Feed processing and producing feeding device

A feeding device and feed processing technology, applied in feed, food science, application and other directions, can solve the problem of time-consuming and laborious, and achieve the effect of avoiding pipeline blockage, reducing the difficulty of feeding, and saving feeding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

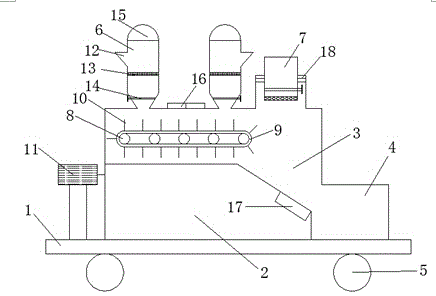

[0018] The invention provides a feeding device for feed processing and production, which can add various materials at the same time, and can avoid the dust in the crushed materials from floating around and polluting the environment when feeding, and will not affect the health of the operator at the same time. The mesh screen can remove large particles that do not meet the requirements. After adding a vibrator, it can avoid pipeline blockage during the transportation process. There is a small material bucket, which can add small materials while adding large materials, saving feeding time. The difficulty of feeding is reduced.

[0019] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0020] Such as figure 1 As shown, a feeding device for feed processing production includes a base plate 1, a support 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com