Transfer mechanism

A regional and tubular technology, applied in the field of transfer mechanism, can solve the problems of affecting the overall quality of the pipe, reducing the ability of the pipe to resist pitting corrosion, shortening the service life of the pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

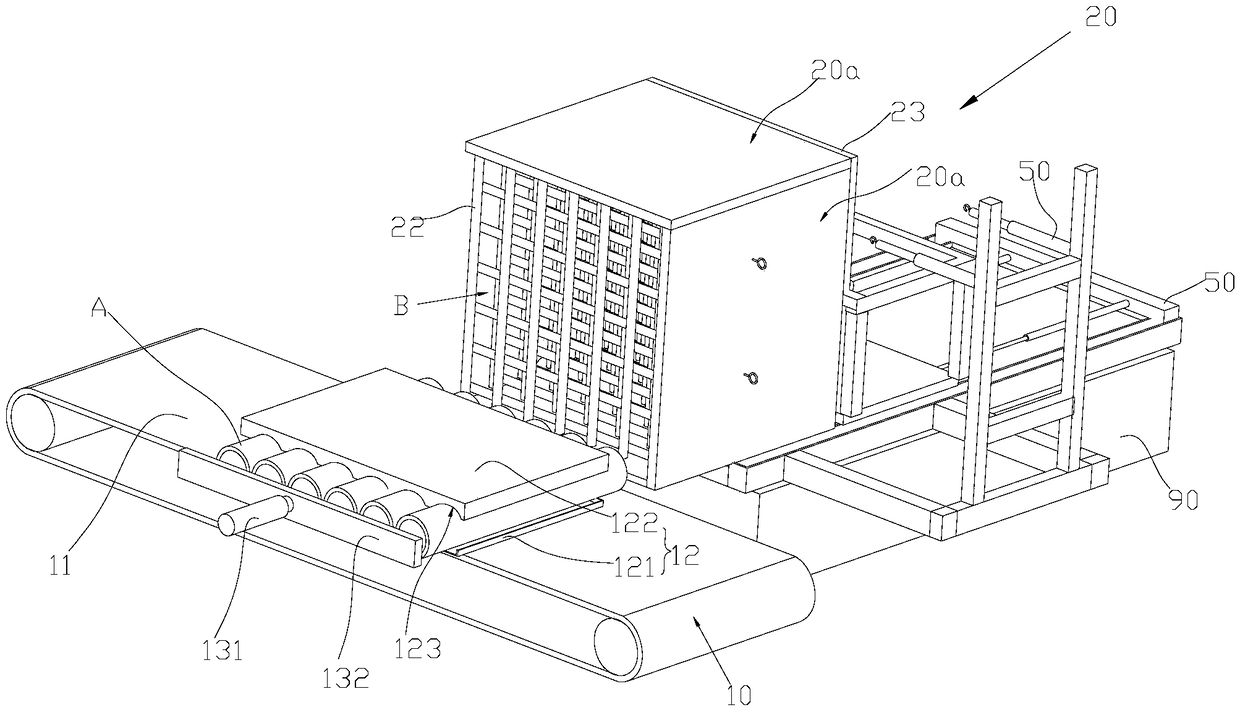

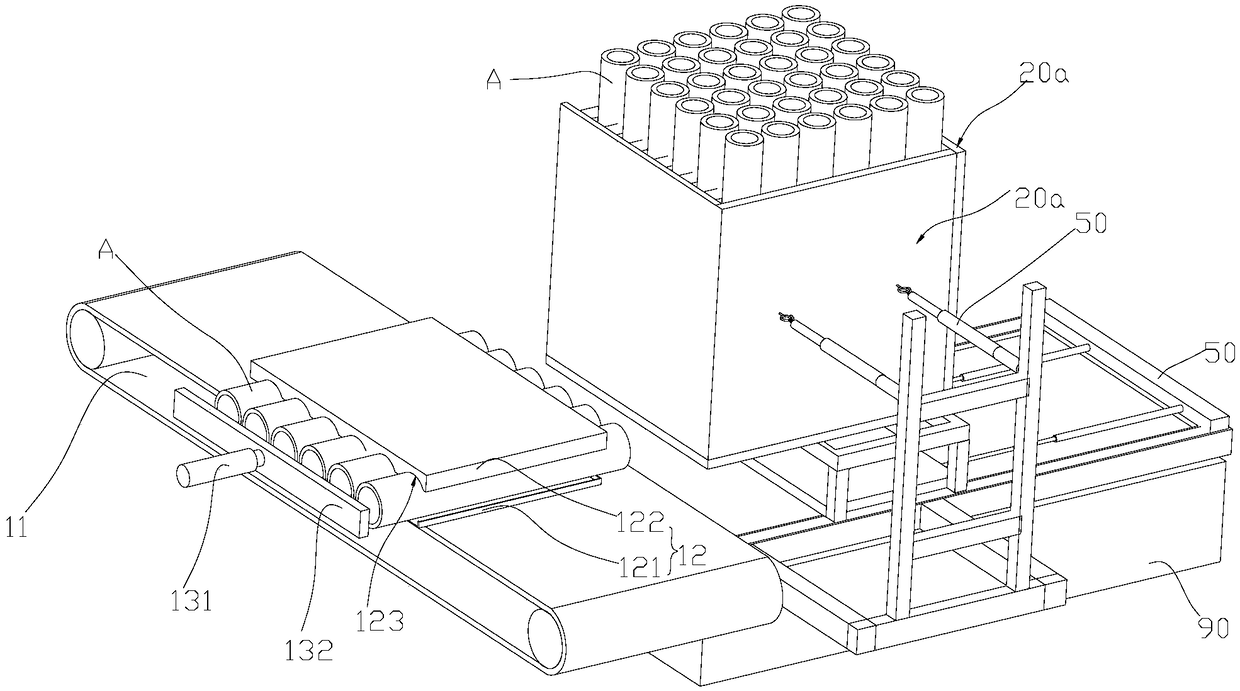

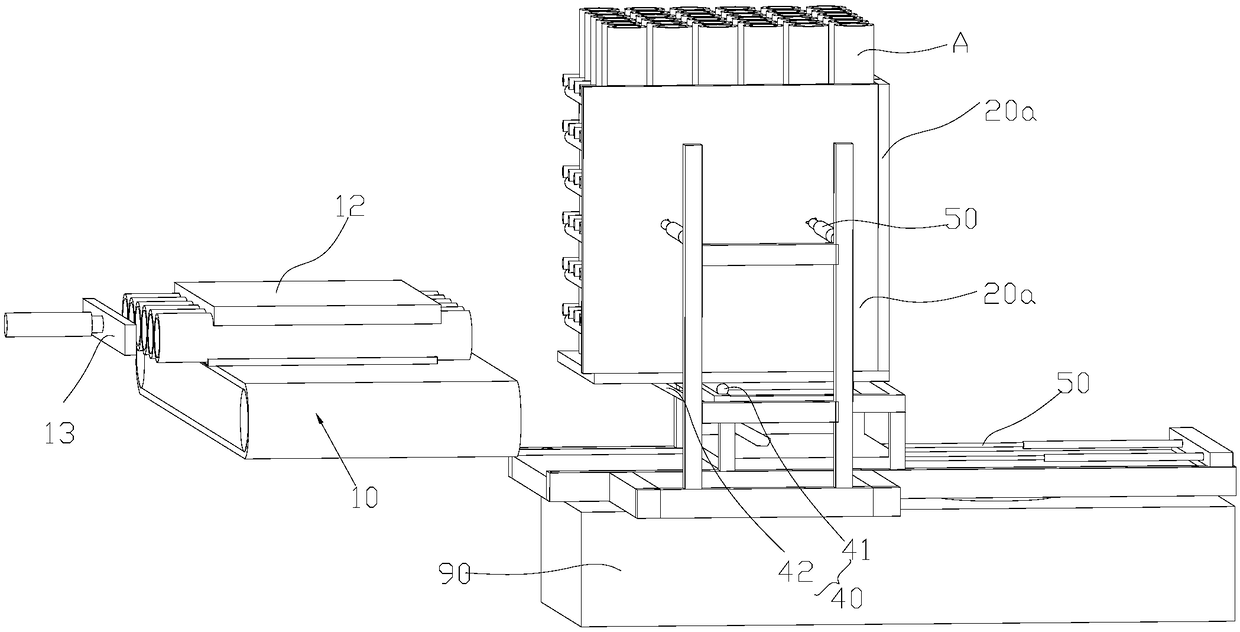

[0014] A transfer mechanism, the transfer mechanism 20 is provided with a plurality of circular or rectangular tubular areas B for accommodating the pipes A to be processed, one end of the tubular areas B is open and the other end is closed, and the cross-sectional size of the tubular areas B is slightly larger than that to be processed For the outer diameter of the pipe A, a plurality of tubular regions B form a grid shape, and the cross-sectional size of the tubular regions B is adjustable, and its minimum value is slightly larger than the outer diameter of the pipe A to be processed.

[0015] The transfer mechanism 20 also includes an overturning unit 40. The overturning unit 40 drives the transfer mechanism 20 to be placed horizontally or vertically. When the transfer mechanism 20 is placed horizontally, the tube length direction of the tubular region B is arranged along the horizontal direction and the tubular region B The opening faces the feeding mechanism 10; when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com