Self-repairing type double-layer oil tank

A double-layer oil tank, self-repairing technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of complex structure of leakage detection device, high technical requirements of maintenance personnel, long maintenance time and other problems, so as to shorten the detection response time. , A wide range of adaptation, the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

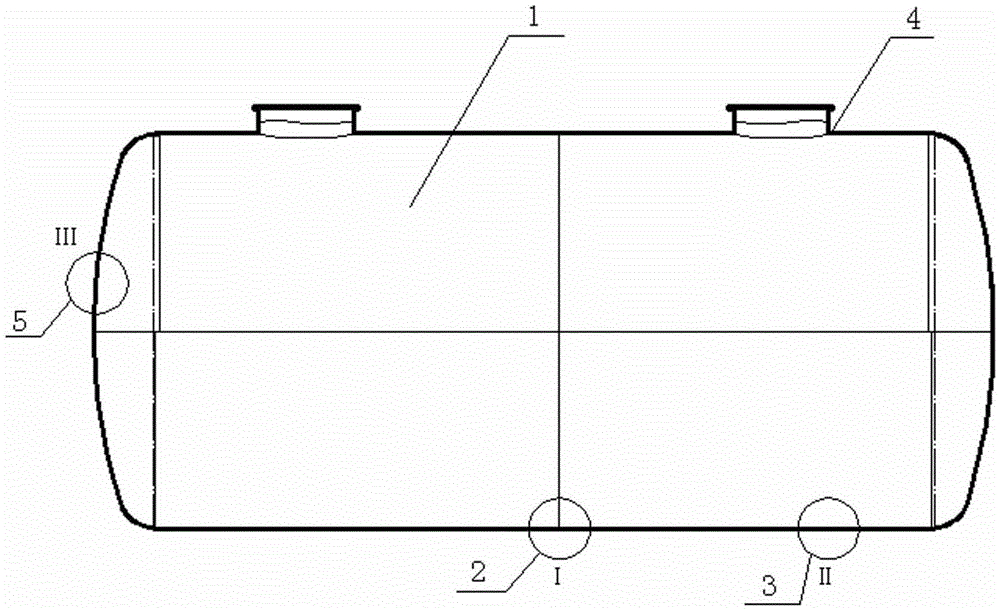

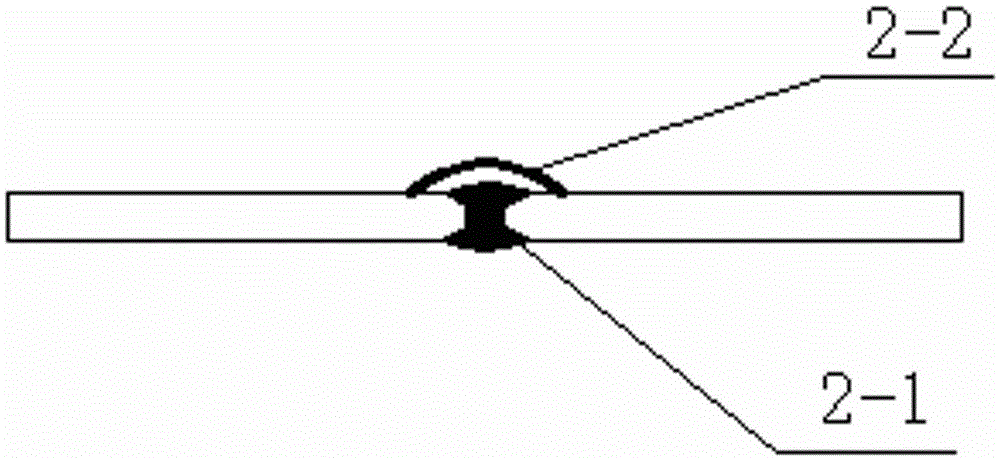

[0022] Such as Figure 1~4 As shown, a self-healing double-layer oil tank includes an inner steel tank body 1 and an outer glass fiber reinforced plastic layer 5, and an intermediate interlayer 3 and a leakage Induction external wire 4, the intermediate interlayer 3 includes rubber particles 3-1, glass fibers 3-2, copper wire group 3-3 and PE film 3-4, the rubber particles 3-1, glass fibers 3-2 and The copper wire group 3-3 is combined with an adhesive, and the side close to the glass fiber reinforced plastic layer 5 is covered with a layer of the PE film 3-4, and the copper wire group 3-3 communicates with the leakage induction external wire 4 , to provide real-time feedback on the leakage of the oil tank, and the rubber particles 3-1 expand when meeting water or oil, so as to repair the leaking area.

[0023] The adjacent steel plates of the steel tank body 1 are welded and connected, and the tank body and the head of the steel tank body 1 are welded and connected. The weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com