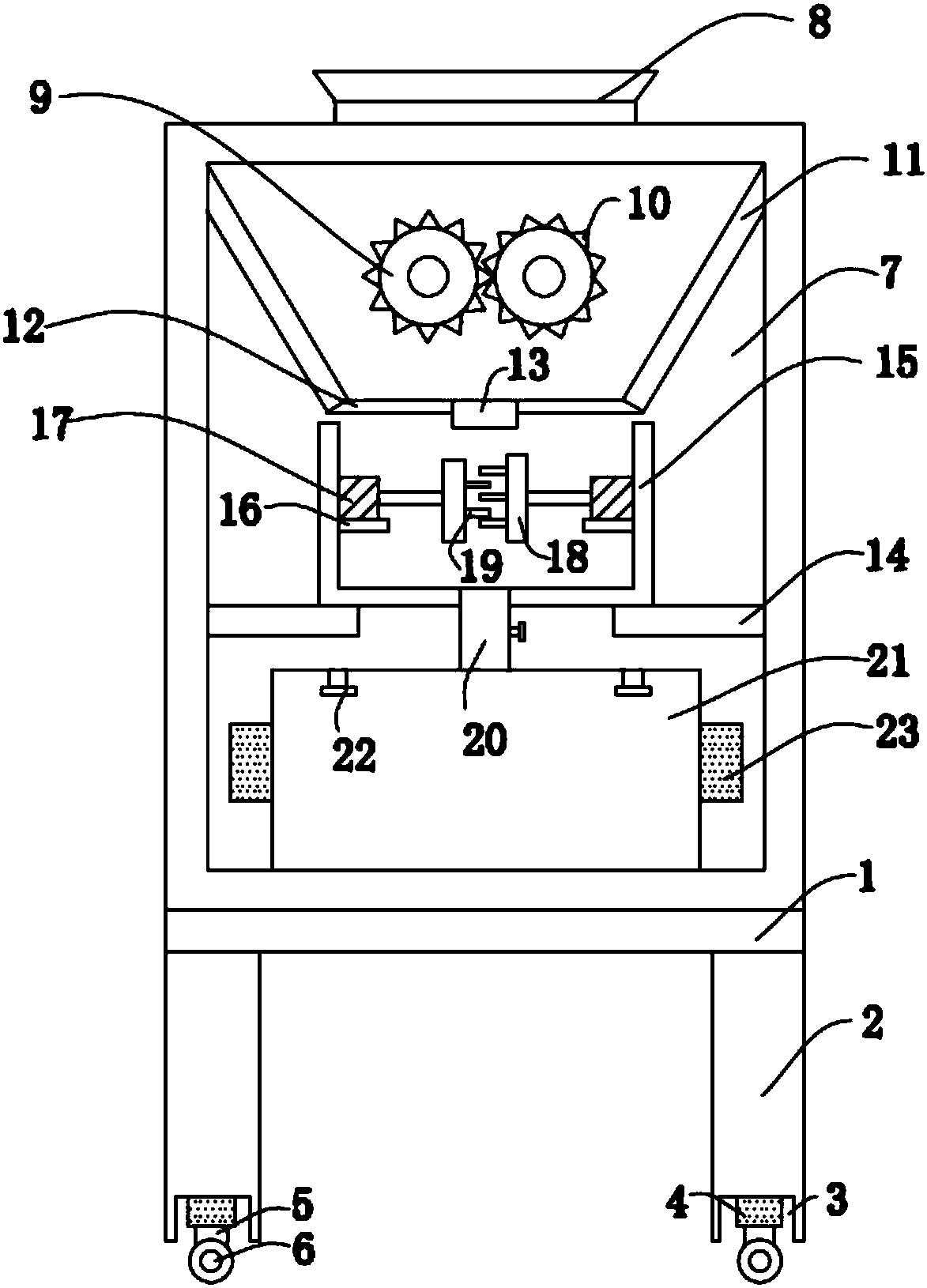

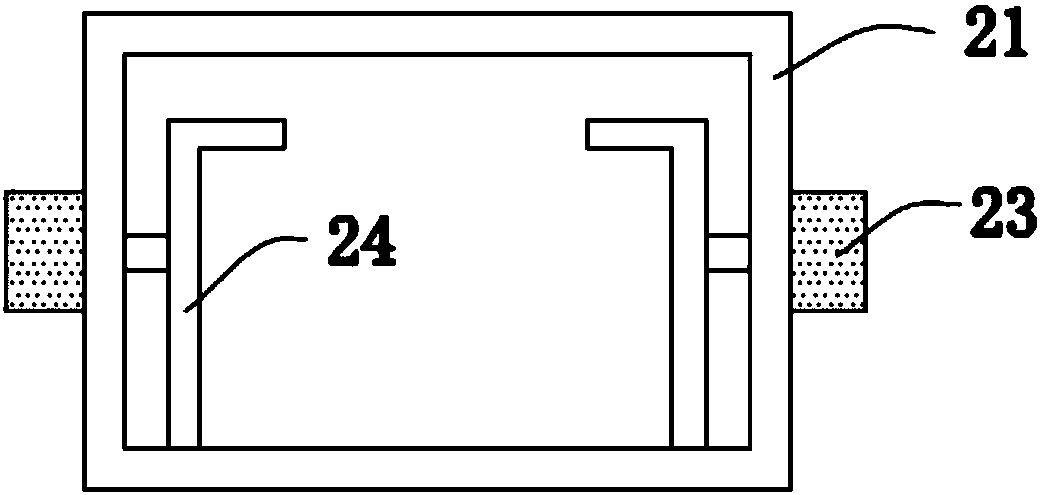

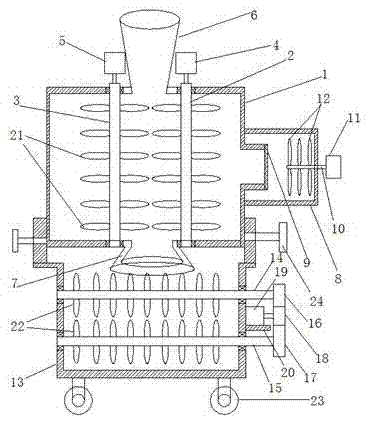

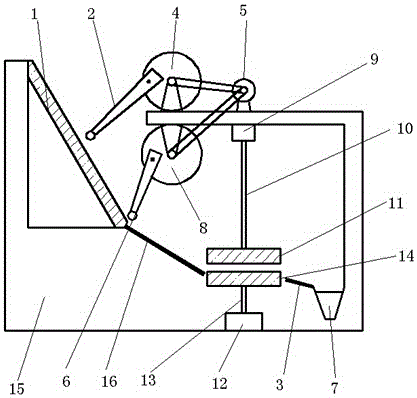

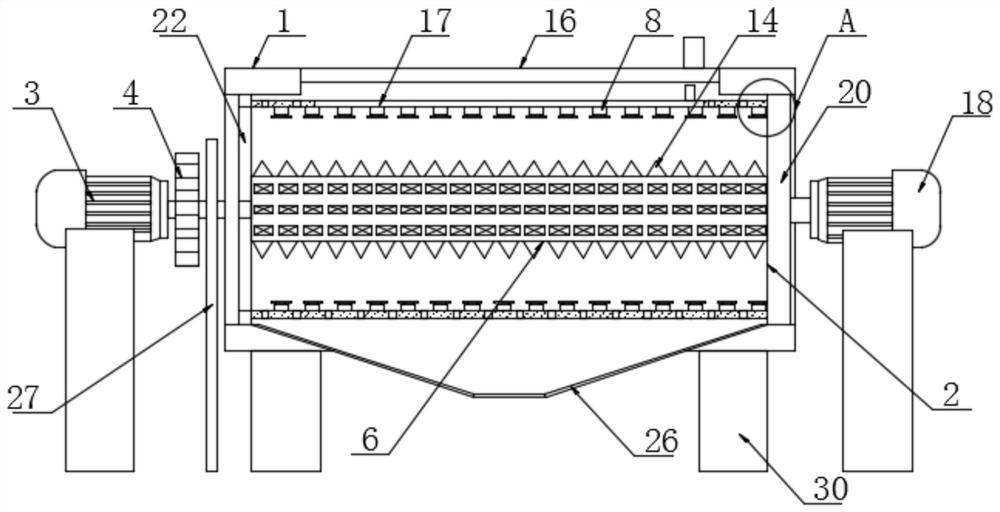

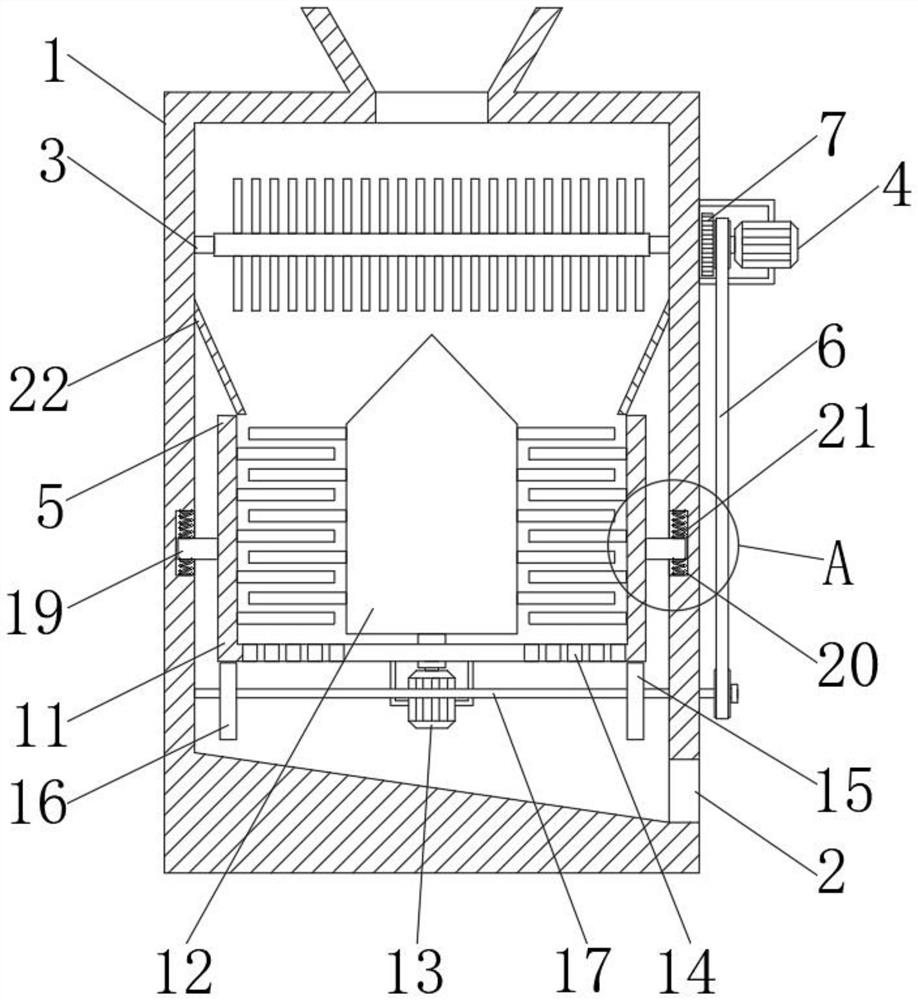

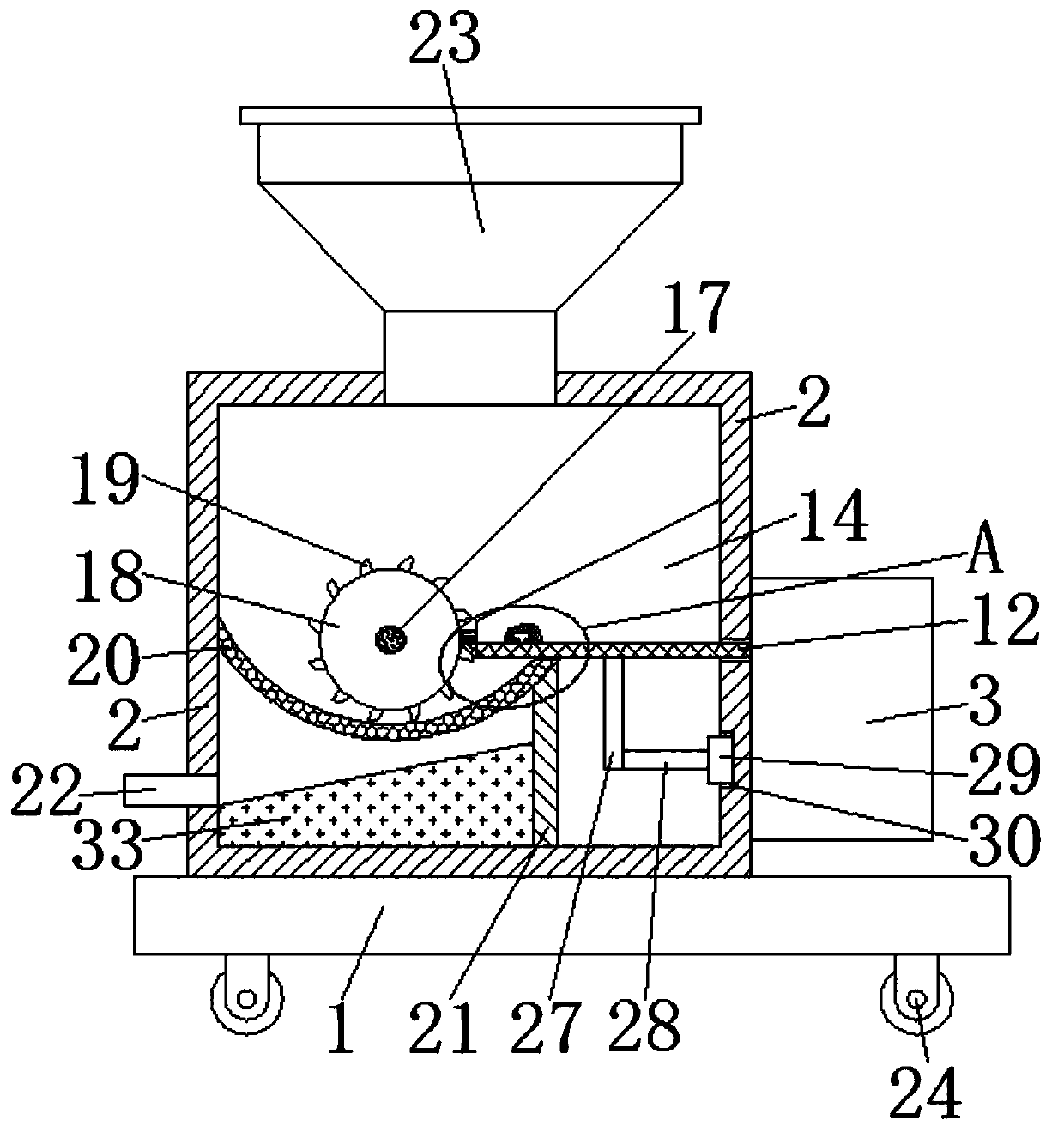

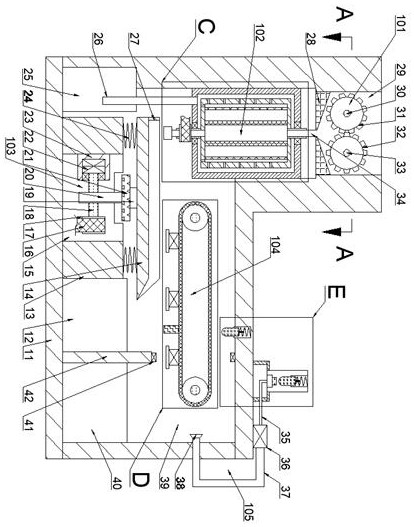

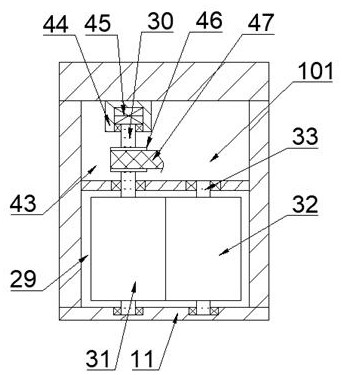

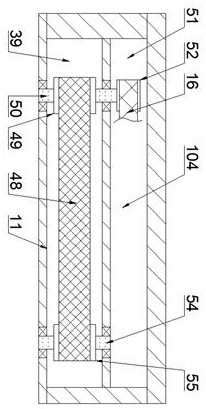

Waste aluminum product crushing and briquetting device

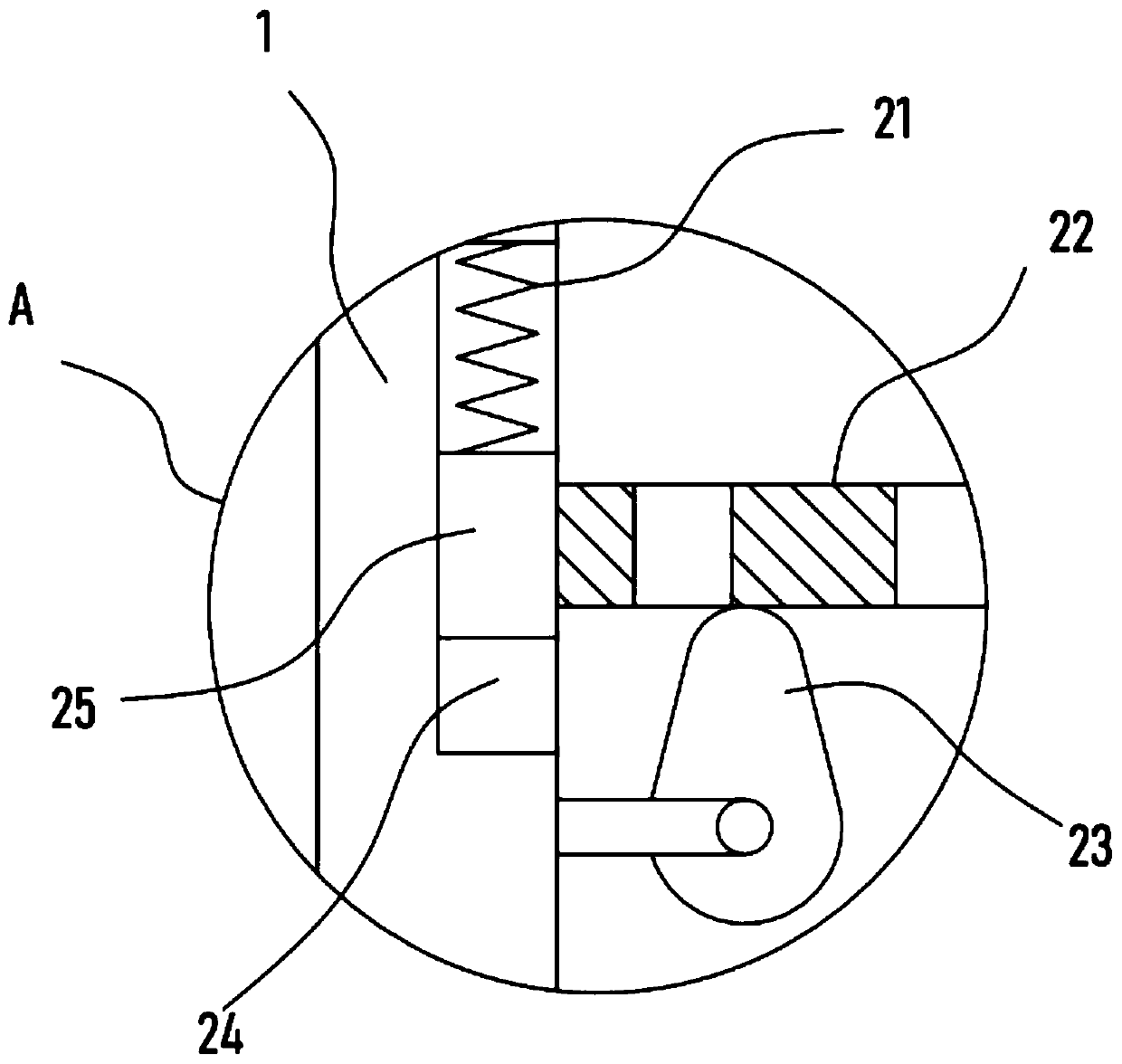

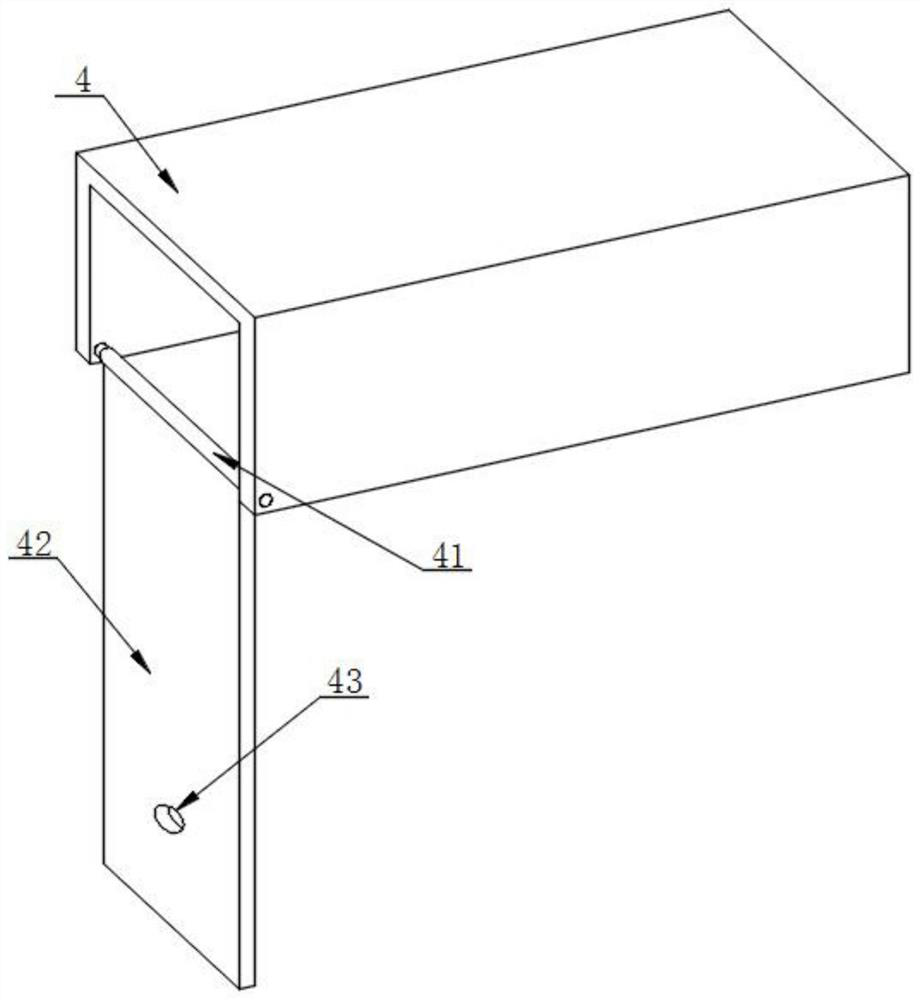

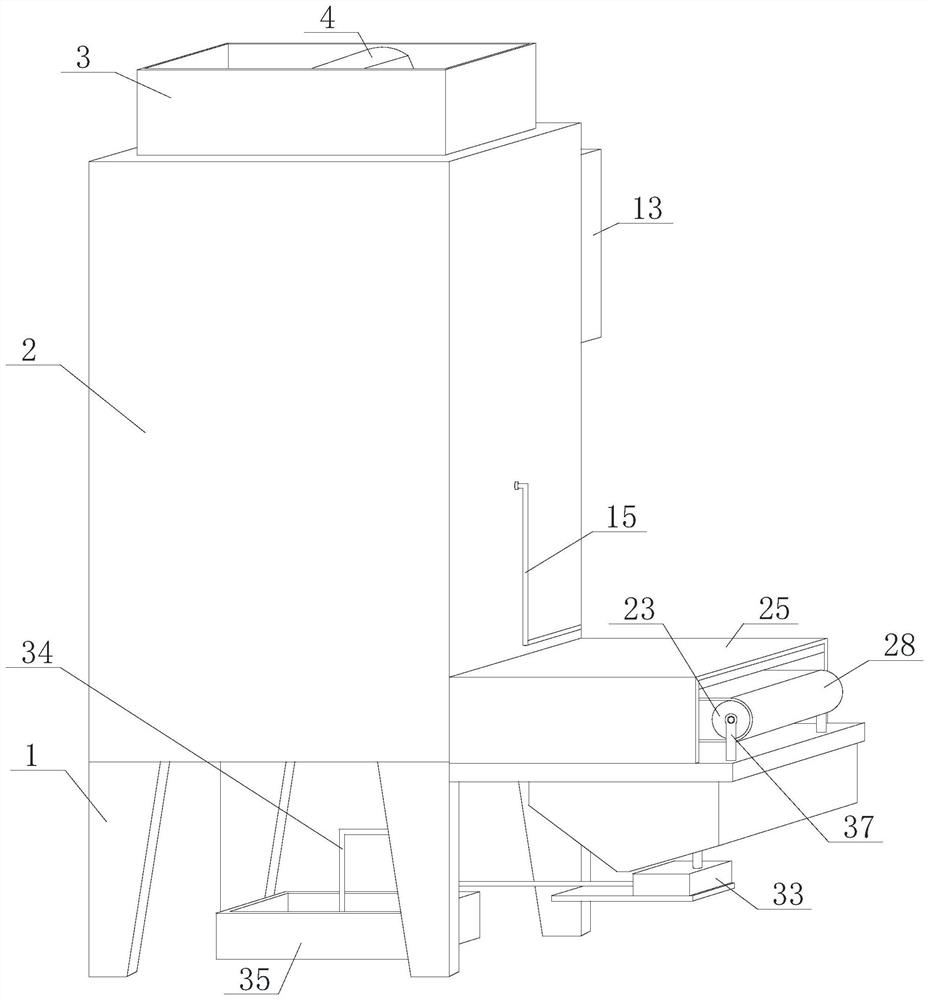

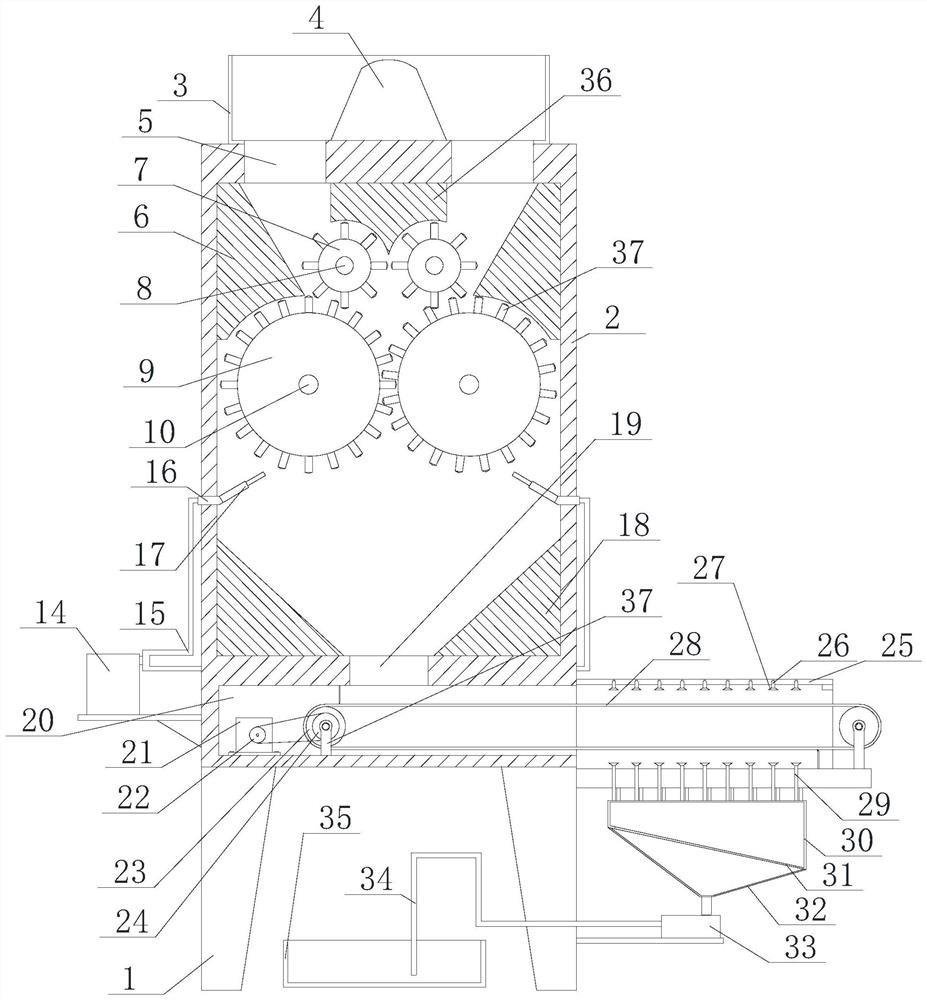

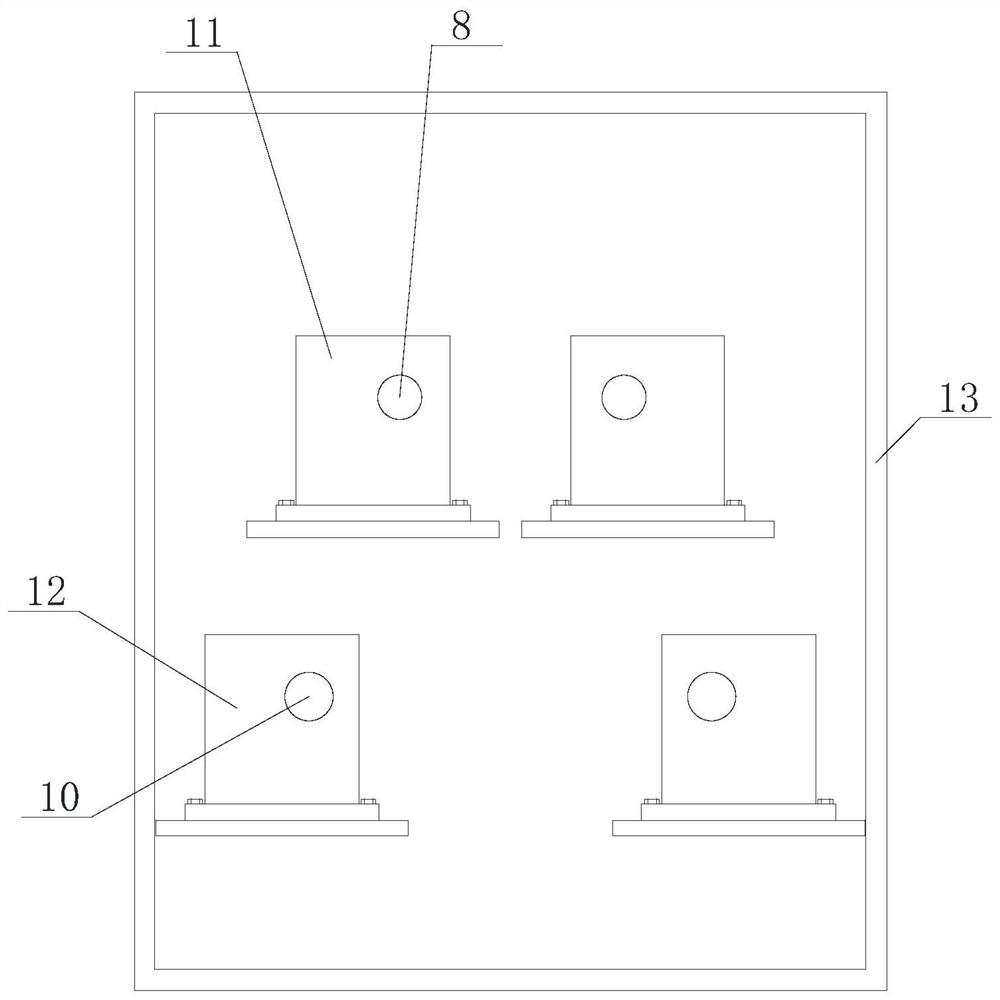

ActiveCN108435308AEasy for primary crushingAchieve secondary crushingCocoaGrain treatmentsHydraulic cylinderCircular disc

The invention discloses a waste aluminum product crushing and briquetting device which comprises a supporting seat. Supporting legs are arranged at the four corners of the bottom of the supporting seat. First hydraulic cylinders are mounted at the tops of the inner sides of grooves. The output end of each first hydraulic cylinder is connected with a rolling wheel support through a piston rod. A rolling wheel is mounted at the bottom of each rolling wheel support. Motors are started, crushing discs can rotate, and therefore second crushing teeth are driven to rotate, and second-stage crushing on waste aluminum products is achieved; second hydraulic cylinders are started to drive compaction blocks to move left and right, and crushed materials entering a briquetting box are compacted; the compaction blocks are arranged in L shapes, the compaction blocks can be conveniently formed to be in block shapes, and storage is convenient; through cooling fans symmetrically arranged at the top of the briquetting box, an inner cavity of the briquetting box can be cooled conveniently, and high practicality is achieved; and the use functionality of the waste aluminum product crushing and briquetting device is greatly improved, the use effect of the waste aluminum product crushing and briquetting device is guaranteed, and the waste aluminum product crushing and briquetting device is suitable forbeing widely popularized.

Owner:江苏竣昌科技有限公司

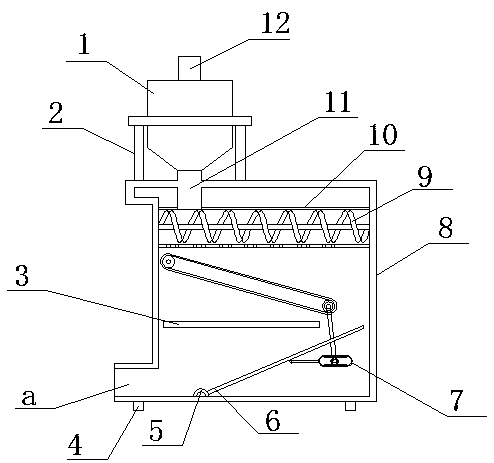

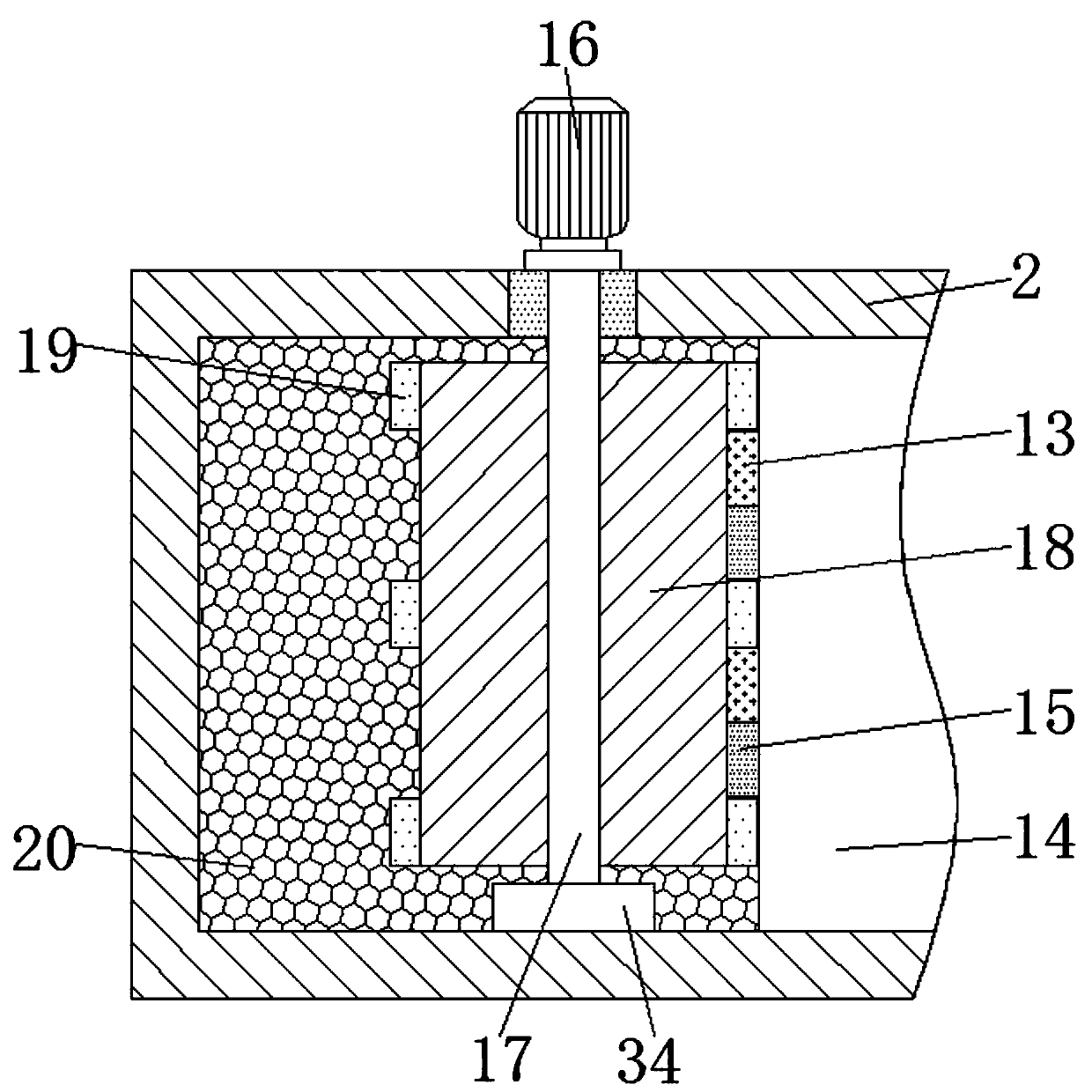

Grain coarse crushing device for agricultural production

InactiveCN108393154AAchieve fragmentationIncrease granularitySievingScreeningDrive shaftSpiral blade

The invention discloses a grain coarse crushing device for agricultural production. The grain coarse crushing device comprises a crushing box, a first motor is fixedly installed at the top of the crushing box vertically, an output shaft of the first motor is coaxially and fixedly provided with a driving shaft extending into the crushing box, the surface of the driving shaft is fixedly provided with a driving belt wheel in a sleeved manner, the right end of a screen plate is hinged to the inner wall of the right side of the crushing box, the left end of the screen plate is fixedly provided withan extending plate extending to the exterior of the crushing box, and a fixing plate is fixedly installed on the outer wall of the left side of the crushing box; and a movable door is rotationally installed on the side wall of the crushing box through a hinge. According to the grain coarse crushing device, the grain particle crushing effect is achieved through rotation of a crushing blade, the rotating shaft is used for driving a longitudinal pulling plate to rotate to pull grains to the crushing blade to achieve secondary crushing, a spiral blade circulates the grains in a lifting barrel tothe crushing box to achieve the repeated crushing effect, the grain refining degree is greatly improved, crushing is more thorough, and the crushing efficiency is high.

Owner:COMMON TECH DEV CO LTD

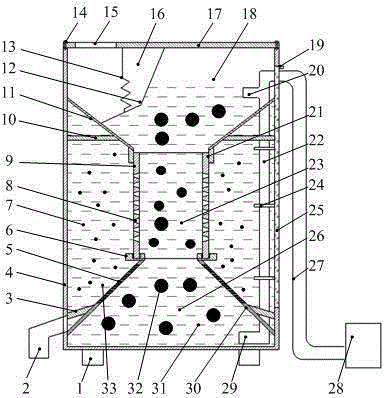

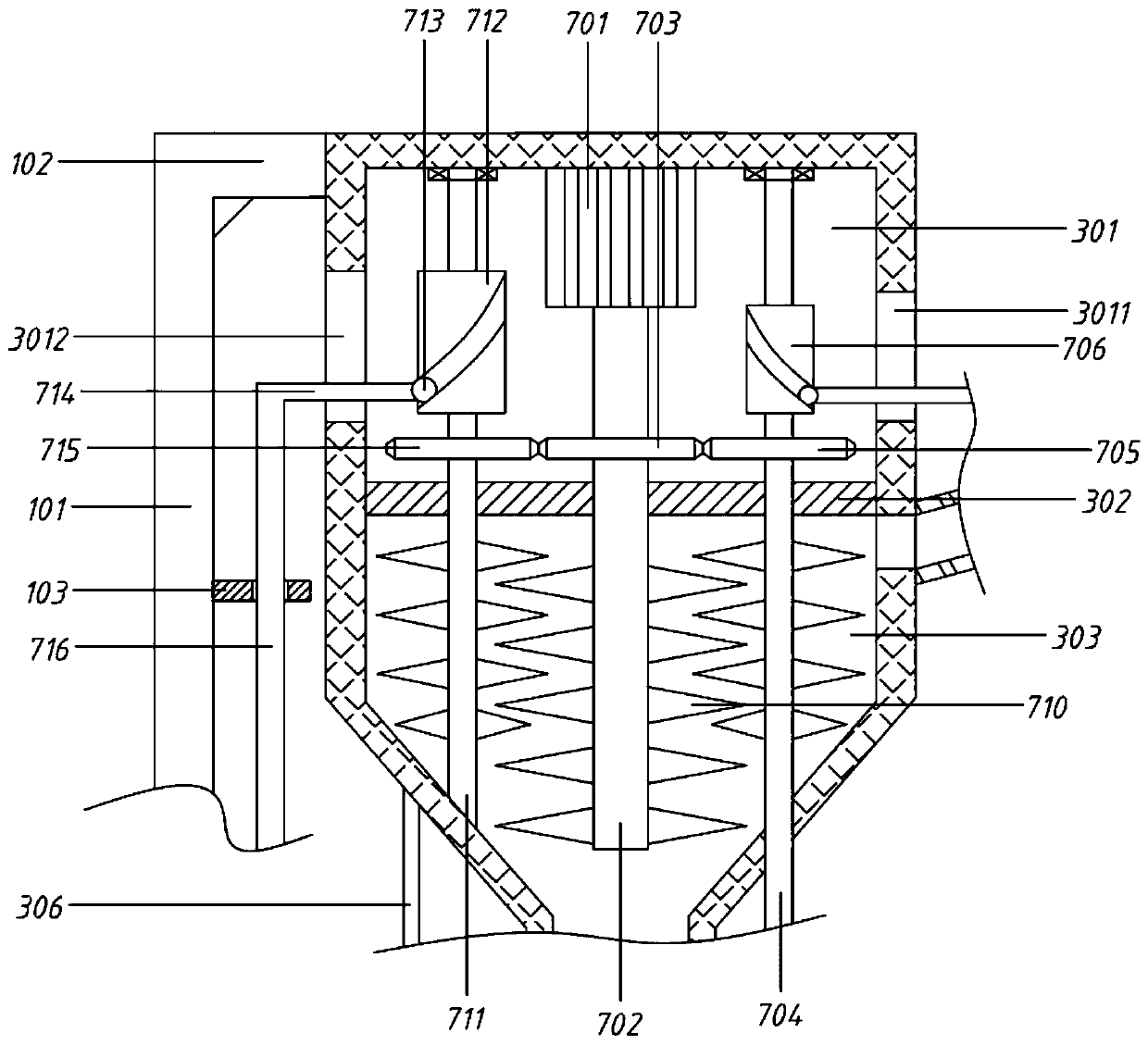

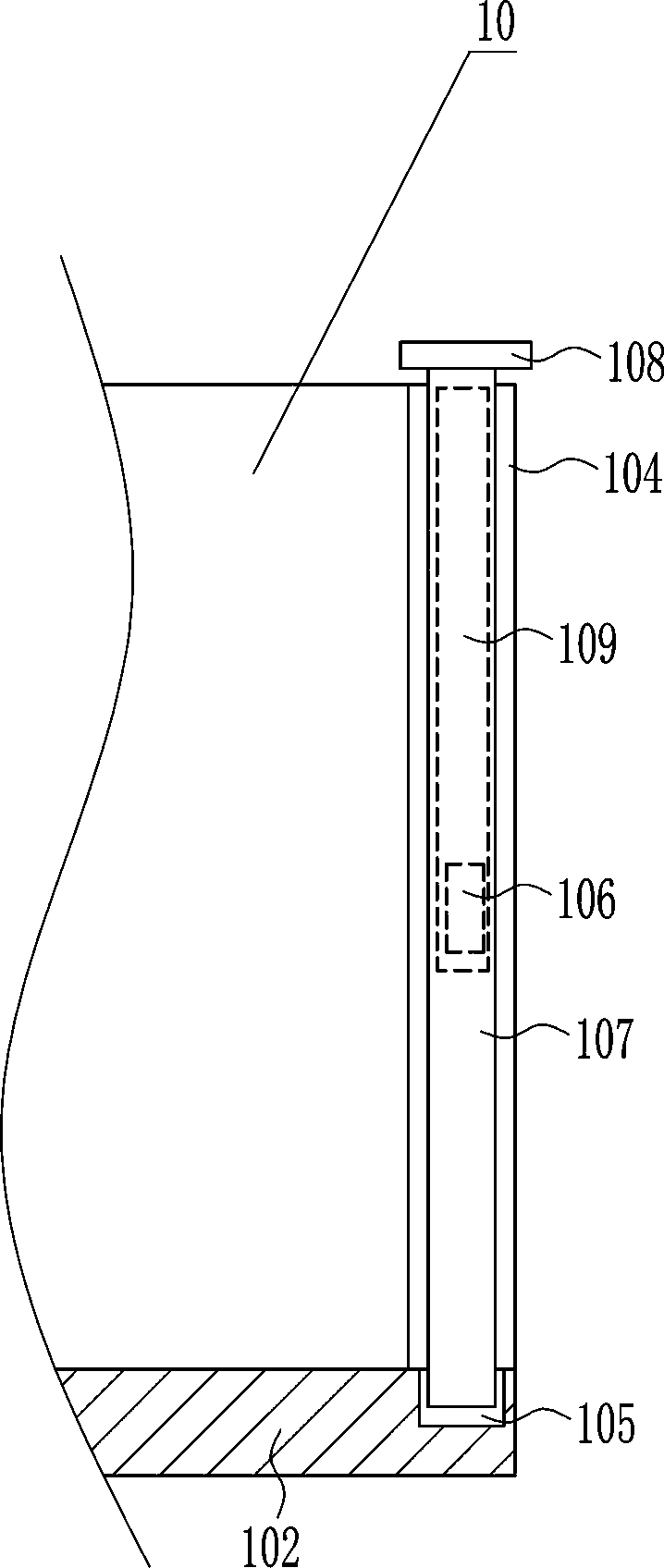

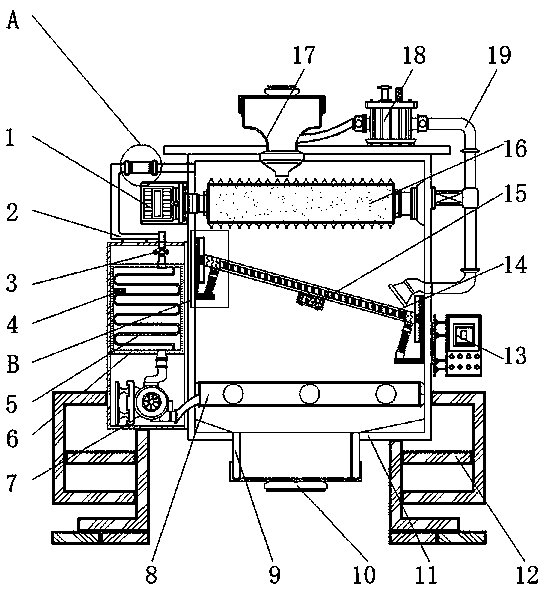

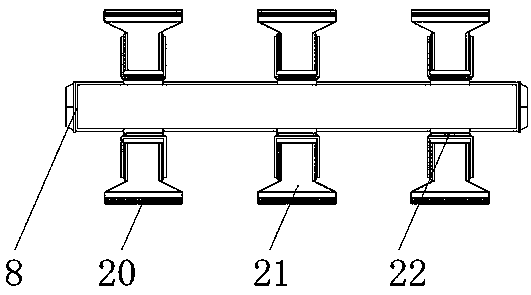

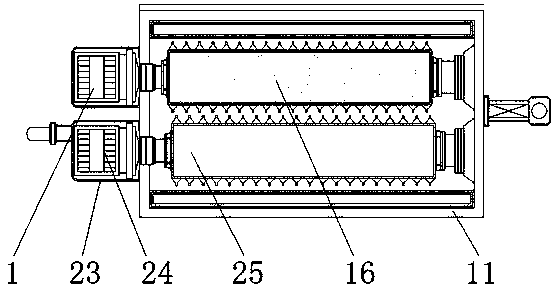

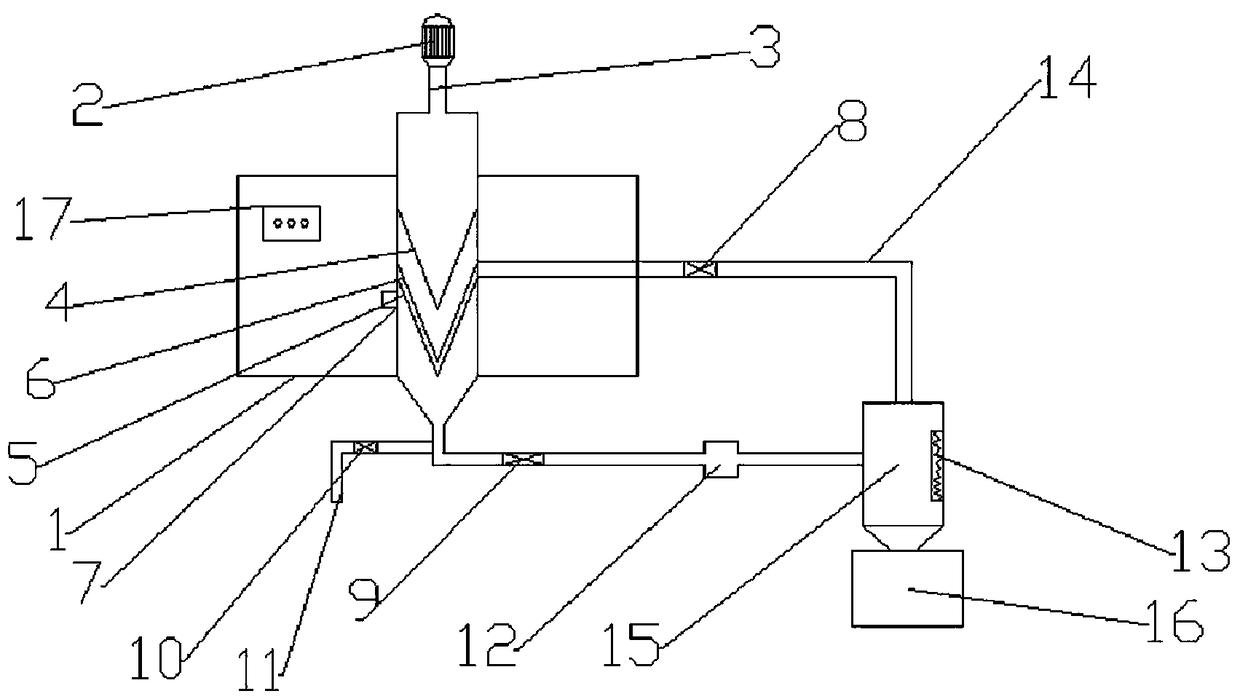

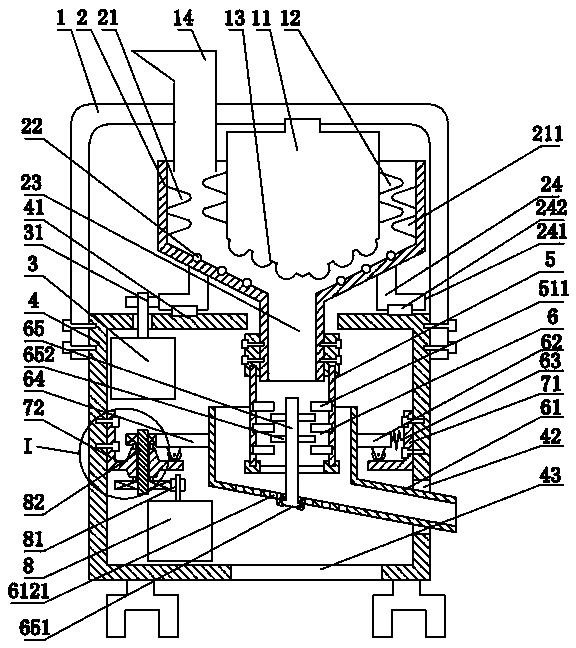

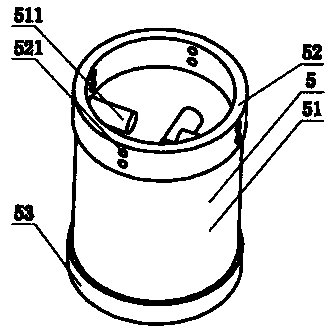

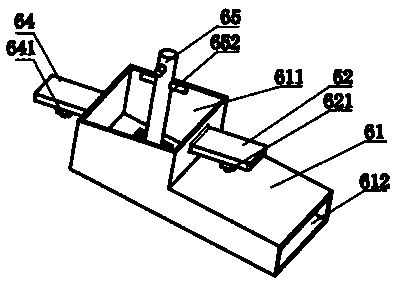

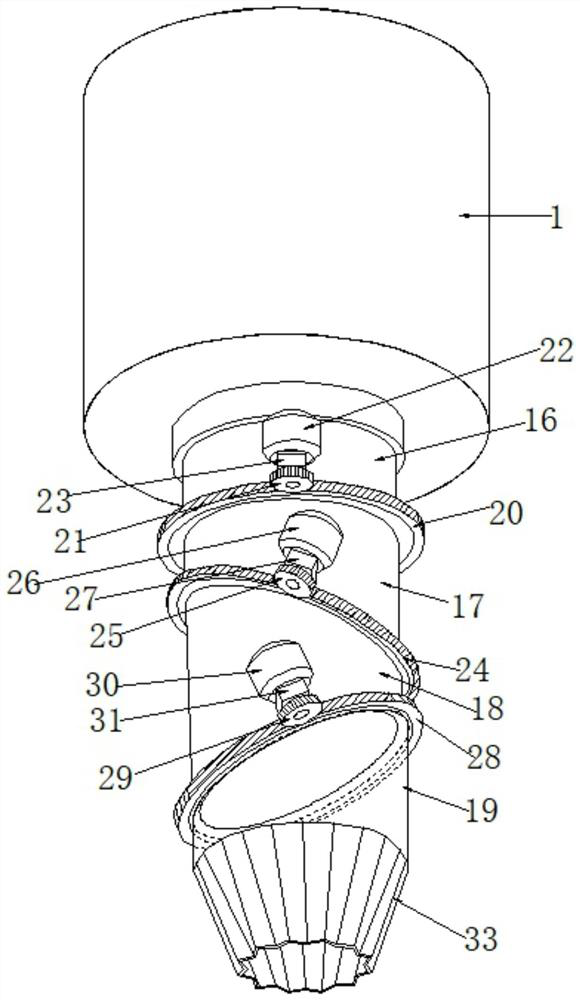

Hedging twisting double-vortex kinetic energy pulping equipment

InactiveCN105155321AAchieve primary crushingAchieve secondary crushingPaper recyclingRaw material divisionFiltrationEngineering

The invention provides hedging twisting double-vortex kinetic energy pulping equipment. The equipment mainly comprises a water charging and feeding device, an air charging device, an upper vortex kinetic energy generating device, a lower vortex kinetic energy generation device, a smashing and filtering device and a liquid slurry storing device. The hedging twisting double-vortex kinetic energy pulping equipment is characterized by reverse vortex hedging twisting material breaking. Feeding amount can be controlled and a water charging and feeding buffering area can be sealed via a buffering plate; a liquid level can be controlled by a highest liquid level indicating rod and a liquid level observation plate; with an anticlockwise upper air inlet and a clockwise lower air inlet and an upper and lower conical cylinders, upper and lower vortex air flows can be accelerated, hedging twisting smashing force and equipment homonymous impact vibration can be achieved; with conical holes having large inner holes and small outer holes and arranged in an intersected way, broken material filtration and blocking prevention can be realized; filtering efficiency and impact stirring can be improved; fluid mutual flow between a slurry storage area and the lower vortex kinetic generation area and slurry storage area impact stirring can be realized via parallel holes.

Owner:UNIV OF JINAN

Sand screening machine capable of preventing filter screen from being blocked for building construction

The invention relates to the technical field of sand screening equipment, in particular to a sand screening machine capable of preventing a filter screen from being blocked for building construction.The sand screening machine capable of preventing the filter screen from being blocked for building construction has the advantages that a first rotating shaft is driven to rotate based on a servo motor, a second rotating shaft is driven to rotate through gear transmission, on one hand, coarse sand enters a crushing cavity from a feeding hopper, crushing is carried out under the action of a crushing cutter; on the other hand, the second rotating shaft further drives a fourth rotating shaft to rotate through a coupler, a crank throw rotates along with the fourth rotating shaft, a first connecting rod and a second connecting rod drive the filter screen to shake left and right, the filtering efficiency is improved, the filter screen is prevented from being blocked; the fact that a filter pipeis detachably connected with the shell is adopted in conjunction with the coupler connection mode of the fourth rotating shaft and the second rotating shaft, so that the filter pipe is integrally detached conveniently, the coarse sand is conveniently removed; and the second rotating shaft is used for driving a first cylindrical cam to rotate, a first supporting rod drives a baffle plate to move upand down, the baffle plate periodically enters and exits a feeding pipe, blocking or communicating for feeding are carried out, and intermittent feeding is achieved.

Owner:安徽乐秀信息科技有限公司

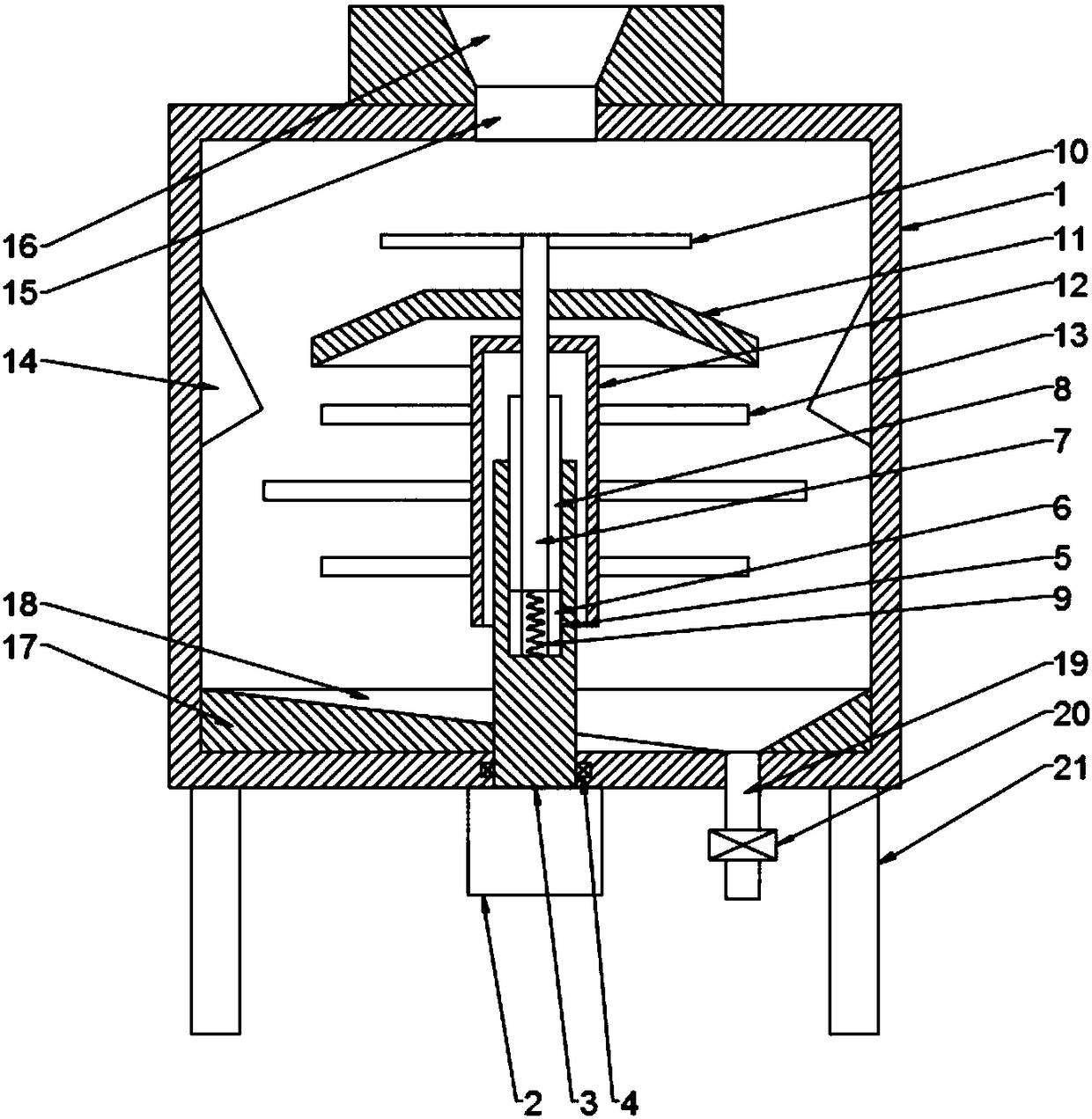

Ceramic waste crushing device based on aperiodic technology

ActiveCN108160214AAchieve secondary crushingGuaranteed complete shreddingGrain treatmentsEngineeringCircular face

The invention discloses a ceramic waste crushing device based on an aperiodic technology. The ceramic waste crushing device comprises a box body, a motor is arranged in the center of the bottom end ofthe box body, and a rotary shaft is fixedly connected with a motor shaft of the motor. A lifting groove hole is formed in the top end of the rotary shaft and internally provided with a lifting rotaryshaft, a spring is fixedly connected to the bottom end of the lifting rotary shaft, and a plurality of crushing rods are arranged at the top end of the outer circular face of the lifting rotary shaftin a circularly arrayed mode. The upper portion of the outer circular face of the lifting rotary shaft is sleeved with a flow guide cover, the outer circular face of the lifting rotary shaft is sleeved with a sleeve matched with the rotary shaft, and a plurality of movable crushing knives with different lengths are evenly arranged on the outer circular face of the sleeve. According to the ceramicwaste crushing device, under the joint effect of the crushing rods and the flow guide cover, preliminary crushing is conducted, waste is thrown to the periphery of an inner cavity of the box body toimpact fixed crushing knives, and thus secondary crushing of the thorn-picking waste is achieved; and ceramic waste fragments subjected to secondary crushing fall at the bottom of the inner cavity ofthe box body, and under the effect of the movable crushing knives, third-time crushing is conducted, so that complete crushing of the ceramic waste is ensured.

Owner:张新兴

Municipal environmental sanitation road ice and snow clearing device

The invention discloses a municipal environmental sanitation road ice and snow clearing device, and relates to the technical field of municipal machinery. The municipal environmental sanitation road ice and snow clearing device comprises a vehicle body, a snow shoveling mechanism comprising a shovel plate is arranged at the end of the vehicle body, a lifting cylinder with a built-in lifting mechanism is vertically fixed on the vehicle body, a crushing mechanism used for crushing ice and snow is arranged below a conveying pipe, a mesh plate is arranged at the bottom of the crushing mechanism ina vibrating mode, and a heating plate is arranged at the bottom of the mesh plate. According to the municipal environmental sanitation road ice and snow clearing device, ice and snow on a road are shoveled through the arranged shovel plate, the ice and snow are primarily crushed through the crushing mechanism, then the ice and snow are conveyed through the lifting mechanism so that the ice and snow can be secondarily crushed in the lifting process; and meanwhile, a crushing roller I and a crushing roller II in the crushing mechanism rotate, and the net plate vibrates up and down so that the ice and snow can be repeatedly crushed and refined by the crushing mechanism, then the heating plate is used for heating and melting the refined ice and snow in the subsequent process, the ice and snowform a stream to flow out, then the ice and snow can be converted into the liquid state from the solid state, and then the ice and snow accumulated on the road can be fundamentally removed.

Owner:包伟进

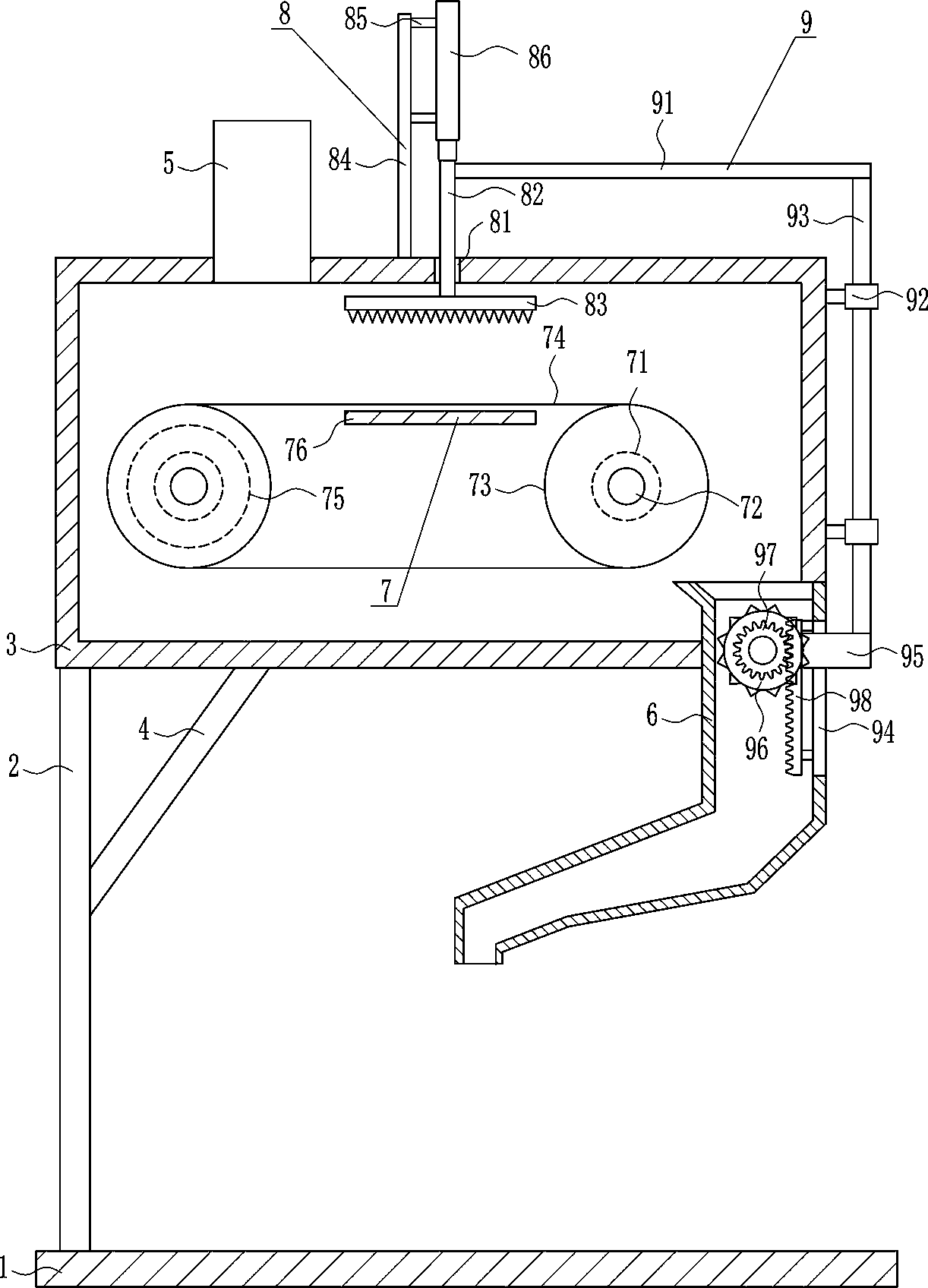

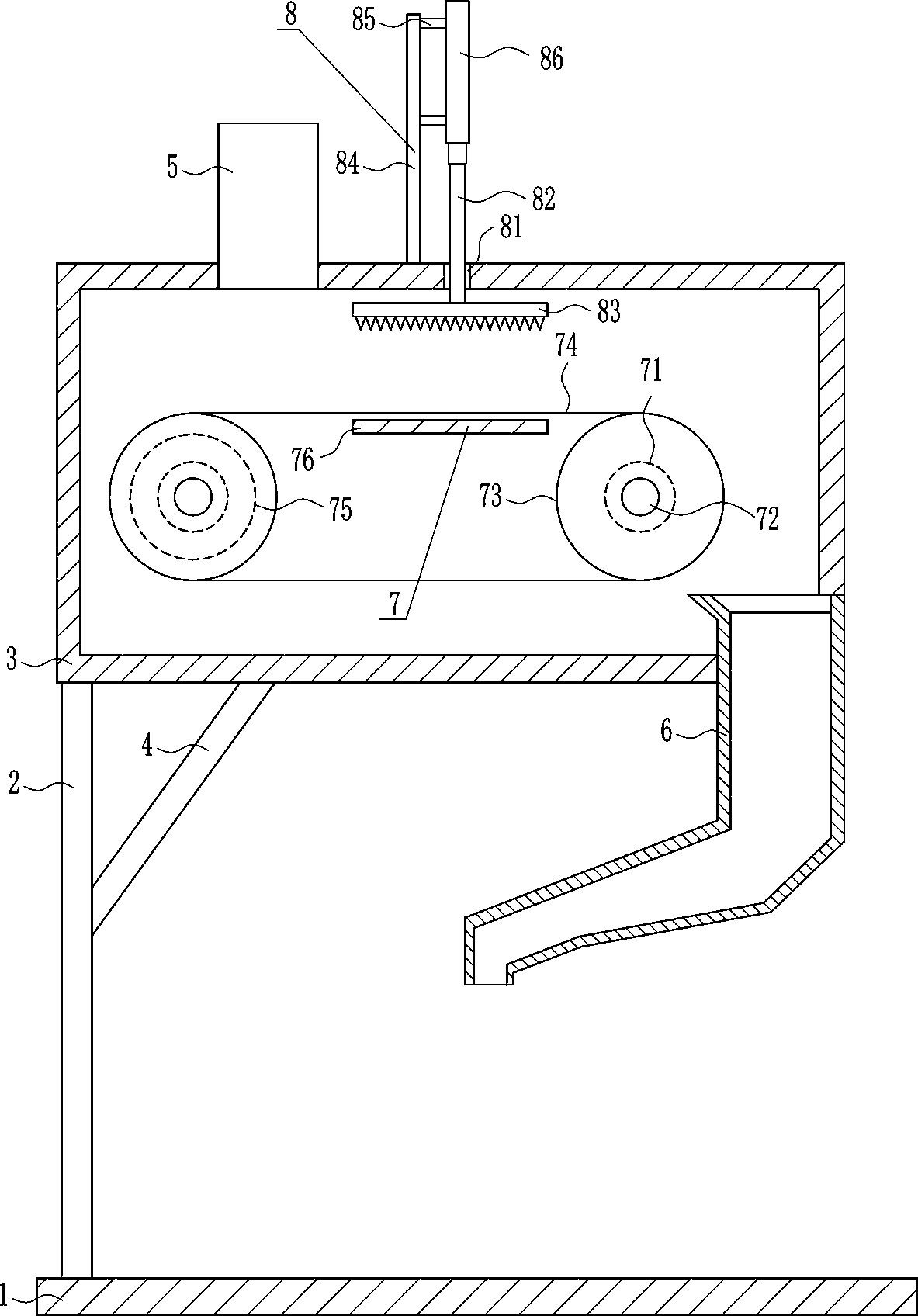

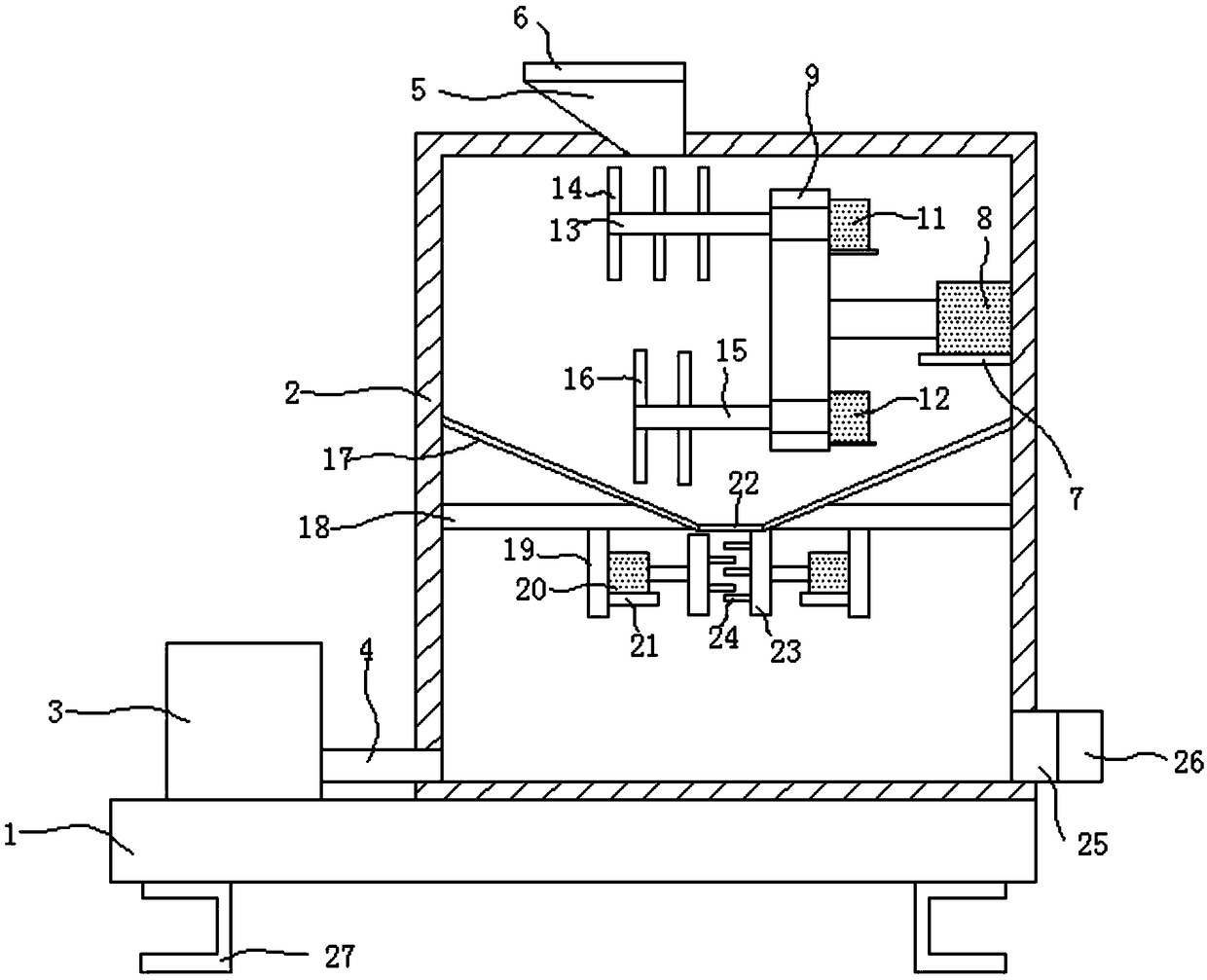

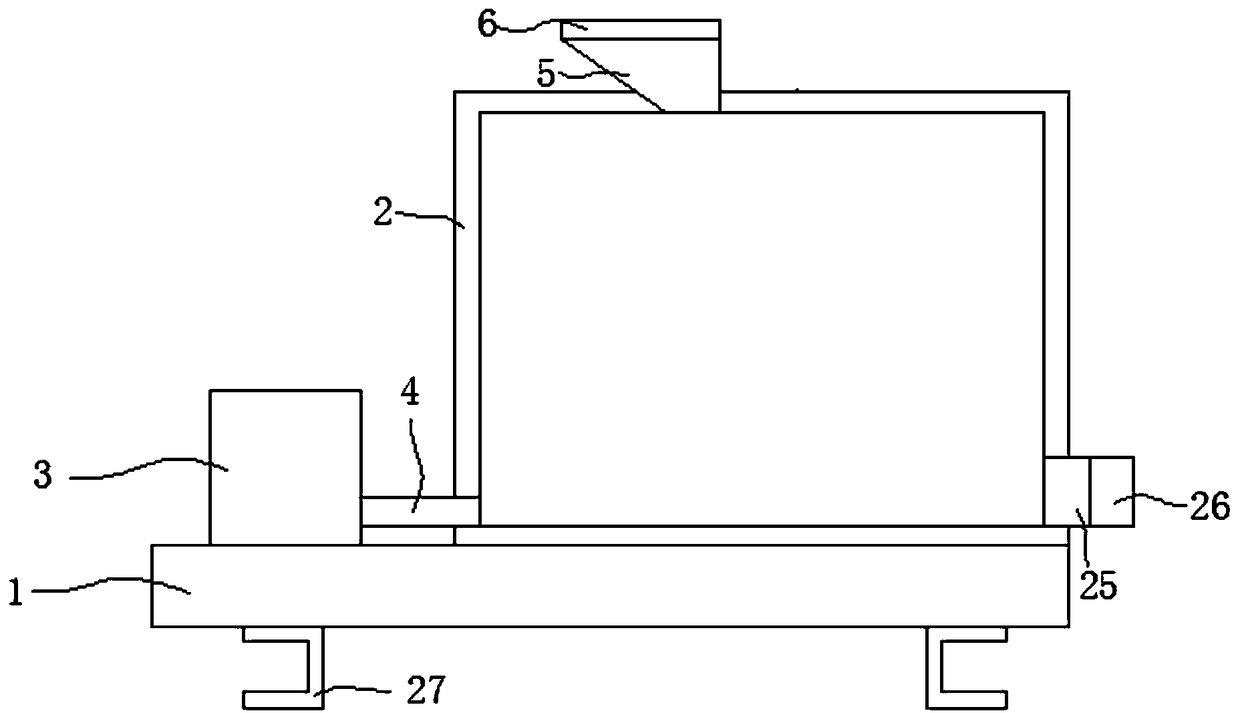

Crushing device for medical glass infusion bottles

InactiveCN108772127APlay a buffer roleAchieve secondary crushingConveyorsGrain treatmentsMedicineBottle

The invention relates to a crushing device, in particular to a crushing device for medical glass infusion bottles. The invention aims at providing a crushing device, which is capable of performing secondary crushing on the glass infusion bottles and also can collect and treat the crushed infusion bottles, for the medical glass infusion bottles. The crushing device for the medical glass infusion bottles is characterized in that the crushing device comprises a bottom plate, a supporting leg, a box body, a reinforcing rib, a feed pipe, and the like, wherein the supporting leg is installed at theleft of the top of the bottom plate, and the box body is installed at the top end of the supporting leg; the reinforcing rib is connected between the left of the bottom of the exterior of the box bodyand the upper part of the right side of the supporting leg; the feed pipe is installed at the left of the top of the exterior of the box body. According to the crushing device for the medical glass infusion bottles, the glass infusion bottles are conveyed by means of a conveying device and are subjected to primary crushing by means of a first crushing device; a second crushing device is also arranged, so that the glass infusion bottles are further crushed; therefore, the effects of enabling the glass infusion bottles to be subjected to the secondary crushing and collecting and treating the crushed infusion bottles can be achieved.

Owner:李春明

Rhizoma atractylodis processing device capable of achieving pulverizing and drying

InactiveCN110756267AReduce heat lossEasy disassembly and cleaningSievingScreeningHot blastElectric machinery

The invention discloses a rhizoma atractylodis processing device capable of achieving pulverizing and drying. A first drive motor, a temperature sensor, a body and a bearing frame are included. Through installation of a silencing cover, a PLC, a heating wire, a temperature sensor, an air guiding main pipe, a body, an air guiding branch pipe and filter cloth, the device can heat gas through the heating wire, the temperature sensor is used for monitoring the gas temperature situation in a hot air cavity constantly, the monitored data are sent to the PLC, once the temperature reaches the preset value, the PLC can control the heating wire to power off and stop heating, and a good temperature control heating function is achieved. By utilization of the functions of the air guiding main pipe andthe air guiding branch pipe, hot airflow can be evenly guided into the body, and uniformity during drying is improved; and through the arrangement of the filter cloth, the situation that dust scraps in the body enter the air guiding main pipe and the air guiding branch pipe, and blockage is caused can be avoided, and accordingly the practicability of the device is enhanced.

Owner:湖北宏图中药材科技有限公司

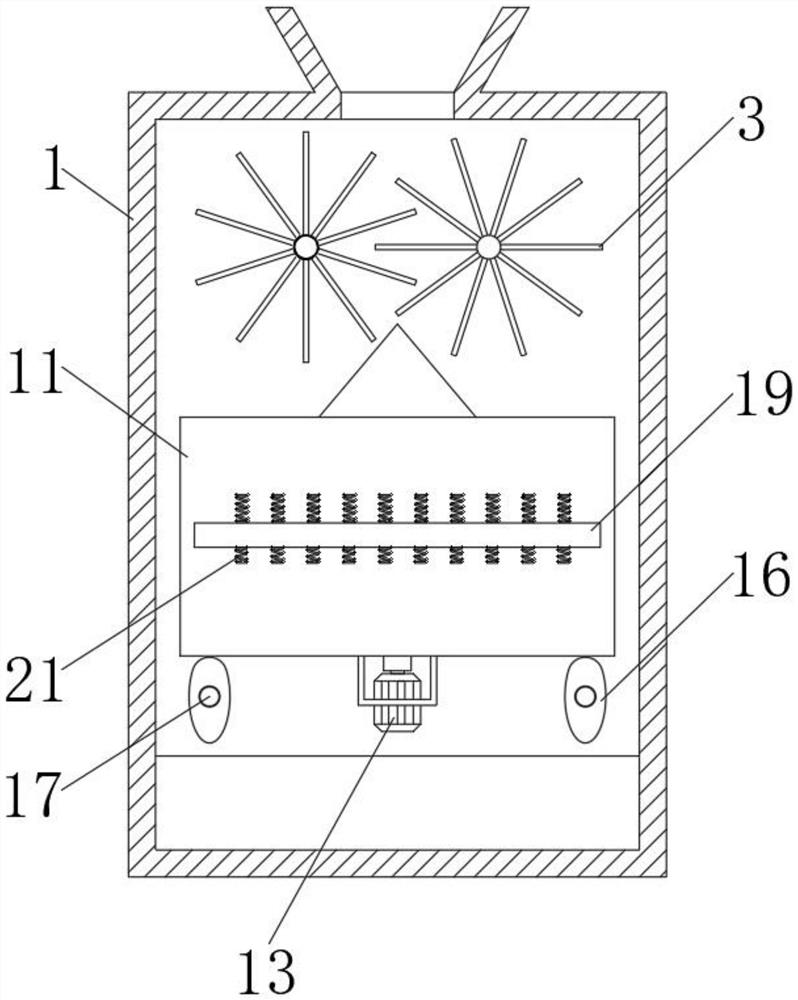

Multifunctional straw fodder producing and pulverizing processing machine

InactiveCN106861881AAchieve secondary crushingGood effect on crushing strawGrain treatmentsAgricultural engineeringDrive motor

The invention belongs to the technical field of agricultural machinery and equipment, and discloses a multifunctional straw feed production crushing machine. A left crushing shaft and a right crushing shaft are installed on the left and right sides of the first straw crushing cavity, and a left drive motor is installed on the top of the left crushing shaft. The right drive motor is installed on the top of the right crushing shaft, the dust removal port is set on the left side wall of the first straw crushing chamber, the bottom of the first straw crushing chamber is provided with a straw discharge cylinder, and the dust removal cover is installed on the left side of the first straw crushing chamber. The second straw crushing chamber is installed at the bottom of the first straw crushing chamber through fixing bolts, the fan shaft is installed in the dust removal cover, the dust removal blade is installed on the fan shaft, the drive motor is installed on the right end of the fan shaft, and the upper part of the second straw crushing chamber is installed. As for the crushing shaft, the lower crushing shaft is installed in the lower part of the second straw crushing cavity. The present invention adopts the design of the first straw crushing chamber and the second straw crushing chamber to realize the secondary crushing of the straw, which has good straw crushing effect and high crushing efficiency.

Owner:SHAANXI SHANZE AGRI SCI & TECH

Glass crushing device

ActiveCN111468273AThe glass is crushed fully and evenlySave human effortGlass recyclingGrain treatmentsComposite materialEngineering

The invention relates to a glass crushing device. The glass crushing device comprises a box body, a driving mechanism, a first crushing mechanism, a second crushing mechanism and a third crushing mechanism; the first crushing mechanism, the second crushing mechanism and the third crushing mechanism are sequentially arranged in the box body from top to bottom; and the driving mechanism comprises two driving assemblies. According to the glass crushing device, glass is subjected to primary crushing through the first crushing mechanism, a bottom plate vibrates through a vibration mechanism, and collision between the glass and a crushing head is intensified, so that the glass is crushed more sufficiently; the glass is subjected to secondary grinding through the second crushing mechanism, secondary crushing is achieved, and meanwhile, a stirring roller has the stirring effect, so that the glass is crushed more sufficiently and uniformly; the glass is subjected to three-stage crushing throughthe third crushing mechanism, so that the glass is ground into powder; and large glass blocks are crushed into powder step by step through the three stages of crushing mechanisms, the glass is crushed more sufficiently and uniformly, manpower is saved, and the working efficiency is improved.

Owner:山东正信药用玻璃有限公司

Clean-type two-jaw breaking grinding machine and control system thereof

InactiveCN108325692AAchieve a brokenAchieve secondary crushingUsing liquid separation agentDirt cleaningMotor driveControl system

The invention discloses a clean-type two-jaw breaking grinding machine and a control system thereof. The clean-type two-jaw breaking grinding machine comprises a breaking stationary jaw, a first breaking movable jaw, a first breaking flywheel, a breaking motor, a second breaking movable jaw, a second breaking flywheel, a first grinding motor, a first grinding main shaft, a first grinding disc, a second grinding motor, a second grinding main shaft, a second grinding disc, a rack, a breaking discharge channel, a grinding discharge channel, a discharge hopper, a dust hopper, an air pump and a dust collecting box; and the control system consists of a raw material detection module, a material grinding detection module, a flow detection module, a PLC, a first grinding motor driving module, a second grinding motor driving module and a contactor. The clean-type two-jaw breaking grinding machine can achieve primary breaking, secondary breaking and grinding on a raw material, so that the degreeof size reduction of the raw material is raised, and the breaking time is shortened; and the air pump can be started during machining to suck dust, so that the cleaning property and safety are improved.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

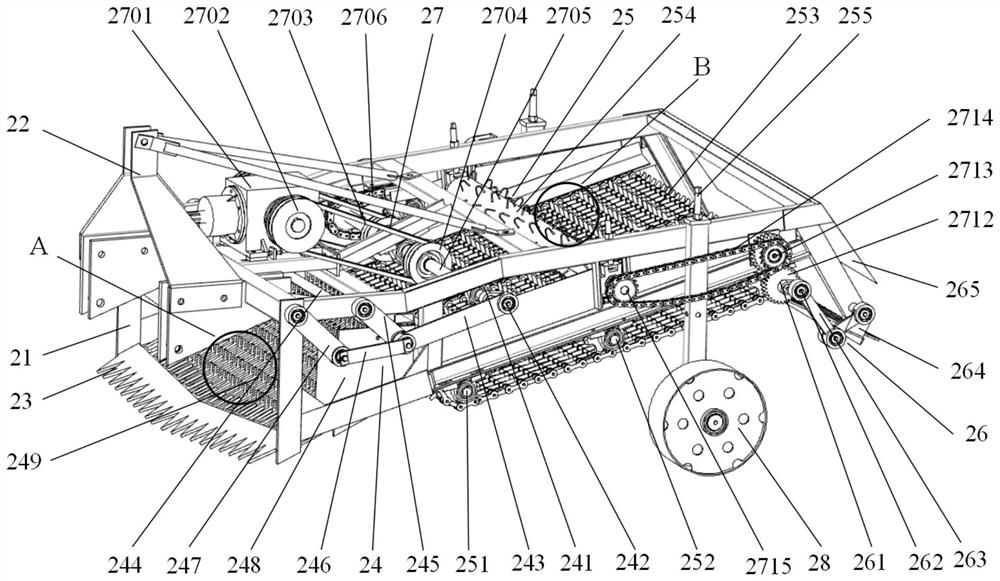

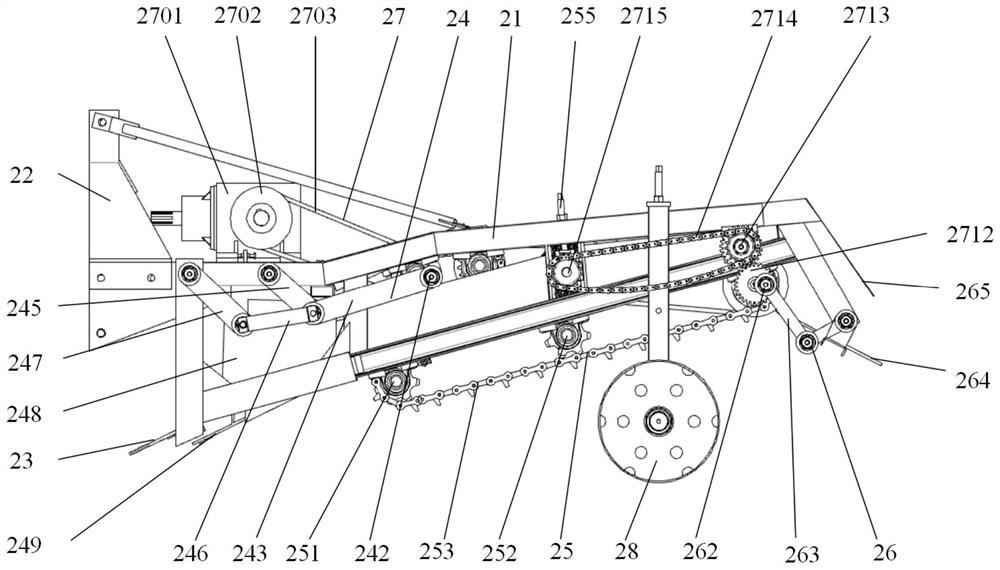

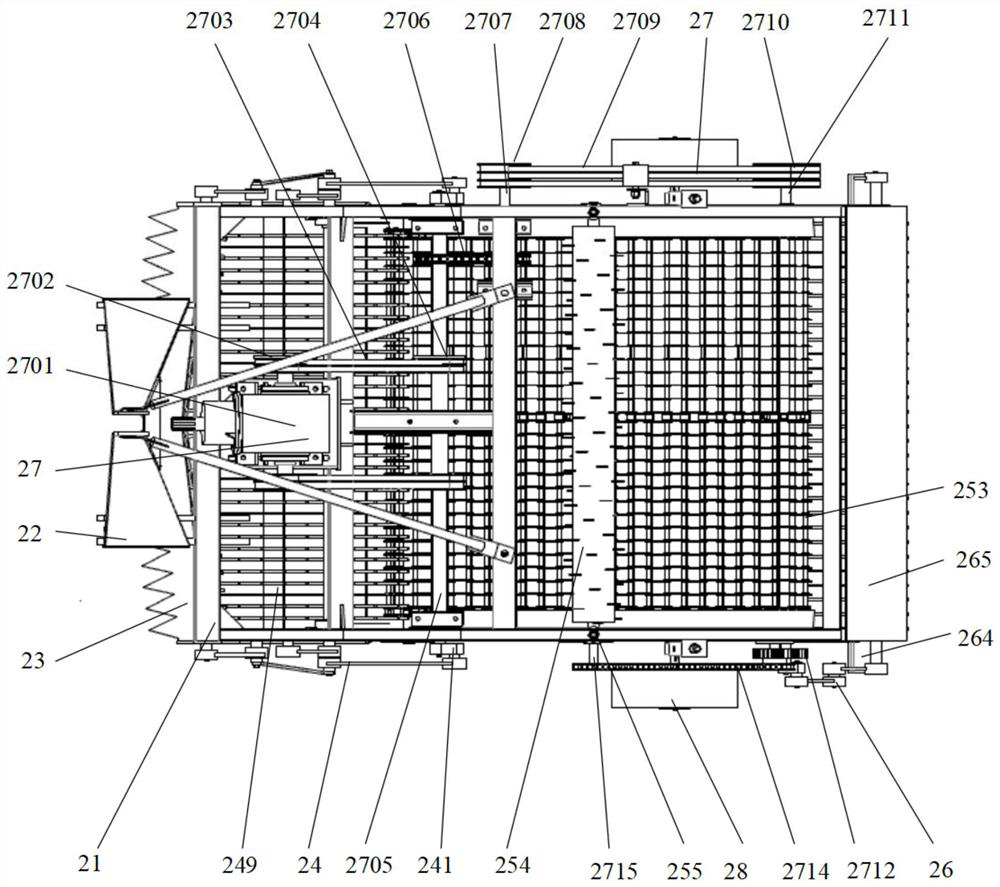

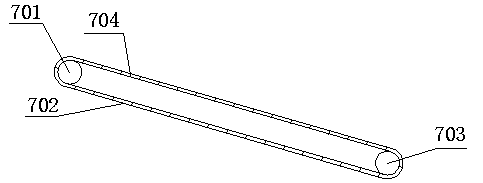

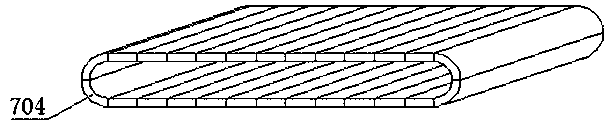

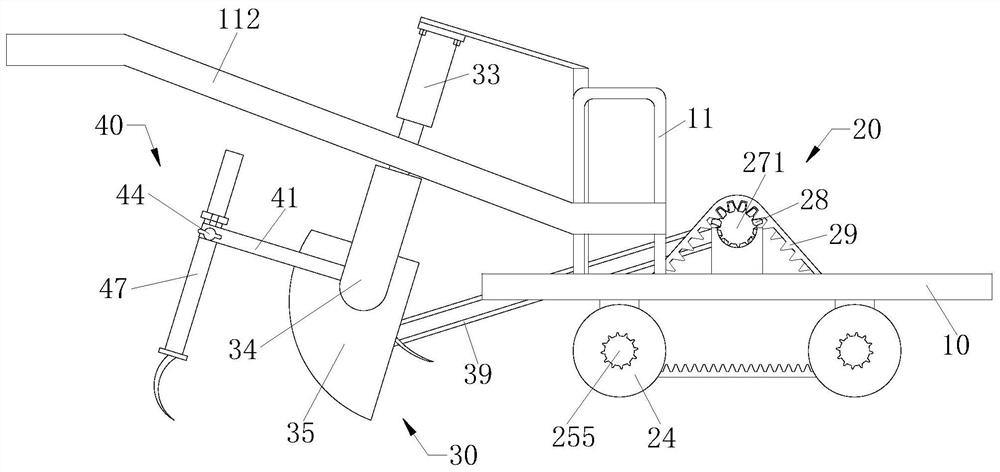

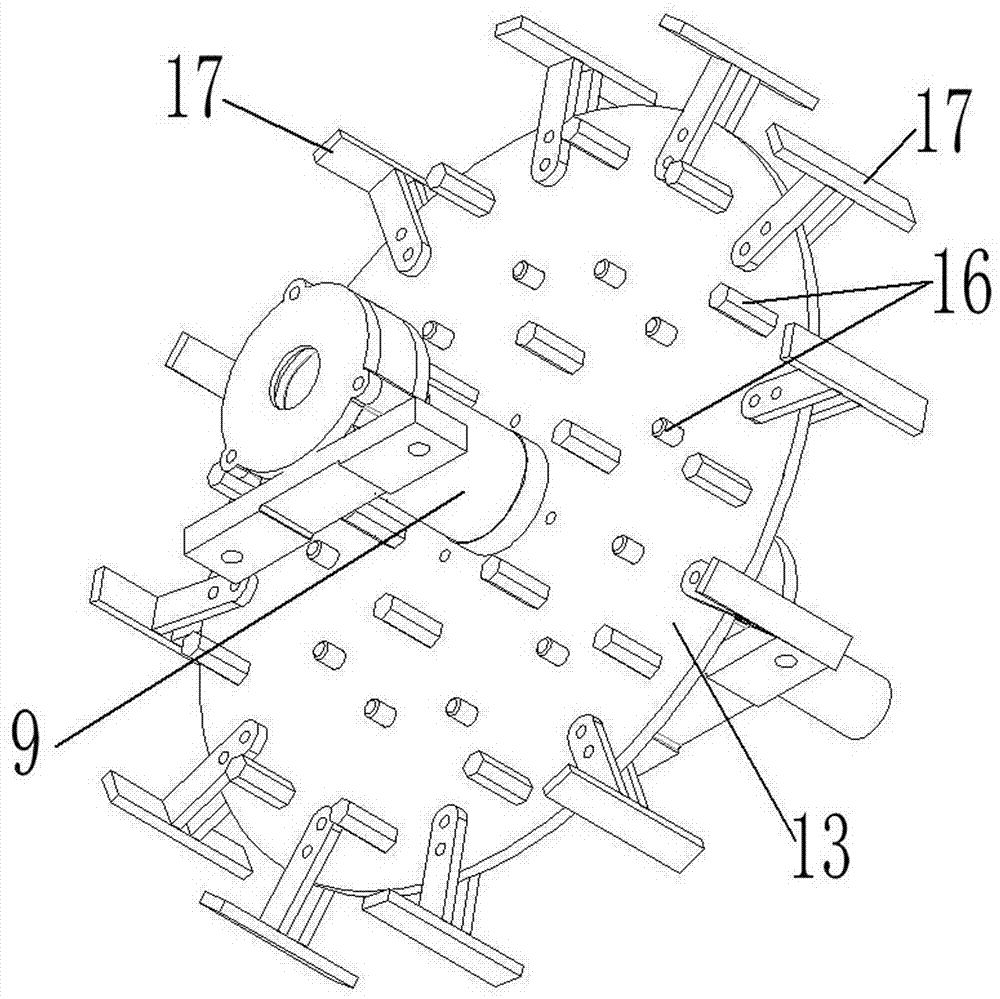

Multi-stage soil-breaking rhizoma chuanxiong digger

InactiveCN113179737AAchieve separationAchieving first-class broken soilDiggersAgricultural engineeringStructural engineering

The invention relates to the field of agricultural machinery, and provides a multi-stage soil-breaking rhizoma chuanxiong digger which comprises a rack, and a digging shovel, a throwing, soil breaking, separating and conveying component, a tooth type soil breaking, separating and conveying component and a cleaning component are sequentially arranged on the rack from left to right; the throwing, soil breaking, separating and conveying component comprises a soil shaking sieve, and breaking nails for breaking soil are arranged on the soil shaking sieve; the tooth type soil breaking, separating and conveying component comprises a conveying chain belt, and separating teeth are arranged on the conveying chain belt; the cleaning component comprises a soil cleaning plate rotationally connected with the rack and a baffle arranged above the soil cleaning plate; and one end of the soil shaking sieve is located below the digging shovel, one end of the conveying chain belt is located below the other end of the soil shaking sieve, and one end of the soil cleaning plate is located below the other end of the conveying chain belt. The problems that in the prior art, the soil breaking and separating effects are poor in the rhizoma chuanxiong digging and harvesting process, which causes soil blockage and low stem exposure rate are solved.

Owner:XIHUA UNIV

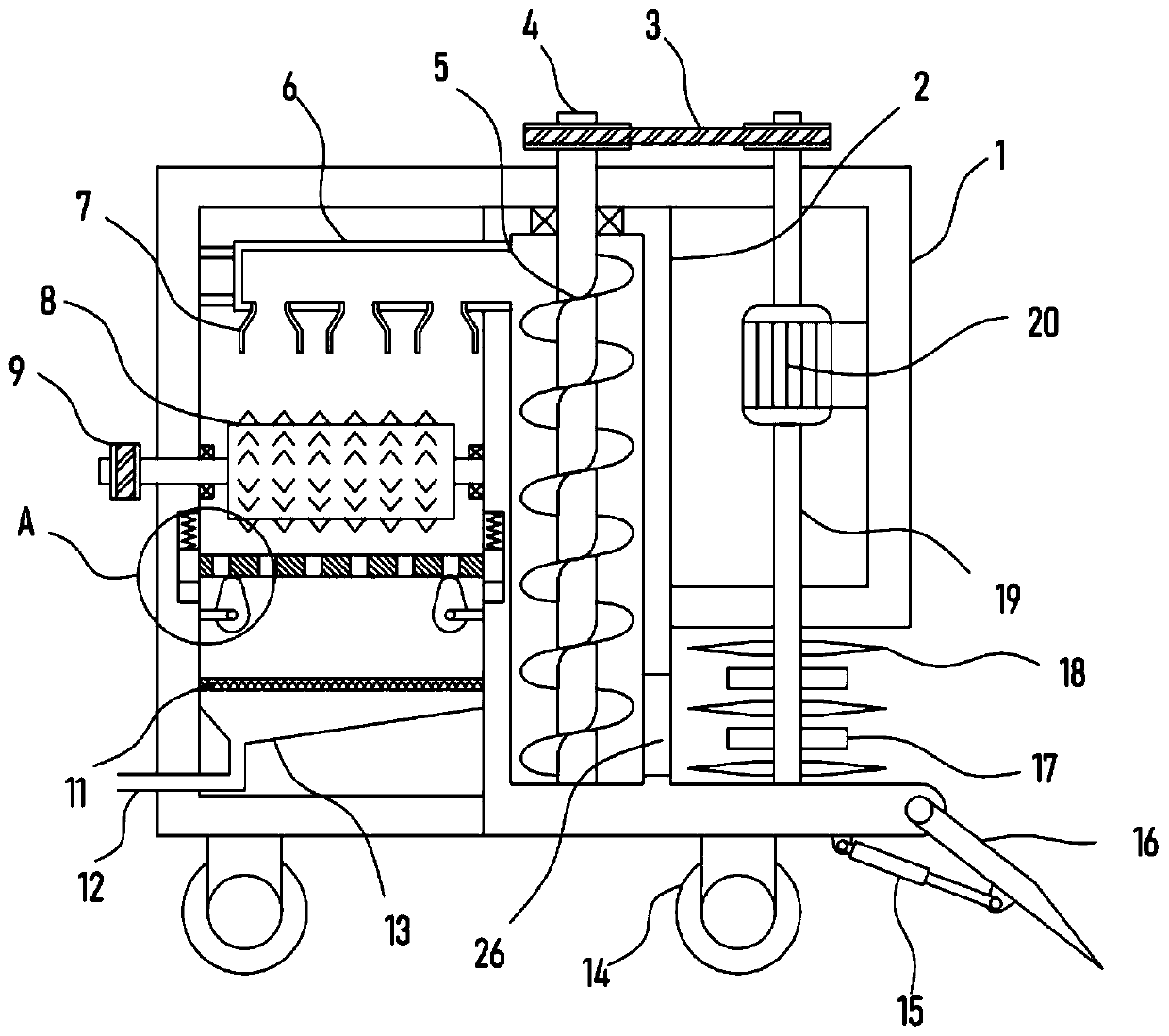

Fuel briquetting equipment for heat storage combustion

PendingCN114211812AReduce energy consumptionImprove work efficiencySievingScreeningEngineeringCombustion

The invention discloses fuel briquetting equipment for heat storage combustion, and particularly relates to the field of briquetting, the fuel briquetting equipment comprises a box body, two crushing rollers are rotatably mounted between two inner walls of the top of an inner cavity of the box body, a filter screen is arranged below the two crushing rollers, a mold shell is arranged in the box body, and a conveying device is arranged between two inner walls of the bottom of the box body; the two mold shells are symmetrically distributed and are fixedly mounted on the inner wall of the box body, a vertical plate is fixedly mounted at the bottom of an inner cavity of the box body, a swing mechanism is arranged on one side of the vertical plate, and the swing mechanism and the mold shells are matched to achieve fuel briquetting; and crushing boxes which are symmetrically arranged are fixedly mounted on the two outer sides of the box body. The briquetting equipment not only has the function of briquetting fuel, but also realizes the function of secondary crushing of large fuel particles, the screening effect of the filter screen is improved, the function of the equipment is increased, and the practicability of the equipment is greatly improved.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

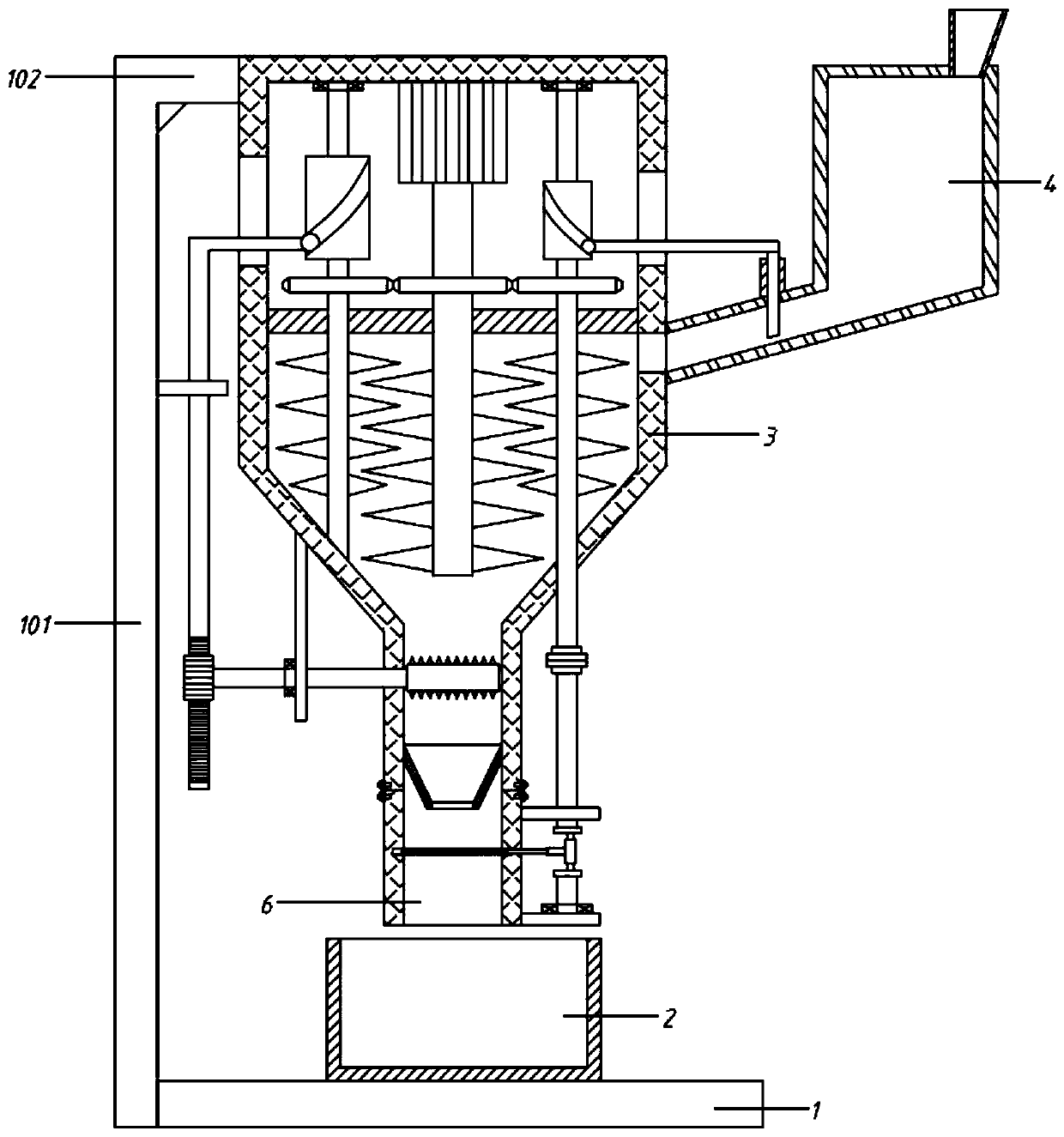

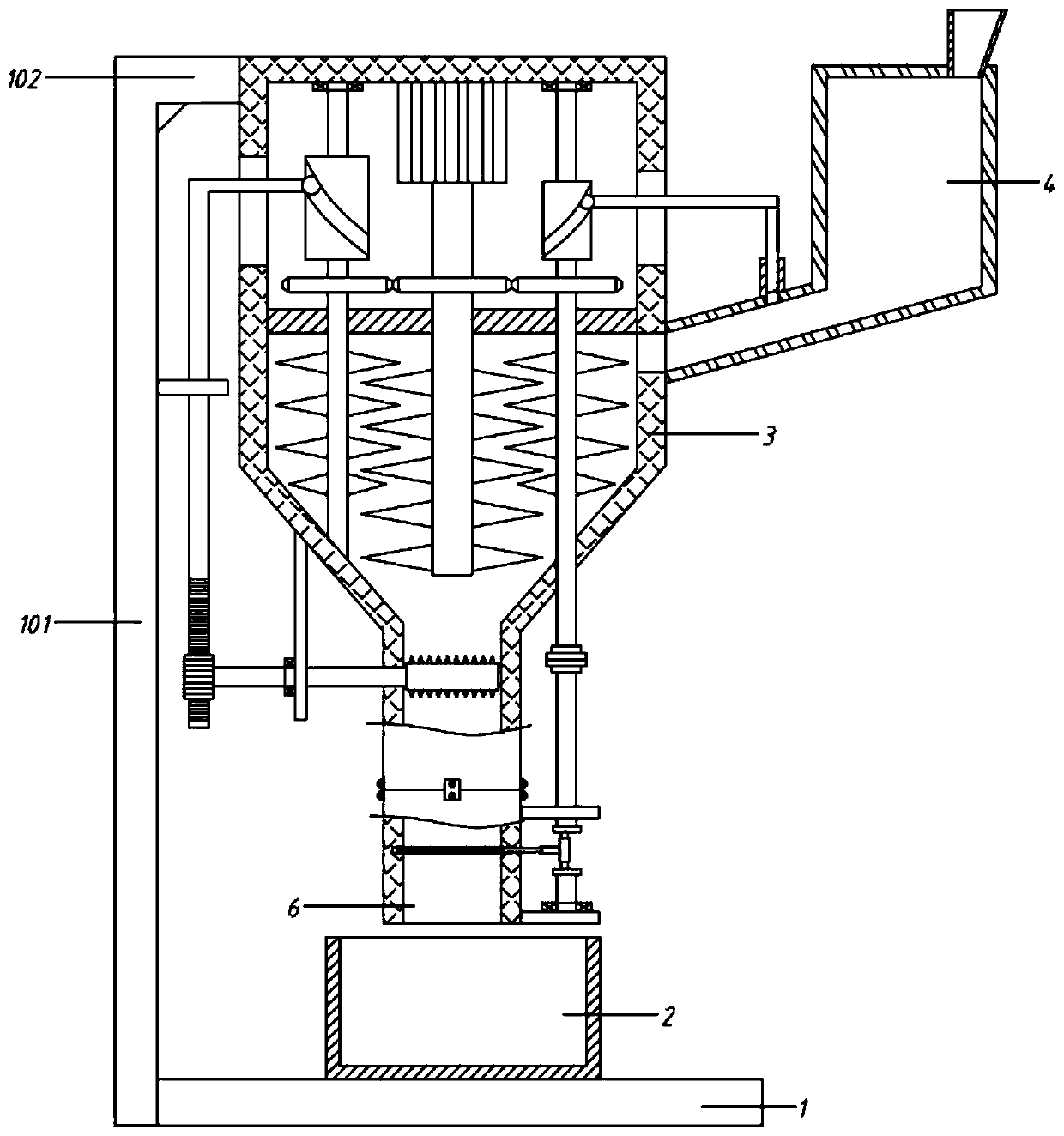

Method and device for sensible heat recovery of quenched dry crushing molten blast furnace slag

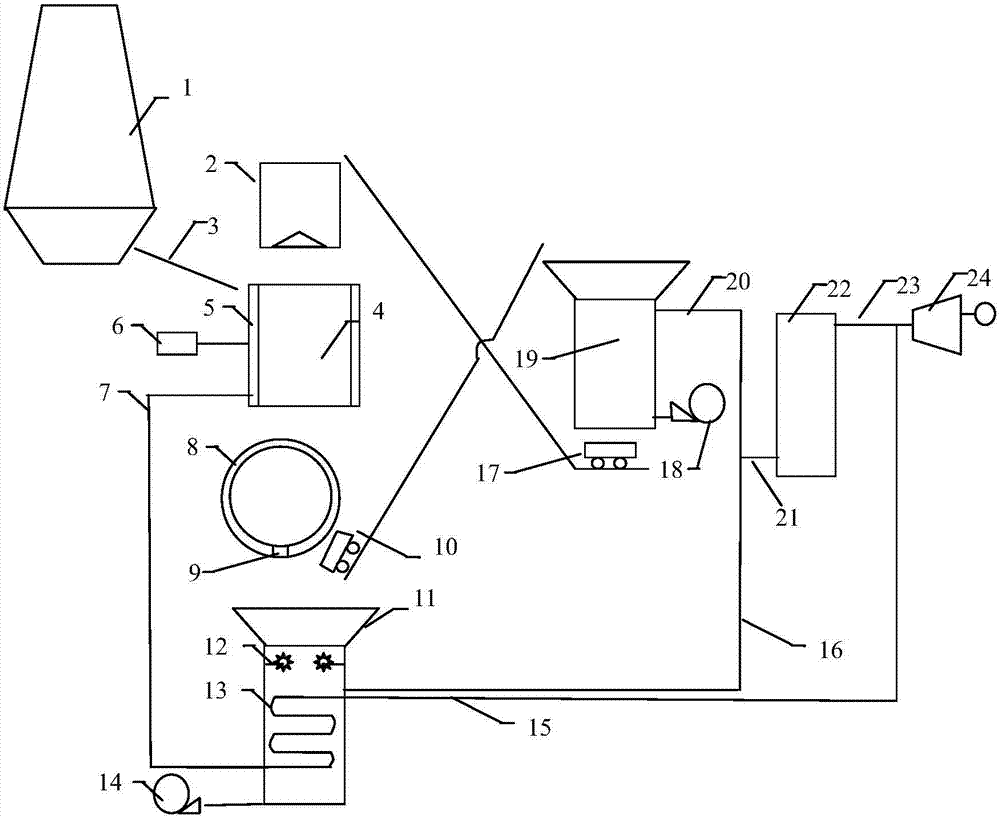

ActiveCN103820588BShorten the heat transfer solidification timeAchieve zero usageMetal recyclingProcess efficiency improvementRecovery methodSlag

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

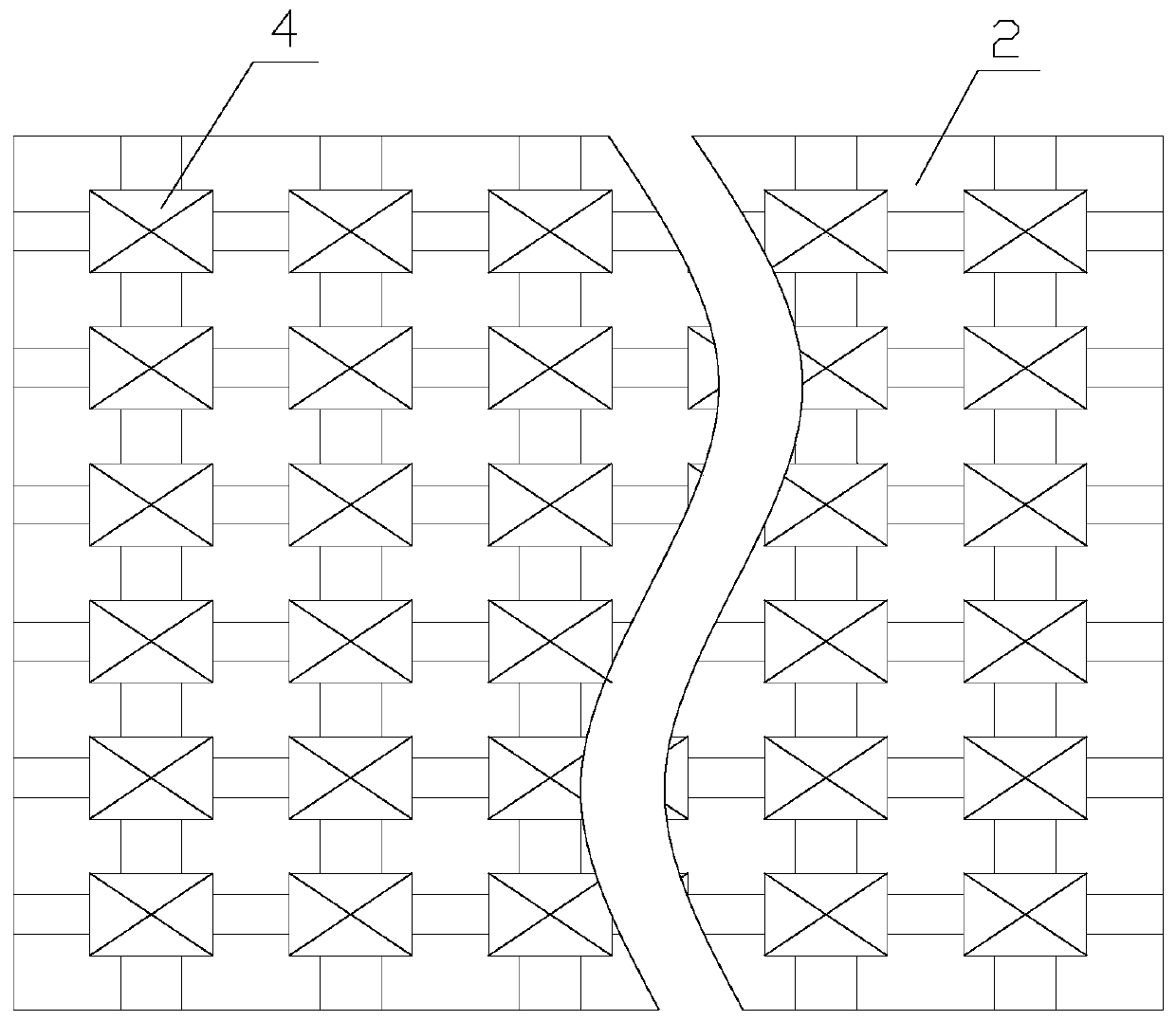

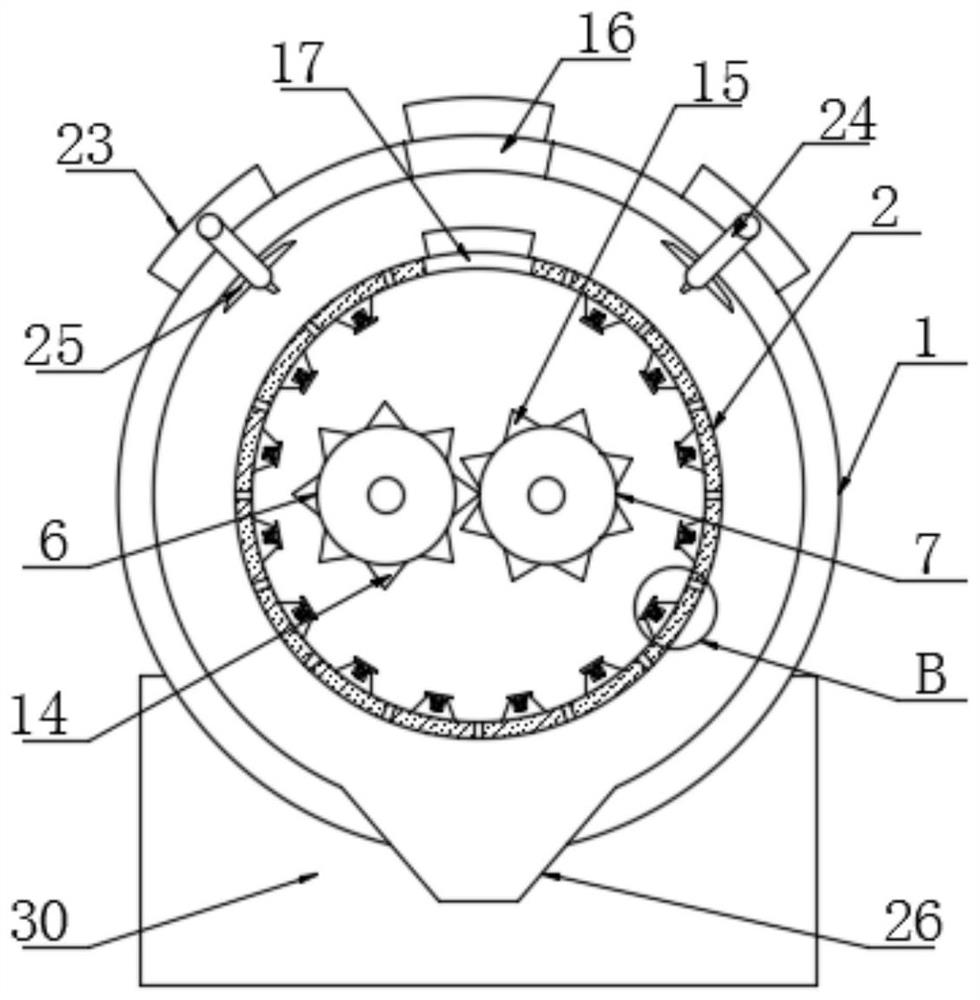

Ring hammer crusher

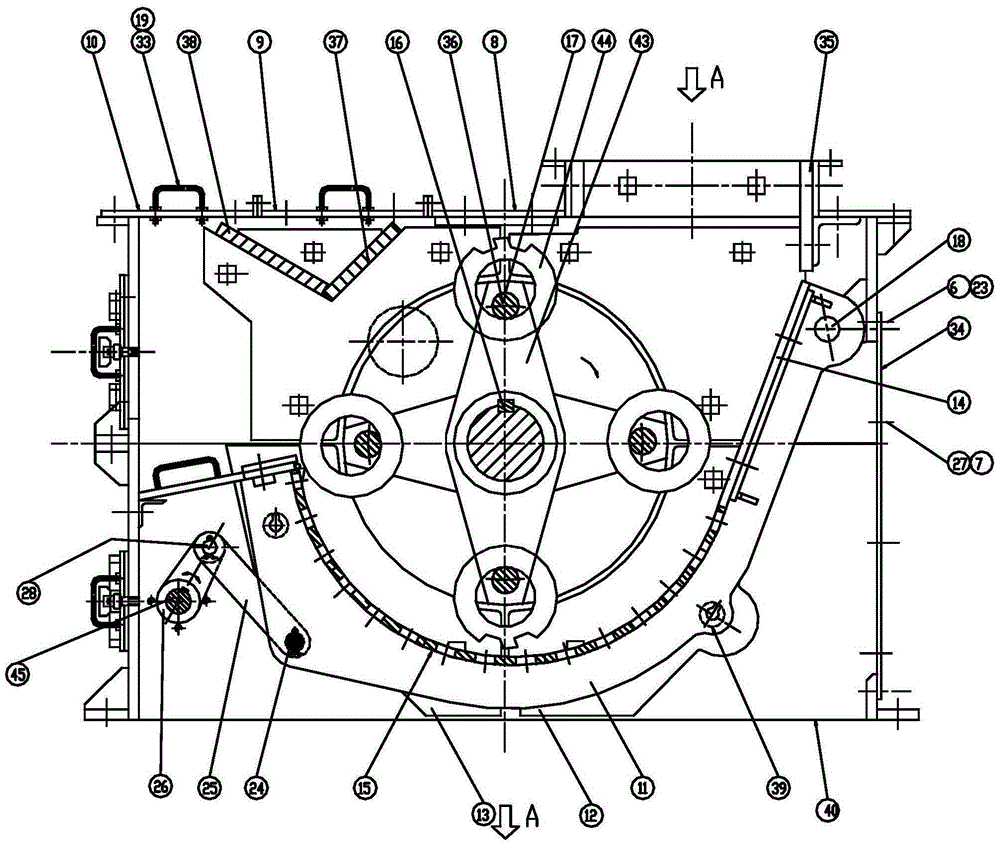

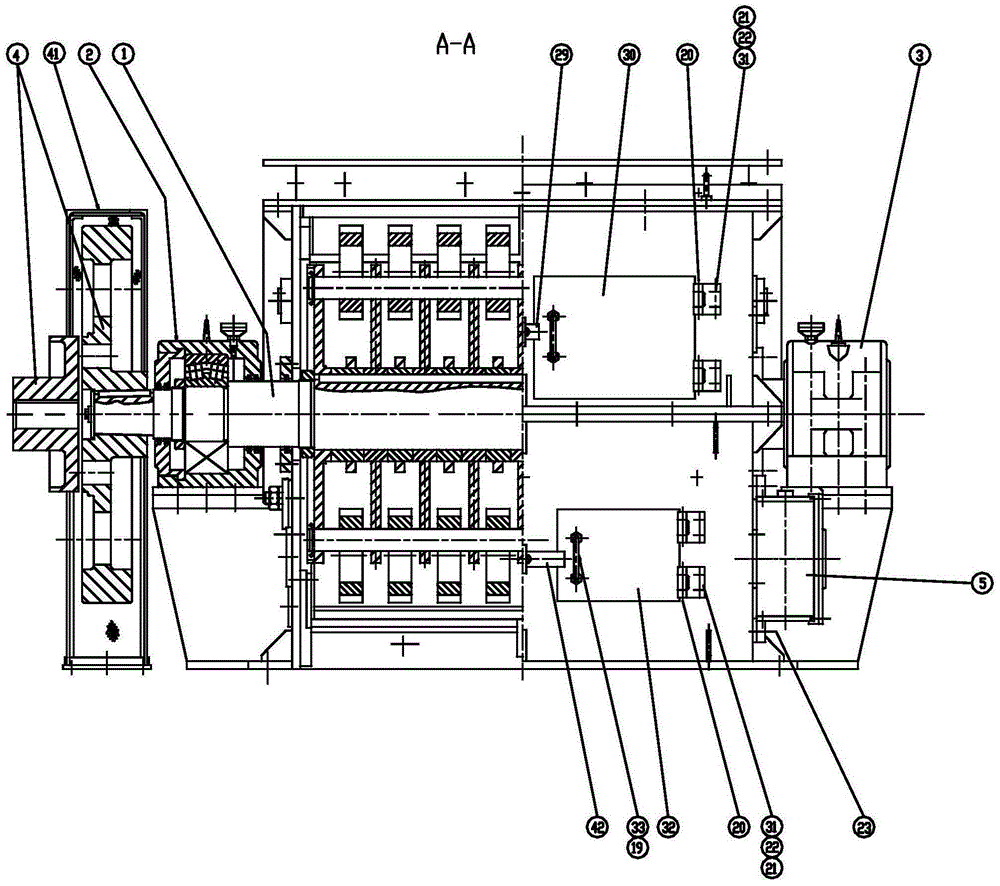

InactiveCN105170236AIncrease production capacityImprove efficiencyGrain treatmentsEngineeringCrusher

The invention discloses a ring hammer crusher which is used for crushing beneficiation. The ring hammer crusher comprises a box body. A material inlet is formed in the top of the box body. A rotor is installed in the box body. A plurality of sets of crushing arms are installed on the rotor. Every two adjacent sets of crushing arms are arranged in a crossed manner. Holes are formed in the two ends of each crushing arm. Pin shafts are installed in holes in the same ends of the crushing arms. A plurality of crushing hammers are arranged on the pin shafts in a sleeving manner. Each crushing hammer is located between corresponding two adjacent crushing arms. A middle structure, a structure I and a structure II are installed on the lower portion in the box body and used for connecting a net plate and a crushing plate. The right end of the middle structure is hinged to the inner wall of the box body, and the left end of the middle structure is hinged to one end of a connecting rod. The other end of the connecting rod is connected with one end of a stirring rod, and the other end of the stirring rod is connected with the inner wall of the box body. The structure I and the structure II are connected with the middle structure. The crushing plate is installed below the material inlet and at the right end of the middle structure. A first counter-attack plate and a second counter-attack plate are installed on the upper right part in the box body.

Owner:SHAANXI UNIV OF SCI & TECH

Smashing device for traditional Chinese medicines

The invention discloses a smashing device for traditional Chinese medicines, which comprises a base. A smashing machine body is arranged on the top of the base, and a first support is arranged on theright side of an inner cavity of the smashing machine body. A second motor and a third motor are started to enable a first rotation rod and a second rotation rod to rotate; smashing blades arranged onthe rotation rods enable medlar in the smashing machine body to be smashed primarily; first smashing blades and second smashing blades are arranged in a mutually staggered mode so that the traditional Chinese medicines can be smashed more evenly; material guiding plates are obliquely arranged so that the traditional Chinese medicines smashed primarily can fall at a material guiding opening; stripholes are formed at the material guiding opening so that the traditional Chinese medicines smashed primarily can fall slowly; a fourth motor is started to enable smashing discs to rotate so as to drive smashing teeth to rotate, and thus the traditional Chinese medicines are smashed secondarily; and the smashing teeth on the left and right sides are arranged in a mutually staggered mode so that traditional Chinese medicines can be smashed more thoroughly. The using effect of the smashing device is guaranteed, and the smashing device is suitable for being widely popularized.

Owner:黄丽佳

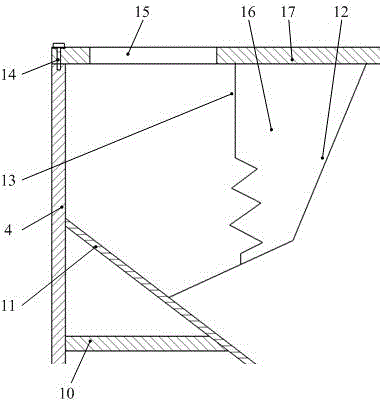

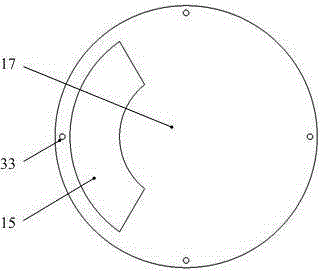

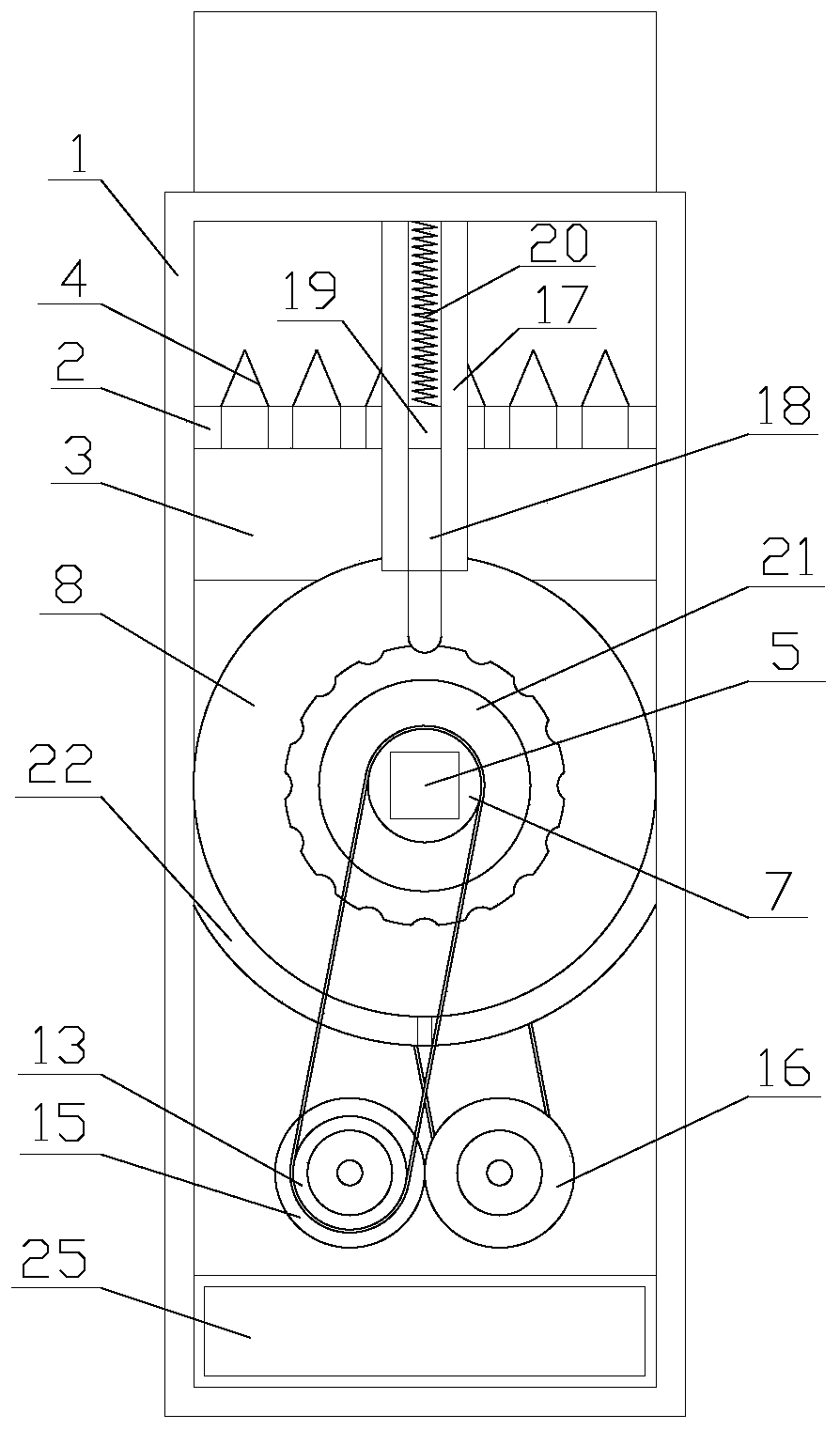

Traditional Chinese medicine crushing device

InactiveCN108554585AImprove crushing efficiencyAchieve secondary crushingDrying gas arrangementsGrain treatmentsHerb medicineMedicine

The invention discloses a traditional Chinese medicine crushing device, belonging to the technical field of traditional Chinese medicine herb crushing equipment. A control switch (17) is arranged at the upper left part of a machine body (1), an engine (2) is connected with a rotating shaft (3), and the rotating shaft (3) is connected with a grinding head (4). A valve I (8), a valve II (9), a valveIII (10) and a negative pressure chamber (12) are arranged in an air delivery pipe (14). A baffle plate (6) is arranged under a grinding groove (5), and a baffle plate control switch (7) is connectedwith the baffle plate (6). The air delivery pipe (14) is connected with a drying oven (15), and a powder collecting box (16) is arranged under the drying oven (15). The traditional Chinese medicine crushing device has a good crushing effect.

Owner:戴琪

Coal briquette crusher for coal mine

InactiveCN111871519AAchieve secondary crushingReasonable structural designDispersed particle filtrationDirt cleaningCoal briquetteAir pump

The invention discloses a coal briquette crusher for a coal mine. The coal briquette crusher comprises supports, a shell, a feeding hopper, a dividing block, feeding inlets, side blocking blocks, upper crushing rollers, upper connecting shafts, lower crushing rollers, lower connecting shafts, upper driving motors, lower driving motors, a power box, an air-blowing pump, branch pipes, fixing pipes,nozzles, guiding blocks, a discharging outlet, a falling cavity, a transport motor, a driving belt pulley, conveying rollers, a driven belt pulley, an outer cover shell, upper air-suction pipes, air-suction discs, a conveying belt, lower air-suction pipes, a filter shell, a filter screen, an air-guiding shell, an air-suction pump, a gas transmission pipe, a water tank, an upper blocking block andsupport rods. The coal briquette crusher is reasonable in structure design, through the two upper crushing rollers and the two lower crushing rollers, coal briquettes are secondarily crushed, that is,the large coal briquettes are first crushed into medium-sized coal briquettes, and then the medium-sized coal briquettes are crushed into small coal briquettes, so that the crushing effect is good, the good crushing effect is achieved through the simple structure, and meanwhile, jamming can be further avoided.

Owner:衡成东

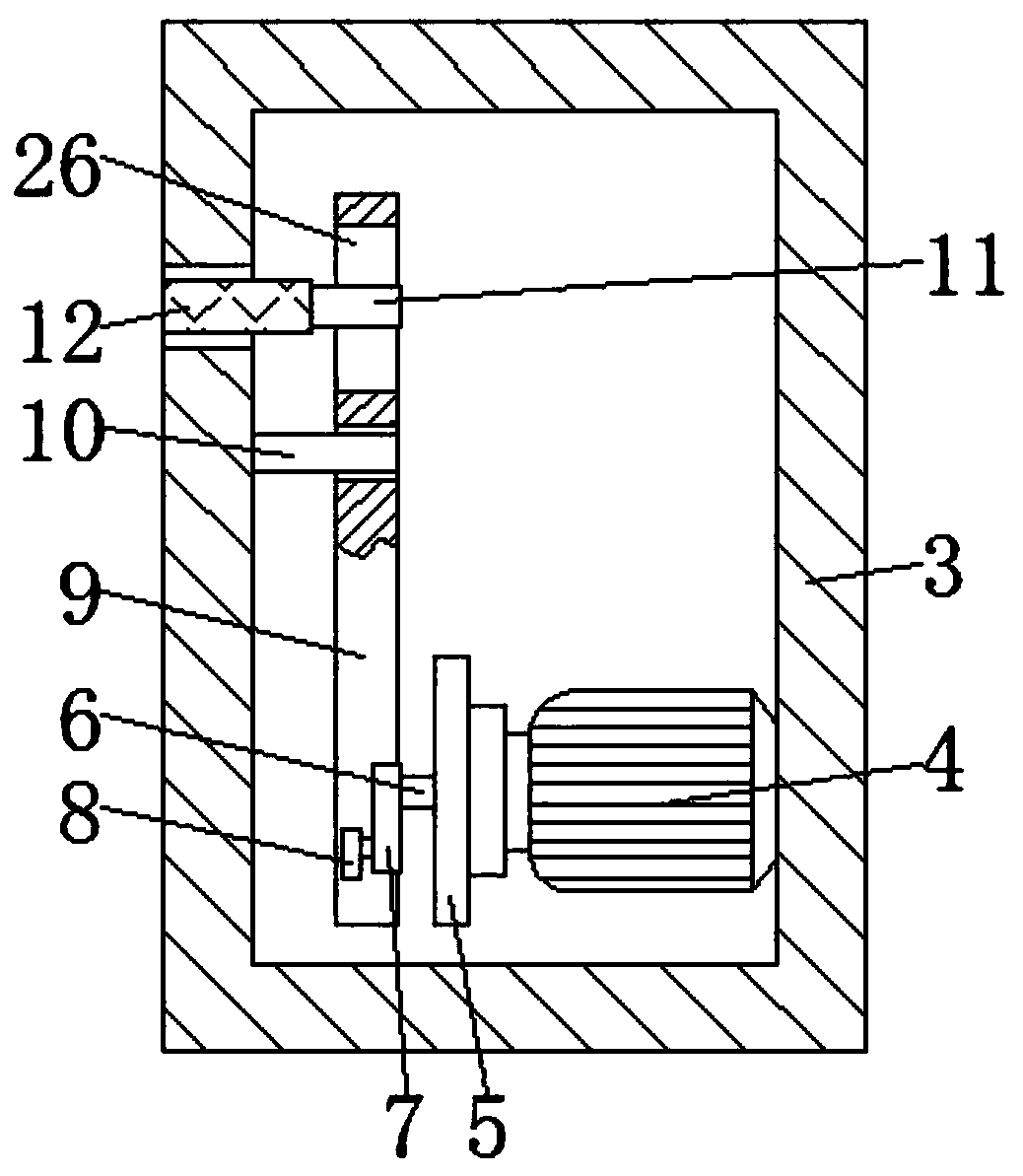

Double-jaw crushing and grinding machine and control system thereof

InactiveCN106607114AAchieve a brokenAchieve secondary crushingCocoaGrain treatmentsMotor driveControl system

The invention discloses a double-jaw crushing and grinding machine and a control system thereof. The machine comprises a fixed crushing jaw, a first moving crushing jaw, a first crushing fly wheel, a crushing motor, a second moving crushing jaw, a second rushing fly wheel, a first grinding motor, a first grinding spindle, a first grinding disk, a second grinding motor, a second grinding spindle, a second grinding disk, a rack, a crushing discharging chute, a grinding discharging chute and a discharging hopper. The control system comprises a raw material detection module, a material grinding detection module, a flow detection module, a programmable logic controller (PLC), a first grinding motor driving module, a second grinding motor driving module and a contactor. With the machine, primary crushing, secondary crushing and grinding of raw materials can be realized, the crushing degree of the raw materials is increased, and the crushing time is shortened.

Owner:罗浩

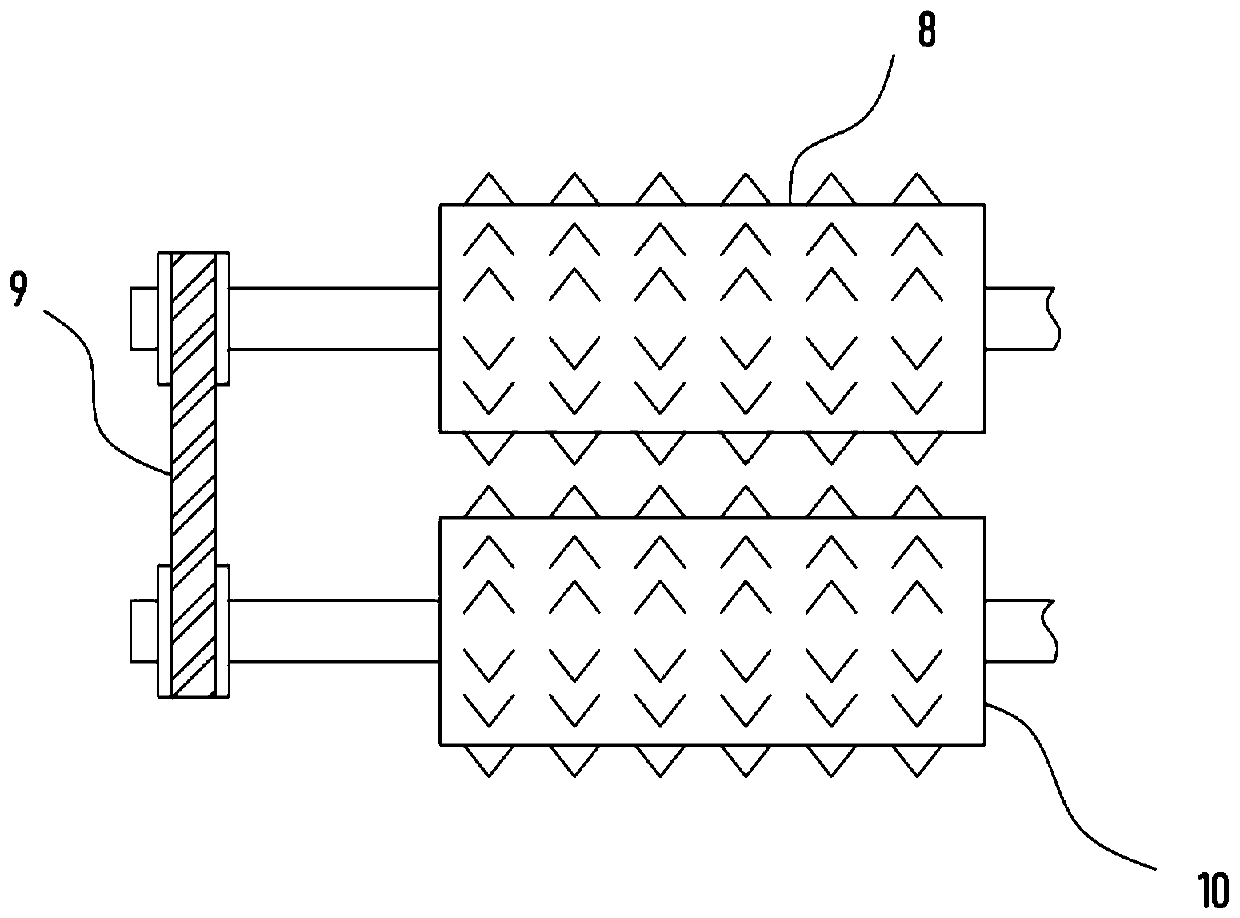

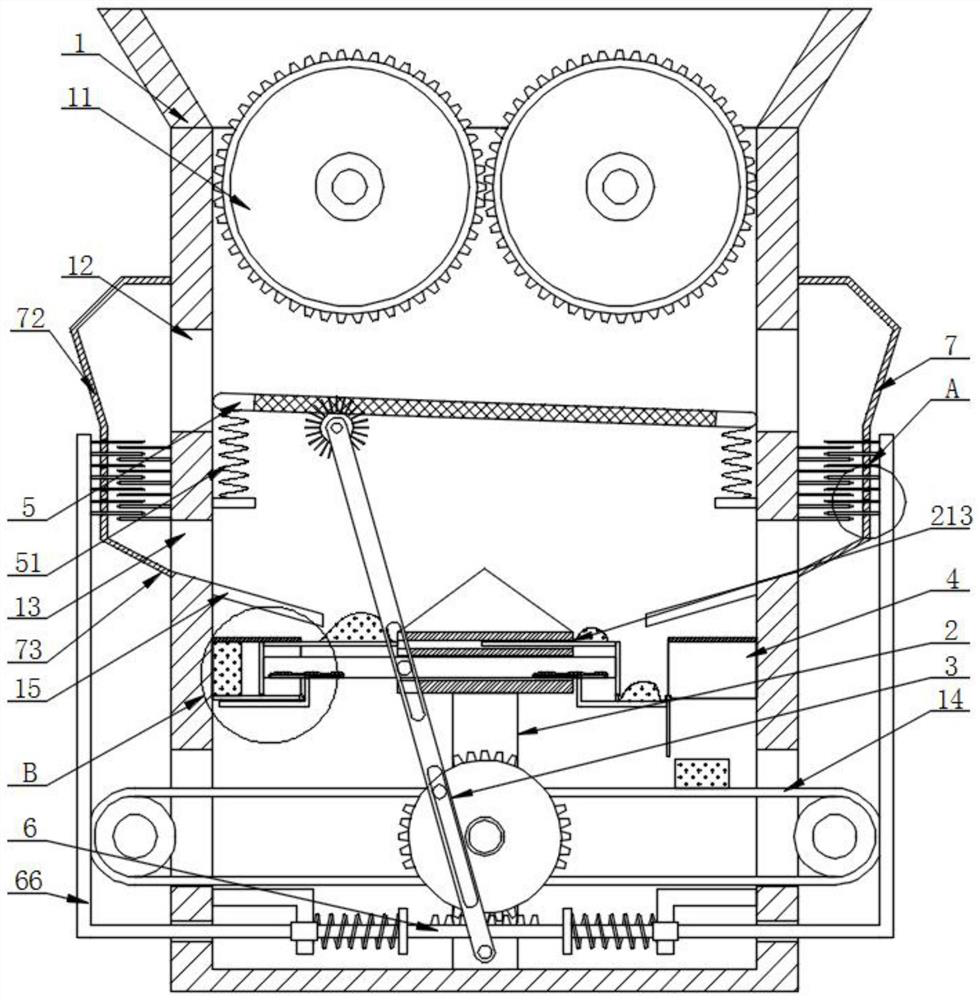

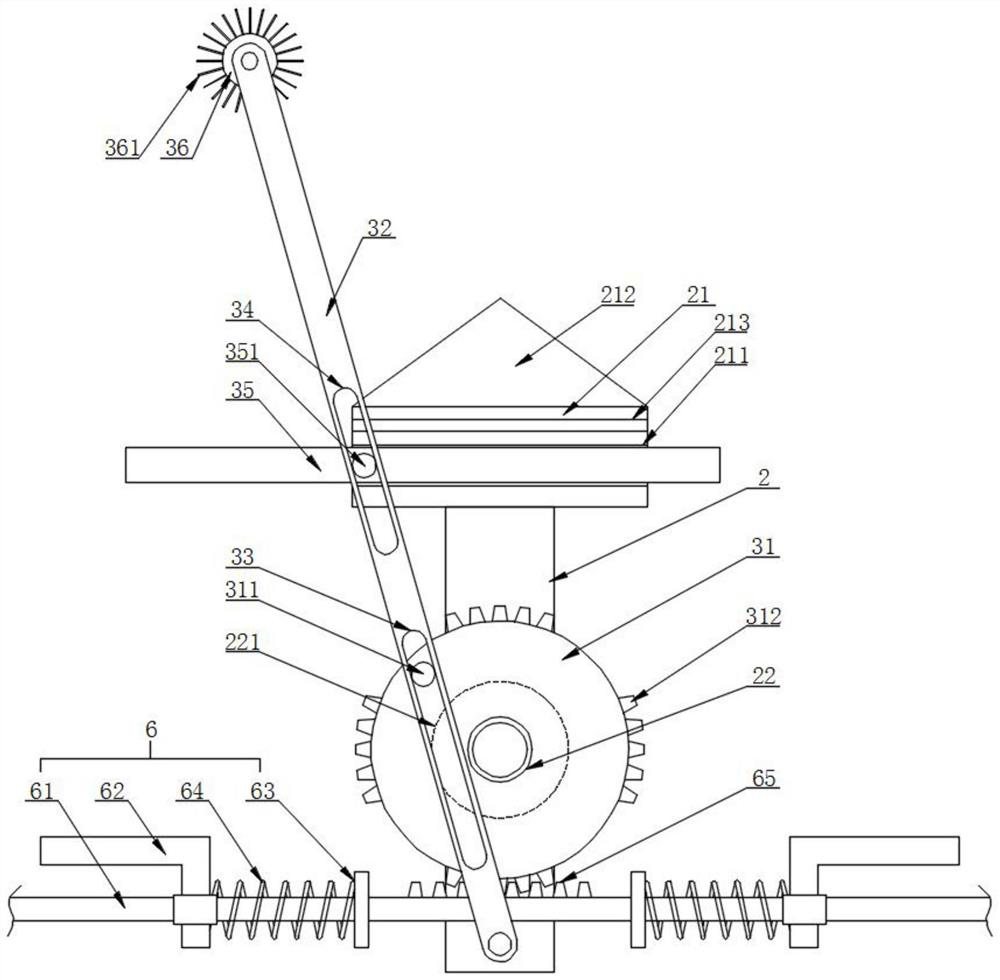

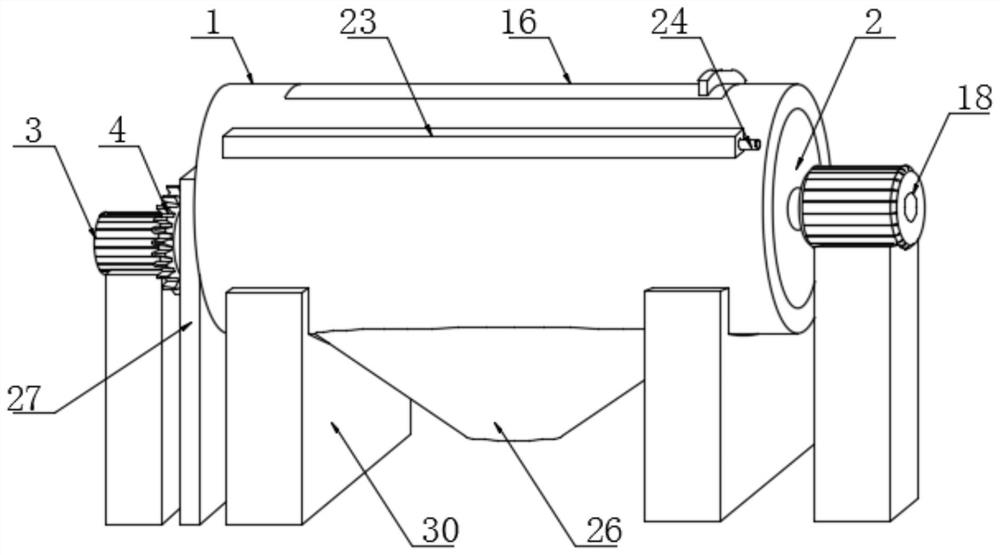

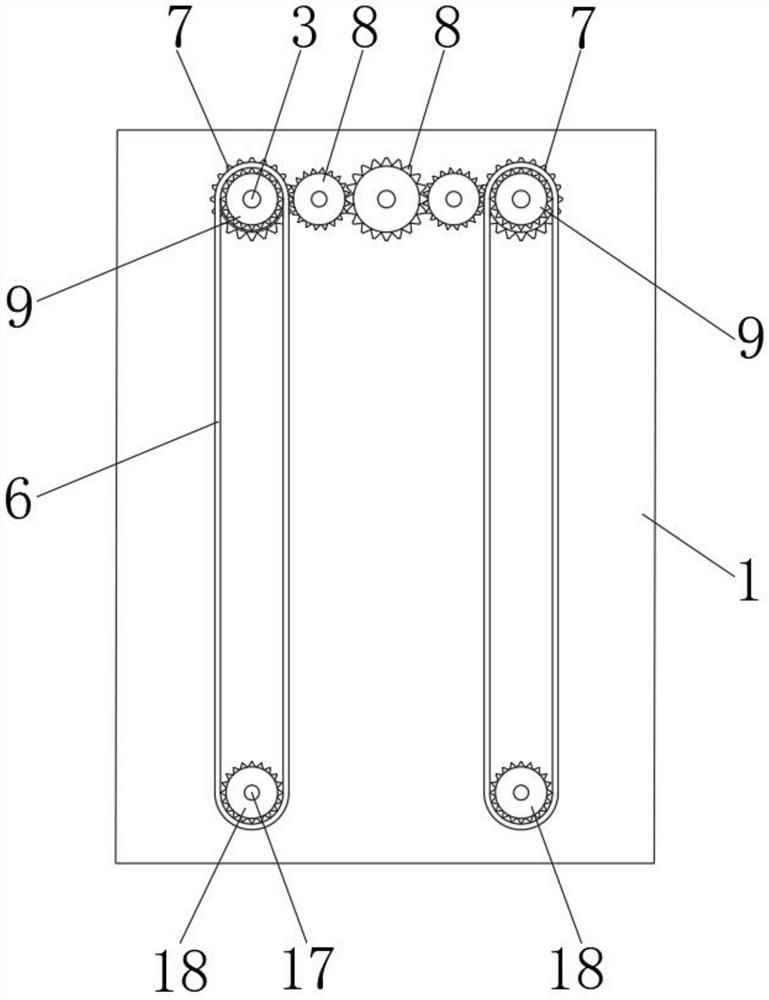

Waste novel energy vehicle lithium battery recycling equipment with secondary crushing system

InactiveCN111420782AAchieve secondary crushingRealize vibration dischargeWaste accumulators reclaimingGrain treatmentsNew energyGear wheel

The invention relates to waste novel energy vehicle lithium battery recycling equipment with a secondary crushing system. The waste novel energy vehicle lithium battery recycling equipment comprises acrusher, a hinge, a discharge plate, a box body, a packing auger crushing blade, a packing auger barrel, a driven chain wheel, a chain, a drive chain wheel, a magnetic plate, an electric motor, an ejector head, a transmission shaft, a ring-shaped rack, an incomplete gear and a transmission belt, wherein the crusher is arranged at the top end of the box body through brackets; the packing auger crushing blade is rotatably connected inside the packing auger barrel; the discharge plate is rotatably connected to the bottom end surface inside the box body through the hinge; the drive chain wheel isconnected to the driven chain wheel through the chain; the magnetic plate is arranged at the inner end of the chain; the transmission shaft is rotatably connected inside the box body; the output endof the electric motor is in transmission connection to the transmission shaft through the transmission belt; the incomplete gear is mounted on the transmission shaft; the ring-shaped rack is in sliding connection inside the box body; and the ejector head is fixedly connected to the ring-shaped rack through a connecting rod. The waste novel energy vehicle lithium battery recycling equipment improves sorting effect, increases a recovery rate, improves recovery efficiency, is excellent in structure and is high in practicability.

Owner:柳州永安行汽车科技有限公司

Energy-saving and environment-friendly construction waste regenerated aggregate device and treatment method

InactiveCN111570059AAchieve secondary crushingRealize the filtering functionGrain treatmentsDrive wheelElectric machine

The invention discloses an energy-saving and environment-friendly construction waste regenerated aggregate device and a treatment method. An extrusion body and a feeding channel are fixedly arranged on the top of an upper machine cover, the feeding channel and the extrusion body both extend into a funnel body, a driving wheel disc is installed on the lower portion of the funnel body, a bearing isinstalled below the driving wheel disc, a gear face is arranged on the outer ring of the funnel body, a motor shaft of a rotating motor penetrates through the top wall of a lower machine cover and then is provided with a first gear matched with the gear face, a first matching groove matched with the bearing is formed in the outer side of the top wall of the lower machine cover, a passing opening is formed in the middle of the top wall of the lower machine cover, a lower crushing pipe is installed on the outer side of a discharging outlet, a crushing rod is arranged in a pipe body of lower crushing pipe, a screening inlet is formed in the top of a screening groove body, a swing pressing rod is installed in the inner part of the screening groove body, a discharging channel is formed in the bottom of the screening groove body, the swing pressing rod extends into the pipe body, and scattering holes are formed in the bottom wall of the discharging channel. According to the energy-saving andenvironment-friendly construction waste regenerated aggregate device and the treatment method, construction waste can be effectively utilized to be processed into aggregate to serve as an engineeringconstruction material, so that waste utilization is achieved, and the energy-saving and environment-friendly construction waste regenerated aggregate device and the treatment method is suitable for being widely applied to construction waste treatment.

Owner:徐立军

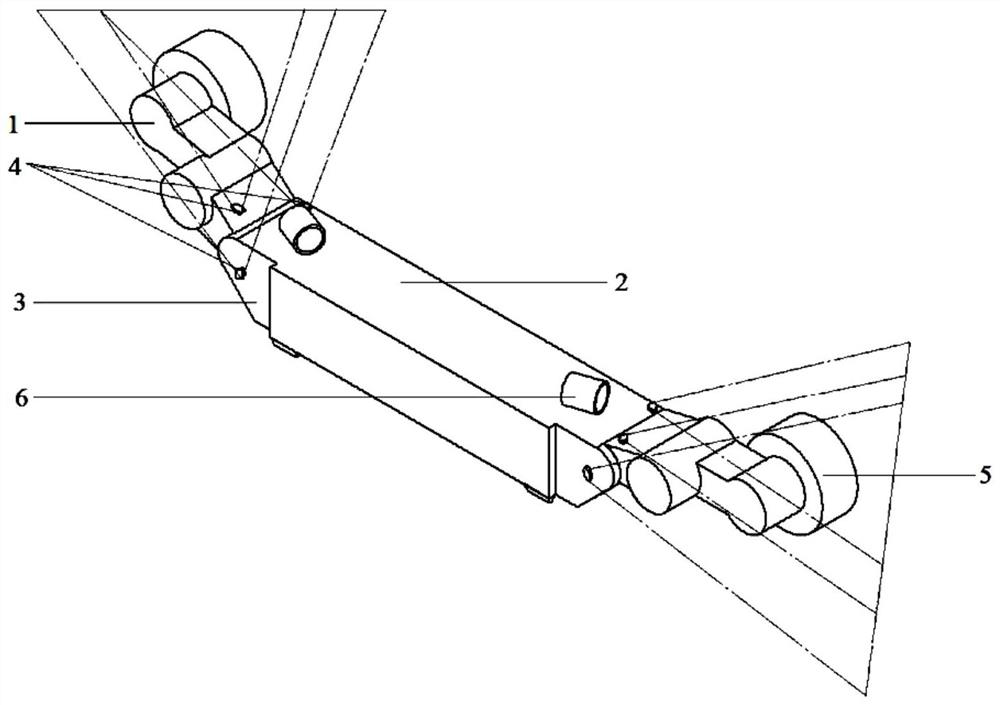

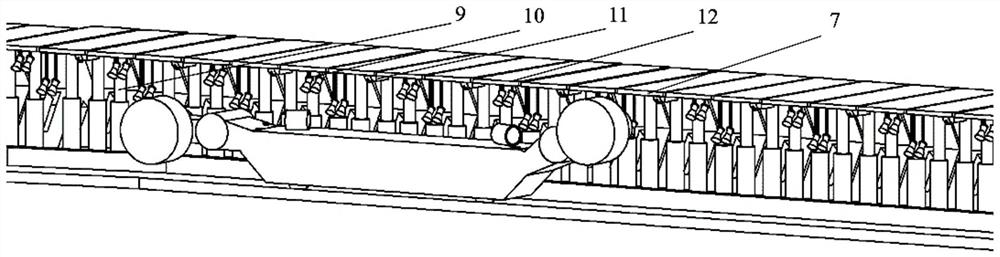

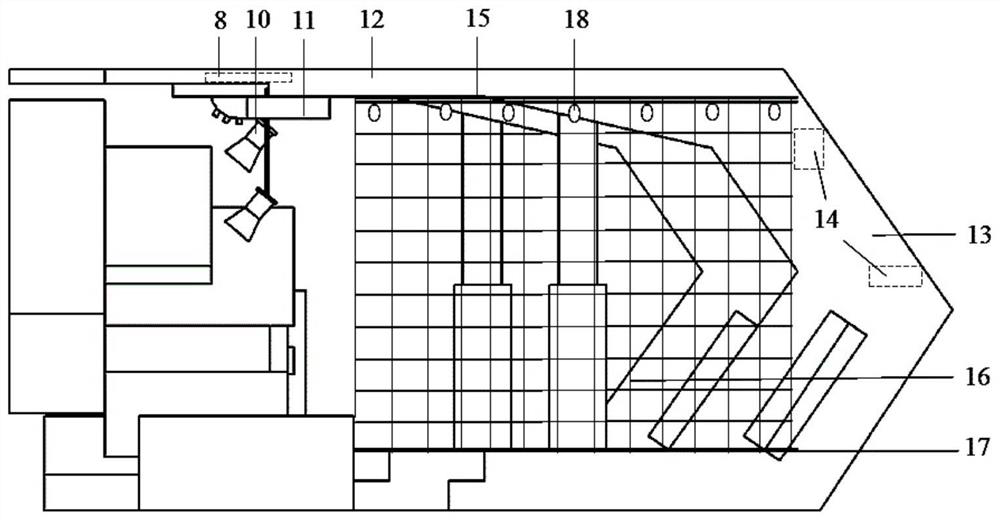

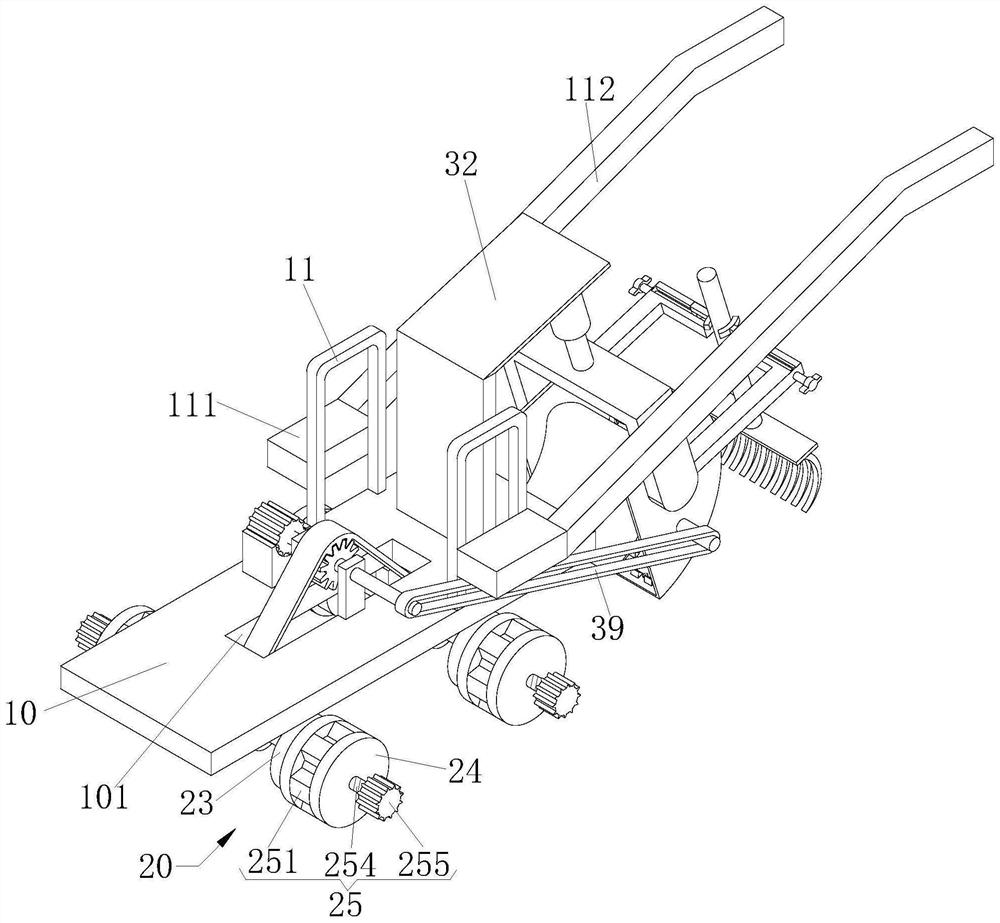

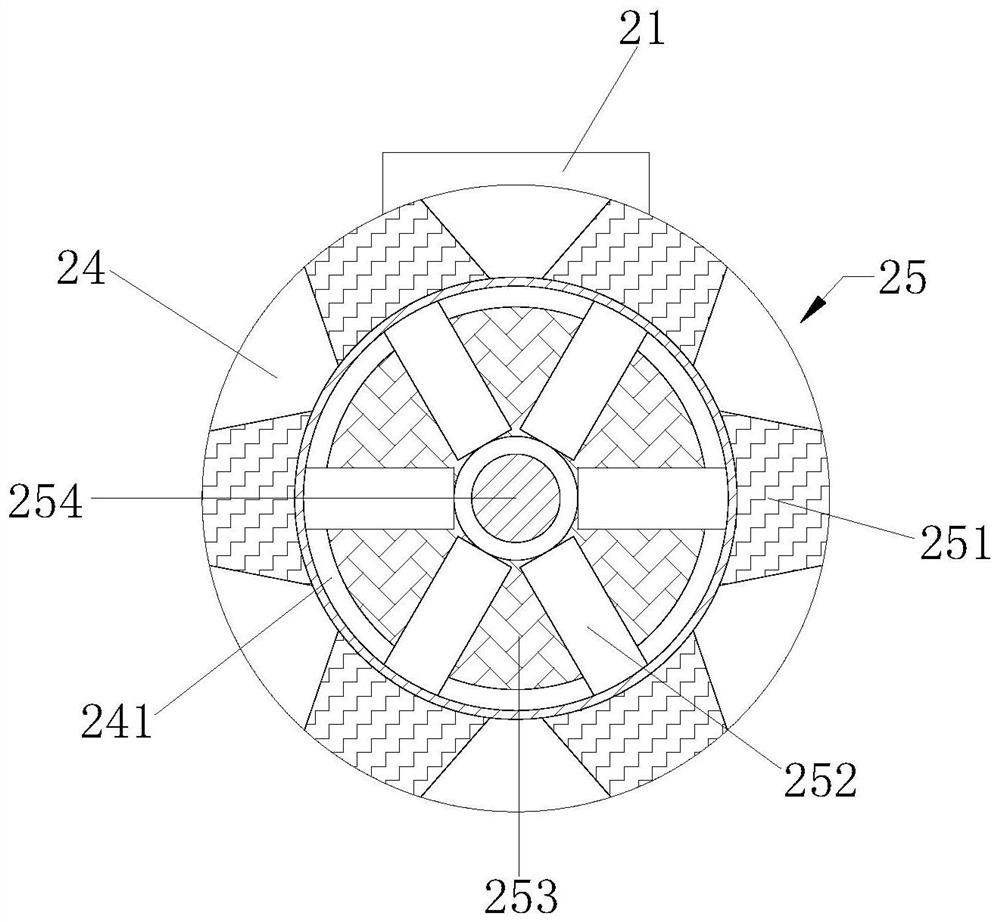

Large-mining-height fully mechanized coal mining face multi-stage multi-dimensional atomization dust prevention and control method and device

PendingCN113027452AEfficient captureInhibit movement of manned workspaceDust removalFire preventionMining engineeringSprayer

The invention belongs to the technical field of coal mine dust prevention and control, and discloses a large-mining-height fully mechanized coal mining face multi-stage multi-dimensional atomization dust prevention and control method and device. In the large-mining-height fully mechanized coal mining face multi-stage multi-dimensional atomization dust prevention and control device, a roller is fixed to a coal mining machine rocker arm, and the coal mining machine rocker arm is connected with a coal mining machine body; the coal mining machine body is provided with a coal mining machine body upper end face and a coal mining machine body cambered surface, and wet-type hydrodynamic dust removers are arranged on the left end face and the right end face of the upper end face of the coal mining machine body; and the coal mining machine rocker arm, the upper end face of the coal mining machine body and the arc face of the coal mining machine body are all provided with composite nozzle sprayers. According to the large-mining-height fully mechanized coal mining face multi-stage multi-dimensional atomization dust prevention and control method and device, a composite nozzle sprayer group and the wet-type hydrodynamic dust removers are arranged in a coal mining machine area, so that the coal mining machine is inhibited from moving to manned working spaces such as a frame front space and a sidewalk; and by arranging the composite nozzle sprayers, formed fog drops capture dust generated by cutting of the roller, dust generated by cutting collapse and floating dust raised by rotation of the roller can be effectively captured, and the dust is prevented from escaping to a working face space.

Owner:SHANDONG UNIV OF SCI & TECH

Agricultural ploughing robot

ActiveCN113099746AReduce labor intensityImprove efficiencySpadesPloughsAgricultural engineeringBiology

The invention relates to an agricultural ploughing robot. The agricultural ploughing robot comprises a bottom plate and a transmission device arranged on the outer side of the bottom plate, a ground breaking device is arranged on the left side of the bottom plate, and a uniformizing device is arranged on the outer side of a bucket. Through cooperation of the bucket, leaking holes, iron nails and crushing iron sheets, the bucket can turn over soil in a paddy field to be constructed, when the bucket excavates the soil in the paddy field, water in the paddy field is discharged through the leaking holes, so that the resistance of water flow to the bucket is reduced, and the labor intensity of farmers is reduced; and a crushing roller shaft can drive the crushing iron sheets to rotate synchronously, so that the crushing iron sheets and the iron nails are matched in a staggered mode, soil excavated by the bucket can be crushed, soil separation is more sufficient, the air permeability of the soil is improved, and the soil is kept loose; and the soil adhering to the inner wall of the bucket can be removed through the crushing iron sheets, and the situation that the crushing effect of the crushing iron sheets on the soil is affected after the soil is accumulated is prevented.

Owner:湖南田牧之家农业装备有限公司

Raw material crushing device for resin toy production and processing

InactiveCN111604119AAchieve secondary crushingImprove crushing effectCleaning using gasesGrain treatmentsGear wheelServomotor

The invention discloses a raw material crushing device for resin toy production and processing, and particularly relates to the technical field of resin crushing devices. The raw material crushing device comprises a shell, wherein a crushing chamber is arranged in an inner cavity of the shell; a second servo motor is arranged on one side of the shell; the end of an output shaft of the second servomotor is fixedly connected with the crushing chamber; a first servo motor is arranged on the other side of the shell; a first gear is arranged outside the end of an output shaft of the first servo motor in a sleeving mode; and a second gear is arranged on one side of the first gear in a matched mode. According to the raw material crushing device, the first servo motor, a first crushing roller, asecond crushing roller, the second servo motor, a fixing block, a rebound plate and other structures are arranged, so that during use, under the action of the rebound plate, materials can be bounced at any time, can roll along with the rotation of the crushing chamber, and then fall into the space between the two crushing rollers for crushing, secondary crushing is realized, then the crushing effect of the device is improved, and the crushing efficiency can be improved.

Owner:赣县洪顺工艺厂

Rolling type small flowerpot soil spreading device used for garden for simulating of running robot

InactiveCN113079874AAvoid affecting transplanting workRealize the rolling functionSievingScreeningAgricultural engineeringEnvironmental geology

The invention discloses a rolling type small flowerpot soil spreading device used for a garden for simulating of a running robot. The rolling type small flowerpot soil spreading device comprises a box body, wherein the bottom parts of two sides of the box body are independently provided with supporting frames; the bottom of each supporting frame is provided with a supporting foot; the top of the box body is provided with a material feeding hopper; the bottom of the box body is provided with a material outlet; a material discharging part is arranged below the material outlet; a rolling device is arranged in the box body; the lower part between the supporting frames on two ends is provided with a fixing frame; in addition, two sides of the fixing frame are independently fixedly connected with the lower parts of the corresponding side edges of the supporting frames through a horizontal plate; and a flowerpot body is arranged in the fixing frame. The rolling type small flowerpot soil spreading device has the beneficial effects that the rolling device capable of simulating the structural form of the running robot is adopted to roll soil to avoid a phenomenon that caking soil directly falls into the flowerpot to affect subsequent transplantation work, meanwhile, working labor force of a manual operation is reduced, and working efficiency is improved.

Owner:夏爱莲

Rubber crushing device for rubber production and processing

InactiveCN112476864AAchieve the first smashAchieve secondary crushingSievingScreeningComposite materialCrumb rubber

The invention discloses a rubber crushing device for rubber production and processing. The device comprises a stirring box, a feed port and a discharge port arranged at the top and the bottom of the stirring box, and two first crushing rods arranged in the stirring box, and any end of each first crushing rod penetrates through the stirring box and is fixedly provided with a driving piece capable of driving the first crushing rod to move; according to the rubber crushing device for rubber production and processing, the first crushing rods can be driven to move through the arranged driving pieces, rubber is crushed for the first time, and the rubber can be crushed for the second time through an arranged crushing piece when the rubber crushing piece is used; and during crushing, only rubber particles conforming to the size can fall out of the crushing piece, so that the situation that rubber not conforming to the size needs to be reworked and crushed during use is avoided, the working efficiency is improved, and use is extremely good.

Owner:湖南宝烽设备股份有限公司

Crushing device with good crushing effect for tungsten powder production

The invention discloses a crushing device with a good crushing effect for tungsten powder production. The crushing device comprises a first transverse plate. A crushing box is fixedly connected to theleft side of the top of the first transverse plate, a transmission box is fixedly connected to the right side of the crushing box, and a first motor is fixedly connected to the right side of the inner wall of the transmission box. By arranging the first transverse plate, the crushing box, the transmission box, the first motor, a turnplate, a first fixed column, a first transmission bar, a first fixed block, a second transmission bar, a second fixed column, a third fixed column, a second transverse plate, a first crushing plate, a first inclined block, a second crushing plate, a second motor,a movable column, a pressing wheel, a third crushing plate, a filter screen, a fixed plate, a discharging pipe, a feeding cabin and a roller matched in use, the crushing device solves the problem thatexisting tungsten powder particles are not uniformly crushed. The crushing device with the good crushing effect for tungsten powder production has the advantage of being good in crushing effect and is convenient for a user to crush and process tungsten powder, and the practicality of the crushing device is improved.

Owner:赣州市光华有色金属有限公司

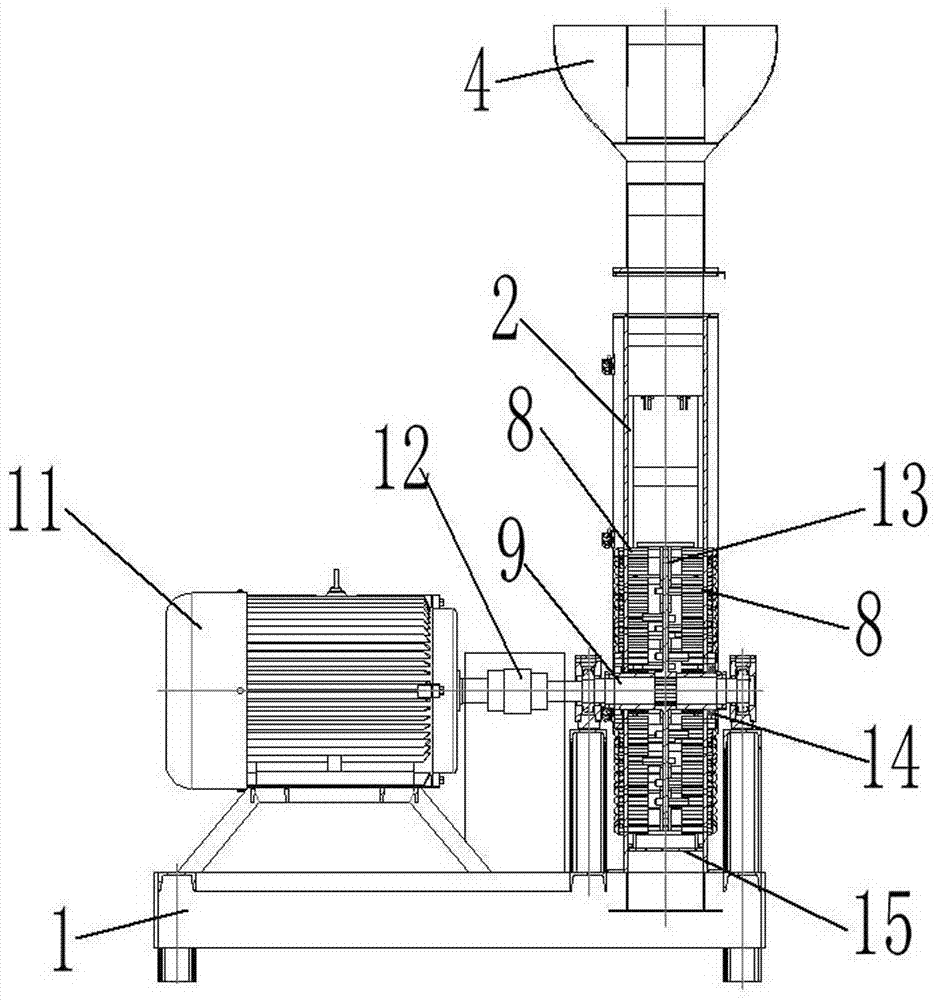

Tooth-claw type crusher

A tooth-claw type crusher comprises a machine base, a machine case, a feed hopper, a motor, a plurality of tooth claws II, a plurality of tooth claws I, flat tooth ends and a screening plate. A circulation layer is destroyed through a containing cavity in the machine case. The motion direction of large-particle materials moving in a manner of attaching to the screening plate is changed. Fine powder with the qualified particle size falls into a discharge port through the screening plate so that the fine powder with the qualified particle size can be transferred out in time. The condition of over-crushing is effectively avoided. The problems of large power consumption and low working efficiency caused due to the fact that products with the qualified particle size cannot be discharged of a feed grinder in time in the prior art are solved. As the screening plate is of a raindrop-shaped structure, the design of a raindrop-shaped crushing chamber can be adopted for a cavity, the circulation layer formed by materials during rotating can be destroyed, and the materials can make full contact with the tooth claws and the flat teeth. Moreover, materials on the two sides of a rotor disk are uniform, secondary crushing is achieved really, and the crushing efficiency is greatly improved.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

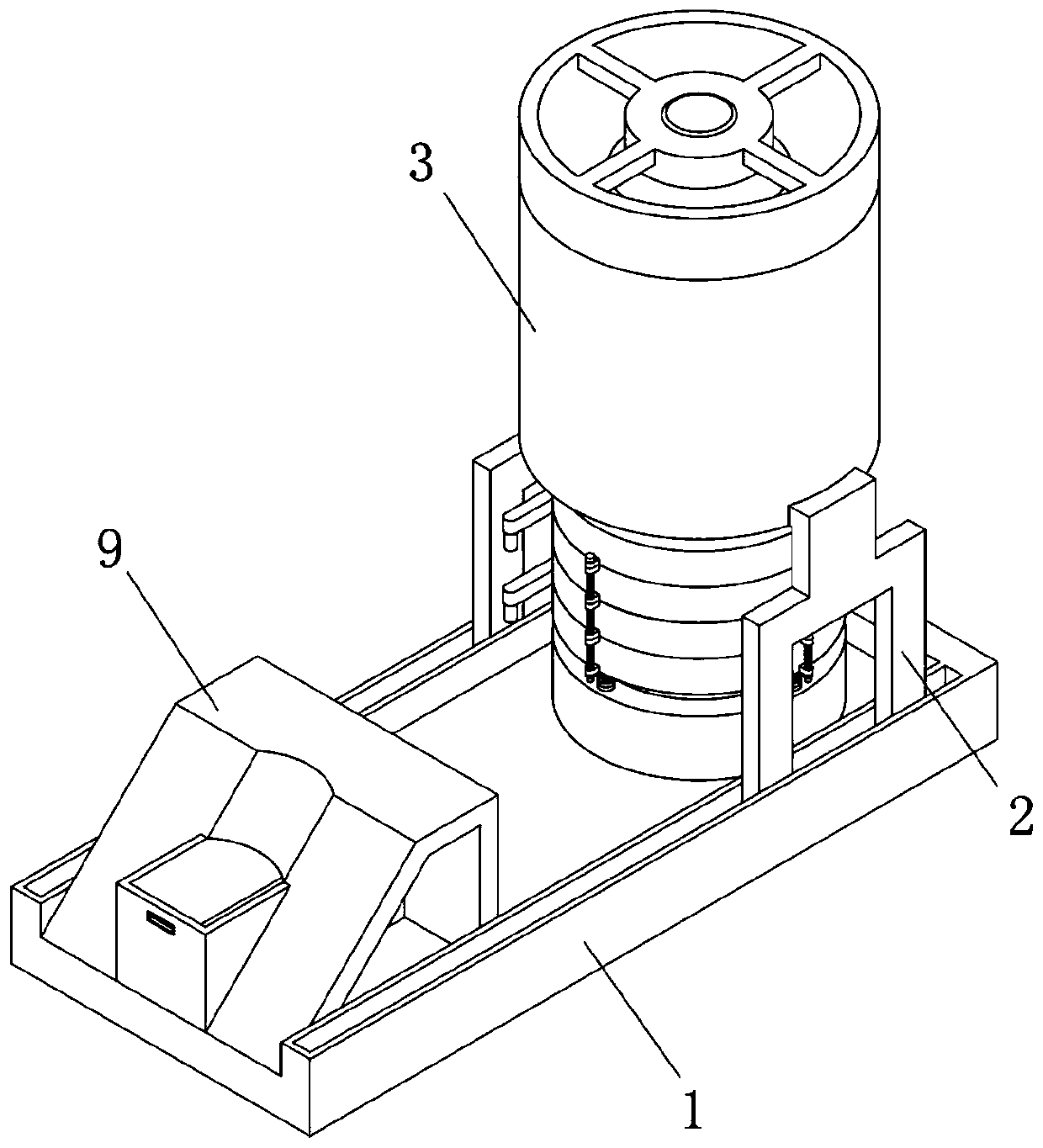

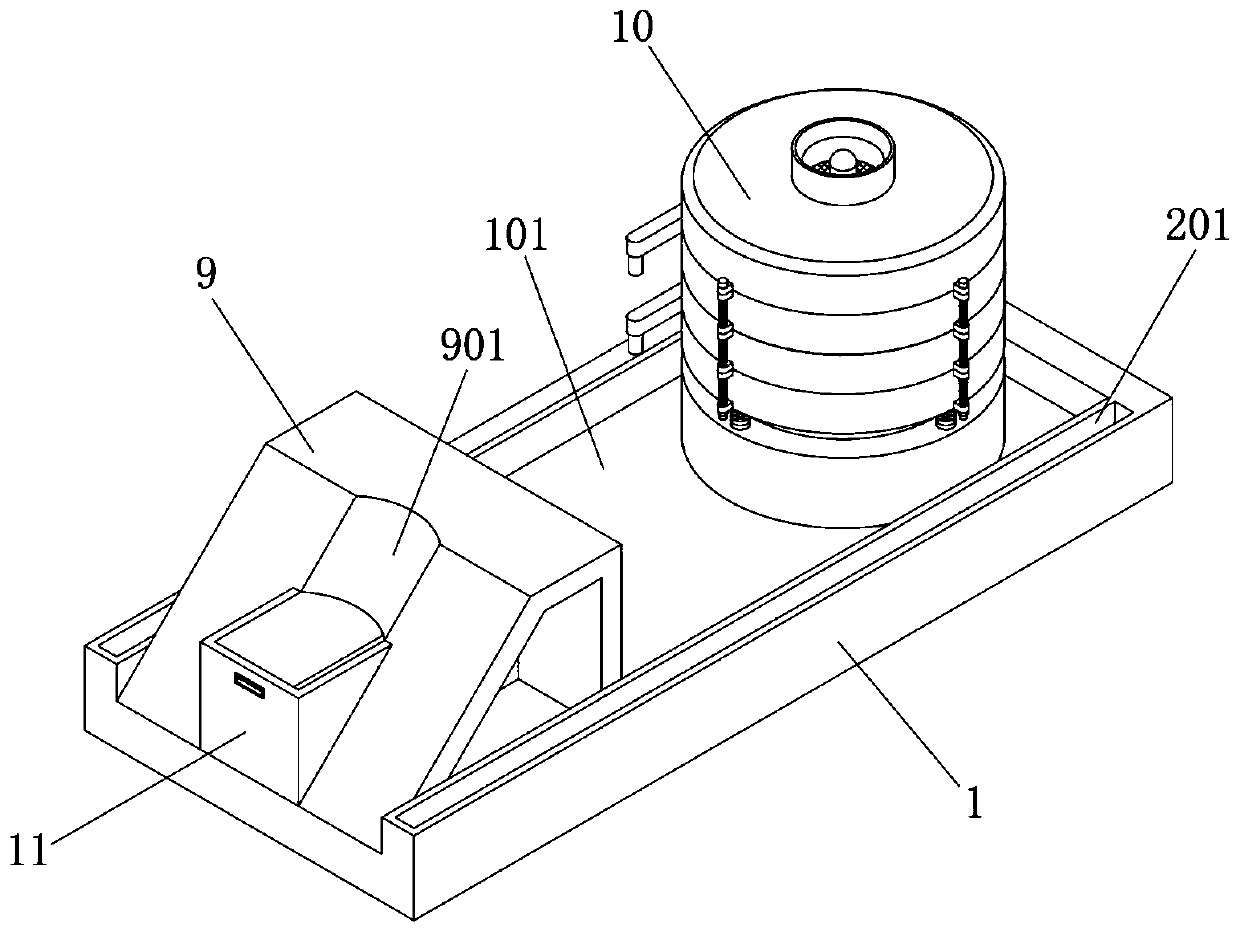

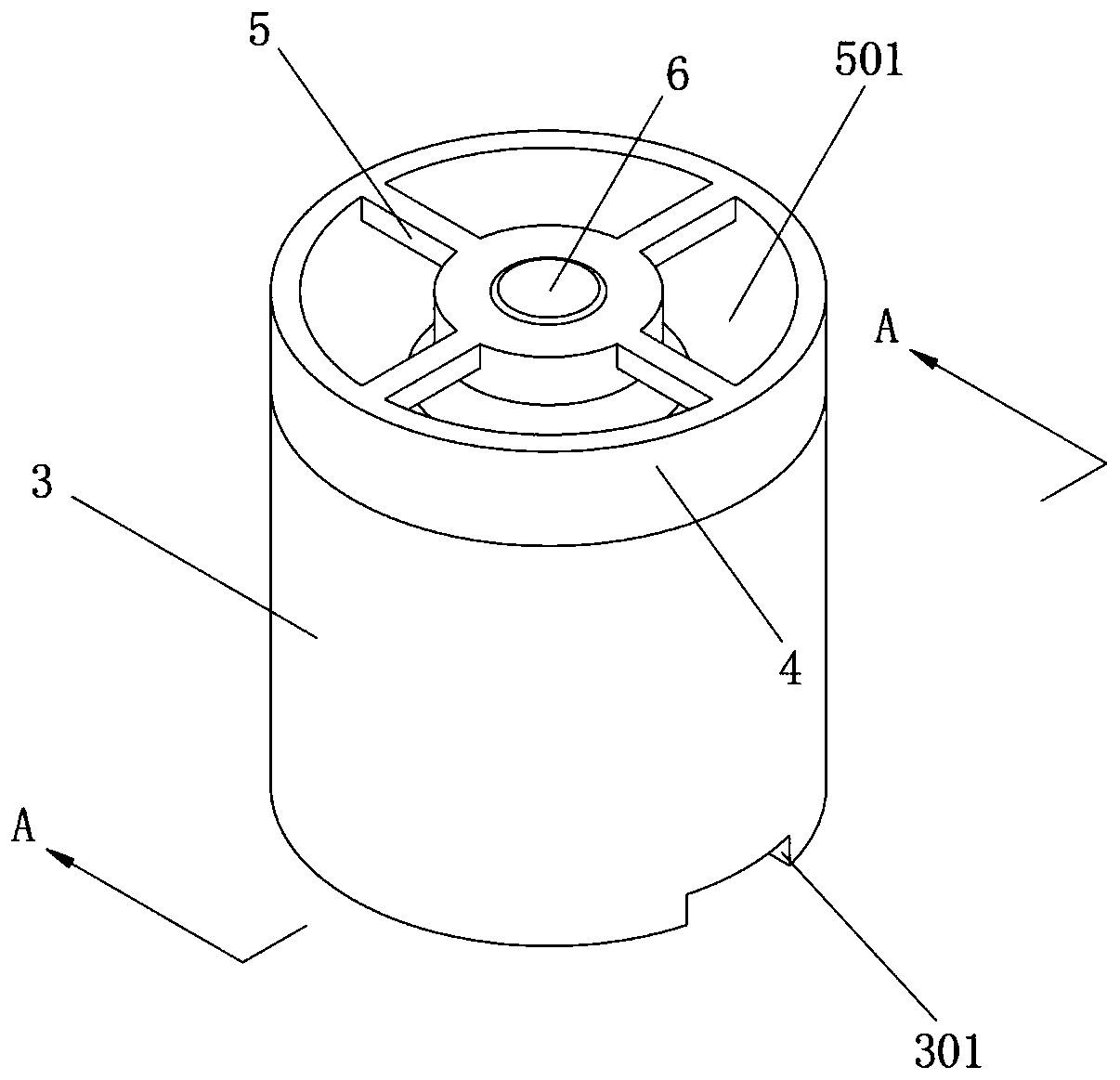

Two-stage raw material crushing device for industrial production of zinc sulfate

The invention discloses a two-stage raw material crushing device for industrial production of zinc sulfate. The two-stage raw material crushing device comprises a mounting substrate, a crushing box and a discharging structure. The crushing box is mounted on the mounting substrate and can move and be adjusted. The discharging structure is arranged on the mounting substrate and is matched with the crushing box. The crushing box is of a cylindrical structure, and a crushing bin is formed in the top end of the crushing box. The edge of the crushing bin is constructed into a conical side wall, anda discharging cavity communicating with the outside is formed in the bottom end of the crushing bin. The top end of the crushing bin is covered with a sealing cover, and the discharging cavity in thebottom end of the crushing bin is sealed by a sealing gate. Crushing equipment is mounted on the sealing cover and extends into the crushing bin, and multiple edge ridges matched with the crushing binare constructed on the inner wall of the crushing bin in an annular array manner. A grinding mechanism is mounted in the discharging cavity in the bottom end of the crushing bin. The raw material crushing device for industrial production of th zinc sulfate is efficient in crushing, the size of particles is easy to control, separation and collection are carried out as required, and high applicability is achieved.

Owner:黄秀洁

Tailing recovery treatment equipment

InactiveCN111841733AAchieve secondary crushingRealize transportationMagnetic separationGrain treatmentsThermodynamicsMechanical engineering

The invention discloses tailing recovery treatment equipment. The tailing recovery treatment equipment comprises an equipment box body, and the tailing recovery treatment equipment is characterized inthat the front side end wall of the equipment box body is fixedly connected with a main transmission cavity; a grinding device is arranged in the main transmission cavity, and is used for primarily grinding tailings; the left side end wall of the equipment box body is fixedly connected with a drainage box; a filter device is arranged in the drainage box; the lower side end wall of the equipment box body is fixedly connected with a base; a secondary transmission cavity is formed in the base; a vibration device is arranged in the secondary transmission cavity; the front side end wall of the equipment box body is fixedly connected with a conveying cavity; a screening device is arranged in the conveying cavity; and the upper side end wall of the equipment box body is fixedly connected with anair injection device. The tailing recovery treatment equipment can realize the recycling of magnetic minerals in the tailings, reduces the resource waste, and is relatively high in use efficiency.

Owner:磐安叶层煤矿设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com