Upper and lower synchronous feeding mechanisms of thin-material lockstitch sewing machine and feeding method thereof

A technology of feeding mechanism and lockstitch sewing machine, applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems of complexity, high cost, unsuitable for popularization and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

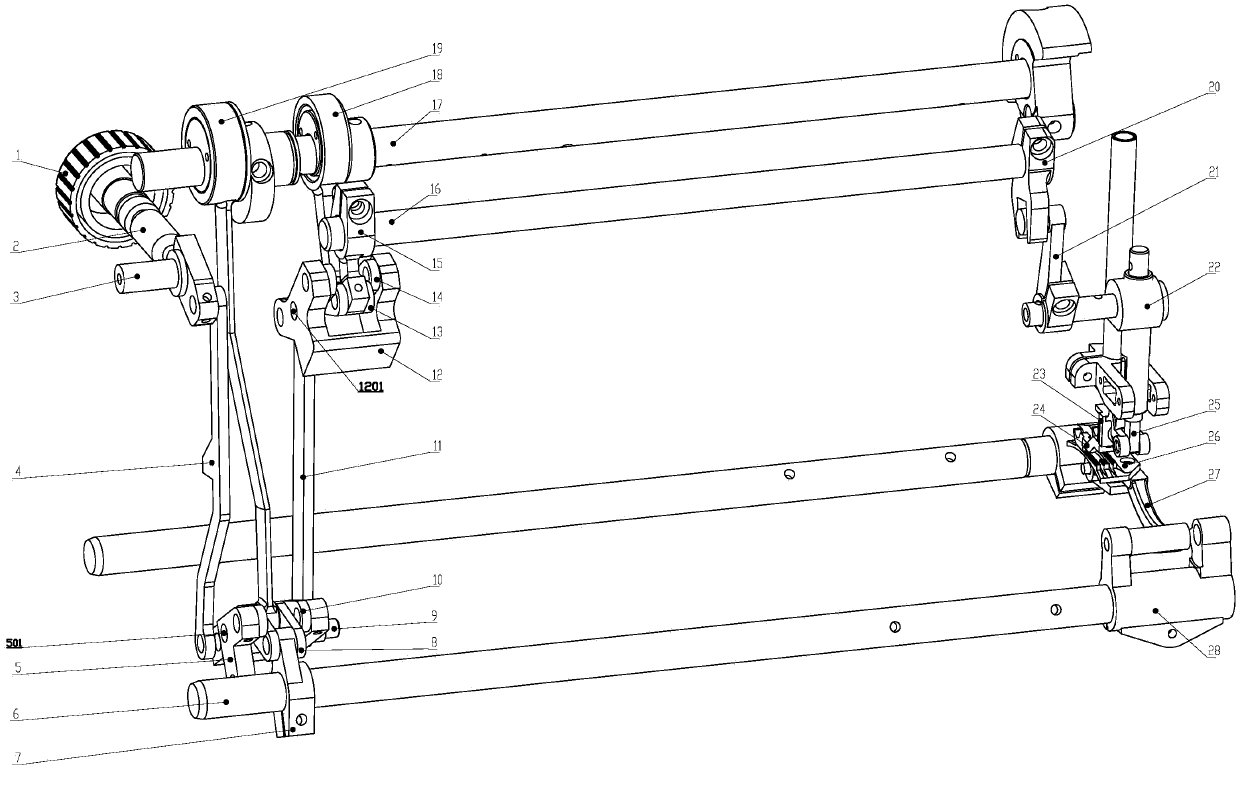

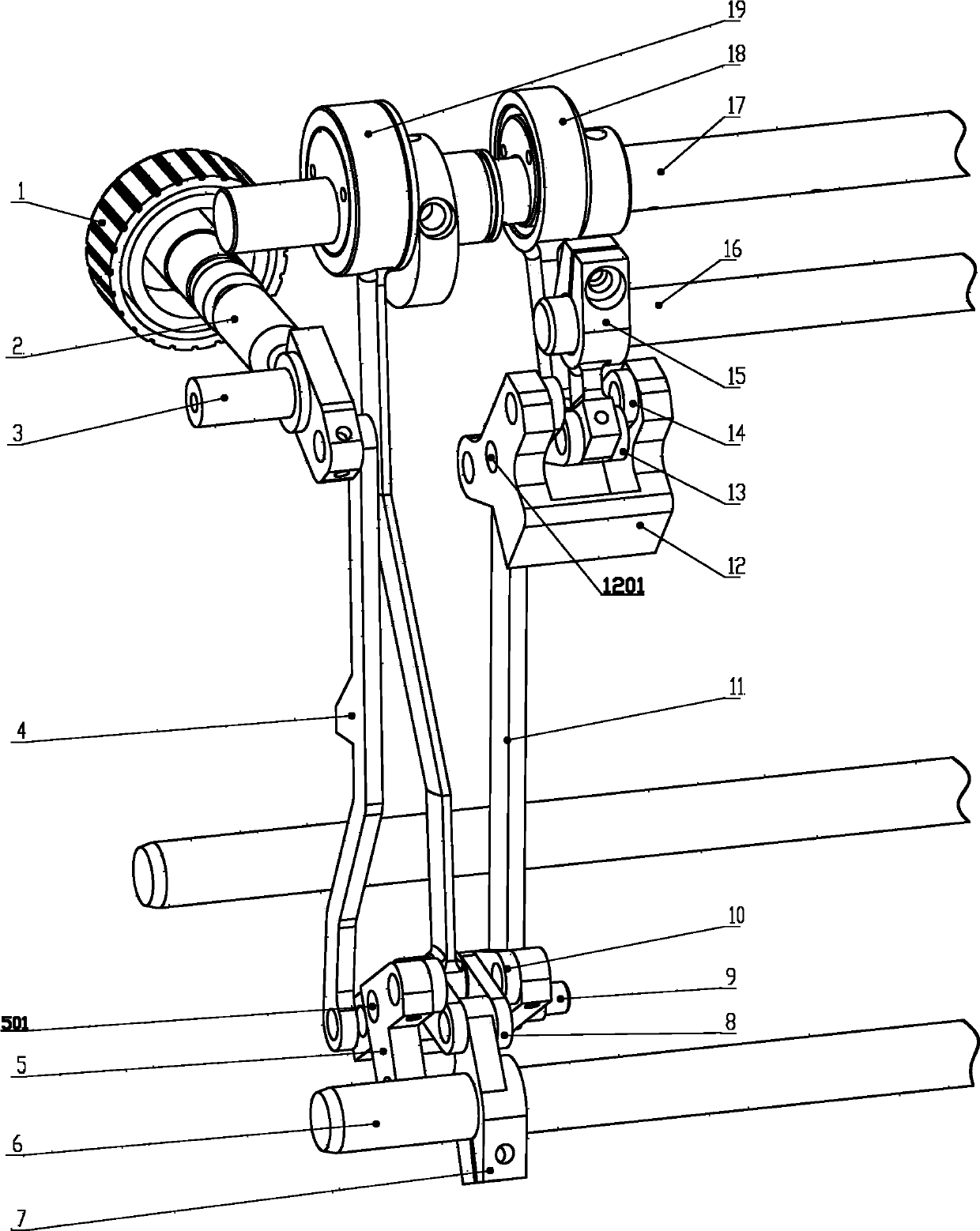

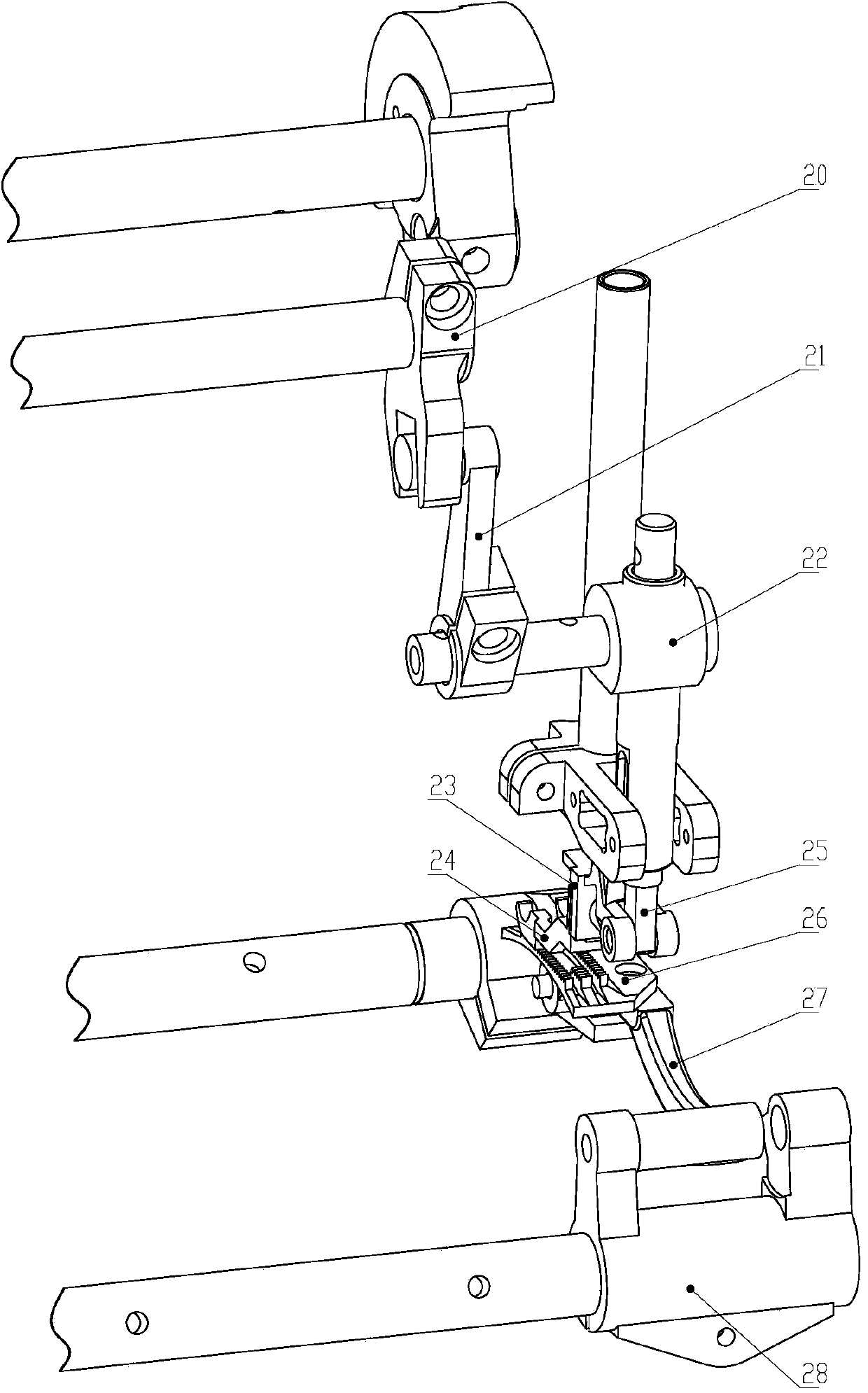

[0019] The implementation mode takes the feeding method of the synchronous feeding mechanism of the thin material lockstitch sewing machine as an example, such as Figure 1 ~ Figure 4 As shown, the synchronous feeding mechanism is provided with an upper synchronous feeding mechanism and a lower synchronous feeding mechanism, and the upper pin hole 1201 of the upper feeding swing plate seat 12 of the upper synchronous feeding mechanism is installed on the casing of the lockstitch sewing machine through a pin connection ( figure 1 The casing of the pin shaft and lockstitch sewing machine described in the above, as well as the thin material lockstitch sewing machine and the electric device are not drawn), when the upper feeding swing plate seat swings around the pin shaft, it drives the upper feeding mechanism to change the swing range, changing the upper feeding Tooth 24 stroke.

[0020] The lower pin hole 501 of the lower feeding swing plate base 5 of the lower synchronous feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com