Multi-screw measurement feeding and mixed conveying system

A conveying system and metering feeding technology, applied in the field of multi-screw metering feeding and mixing conveying systems, can solve the problems of dust pollution, difficulty in meeting process requirements, and easy agglomeration of ultra-fine powder, achieving a high degree of automation and improving production. Efficiency and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

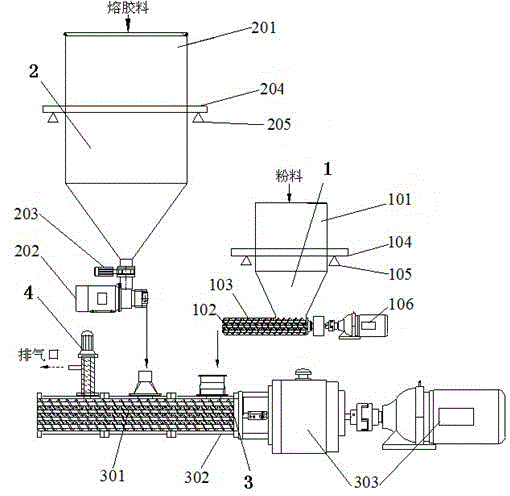

[0017] Such as figure 1 As shown, a multi-screw metering feeding and mixing conveying system includes a counter-rotating multi-screw powder metering feeder 1, a colloid metering feeder 2, a co-rotating multi-screw mixing conveyor 3 and a co-rotating twin-screw exhaust device 4. The co-rotating multi-screw mixing conveyor 3 includes a barrel 302, and the barrel includes a first-section barrel, a second-section barrel, and a third-section barrel connected in sequence, and the first section barrel There is a feeding opening on the upper side, which is sealed with a soft connection with the powder metering feeder 1; there is a colloid feeding port on the upper side of the second section of the cylinder, and the colloid feeding port uses a perforated plate to divert the colloid and evenly drip it On the surface of the powder in the barrel; the upper side of the third secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com