Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Continuous leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous leakage. 2016 2017 2018 2019 Billable/Specific Code. N39.45 is a billable/specific ICD-10-CM code that can be used to indicate a diagnosis for ...

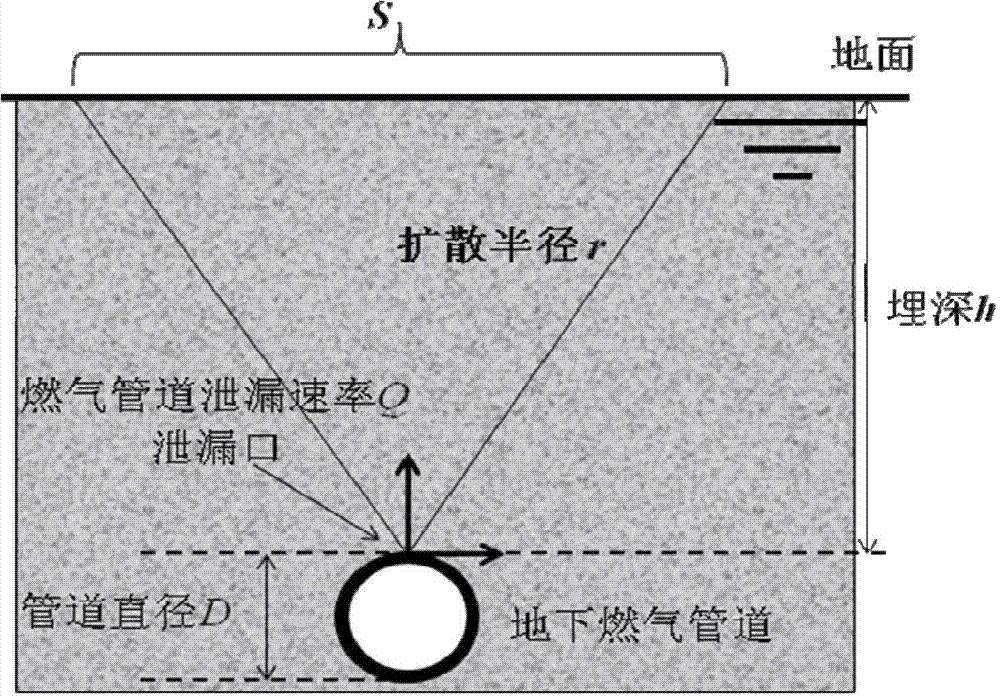

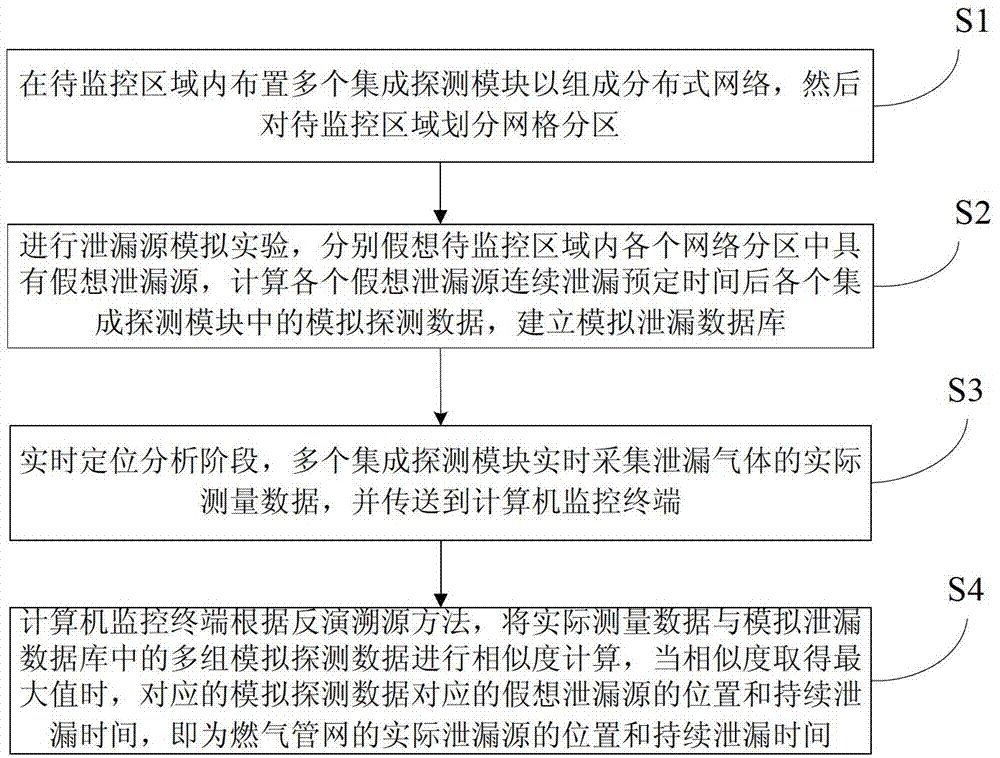

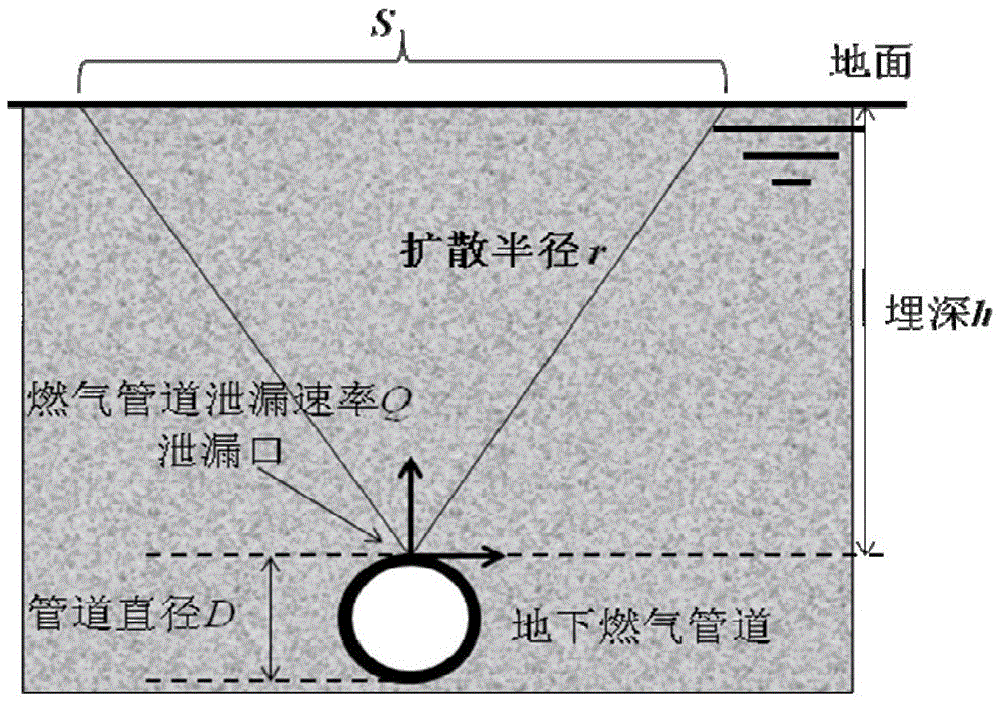

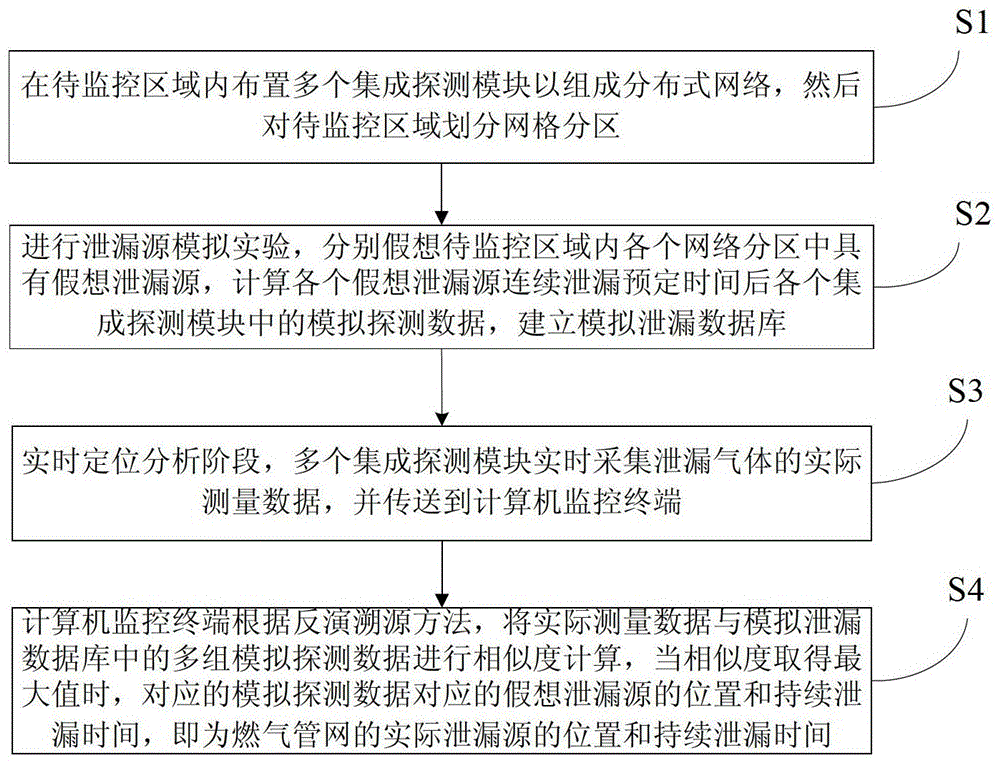

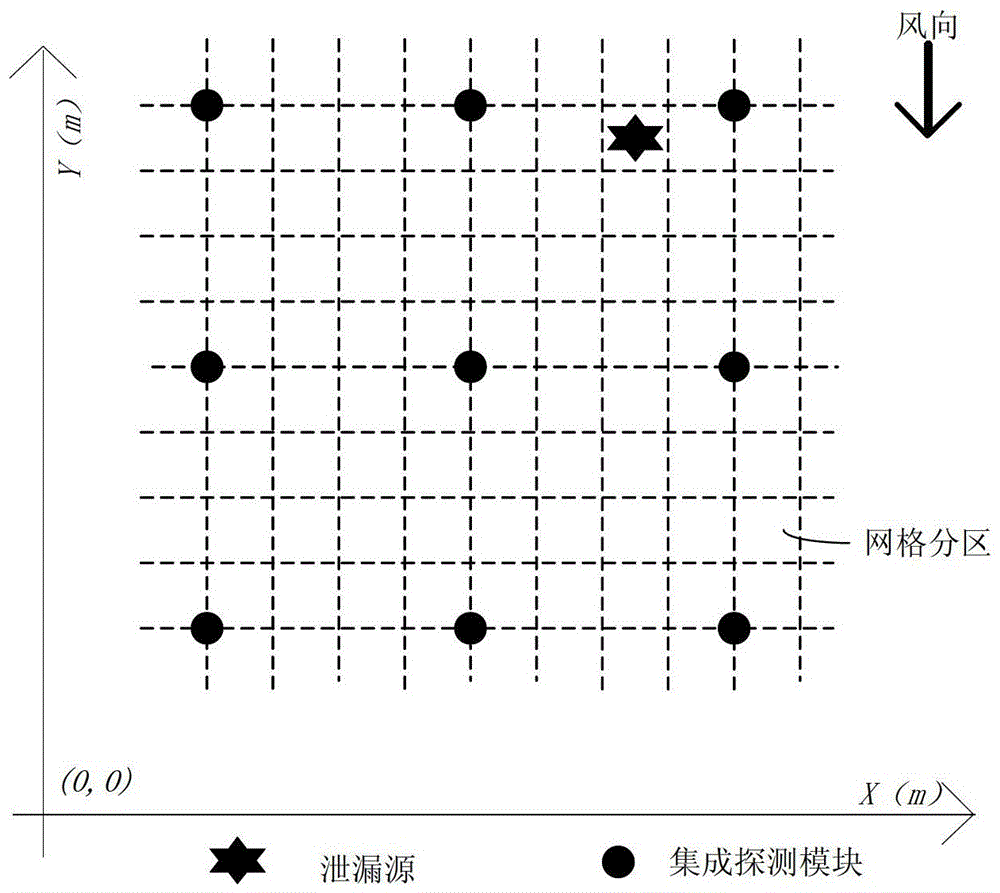

Real-time positioning analysis method and system for fuel gas pipeline network leakage source

The invention discloses a real-time positioning analysis method and system for a fuel gas pipeline network leakage source, wherein the method comprising the following steps: a plurality of integrated detection modules are arranged in a region to be monitored, and the region to be monitored is divided into grid sub-areas; a hypothesis that each grid sub-area in the area to be monitored has a fictitious leakage source is carried out, another hypothesis of simulated detection data of the integrated detection modules is carried out after the fictitious leakage source continuously leaks for a preset time, and a simulated leakage database is established; the integrated detection modules acquire the practical measurement data of leaked gases in real time, and the practical measurement data is transmitted to a computer monitoring terminal; similarity calculation of the practical measurement data and a plurality of simulated detection data in the simulated leakage database is carried out, when the similarity reaches the maximal value, the position and time of the hypothesis leakage source and the continuous leakage time which are corresponding to the simulated detection data are the position and time of the practical leakage source and the time of the continuous leakage time. Through the adoption of the method and the system, the position of the practical leakage source can be quickly found out.

Owner:TSINGHUA UNIV

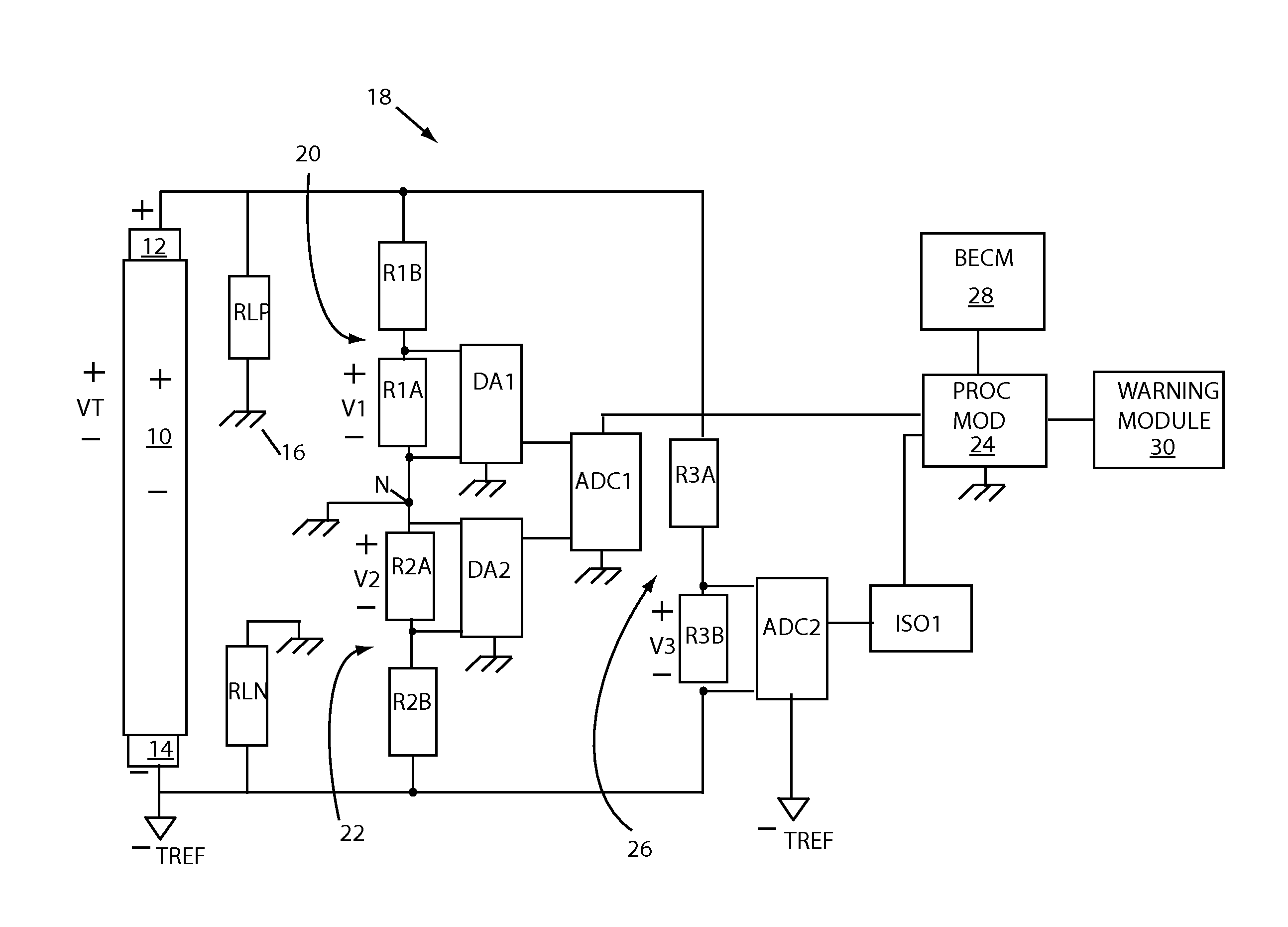

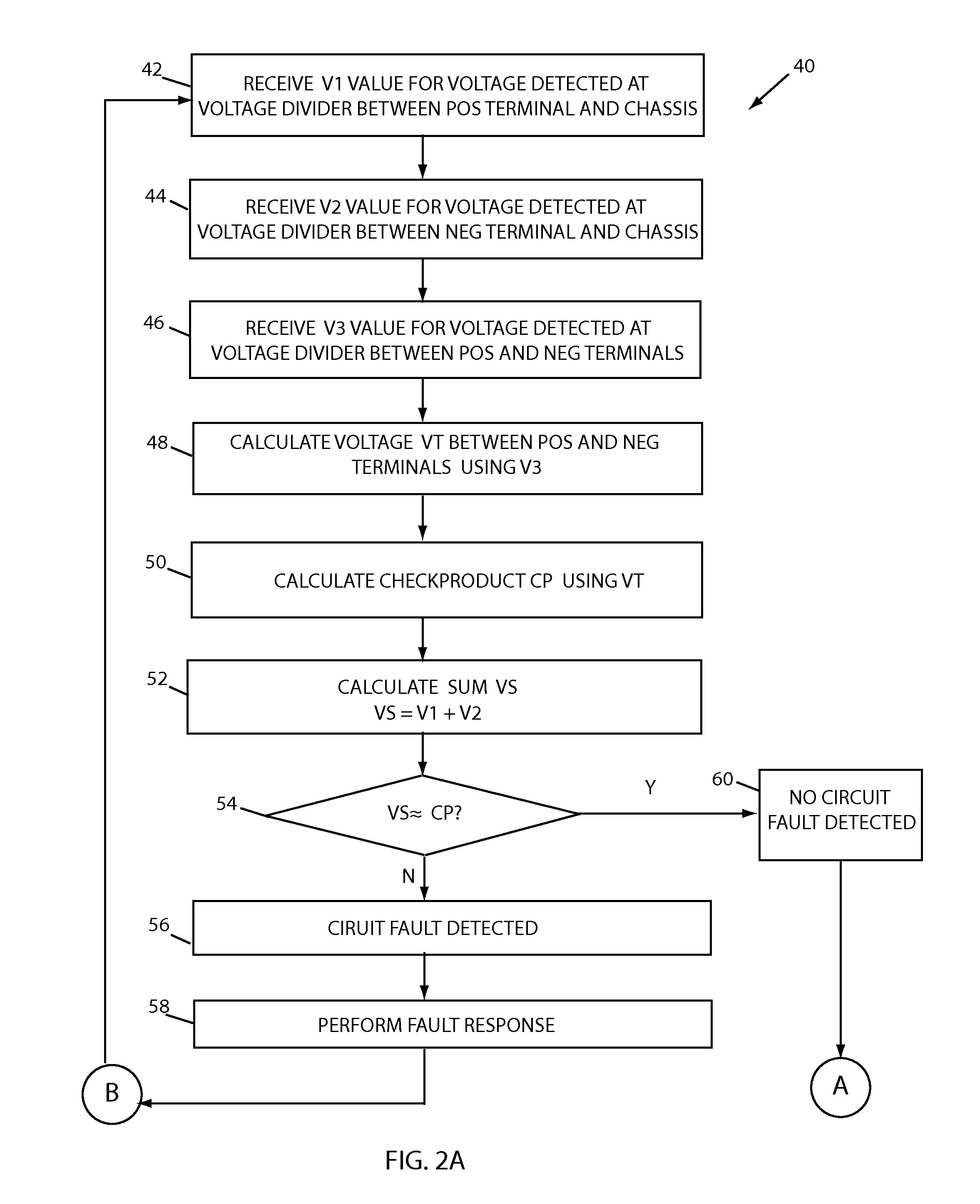

Continuous Leakage Detection Circuit with Integrated Robustness Check and Balanced Fault Detection

ActiveUS20150346257A1Continuous detectionWithout usingElectric devicesTesting electric installations on transportVoltage dividerEnergy storage

A leakage detection circuit with integrated robustness check provides leakage detection and continuous robustness check capability. A circuit can include a first voltage divider coupled to a chassis ground and a positive terminal of a traction energy storage device (ESD). A second voltage divider, connected in series to the first voltage divider, can be coupled to the chassis ground and a negative terminal of the ESD. A third voltage divider can be coupled to both the positive and negative ESD terminals. A checkproduct based on a voltage detected at the third voltage divider can be compared to a sum VS of voltages detected at first and second voltage dividers to check for a circuit fault. Voltages detected at the first and second voltage dividers, and SOC values, can be used to detect leakage faults, including balanced leakage faults, and a fault response can be performed.

Owner:FORD GLOBAL TECH LLC

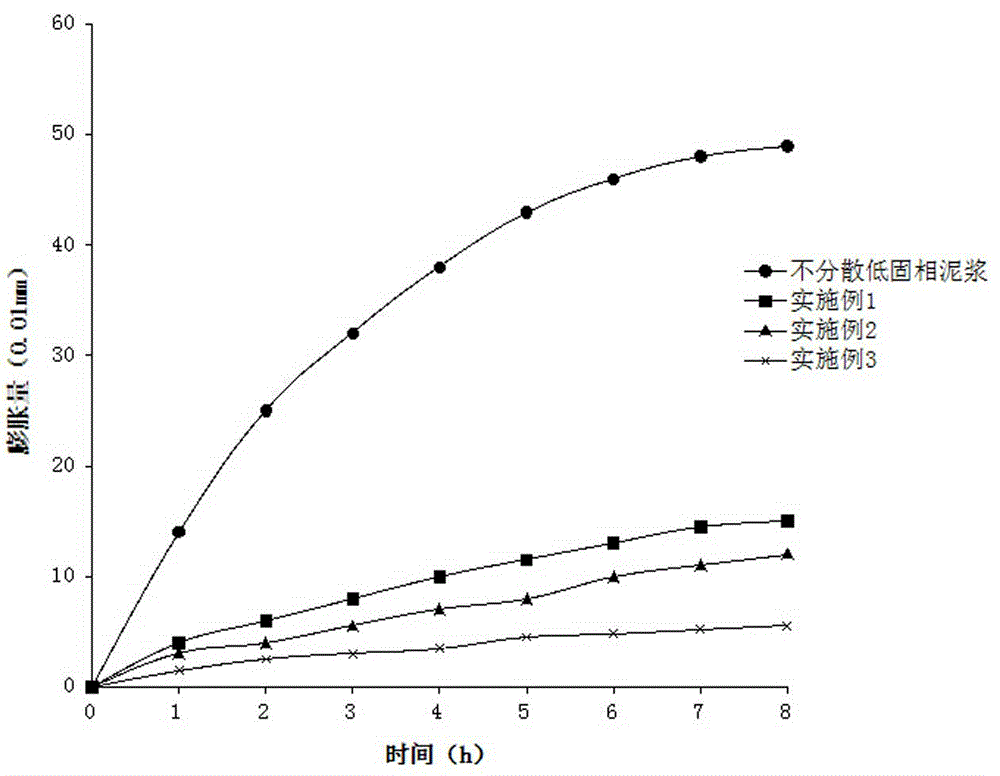

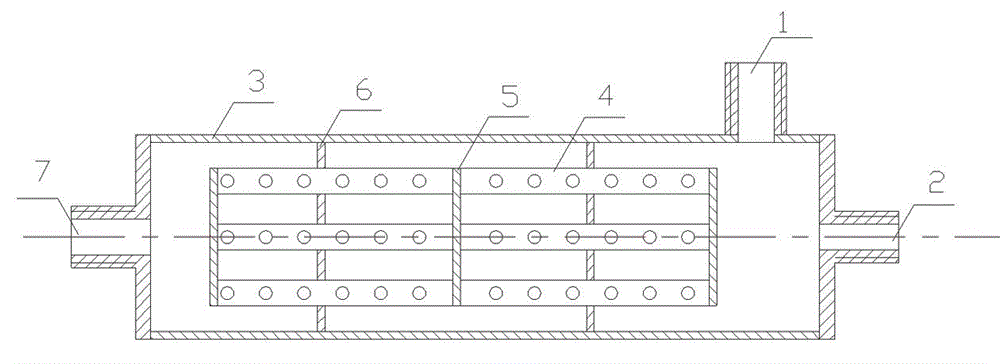

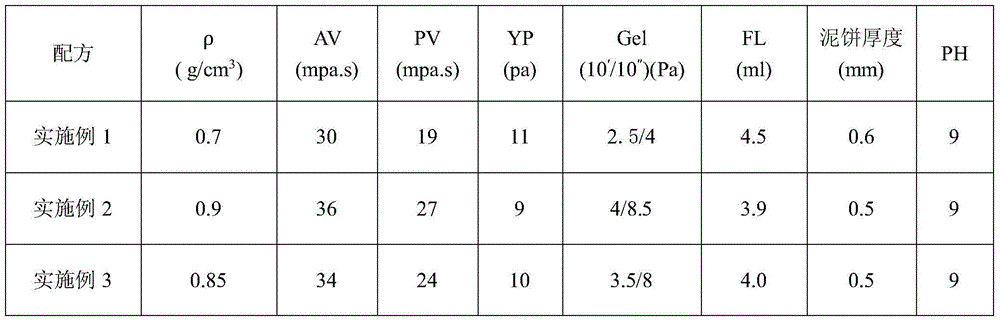

Anti-collapse and anti-leakage drilling washing fluid used during drilling and field production method thereof

ActiveCN104893696AImprove drilling efficiencyLower Drilling CostsDrilling compositionFoaming agentUltimate tensile strength

The invention discloses an anti-collapse and anti-leakage drilling washing fluid used during drilling and a field production method thereof, belongs to the technical field of geological core drilling technology, and aims to solve the problem that drilling washing fluid is poor in wall protecting effect under the stratum conditions of strong breaking and continuous leakage. The drilling washing fluid is characterized in that 30-50kg of bentonite, 2-4kg of soda ash, 2-5kg of tackifier, 20-50kg of fluid loss agent, 5-15kg of flow pattern regulator, 30-80kg of bridging agent, 20-50kg of blocking agent, 10-30kg of inhibitor and 1-3L of foaming agent are added to each cubic meter of water. The anti-collapse and anti-leakage drilling washing fluid has the advantages that the drilling washing fluid is good in collapse preventing effect, fast in leakage blocking, high in leakage blocking strength, wide in adaptive crack width range, and widely applicable to the drilling of water-sensitive and loose and broken stratums, low-pressure leakage layers and fracture hole developed stratums.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

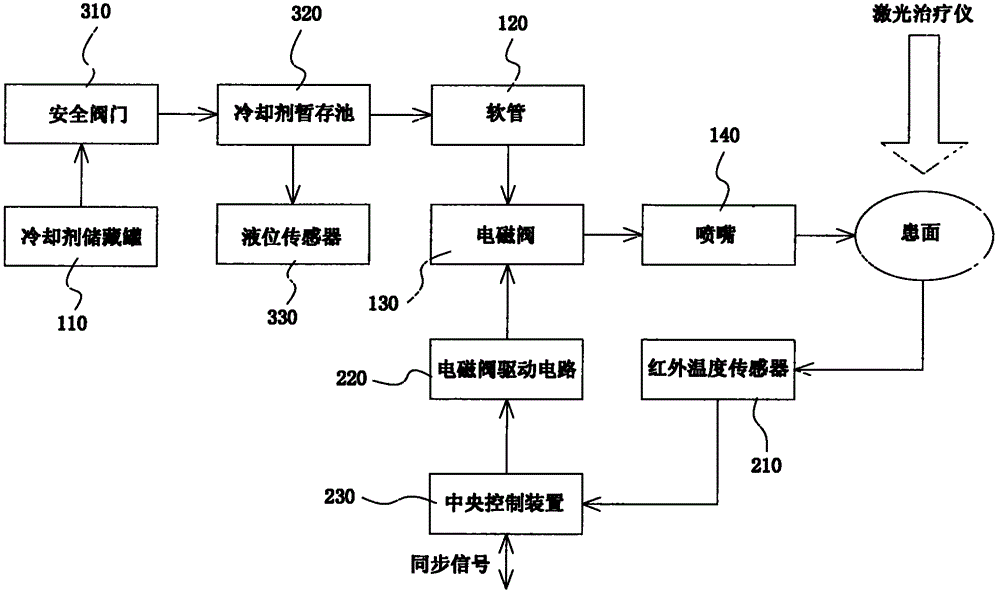

Skin cooling device for laser therapy

The invention relates to a skin cooling device for laser therapy. The skin cooling device comprises a coolant storage tank, a hose, an electromagnetic valve, a nozzle, an infrared temperature sensor, an electromagnetic valve driving circuit and a central control device, wherein the coolant storage tank is connected with the nozzle through the hose; the electromagnetic valve is arranged on a passage between the nozzle and the hose; the infrared temperature sensor is used for monitoring temperature of an affected face; the electromagnetic valve driving circuit is used for driving the electromagnetic valve to work; the infrared temperature sensor is in circuit connection with the central control device; and the central control device is in circuit connection with the electromagnetic valve driving circuit and a laser therapeutic apparatus. The skin cooling device has the beneficial effects that 1, a temperature monitor is arranged, so that whether an atomized coolant is sprayed can be monitored, the spray amount of the coolant is monitored, and the phenomenon of tissue burn caused by insufficient coolant spray is avoided, 2, the coolant is firstly pre-sprayed once for judging whether the work is normal and then the coolant is sprayed formally in order to solve the problem of time delay of heat transfer, and 3, a safety valve is used for cutting off a cooling pipeline when accidental leakage of the pipeline occurs so as to prevent continuous leakage.

Owner:长光华雷(苏州)医疗科技有限公司

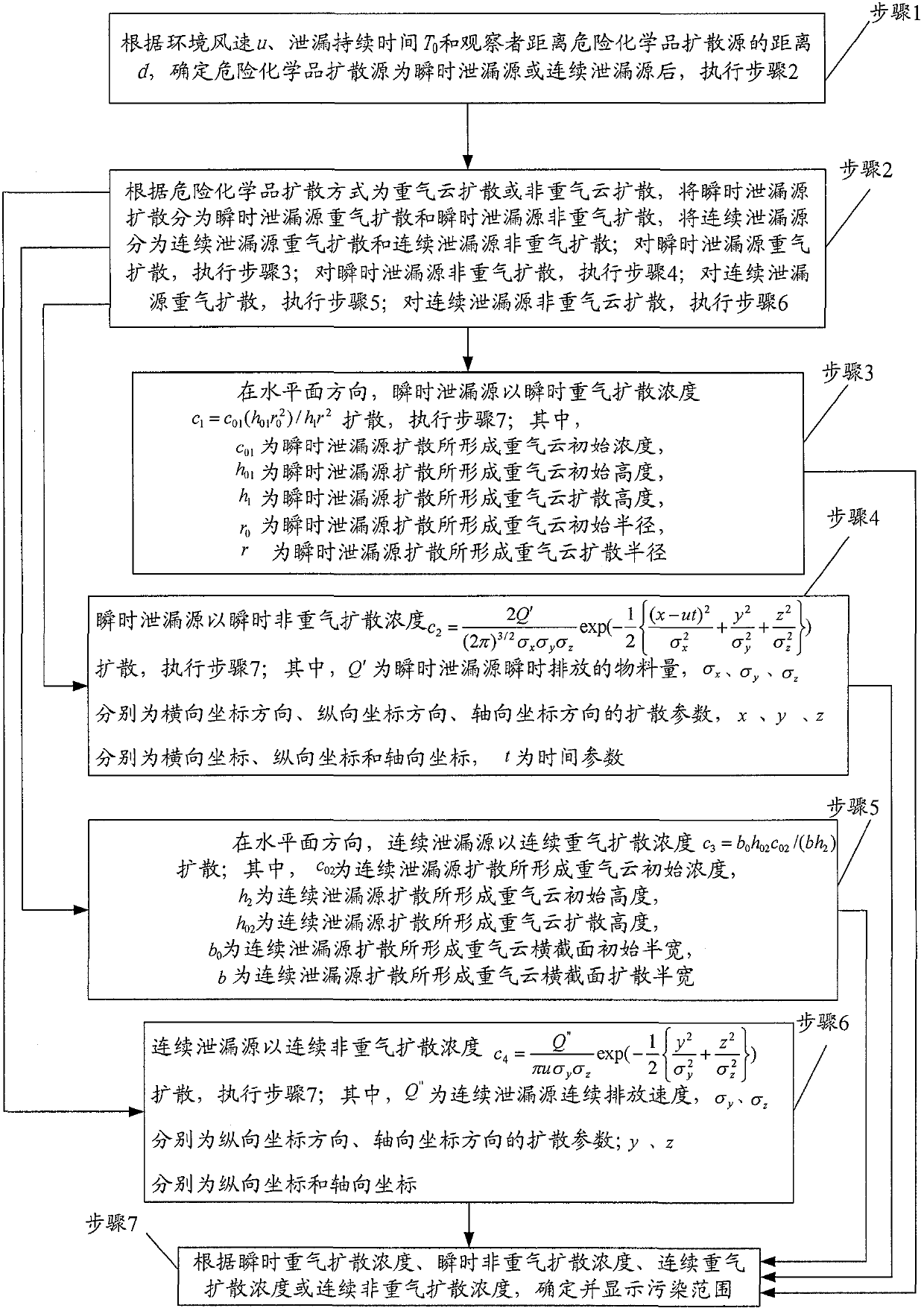

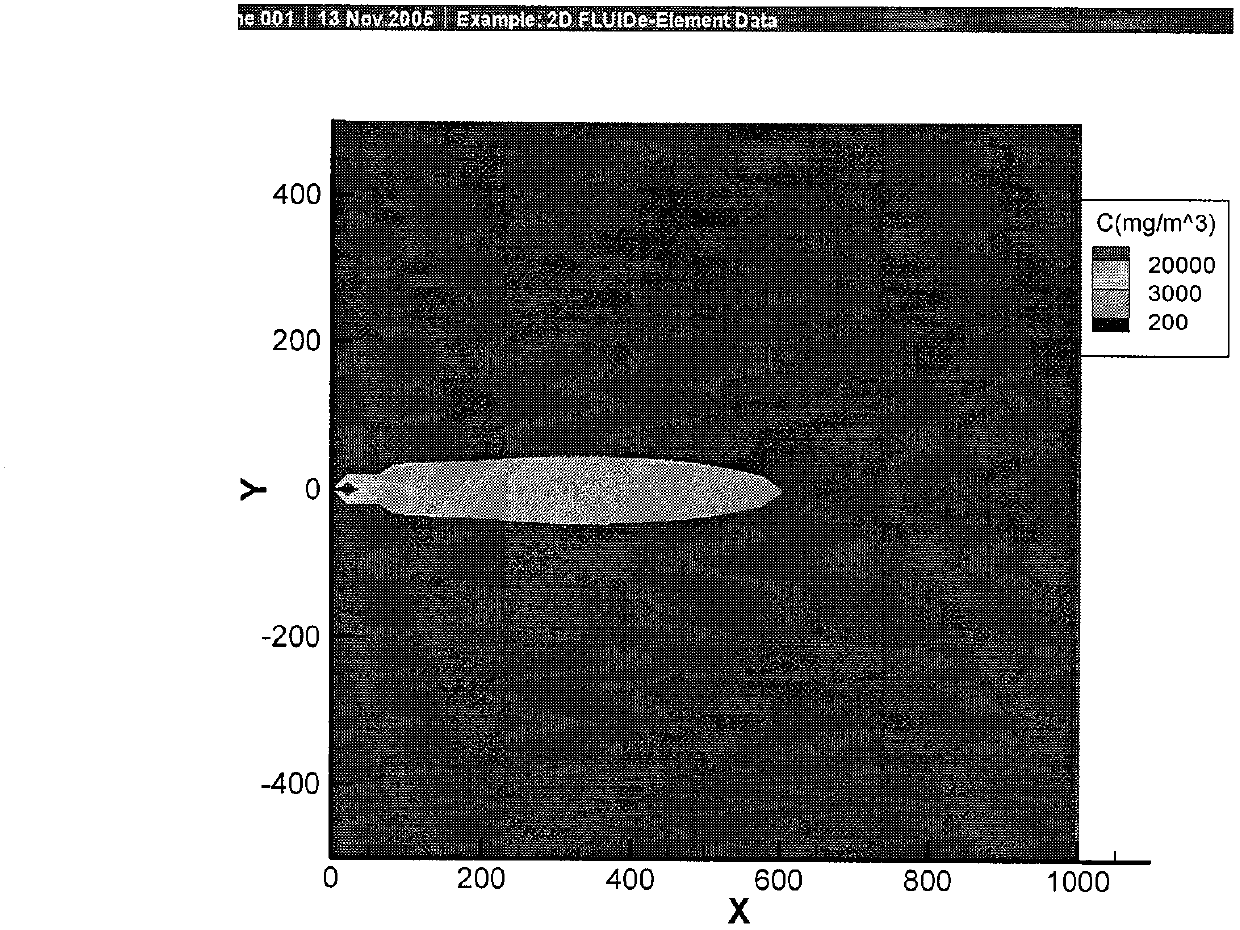

Dangerous chemical leakage pollution evaluation method

InactiveCN102096768AVisual display of pollution rangeEasy to useData processing applicationsSpecial data processing applicationsPetrochemicalPollution

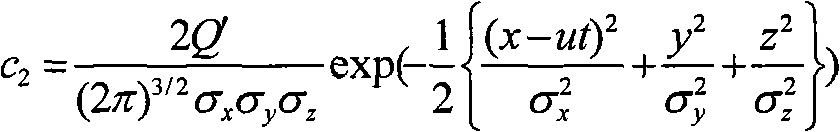

The invention provides a dangerous chemical leakage pollution evaluation method. The method comprises the following steps: (1) determining a dangerous chemical dispersion source as an instantaneous leakage source or a continuous leakage source; (2) dividing the source dispersion into heavy gas dispersion and non-heavy gas dispersion of the instantaneous leakage source, and heavy gas dispersion and non-heavy gas dispersion of the continuous leakage source; (3) causing the heavy gas of the instantaneous leakage source to disperse at a concentration meeting a formula shown in the specification; (4) causing the non-heavy gas of the instantaneous leakage source to disperse at a concentration meeting a formula shown in the specification; (5) causing the heavy gas of the continuous leakage source to disperse at a concentration meeting the formula c=b0h0c0 / (bh) in the horizontal direction; (6) causing the non-heavy gas cloud of the continuous leakage source to disperse at a concentration meeting a formula shown in the specification; and (7) determining and displaying the pollution range. The method has the characteristics of accuracy, intuition and the like, is simple to use and can be widely used in the industries of chemical engineering, petrochemical, natural gas and the like.

Owner:HENAN POLYTECHNIC UNIV

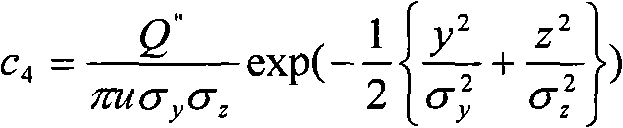

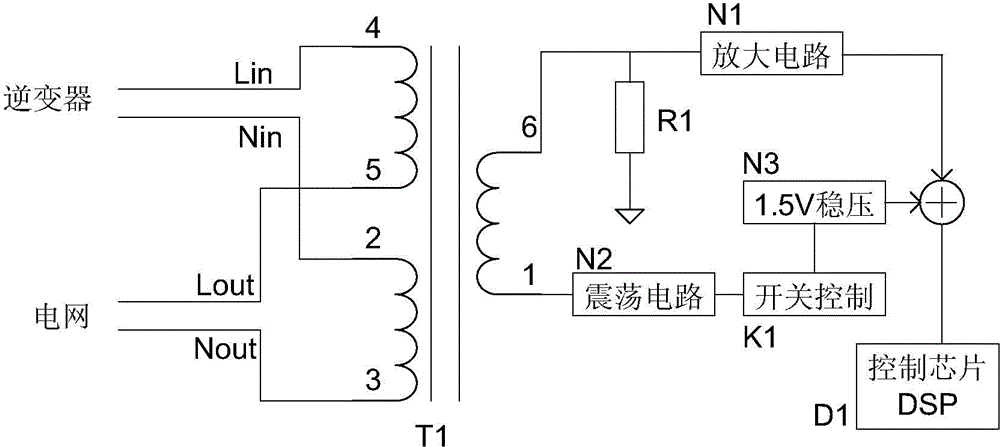

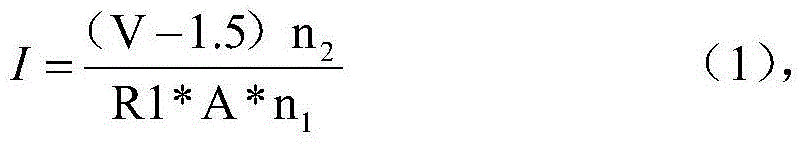

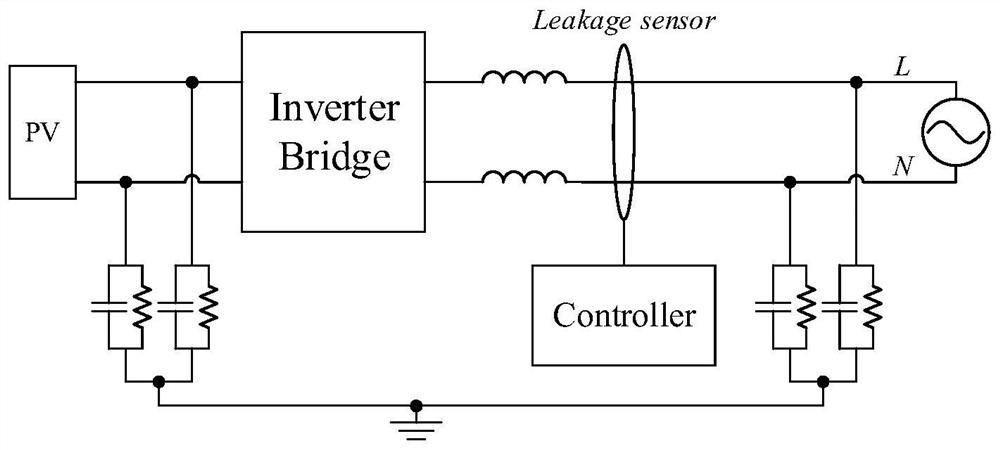

Detection device and method for residual current of photovoltaic array

InactiveCN104133099AWith real-time detectionAccurate and effective detectionElectrical testingEffective value measurementsElectricityInductor

The invention discloses a detection device and method for residual current of a photovoltaic array. The device includes an electricity leakage detection mutual inductor, a DSP control chip, an active filtering amplification circuit, a 1.5V voltage stabilizing circuit, an oscillation circuit, and a switch control circuit. The method obtains the value of a leakage current I through formula computing and judges a continuous leakage current and an abrupt-change leakage current according to the leakage current I. The detection device and method have the characteristics of real-time detection and capable of effectively detecting the leakage current of the photovoltaic array.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

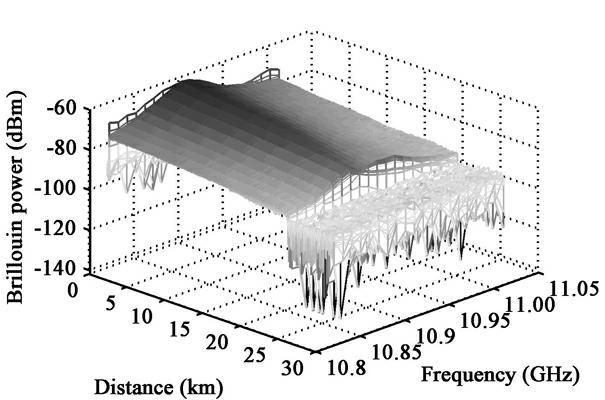

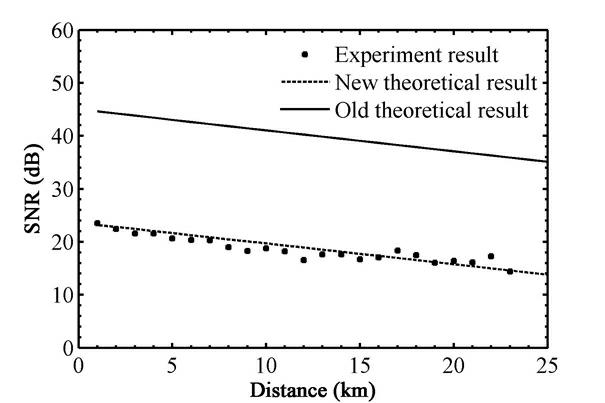

Method for precisely estimating signal to noise ratio of EOM (Electro-Optic Modulator) pulse modulated BOTDR (Brillouin Optical Time Domain Reflectometer)

The invention relates to a method for precisely estimating the signal to noise ratio of an EOM (Electro-Optic Modulator) pulse modulated BOTDR (Brillouin Optical Time Domain Reflectometer), which comprises the steps of: taking EOM modulated pulse as overlapping of ideal pulse light and continuous leakage light to determine the peak value power Pp and leakage power Pb of the modulated pulse light, the pulse width w and the length L of a sensing optical fiber, wherein the ideal pulse light peak value power is Pp-Pb, the constant power of the continuous leakage light is Pb and the EMO extinction ratio is ER=Pp / Pb; and the power of the self-releasing Brillouin scattering spectrum excited by the ideal pulse light at the central frequency meets a certain formula. The method takes the pulse light modulated by an electro-optical intensity modulator as the overlapping of the pulse light with the ideal extinction ratio and the leakage light, and takes the optical fiber as a linear system, so as to respectively obtain the self-releasing Brillouin scattering light generated by the pulse light with the ideal extinction ratio and the leakage light, and investigates the impact of the leakage light on root-mean-square error of a power curve when a signal is obtained by the coherent detection manner so as to acquire the signal to noise ratio of the BOTDR system.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

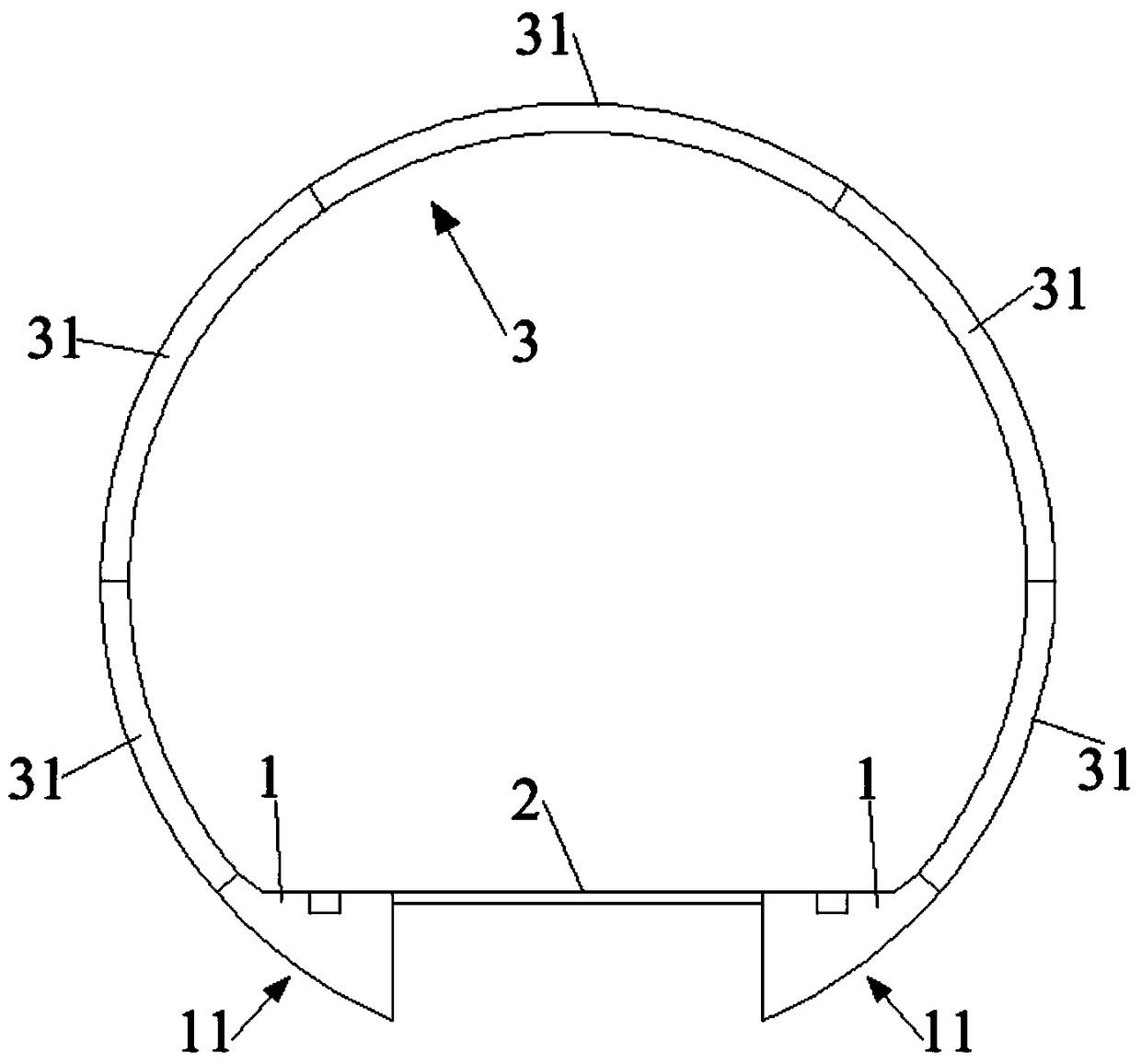

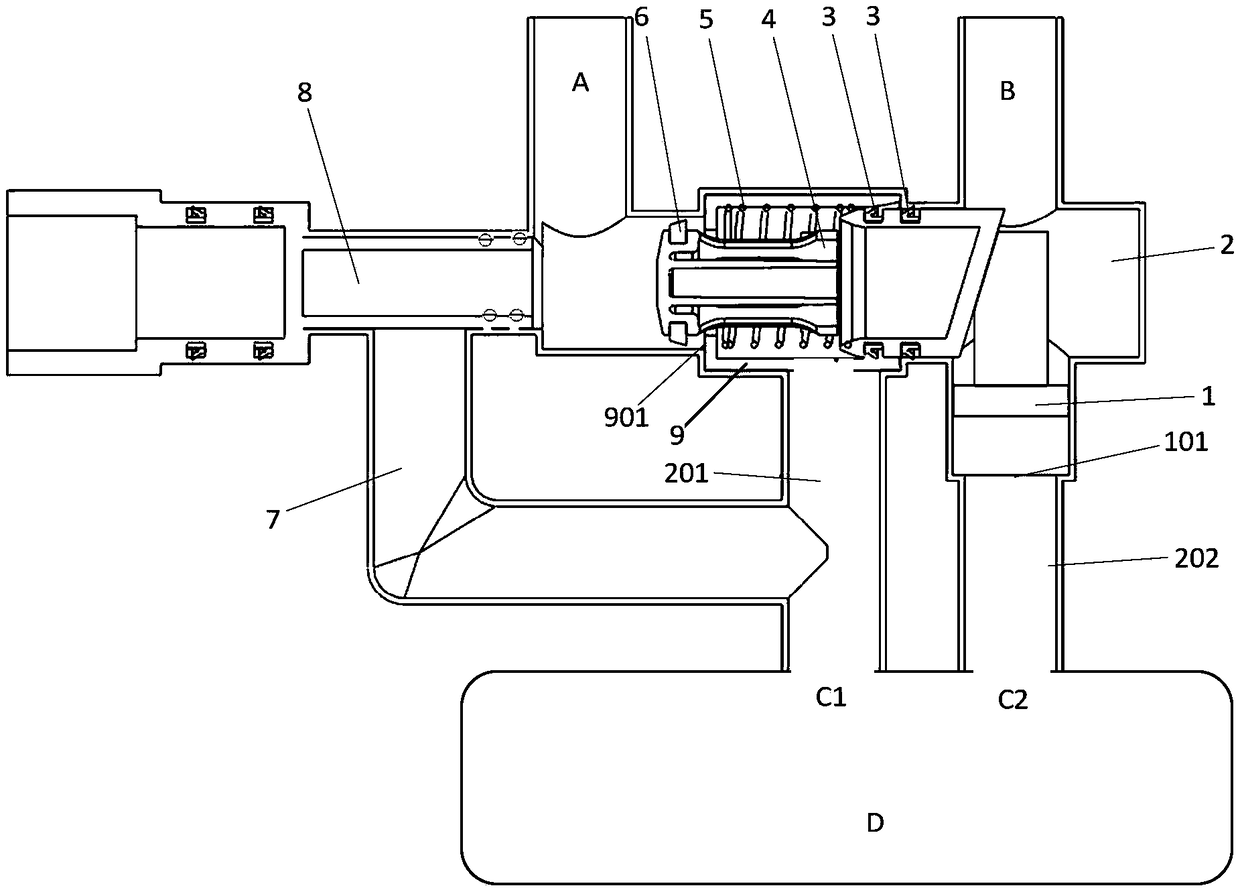

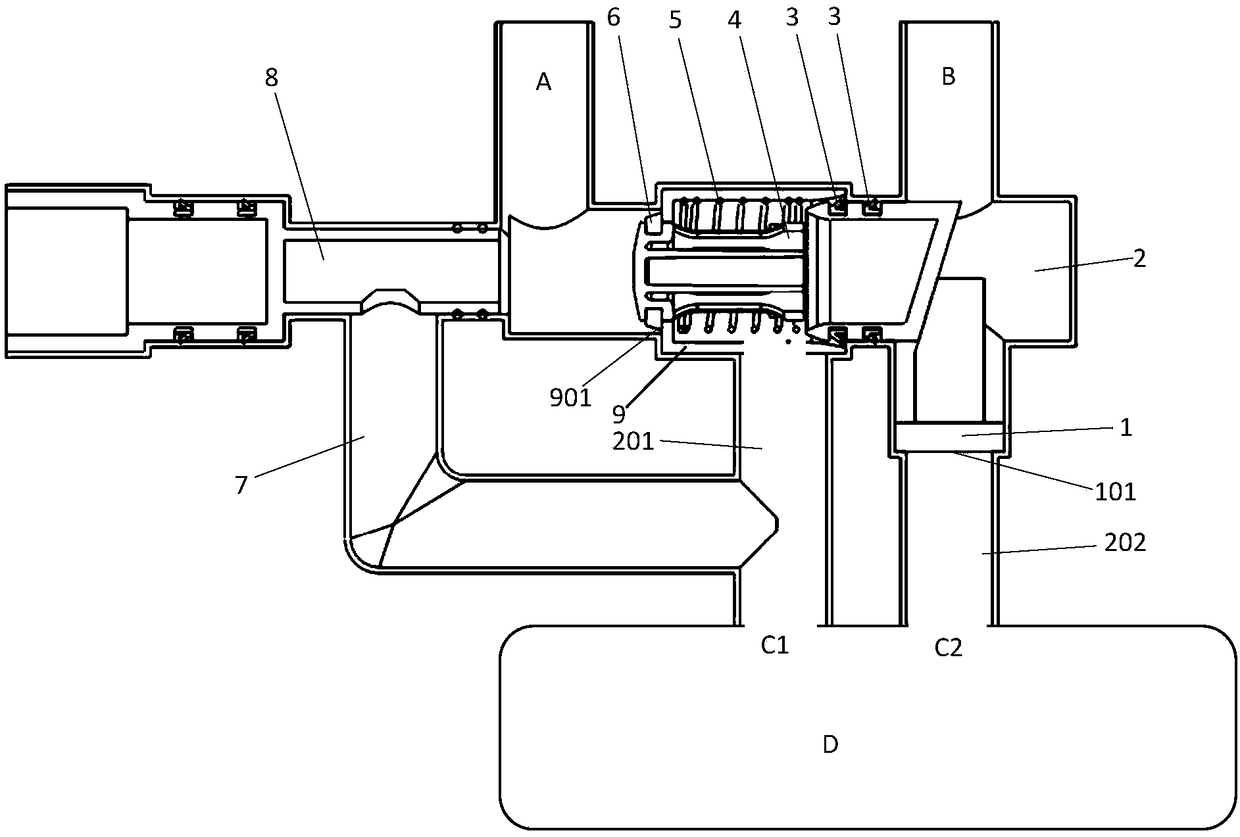

Reinforcement device of shield tunnel segment in shaped tunnel and installation method thereof

InactiveCN109026061ASolve the deformationBalance reinforcementUnderground chambersTunnel liningContinuous leakageBuilding construction

The invention relates to the technical field of shield tunnel segment construction, in particular to a reinforcement device of shield tunnel segment in a shaped tunnel and an installation method thereof. The reinforcement device comprises two bracket supports, connecting plates and supporting plates. The two bracket supports are oppositely arranged on a track bed at both sides of a track, and theconnecting plate is used to connect two oppositely arranged bracket supports. The supporting plate is in the form of a C with an opening, and is fitted to the surface of the shield tunnel segment in the tunnel. The supporting plates on both sides of the opening are respectively connected with two oppositely arranged bracket supports. The reinforcement device of shield tunnel segment in shaped tunnel provides a reinforcement device with supporting plates, bracket supports and connecting plates, which forms a ring support for shield tunnel segments in a tunnel, so that the shield tunnel segmentsin the circumferential direction of the tunnel can be evenly reinforced. The problems of continuous leakage and easy deformation of tunnel are solved effectively.

Owner:SHANGHAI MECHANIZED CONSTR GRP

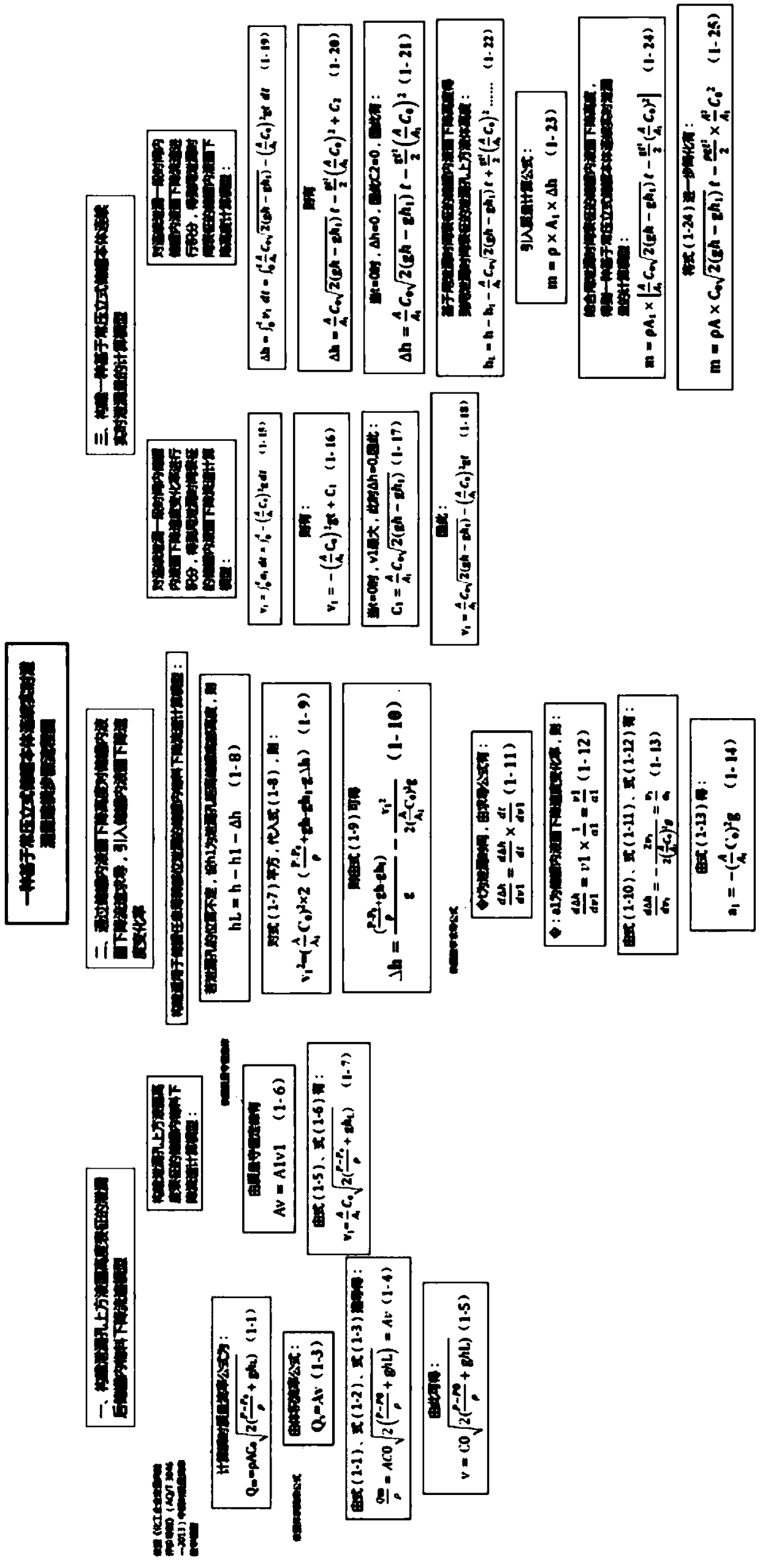

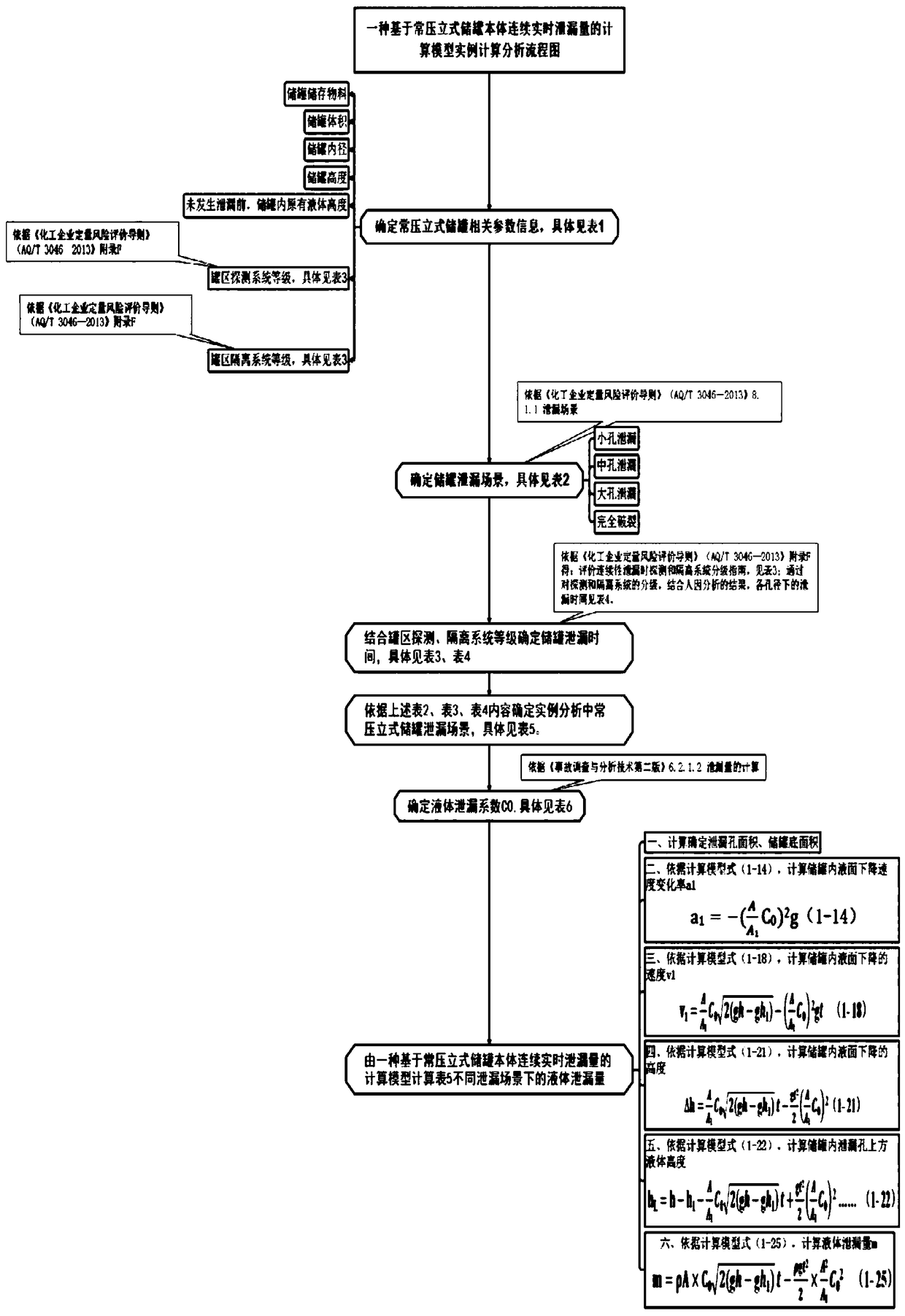

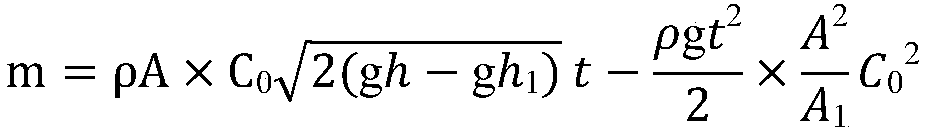

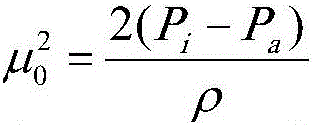

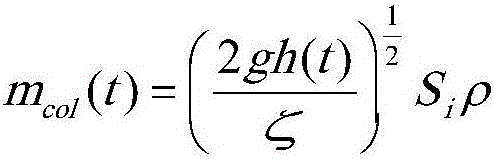

A continuous real-time leakage calculation model based on atmospheric vertical storage tank body

ActiveCN109033553AHigh precisionPrevent and control risksDesign optimisation/simulationResourcesMathematical modelEngineering

The invention discloses a continuous real-time leakage calculation model based on atmospheric vertical storage tank body. Firstly, based on the instantaneous mass flow rate mathematical model of liquid flowing out through the hole of the tank after the leakage of the atmospheric pressure vertical storage tank, according to the volume flow rate formula and the law of mass conservation, the materialdescending velocity model of the tank after the leakage, which is characterized by the liquid level height above the leakage hole, is constructed; secondly, the descending velocity of the liquid level in the storage tank is derived through the descend height of the liquid level in the storage tank, and the descending velocity change rate of the liquid level in the storage tank is introduced; thirdly, a calculation model of continuous real-time leakage of tank body is established by integrating the rate of change of liquid level descending velocity and the liquid level descending velocity in the tank during a period of continuous leakage. The calculation model of the invention can improve the accuracy of the continuous real-time leakage quantity calculation of the storage tank body, and the calculation of the continuous leakage quantity in any leakage time period is not affected by the leakage position of the storage tank body, and has a broad application prospect in the calculation ofthe continuous real-time leakage quantity of the atmospheric vertical storage tank body.

Owner:GUANGXI UNIV

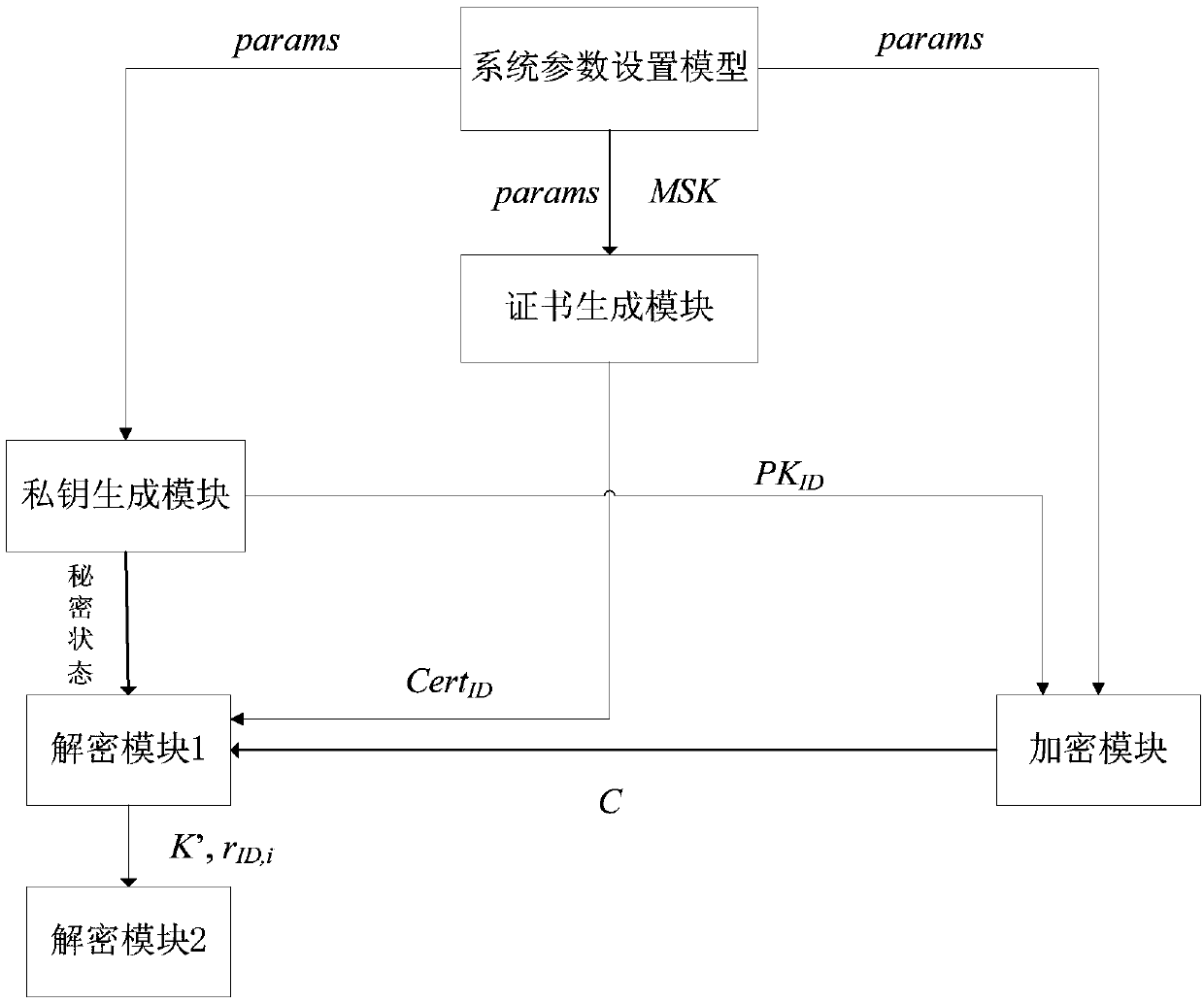

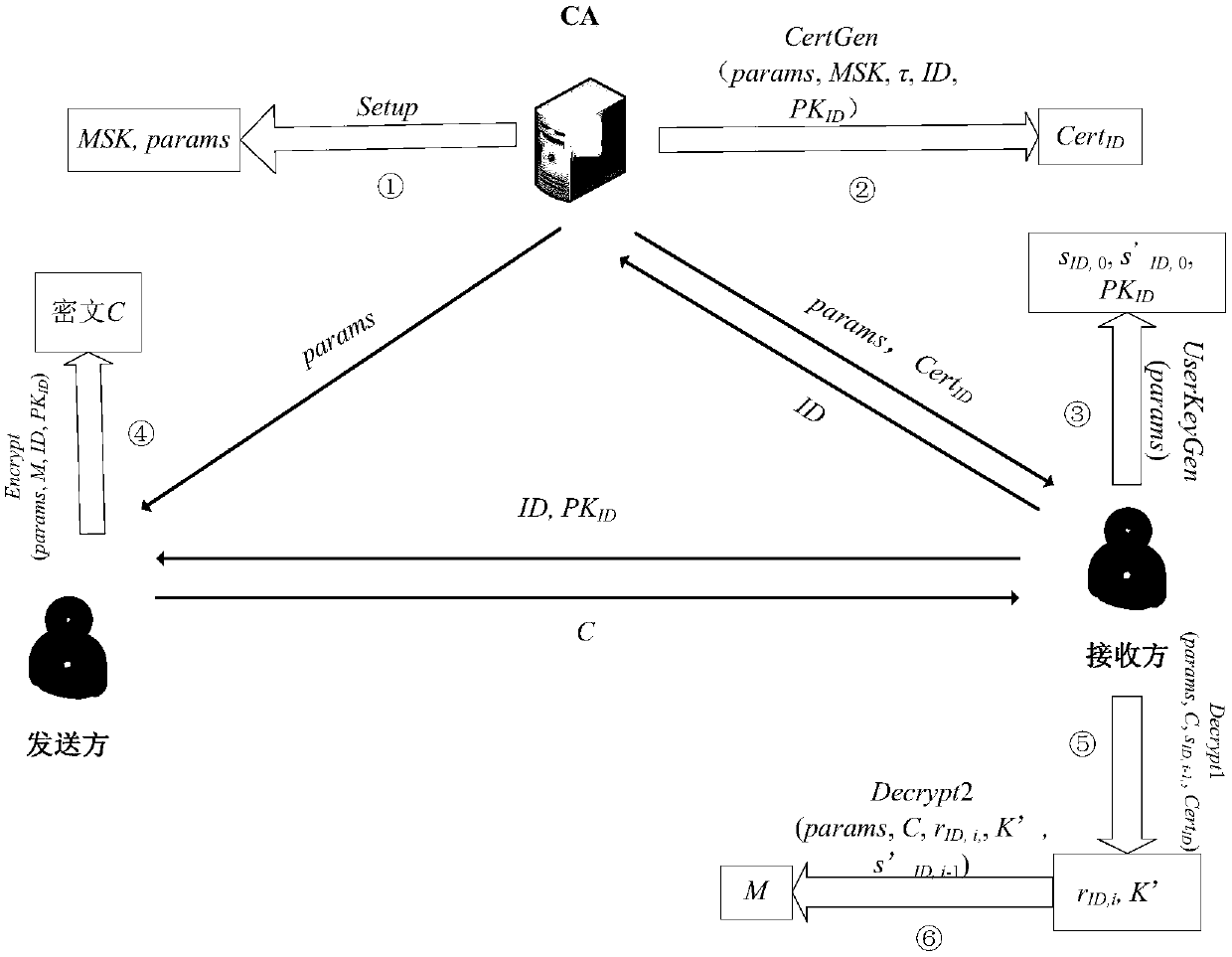

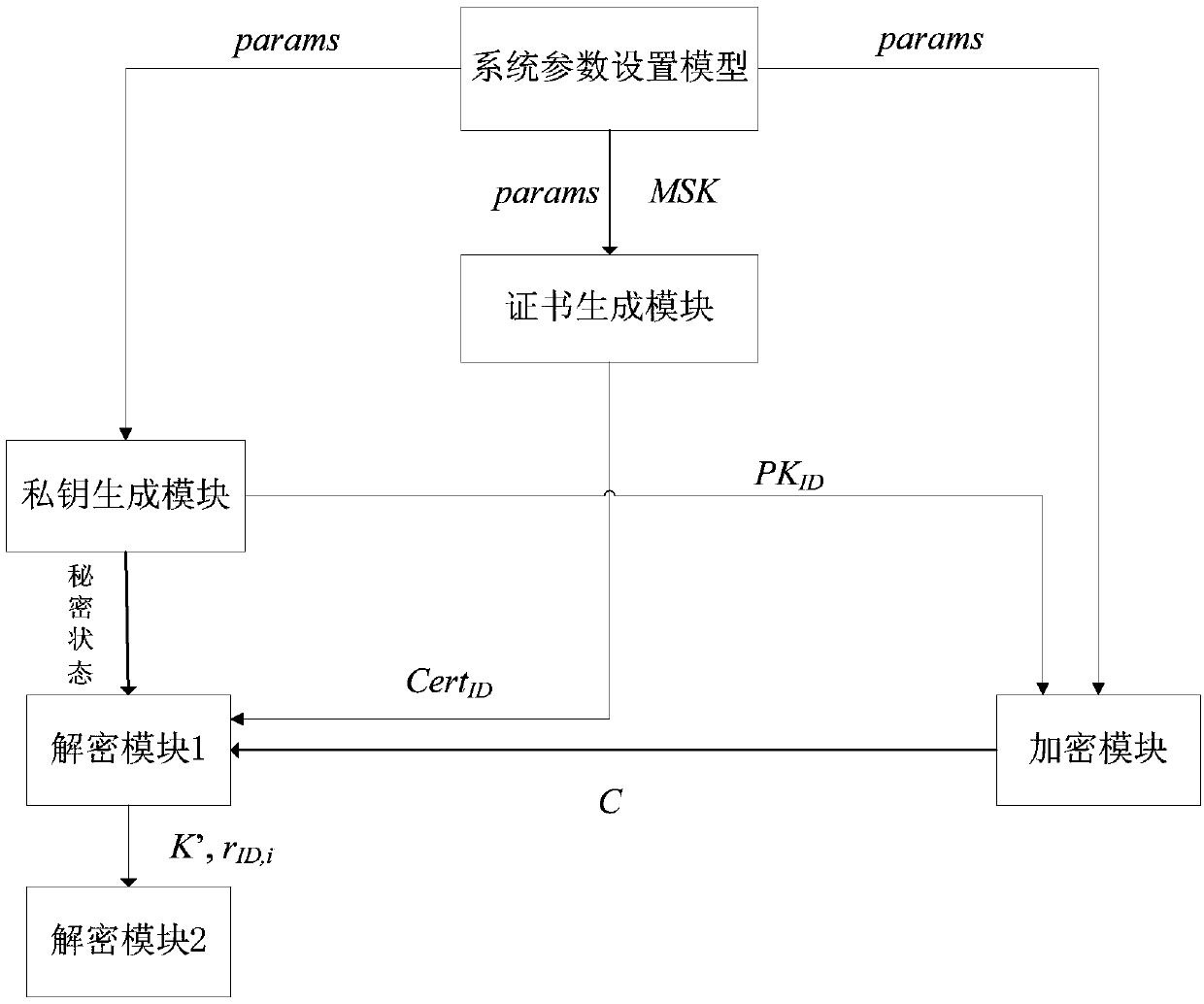

Encryption system and method of resistance to continuous leakage based on certificate

InactiveCN106559224AFix persistent leaksUser identity/authority verificationCryptographic attack countermeasuresCiphertextKey generation

The present invention provides an encryption system of resistance to continuous leakage based on a certificate. The system comprises a system parameter arrangement module, a private key generation module, a certificate generation module, an encryption module, a first decryption module and a second decryption module. The system parameter arrangement module generates the common parameters and main private keys of the system, wherein the common parameters are sent to other module; the private key generation module generates user's public and private keys and an initial secret state; the certificate generation module generate a user's certificate; the encryption module performs encryption of the information and sends the encryption information to the decryption modules; the first decryption module and the second decryption module perform decryption of the cryptograph to obtain the plaintext information. The system can resist the continuous leakage, namely in the side channel attack environment, even though the opponent continuously obtain the part of the information of the secret state, the opponent cannot obtain the whole private key. The present invention further provides an encryption method of resistance to continuous leakage based on a certificate.

Owner:HOHAI UNIV

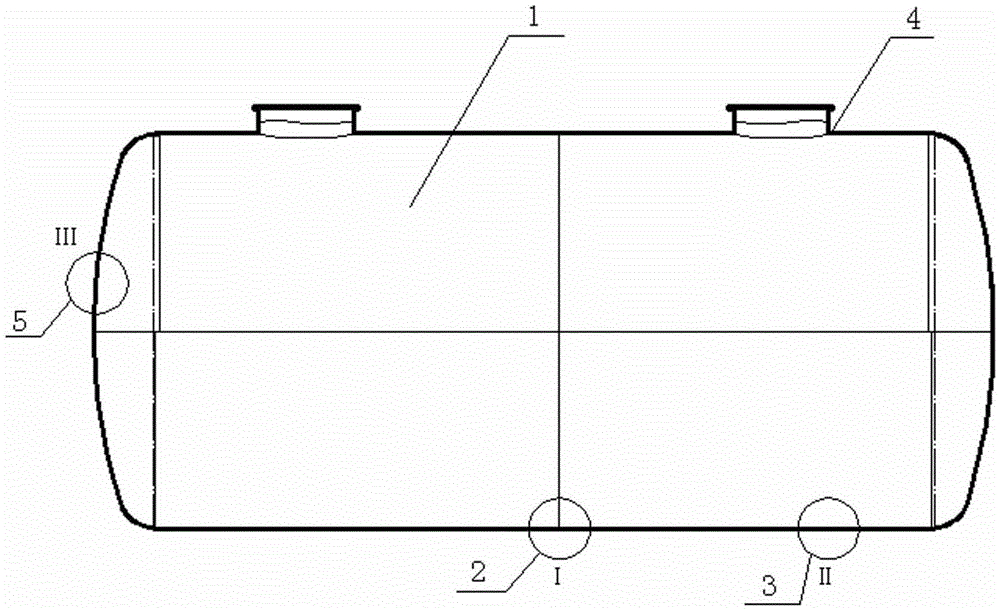

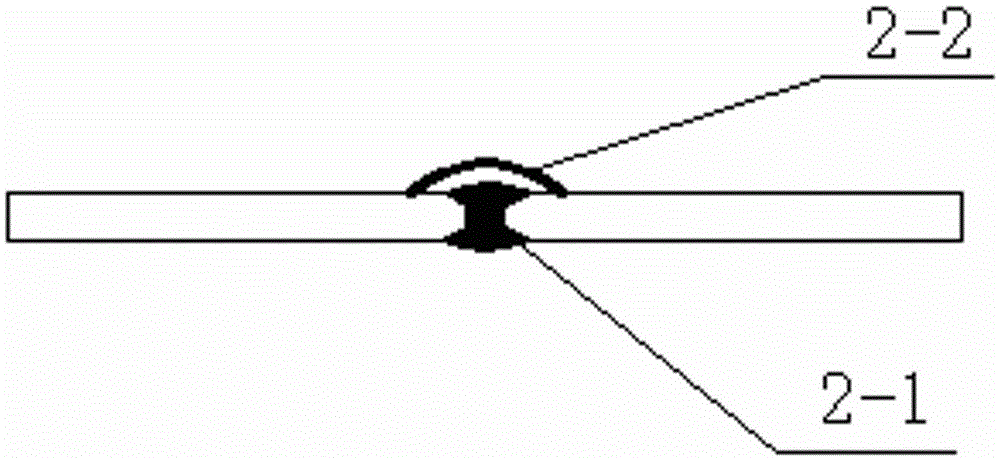

Self-repairing type double-layer oil tank

The invention discloses a self-repairing type double-layer oil tank. The self-repairing type double-layer oil tank comprises a steel tank body at the inner layer and a glass fiber reinforced plastic layer at the outer layer. A middle interlayer and an outer leakage induction wire are arranged between the steel tank body and the glass fiber reinforced plastic layer. The middle interlayer comprises rubber particles, glass fibers, copper wire sets and a polyethylene (PE) film. The rubber particles, the glass fibers and the copper wire sets are compounded into a whole through an adhesion agent. The side, close to the glass fiber reinforced plastic layer, of the interlayer is coated with a layer of PE film. The copper wire sets are communicated with the outer leakage induction wire. The copper wire sets of the self-repairing type double-layer oil tank are arranged according to a specific order, and the leakage situation of the oil tank can be accurately determined; when leakage occurs, the rubber particles can be expanded when encountering water and oil and all the irregular surfaces, holes and gaps of junctures are filled with the rubber particles, so that continuous leakage is prevented. The self-repairing type double-layer oil tank is scientific and reasonable in design, simple in structure, broad in application range, capable of achieving rapid defect detection and automatic repairing during leakage and convenient and rapid to use, and maintenance is reduced.

Owner:保定长空石油工业股份有限公司

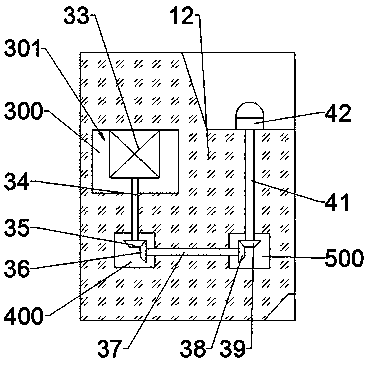

Intelligent household fuel gas explosion-proof system

ActiveCN109899592AAvoid detection errorsImprove accuracyOperating means/releasing devices for valvesAlarmsControl systemEngineering

The invention discloses an intelligent household fuel gas explosion-proof system. The system comprises a detection box, a mounting plate and a control system, a control box is fixedly connected to theleft lower corner of the inner cavity of the detection box, a first gas concentration detector is arranged on the right wall of the detection box in a penetrating manner, the inner part of the rightwall of the control box and the outside of the first gas concentration detector are filled with hot melt adhesive, and the invention relates to the technical field. According to the intelligent household fuel gas explosion-proof system, an independent space can be formed at a pipeline joint which easily leaks fuel gas, the concentration of gas inside the pipeline joint can be detected, the gas leakage phenomenon can be detected in time, a miniature electric telescopic rod can be used for pushing the button switch to enable the sealing valve to be closed, so that the continuous leakage of the fuel gas is avoided, the electronic devices in the detection box can be isolated from the fuel gas by arranging the hot melt adhesive and the sealing plate, the sealing property of the sealing valve iskept by the sealing film, the gas combustion explosion caused by electrifying of the electronic element can be avoided, and the explosion-proof performance is ensured.

Owner:义乌市吉龙科技有限公司

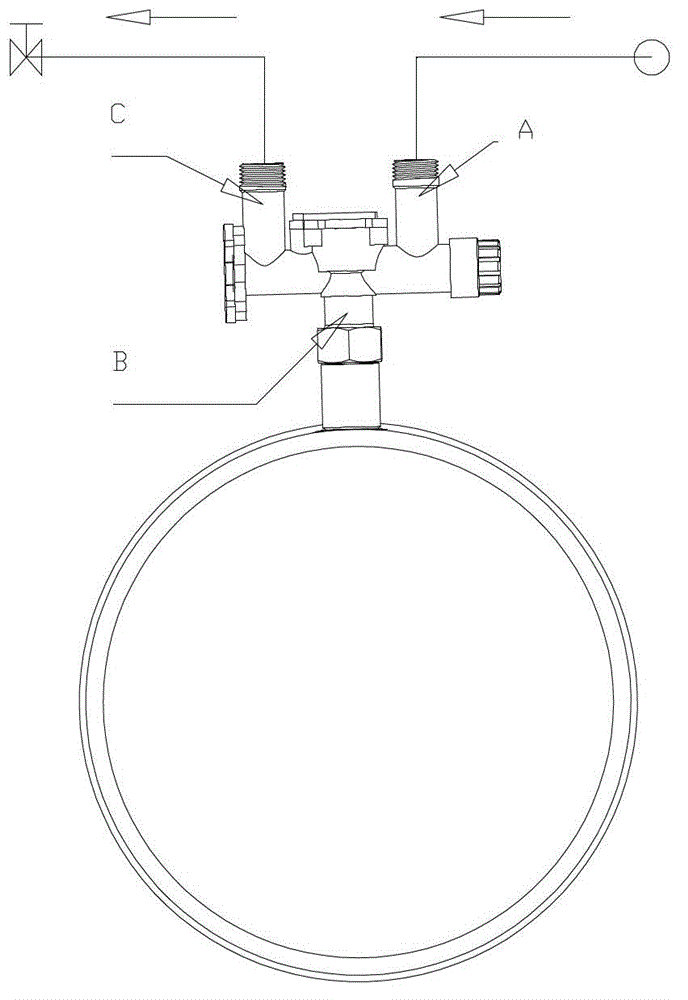

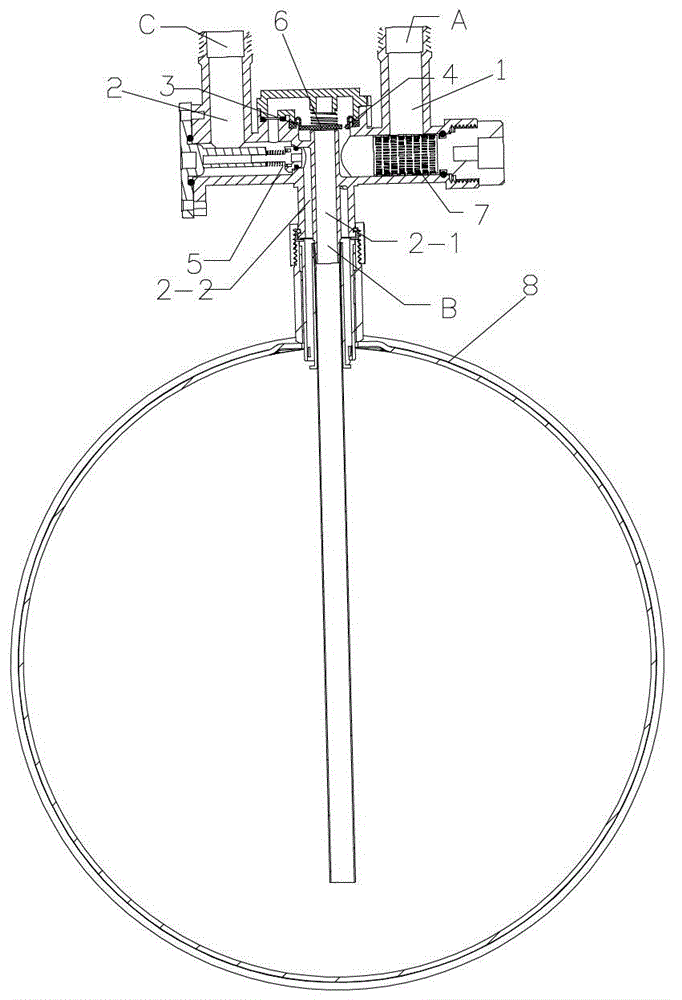

Leakproof device for water storing container

InactiveCN102878686AGuaranteed continuous water supplyThere will be no signal misjudgment problemFluid heatersMechanical apparatusWater useWater source

The invention relates to a leakproof device for a water storing container, belonging to the technical field of the control of a fluid transportation pipeline. The device comprises a first port communicated with a water supply pipeline, a second port communicated with the water storing container, and a third port communicated with a water use end. The leakproof device is characterized in that the second port is formed by a water inlet cavity and a water outlet cavity, which are separated form each other; a first water flowing passageway arranged between the first port and the water inlet cavity of the second port is provided with a on-off controller, and the water outlet cavity is communicated with the third port by a second water flowing passageway; when the water use end is turned off, the on-off controller is under the status of switching off the first water flowing passageway; and when the water use end is turned on, the on-off controller is under the status of switching on the first water flowing passageway. Therefore, when the water use end is turned off and users does not need to use water, the first water flowing passageway is turned off, and even if the water storing container leaks, the water of a water source can not be compensated to the water storing container, so that the continuous leakage can be effectively avoided no matter whether the leakage is known by the user or not.

Owner:A O SMITH CHINA WATER HEATER CO LTD

Dangerous chemical leakage pollution evaluation method

InactiveCN102096768BPollution assessment method is accurateVisual display of pollution rangeSpecial data processing applicationsEngineeringPetrochemical

The invention provides a dangerous chemical leakage pollution evaluation method. The method comprises the following steps: (1) determining a dangerous chemical dispersion source as an instantaneous leakage source or a continuous leakage source; (2) dividing the source dispersion into heavy gas dispersion and non-heavy gas dispersion of the instantaneous leakage source, and heavy gas dispersion and non-heavy gas dispersion of the continuous leakage source; (3) causing the heavy gas of the instantaneous leakage source to disperse at a concentration meeting a formula shown in the specification; (4) causing the non-heavy gas of the instantaneous leakage source to disperse at a concentration meeting a formula shown in the specification; (5) causing the heavy gas of the continuous leakage source to disperse at a concentration meeting the formula c=b0h0c0 / (bh) in the horizontal direction; (6) causing the non-heavy gas cloud of the continuous leakage source to disperse at a concentration meeting a formula shown in the specification; and (7) determining and displaying the pollution range. The method has the characteristics of accuracy, intuition and the like, is simple to use and can be widely used in the industries of chemical engineering, petrochemical, natural gas and the like.

Owner:HENAN POLYTECHNIC UNIV

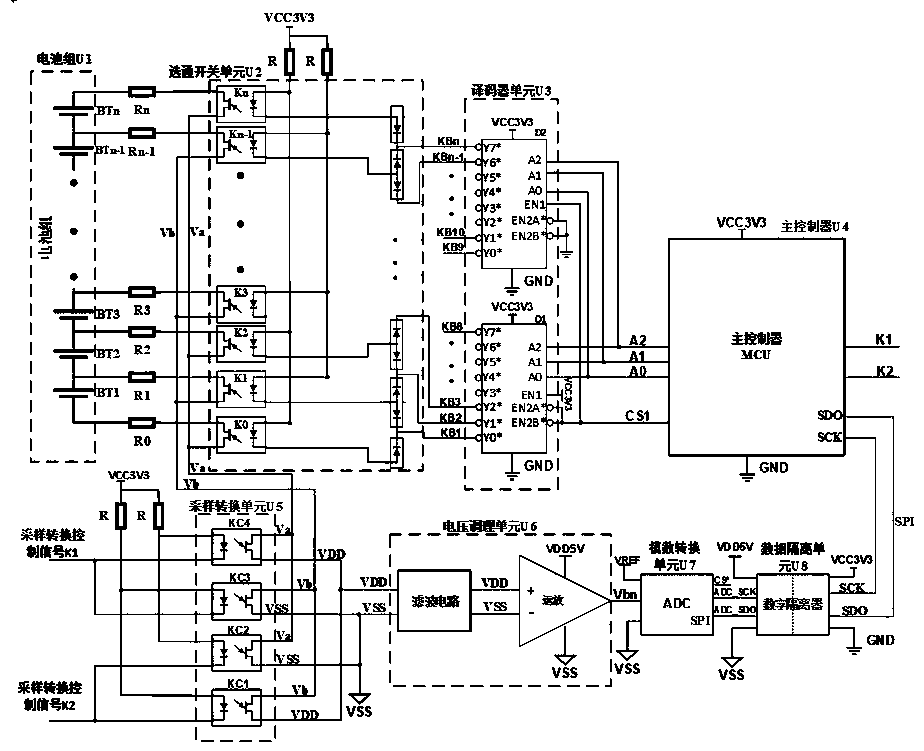

Battery set core voltage sampling circuit

PendingCN108459275AImprove anti-interference abilityImprove securityElectrical testingElectrical batteryEngineering

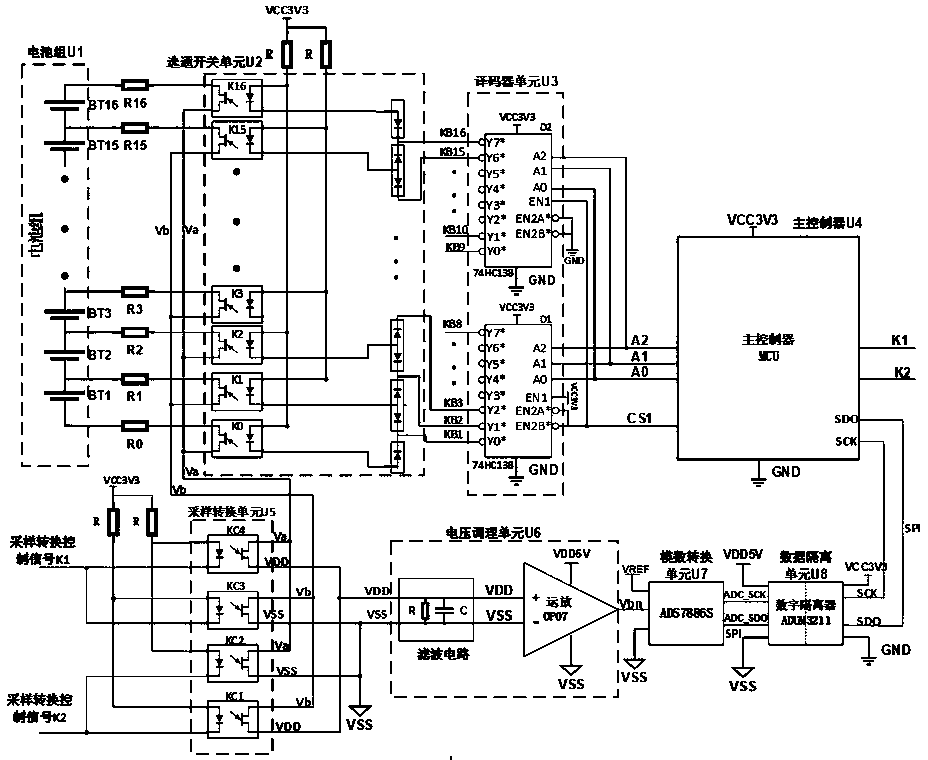

The name of the invention is a battery set core voltage sampling circuit, belongs to the technical field of a battery management system and mainly aims to solve problems of poor anti-interference property, poor stability and bad influence on consistency and the service life caused by the continuous leakage current of batteries because of having no isolation between a core voltage sampling circuitin the prior art and a voltage dividing sampling resistor. The battery set core voltage sampling circuit is mainly characterized by comprising a battery set, a gate switch unit, a decoder unit, a maincontroller, a sampling conversion unit, a voltage conditioning unit, an analog to digital conversion unit and a data isolation unit, wherein the gate switch unit and the sampling conversion unit areconnected through buses Va and Vb, the voltage conditioning unit is composed of a filter circuit and a negative feedback amplifying circuit, the negative feedback amplifying circuit is supplied with power through an isolation power source, and the power source ground is connected with a signal of the sampling conversion unit with a low sampling output voltage. The battery set core voltage samplingcircuit is advantaged in that good anti-interference property, good safety, strong scalability and relatively low cost are realized, and the battery set core voltage sampling circuit is mainly used for sampling and detecting multiple single cores of the battery set.

Owner:骆驼集团武汉光谷研发中心有限公司

Gas pipeline network leakage source real-time location analysis method and system

The invention discloses a real-time positioning analysis method and system for a fuel gas pipeline network leakage source, wherein the method comprising the following steps: a plurality of integrated detection modules are arranged in a region to be monitored, and the region to be monitored is divided into grid sub-areas; a hypothesis that each grid sub-area in the area to be monitored has a fictitious leakage source is carried out, another hypothesis of simulated detection data of the integrated detection modules is carried out after the fictitious leakage source continuously leaks for a preset time, and a simulated leakage database is established; the integrated detection modules acquire the practical measurement data of leaked gases in real time, and the practical measurement data is transmitted to a computer monitoring terminal; similarity calculation of the practical measurement data and a plurality of simulated detection data in the simulated leakage database is carried out, when the similarity reaches the maximal value, the position and time of the hypothesis leakage source and the continuous leakage time which are corresponding to the simulated detection data are the position and time of the practical leakage source and the time of the continuous leakage time. Through the adoption of the method and the system, the position of the practical leakage source can be quickly found out.

Owner:TSINGHUA UNIV

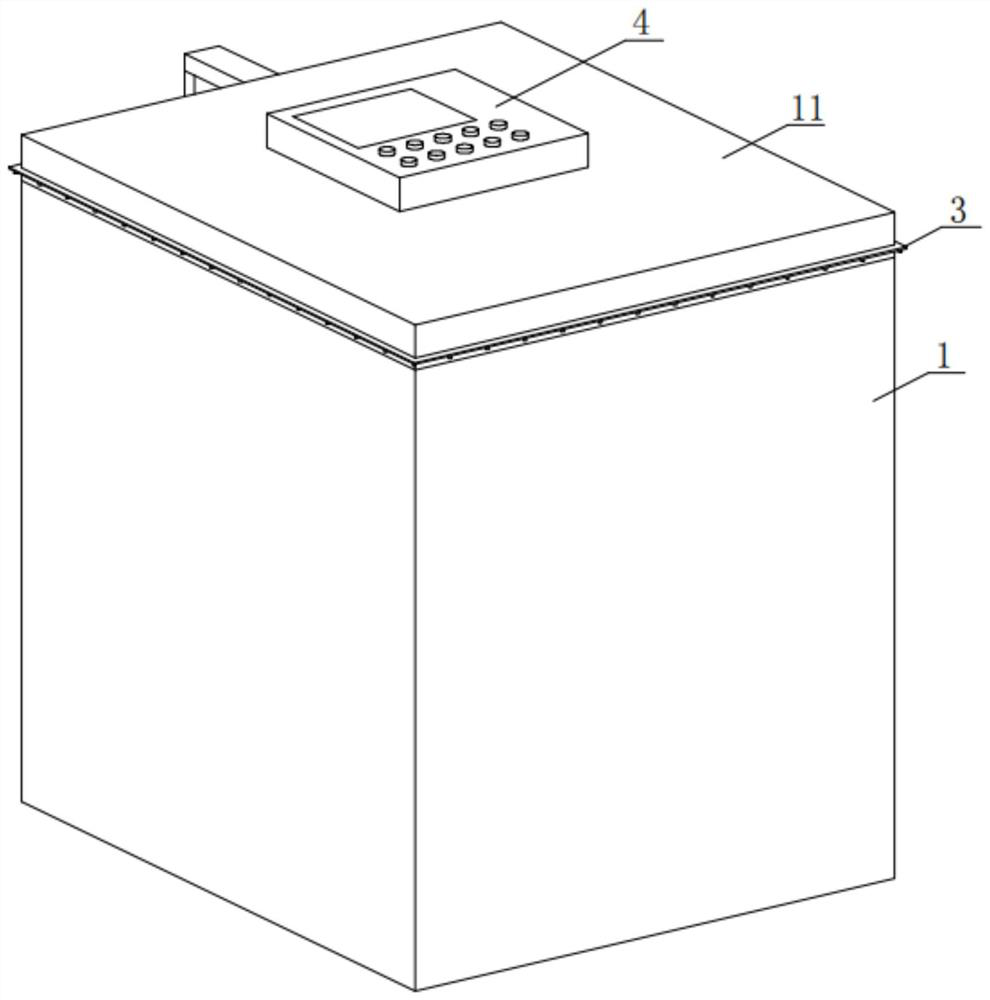

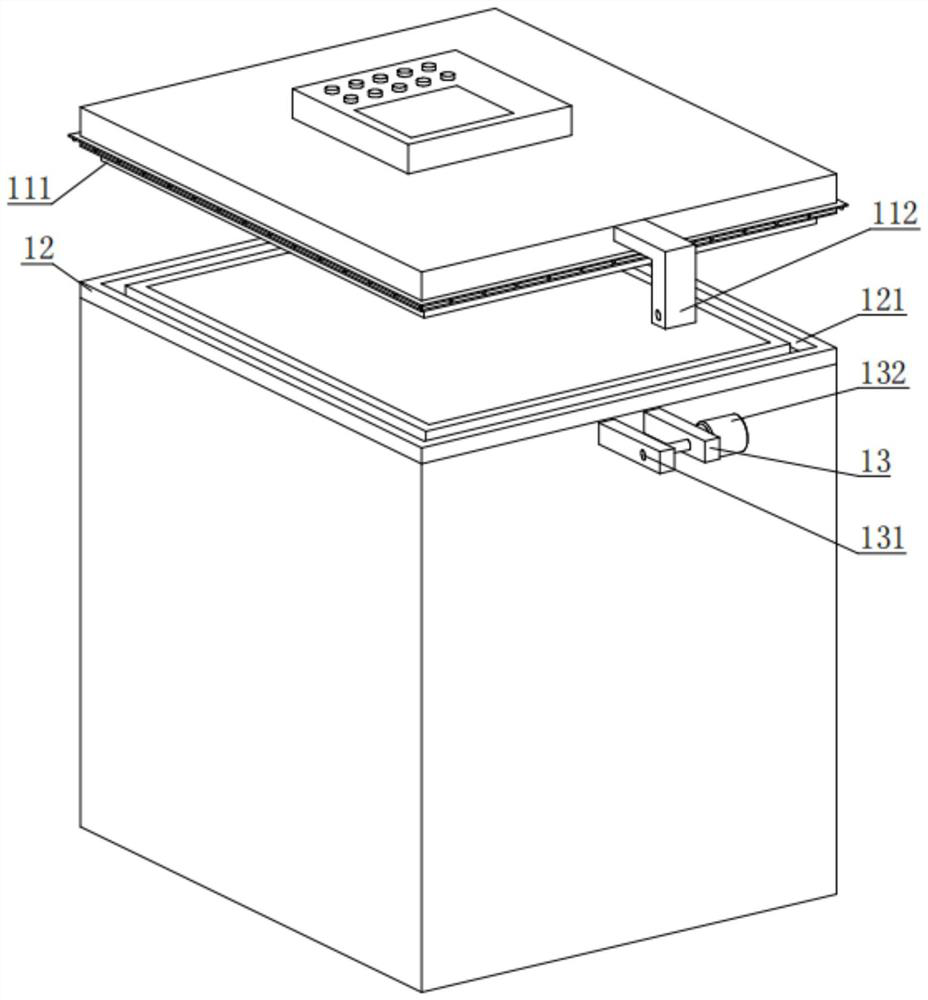

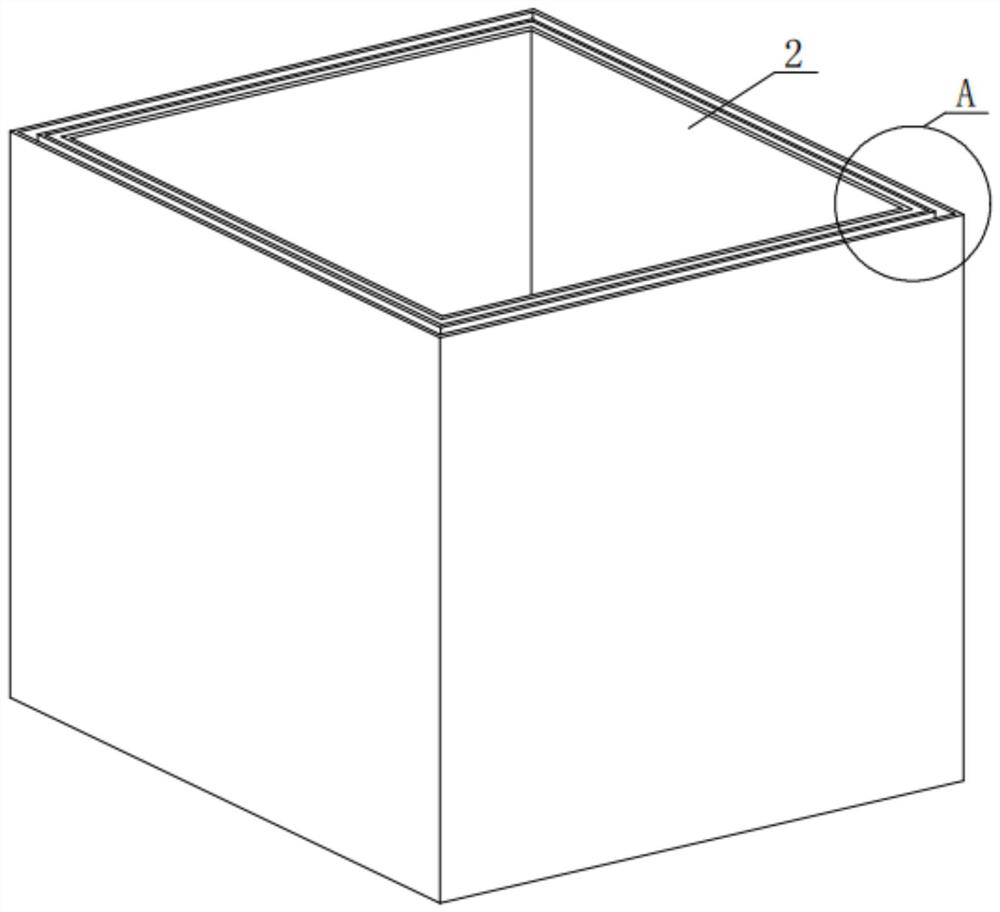

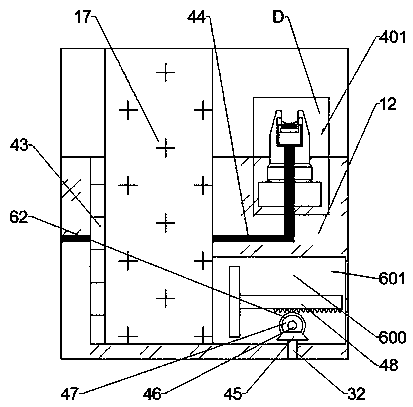

Freezing box cold air leakage detection and early warning device for cold chain equipment and implementation method of device

InactiveCN113485221AEasy to useGuaranteed tightnessProgramme controlComputer controlCold airCold chain

The invention discloses a freezing box cold air leakage detection and early warning device for cold chain equipment and an implementation method of the device and belongs to the technical field of cold air leakage detection. The device comprises a freezing box body and an inner box body arranged in the freezing box body; a box cover is arranged above the freezing box body; and cold air detection equipment is arranged between the box cover and the freezing box body. According to the freezing box cold air leakage detection early warning device for the cold chain equipment and the implementation method of the device, cold air is effectively blocked, leakage is prevented, air propagation temperature is effectively isolated, temperature transmission is prevented, the using effect of the freezing box body is improved, adjustability of the freezing box body is guaranteed, the service life of the whole device is prolonged; so that remote reminding can be conducted, personnel can conveniently conduct inspection; objects in the freezing box body can be effectively monitored in real time, the quality of the objects is guaranteed, and continuous leakage of cold air is prevented; and automatic handling can be conducted under the condition that no person handles the objects, damage is reduced to the maximum extent, intelligence is guaranteed, and use convenience is improved.

Owner:泱焓冷链系统(江苏)有限公司

Design method for LNG leakage collection tray

ActiveCN106055739AImplement leak collection protectionGeometric CADSpecial data processing applicationsRelational modelCofferdam

The invention discloses a design method for an LNG leakage collection tray. The method comprises the steps that an input-output dynamic relation model of LNG leakage in the collection tray is established, an initial value is assigned to the model, and recursive calling is conducted according to a set step length, so that a curve about time-based changing of the mass of LNG stored in the collection tray can be obtained; and according to the curve, a bottom disk area of the collection tray, a cofferdam height and a sectional area of a collection pipe connected to the collection tray can be determined. The curve obeys the changing rules that when a liquid level of the LNG in the collection tray reaches a certain height, the continuous leakage under an original scale does not cause further increase of the LNG liquid level; and with weakening and stopping of the leakage, collection and evaporation effects can be continued, and the LNG liquid level in the collection tray gradually decreases till the liquid level approaches zero.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

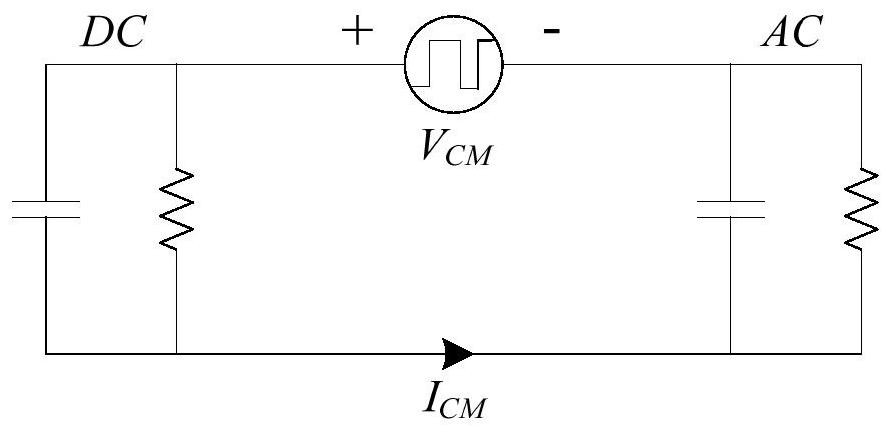

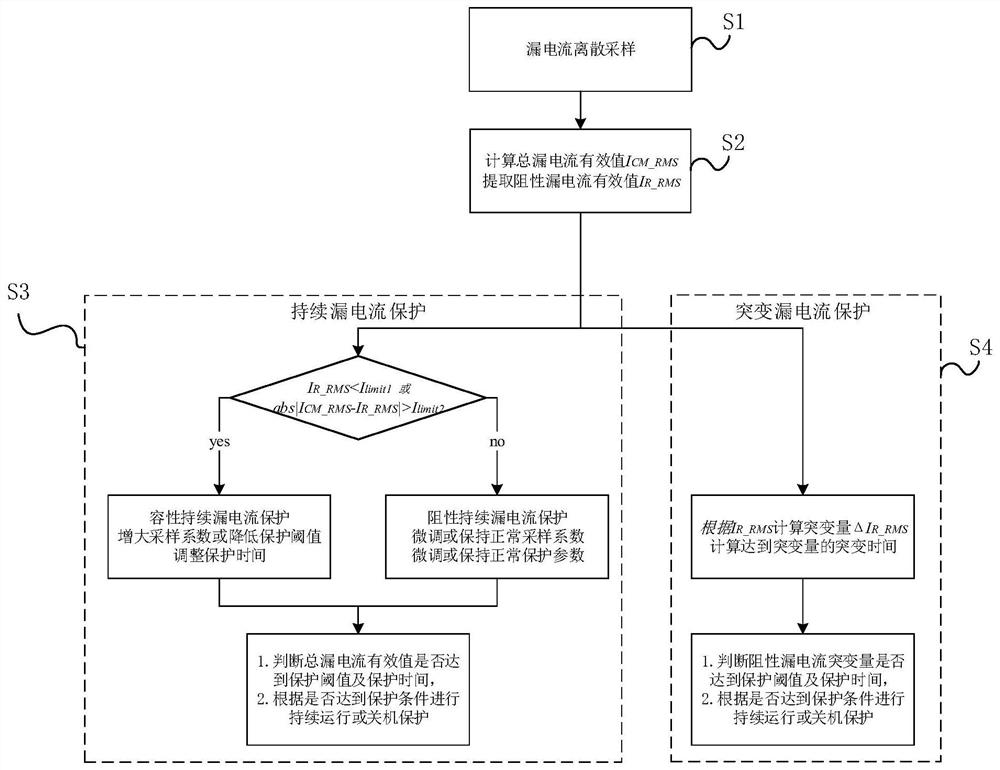

Leakage current detection protection method and device

ActiveCN111864695AImprove accuracyImprove real-time performanceArrangements responsive to undervoltageComputational physicsDrain current

The invention relates to a leakage current detection protection method and device. The method comprises the following steps: a leakage current sampling step: carrying out discrete sampling on leakagecurrent; a leakage current calculation step: calculating a total leakage current effective value and a resistive leakage current effective value according to the sampling data; a continuous leakage current protection step: judging whether the main component of the leakage current is capacitive or resistive according to the effective value of the resistive leakage current, and then respectively taking corresponding continuous leakage current protection measures; and an abrupt change leakage current protection step: calculating the abrupt change amount and the abrupt change speed of the leakagecurrent according to the effective value of the resistive leakage current so as to calculate the abrupt change time reaching the abrupt change amount, and carrying out abrupt change leakage current protection according to the abrupt change time. Compared with the prior art, the method and the device have the advantages of high detection protection accuracy, good real-time performance, low hardwarecost and the like.

Owner:TONGJI UNIV

Harmful gas leakage alarm equipment suitable for petroleum refineries

InactiveCN107727800AAchieve circulationAchieve sealingMaterial analysisHydraulic cylinderGas chamber

The invention discloses harmful gas leakage alarm equipment suitable for petroleum refineries. The harmful gas leakage alarm equipment suitable for petroleum refineries comprises a number 1 gas pipe,a controllable gas chamber, installation thread inserts, a number 2 gas pipe, a power line, a protective cover, a rollback switch, a controller, fixing screws, and a controller pedestal; the two installation thread inserts are arranged on the two ends of the controllable gas chamber respectively; the installation thread insert on the right side is connected with the number 2 gas pipe through threaded connection. The beneficial effects are that: when gas leakage is detected by a gas detection device of the harmful gas leakage equipment, a hydraulic cylinder is controlled to push a telescopic rod to push out, so that a movable support rod which is used for supporting the top of a sealing device is pushed out to be inclined, a spring is used for jacking the sealing device up, and sealing of the controllable gas chamber is realized; in alarming, gas rapid automatic sealing is realized, continuous leakage of harmful gas is prevented effectively, and environment pollution is avoided.

Owner:安徽科恒电力科技有限公司

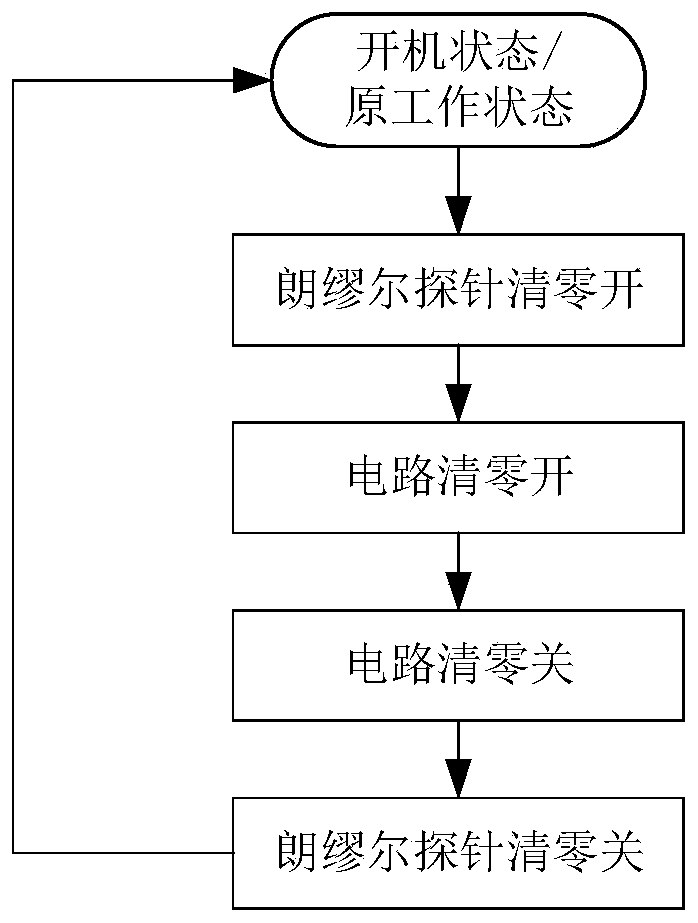

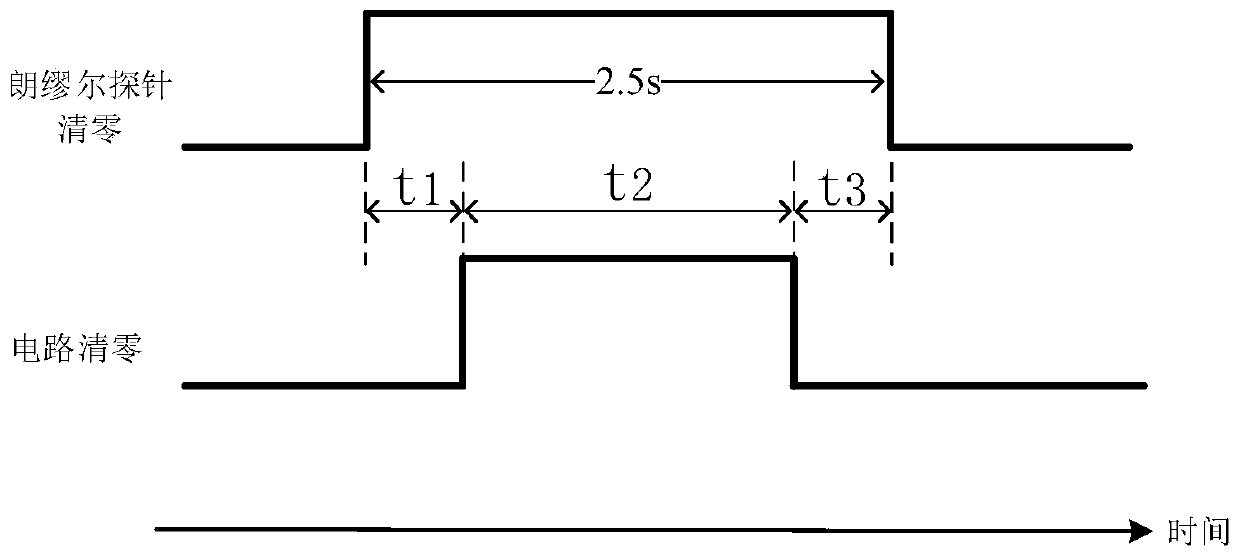

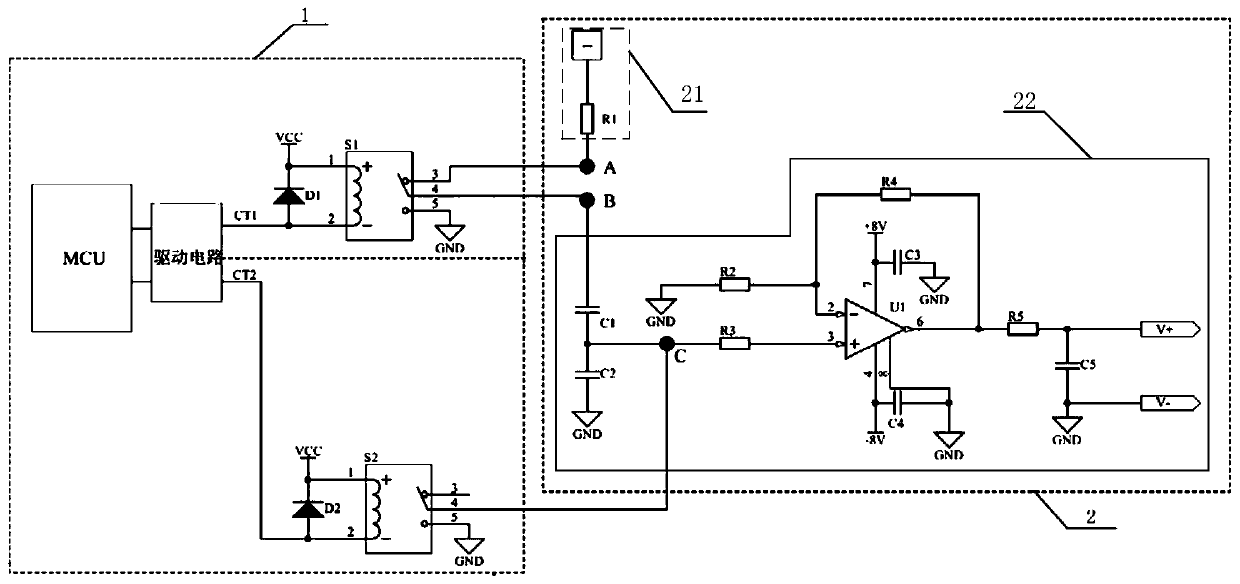

Electrostatic charge clearing method and circuit of space station potential detector

ActiveCN109752602ASolve Signal DriftAccurate and reliable measurementElectrostatic field measurementsCapacitanceElectricity

The invention discloses an electrostatic charge clearing method and circuit of a space station potential detector. The problem of signal drift caused by an inherent leakage current of the differentialcapacitance voltage division type space station potential detector is effectively solved. Through electrostatic charge clearing, a voltage dividing capacitor is restored to be in a power-on initial charge balance state before measurement. The problem that an error exceeds the standard due to continuous leakage of electrostatic charge can be effectively solved when the floating potential of a space station is measured, so that the floating potential measurement in the potential detection of the space station is more accurate and credible. The method is simple, practical and reliable.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

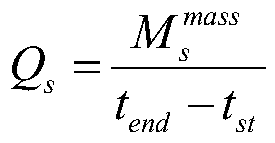

Method for calculating evaporation rate of low-temperature pool liquid under continuous leakage condition

The invention relates to an experimental method for calculating the evaporation rate of a low-temperature liquid pool liquid under a continuous leakage condition; the experimental method comprises thefollowing steps that the leakage mass of liquid nitrogen needing to be tested is determined firstly, then the liquid nitrogen is leaked to a flat plate at a constant speed, and the mass rate of leakage is calculated; then, an electronic scale is used for measuring the change of the mass of the flat plate along with time; meanwhile, the change of the radius of the pool liquid along with time is recorded, and the area of the pool liquid is calculated; and next, the evaporation rate of the mass is calculated, so as to obtain the evaporation rate of the low-temperature expansion pool. The methodhas the advantages that the equipment is simple, the manufacturing is easy, the occupied area is small, the experiment operation is convenient, the experiment process is easy to control, the calculation method is simple, and the method is particularly suitable for small laboratory measurement. Meanwhile, a large amount of experimental data can be obtained by easily changing the leakage conditions,the conditions of the experimental environment and a concrete plate and the like.

Owner:SOUTHWEST PETROLEUM UNIV

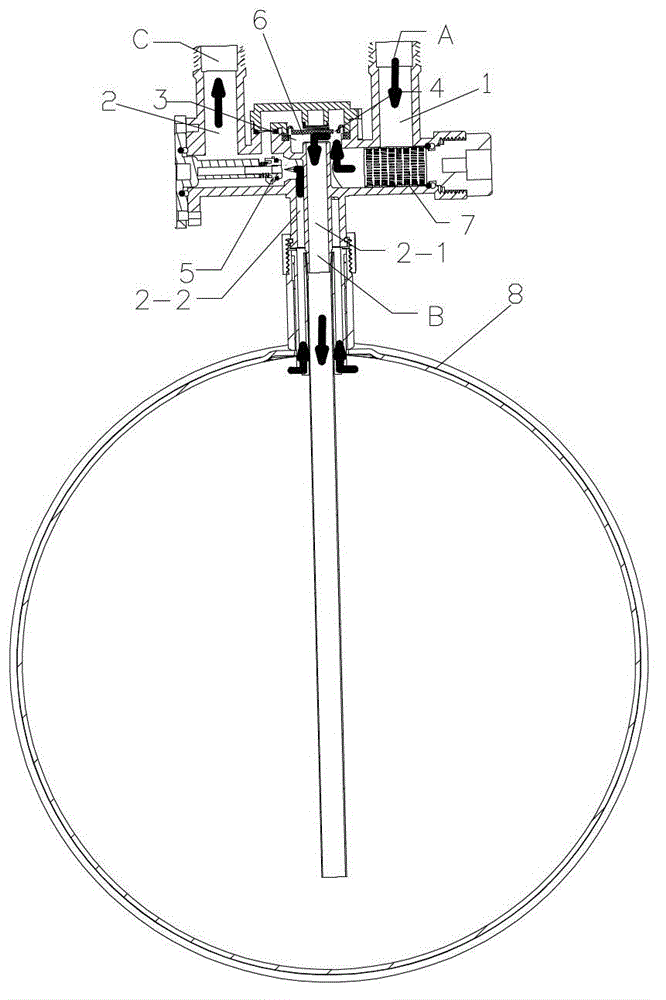

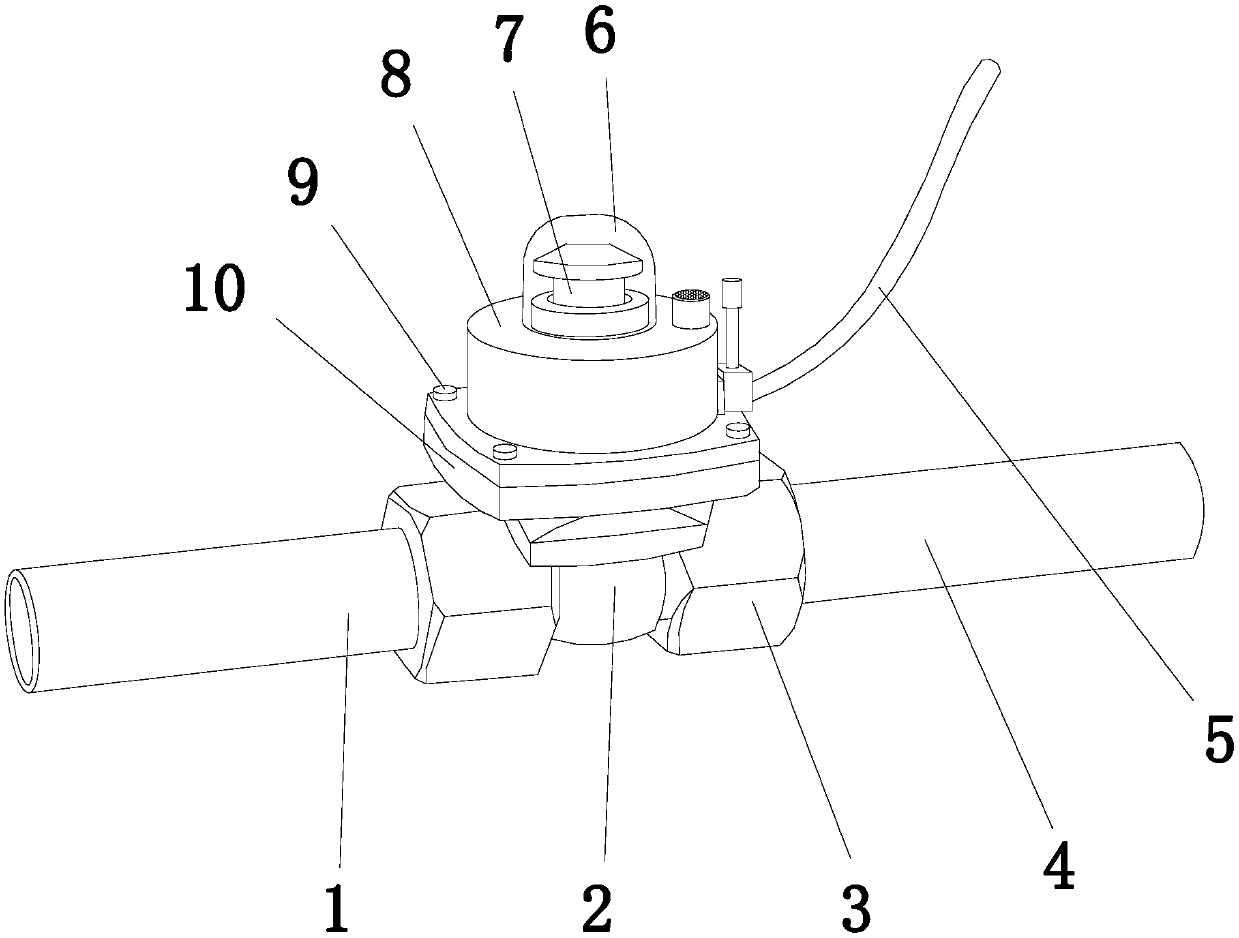

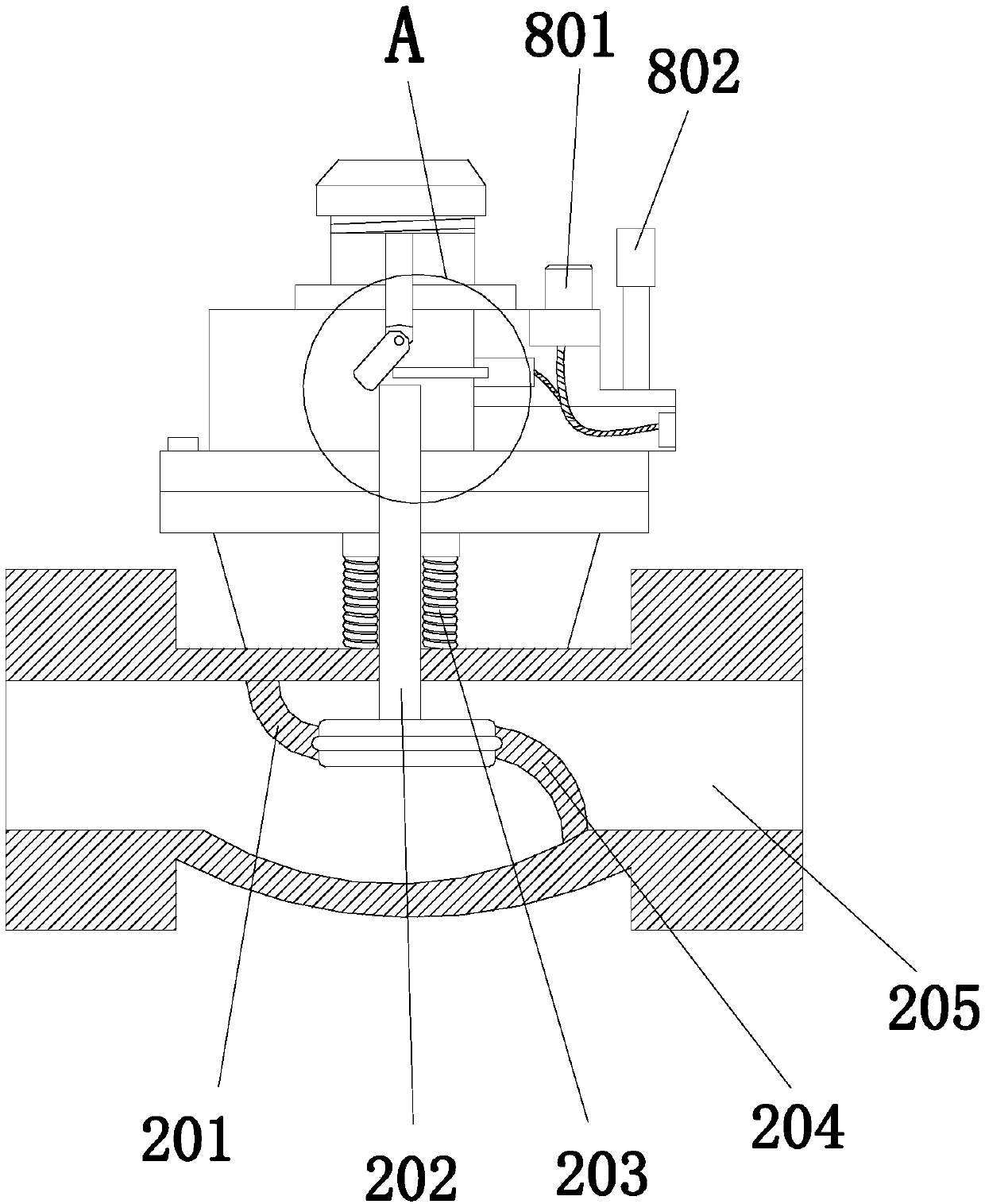

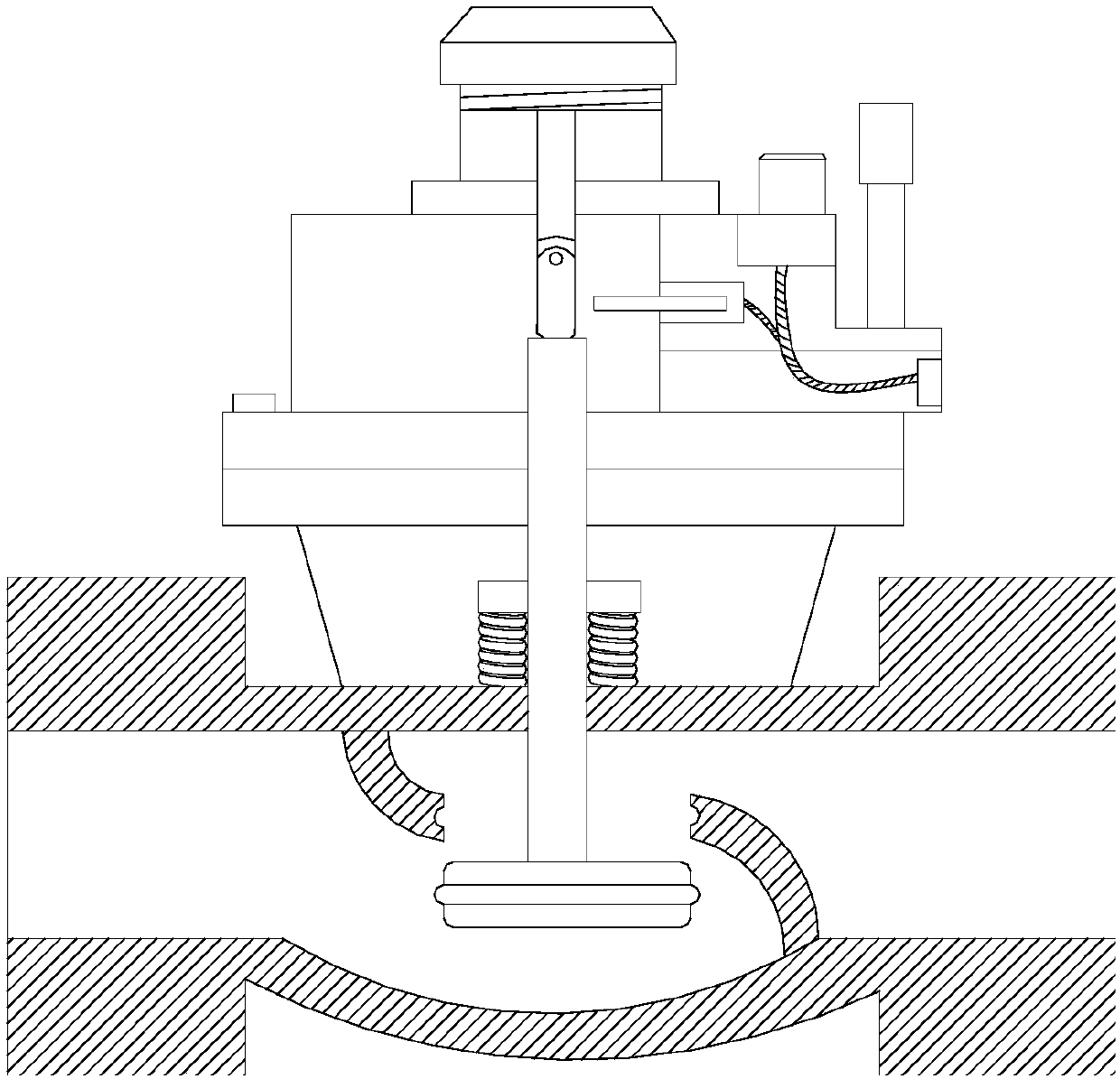

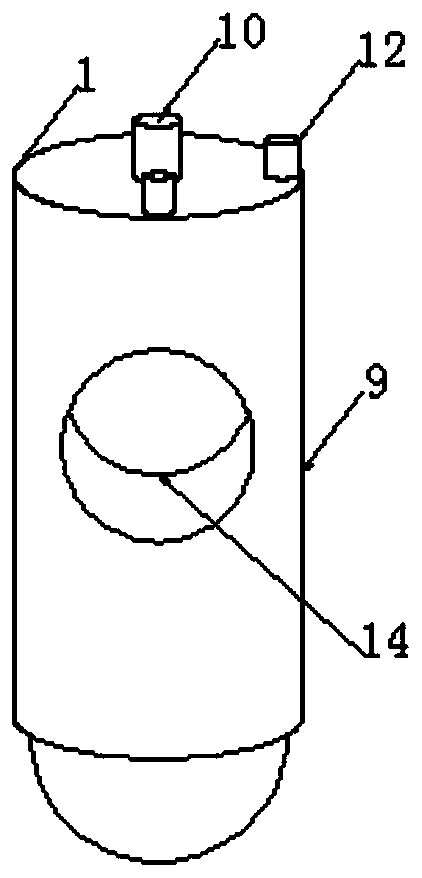

Liquid continuous-leakage preventing device

PendingCN108895194APrevent continuous leakageImprove safety and reliabilityOperating means/releasing devices for valvesContinuous leakageInternal cavity

The invention provides a liquid continuous-leakage preventing device, comprising a slider, a casing, a first seal part, a valve spool, a reset spring, a second seal part and a valve body. The left endof the casing is connected with a liquid inlet end while the right end thereof is connected with a liquid outlet end; the valve body is arranged in the middle of the casing and disposed between the liquid inlet end and the liquid outlet end; the valve spool is arranged in the valve body and sleeved with the reset spring, and the left end of the reset spring is abutted against the left end of an inner cavity of the valve body while the right end thereof is abutted against a step on the valve spool; the second seal part is arranged at the left end of the valve spool, and disposed at the left side of the left seal surface of the valve body; the first seal part is arranged at the right end of the valve spool and disposed between the valve spool and the casing and / or valve body; the valve bodyis communicated with a first bypass pipe and the casing on the right side of the valve spool is communicated with a second bypass pipe; a bevel is arranged at the right end of the valve spool, the slider is arranged in the right end of the casing, one end of the slider fits the right end of the valve spool through the bevel. The device can automatically prevent continuous leakage of containers.

Owner:ARISTON THERMO CHINA

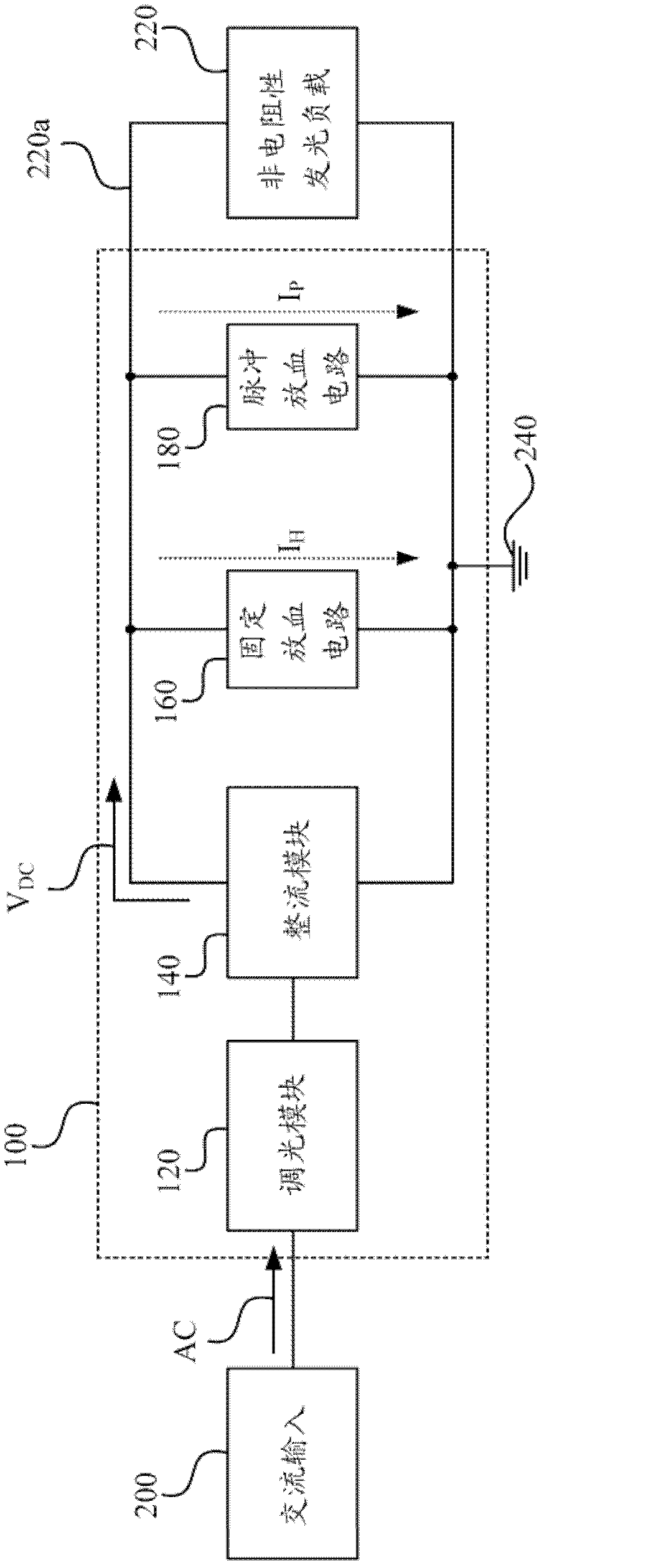

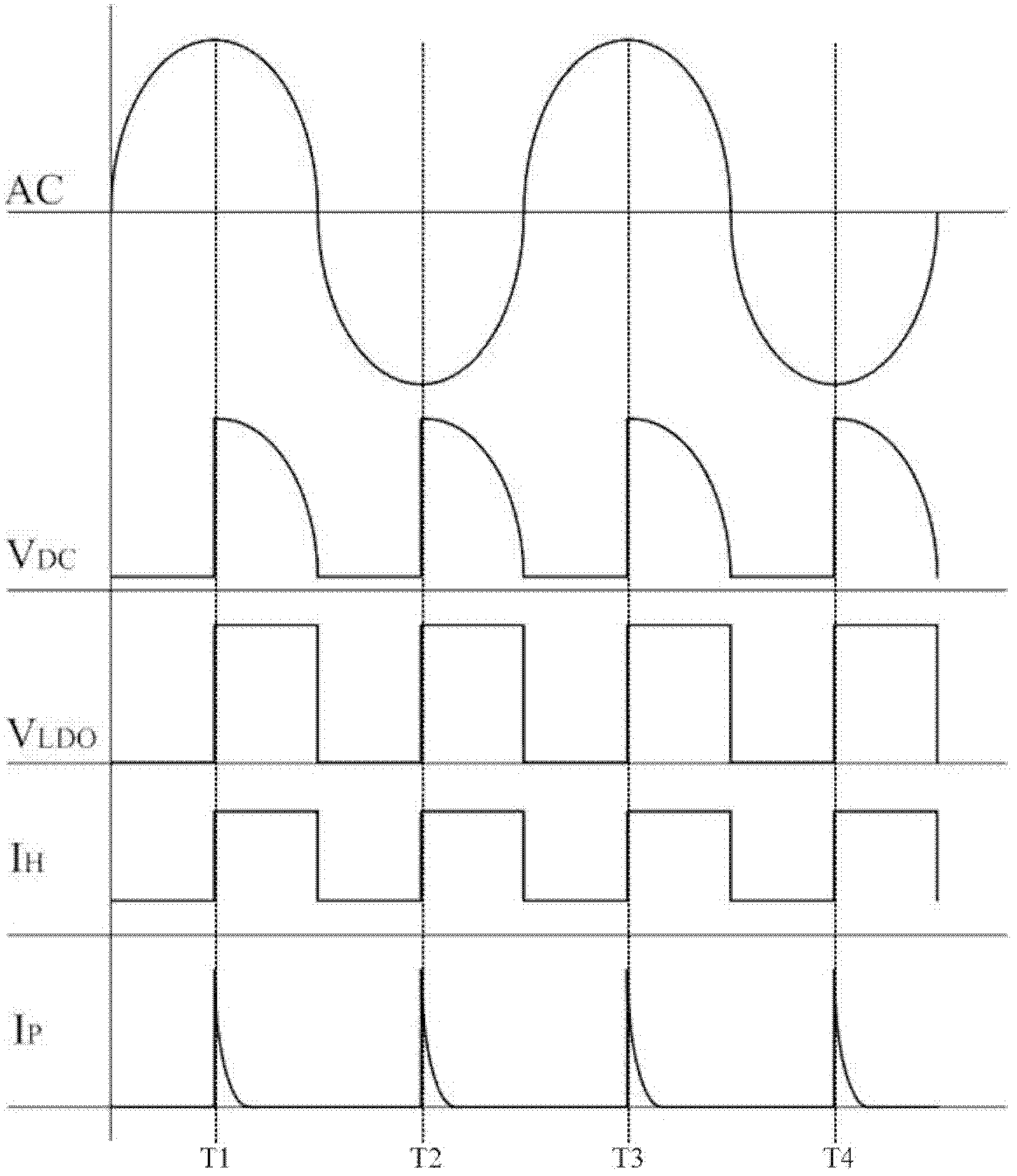

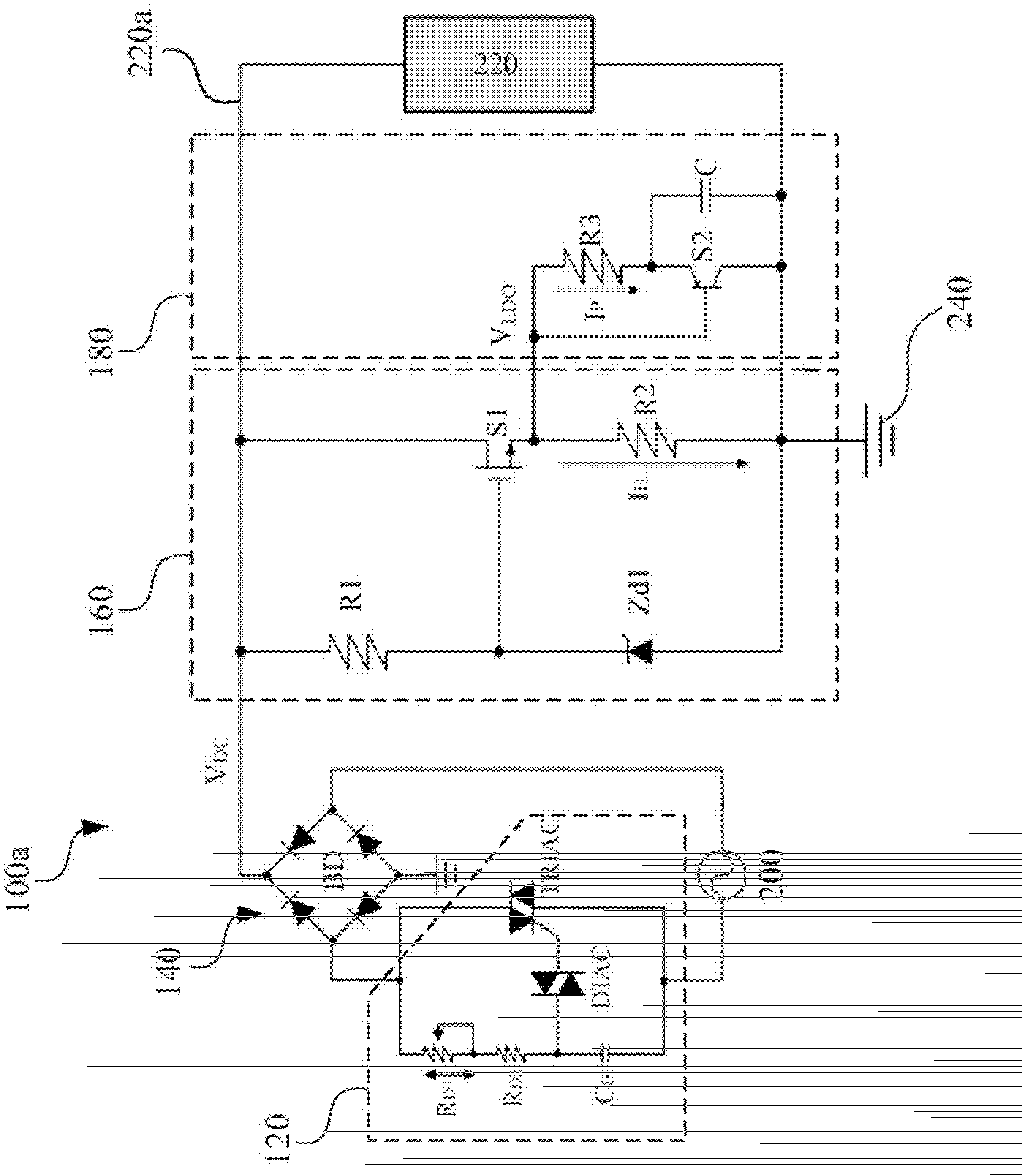

Illumination driving circuit

ActiveCN103384427AStable conductionEnsure conduction stabilityElectric light circuit arrangementEnergy saving control techniquesDimmerDriving circuit

The invention provides an illumination driving circuit which is coupled between an alternating circuit input and a non-resistiveness light-emitting load. The illumination driving circuit comprises a light-dimmer module, a rectifier module, a fixed leakage circuit and a pulse leakage circuit. The light-dimmer module is coupled with the alternating circuit input to generate a periodical drive signal, and the periodical drive signal comprises a plurality of periodical drive pulses. The rectifier module rectifies the periodical drive signal and sends the rectified periodical drive signal to a positive pole side of the non-resistiveness light-emitting load. The fixed leakage circuit continually draws a continuous leakage current from the positive pole side of the non-resistiveness light-emitting load in the duration of the drive pulses. The pulse leakage circuit transiently draws a pulse leakage current from the positive pole side of the non-resistiveness light-emitting load at trigger time points of the drive pulses.

Owner:HIMAX ANALOGIC INC

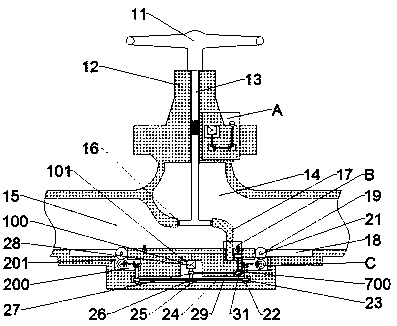

Intelligent automatic leak-proof valve

The invention discloses an intelligent automatic leak-proof valve. The intelligent automatic leak-proof valve comprises a valve body, wherein a valve seat is fixedly installed at the lower end of thevalve body, the two sides of the valve seat are fixedly provided with an inlet cavity and a discharging cavity correspondingly, the specification of the inlet cavity and the specification of the discharging cavity are consistent, and the center position of the upper end surface of the valve body is fixedly provided with a driving motor; and the upper end surface of the driving motor is fixedly provided with a controller, one side of the valve seat is fixedly provided with a gas flowmeter, two measuring ports of the gas flowmeter penetrate through the cavity wall of the inlet cavity and the cavity wall of the discharging cavity correspondingly and extend into the corresponding cavity, a valve cavity is formed in the valve seat, a valve column is arranged in the valve cavity, the valve column is matched with the valve cavity, and a driving shaft is fixedly connected to the circle center position of the upper end surface of the valve column. The intelligent automatic leak-proof valve hasthe advantages that the change of fuel gas entering the valve can be detected in real time, once the vertical large fluctuation is generated, it is shown that the fuel gas is leaked from the valve; and meanwhile, the driving motor is started by the controller to drive the valve column to rotate, an input port of the valve is timely plugged, and continuous leakage of the fuel gas is avoided.

Owner:义乌市吉龙科技有限公司

Encryption method for preventing continuous leakage attacks

InactiveCN104168266AImprove securityKey distribution for secure communicationUser identity/authority verificationKey generationSecurity system

The invention discloses an encryption method for preventing continuous leakage attacks. The method includes the following steps: secret-key generation, encryption method generation, secret-key updating and information decryption. Through the above-mentioned method, the encryption method for preventing the continuous leakage attacks designs a method for preventing continuous initiation of leakage attacks of secret information by an attacker on the basis of a quadratic residue difficulty hypothesis and through updating of portions stored in different devices, the attacker is still incapable of cracking a security system to obtain secret information even content of part of the encryption information is obtained so that the security of the encryption method is improved.

Owner:SUZHOU UNIV

Indoor pipeline leakage prevention device

ActiveCN110388571AAvoid wastingSimple structurePipe elementsPipeline systemsWater resourcesWaste management

The invention discloses an indoor pipeline leakage prevention device. The device comprises a valve, wherein a rotatable rotating handle is arranged in the valve; a screw is fixed at the bottom end ofthe rotating handle, and is connected with the valve through a thread; a water inlet pipe with a leftward opening is arranged in the valve, and a water outlet pipe with a rightward opening is arrangedin the valve. The device has the advantages of being simple in structure and convenient to maintain and use. The device can automatically seal the leaking valve and pipelines to prevent continuous leakage; besides, people can be reminded of timely maintenance and inspection to prevent waste of water resources, and economic losses caused by pipeline leakage are reduced.

Owner:浙江金果知识产权有限公司

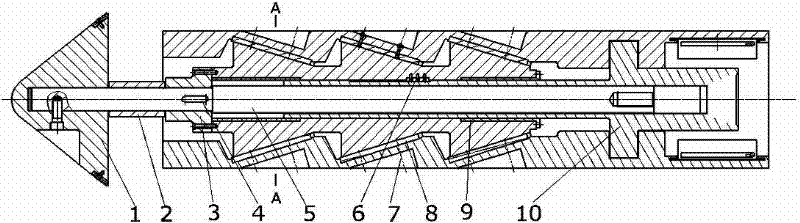

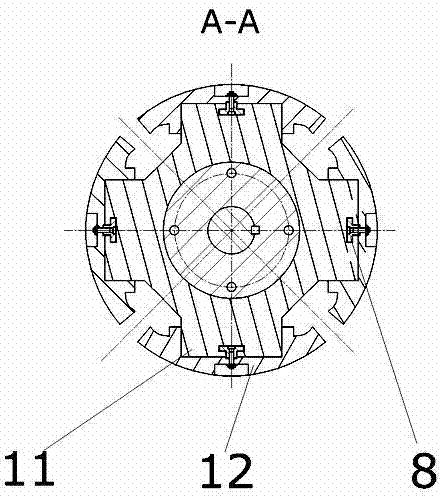

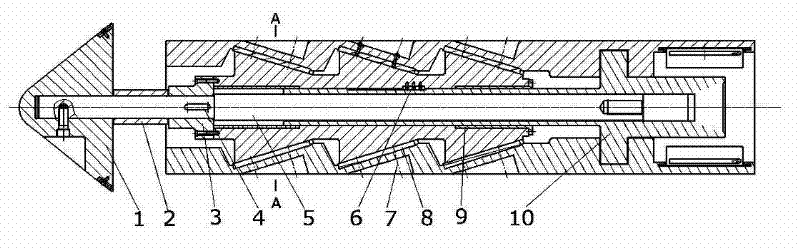

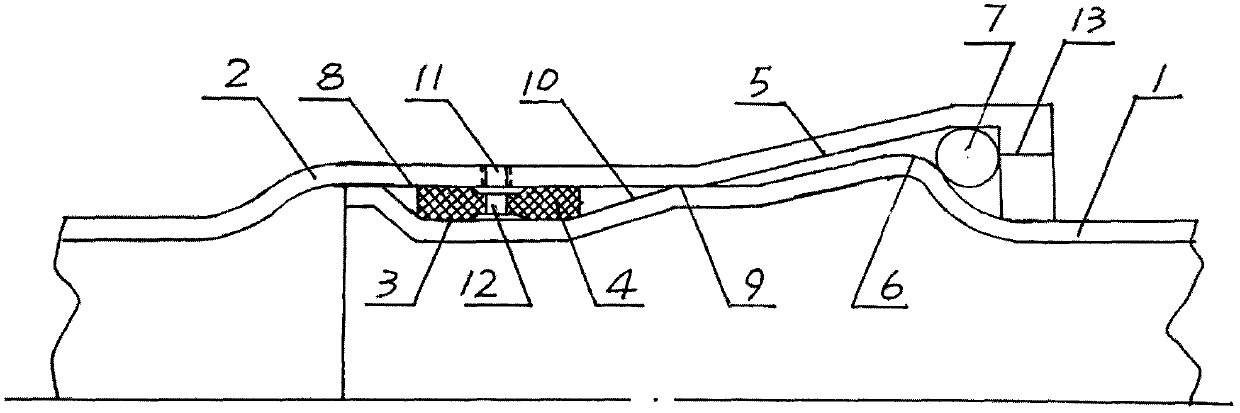

Leakage blocking device for leaking oil well

The invention relates to a leakage blocking device for a leaking oil well, which is characterized by comprising a sleeve pipe (10), wherein a diverging cone (11) capable of axially sliding along the sleeve pipe is sheathed on the left side of the sleeve pipe (10), a group of fan-shaped blocks (12) in axial arrangement and radial diverging are arranged on the diverging cone (11), the fan-shaped blocks (12) have wedge-shaped inner surfaces matched with corresponding wedge-shaped surfaces of the diverging cone (11), in addition, the two matched wedge-shaped surfaces are in matched connection with chutes through slide blocks in axial arrangement, a pull rod (5) penetrating through the sleeve pipe is arranged in the sleeve pipe (10), the left end of the pull rod (5) is connected with an umbrella-shaped end cover (1), and a shaft coupler (3) which is in matched connection with the left end surface of the diverging cone (11) and can drive the diverging cone (11) to axially move is arranged on the pull rod (5) arranged at the right side of the umbrella-shaped end cover (1). The leakage blocking device for the leaking oil well has the beneficial effects that the whole device is designed on the basis of the expansion principle of an expansion shaft, the leakage position can be fast blocked, a good leakage blocking effect is realized, and the great environment pollution caused by continuous leakage, the energy waste and the economic loss caused by the pollution are avoided.

Owner:ANHUI SCI & TECH UNIV +1

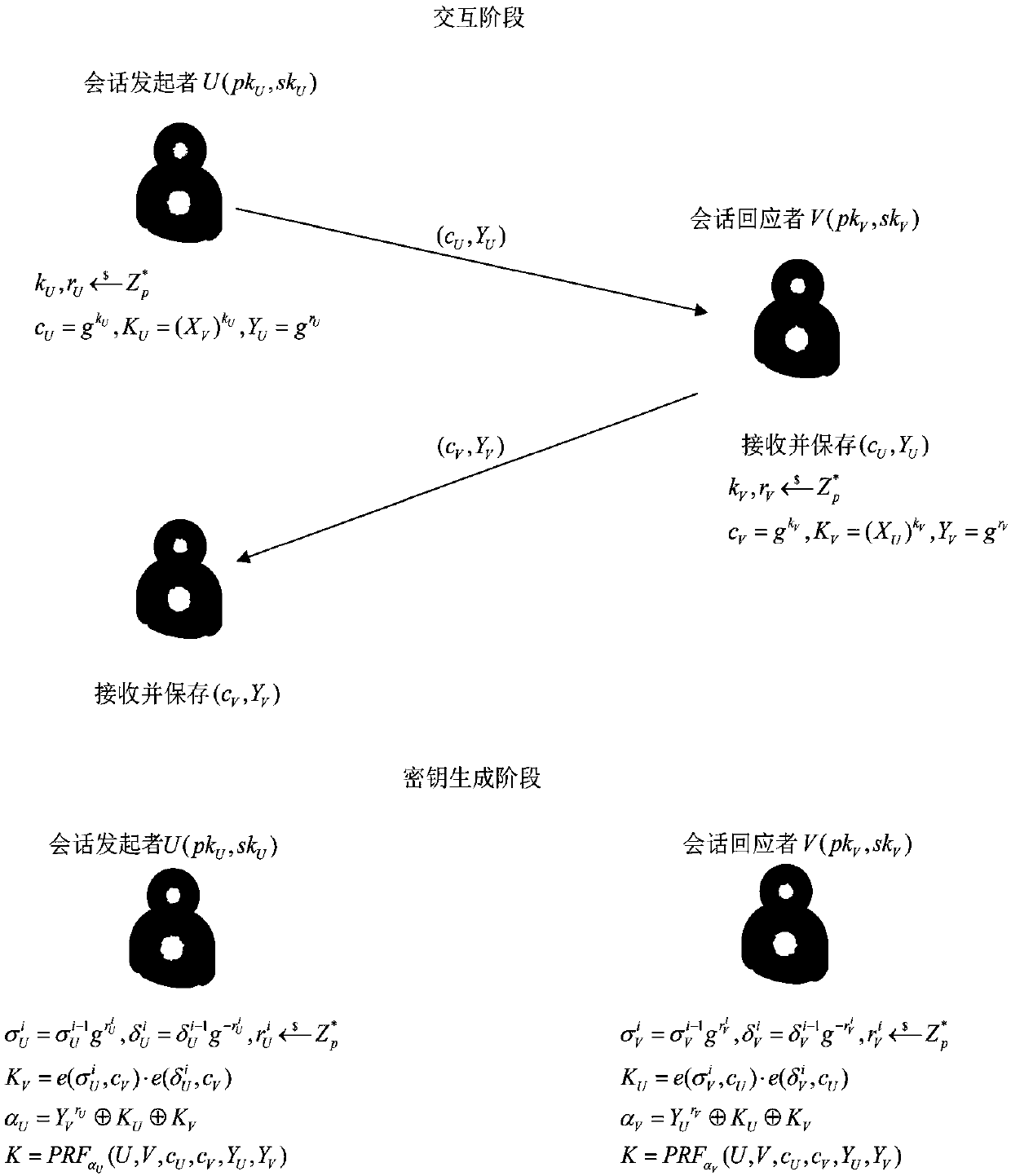

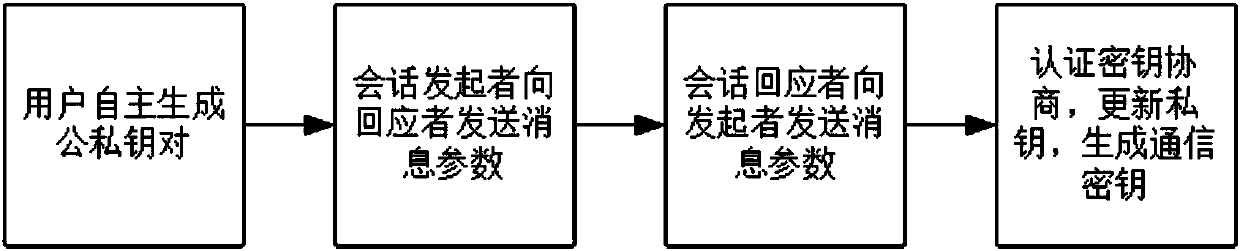

Authentication key negotiation method and system against continuous leakage

InactiveCN108599948ANo support requiredImprove securityKey distribution for secure communicationPublic key for secure communicationSecure communicationProvable security

The invention discloses an authentication key negotiation method and system against continuous leakage. The system is composed of two users, respectively a session initiator and a responder; and eachuser has a pair of public and private keys. The method in the invention first performs system initialization and then performs a first interaction, and the session initiator sends a message parameterto the responder; then a second interaction is carried out, and the session responder responds to the initiator with the message parameter; finally, the session initiator and the responder authenticate key negotiation, update own private keys and generate a common communication key. The authentication key negotiation method and system against continuous leakage in the invention are particularly suitable for the secure communication of both parties, are high in security as having achieved cryptographically provable security, and is high in practicability as being able to execute safely and stably still in a continuous leakage environment; and in combination with an elliptic curve and bilinear pairing technology, a session key authentication negotiation protocol against continuous leakage isproposed, and the scheme efficiency is high.

Owner:HUBEI UNIV OF TECH

High-performance leakage-proof flexible joint

The invention discloses a high-performance leakage-proof flexible joint. The internal-pressure, external-pressure and negative-pressure inspections can be singly performed on connected joints after connection. The joint leakage is caused by such factors as aging of rubber rings, nonuniform settlement of a foundation or bearing of radial loads in the pipe work; and sealing rubber rings are axiallyshifted into an inclined surface with a lift angle under the pressure effect of conveying mediums to increase radial pressure, so that the contact pressure of sealing contact surfaces is higher than the pressure of the mediums to automatically stop continuous leakage of the joints.

Owner:程宇婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com