Heating furnace discharging platform system for thermoforming production line

A production line and heating furnace technology, which is applied in the field of heating furnace discharge system of thermoforming production line, can solve problems such as sheet lifting, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

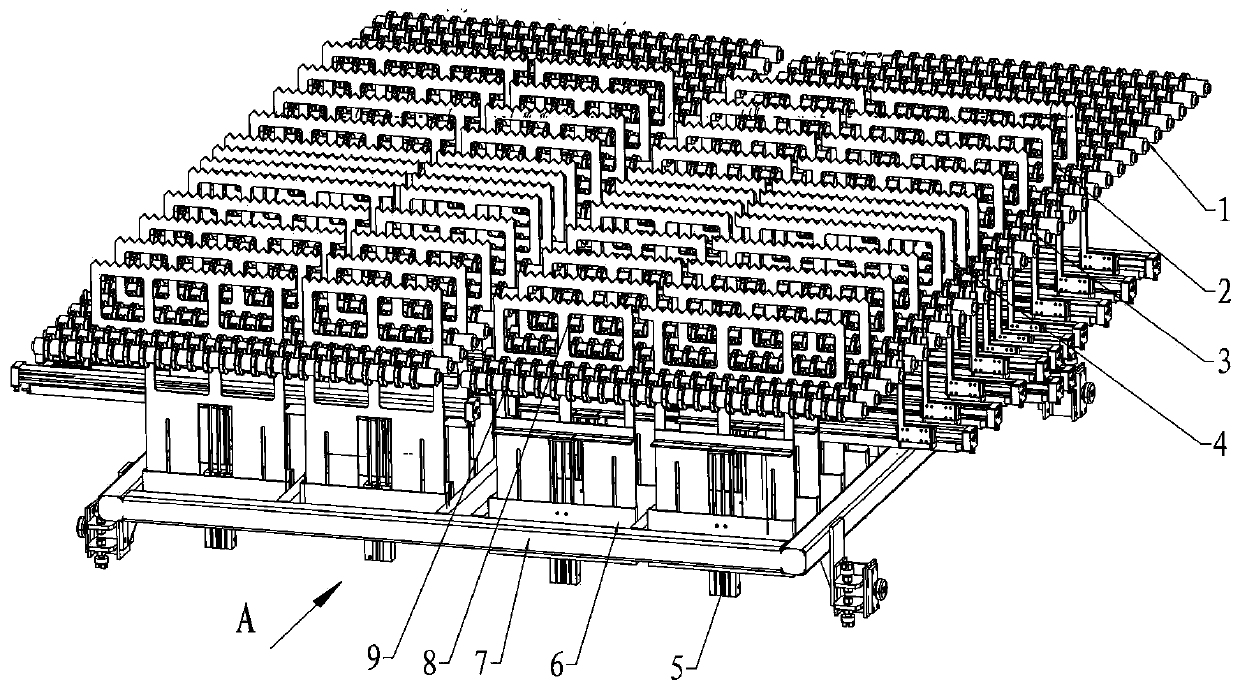

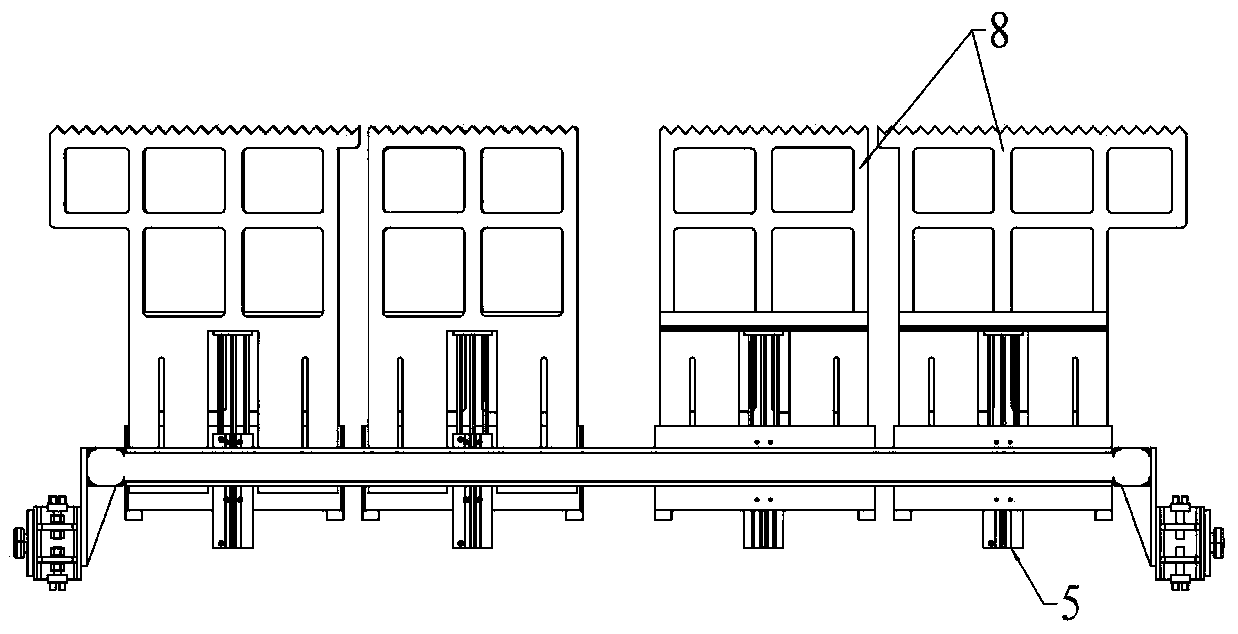

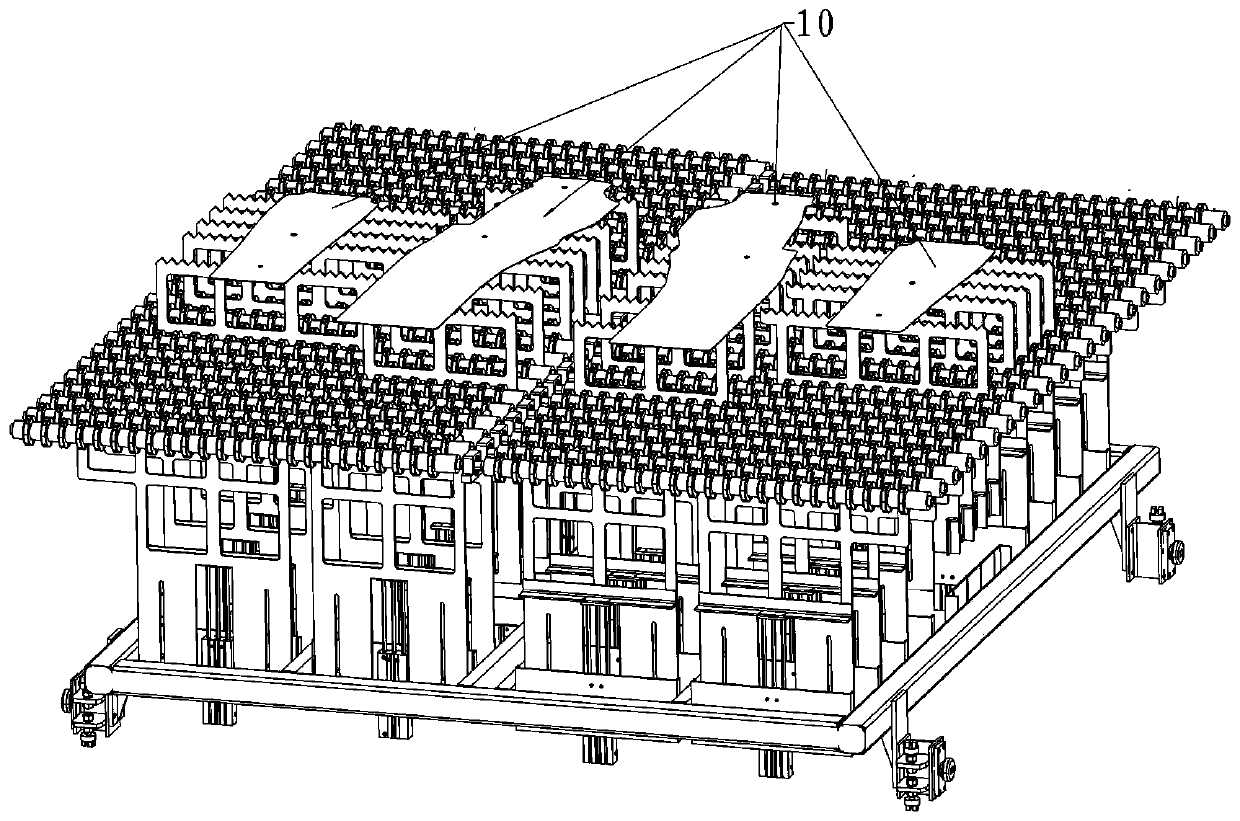

[0028] See figure 1 , The present invention includes a base 7, several furnace rollers 1 for conveying product sheets, and several rows of lifting tool holders assembled on the base. The furnace rollers are evenly distributed on each furnace roller and the high temperature resistant roller ring 9 is evenly distributed. The lifting tool rest is composed of two parts, which are several rows of conventional lifting tool rests 4 and several rows of adjustable lifting tool rests 2. Several rows of conventional lifting tool holders are assembled on the conventional lifting tool holder installation frame. The conventional lifting tool holder installation frame is located in the middle of the base. The servo motor drives the lifting and falling of the conventional lifting tool holder installation frame through the transmission mechanism. The normal lifting tool post performs a unified lifting action. The conventional lifting tool post and the conventional lifting tool post installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com