Anti-collapse and anti-leakage drilling washing fluid used during drilling and field production method thereof

A drilling flushing fluid and anti-slump technology, which is applied in the field of geological core drilling, can solve the problems of difficulty in exerting the anti-collapse ability of the upper carbonaceous slate layer, high costs of flushing fluid and plugging, and low drilling efficiency, and can adapt to the width of cracks. Wide range, fast plugging speed, and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

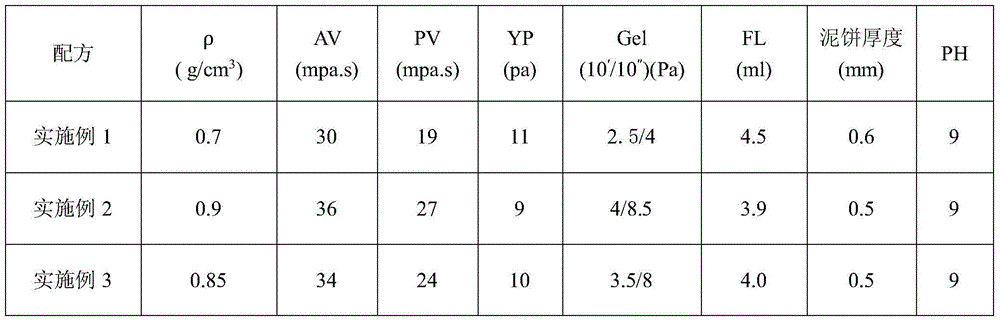

Embodiment 1

[0040] Indoor test: Add 30g of bentonite and 2g of soda ash to 1000ml of clear water, stir at 11000r / min for 10min and then let it stand for 24h as the base slurry; Type regulator 15g, bridging agent 30g, plugging agent 50g, inhibitor 10g, foaming agent 3mL, after adding each agent, add the next agent after stirring evenly, and finally stir evenly to get the described MWD. Slump leak-proof borehole flushing fluid.

Embodiment 2

[0042] Indoor test: Add 50g of bentonite and 4g of soda ash to 1000ml of clear water, stir at 11000r / min for 10min and then let it stand for 24h as the base slurry; Type regulator 5g, bridging agent 80g, plugging agent 20g, inhibitor 30g, foaming agent 1mL, every time adding a dose, add the next dose after stirring evenly, and finally stir evenly to obtain the described anti-corrosion agent while drilling. Slump leak-proof borehole flushing fluid.

Embodiment 3

[0044] Indoor test: Add 40g of bentonite and 3g of soda ash to 1000ml of clear water, stir at 11000r / min for 10min and then let it stand for 24h as the base slurry; Type regulator 10g, bridging agent 50g, plugging agent 40g, inhibitor 20g, foaming agent 2mL, every time adding a dose, add the next dose after stirring evenly, and finally stir evenly to get the described anti-drilling agent. Slump leak-proof borehole flushing fluid.

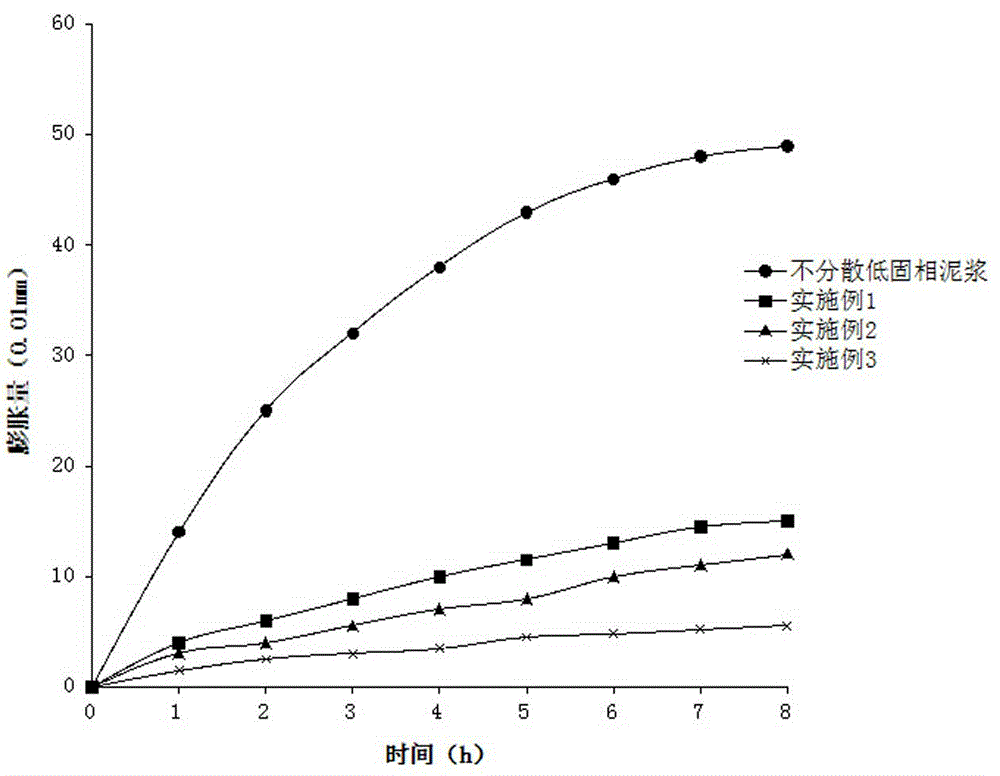

[0045] Indoor performance test: mainly carry out various indoor performance tests on the anti-slump and anti-leakage drilling flushing fluid prepared in the aforementioned three embodiments. Among them, the non-dispersible low-solid phase mud mentioned in the following comparison test is a mud system commonly used in geological drilling, and its formula is, by mass fraction: 4% bentonite + 0.2% soda ash + 0.3% high viscosity sodium carboxymethyl cellulose +75ppm hydrolyzed polyacrylamide.

[0046] ①Basic performance test: It mainly includes perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com